Femtosecond Laser-Induced Damage Characterization of Multilayer Dielectric Coatings

Abstract

1. Introduction

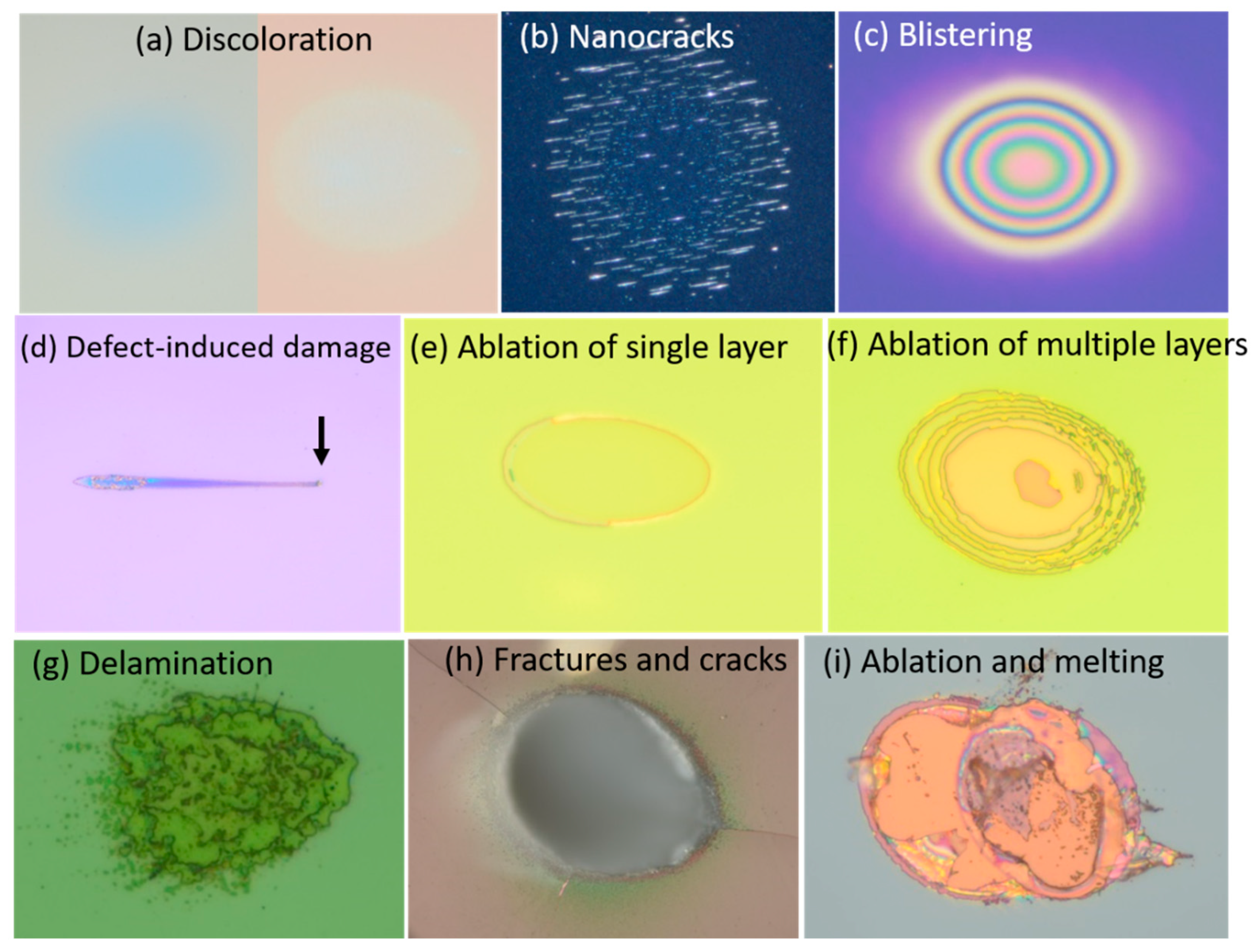

2. Fs Laser-Induced Damage of Multilayer Dielectric Coatings

3. Experimental Details

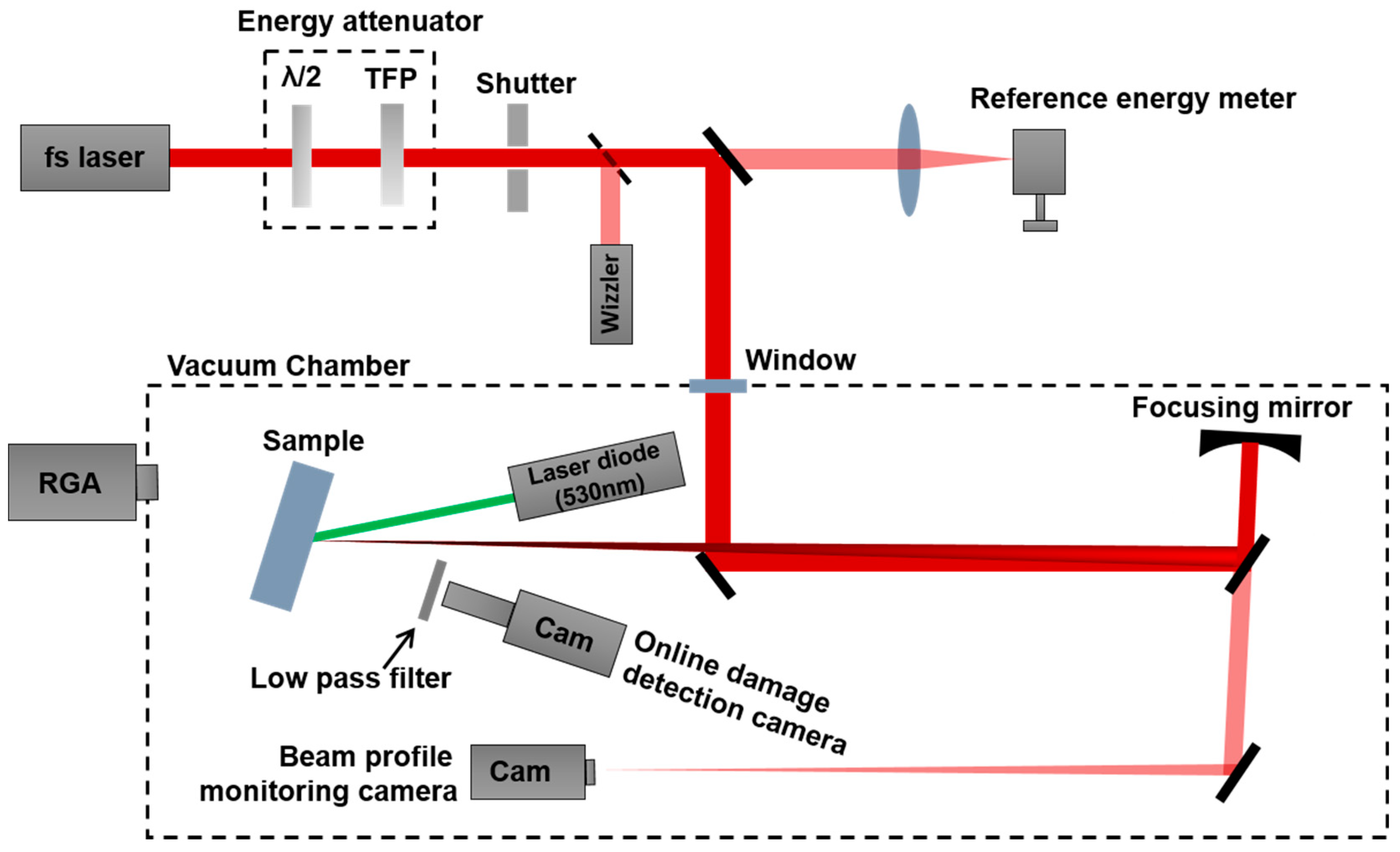

3.1. Experimental Setup

3.2. Test Methods

3.3. Materials

4. LIDT Results

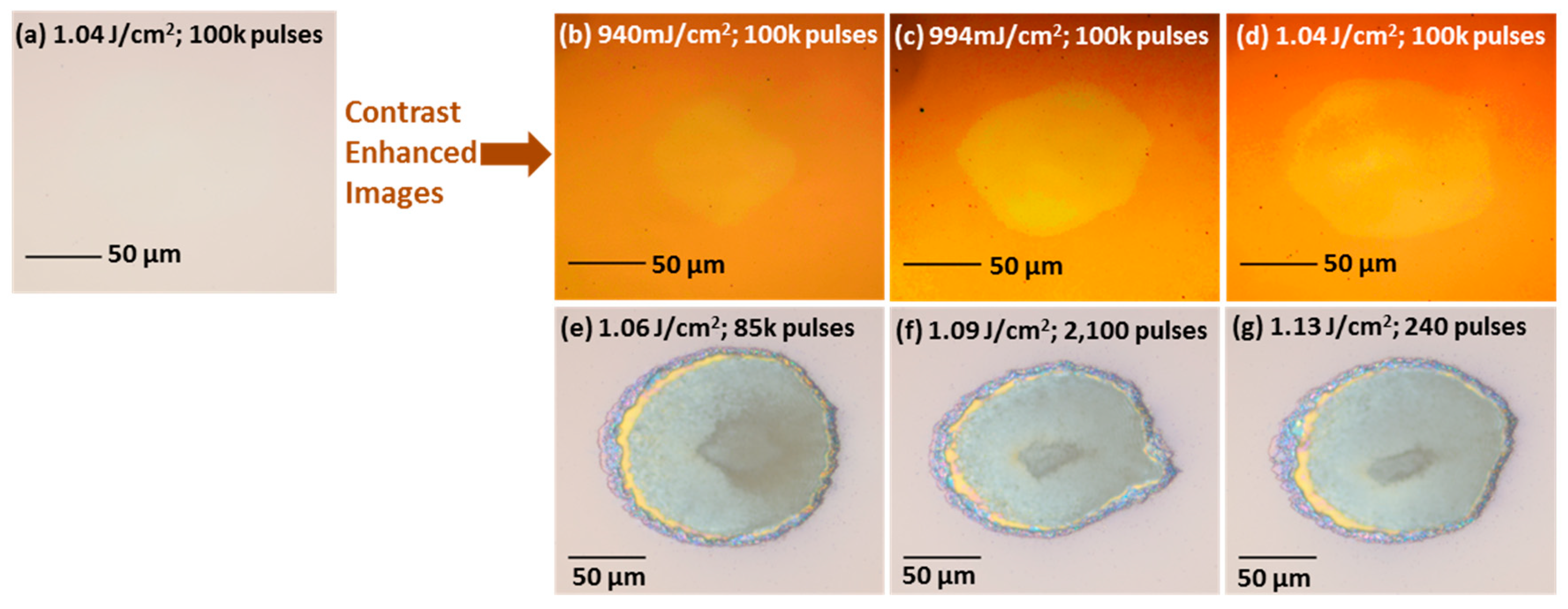

4.1. ISO S-on-1 Method

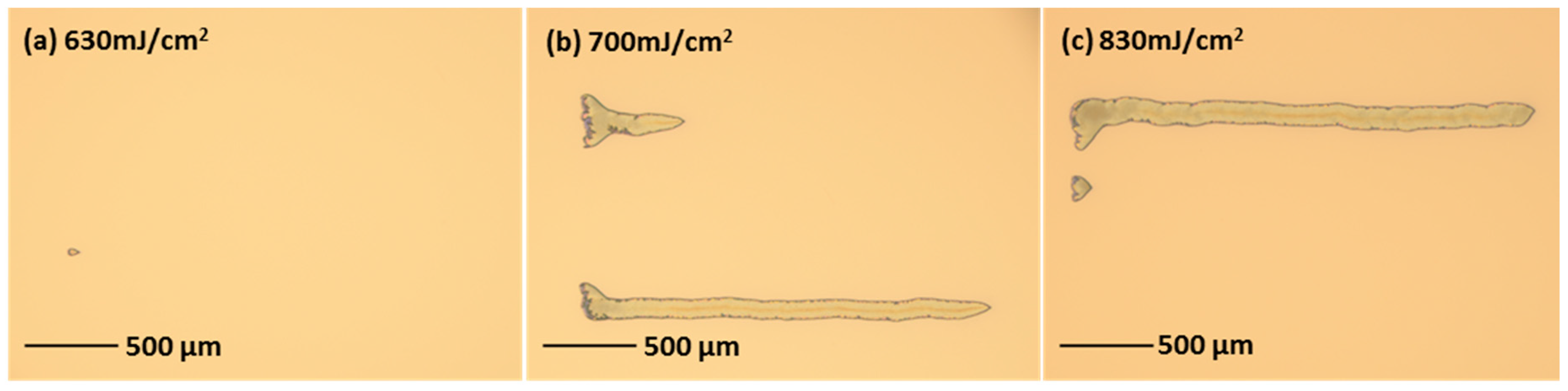

4.2. Raster Scan Method

4.3. R-on-1 Method

5. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Backus, S.; Durfee, C.G., III; Murnane, M.M.; Kapteyn, H.C. High power ultrafast lasers. Rev. Sci. Instrum. 1998, 69, 1207–1223. [Google Scholar] [CrossRef]

- Danson, C.N.; Haefner, C.; Bromage, J.; Butcher, T.; Chanteloup, J.-C.F.; Chowdhury, E.A.; Galvanauskas, A.; Gizzi, L.A.; Hein, J.; Hillier, D.I.; et al. Petawatt and exawatt class lasers worldwide. High Power Laser Sci. Eng. 2019, 7, 1–54. [Google Scholar] [CrossRef]

- Mourou, G. Nobel Lecture: Extreme light physics and application. Rev. Mod. Phys. 2019, 91, 030501. [Google Scholar] [CrossRef]

- Rus, B.; Bakule, P.; Kramer, D.; Korn, G.; Green, J.T.; Nóvak, J.; Fibrich, M.; Batysta, F.; Thoma, J.; Naylon, J.; et al. ELI-Beamlines laser systems: Status and design options. In Proceedings of the SPIE 87801, High-Power, High-Energy, and High-Intensity Laser Technology; and Research Using Extreme Light: Entering New Frontiers with Petawatt-Class Lasers, 87801T, Prague, Czech Republic, 7 May 2013; SPIE: Bellingham, WA, USA, 2013. [Google Scholar]

- Rus, B.; Bakule, P.; Kramer, D.; Naylon, J.; Thoma, J.; Green, J.T.; Antipenkov, R.; Fibrich, M.; Novák, J.; Batysta, F.; et al. ELI-Beamlines: Development of next generation short-pulse laser systems. In Proceedings of the SPIE 95150; Research Using Extreme Light: Entering New Frontiers with Petawatt-Class Lasers II, 95150F, Prague, Czech Republic, 12 May 2015; SPIE: Bellingham, WA, USA, 2015. [Google Scholar]

- Rus, B.; Bakule, P.; Kramer, D.; Naylon, J.; Thoma, J.; Fibrich, M.; Green, J.T.; Lagron, J.C.; Antipenkov, R.; Bartoníček, J.; et al. ELI-Beamlines: Progress in development of next generation short-pulse laser systems. In Proceedings of the SPIE 10241; Research Using Extreme Light: Entering New Frontiers with Petawatt-Class Lasers III, 102410J, Prague, Czech Republic, 26 June 2017; SPIE: Bellingham, WA, USA, 2017. [Google Scholar]

- Mourou, G.A.; Barty, C.P.; Perry, M.D. Ultrahigh-Intensity Lasers: Physics of the Extreme on a Tabletop. Phys. Today 1998, 51, 22–28. [Google Scholar] [CrossRef]

- Salamin, Y.I.; Hu, S.X.; Hatsagortsyan, K.Z.; Keitel, C.H. Relativistic high-power laser–matter interactions. Phys. Rep. 2006, 427, 41–155. [Google Scholar] [CrossRef]

- Malka, V.; Fritzler, S.; Lefebvre, E.; Aleonard, M.M.; Burgy, F.; Chambaret, J.P.; Chemin, J.F.; Krushelnick, K.; Malka, G.; Mangles, S.P.D.; et al. Electron acceleration by a wake field forced by an intense ultrashort laser pulse. Science 2002, 298, 1596–1600. [Google Scholar] [CrossRef] [PubMed]

- Snavely, R.A.; Key, M.H.; Hatchett, S.P.; Cowan, T.E.; Roth, M.; Phillips, T.W.; Stoyer, M.A.; Henry, E.A.; Sangster, T.C.; Singh, M.S.; et al. Intense high-energy proton beams from petawatt-laser irradiation of solids. Phys. Rev. Lett. 2000, 85, 2945. [Google Scholar] [CrossRef] [PubMed]

- Remington, B.A.; Arnett, D.; Paul, R.; Takabe, H. Modeling astrophysical phenomena in the laboratory with intense lasers. Science 1999, 284, 1488–1493. [Google Scholar] [CrossRef]

- Bulanov, S.V.; Khoroshkov, V.S. Feasibility of using laser ion accelerators in proton therapy. Plasma Phys. Rep. 2002, 28, 453–456. [Google Scholar] [CrossRef]

- Seres, J.; Seres, E.; Verhoef, A.J.; Tempea, G.; Streli, C.; Wobrauschek, P.; Yakovlev, V.; Scrinzi, A.; Spielmann, C.; Krausz, F. Source of coherent kiloelectronvolt X-rays. Nature 2005, 433, 596. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Spielmann, C.; Walker, B.C.; Barty, C.P.J. Generation of hard x rays by ultrafast terawatt lasers. Rev. Sci. Instrum. 2001, 72, 41–47. [Google Scholar] [CrossRef]

- Schiltz, D.; Patel, D.; Baumgarten, C.; Reagan, B.A.; Rocca, J.J.; Menoni, C.S. Strategies to increase laser damage performance of Ta2O5/SiO2 mirrors by modifications of the top layer design. Appl. Opt. 2017, 56, C136–C139. [Google Scholar] [CrossRef] [PubMed]

- Apfel, J.H. Optical coating design with reduced electric field intensity. Appl. Opt. 1977, 16, 1880–1885. [Google Scholar] [CrossRef] [PubMed]

- Gallais, L.; Commandré, M. Laser-induced damage thresholds of bulk and coating optical materials at 1030 nm, 500 fs. Appl. Opt. 2014, 53, A186–A196. [Google Scholar] [CrossRef]

- Mangote, B.; Gallais, L.; Commandré, M.; Mende, M.; Jensen, L.; Ehlers, H.; Jupé, M.; Ristau, D.; Melninkaitis, A.; Mirauskas, J.; et al. Femtosecond laser damage resistance of oxide and mixture oxide optical coatings. Opt. Lett. 2012, 37, 1478–1480. [Google Scholar] [CrossRef]

- Papernov, S. Defect-induced damage. In Laser-Induced Damage in Optical Materials; Ristau, D., Ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 25–73. [Google Scholar]

- Jasapara, J.; Nampoothiri, A.V.V.; Rudolph, W.; Ristau, D.; Starke, K. Femtosecond laser pulse induced breakdown in dielectric thin films. Phys. Rev. B 2001, 63, 045117. [Google Scholar] [CrossRef]

- Negres, R.A.; Stolz, C.J.; Thomas, M.D.; Caputo, M. 1064-nm, nanosecond laser mirror thin film damage competition. In Proceedings of the SPIE 10805, Laser-Induced Damage in Optical Materials 2018: 50th Anniversary Conference, Boulder, CO, USA, 16 November 2018; SPIE: Bellingham, WA, USA, 2018. [Google Scholar]

- Stolz, C.J.; Negres, R.A. Ten-year summary of the Boulder Damage Symposium annual thin film laser damage competition. Opt. Eng. 2018, 57, 121910. [Google Scholar] [CrossRef]

- Ristau, D. Laser-Induced Damage in Optical Materials; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- ISO 21254-1:2011, Lasers and Laser-Related Equipment—Test Methods for Laser-Induced Damage Threshold—Part 1: Definitions and General Principles; ISO: Geneva, Switzerland, 2011.

- Stuart, B.C.; Feit, M.D.; Herman, S.; Rubenchik, A.M.; Shore, B.W.; Perry, M.D. Nanosecond-to-femtosecond laser-induced breakdown in dielectrics. Phys. Rev. B 1996, 53, 1749. [Google Scholar] [CrossRef]

- Guizard, S.; Klimentov, S.; Mouskeftaras, A.; Fedorov, N.; Geoffroy, G.; Vilmart, G. Ultrafast Breakdown of dielectrics: Energy absorption mechanisms investigated by double pulse experiments. Appl. Surf. Sci. 2015, 336, 206–211. [Google Scholar] [CrossRef]

- Velpula, P.K.; Bhuyan, M.K.; Courvoisier, F.; Zhang, H.; Colombier, J.P.; Stoian, R. Spatio-temporal dynamics in nondiffractive Bessel ultrafast laser nanoscale volume structuring. Laser Photonics Rev. 2016, 10, 230–244. [Google Scholar] [CrossRef]

- Ashkenasi, D.; Lorenz, M.; Stoian, R.; Rosenfeld, A. Surface damage threshold and structuring of dielectrics using femtosecond laser pulses: The role of incubation. Appl. Surf. Sci. 1999, 150, 101–106. [Google Scholar] [CrossRef]

- Chmel, A.E. Fatigue laser-induced damage in transparent materials. Mater. Sci. Eng. B 1997, 49, 175–190. [Google Scholar] [CrossRef]

- Gallais, L.; Natoli, J.Y.; Amra, C. Statistical study of single and multiple pulse laser-induced damage in glasses. Opt. Express 2002, 10, 1465–1474. [Google Scholar] [CrossRef] [PubMed]

- Merkle, L.D.; Koumvakalis, N.; Bass, M. Laser-induced bulk damage in SiO2 at 1.064, 0.532, and 0.355 μm. J. Appl. Phys. 1984, 55, 772–775. [Google Scholar] [CrossRef]

- Kitriotis, D.; Merkle, L.D. Multiple pulse laser-induced damage phenomena in silicates. Appl. Opt. 1989, 28, 949–958. [Google Scholar] [CrossRef]

- Hildenbrand, A.; Wagner, F.R.; Akhouayri, H.; Natoli, J.Y.; Commandre, M.; Théodore, F.; Albrecht, H. Laser-induced damage investigation at 1064 nmin KTiOPO 4 crystals and its analogy with RbTiOPO 4. Appl. Opt. 2009, 48, 4263–4269. [Google Scholar] [CrossRef]

- O’Connell, R.M.; Deaton, T.F.; Saito, T.T. Single-and multiple-shot laser-damage properties of commercial grade PMMA. Appl. Opt. 1984, 23, 682–688. [Google Scholar] [CrossRef]

- Velpula, P.K.; Ďurák, M.; Kramer, D.; Meadows, A.R.; Vilémová, M.; Rus, B. Evolution of femtosecond laser damage in a hafnia–silica multi-layer dielectric coating. Opt. Lett. 2019, 44, 5342–5345. [Google Scholar] [CrossRef]

- McDonald, J.P.; Mistry, V.R.; Ray, K.E.; Yalisove, S.M.; Nees, J.A.; Moody, N.R. Femtosecond-laser-induced delamination and blister formation in thermal oxide films on silicon (100). Appl. Phys. Lett. 2006, 88, 153121. [Google Scholar] [CrossRef]

- Ďurák, M.; Kramer, D.; Velpula, P.K.; Meadows, A.R.; Cupal, J.; Rus, B. Comparison of different LIDT testing protocols for PW and multi-PW class high-reflectivity coatings. In Proceedings of the SPIE 10014, Laser-Induced Damage in Optical Materials 2016, Boulder, CO, USA, 6 December 2016; SPIE: Bellingham, WA, USA, 2016. [Google Scholar]

- ISO 21254-2:2011 Lasers and Laser-Related Equipment—Test Methods for Laser-Induced Damage Threshold—Part 2: Threshold Determination; ISO: Geneva, Switzerland, 2011.

- Ďurák, M.; Velpula, P.K.; Kramer, D.; Cupal, J.; Medřík, T.; Hřebíček, J.; Golasowski, J.; Peceli, D.; Kozlová, M.; Rus, B. Laser-induced damage threshold tests of ultrafast multilayer dielectric coatings in various environmental conditions relevant for operation of ELI beamlines laser systems. Opt. Eng. 2016, 56, 011024. [Google Scholar] [CrossRef]

- Wolfe, C.R.; Kozlowski, M.R.; Campbell, J.H.; Rainer, F.; Morgan, A.J.; Gonzales, R.P. Laser conditioning of optical thin films. In Proceedings of the SPIE 1438, Laser-Induced Damage in Optical Materials 1989; Bennett, H.E., Chase, L.L., Guenther, A.H., Newnam, B.E., Soileau, M.J., Eds.; SPIE: Bellingham, WA, USA, 2016; pp. 360–375. [Google Scholar]

- Harthcock, C.; Qiu, S.R.; Mirkarimi, P.B.; Negres, R.A.; Guss, G.; Menor, M.G.; Bhowmik, G.; Huang, M. Origin and effect of film sub-stoichiometry on ultraviolet, ns-laser damage resistance of hafnia single layers. Opt. Mater. Express 2020, 10, 937–951. [Google Scholar] [CrossRef]

- Negres, R.A.; Carr, C.W.; Laurence, T.A.; Stanion, K.; Guss, G.; Cross, D.A.; Wegner, P.J.; Stolz, C.J. Laser-induced damage of intrinsic and extrinsic defects by picosecond pulses on multilayer dielectric coatings for petawatt-class lasers. Opt. Eng. 2016, 56, 011008. [Google Scholar] [CrossRef]

- Batavičiūtė, G.; Ščiuka, M.; Melninkaitis, A. Direct comparison of defect ensembles extracted from damage probability and raster scan measurements. J. Appl. Phys. 2015, 118, 105306. [Google Scholar] [CrossRef]

| Coating Materials | Coating Method | HR Central Wavelength at 45 deg | HR Bandwidth for S-pol | Angle of Incidence Used for LIDT Tests | GDD |

|---|---|---|---|---|---|

| Ta2O5/HfO2/SiO2 | IBS | 800 nm | 180 nm | 45 deg | ≤ 20 fs2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Velpula, P.K.; Kramer, D.; Rus, B. Femtosecond Laser-Induced Damage Characterization of Multilayer Dielectric Coatings. Coatings 2020, 10, 603. https://doi.org/10.3390/coatings10060603

Velpula PK, Kramer D, Rus B. Femtosecond Laser-Induced Damage Characterization of Multilayer Dielectric Coatings. Coatings. 2020; 10(6):603. https://doi.org/10.3390/coatings10060603

Chicago/Turabian StyleVelpula, Praveen Kumar, Daniel Kramer, and Bedrich Rus. 2020. "Femtosecond Laser-Induced Damage Characterization of Multilayer Dielectric Coatings" Coatings 10, no. 6: 603. https://doi.org/10.3390/coatings10060603

APA StyleVelpula, P. K., Kramer, D., & Rus, B. (2020). Femtosecond Laser-Induced Damage Characterization of Multilayer Dielectric Coatings. Coatings, 10(6), 603. https://doi.org/10.3390/coatings10060603