Effect of Electrode Covering Composition on the Microstructure, Wear, and Economic Feasibility of Fe-C-Cr Manual Arc-Welded Hardfacings

Abstract

1. Introduction

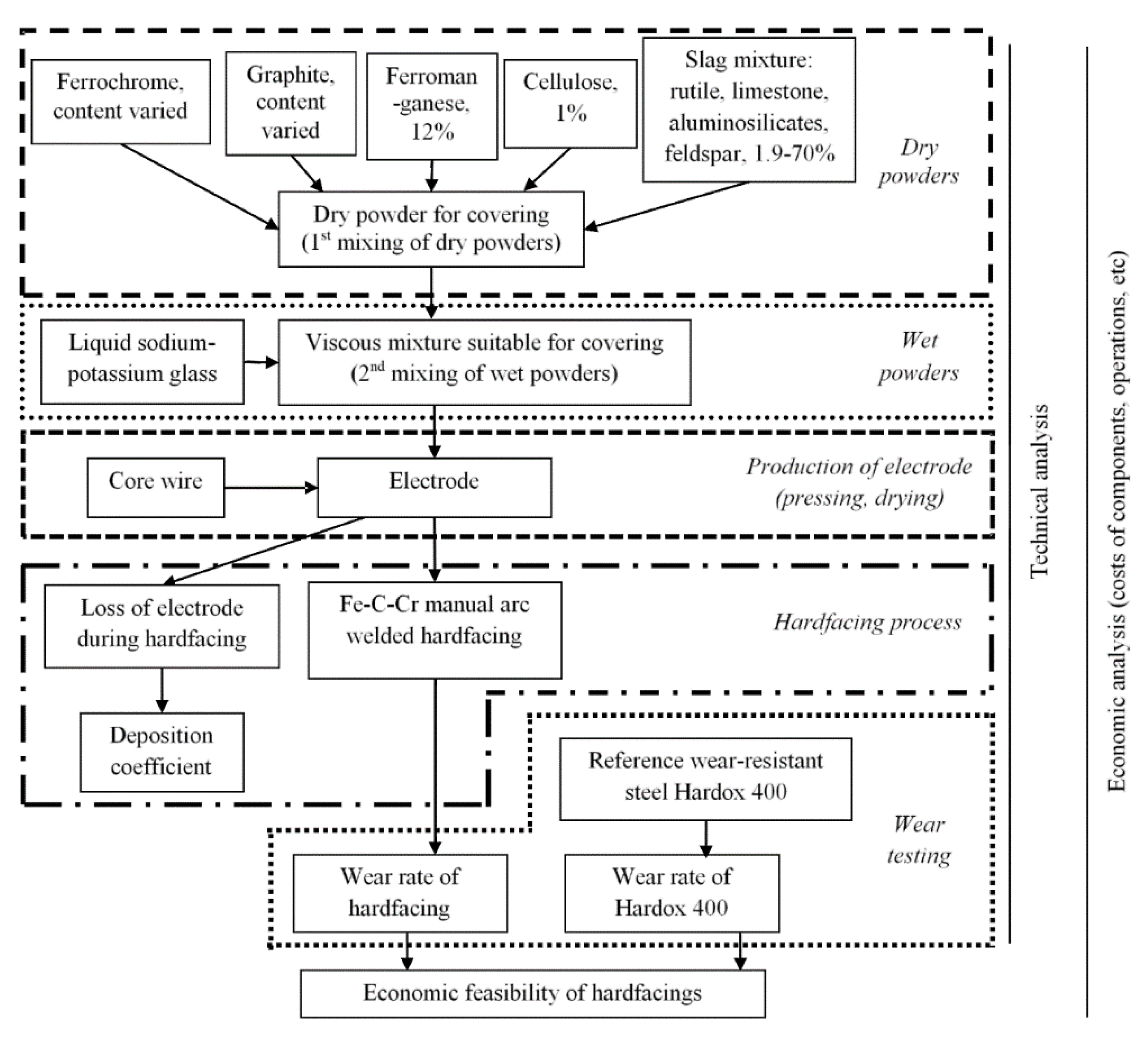

2. Materials and Methods

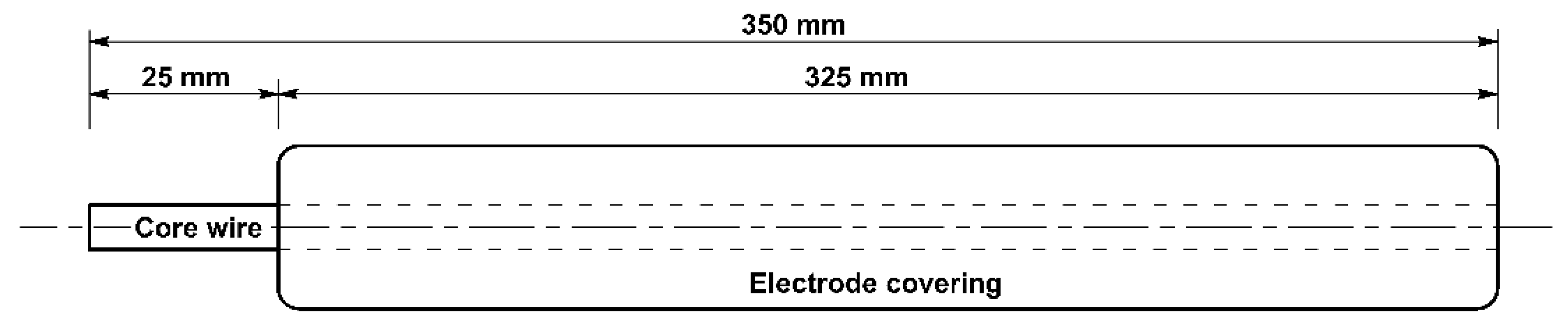

2.1. Production of Electrodes

2.2. Evaluation of the Economic Feasibility of Hardfacings

- -

- arc burning time was approximately 35% of the working time;

- -

- one electrode with the diameter of the wire being 3.2 mm melted in 1.6–2.0 min; therefore, 16 electrodes were deposited per hour during the hardfacing process, including the time for electrode exchange.

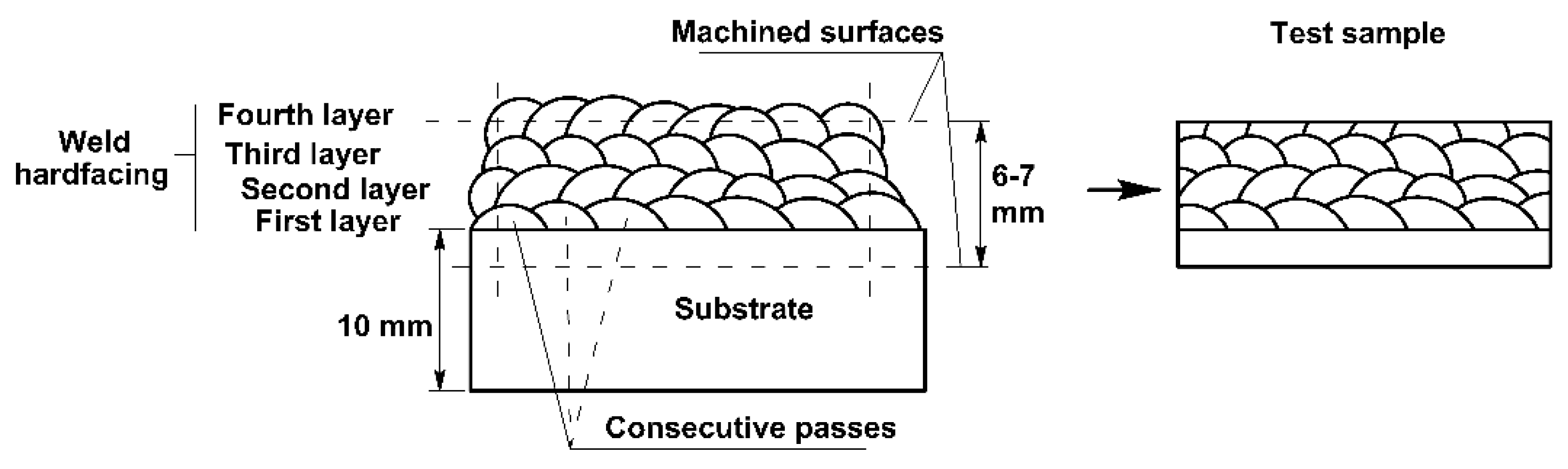

2.3. Deposition of Hardfacings

3. Results and Discussion

3.1. Composition and Hardness of Hardfacings

- Varied graphite and ferrochrome contents in the electrode covering (Codes 565, 604, 613, 622, 632, 631, and 647; hereinafter indicated as Group 565/647).

- Similar graphite content and varied ferrochrome content in the electrode covering (Codes 591, 601, 611, 621, and 631; hereinafter indicated as Group 591/631).

- Similar ferrochrome content and varied graphite content in the electrode covering (Codes 611, 612, 613, and 614; hereinafter indicated as Group 611/614).

- The remaining electrodes (590, 592, 593, 602, 603, 623, 624, and 633) were produced to track the effect of the electrode covering composition on the resulting composition and hardness of the hardfacing.

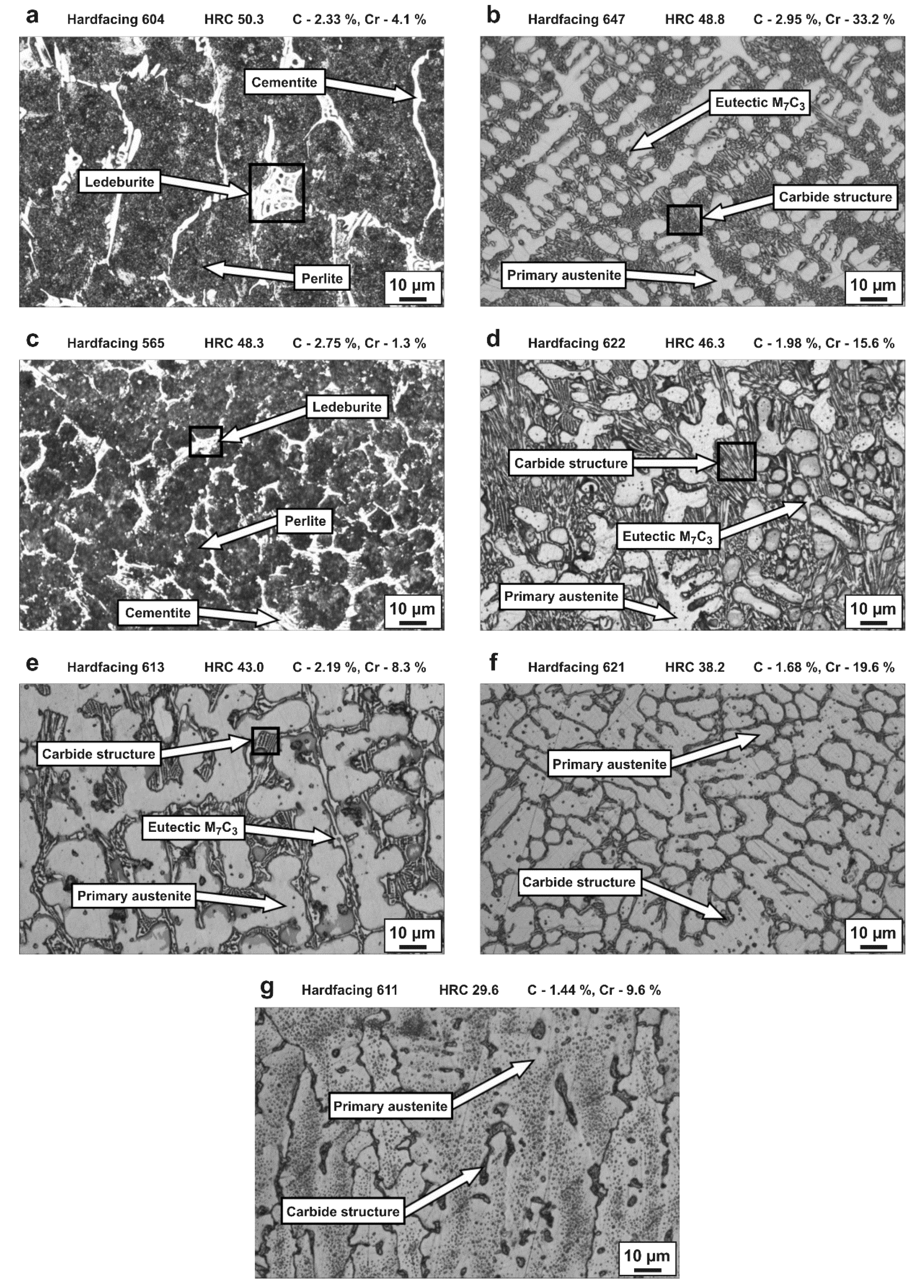

3.2. Microstructure of the Hardfacings

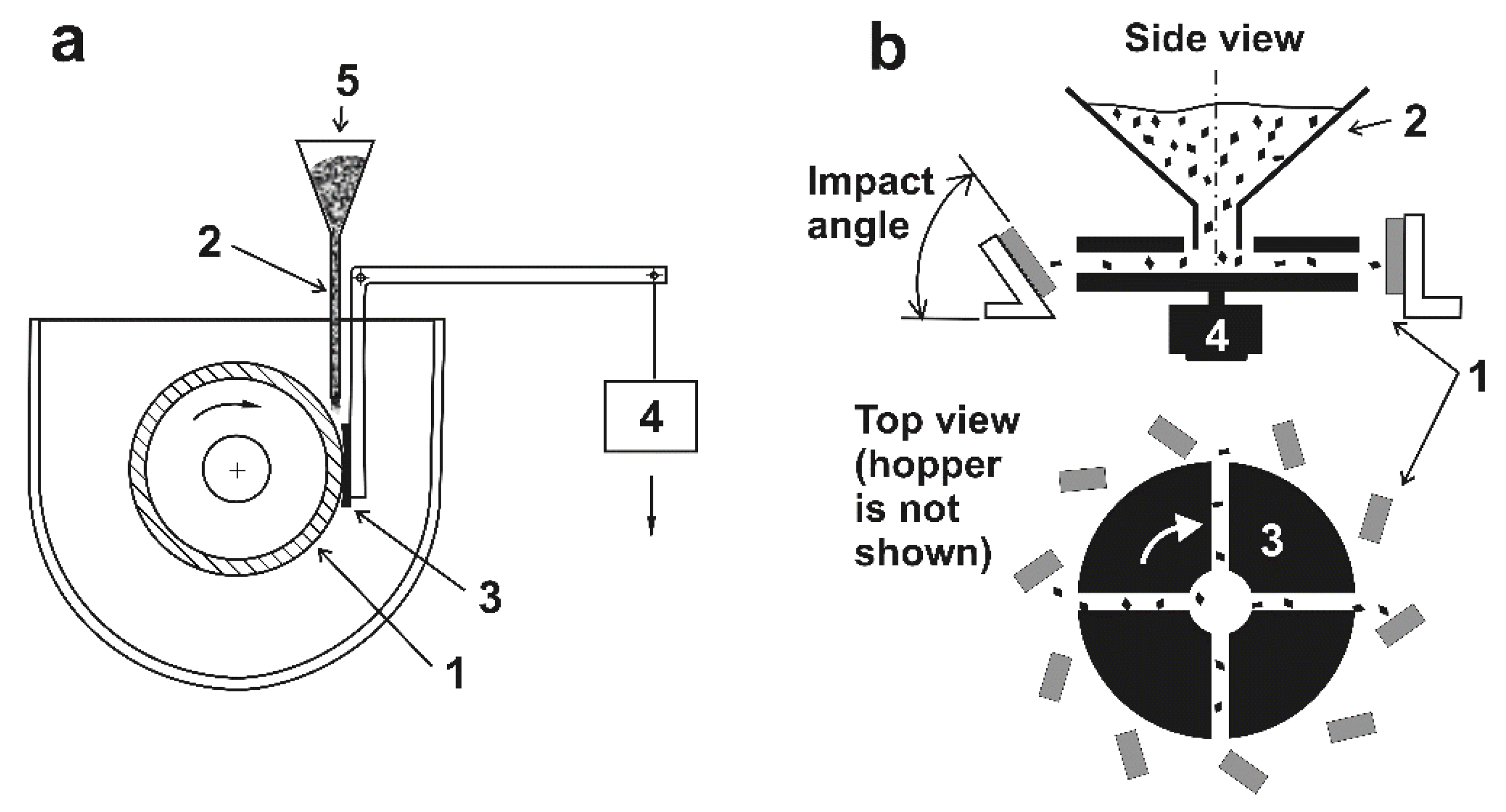

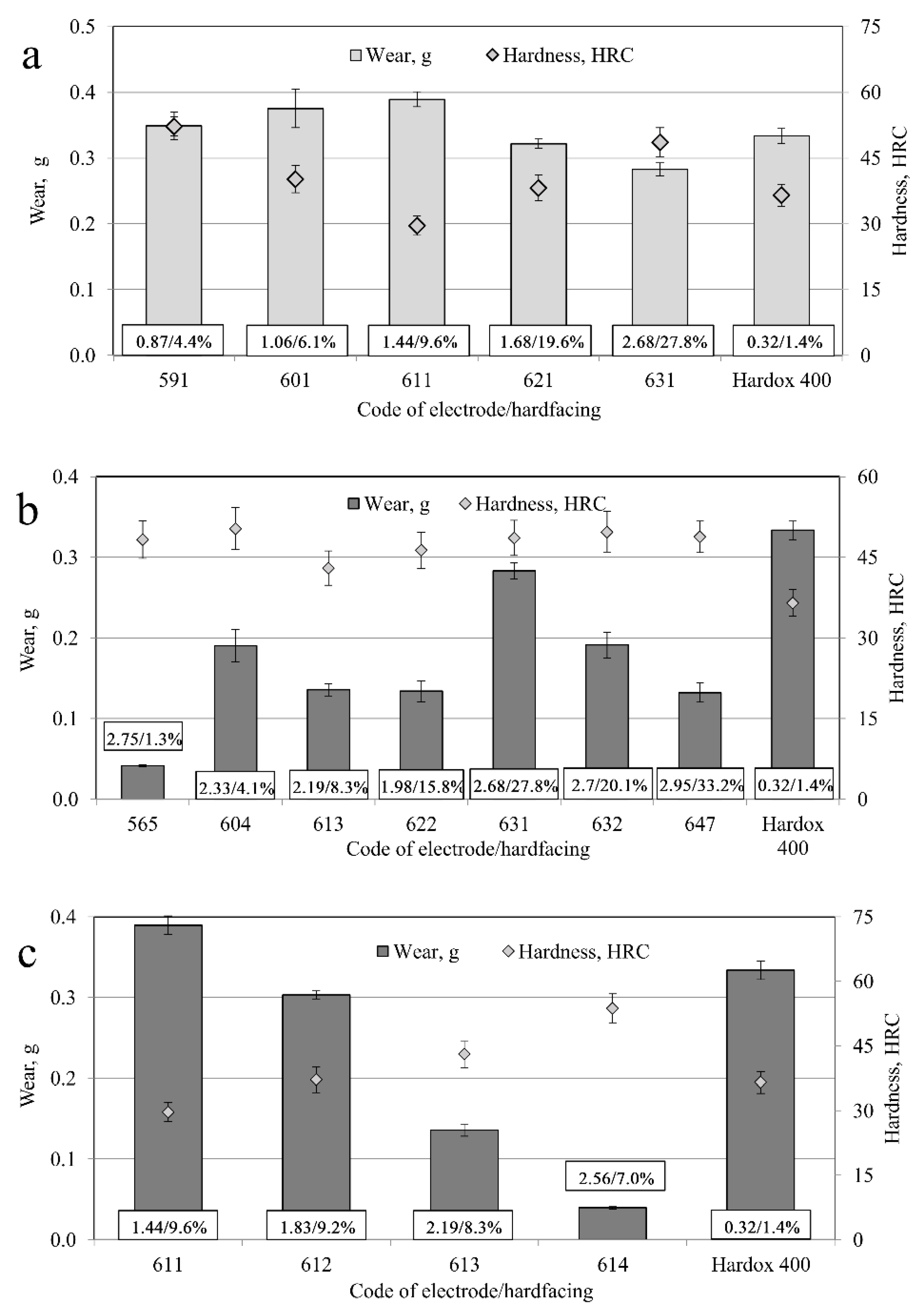

3.3. Wear of Hardfacings in Low-Stress Abrasive Conditions

3.4. Wear of Hardfacings in Average-Stress Abrasive Conditions

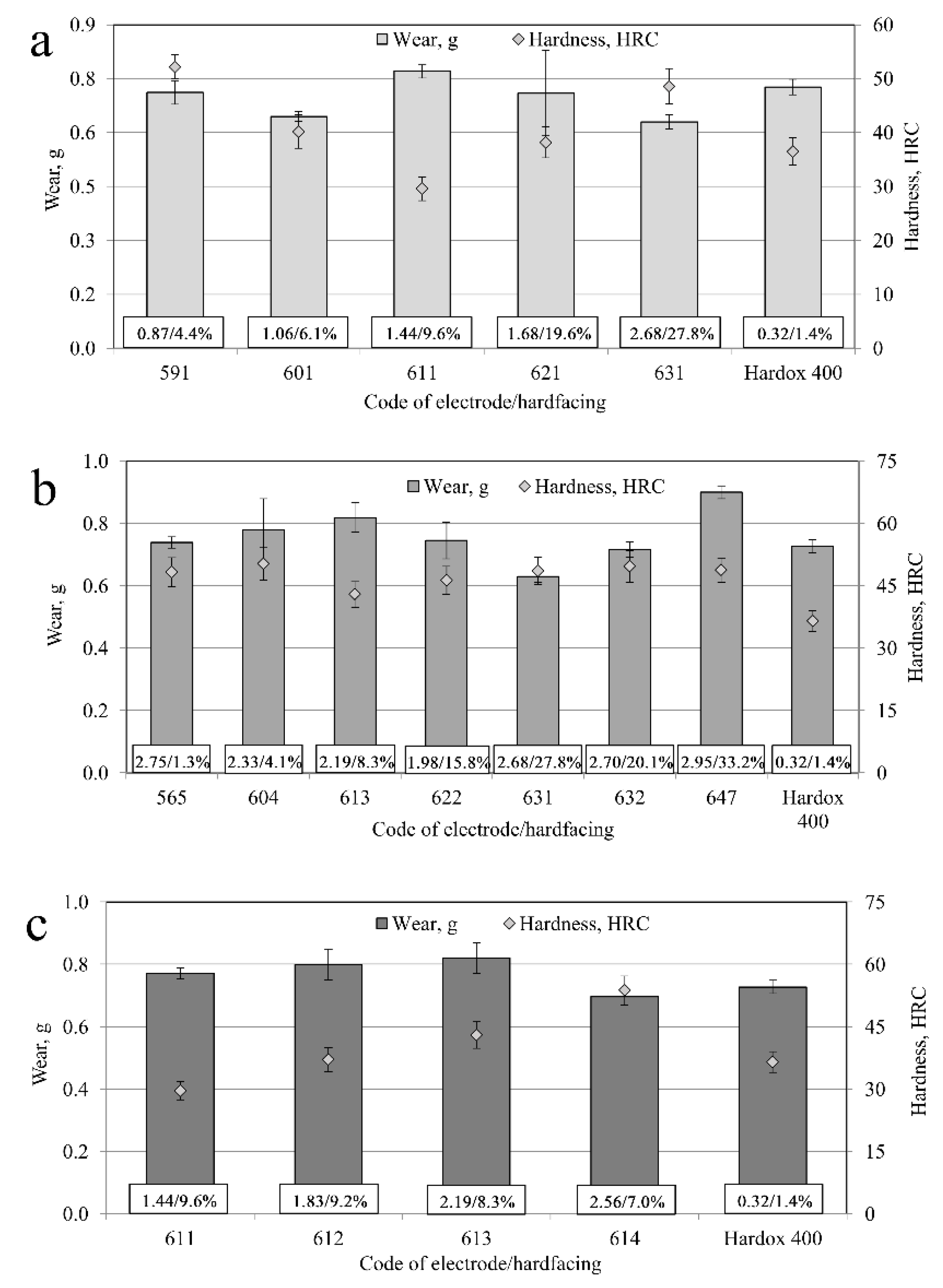

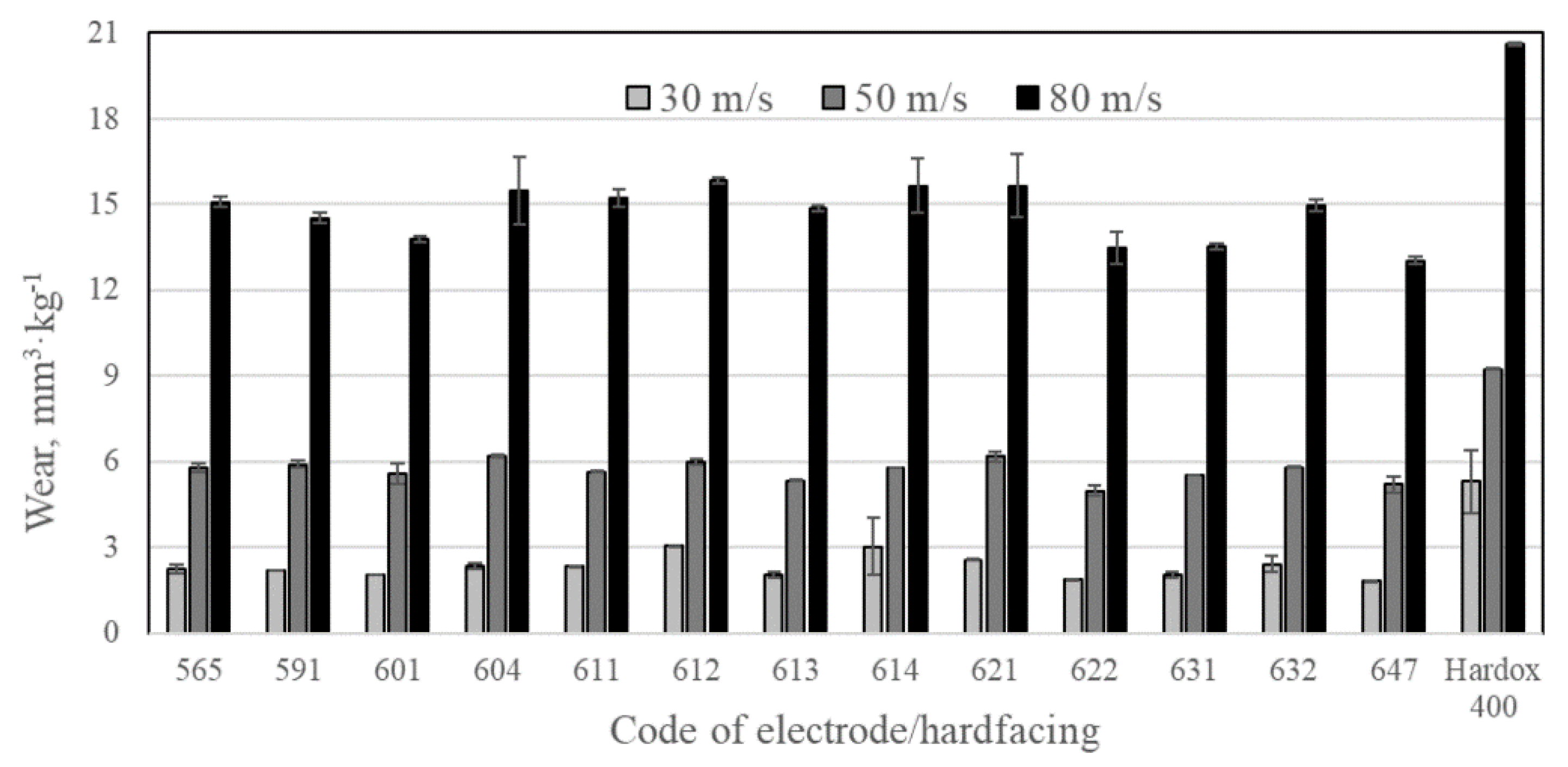

3.5. Wear of Hardfacings under Average- and High-Stress Erosive Conditions

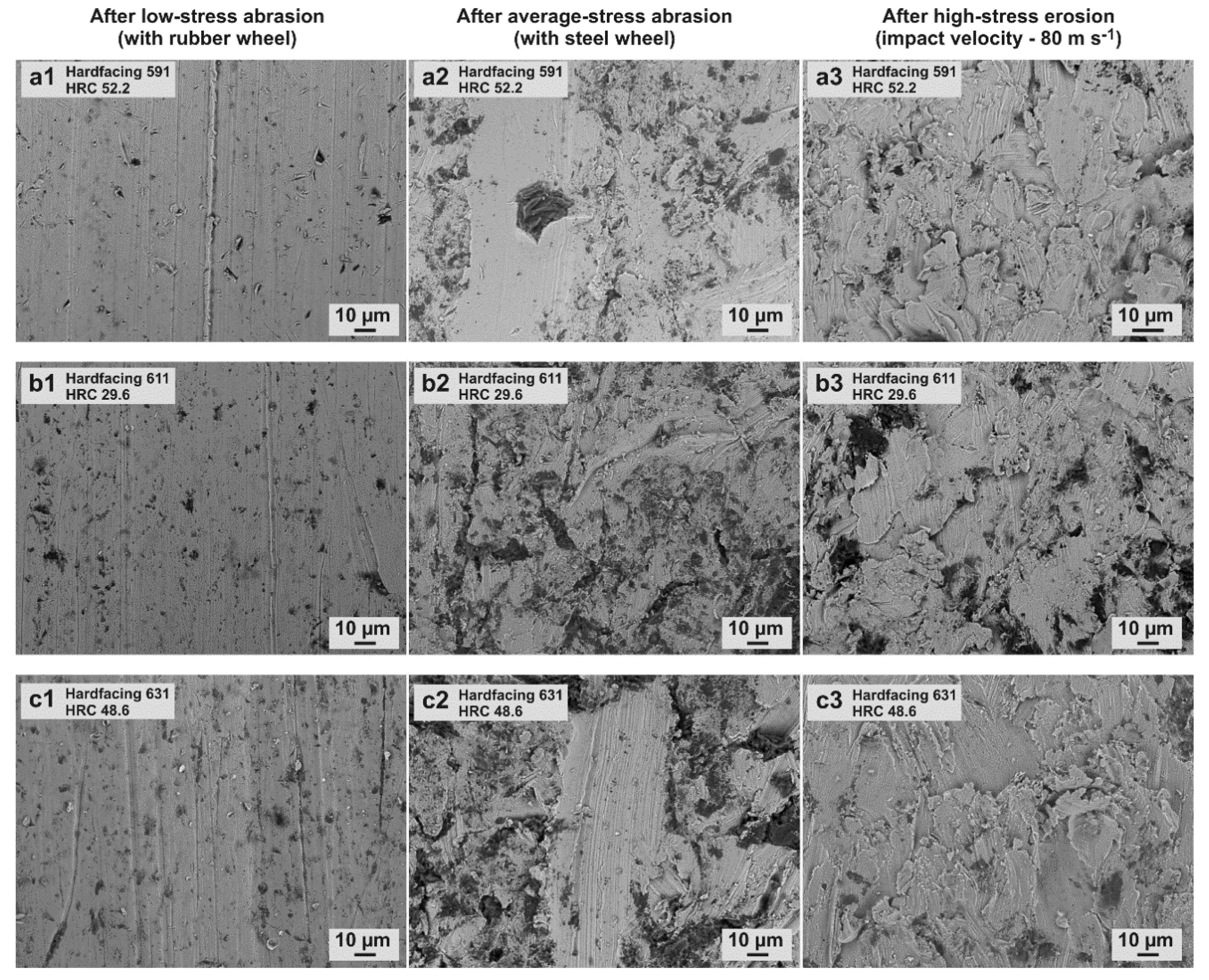

3.6. Analysis of Worn Surfaces

3.7. Technical and Economic Assessment of Hardfacings

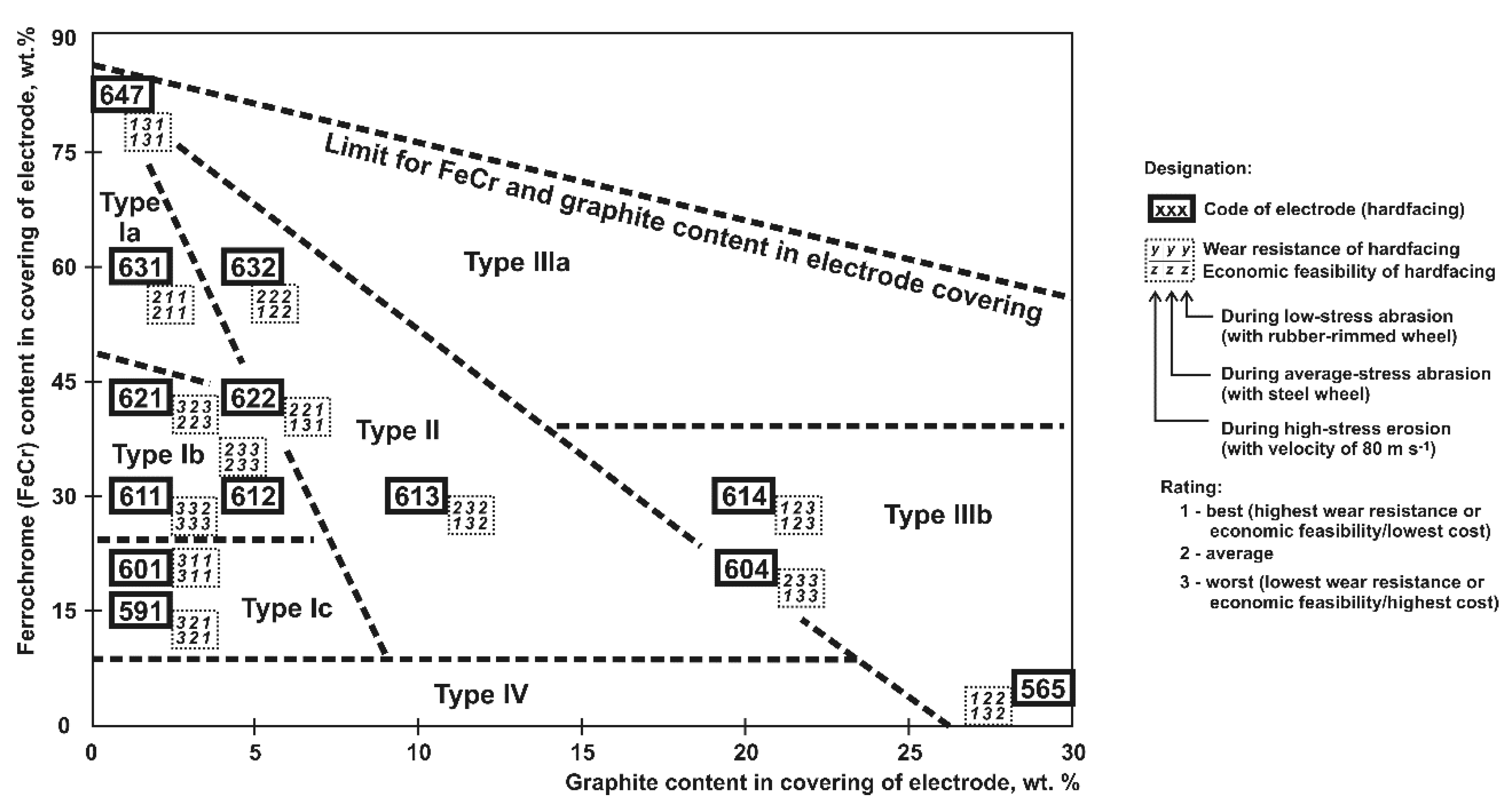

3.8. Analysis of Wear and Economic Feasibility

4. Conclusions

- Four groups of electrode coverings with adjusted proportions of initial components were produced to study the effects of these components on the resulting carbon and chromium contents, microstructure, hardness, and wear resistance of Fe–C–Cr hardfacings, which were manufactured by manual arc welding.

- The graphite and ferrochrome contents (among the dry components of electrode coverings) were varied from 0.1 to 30.0% and from 5.3 to 85.0%, respectively, which resulted in carbon and chromium contents of the hardfacings of 0.87 to 2.95% and 1.3 to 33.2%, respectively. The major phases composing the microstructures of the manufactured hardfacings and influencing the final properties were austenite, perlite, ledeburite, and various carbides, including eutectic M7C3.

- It was found that, in general, high hardness (a range of 29.6–53.5 HRC was obtained) could serve as an indicator of expected high wear resistance, whereas the microstructure, influenced by cooling rates and the presence of defects, such as pores or cracks, could be responsible for significant deterioration of the final properties of hardfacings.

- The strongest effect of carbon on the wear resistance of hardfacings was observed under low-stress abrasive conditions. The wear intensity ratio (wear resistance of hardfacings with respect to Hardox 400) was improved (by increasing the carbon content) from 0.86 to 7.77. The best results of the relative wear resistance under erosive conditions were also obtained under conditions with lower stress levels (1.58, 1.87, and 2.94 times at particle impingement speeds of 80, 50, and 30 m∙s−1, respectively).

- The price of Fe–C–Cr electrodes for manual arc welding ranged from 1.32 to 2.15 €∙kg−1. If all the costs required to manufacture hardfacings were taken into account (deposition coefficient, hardfacing productivity, labor cost), then the final price of the hardfacings ranged from 11.05 to 20.12 €∙kg−1.

- If the wear intensity ratio was taken into account, then hardfacings were the most economically feasible under low-stress abrasive conditions (the cost could be reduced down to 12.4% of that for Hardox 400, i.e., 7.8 times), whereas for erosion at 80, 50, and 30 m∙s−1, the price could be reduced down to 63.3, 53.5, and 34.0% (up to 2.9 times) that for Hardox 400, respectively.

- In general, Electrode 614, with graphite and ferrochrome contents of 20% and 30% in the covering, respectively, could be proposed as a universal option that performed quite well under all conditions. This could be influenced by the highest resulting titanium (TiC) contents among the investigated hardfacings.

Author Contributions

Funding

Conflicts of Interest

References

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Sadeghi, F.; Najafi, H.; Abbasi, A. The effect of Ta substitution for Nb on the microstructure and wear resistance of an Fe–Cr–C hardfacing alloy. Surf. Coat. Tech. 2017, 324, 85–91. [Google Scholar] [CrossRef]

- Jankauskas, V.; Kreivaitis, R.; Milčius, D.; Baltušnikas, A. Analysis of abrasive wear performance of arc welded hard layers. Wear 2008, 265, 1626–1632. [Google Scholar] [CrossRef]

- Narayanaswamy, B.; Hodgson, P.; Beladi, H. Effect of microstructure on abrasive wear behaviour. Agric. Eng. Res. Papers. 2015, 47, 1–4. [Google Scholar]

- Hornung, J.; Zikin, A.; Pichelbauer, K.; Kalin, M.; Kirchgaßner, M. Influence of cooling speed on the microstructure and wear behaviour of hypereutectic Fe–Cr–C hardfacings. Mater. Sci. Eng. 2013, 576, 243–251. [Google Scholar] [CrossRef]

- Jankauskas, V. Strengthening machine elements working under abrasive environment by alloying with hard layers and their estimation. Mechanika 2006, 57, 55–60. [Google Scholar]

- Veinthal, R.; Sergejev, F.; Zikin, A.; Tarbe, R.; Hornung, J. Abrasive impact wear and surface fatigue wear behaviour of Fe–Cr–C PTA overlays. Wear 2013, 301, 102–108. [Google Scholar] [CrossRef]

- Liu, H.Y.; Song, Z.L.; Cao, Q.; Chen, S.P.; Meng, Q.S. Microstructure and properties of Fe–Cr–C hardfacing alloys reinforced with TiC-NbC. J. Iron Steel Res. Int. 2016, 23, 276–280. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, Y.; Xing, X.; Wang, J.; Yang, Y.; Yang, Q. Agglomeration model of (Fe,Cr)7C3 carbide in hypereutectic Fe–Cr–C alloy. Mater. Lett. 2016, 183, 272–276. [Google Scholar] [CrossRef]

- Yüksel, N.; Sahin, S. Wear behavior–hardness–microstructure relation of Fe–Cr–C and Fe–Cr–C–B based hardfacing alloys. Mater. Des. 2014, 58, 491–498. [Google Scholar] [CrossRef]

- Chang, C.M.; Chen, Y.C.; Wu, W. Microstructural and abrasive characteristics of high carbon Fe–Cr–C hardfacing alloys. Tribol. Int. 2010, 43, 929–934. [Google Scholar] [CrossRef]

- Ye, F.; Hojamberdiev, M.; Xu, Y.; Zhong, L.; Yan, H.; Chen, Z. (Fe,Cr)7C3/Fe surface gradient composite: Microstructure, microhardness, and wear resistance. Mater. Chem. Phys. 2014, 147, 823–830. [Google Scholar] [CrossRef]

- Buchely, M.-F.; Gutierrez, J.-C.; León, L.-M.; Toro, A. The effect of microstructure on abrasive wear of hardfacing alloys. Wear 2005, 259, 52–61. [Google Scholar] [CrossRef]

- Correa, E.-O.; Alcântara, N.-G.; Valeriano, L.-C.; Barbedo, N.-D.; Chaves, R.R. The Effect of Microstructure on Abrasive Wear of a Fe-Cr-C-Nb Hardfacing Alloy Deposited by the Open Arc Welding Process. Surf. Coat. Tech. 2015, 276, 479–484. [Google Scholar] [CrossRef]

- Falat, L.; Džupon, M.; Ťavodová, M.; Hnilica, R.; L’uptáčiková, V.; Čiripová, L.; Homolová, V.; Ďurišinová, K. Microstructure and Abrasive Wear Resistance of Various Alloy Hardfacings for Application on Heavy-Duty Chipper Tools in Forestry Shredding and Mulching Operations. Materials 2019, 12, 2212. [Google Scholar] [CrossRef]

- Medyński, D.; Samociuk, B.; Janus, A.; Checmanowski, J. Effect of Cr, Mo and Al on Microstructure, Abrasive Wear and Corrosion Resistance of Ni-Mn-Cu Cast Iron. Materials 2019, 12, 3500. [Google Scholar] [CrossRef]

- Vuorinen, E.; Heino, V.; Ojala, N.; Haiko, O.; Hedayati, A. Erosive-Abrasive Wear Behavior of Carbide-Free Bainitic and Boron Steels Compared in Simulated Field Conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 3–13. [Google Scholar] [CrossRef]

- Sathiya, P.; Mishra, M.-K.; Shanmugarajan, B. Effect of Shielding Gases on Microstructure and Mechanical Properties of Super Austenitic Stainless Steel by Hybrid Welding. Mater.Des. 2018, 33, 203–212. [Google Scholar] [CrossRef]

- Katsich, C.; Badisch, E.; Roy, M.; Heath, G.R.; Franek, F. Erosive wear of hardfaced Fe–Cr–C alloys at elevated temperature. Wear 2009, 267, 1856–1864. [Google Scholar] [CrossRef]

- Yang, J.; Tian, J.; Hao, F.; Dan, T.; Ren, X.; Yang, Y.; Yang, Q. Microstructure and wear resistance of the hypereutectic Fe–Cr–C alloy hardfacing metals with different La2O3 additives. Appl. Surf. Sci. 2014, 289, 437–444. [Google Scholar] [CrossRef]

- Sidlin, Z.A. Manufacture of Electrodes for Manual Arc Welding; Ekotekhnologiya: Kyiv, Ukraine, 2009. (In Russian) [Google Scholar]

- Kushnerev, D.M.; Bulat, A.; Gnatenko, M.F. Handbook. Materials for Production Covered Electrodes for Manual Arc Welding, Their Suppliers; Velma: Kyiv, Ukraine, 1997. (In Russian) [Google Scholar]

- Jankauskas, V.; Antonov, M.; Varnauskas, V.; Skirkus, R.; Goljandin, D. Effect of WC grain size and content on low stress abrasive wear of manual arc welded hardfacings with low-carbon or stainless steel matrix. Wear 2015, 328–329, 378–390. [Google Scholar] [CrossRef]

- Jankauskas, V.; Katinas, E.; Skirkus, R.; Aleknevičienė, V. The method of hardening soil rippers by surfacing and technical–economic assessment. J. Frict. Wear 2014, 35, 270–277. [Google Scholar] [CrossRef]

- GOST 23.201–78—Standard. Products Wear Resistance Assurance. Gas Abrasive Wear Testing of Materials and Coatings with Centrifugal Accelerator, 1978. Available online: http://protect.gost.ru/document.aspx?control=7&id=156361 (accessed on 21 March 2020). (In Russian).

- Günther, K.; Bergmann, J.P.; Suchodoll, D. Hot wire-assisted gas metal arc welding of hypereutectic FeCrC hardfacing alloys: Microstructure and wear properties. Surf. Coat. Tech. 2018, 334, 420–428. [Google Scholar] [CrossRef]

- Fan, C.; Chen, M.-C.; Chang, C.-M.; Wu, W. Microstructure change caused by (Cr,Fe)23C6 carbides in high chromium Fe–Cr–C hardfacing alloys. Surf. Coat. Tech. 2006, 201, 908–912. [Google Scholar] [CrossRef]

- Gu, J.; Xiao, P.; Song, J.; Li, Z.h.; Lu, R. Sintering of a hypoeutectic high chromium cast iron as well as its microstructure and properties. J. Alloys Comp. 2018, 740, 485–491. [Google Scholar] [CrossRef]

- Chang, C.-M.; Chen, L.-H.; Lin, C.-M.; Chen, J.-H.; Wu, W. Microstructure and wear characteristics of hypereutectic Fe–Cr–C cladding with various carbon contents. Surf. Coat. Tech. 2010, 205, 245–250. [Google Scholar] [CrossRef]

- Badisch, E.; Katsich, C.; Winkelmann, H.; Franek, F.; Roy, M. Wear behaviour of hardfaced Fe-Cr-C alloy and austenitic steel under 2-body and 3-body conditions at elevated temperature. Tribol. Int. 2010, 43, 1234–1244. [Google Scholar] [CrossRef]

- Antonov, M.; Hussainova, I.; Pirso, J.; Volobueva, O. Assessment of mechanically mixed layer developed during high temperature erosion of cermets. Wear 2007, 263, 878–886. [Google Scholar] [CrossRef]

- Antonov, M.; Hussainova, I. Cermets surface transformation under erosive and abrasive wear. Tribol. Int. 2010, 43, 1566–1575. [Google Scholar] [CrossRef]

| Ferrochrome, % | ||||||||

|---|---|---|---|---|---|---|---|---|

| 5.3 | 15.0 | 21.2 | 30.0 | 42.4 | 60.0 | 85.0 | ||

| Graphite, % | 0.1 | – | – | – | – | – | – | 647/2.95/33.2 |

| 1.0 | – | * 590/0.61/4.3 | – | – | – | – | – | |

| 2.0 | – | 591/0.87/4.4 | 601/1.06/6.1 | 611/1.44/9.6 | 621/1.68/19.6 | 631/2.68/25.1 | – | |

| 5.0 | – | * 592/1.01/4.4 | * 602/1.33/5.6 | 612/1.83/9.2 | 622/1.98/15.8 | 632/2.93/20.1 | ||

| 10.0 | – | * 593/1.62/4.7 | * 603/1.72/4.9 | 613/2.19/8.3 | * 623/2.03/9.4 | * 633/2.93/19.5 | – | |

| 20.0 | – | – | 604/2.33/4.1 | 614/2.56/7.0 | * 624/2.43/7.4 | – | – | |

| 30.0 | 565/2.75/1.3 | – | – | – | – | – | – | |

| Title | Unit | Code of Electrode | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 565 | 591 | 601 | 604 | 611 | 612 | 613 | 614 | 621 | 622 | 631 | 632 | 647 | ||

| Composition of electrode covering (dry powders) | ||||||||||||||

| Ferrochrome | % | 5.3 | 15 | 21.2 | 21.2 | 30 | 30 | 30 | 30 | 42.4 | 42.4 | 60 | 60 | 85 |

| Graphite | % | 30 | 2 | 2 | 20 | 2 | 5 | 10 | 20 | 2 | 5 | 2 | 5 | 0.1 |

| Ferromanganese | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Cellulose | % | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Slag materials | % | 51.7 | 70.0 | 63.8 | 45.8 | 55.0 | 52 | 47.0 | 37 | 42.6 | 39.6 | 25.0 | 22.0 | 1.9 |

| Total | % | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Other technical parameters | ||||||||||||||

| Mass of one electrode (M) | g | 37.75 | 34.25 | 33.75 | 32.50 | 34.65 | 35.95 | 35.35 | 34.45 | 36.50 | 40.20 | 41.05 | 39.20 | 47.50 |

| Electrode covering wt. rate L with respect to M (see Equation (3)) | % | 73.0 | 56.2 | 53.9 | 47.9 | 58.2 | 64.4 | 61.5 | 57.2 | 67.0 | 84.7 | 88.8 | 79.9 | 119.7 |

| Cost of electrode components and electrodes per 1 kg of electrode | ||||||||||||||

| Wire | €∙kg−1 | 0.36 | 0.40 | 0.40 | 0.42 | 0.39 | 0.38 | 0.38 | 0.39 | 0.37 | 0.34 | 0.33 | 0.35 | 0.29 |

| Covering | €∙kg−1 | 0.92 | 0.42 | 0.44 | 0.67 | 0.53 | 0.62 | 0.69 | 0.82 | 0.69 | 0.84 | 0.96 | 0.98 | 1.36 |

| Production costs | €∙kg−1 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 |

| Total (S1 kg electrode) | €∙kg−1 | 1.78 | 1.32 | 1.35 | 1.59 | 1.43 | 1.51 | 1.58 | 1.72 | 1.56 | 1.68 | 1.80 | 1.83 | 2.15 |

| Parameter | Description | |

|---|---|---|

| Scheme | Block–on–Wheel | |

| Contact stress | Low | Average |

| Description of the wheel (Ø229 mm, width 12.7 mm) | Rubber-rimmed steel wheel, with rubber of hardness Shore A-60 | Steel wheel with hardness 165 HB |

| Abrasive | Silica quartz sand with size 200–425 μm from SC Anykščių kvarcas; feed rate 250–300 g min−1 | |

| Circumferential velocity | 2.4 m s−1 | |

| Linear abrasion | 4320 m/30 min | 1440 m/10 min |

| Load | 130 N | 85 N |

| Atmosphere | Air, 23 ± 2 °C, relative humidity 45 ± 5% | |

| Code | Chemical Composition of Hardfacing, % | Hardness, HRC | ||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Ti | ||

| 565 | 2.75 | 1.94 | 2.18 | 1.3 | 1.25 | 48.3 ± 3.5 |

| 591 | 0.87 | 0.57 | 1.38 | 4.4 | 0.06 | 52.2 ± 2.2 |

| 601 | 1.06 | 0.96 | 1.54 | 6.1 | 0.09 | 40.2 ± 3.1 |

| 604 | 2.33 | 1.62 | 1.55 | 4.1 | 0.44 | 50.3 ± 3.9 |

| 611 | 1.44 | 0.87 | 1.83 | 9.6 | 0.09 | 29.6 ± 2.2 |

| 612 | 1.83 | 0.93 | 2.08 | 9.2 | 0.12 | 37.1 ± 2.9 |

| 613 | 2.19 | 1.33 | 2.67 | 8.3 | 0.33 | 43.0 ± 3.2 |

| 614 | 2.56 | 1.44 | 2.46 | 7.0 | 1.08 | 53.7 ± 3.4 |

| 621 | 1.68 | 1.17 | 2.26 | 19.6 | 0.12 | 38.2 ± 2.9 |

| 622 | 1.98 | 0.81 | 3.88 | 15.6 | 0.30 | 46.3 ± 3.4 |

| 631 | 2.68 | 1.42 | 3.45 | 27.8 | 0.18 | 48.6 ± 3.3 |

| 632 | 2.70 | 1.36 | 3.96 | 20.1 | 0.33 | 49.7 ± 3.8 |

| 647 | 2.95 | 0.28 | 3.92 | 33.2 | 0.04 | 48.8 ± 2.9 |

| Reference material: Hardox 400 steel. Chemical composition (%): C: 0.32; Si: 0.7; Mn: 1.6; Cr: 1.4; Mo: 0.6; Ni: 1.5; B: 0.004; P: 0.02; S: 0.01. Microstructure: fine-grained martensite. | 36.5 ± 2.5 | |||||

| Parameter | Unit | Code of Electrode | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 565 | 591 | 601 | 604 | 611 | 612 | 613 | 614 | 621 | 622 | 631 | 632 | 647 | ||

| η—deposition coefficient | 0.50 | 0.57 | 0.59 | 0.60 | 0.61 | 0.60 | 0.60 | 0.61 | 0.64 | 0.62 | 0.68 | 0.69 | 0.79 | |

| Mass of electrode required to deposit 1 kg of hardfacing | kg | 2.00 | 1.75 | 1.69 | 1.67 | 1.64 | 1.67 | 1.67 | 1.64 | 1.56 | 1.61 | 1.47 | 1.45 | 1.27 |

| Hardfacing material cost (S 1kg Hardfacing material) | €∙kg−1 | 3.56 | 2.31 | 2.28 | 2.65 | 2.34 | 2.52 | 2.63 | 2.82 | 2.44 | 2.71 | 2.64 | 2.65 | 2.72 |

| Hardfacing productivity (P) | kg∙h−1 | 0.30 | 0.31 | 0.32 | 0.31 | 0.34 | 0.35 | 0.34 | 0.34 | 0.37 | 0.40 | 0.45 | 0.43 | 0.60 |

| Labor cost | €∙kg−1 | 16.56 | 16.01 | 15.69 | 16.03 | 14.78 | 14.49 | 14.73 | 14.87 | 13.38 | 16.56 | 16.01 | 15.69 | 16.03 |

| Cost of deposited hardfacing (S 1 kg Hardfacing) | €∙kg−1 | 20.12 | 18.32 | 17.98 | 18.68 | 17.13 | 17.00 | 17.37 | 17.69 | 15.82 | 15.25 | 13.84 | 14.20 | 11.05 |

| Cost of repair with Hardox 400 (S 1 kg Repair with Hardox 400) | €∙kg−1 | 12.00 | ||||||||||||

| Wear intensity ratio ε (wear resistance of hardfacings; see Equation (7)) | ||||||||||||||

| Low-stress abrasion | – | 8.05 | 0.96 | 0.89 | 1.76 | 0.86 | 1.10 | 2.46 | 7.77 | 1.04 | 2.49 | 1.18 | 1.75 | 2.53 |

| Average-stress abrasion | – | 0.98 | 1.02 | 1.13 | 0.93 | 0.94 | 0.91 | 0.89 | 1.04 | 1.02 | 0.98 | 1.16 | 1.02 | 0.81 |

| Average-stress erosion at 30 m s−1 | – | 2.38 | 2.43 | 2.58 | 2.26 | 2.29 | 1.75 | 2.61 | 1.76 | 2.07 | 2.86 | 2.58 | 2.20 | 2.94 |

| High-stress erosion at 50 m s−1 | – | 1.60 | 1.57 | 1.66 | 1.49 | 1.64 | 1.54 | 1.74 | 1.06 | 1.50 | 1.87 | 1.68 | 1.59 | 1.78 |

| High-stress erosion at 80 m s−1 | – | 1.37 | 1.42 | 1.49 | 1.33 | 1.35 | 1.30 | 1.39 | 1.32 | 1.32 | 1.53 | 1.52 | 1.38 | 1.58 |

| Relative cost of hardfacings under different wear conditions taking into account the wear intensity ratio (see Equation (8)) | ||||||||||||||

| Low-stress abrasion | €∙kg−1 | 1.49 | 12.50 | 13.48 | 6.82 | 13.95 | 10.91 | 4.88 | 1.54 | 11.54 | 4.82 | 10.17 | 6.86 | 4.74 |

| Average-stress abrasion | €∙kg−1 | 12.24 | 11.76 | 10.62 | 12.90 | 12.77 | 13.19 | 13.53 | 11.54 | 11.76 | 12.24 | 10.34 | 11.76 | 14.81 |

| Average-stress erosion at 30 m s–1 | €∙kg−1 | 5.04 | 4.94 | 4.65 | 5.31 | 5.24 | 6.86 | 4.60 | 6.82 | 5.80 | 4.20 | 4.65 | 5.45 | 4.08 |

| High-stress erosion at 50 m s–1 | €∙kg−1 | 7.50 | 7.67 | 7.23 | 8.05 | 7.32 | 7.79 | 6.90 | 11.32 | 8.00 | 6.42 | 7.14 | 7.55 | 6.74 |

| High-stress erosion at 80 m s–1 | €∙kg−1 | 8.76 | 8.45 | 8.05 | 9.02 | 8.89 | 9.23 | 8.63 | 9.09 | 9.09 | 7.84 | 7.89 | 8.70 | 7.59 |

| Relative cost of hardfacing K (%; see Equation (9)) | ||||||||||||||

| Low-stress abrasion | % | 12.4 | 104.2 | 112.3 | 56.8 | 116.3 | 90.9 | 40.7 | 12.8 | 96.2 | 40.2 | 84.8 | 57.2 | 39.5 |

| Average-stress abrasion | % | 102.0 | 98.0 | 88.5 | 107.5 | 106.4 | 109.9 | 112.8 | 96.2 | 98.0 | 102.0 | 86.2 | 98.0 | 123.4 |

| Average-stress erosion at 30 m s−1 | % | 42.0 | 41.2 | 38.8 | 44.3 | 43.7 | 57.2 | 38.3 | 56.8 | 48.3 | 35.0 | 38.8 | 45.4 | 34.0 |

| High-stress erosion at 50 m s−1 | % | 62.5 | 63.9 | 60.3 | 67.1 | 61.0 | 64.9 | 57.5 | 94.3 | 66.7 | 53.5 | 59.5 | 62.9 | 56.2 |

| High-stress erosion at 80 m s−1 | % | 73.0 | 70.4 | 67.1 | 75.2 | 74.1 | 76.9 | 71.9 | 75.8 | 75.8 | 65.3 | 65.8 | 72.5 | 63.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jankauskas, V.; Katinas, E.; Laskauskas, A.; Antonov, M.; Varnauskas, V.; Gedzevičius, I.; Aleknevičienė, V. Effect of Electrode Covering Composition on the Microstructure, Wear, and Economic Feasibility of Fe-C-Cr Manual Arc-Welded Hardfacings. Coatings 2020, 10, 294. https://doi.org/10.3390/coatings10030294

Jankauskas V, Katinas E, Laskauskas A, Antonov M, Varnauskas V, Gedzevičius I, Aleknevičienė V. Effect of Electrode Covering Composition on the Microstructure, Wear, and Economic Feasibility of Fe-C-Cr Manual Arc-Welded Hardfacings. Coatings. 2020; 10(3):294. https://doi.org/10.3390/coatings10030294

Chicago/Turabian StyleJankauskas, Vytenis, Egidijus Katinas, Artūras Laskauskas, Maksim Antonov, Valentinas Varnauskas, Irmantas Gedzevičius, and Vilija Aleknevičienė. 2020. "Effect of Electrode Covering Composition on the Microstructure, Wear, and Economic Feasibility of Fe-C-Cr Manual Arc-Welded Hardfacings" Coatings 10, no. 3: 294. https://doi.org/10.3390/coatings10030294

APA StyleJankauskas, V., Katinas, E., Laskauskas, A., Antonov, M., Varnauskas, V., Gedzevičius, I., & Aleknevičienė, V. (2020). Effect of Electrode Covering Composition on the Microstructure, Wear, and Economic Feasibility of Fe-C-Cr Manual Arc-Welded Hardfacings. Coatings, 10(3), 294. https://doi.org/10.3390/coatings10030294