Abstract

An atmospheric plasma treatment strategy was developed to prepare two-dimensional (2D) molybdenum disulfide (MoS2) and graphitic carbon nitride (g-C3N4) nanosheets from (NH4)2MoS4 and bulk g-C3N4, respectively. The moderate temperature of plasma is beneficial for exfoliating bulk materials to thinner nanosheets. The thicknesses of as-prepared MoS2 and g-C3N4 nanosheets are 2–3 nm and 1.2 nm, respectively. They exhibited excellent photocatalytic activity on account of the nanosheet structure, larger surface area, more flexible photophysical properties, and longer charge carrier average lifetime. Under visible light irradiation, the hydrogen production rates of MoS2 and g-C3N4 by plasma were 3.3 and 1.5 times higher than the corresponding bulk materials, respectively. And g-C3N4 by plasma exhibited 2.5 and 1.3 times degradation rates on bulk that for methyl orange and rhodamine B, respectively. The mechanism of plasma preparation was proposed on account of microstructure characterization and online mass spectroscopy, which indicated that gas etching, gas expansion, and the repulsive force of electron play the key roles in the plasma exfoliation. Plasma as an environmentally benign approach provides a general platform for fabricating ultrathin nanosheet materials with prospective applications as photocatalysts for pollutant degradation and water splitting.

1. Introduction

Photocatalytic technology is a fascinating strategy in addressing energy shortages and environmental pollution [1,2,3,4,5]. Two-dimensional (2D) materials have a wide range of applications in the field of photocatalysis due to their special structure and excellent optical and electrical properties [6,7,8]. 2D nanosheets made of a few atomic layers are mainly synthesized from layered structural materials. Graphene is the typical 2D material [9,10,11], and has been applied in catalysts and electronics. In recent years, other layered structural materials, for example, metal-free materials [12], transitional metal dichalcogenides [13], and transitional metal carbides [14] have also been exfoliated into 2D nanosheets to explore their unique properties and applications. However, the preparation method is an important factor that restricts the performance and production of two-dimensional materials. At present, there are some commonly methods for produce 2D materials, such as ultrasonication [15], hydrothermal method [16] and chemical vapor deposition method [17], etc. However, a fast, high yield, and an environmentally-friendly method for 2D materials manufacture is still urgently needed.

Dielectric barrier discharge (DBD) plasma is a kind of cold plasma used to prepare nano-sized materials in atmosphere. DBD plasma has excellent advantages in the preparation of nanomaterials, which can be attributed to its large amount of active substances, ambient temperature and nonequilibrium state [18,19,20]. DBD plasma is more remarkably used in a more controlled method for producing structures and in surface induction processes, in comparison with the traditional thermal methods [21,22]. Wang et al. utilized water plasma to prepare 2D layered double hydroxide nanosheets to improve the rate of oxygen evolution reaction [23]. N-doped graphene was exfoliated by DBD plasma for oxygen reduction reaction [24]. Our group developed a way to prepare graphene using atmospheric plasma and proposed the preparation mechanism [25].

Both MoS2 and g-C3N4, typical two-dimensional layered materials, are the most interesting photocatalysts. MoS2, a typical transitional metal dichalcogenides with a sandwich layered structure, has been far and wide exploited in photocatalytic H2 production [26,27]. g-C3N4, a non-metal semiconductor with a grapheme-like layered structure that was successfully used in split water and degrade organic contaminants under visible light irradiation [28]. Nevertheless, their photocatalytic performance was limited for bare bulk structure [29,30,31]. Hence, much research has been conducted to improve their photolytic activity, such as preparing ultrathin MoS2 nanosheets and exfoliating thick g-C3N4 into few layers nanosheets. Xie et al. synthesized MoS2 nanosheets by hydrothermal method, with a thickness of 5.9 nm by hydrothermal method, corresponding to 9 S-MO-S atomic layers [32]. Niu et al. used direct thermal treatment to prepare g-C3N4 nanosheets with a yield of around 6%, and its thickness is about 2 nm [33]. Zhang et al. utilized bulk g-C3N4 as the precursor and produced the g-C3N4 nanosheets by ultrasonic treatment [34].

Here, we developed a novel process of DBD plasma to the preparation of ultrathin MoS2 nanosheets and g-C3N4 nanosheets from (NH4)2MoS4 and bulk g-C3N4, respectively. Compared to the traditional methods, this method has the advantages of high yield and environmentally friendly (without solvent). The structure, morphology, and property of prepared MoS2 nanosheets and g-C3N4 nanosheets were studied. Moreover, the photolytic activity was evaluated by H2 evolution reaction and organic degradation under visible light irradiation. Finally, we believe that the plasma method can be a universal method for two-dimensional material preparation.

2. Experimental

2.1. Sample Preparation

All the materials were purchased from Shanghai Aladdin Biochemical Technology Co. (Shanghai, China). All chemicals are used directly without further purification.

Synthesis of MoS2 nanosheets. 0.5 g of (NH4)2MoS4 powder was treated by DBD plasma in H2/Ar atmosphere, and the process was carried out at moderate temperature. Details of the DBD plasma treatment have been described previously. [25] More details about DBD treatment can be found in the Supplementary Material. The schematic representation of DBD plasma setup can be found in Figure S1. The sample was placed in the quartz ring between the two electrodes of DBD plasma generator. Total DBD treatment time was 1 h. The temperature of the DBD was measured by infrared imaging (Ircon, 100PHT, Everett, WA, USA), indicating that the DBD plasma process was at around 150 °C (Figure S2).

Synthesis of g-C3N4 nanosheets. 0.5 g of bulk g-C3N4 powder was treated by DBD plasma at moderate temperature and air atmosphere. The specific processing is the same as described above.

Images of samples (Figure S3) reveals color change before and after plasma treatment.

2.2. Characterizations

The crystalline phase of g-C3N4 and MoS2 were analyzed on D/Max-2500 V diffractometer (Cu Kα α = 0.154 nm, 4°/min, Rigaku, Tokyo, Japan). The field emission scanning electron microscopy (SEM) and high-resolution transmission electron microscopy (HRTEM) images were obtained from Zeiss-Merlin scanning electron microscopy (Jena, Germany) and JEOL-2100F transmission electron microscopy (Tokyo, Japan), respectively. X-ray photoelectron spectroscopy (XPS) was conducted on a Perkin Elmer PHI-1600 system (MA, USA). An atomic force microscope (AFM) was used on Agilent 5500 (CA, USA). The FTIR of the prepared samples were analyzed using a Nicolet-560 (MN, USA). Optical properties were measured on a UV-vis spectrophotometer (UV-2600, Shimadzu, Kyoto, Japan). The photoluminescence (PL) spectra and time-resolved fluorescence decay spectra was surveyed on a HORIBA Jobin Yvon Fluorolog-3 spectrophotometer (Paris, France) with an excitation wavelength at 330 nm. The N2 Brunauer-Emmett-Teller (BET) surface area was measured on a Nova Automated Gas Sorption System (Quantachrome Corporation, FL, USA) after degassed at 150 °C for 4 h. The gas products were monitored online and analyzed with an SHP8400PMS-L mass spectrometer (SDPTOP, Shanghai, China).

2.3. Photocatalytic Activity

The photocatalytic H2 production experiment was carried out by the Perfect Light IIIAG system (Beijing, China). The visible light source used in the experiment was a 300 W Xe lamp (420 nm filter).

Hydrogen production over Eosin Y-sensitized MoS2. 15 mL Triethanolamine (TEOA) was mixed with 85 mL of deionized water, then 25 mg MoS2 and 70 mg Eosin Y were sonicated in a short time to make it evenly dispersed in the solution, and finally the solution was made to drop PH = 7 by adding concentrated hydrochloric acid. The reactor continued to vacuum and circulate cold water to eliminate the influence of other factors on the experiment. Gas chromatography can accurately determine the amount of hydrogen in the system.

Hydrogen production over Pt/g-C3N4. 100 mg powder samples was dispersed in deionized water. 67 µL H2PtCl6 (Pt/g-C3N4: 0.5 wt %) was dispersed in the suspension. Under visible light, photoreduction and H2 production were conducted on a Perfect Light IIIAG system. 10 vol % triethanolamine was added as sacrificial reagent. The other steps were the same as above.

Degrading pollutants by g-C3N4. Briefly, 50 mg catalyst was dispersed in 100 mL of 20 mg/L RhB or 10 mg/L MO solution, and the suspension was then placed into a 200 mL vessel with continuous stirring. Dark treatment of 30 min was necessary to approach an adsorption/desorption equilibrium, and a 300 W Xe lamp and 420 nm cutoff filter was used to supply visible light. 3 mL of solution was taken at intervals, and then the supernatant was obtained by high-speed centrifugation. The concentration was measured by UV-2600 spectrophotometer (Kyoto, Japan).

2.4. Photoelectrochemical Measurements

The Photocurrent density was conducted at the electrochemical analyzer. A three-electrode electrochemical cell was used for the measurements, tin oxide mixed with fluorine (FTO) conductive glass loaded with a sample as an working electrode, and its reference electrode and counter electrode were Hg/HgO electrode and Pt wire, respectively. The 0.1 M Na2SO4 solution containing 1 mM Eosin-y was used as an electrolyte. A 300 W Xe lamp equipped with 500 nm bandpass filter acts as the solar light source. At the beginning of the test, we fully introduced N2 into the electrolyte to remove dissolved oxygen.

3. Results and Discussion

3.1. Sample Characterization

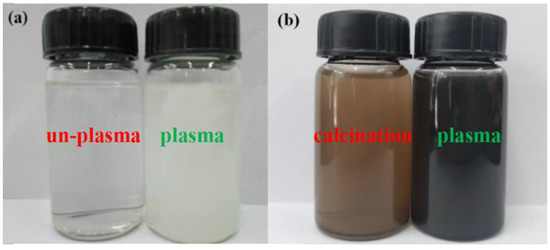

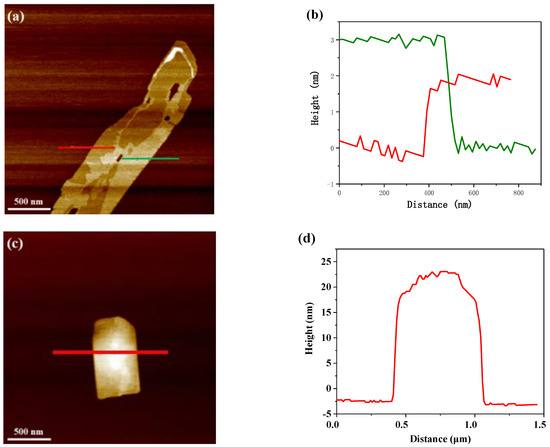

Figure 1a shows the dispersion of g-C3N4 in isopropanol before and after DBD plasma treatment. The plasma treated sample was a suspension in the liquid and has a lighter color than un-treated samples. It is in agreement with 2D g-C3N4 nanosheets described in the literature [35]. Figure 1b shows MoS2 were dispersed in deionized water after 10 min ultrasonication and allowed to stand for 24 h. Through observation, the samples by DBD plasma were found to maintain better dispersibility than samples by calcination. This indicates that the sample prepared by DBD has smaller size or thinner nanosheets [32].

Figure 1.

Images of (a) g-C3N4 suspensions with and without DBD plasma treatment, (b) MoS2 suspensions by DBD plasma and calcination treatment.

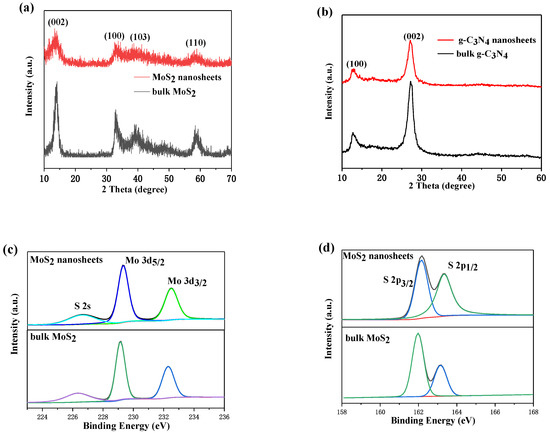

Figure 2a show XRD patterns of two different structures of MoS2 by calcination and DBD plasma. The as-prepared bulk MoS2 and MoS2 nanosheets exhibit similar (002), (100), (103) and (110) planes at 14.1°, 32.9°, 39.5° and 58.7°, respectively, which can be indicated as hexagonal 2H-MoS2 (JCPDS 75-1539) [36]. It shows that the DBD plasma can successfully decompose (NH4)2MoS4 to MoS2. The peaks intensity of MoS2 nanosheets by plasma is weaker than that of bulk MoS2, indicating the crystallinity is low and meet the characteristics of the two-dimensional structure [37]. Figure 2b show the XRD patterns of two different structures of g-C3N4. They both exhibited two peaks at 13.0° and 27.2°, corresponding to the (100) and (002) planes of g-C3N4 (JCPDS 87-1526), respectively [9,37]. It shows the structure of interlayer stacking and conjugated aromatic system stacking. It indicates that both of samples have identical crystal structures. In addition, the intensity of the peak at 13.0° of samples remarkably decreased after DBD plasma treatment, which is consistent with typical XRD patterns of 2D g-C3N4 nanosheets in previous reports [38,39]. The result confirms that DBD plasma can exfoliate bulk g-C3N4 into nanosheets successfully.

Figure 2.

XRD patterns of (a) bulk MoS2 and MoS2 nanosheets, (b) bulk g-C3N4 and g-C3N4 nanosheets. XPS spectra (c) Mo 3d and (d) S 2p of bulk MoS2 and MoS2 nanosheets. (e) C 1s and (f) N 1s of bulk g-C3N4 and g-C3N4 nanosheets.

The XPS survey spectra of MoS2 and g-C3N4 can be seen from Figure S4 in Supplementary Material, and the atomic concentration of those were shown in Tables S1 and S2. They exhibted that the as-obtained samples matched the theoretical chemical formulas.

Figure 2c,d show the high-resolution Mo 3d and S 2p XPS spectra of MoS2 samples. As can be seen from Figure 2c, there are three peaks located at 226.4 eV, 229.2 eV and 232.5 eV, the first peak can be ascribed to S 2s, and the latter two peaks correspond to Mo 3d5/2 and Mo 3d3/2, respectively [40]. Figure 2d shows the S 2p spectrum containing two peaks with binding energies of 162.0 eV and 163.5 eV, corresponding to S 2p3/2 and S 2p1/2, respectively [41]. The results indicate that this samples are MoS2 with Mo4+ and S2−. Bulk MoS2 and MoS2 nanosheets all exhibited similar XPS spectrum, indicating MoS2 by DBD and calcination have similar chemical structural compositions.

Figure 2e,f show the XPS spectra of g-C3N4 samples. C 1s spectra is shown in Figure 2e. Two symmetrical peaks at 284.8 and 288.4 eV were observed in both g-C3N4 nanosheets and bulk. The peak at 284.8 eV can be ascribed to the inherent adventitious carbon, and the other peak located at 288.4 eV was identified as sp2-hybridized carbon (N–C=N) in g-C3N4 chemical structure [42,43,44]. Figure 2e shows the N 1s spectra of g-C3N4 samples. To analyze the chemical bonds of the functional groups, the N 1s spectra are deconvoluted into four peaks at 398.6, 399.3, 400.0, and 401.2 eV, respectively. The peak at 398.6 eV is attributed to the sp2-hybridized nitrogen that existed in triazine rings (C–N=C); the peak at 399.3 eV is ascribed to the N atoms bonded to three sp2 carbon atoms (N–(C)3); the peak at 400.0 eV is attributed to the presence of amide (N–C=O); and the peak at 401.3 eV is due to the existence of amino functional groups (C–N–H). The other peak at 404.3 eV is ascribed to π-excitations [35,42,43,44]. Overall, g-C3N4 nanosheets exhibit the same chemical composition and element coordination as bulk g-C3N4. The result confirms that the DBD plasma process do not change the basic chemical composition of bulk g-C3N4 when g-C3N4 nanosheets is generated.

The chemical construction of plasma-prepared g-C3N4 nanosheets was characterized by the FTIR spectra. Figure S5 shows that bulk g-C3N4 have a sharp peak at 810 cm−1 is assigned to the heptazine ring system, other peaks in the region of around 1000–1800 cm−1 are attributed to bridging C–NH–C units or trigonal C–N–(C)–C units, the broad peak at 3000–3600 cm−1 is ascribed to N–H and O–H stretching [45,46,47,48]. The spectrum of g-C3N4 nanosheets exhibit almost the same peaks with bulk g-C3N4, confirming ultrathin nanosheets prepared by cold plasma are indeed g-C3N4 nanosheets that possess the uniform chemical structure as the layered bulk g-C3N4. The results are in agreement with XPS and XRD, further confirming that the basic chemical composition have no change by plasma treatment.

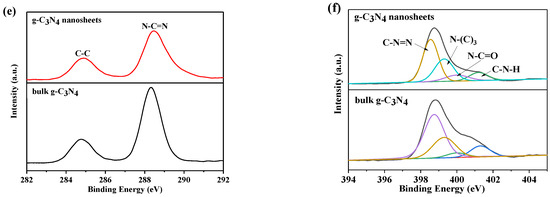

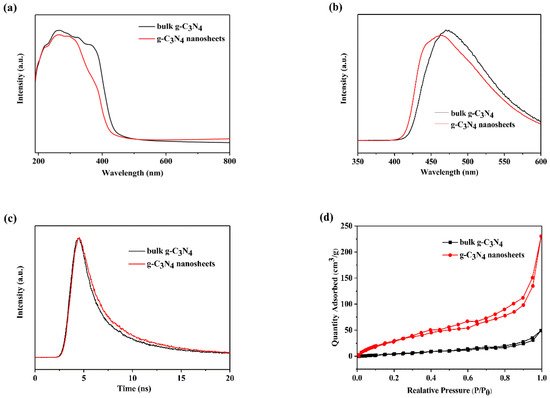

Figure 3a shows that UV-vis diffuse reflectance spectra, and it revealed photo absorption properties of bulk g-C3N4 and g-C3N4 nanosheets. After plasma treatment, g-C3N4 nanosheets showed an obvious blue shift, which is typical for 2D materials. Based on the absorption edge, the band gaps were 2.70 and 2.75 eV for bulk and 2D g-C3N4, respectively. Due to the quantum confinement effect, 2D g-C3N4 has a bigger band gap and increases the charge carrier generated ability which will enhance the photocatalytic performance [31,33].

Figure 3.

(a) UV-vis diffuse reflectance spectra (DRS) of bulk g-C3N4 and g-C3N4 nanosheets. (b) Photoluminescence (PL) spectra and (c) time-resolved fluorescence decay spectra of bulk g-C3N4 and g-C3N4 nanosheets. (d) N2 adsorption-desorption isotherms of bulk g-C3N4 and g-C3N4 nanosheets.

Photoluminescence (PL) and time-resolved fluorescence decay spectra are employed to investigate the charge carrier separation and recombination properties of g-C3N4 nanosheets by plasma treatment. Figure 3b depicts the PL spectra of bulk g-C3N4 and g-C3N4 nanosheets, and a blue shift can be obviously observed in the g-C3N4 nanosheets due to the quantum confinement effect [49]. This result is consistent with UV-vis DRS result.

Figure 3c shows the time-resolved fluorescence decay spectra of bulk g-C3N4 and g-C3N4 nanosheet. The fluorescent intensities of both samples decay exponentially. However, the g-C3N4 nanosheets exhibited slower decay kinetics than bulk samples. Hence, the lifetime of the photo-induced charge carriers of plasma-exfoliated g-C3N4 nanosheets was longer than that of bulk g-C3N4. According to the fitting calculation of the spectra data, the average lifetime of charge carriers was 6.7 and 6.3 ns for bulk and 2D g-C3N4, respectively. The recombination of charge carriers was restrained in g-C3N4 nanosheets. It means that 2D g-C3N4 by plasma have a more flexible electron transfer ability than bulk g-C3N4. It is also favorable for photocatalytic performance.

Figure 3d exhibits nitrogen adsorption–desorption isotherms. The isotherms of both g-C3N4 exhibit type-1 curve with H3 hysteresis loops. In addition, the BET surface area of g-C3N4 nanosheets increased from 41.79 to 136.8 m2/g via plasma treatment, which due to the special sheet structure. Hence, plasma-exfoliated g-C3N4 nanosheets have better photocatalytic activity than bulk that due to the presence of more active sites on a larger specific surface area.

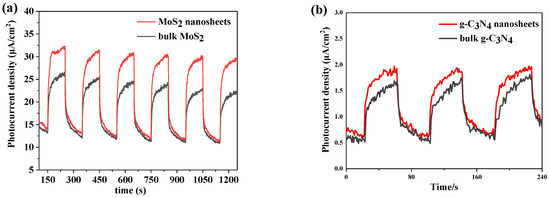

Figure 4 shows the photocurrent density of MoS2 and g-C3N4. Figure 4a shows that MoS2 nanosheets exhibit the higher photocurrent density than bulk MoS2, indicating MoS2 nanosheets by plasma have higher photoelectric conversion efficiency. Figure 4b shows the photocurrent density of bulk g-C3N4 and g-C3N4 nanosheets. g-C3N4 nanosheets also have higher photocurrent density. These results are consistent with the above results.

Figure 4.

Photocurrent density vs time for (a) bulk MoS2 and MoS2 nanosheets, (b) bulk g-C3N4 and g-C3N4 nanosheets.

3.2. Morphology

The morphology of g-C3N4 nanosheets and bulk g-C3N4 were analyzed by FESEM. Figure S6 show that bulk g-C3N4 are aggregated particles and layered structures, whereas g-C3N4 nanosheets significantly exhibited a different microstructure that is more loose than bulk g-C3N4, further confirming that plasma treatment can change structure of bulk g-C3N4. Further discussion will be given along with TEM results.

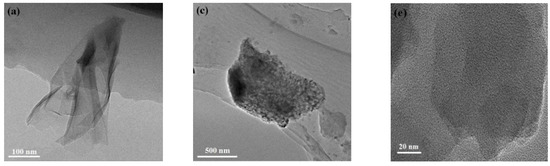

TEM images of MoS2 and g-C3N4 are shown in Figure 5. Figure 5a,b show that MoS2 prepared by plasma exhibited large area of nanosheet structure with wrinkle-like, indicating that the thickness of the nanosheet was very thin. Figure 5c,d show the microstructure of the bulk MoS2, which can be observed to be the thick flat structure composed of particle packing. Figure 5e,f are TEM images of both g-C3N4 samples. They show that the samples by plasma are almost transparent. Hence, bulk g-C3N4 is also successfully exfoliated into thin g-C3N4 nanosheets by DBD plasma treatment [50,51,52], which is in agreement with previous results.

Figure 5.

TEM images of (a,b) MoS2 nanosheets, (c,d) bulk MoS2, (e) bulk g-C3N4 and (f) g-C3N4 nanosheets.

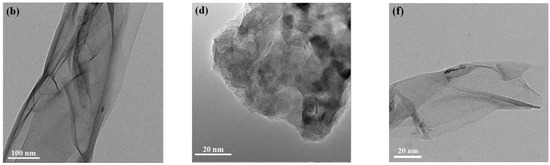

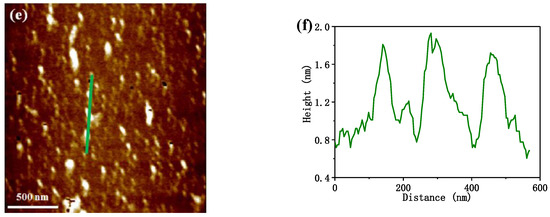

Atomic force microscope (AFM) was conducted measure the thickness of the as-prepared ultrathin sheets. As shown in Figure 6a,b, there are micron-sized nanosheets of MoS2 by plasma, with varying thickness due to the folds and bends of the edges. Heights of 2.04 nm and 3.18 nm of the flakes were observed, corresponding to the green and red lines. It indicates a MoS2 layer less than 5 “S-MO-S” atomic layers [53]. Figure 6c,d show 20 nm–25 nm thickness of bulk MoS2, due to the uneven accumulation of particles on its surface. As shown in Figure 6e,f, g-C3N4 nanosheets are deposited on the mica and exhibited a uniform thickness of approximately 1.2 nm, which corresponds to a g-C3N4 layer has 3 single atom layers [54,55]. The results are consistent with the observation from TEM. This further confirms that DBD plasma treatment can successfully prepare ultrathin MoS2 nanosheets and g-C3N4 nanosheets.

Figure 6.

AFM image and corresponding cross-section profile of (a,b) MoS2 nanosheets, (c,d) bulk MoS2 and (e,f) g-C3N4 nanosheets.

3.3. Mechanism Analysis

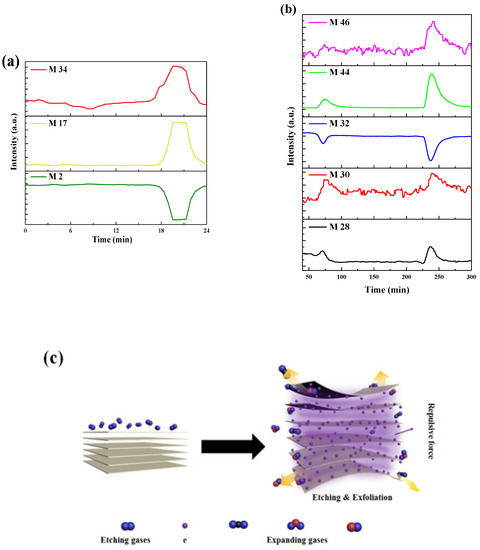

To verify that the mode of action was operative during the DBD plasma treatment process for (NH4)2MoS4 to MoS2 nanosheets and bulk g-C3N4 to 2D g-C3N4, the DBD plasma reactor was connected to an online mass spectrum. It is used to analyze the intermediate product during the plasma process. H2/Ar was continuously purged into the plasma reactor. Figure 7a shows the components during the preparation process of MoS2 nanosheets, measured by mass spectrometry. As mentioned in Experimental procedures, the plasma treatment process was a batch operation of 3 min for each experiment. It shows that the sample has been treated at 18 min. M 17 and M 34 have peaks between 18 min and 23 min. The changes of M 17 and M 34 corresponding to NH3 and H2S were generated in DBD plasma treatment. Moreover, M 2 was decreased that exhibit the opposite variation trend. It confirms that H2 was consumed in DBD plasma treatment. Overall, the mass spectrum results show that H2 served as etching sources to react with (NH4)2MoS4 and gaseous ammonia and hydrogen sulfide were generated in plasma process. The characteristic peak of H2O is not found. The large amount of gas generated is expanded to open the layers of bulk (NH4)2MoS4 to MoS2 nanosheets.

Figure 7.

Mass spectrum during DBD plasma treatment process of (a) MoS2 nanosheets and (b) g-C3N4 nanosheets. (c) Brief schematic illustration DBD plasma exfoliation process.

Figure 7b shows the components during the preparation process from g-C3N4 nanosheets measured by mass spectrometry. It shows that the bulk g-C3N4 has been treated twice at about 30 min and 50 min, respectively. It indicates that M 28, M 30, M 44, and M 46 increase and then returned to being constant. The changes of M 28, M 30 and M 46 imply that CO, NO and NO2 were generated. M 44 shows the change in CO2 or N2O that confirm bulk g-C3N4 was oxidized into gaseous oxide during DBD plasma treatment. Nevertheless, M 32 decreases indicated O2 was consumed in plasma treatment. The results show that O2 served as oxidant to react with bulk g-C3N4 and that gaseous oxycarbide and oxynitride were generated in an plasma process.

Figure 7c illustrates the schematic of MoS2 nanosheets and g-C3N4 nanosheets were generated in DBD plasma. According to the above analysis, etching and gas expansion are the main reasons for exfoliation process. In addition, we propose electrons would adhere to the surface or between the layers of bulk materials in plasma, and the repulsive force would exfoliate bulk materials into two-dimension nanosheets. It also facilitates the exfoliation.

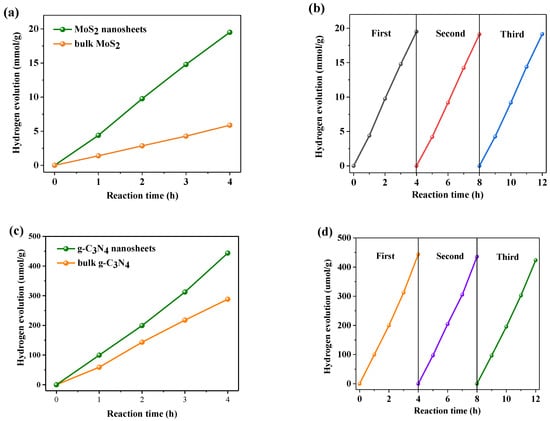

3.4. Photocatalytic Activity

The photocatalytic performance of MoS2 nanosheets are evaluated by hydrogen production. Hydrogen production is tested in dye sensitization systems under optical light. Figure 8a shows that the hydrogen production of MoS2 nanosheets reaches 4.88 mmol/g per hour. However, the hydrogen production of bulk MoS2 is only 1.47 mmol/g per hour. The former is about 3.3 times that of the latter. It shows that MoS2 nanosheets by plasma has excellent hydrogen production activity, which is attributed to its thinner sheet structure and better charge transfer efficiency. As can be seen from Figure 8b, there was no remarkable decrease in the hydrogen production of MoS2 nanosheets after three cycles of experiments, indicating that it has superior stability.

Figure 8.

(a) Photocatalytic H2 evolution rates and (b) stability of bulk MoS2 and MoS2 nanosheets under visible light irradiation, (c) Photocatalytic H2 evolution rates and (d) stability of bulk g-C3N4 and g-C3N4 nanosheets.

In order to evaluate the activity of 2D g-C3N4 by DBD plasma, H2 evolution and RhB/MO degradation reactions were conducted in optical light irradiation. Figure 8c shows that 0.5% Pt/g-C3N4 nanosheets demonstrated better catalytic performance than bulk that in water splitting, whose H2 evolution can reached 5.5 µmol/h and was 1.5 times of the latter. Therefore, the 2D nanosheets obtained by plasma treatment have superior properties in photocatalytic reactions. In addition, 2D structure provides faster electron transfer rate and extended lifetime of electrons and holes. The obtained 2D g-C3N4 exhibits a large specific surface area. This is in agreement with the previous characterization results. All these factors contribute to the superior H2 evolution rate. Figure 8d shows the hydrogen production cycle stability experiment of g-C3N4 nanosheets. After 12 h, the hydrogen production amount only slightly decreased, indicating that it has good stability.

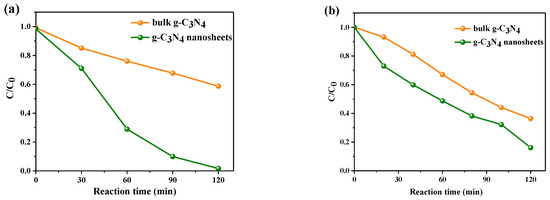

Figure 9a shows that the concentration of the MO solution continuously decreased under visible light exposure from a starting concentration of 10 mg/L with both g-C3N4. The 2D g-C3N4 successfully degraded the MO in 2 h, and the rate is 2.5 times faster than the bulk. Figure 9b also shows the degradation reaction of the RhB solution (20 mg/L). g-C3N4 nanosheets exhibit a favorable degradation rate, and the rate of that is 1.3 times that of thick g-C3N4.

Figure 9.

Photocatalytic activity of bulk g-C3N4 and as prepared g-C3N4 nanosheets for the degradation of (a) MO and (b) RhB under visible light irradiation.

Therefore, 2D structure nanosheets obtain by plasma have better photocatalytic performance under visible light irradiation, which was consistent with the previous report on two-dimesional nanosheet materials, further proving that the DBD plasma can be used as a facile method for preparing MoS2 and g-C3N4 nanosheets.

4. Conclusions

Plasma as the environmentally benign approach provides a general platform for fabricating ultrathin nanosheets with prospective applications as photocatalysts for H2 evolution and pollutant degradation. MoS2 nanosheets and g-C3N4 nanosheets were successfully prepared utilizing a novel atmospheric plasma method at a moderate temperature. The gas etching and gas expansion process along with the repulsive force between electrons are the main reasons for plasma exfoliate the bulk precursors of layered structure to ultrathin nanosheets. The obtained MoS2 and g-C3N4 nanosheets have several atomic layer thickness. Furthermore, a 2D structure MoS2 and g-C3N4 nanosheets exhibits a larger surface area, and more flexible photophysical properties. The nano structure could ensure an easier electron transfer during the reaction. The plasma method show potential for the fast, solvent-free, low temperature, and large-scale application for the preparation of 2-dimensional nanomaterials.

Supplementary Materials

The following are available online at https://www.mdpi.com/2079-4991/9/8/1139/s1. Figure S1: Schematic of DBD plasma system, Figure S2: IR image of the reaction system during DBD treatment, Figure S3: Image of (a) g-C3N4 and (b) MoS2 before DBD treatment and after DBD treatment, Figure S4: XPS survey spectra of (a) MoS2 and (b) g-C3N4, Figure S5: FTIR spectra of bulk g-C3N4 and g-C3N4 nanosheets, Figure S6: SEM of (a) bulk g-C3N4 and (b) g-C3N4 nanosheets, Table S1: The atomic concentration of all elements in MoS2, Table S2: The atomic concentration of all elements in g-C3N4.

Author Contributions

Z.W. (Zhao Wang) and Q.X.Y. conceived the experiments. Z.W. (Zhenhai Wang) conducted the preparation experiment. B.Z. conducted the photocatalysis experiment. X.P. and L.Z. set up the experimental device. B.Z. and Z.W. (Zhenhai Wang) wrote the original draft of the manuscript.

Funding

The support from the National Key Research and Development Program of China (No. 2016YFF0102503) and National Natural Science Foundation of China (No. 21878214) are greatly appreciated.

Conflicts of Interest

The authors declare no competing interests.

References

- Fu, J.W.; Yu, J.G.; Jiang, C.J.; Cheng, B. g-C3N4-Based Heterostructured Photocatalysts. Adv. Energy Mater. 2018, 8, 1701503. [Google Scholar] [CrossRef]

- Hisatomi, T.; Kubota, J.; Domen, K. Recent advances in semiconductors for photocatalytic and photoelectrochemical water splitting. Chem. Soc. Rev. 2014, 43, 752–7535. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.Q.; Wang, W.; Wang, F.; Di, L.B.; Yang, S.C.; Zhu, S.J.; Yao, Y.B.; Ma, C.H.; Dai, B.; Yu, F. Enhanced Photocatalytic Degradation of Organic Dyes via Defect-Rich TiO2 Prepared by Dielectric Barrier Discharge Plasma. Nanomaterials 2019, 9, 720. [Google Scholar] [CrossRef] [PubMed]

- Di, L.B.; Xu, Z.J.; Wang, K.; Zhang, X.L. A facile method for preparing Pt/TiO2 photocatalyst with enhanced activity using dielectric barrier discharge. Catal. Today 2013, 211, 109–113. [Google Scholar] [CrossRef]

- Haque, F.; Daeneke, T.; Kalantar-Zadeh, K.; Ou, J.Z. Two-Dimensional Transition Metal Oxide and Chalcogenide-Based Photocatalysts. Nano-Micro Lett. 2018, 10, 23. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.B.; Choudhary, N.; Han, G.H.; Park, J.H.; Akinwande, D.; Lee, Y.H. Recent development of two-dimensional transition metal dichalcogenides and their applications. Mater. Today 2017, 20, 116–130. [Google Scholar] [CrossRef]

- Tan, C.L.; Cao, X.H.; Wu, X.J.; He, Q.Y.; Yang, J.; Zhang, X.; Chen, J.Z.; Zhao, W.; Han, S.K.; Nam, G.; et al. Recent Advances in Ultrathin Two-Dimensional Nanomaterials. Chem. Rev. 2017, 117, 6225–6331. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, H.; Peng, W. 2D Transition Metal Dichalcogenides and Graphene-Based Ternary Composites for Photocatalytic Hydrogen Evolution and Pollutants Degradation. Nanomaterials 2017, 7, 62. [Google Scholar] [CrossRef]

- Liu, P.B.; Zhang, Y.Q.; Yan, J.; Huang, Y.; Xia, L.; Guang, Z.X. Synthesis of lightweight N-doped graphene foams with open reticular structure for high-efficiency electromagnetic wave absorption. Chem. Eng. J. 2019, 368, 285–298. [Google Scholar] [CrossRef]

- Truong, L.; Jerng, S.; Roy, S.B.; Jeon, J.H.; Kim, K.; Akbar, K.; Yi, Y.; Chun, S. Chrysanthemum-Like CoP Nanostructures on Vertical Graphene Nanohills as Versatile Electrocatalysts for Water Splitting. ACS Sustain. Chem. Eng. 2019, 7, 4625–4630. [Google Scholar] [CrossRef]

- He, Q.G.; Liu, J.; Tian, Y.L.; Wu, Y.Y.; Magesa, F.; Deng, P.H.; Li, G.L. Facile Preparation of Cu2O Nanoparticles and Reduced Graphene Oxide Nanocomposite for Electrochemical Sensing of Rhodamine B. Nanomaterials 2019, 9, 958. [Google Scholar] [CrossRef] [PubMed]

- Nikokavoura, A.; Trapalis, C. Graphene and g-C3N4 based photocatalysts for NOx removal: A review. Appl. Surf. Sci. 2018, 430, 18–52. [Google Scholar] [CrossRef]

- Krasian, T.; Punyodom, W.; Worajittiphon, P. A hybrid of 2D materials (MoS2 and WS2) as an effective performance enhancer for poly (lactic acid) fibrous mats in oil adsorption and oil/water separation. Chem. Eng. J. 2019, 369, 563–575. [Google Scholar] [CrossRef]

- Huang, K.; Li, Z.J.; Lin, J.; Han, G.; Huang, P. Two-dimensional transition metal carbides and nitrides (MXenes) for biomedical applications. Chem. Soc. Rev. 2018, 47, 5109–5124. [Google Scholar] [CrossRef] [PubMed]

- Park, S.Y.; Kim, Y.H.; Lee, S.Y.; Sohn, W.; Lee, J.E.; Kim, D.H.; Shim, Y.; Kwon, K.C.; Choi, K.S.; Yoo, H.J.; et al. Highly selective and sensitive chemoresistive humidity sensors based on rGO/MoS2 van der Waals composites. J. Mater. Chem. A 2018, 6, 5016–5024. [Google Scholar] [CrossRef]

- Xie, J.F.; Zhang, J.J.; Li, S.; Grote, F.B.; Zhang, X.D.; Zhang, H.; Wang, R.X.; Lei, Y.; Pan, B.C.; Xie, Y. Controllable Disorder Engineering in Oxygen-Incorporated MoS2 Ultrathin Nanosheets for Efficient Hydrogen Evolution. J. Am. Chem. Soc. 2013, 135, 17881–17888. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.Y.; Liu, B.; Zou, X.L.; Cheng, H.M. Chemical Vapor Deposition Growth and Applications of Two-Dimensional Materials and Their Heterostructures. Chem. Rev. 2018, 118, 6091–6133. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, Y.; Neyts, E.C.; Cao, X.X.; Zhang, X.S.; Jang, B.W.L.; Liu, C.J. Catalyst Preparation with Plasmas: How Does It Work? ACS Catal. 2018, 8, 2093–2110. [Google Scholar] [CrossRef]

- Di, L.B.; Zhang, J.S.; Zhang, X.L. A review on the recent progress, challenges, and perspectives of atmospheric-pressure cold plasma for preparation of supported metal catalysts. Plasma Process. Polym. 2018, 15, 1700234. [Google Scholar] [CrossRef]

- Zhang, J.S.; Di, L.B.; Yu, F.; Duan, D.Z.; Zhang, X.L. Atmospheric-Pressure Cold Plasma Activating Au/P25 for CO Oxidation: Effect of Working Gas. Nanomaterials 2018, 8, 742. [Google Scholar] [CrossRef]

- Sun, Q.D.; Yu, B.; Liu, C.J. Characterization of ZnO Nanotube Fabricated by the Plasma Decomposition of Zn(OH)2 Via Dielectric Barrier Discharge. Plasma Chem. Plasma Process. 2012, 32, 201–209. [Google Scholar] [CrossRef]

- Neyts, E.C.; Ostrikov, K.K.; Sunkara, M.K.; Bogaerts, A. Plasma Catalysis: Synergistic Effects at the Nanoscale. Chem. Rev. 2015, 115, 13408–13446. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Wang, Y.Y.; Liu, D.D.; Zou, Y.Q.; Wang, S.Y. Water-Plasma-Enabled Exfoliation of Ultrathin Layered Double Hydroxide Nanosheets with Multivacancies for Water Oxidation. Adv. Mater. 2017, 29, 1701546. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.Q.; Yu, F.; Zhu, M.Y.; Ma, C.H.; Zhao, D.; Wang, C.; Zhou, A.M.; Dai, B.; Ji, J.Y.; Guo, X.H. N-Doping of plasma exfoliated graphene oxide via dielectric barrier discharge plasma treatment for the oxygen reduction reaction. J. Mater. Chem. A 2018, 6, 2011–2017. [Google Scholar] [CrossRef]

- Peng, X.F.; Wang, Z.H.; Wang, Z.; Gong, J.B.; Hao, H.X. Electron reduction for the preparation of rGO with high electrochemical activity. Catal. Today 2019, 2, 1–6. [Google Scholar] [CrossRef]

- Guo, L.; Yang, Z.; Marcus, K.; Li, Z.; Luo, B.; Zhou, L.; Wang, X.; Du, Y.; Yang, Y. MoS2/TiO2 heterostructures as nonmetal plasmonic photocatalysts for highly efficient hydrogen evolution. Energy Environ. Sci. 2018, 11, 106–114. [Google Scholar] [CrossRef]

- Li, Z.Z.; Meng, X.C.; Zhang, Z.S. Recent development on MoS2-based photocatalysis: A review. J. Photochem. Photobiol. C Photochem. Rev. 2018, 35, 39–55. [Google Scholar] [CrossRef]

- Wang, X.; Maeda, K.; Thomas, A.; Takanabe, K.; Xin, G.; Carlsson, J.M.; Domen, K.; Antonietti, M. A metal-free polymeric photocatalyst for hydrogen production from water under visible light. Nat. Mater. 2009, 8, 76–80. [Google Scholar] [CrossRef]

- Yin, S.M.; Han, J.Y.; Zhou, T.H.; Xu, R. Recent progress in g-C3N4 based low cost photocatalytic system: Activity enhancement and emerging applications. Catal. Sci. Technol. 2015, 5, 5048–5061. [Google Scholar] [CrossRef]

- Wang, Y.G.; Li, Y.G.; Bai, X.; Cai, Q.; Liu, C.L.; Zuo, Y.H.; Kang, S.F.; Cui, L.F. Facile synthesis of Y-doped graphitic carbon nitride with enhanced photocatalytic performance. Catal. Commun. 2016, 84, 179–182. [Google Scholar] [CrossRef]

- Wang, G.Z.; Zhou, F.; Yuan, B.F.; Xiao, S.Y.; Kuang, A.L.; Zhong, M.M.; Dang, S.H.; Long, X.J.; Zhang, W.L. Strain-Tunable Visible-Light-Responsive Photocatalytic Properties of Two-Dimensional CdS/g-C3N4: A Hybrid Density Functional Study. Nanomaterials 2019, 9, 244. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.F.; Zhang, H.; Li, S.; Wang, R.X.; Sun, X.; Zhou, M.; Zhou, J.F.; Lou, X.W.D.; Xie, Y. Defect-Rich MoS2 Ultrathin Nanosheets with Additional Active Edge Sites for Enhanced Electrocatalytic Hydrogen Evolution. Adv. Mater. 2013, 25, 5807–5813. [Google Scholar] [CrossRef] [PubMed]

- Niu, P.; Zhang, L.L.; Liu, G.; Cheng, H.M. Graphene-Like Carbon Nitride Nanosheets for Improved Photocatalytic Activities. Adv. Funct. Mater. 2012, 22, 4763–4770. [Google Scholar] [CrossRef]

- Yang, S.; Gong, Y.; Zhang, J.; Zhan, L.; Ma, L.; Fang, Z.; Vajtai, R.; Wang, X.; Ajayan, P.M. Exfoliated Graphitic Carbon Nitride Nanosheets as Efficient Catalysts for Hydrogen Evolution Under Visible Light. Adv. Mater. 2013, 25, 2452–2456. [Google Scholar] [CrossRef] [PubMed]

- Ong, W.J.; Tan, L.L.; Ng, Y.H.; Yong, S.T.; Chai, S.P. Graphitic Carbon Nitride (g-C3N4)-Based Photocatalysts for Artificial Photosynthesis and Environmental Remediation: Are We a Step Closer To Achieving Sustainability? Chem. Rev. 2016, 116, 7159–7329. [Google Scholar] [CrossRef] [PubMed]

- Jia, T.T.; Li, M.M.J.; Ye, L.; Wise Man, S.; Liu, G.L.; Qu, J.; Nakagawa, K.; Tsang, S.C.E. The remarkable activity and stability of a dye-sensitized single molecular layer MoS2 ensemble for photocatalytic hydrogen production. Chem. Commun. 2015, 51, 13496–13499. [Google Scholar] [CrossRef] [PubMed]

- Choudhary, N.; Islam, M.A.; Kim, J.H.; Ko, T.; Schropp, A.; Hurtado, L.; Weitzman, D.; Zhai, L.; Jung, Y. Two-dimensional transition metal dichalcogenide hybrid materials for energy applications. Nano Today 2018, 19, 16–40. [Google Scholar] [CrossRef]

- Lin, Q.Y.; Li, L.; Liang, S.J.; Liu, M.H.; Bi, J.H.; Wu, L. Efficient synthesis of monolayer carbon nitride 2D nanosheet with tunable concentration and enhanced visible-light photocatalytic activities. Appl. Catal. B Environ. 2015, 163, 135–142. [Google Scholar] [CrossRef]

- Zhang, J.S.; Chen, Y.; Wang, X.C. Two-dimensional covalent carbon nitride nanosheets: Synthesis, functionalization, and applications. Energy Environ. Sci. 2015, 8, 3092–3108. [Google Scholar] [CrossRef]

- Latorre Sánchez, M.; Esteve Adell, I.; Primo, A.; García, H. Innovative preparation of MoS2–graphene heterostructures based on alginate containing (NH4)2MoS4 and their photocatalytic activity for H2 generation. Carbon 2015, 81, 587–596. [Google Scholar] [CrossRef]

- Zheng, S.Z.; Zheng, L.J.; Zhu, Z.Y.; Chen, J.; Kang, J.L.; Huang, Z.L.; Yang, D.C. MoS2 Nanosheet Arrays Rooted on Hollow rGO Spheres as Bifunctional Hydrogen Evolution Catalyst and Supercapacitor Electrode. Nano-Micro Lett. 2018, 10, 23. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Wang, G.; Jiang, C.; Bao, H.; Xu, Q. Synthesis of core-shell TiO2 @g-C3N4 hollow microspheres for efficient photocatalytic degradation of rhodamine B under visible light. Appl. Surf. Sci. 2018, 430, 263–272. [Google Scholar] [CrossRef]

- Li, F.T.; Liu, S.J.; Xue, Y.B.; Wang, X.J.; Hao, Y.J.; Zhao, J.; Liu, R.H.; Zhao, D.S. Structure Modification Function of g-C3N4 for Al2O3 in the In Situ Hydrothermal Process for Enhanced Photocatalytic Activity. Chem. A Eur. J. 2015, 21, 10149–10159. [Google Scholar] [CrossRef] [PubMed]

- Xia, P.F.; Zhu, B.C.; Yu, J.G.; Cao, S.W.; Jaroniec, M. Ultra-thin nanosheet assemblies of graphitic carbon nitride for enhanced photocatalytic CO2 reduction. J. Mater. Chem. A 2017, 5, 3230–3238. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Su, C.S.; Ren, H.; Li, M.; Zhu, L.F.; Ge, S.; Wang, M.; Zhang, Z.L.; Li, L.; Cao, X.B. In-Situ Fabrication of g-C3N4/ZnO Nanocomposites for Photocatalytic Degradation of Methylene Blue: Synthesis Procedure Does Matter. Nanomaterials 2019, 9, 215. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liu, E.Z.; Ma, Y.N.; Hu, X.Y.; Wan, J.; Sun, L.; Fan, J. Synthesis of MoS2/g-C3N4 nanosheets as 2D heterojunction photocatalysts with enhanced visible light activity. Appl. Surf. Sci. 2016, 364, 694–702. [Google Scholar] [CrossRef]

- Zou, L.R.; Huang, G.F.; Li, D.F.; Liu, J.H.; Pan, A.L.; Huang, W.Q. A facile and rapid route for synthesis of g-C3N4 nanosheets with high adsorption capacity and photocatalytic activity. RSC Adv. 2016, 6, 86688–86694. [Google Scholar] [CrossRef]

- Cai, X.G.; He, J.Y.; Chen, L.; Chen, K.; Li, Y.L.; Zhang, K.S.; Jin, Z.; Liu, J.Y.; Wang, C.M.; Wang, X.G.; et al. A 2D-g-C3N4 nanosheet as an eco-friendly adsorbent for various environmental pollutants in water. Chemosphere 2017, 171, 192–201. [Google Scholar] [CrossRef]

- Ding, W.; Liu, S.Q.; He, Z. One-step synthesis of graphitic carbon nitride nanosheets for efficient catalysis of phenol removal under visible light. Chin. J. Catal. 2017, 38, 1711–1718. [Google Scholar] [CrossRef]

- Li, Y.F.; Fang, L.; Jin, R.X.; Yang, Y.; Fang, X.; Xing, Y.; Song, S.Y. Preparation and enhanced visible light photocatalytic activity of novel g-C3N4 nanosheets loaded with Ag2CO3 nanoparticles. Nanoscale 2015, 7, 758–764. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, L.W.; Shi, R.; Zhu, Y.F. Chemical exfoliation of graphitic carbon nitride for efficient heterogeneous photocatalysis. J. Mater. Chem. A 2013, 1, 14766–14772. [Google Scholar] [CrossRef]

- Miao, H.; Zhang, G.W.; Hu, X.Y.; Mu, J.L.; Han, T.X.; Fan, J.; Zhu, C.J.; Song, L.X.; Bai, J.T.; Hou, X. A novel strategy to prepare 2D g-C3N4 nanosheets and their photoelectrochemical properties. J. Alloys Compd. 2017, 690, 669–676. [Google Scholar] [CrossRef]

- Xiao, J.W.; Zhang, Y.; Chen, H.J.; Xu, N.S.; Deng, S.Z. Enhanced Performance of a Monolayer MoS2/WSe2 Heterojunction as a Photoelectrochemical Cathode. Nano-Micro Lett. 2018, 10, 60. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.S.; Zhai, C.Y.; Sun, M.J.; Hu, Y.F.; Yan, B.; Du, Y.K. Ultrathin graphitic C3N4 nanosheet as a promising visible-light-activated support for boosting photoelectrocatalytic methanol oxidation. Appl. Catal. B Environ. 2017, 203, 108–115. [Google Scholar] [CrossRef]

- Wang, M.; Shen, M.; Zhang, L.X.; Tian, J.J.; Jin, X.X.; Zhou, Y.J.; Shi, J.L. 2D-2D MnO2/g-C3N4 heterojunction photocatalyst: In-situ synthesis and enhanced CO2 reduction activity. Carbon 2017, 120, 23–31. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).