Abstract

In polymer processing, the formation of undesired fouling hinders the plastic manufacturing processes. Hence, the use of emulsions as releasing agents is mandatory and their affinity to the mold substrates plays a crucial role. Therefore, this research work has been focused on the wetting properties of commercial water-based release agents (namely Marbocote® W2140, EP, EV-333) towards different Physical Vapor Deposition (PVD) nitride coatings (AlTiN, NbN, ZrN and TiN), usually adopted in the industrial manufacture of Hydrogenated Nitrile Butadiene Rubber (HNBR). The investigated solid substrates were characterized by means of profilometry, SEM/EDX and Surface Free Energy (SFE) analyses, whereas, tensiometric determinations were acquired on the commercial pure and diluted emulsions. The release agents/mold substrates wettability features were studied by means of the work of adhesion and the spreading coefficient. Finally, nitride-coated mold seals were directly tested in an industrial plant with the most performing release agent in terms of adhesive features; for the first time, a deep correlation between the service life, in terms of number of molded seals, and surface (contact angles, work of adhesion and spreading coefficient)/electrochemical (OCP) features was drawn.

1. Introduction

Polymer processing technology, including injection and compression molding [1,2,3], entails a prolonged polymer/metal tool contact. Hence their adhesion [4,5,6], depending on the process conditions, the solid tool surface features (type, roughness and surface free energy) and the polymer chemistry, plays a pivotal role in affecting the quality of the final plastic product.

However, when the affinity between the polymers and the mold substrates is relatively low, the formation of mold fouling [7] occurs, causing the interruption of the plastic manufacturing process. Specifically, mold fouling is a layer of material, which forms on the surface of metal molds during the rubber vulcanization. Indeed, it is the result of thermochemical changes in components of rubber compounds during high temperature molding condition, impeding the heat transfer from the mold to the polymer. Thus, in order to obtain defect-free rubber articles, mold fouling must be removed from the metal surface tools by means of regular cleanings, therefore representing an onerous step for the industry (i.e. the production line shutdown, the use of expensive chemical products).

Hence, two approaches can be followed to limit the mold fouling phenomena. The first one consists in the modification of the rubber formulation, for example by choosing the right plasticizing agents, such as extender oils [8,9]. The second approach involves the use of release agents [10,11] (typically emulsion-based compounds [12,13]), which are applied to the mold surfaces to ensure the total removal of the undesired products from the surfaces themselves. Regarding the former, the plasticizer is fundamental for the vulcanizing process, because this component allows the phase transitions. However, bad plasticizers and other compounding ingredients of the rubber formulation can migrate to the interface increasing catalytic reactions [7], thus resulting in the formation of mold fouling. The main drawbacks of this approach are due to both the secrecy of the rubber formulation, that in the most cases is covered by patent or at least by internal know-how, and the low propensity to modify internal recipes. On the contrary, as concern the second modus operandi, the release agents allow the reduction of mold fouling; they are deposited as a very thin layer to the mold surfaces, covering them uniformly and acting as a barrier that prevents the rubber sticking.

Nowadays, among several mold materials, nitride-coated (e.g. TiN, AlTiN and CrN [5,14,15]) metal substrates, obtained by Physical Vapor Deposition (PVD) method, show improved mechanical properties and good wear/corrosion resistance [14,16,17,18].

The surface wettability by a liquid is defined in terms of both spreading coefficient (S) and work of adhesion (Wa), by evaluating both the surface free energy of substrate and the surface tension (γ) of the liquid. Thus, if these two proprieties are similar, the mold release spontaneously wets the surface. Sun et al. [6] reported that the molding releasing capability is directly associated with the surface free energy of various magnetron sputtered coatings. Lugscheider et al. [5] affirmed that a very high adhesion is achieved on PVD substrates with high surface energy, in particular high surface shares. Notwithstanding the recent works, there is still a lack of understanding of the mold fouling causes; and this represents, nowadays, a real and costly industrial problem.

Hence, in the present research work the interaction between four different PVD coatings, adopted for the protection of steel molds, and three releasing agents is studied, in order to obtain a uniform film, successfully preventing the mold fouling formation in the case of hydrogenated nitrile butadiene rubber materials. Moreover, the real efficiency, in terms of number of molded seals, is demonstrated to be strictly correlated by both wettability and electrochemical (Open Circuit Potential, OCP measurements) results.

2. Materials and Methods

2.1. PVD Coatings

The samples used in this research study were made by Vacuum Cathodic Arc [17]: this technique is one of the several methods to obtain nitride/carbide-based PVD coatings of different metals (Cr, Zr, Ti, Mo). A martensitic stainless steel (X155CrMoV12, K110 Bohler stee, DIN 1.2379, AISI D2) was used as the coatings substrate, with a nominal chemical composition of C 1.55%; Si 0.30%; Mn 0.30%; Cr 11.5%; Mo 0.70%; V 1.00% [14] (see Figure S1). All the PVD coatings (AlTiN, NbN, ZrN and TiN) were produced by CRT company (Nerviano, Milan, Italy) and prepared by means of cathodic arc deposition technique under controlled temperature (350 °C for NbN; 450 °C for AlTiN, ZrN and TiN) and pressure (1.5 Pa for NbN; 2.5 Pa for AlTiN, ZrN and TiN). In the case of NbN and AlTiN, the final coatings were composed by multilayers, 4 (Cr, CrN, CrN+NbN and NbN) and 8 (TiN, AlTiN, 5 subsequent layers of AlTiN+TiN and lastly AlTiN one), respectively; TiN and ZrN, instead, were deposited as a single layer. In a previous work [14], similar PVD coatings have been characterized and studied concerning either the mechanical features (such as the hardness and the critical load) or the corrosion resistance in different environments.

The average thickness (δ) and elemental analysis of the deposited films were determined by Scanning Electron Microscopy using a Leo 1430 SEM (Zeiss, Oberkochen, Germany), equipped with energy-dispersive X-ray spectroscopy (Oxford, UK), operating at 20 kV, WD = 15 mm. For each coating, the thickness was measured during SEM examination of cross-sectioned samples observed at different magnifications. Besides, for EDX analysis, the whole section area was considered (i.e. around 400 μm2).

Micro-hardness was tested using a CSM micro-combi tester (Graz, Austria) in micro-indentation mode (applied force of 10 mN with the indentation depth limited to approximately 10% of PVD thickness).

The surface roughness (R) of the PVD coatings was measured by a Bruker Dektak XT contact profilometer (Bruker Italy S.r.l., Milan, Italy), equipped with a diamond pin (2.5 μm in thickness) running on the object surface and following local surface irregularities. The cursor is linked with an optical transductor. The vertical displacements are recorded by a photoelectric cell and amplified. Each measurement was 2.4 mm in length and a 10 mm interval separated two parallel measurements. For a given test line, the roughness was defined in µm as the arithmetic mean of peaks above and under the baseline. Each analysis was repeated five times for statistical purpose.

2.2. Mold Release Agents

Three commercial mold release agents were adopted to evaluate their features as preventing substances for the mold fouling. Particularly, Marbocote® W2140 (by Marbo S.p.A., Pogliano Milanese, Italy) is a water-based release agent for the release of natural and synthetic rubber. This product has been specifically formulated to minimize mold build-up, forming a durable film on the mold surface capable of providing many releases before reapplication is necessary. The polymeric resin used in Marbocote® W2140 reacts when heated (T > 60 °C). Moreover, it is supplied ready to use, no shaking or mixing is required. EP (by Novema S.r.l.) release agent is an oxidized polyethylene wax (15%)-based emulsion stabilized by C11,C13-branched ethoxylated alcohols (2.5%). Lastly, EV-333 (by Cinea S.a.S.) is a water-based release agent composed by a complex mixture of paraffinic waxes and oils.

2.3. Interaction Releasing Agents-PVD Coatings Analyses

To study the interactions between the releasing agents and the PVD coatings, emulsions surface tension (γlv) analyses were performed using digital tensiometer Gibertini following the Du-Noüy Method [12,19]. The liquid-solid surface tension (γls) was calculated by using the Young equation:

where θY is the Young contact angle at the air/liquid/solid junction.

γlvcosθY = γsv − γls

The work of adhesion, Wa and the spreading coefficient, Sls are calculated as follows:

Wa = γsv + γlv − γls

Sls = γsv − γlv − γls

If Sls is positive, spreading will occur spontaneously. As θY is finite, Sls is always negative and if the contact angle is zero, complete wetting/spreading occurs [20,21].

Static contact angle analyses [22] were performed using Krüss Easy Drop instrument (Hamburg, Germany). Milli-Q water, diethylene glycol, glycerol and diiodomethane were adopted for the determination of the SFE [23] or solid-vapor surface tension (γsv) of the tested molds, using the Owens, Wendt, Rabel and Kaeble (OWRK) method [24]. Before the contact angle determinations, all surfaces were cleaned by using acetone/iso-propanol (two stage-cleaning) to remove organic impurities (e.g. greases and oils) present on the surface. Four different solvents (water, diiodomethane, diethylene glycol and glycerol), whose surface tension values (γlv) and the respective polar (γlvp) and disperse (γlvd) components are known in the literature [25], were deposited onto all the tested coatings.

The corrosion behavior of each coating was carried out using an electrochemical O-ring type cell, with 1 cm2 active surface area as a working electrode and a Pt coil as a counter electrode, which is connected to the cell via a U-tube and a Luggin’s capillary. All the experiments were carried out at room temperature, under open-air conditions and 4 h data acquisition. The electrochemical system was connected to a Gamry Interface 1000 Multipotentiostat with four channels, coupled to a computer with dedicated software (version 7.8). All experiments were performed at room temperature and under open-air conditions. Single-cycle anodic polarizations were conducted in sodium sulfate solution (0.1 M Na2SO4, pH 5.5). Scan rate of 0.17 mV s−1, equilibration time of 5 min, and reverse current of 2 mA cm−2 were used. Each experiment was replicated at least twice until the same behavior was confirmed. In order to evaluate the chemical interaction between the releasing agents and the PVD coatings, open circuit potential (OCP) measurements were performed. The electrochemical characterization was carried out using the same electrochemical cell, described previously. The release agent Marbocote® W2140 (diluted 1:2) was used as electrolyte to mimic industrial applications of plastic molding. Every experiment was replicated twice for each PVD coating.

2.4. Industrial Molding Set-Up

PVD Coatings used in this study were tested directly on the production lines of the SKF company (Gazzada, Italy), where the release agent was sprayed at room temperature on the surface of the PVD-coated molds as a diluted solution. The HNBR vulcanization was carried out on a hydraulic press at temperature of 180 °C and a pressure of 20 MPa [26]. The service life is defined as the number of molded seals successfully obtained with the same molding apparatus, before it becomes unusable.

3. Results and Discussion

3.1. PVD Coatings Properties

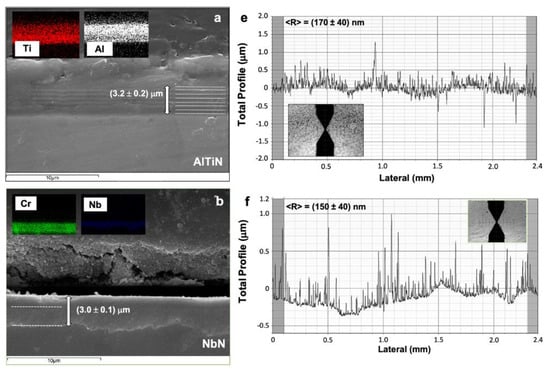

The design and cross-sectional SEM images of all the investigated PVD coatings along with the relative thickness values are shown in Figure 1. It is visible that NbN and, even more, AlTiN are multilayers coatings, whereas ZrN and TiN display a dense structure without clear imperfections. Furthermore, no configuration shows any cracks or delaminations at the interface, thus appearing adherent, compact and uniformly distributed along the surface profile [14].

Figure 1.

SEM micrographs and profilometry maps of (a,e) AlTiN, (b,f) NbN, (c,g) ZrN and (d,h) TiN. Insets: (a–e) EDX maps and coatings thickness; (f–l) optical micrographs and roughness values.

All the coatings possess a micrometric thickness, notably in the range between 1.4 μm for TiN and 3.7 μm of ZrN. Moreover, energy-dispersive x-ray spectroscopy analyses revealed the elemental composition of the studied metal layers (insets of Figure 1a–d). In all the cases, the effective presence of the metal used to fabricate the PVD coatings was confirmed.

In Table 1, hardness (HV, second column) and corrosion potentials (Ecorr, third column, and Figure S2) of the PVD coatings are displayed. The former is in agreement with the literature data for molding applications [27], reaching values higher than 2600 HV. Conversely, each PVD sample has a negative free corrosion potential, as expected, showing the highest absolute value (−0.22 V vs SCE) in the case of NbN. Indeed, as already stated in a previous work [14], this behavior can be correlated to the scratch test results, which reveal the upper niobium layer is too fragile, thus leading to the possible failure of the overall coating.

Table 1.

Average values of hardness (HV), corrosion potential in Na2SO4 (pH 5.5) and roughness (<R>) values for each studied physical vapor deposition (PVD) coating.

More interestingly, the corrosion potentials for the Ti-based coatings (AlTiN and TiN) showed optimal performances in Na2SO4 medium (around −20/−30 mV vs SCE), resulting the most performing samples in terms of corrosion resistance.

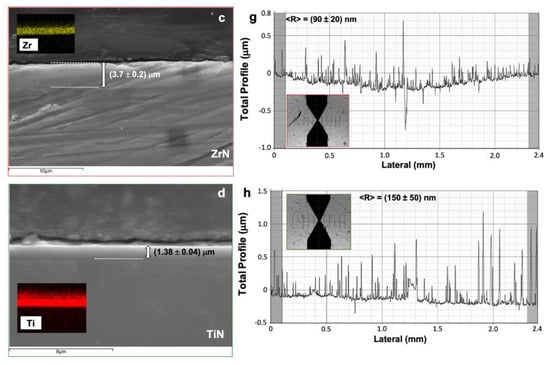

Besides, the surface roughness was evaluated by means of contact profilometer. Figure 1e–h show the surface profile along with the relative roughness data (see Table 1, fourth column), reported as average value upon five measurements for each coating. Results indicate it ranges from 90 nm of ZrN to a maximum of 170 nm of AlTiN substrate. Since roughness parameter is widely stated to influence the surface features in terms of wettability and substrate surface free energy [6], these properties have been investigated. Primarily, the SFE values were determined in an indirect way through the evaluation of contact angle (θ) by using four different solvents, according to the OWRK method [28]. The contact angles values are shown in Table 2, whereas the linear SFE fitting trends for all the PVD coatings are reported in Figure 2.

Table 2.

Contact angle values by using different solvents for the tested samples and relative Surface Free Energy (SFE) of the investigated coatings, alongside with both polar (SFEp) and disperse (SFEd) components.

Figure 2.

Surface Free Energy by Owens Wendt Rabel Kaeble (OWRK) elaboration for all the investigated coatings.

Notably, an initial idea of the solid surface energy behavior can be already drawn from the appearing water contact angle. Indeed, a bad wetting by water, i.e. high value of contact angle, indicates a low surface energy and a low polar component.

The SFE is then a direct measure for the adhesiveness of a surface [29]: a high SFE value along with a high polar component should guarantee an optimal adhesion capacity of the coatings, and vice versa. Thus, comparing the water contact angle values in Table 2, AlTiN coating seems to have the highest adhesion resistance among the investigated coatings, followed digressively by NbN, ZrN and TiN that possess a water contact angle having the same order of magnitude.

Once the contact angle values were assessed, the total SFE together with its polar and disperse components were calculated and reported in Table 2 (sixth–eighth column). Notably, all the coatings have similar SFE values, however AlTiN and NbN have the lowest polar component with respect to ZrN and TiN. The present results are fully in accordance with the surface free energy data of nitride-based coatings reported in the recent literature [4,5,6]. Sun et al. [6] reported a value of around 40 (polarity fraction of 17%) and 38 (polarity fraction of 8%) mN m−1 for TiN and ZrN, respectively. Moreover, AlTiN clad low-alloyed steel substrate has a total SFE of 38 mN m−1, whose polar component is about 10 mN m−1, as stated by Lugscheider et al. [29]. Hence, these two PVD-coated surfaces seem to have a higher adhesion resistance towards high polar solvents than the other substrates [29]. Moreover, a lower roughness surfaces implies a lower surface free energy, as already mentioned by Sun et al. [6].

3.2. Release Agents Characterization

In order to establish the best PVD coating in terms of release agent adhesion and spreading, alongside the solid substrates SFE calculation, the surface tension of the three commercial release agents (namely Marbocote® W2140, Ep and EV-333) was determined by tensiometric method. These emulsions are reported to be efficiently used as mold releasing agents [11,13,30], largely diluted due to their high viscosity. The surface tension results are reported in Table 3.

Table 3.

Surface tension values for pure (100 %wt) and diluted (25 %wt, 50 %wt) release agents.

Herein, the three emulsions were tested as is, diluted with MilliQ water 50% and 25% (by weight). The obtained surface tension data range from 33 mN m−1 for Marbocote® W2140 to 43 mN m−1 for EV-333, in the pure form. Moreover, a very slight increase (of a couple of units) was observed by diluting them with water (Table 3, second column), thus highlighting the dilution scarcely affects the surface tension value of such emulsions. Hence, we can conclude that the final performance of the molding release agents is independent from the phase volume of the emulsion. This fact could potentially reduce the industrial process in terms of costs.

3.3. Work of Adhesion (Wa) and Spreading Coefficient (S)

The contact angles, work of adhesion (Wa) and spreading coefficient (S) results obtained with the three releasing agents are displayed in Table 4. From a theoretical point of view, the spreading coefficient higher than zero corresponds to a spontaneous wetting [19,20]; if the contact angle is zero, complete wetting/spreading occurs. However, as θ is finite, S is always negative. Hence, less negative values correspond to a more favorable spreading of the emulsions on the substrates. Besides, the higher the value of Wa, the stronger the adsorption of the emulsion film at the metal surface [20,31]. Thus, both these two parameters can be easily connected to the spreading performance of the tested releasing agents. Notwithstanding the negative value of the coefficient of spreading, typical of this release agent/metal interface [12,29], all the emulsions show good wettability properties towards the PVD-coated specimens (Table 4, second column). Particularly, by varying the emulsion type and, subsequently, their affinity to the substrates, the wettability features vary, accordingly. With both Marbocote® W2140 and EP compounds, the lowest contact angle values were obtained (around 50°). On the contrary, a rise of this parameter was observed for EV-333, confirming the surface tension sequence of the release agents. Notably, the lower the contact angle, the higher the work of adhesion and, hence, the smaller the spreading coefficient (Table 4). Moreover, by comparing these properties within the same emulsion series, contact angles are very similar among the different substrates, and therefore comparable Wa and S values were obtained.

Table 4.

Contact angles, work of adhesion (Wa) and spreading coefficient (S) for commercial molding release agents associated with the cleaned PVD coatings.

Hence, Marbocote® W2140, showing the less negative value of the spreading coefficient, resulted to be the most performing emulsion, capable of spreading more favorably over the molding coatings, forming a more adherent and homogeneous barrier able to facilitate the detachment of the HNBR rubber. Actually, a liquid with the same specific surface tension as the solid on which it rests will wet that solid completely [32].3.4. Simulation of Plant Conditions.

As previously mentioned, up to now, all the measurements were performed on ideally clean surfaces far away from the real industrial operating conditions.

To overcome these problems, the samples were used directly as coming out from the production line and their surfaces have not been degreased by acetone/isopropanol two-step cleaning procedure. Hence, herein, the aim is to underline the correlation between the theoretical conditions observed in laboratory (i.e. perfectly clean surfaces) and the real industrial application.

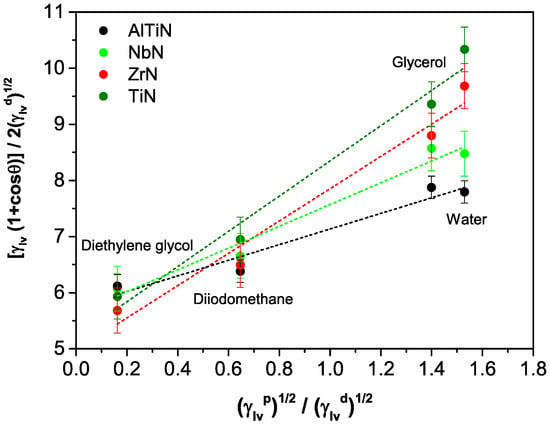

The four coatings were deposited on real molds and these systems worked daily under severe operating conditions. Finally, their performance was tested in terms of number of molded seals (Figure 3), without changing the molding apparatus. This can be interpreted as an actual service life of the materials. Since Marbocote® W2140 revealed to be the most performing compound in terms of spreading behavior, it was chosen as testing release agent model. Thus, histograms in Figure 3a display the real emulsion contact angles on uncleaned PVD-coated samples, as a function of the number of molded seals. Interestingly, for AlTiN and NbN layers an increase of the angles of about 8–10° was observed with respect to those of the cleaned surfaces. This may be due to the fact that these two substrates have the lowest SFE polar component after the cleaning procedure (Figure 2). When the oils/greases are not removed from the surfaces, the surface polarity may further reduce, thus provoking a rise of the emulsion contact angles. Hence, the higher the angles, the lower the work of adhesion (Figure 3b) and the shorter the coatings service life (i.e. lower number of molded seals).

Figure 3.

Correlations between (a) Marbocote® W2140 contact angles on uncleaned PVD coatings, (b) relative work of adhesion (Wa), (c) Open circuit potential (OCP) and number of molded seals.

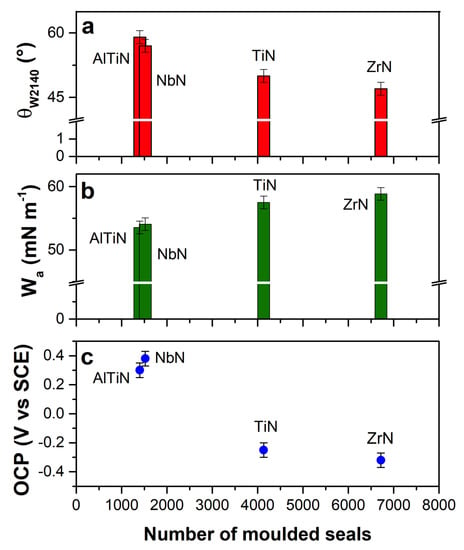

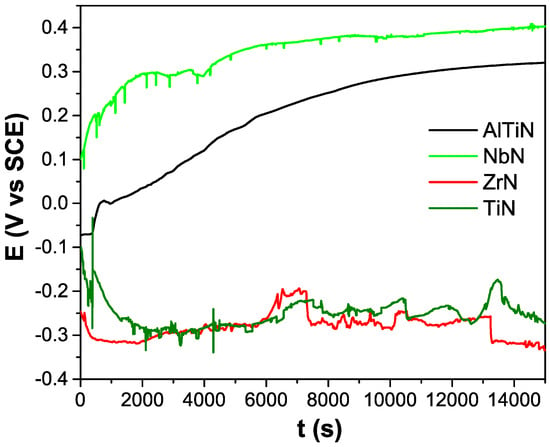

In order to have a further corroboration of our hypothesis, Open Circuit Potential (OCP) measurements were performed (Figure 4).

Figure 4.

OCP measurements of PVD coatings performed in Marbocote® W2140 media.

By means of this technique, a possible outlook on the surface interactions with the release agent medium, in contact with mold-PVD systems, can be assessed [33]. Indeed, the OCP is a parameter which can be strictly linked to the electrochemical oxidation kinetics of a metallic material in a corrosive medium. After a period of immersion, it usually stabilizes around a stationary value. This potential may vary with time as a consequence of changes in the nature of the electrode surface (such as oxidation, formation of the passive layer, adsorption phenomena). Therefore, the open circuit potential is used as a criterion for the corrosion behavior. Once again, AlTiN and NbN showed an electrochemical response completely different (i.e. positive value) from the other two PVD coatings (negative one). These results are fully in agreement with the previous ones, achieved in a salt electrolyte (Table 1, third column). Indeed, during the first period after the immersion into Marbocote® W2140, an abrupt OCP displacement towards positive potentials was noticed (Figure 4, black and light green curves). This initial increase is hypothesized to be related to the formation and thickening of the corresponding oxide films on the metallic surfaces, improving their corrosion protection ability [34]. Afterwards, the potential increases slowly suggesting the growth of the film.

Interestingly, for the first time, we are able to correlate an electrochemical parameter (as OCP) with surface features (contact angle and work of adhesion) and industrial findings (the number of molded seals). Notably, the formation of a passivation layer on AlTiN and NbN coatings modifies the surface features of the molded seals, making them less prone to interact with the polymeric resin contained in the Marbocote® W2140 water-based emulsion. This has led to a drastic decrease of the molding performances for AlTiN and NbN substrates, with respect to TiN and ZrN coatings.

4. Conclusions

Herein, four different PVD coatings were investigated as molding materials, along with three commercial water-based emulsions, used as releasing agents. Notably, diverse layers thicknesses, from 1.4 to 3.7 μm, and roughness factors, i.e. in the range 90–170 nm, were obtained, representing pivotal features for the solid surface free energy values. This last property, evaluated on acetone/iso-propanol cleaned surfaces, was similar (around 30–40 mN m−1) for all the studied materials, with a lower polar share (about 2–3 mN m−1) for AlTiN and NbN than the other two coatings. Concerning the release agents, all the emulsions have a 33–47 mN m−1 surface tension value, which remains almost constant with the increasing of dilution with water. Furthermore, by evaluating the emulsions contact angle with the substrates, Marbocote® W2140 seems to wet better the molds surfaces with respect to the other two water-based release compounds, obtaining the highest work of adhesion and the most favorably spreading coefficient towards all the PDV coatings. Hence, real industrial trials (HNBR molded seals) were carried out in order to evaluate the PVD-coated molds service life. Interestingly, to the authors’ best knowledge, the novelty lies in the fact that, for the first time, we observed a correlation between the surface (Marbocote® W2140 contact angle, work of adhesion and spreading coefficient)/electrochemical (OCP parameter) properties and the number of molded seals, done before their failure. Indeed, TiN and ZrN, that do not form any passivation layer on their surface when in contact with the release agent, showed the greatest number of molded seals. Actually, the oxide layer formed on AlTiN and NbN may have caused coating surface modifications, making them less prone to interact with the release agent. Hence, our new findings can pave the way for the fabrication of novel PVD coatings with specific properties, resulting in more durable materials to be applied as industrial polymer processing molds.

Supplementary Materials

The following are available online at https://www.mdpi.com/2079-6412/10/3/281/s1, Figure S1: (a) Mold apparatus and molded seal; (b) PVD-coated substrates samples. Figure S2: Anodic polarization curves relative to all the investigated coatings performed in 0.1 M Na2SO4 (pH 5.5). Scan rate of 0.17 mV s−1, equilibration time of 5 min and reverse current of 2 mA/cm2.

Author Contributions

Conceptualization, L.D., S.P.M.T. and G.C.; methodology, L.D. and R.B.; formal analysis, L.D. and R.B.; investigation, L.D., R.B. and E.P.; data curation, E.P.; writing—original draft preparation, S.P.M.T. and G.C.; writing—review and editing, S.P.M.T. and G.C.; supervision, G.C. All authors have read and agree to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors. The authors would like to thank CRT Srl (Nerviano, Italy) for PVD samples preparation, and the Regione Lombardia—Fondazione Cariplo joint SmartMatLab project (Fondazione Cariplo 2013–1766 project) for the use of profilometer. Part of this work was carried out at NOLIMITS, an advanced imaging facility established by the Università degli Studi di Milano. Nadia Santo is gratefully acknowledged for cross-section SEM images and EDX analysis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kutz, M. Applied Plastics Engineering Handbook, 2nd ed.; Elsevier Inc.: Oxford, UK, 2016; ISBN 9780323390408. [Google Scholar]

- Meyer, R.W. Handbook of Polyester Molding Compounds and Molding Technology, 2nd ed.; Chapman and Hall: London, UK, 2012; ISBN 0-412-00771-1. [Google Scholar]

- Pruner, H.; Nesch, W. Understanding Injection Molds; Carl Hanser Verlag: Munich, Germany, 2013; ISBN 978-1-56990-527-2. [Google Scholar]

- Navabpour, P.; Teer, D.G.; Hitt, D.J.; Gilbert, M. Evaluation of non-stick properties of magnetron-sputtered coatings for molds used for the processing of polymers. Surf. Coat. Technol. 2006, 201, 3802–3809. [Google Scholar] [CrossRef]

- Lugscheider, E.; Bobzin, K.; Möller, M. The Effect of PVD layer constitution on surface free energy. Thin Solid Films 1999, 355, 367–373. [Google Scholar] [CrossRef]

- Sun, C.C.; Lee, S.C.; Dai, S.B.; Tien, S.L.; Chang, C.C.; Fu, Y.S. Surface free energy of non-stick coatings deposited using closed field unbalanced magnetron sputter ion plating. Appl. Surf. Sci. 2007, 253, 4094–4098. [Google Scholar] [CrossRef]

- Hornsby, P.R.; Singh, I.; Daley, J.R.; Firth, J. Mold fouling of elastomers during injection molding. Plast. Rubber Compos. 2006, 35, 331–339. [Google Scholar] [CrossRef]

- Tan, J.; Zhang, S.; Lu, T.; Li, R.; Zhong, T.; Zhu, X. Design and synthesis of ethoxylated esters derived from waste frying oil as anti-ultraviolet and efficient primary plasticizers for poly(vinyl chloride). J. Clean. Prod. 2019, 229, 1274–1282. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Plasticizers, 3rd ed.; ChemTec Publishing: Scarborough, ON, Canada, 2017; ISBN 978-1-895198-97-3. [Google Scholar]

- Wesala, R.J. Mold Release Agents and Means of Application. U.S. Patent 4,491,607, 1 January 1985. [Google Scholar]

- Schneider, A.; Schneider, V.; Wochnowski, H.; Niemeyer, P. Release Agent. U.S. Patent 6,162,290, 19 December 2000. [Google Scholar]

- Olietti, A.; Pargoletti, E.; Diona, A.; Cappelletti, G. A novel optimized mold release oil-in-water emulsion for polyurethane foams production. J. Mol. Liq. 2018, 261, 199–207. [Google Scholar] [CrossRef]

- Althoff, R.; Henning, T.; Lammerting, H. Aqueous Release Agent and Its Use in the Production of Polyurethane Moldings. U.S. Patent 7,811,502, 12 October 2010. [Google Scholar]

- D’Avico, L.; Beltrami, R.; Lecis, N.; Trasatti, S. Corrosion Behavior and Surface Properties of PVD Coatings for Mold Technology Applications. Coatings 2018, 9, 7. [Google Scholar] [CrossRef]

- Shugurov, A.R.; Kazachenok, M.S. Mechanical properties and tribological behavior of magnetron sputtered TiAlN/TiAl multilayer coatings. Surf. Coat. Technol. 2018, 353, 254–262. [Google Scholar] [CrossRef]

- Holleck, H.; Schier, V. Multilayer PVD coatings for wear protection. Surf. Coat. Technol. 1995, 76–77, 328–336. [Google Scholar] [CrossRef]

- Sproul, W.D. Physical vapor deposition tool coatings. Surf. Coat. Technol. 1996, 81, 1–7. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H.; Lei, B.; Leng, Y.X.; Huang, N. Comparison of tribological behaviours of AlCrN and TiAlN coatings—Deposited by physical vapor deposition. Wear 2007, 263, 1423–1429. [Google Scholar] [CrossRef]

- Lotierzo, A.; Pifferi, V.; Ardizzone, S.; Pasqualin, P.; Cappelletti, G. Insight into the role of amines in Metal Working Fluids. Corros. Sci. 2016, 110, 192–199. [Google Scholar] [CrossRef]

- Rosen, M.J. Wetting and Its Modification by Surfactants. In Surfactants Interfacial Phenom; John Wiley & Sons Inc.: New York, NY, USA, 1978; pp. 174–199. [Google Scholar]

- Meroni, D.; Ardizzone, S.; Cappelletti, G.; Ceotto, M.; Ratti, M.; Annunziata, R.; Benaglia, M.; Raimondi, L. Interplay between Chemistry and Texture in Hydrophobic TiO2 Hybrids. J. Phys. Chem. C 2011, 115, 18649–18658. [Google Scholar] [CrossRef]

- Soliveri, G.; Pifferi, V.; Panzarasa, G.; Ardizzone, S.; Cappelletti, G.; Meroni, D.; Sparnacci, K.; Falciola, L. Self-cleaning properties in engineered sensors for dopamine electroanalytical detection. Analyst 2015, 140, 1486–1494. [Google Scholar] [CrossRef]

- Macy, R. Surface tension by the ring method. Applicability of the du Nouy apparatus. J. Chem. Educ. 1935, 12, 573. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Pargoletti, E.; Motta, L.; Comite, V.; Fermo, P.; Cappelletti, G. The hydrophobicity modulation of glass and marble materials by different Si-based coatings. Prog. Org. Coat. 2019, 136, 105260. [Google Scholar] [CrossRef]

- Keller, R. Practical Guide to Hydrogenated Nitrile Butadiene Rubber Technology Practical Guide to Hydrogenated Nitrile Butadiene Rubber Technology; Smithers Rapra: Akron, OH, USA, 2012; ISBN 978-1-84735-521-8. [Google Scholar]

- Lakel, S.; Almi, K.; Berriche, Y. Micro-scale abrasive wear testing of Cr-Nx coatings. Rom. Rep. Phys. 2007, 59, 113. [Google Scholar]

- Cappelletti, G.; Ardizzone, S.; Meroni, D.; Soliveri, G.; Ceotto, M.; Biaggi, C.; Benaglia, M.; Raimondi, L. Wettability of bare and fluorinated silanes: A combined approach based on surface free energy evaluations and dipole moment calculations. J. Colloid Interface Sci. 2013, 389, 284–291. [Google Scholar] [CrossRef]

- Lugscheider, E.; Bobzin, K.U. The influence on surface free energy of PVD coatings. Surf. Coat. Technol. 2001, 142, 755–760. [Google Scholar] [CrossRef]

- Li, Z.; Lu, Z.; Xing, W.; Bao, L.; Wang, P.; Xu, J.; Zhang, Y. A Release Agent, the Preparation and Use Thereof. WO2012103808A1, 9 August 2012. [Google Scholar]

- Cambiella, A.; Benito, J.M.; Pazos, C.; Coca, J.; Ratoi, M.; Spikes, H.A. The effect of emulsifier concentration on the lubricating properties of oil-in-water emulsions. Tribol. Lett. 2006, 22, 53–65. [Google Scholar] [CrossRef]

- Mollet, H.; Grubernmann, A. Formulation Technology; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Arslan, E.; Totik, Y.; Efeoglu, I. The investigation of the tribocorrosion properties of DLC coatings deposited on Ti6Al4V alloys by CFUBMS. Prog. Org. Coat. 2012, 74, 768–771. [Google Scholar] [CrossRef]

- Caiazzo, F.; Sisti, V.; Trasatti, S.; Trasatti, S. Electrochemical Characterization of Multilayer Cr/CrN-Based Coatings. Coatings 2014, 4, 508–526. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).