1. Introduction

Graphene, a single layer of carbon atoms tightly bound in a hexagonal honeycomb lattice, is one of the most exciting two-dimensional materials discovered. Bilayer graphene, consisting of two coupled, single layers with a honeycomb carbon crystal structure, has attracted a great deal of attention because it can exist with a variety of stacking arrangements with intriguing electronic properties [

1,

2,

3]. Unlike monolayer graphene, which possesses a zero bandgap, the electronic structure of bilayer graphene can be significantly modified by external fields, mechanical distortions, and structural variations, enabling a wide range of electronic phenomena from tunable semiconductors to unconventional superconductivity [

4,

5,

6]. Its most common structure is AB (Bernal) stacking, where one layer is shifted relative to the other, leading to distinct electronic behaviors compared to the less stable AA stacking or the fascinating twisted configurations [

7,

8]. The growing sophistication in synthesis, particularly the controlled growth of twisted bilayers, coupled with a deeper understanding of the role of defects and interactions, promises to unlock further potential [

9,

10,

11].

Computational modeling can serve as a route for theoretically understanding the difficult-to-measure properties of graphene. On the continuum scale, the phase-field crystal (PFC) modeling approach describes the thermodynamics and dynamics of phase transformation through an atomically varying order parameter field that is loosely connected to the atomic density field. It is a special type of phase-field model which enables the order parameter to remain stable in both uniform and periodic states, where the periodic state represents the coarsened atomic structure of the crystalline phase on the diffusive time scale [

12,

13,

14].

The original PFC model was predominately used for the study of 2D triangular and three-dimensional (3D) crystal symmetries [

12,

15,

16,

17,

18,

19]. PFC simulations make it possible to study solidification processes and elastoplastic material responses, covering a wide range of phenomena. These phenomena include the formation and co-evolution of microstructural defects such as dislocations and stacking faults [

20], defect formation in epitaxial growth [

21], displacive phase transitions [

22], corrosion rate and morphology of a dealloying metal [

23], voids [

24,

25,

26], and electromigration [

27]. The PFC model possesses both continuum and atomic-scale characteristics, which makes it particularly useful for investigating how atomic-scale structures affect mesoscale properties that govern microstructural evolution. These properties range from interface energy anisotropy [

28,

29] to sublattice ordering in order-disorder transformations [

30] and atomic structures in eutectic growth [

31]. By including a rotationally invariant three-point correlation function for the excess free energy, a structural PFC model was setup to address both the atomically varying defect and microstructures of graphene and its nucleation and diffusional growth kinetics from a disordered state on a surface [

32]. This method allows for a more systematic and adaptable parameterization of diverse crystal structures. The formalism has been extended to reproduce parts of real material phase diagrams, such as those of aluminum and tungsten, by fitting the model parameters to experimental data [

33,

34].

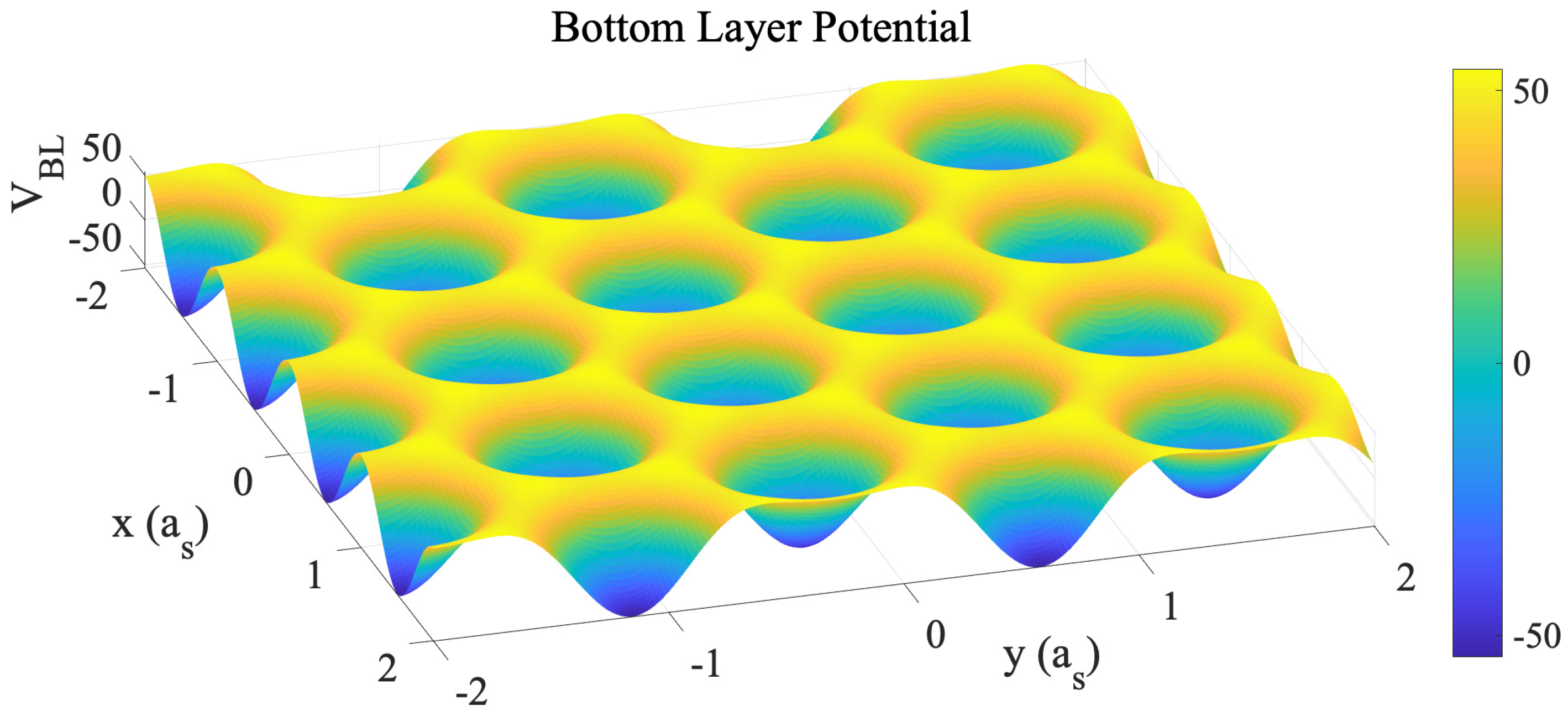

In this work, we develop a PFC model for bilayer graphene by extending the structural PFC approach introduced in [

32]. Following [

32], we employ a structural PFC model that incorporates both two- and three-point correlation kernels in the nonlocal contribution to the free energy. To capture the effect of a second graphene layer on the modeled layer, we introduce a local interaction between the order parameter density and an external potential, referred to as the bottom-layer potential. This approach corresponds to a physical scenario in which the bottom graphene layer is fixed on a substrate, and the layer under consideration is deposited on top of it. The form of the bottom-layer potential is informed by first-principles calculations of the generalized stacking fault energy (GSFE) in bilayer graphene from [

35], which describes the energy variation associated with the lateral displacement of one graphene layer relative to the other. The analytic expression of the GSFE provided in [

35] implies that a potential of the same functional form—though with different coefficients—would exactly reproduce the GSFE in an atomistic simulation [

36]. In our PFC model, we adopt this functional form for the bottom-layer potential, but scale it by an adjustable parameter. The value of this parameter is determined by fitting against molecular dynamics (MD) simulations [

36,

37], which are themselves validated against experimental results, as discussed later in the text.

In the numerical simulations, we first test the growth of graphene phases without the bottom-layer potential by choosing parameters corresponding to the solid region of the phase-field, i.e., ensuring the periodicity for each side of the rectangular domain and initializing the system with Gaussian noise. The results agree with [

32]. We then add bottom-layer potential and again start with Gaussian noise and generate both the AB and BA stacking, where AB and BA stacking have one of the first layer’s sublattice atoms (A or B) directly on top of its opposite sublattice atom (B or A) in the second layer, called AB or BA stacking, respectively, or collectively called Bernal stacking [

38]. Then, we test the case of a long, narrow ribbon domain. The initial condition consists of four parts, continuous AB and BA regions each of nearly 50% of the entire domain, respectively, and two narrow transitions between each of them is set to be a constant with small Gaussian perturbation. We find four transition types, depending on the angle between the transition region and the shifting direction, 0°, 30°, 60°, and 90°. By comparing with the simulation results from atomistic methods [

39,

40], we quantify the strength of the bottom-layer potential by the width of the transition region for each type of transition. Finally, we test the case of a circular AB vs BA stacking. With constant transition region, the center part (even a relatively small one) may evolve to a triangular or hexagonal shape with at least one 5–7 defective ring on each vertex. On the other hand, with uniformly smooth transition from AB to BA, the area of the center part will shrink at a constant speed (even for a relatively large disk).

The simulations are so numerically expensive that they take a long time, i.e., 3–7 days, to reach a steady solidification. In order to solve the system in a large domain efficiently, we use a CUDA C/C++ programming on Nvidia Quadro GV100 (NVIDIA Corporate, Santa Clara, CA, USA) which runs about two orders of magnitude faster than the normal version.

3. Results

3.1. Preliminary Test of the Model

We set the initial phase-field

, where

is a spatially uncorrelated scalar field of Gaussian noise with mean 0 and standard deviation 0.001. As shown in

Figure 3a, when

, i.e.,

, the graphene evolves to a defected structure that agrees with [

32]. Then, we set

with the same initial phase-field, that the graphene evolves to a neat structure as shown in

Figure 3b, and it takes a shorter time to reach such an equilibrium.

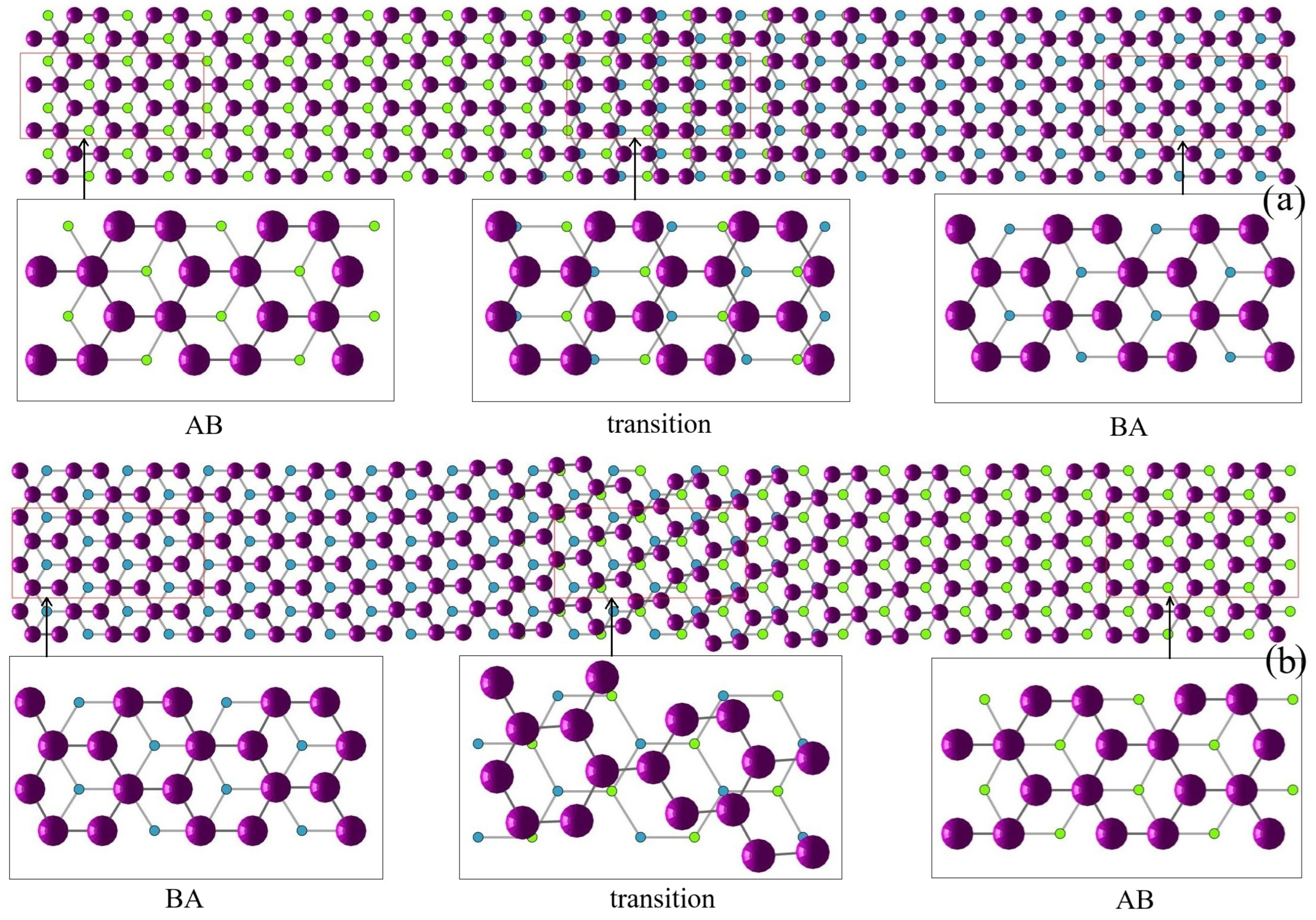

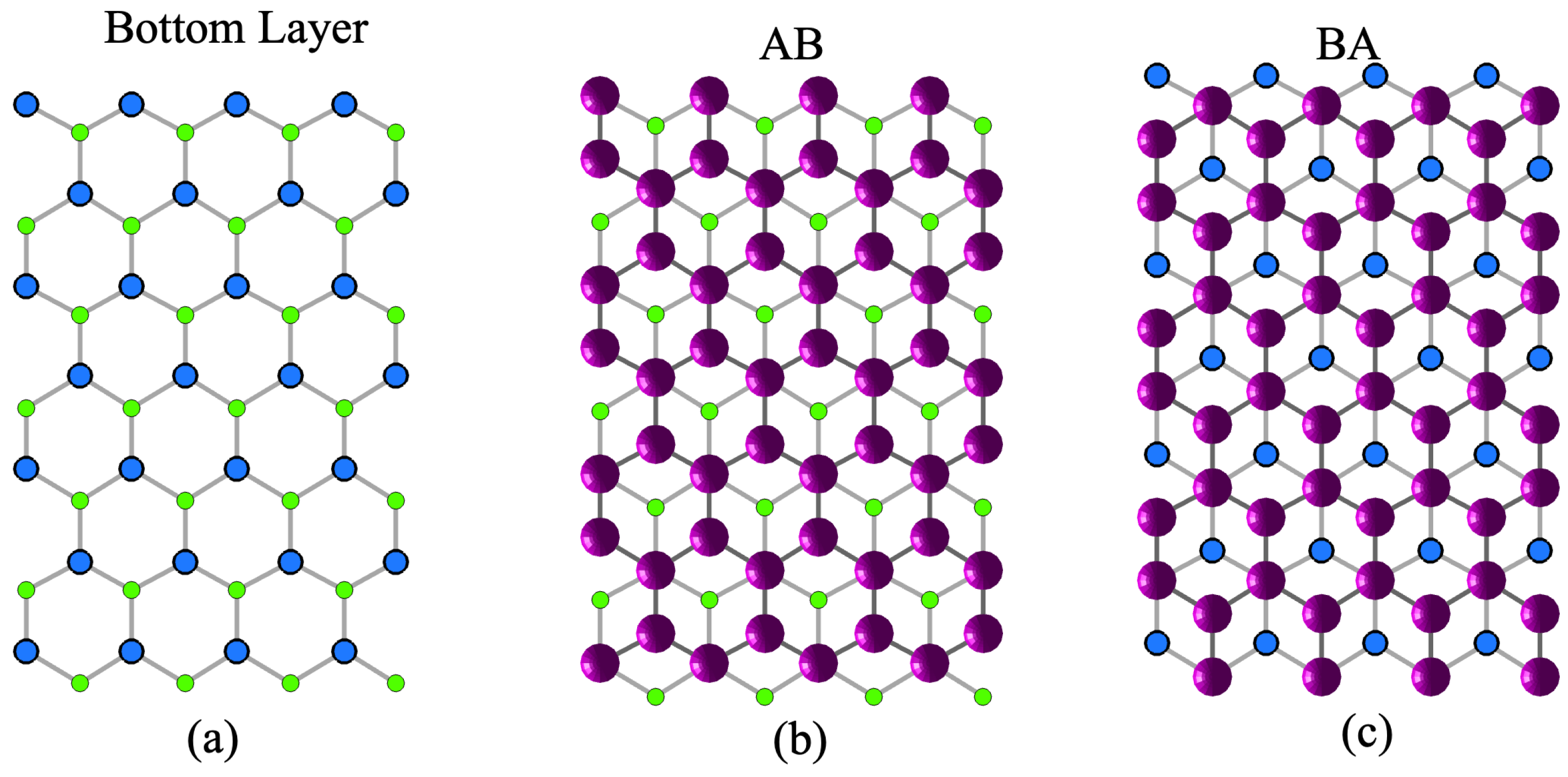

Next, we simulate a group of samples by setting

and initial phase-field again

yet with different random seeds. Both AB and BA stacking phases are found [

38], as shown in

Figure 4. In order to display the structure clearly, in

Figure 4a, we plot the bottom layer the way that the carbon atoms are divided into two groups with one group colored by lighter green and the other by darker blue. One lighter, green atom is near to three darker atoms and vice versa. In

Figure 4b, we plot AB stacking order where the upper layer atoms locate above the darker blue atoms and the center of the hexagons, different from BA stacking, as shown by

Figure 4c where the upper layer atoms locate right above the lighter green atoms and in the center of the hexagons.

We also find that by adding

to a defected graphene, the phase-field will evolve to a well-structured state, like in

Figure 3b.

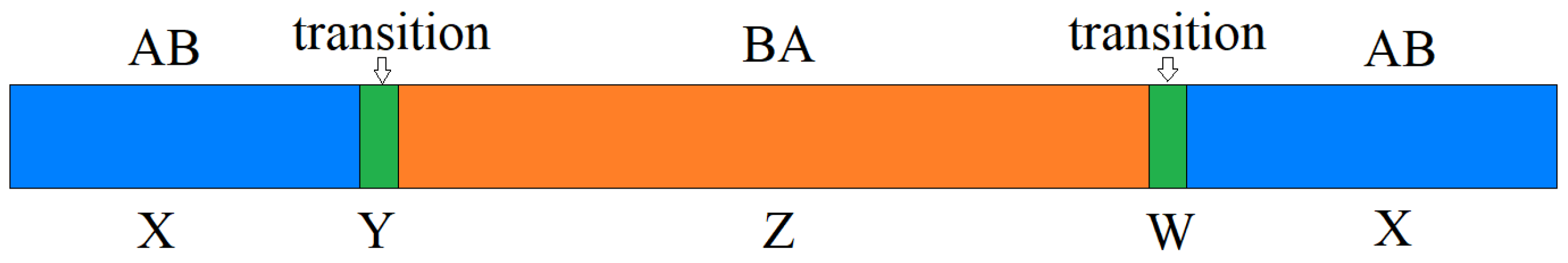

3.2. The Transition Between the AB and BA Stacking Order

Given a long ribbon of bilayer graphene, where AB phase and BA phase are of equal length, we investigate the transition between them. The initial state is a static setup where there are four parallel stripes X-Y-Z-W-X, as shown in

Figure 5, X represents the stacking order AB, Z represents the stacking order BA, and Y, W are disordered. The X and Z region grows as the dynamics start and two interfaces will be created between them. As shown in

Figure 2, there are two boundaries: one from AB to BA and the other from BA to AB.

Here, the angle

between the direction of the transition region and the direction along which the atoms shift is used as the dislocation character. In

Figure 2, for example, the transition region (X-Z-Y) is vertical and the left region is 90 degree (the atoms shift horizontally) as shown in

Figure 2a, while the right region (Y-W-X) is 30 (or

) degree, as shown in

Figure 2b.

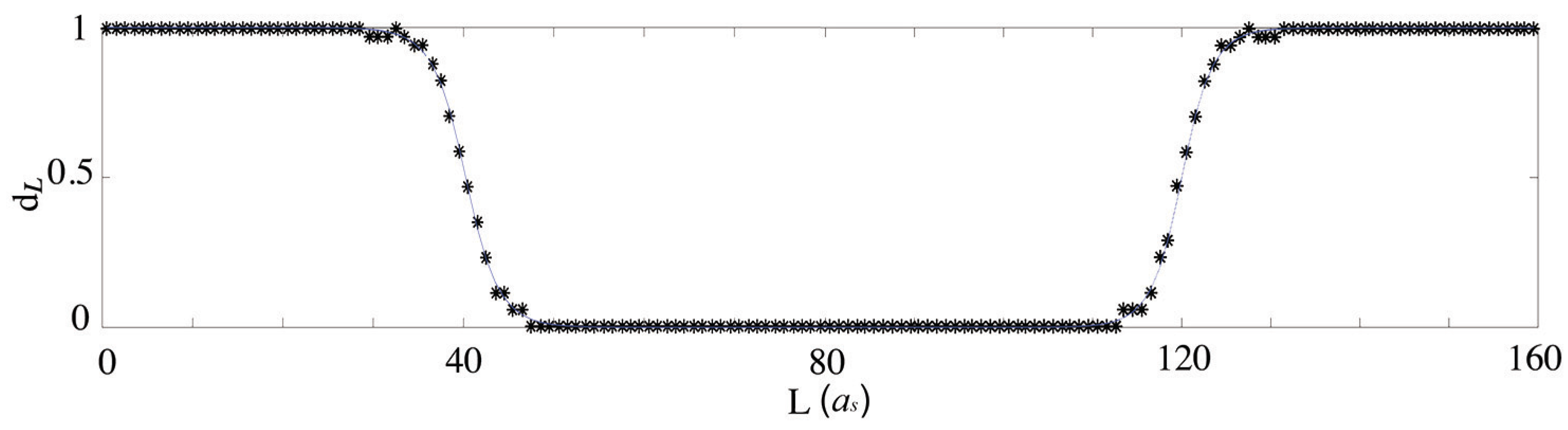

We then compute the thickness of the transition region. Define a nondimensionalized parameter

that measures the distortion between substrate potential

and the graphene field

:

where

is the nondimensionalized

x-

y plane distance between the center of one group of atoms on the bottom layer and the nearest atom centers on the top layer at

, for example, the distance in

x-

y plane between the center of the lighter green circles and the center of pink balls in

Figure 2. Here,

for AB pattern and

for BA pattern. The data is then fitted by the function

where

W is a fitting parameter that stands for the thickness of the transition region.

As shown in

Figure 6,

given the same

, which agrees with previous results [

38].

Furthermore, we find that the interface depends on the constant , i.e., the strength of the bottom-layer potential. This allows tuning of by comparing the width to the one from atomistic simulations and experimental results.

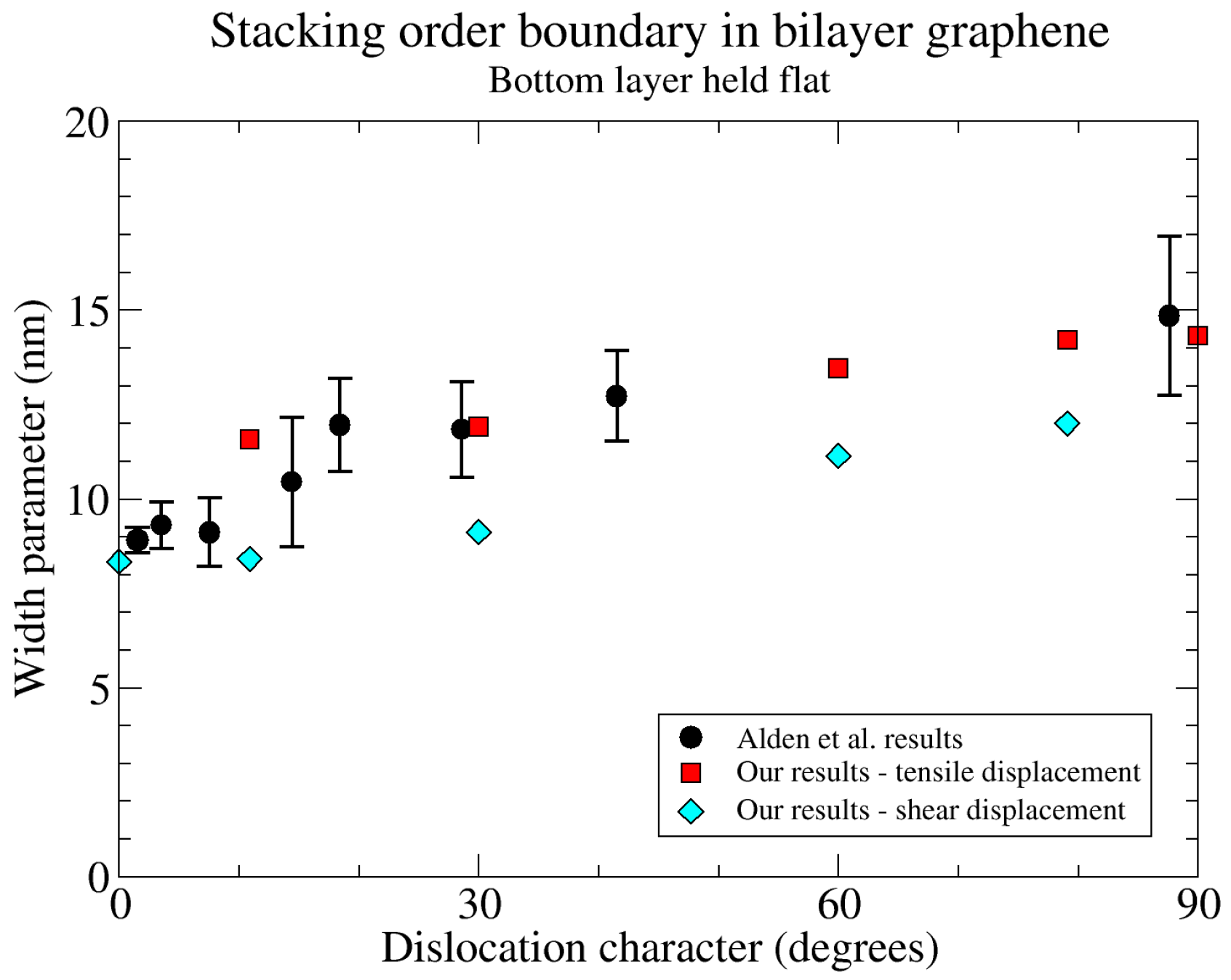

3.3. Atomistic Modeling

Alden and coworkers studied the width of these boundaries using scanning transmission electron microscopy (STEM). They related the width in the STEM images by comparing them to simulated STEM images based on atomic positions given by displacements of

where

is the fraction of the total displacement.

Alden et al.’s primary measurements are for two graphene sheets oriented for Bernal stacking [

38]. In total, there is a four-graphene-layer, free-standing sheet. The other two layers are not near to optimal stacking angles, and influence the in-plane atomic positions in the Bernal-stacking layers only weakly, but keep those sheets flat. The most relevant of our atomistic models is the one where the bottom layer is kept flat, but the atoms in that layer are allowed to relax in plane. The widths from the boundaries in those simulations agree well with Alden et al.’s results. In

Figure 7, we compare the widths of the boundaries in our simulations with the widths of their experimental boundaries as shown in Figure 3H of reference [

38]. The widths in their Figure 3H are full width at half-maximum (FWHM) of the STEM intensity profile. These are converted to the values

w in Equation (

23) shown in

Figure 7 using the appropriate equation from the supplemental material of reference [

38].

We find that Equation (

23) gives an excellent fit to the displacements in both the atomistic and PFC simulations. For the flat bottom simulations, we have examined the displacement parallel to the boundary (shear displacement) and normal to the boundary (tensile displacement) separately for the mixed dislocations. We find that the Equation (

23) fits the separate displacements very well, but that the widths

w differ between the shear and tensile components. That equation also fits the component of the displacement parallel to the burgers vector, which is what we have fitted for the fixed bottom simulations for comparison with the PFC.

3.4. Quantify

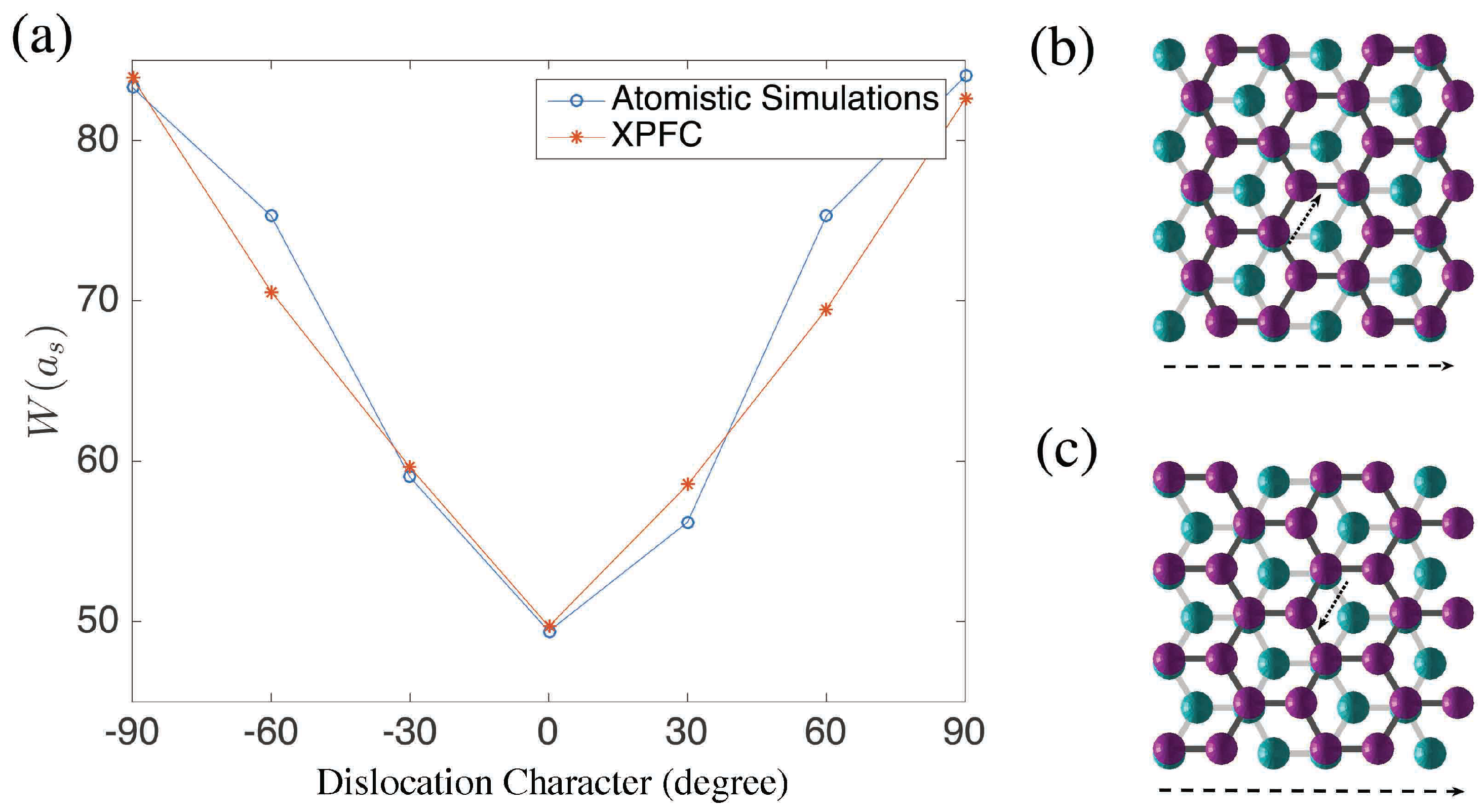

First, we find that

is different from

(this is also how we define + from −). We then investigate into this discrepancy in details and find that in the

case, for example, the distance between nearby atoms along the 30° direction is less than

, while in the

cases, this distance is larger. This can be explained by

Figure 8. Assume that the dislocation between the top and bottom layer increases towards the right hand side. In

Figure 8b, the atoms on the top layer must shift upright, denoted by the dashed arrow. The other way around is impossible because the two layers would then form an AA or BB pattern with maximum bottom-layer potential [

38]. Therefore, the average distance between nearby atoms along the shifting direction will increase. For

Figure 8c, the atoms on the top layer must shift bottom left in order to minimize the bottom-layer potential while the average distance between the atoms along the shifting direction will be smaller than

. As discussed for the MD simulations, if the bottom layer could relax, rather than being represented by

, this would change.

From the fixed-bottom MD simulations, we have the following data: , , , , , and , which we will use to choose a value for . The boundary thickness is a comparatively large because the whole ribbon must be long enough to ensure that at least more than half of the entire domain are good stacking structures. Therefore, we use a domain of , 32 unit blocks with a little less than half of AB and equally of BA, i.e., or .

Starting from , we use a bisection method to pin down the value of , i.e., = 20,000, = 5000, = 12,500, …. We compare the value of and with the atomistic results, that if the relative difference between the PFC results and atomistic results are smaller than for all the cases, we then take that . We did not use the value of or since the domain is a narrow ribbon and the exact direction of the transition region is not quite precise for those two cases.

By this procedure, we found that

is a proper value, considering all the three cases

and

, as shown in

Figure 8. Note that for a single value of

, our PFC results agree reasonably well with our MD simulations for all boundary characters. To illustrate the actual structure of these boundaries, in

Figure 9, we plot the double layer graphene of type 0° and 30° from the PFC simulations.

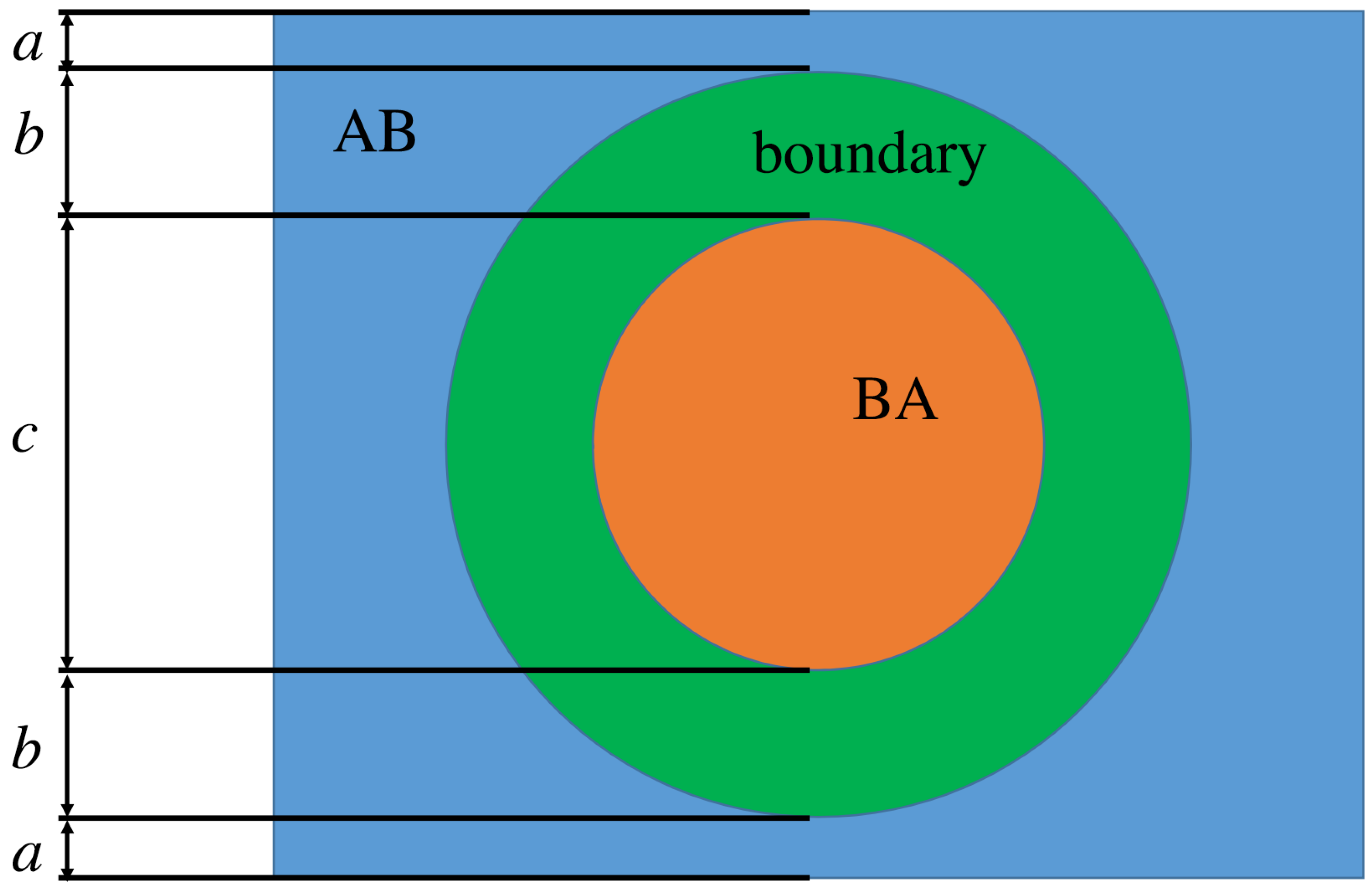

3.5. A Circular Shape Transition Between AB and BA

Another good setup to be investigated into is the dynamics of a (circular) disk-shaped grain of one stacking order, with the rest of the cell the other stacking order. One expects the circular grain to shrink and the final configuration to be a uniform stacking order. However, this is not what is observed in experiments. The initial phase-field is created following

Figure 10, where in the boundary

is a constant.

3.5.1. Stable Inner Region with Defective Carbon Rings

We set

,

, and

, and the transition region is relatively narrow, as shown in

Figure 11a. The outer region is of AB stacking order, and the interior region is of BA stacking order. Once the dynamics start, both of the AB and BA regions grow gradually, as shown in

Figure 11b. They meet each other and form the transition boundary with defected points, as shown in

Figure 11c. Then, the width of the transition boundary increases, as shown in

Figure 11d,e. Finally, the phase-fields reach an equilibrium where the BA stacking order region is similar to a hexagon, as shown in

Figure 11e,f. The direction of each sides of the hexagon region is inconsistent with the orientation of the atomic alignment on the bottom layer. Here, the boundary of the central grain becomes pinned and the defects are somewhat like the situation where the upper layer is deposited on the bottom layer, and there is nucleation and growth of stacking fault regions. The defects that involve a 5-carbon ring next to a 7-carbon ring (couple of 5 and 7 rings) are certainly seen.

In

Figure 11h, we zoom in the boxed region in

Figure 11f, highlighting two of the six vertices. There is one couple of 5 and 7 rings on the bottom left of the boxed region, as shown in

Figure 11h.L, where we further zoom in that patch. The color map shows the phase-field. The red and black dots superimposed on the map correspond to the A and B sites of the bottom graphene layer, respectively. On the upper right patch of

Figure 11h, there are two couples of 5 and 7 rings, as shown in

Figure 11h.R, where we zoom in the phase-field together with the atoms on the bottom layer. Note that with 5 and 7 rings, the transition from AB to BA is sharp. Moreover, with two or three (locates at the bottom vertex) couples of 5 and 7 rings, the transition could be sharper than the one couple case, as shown in

Figure 11f. This partially explains the reason why the hexagon region stagnates (the positions of the defected vertices do not change from

to

).

We then test multiple cases of the c values and find that the inner hexagon region can be stable for a relatively small size, i.e., .

When the transition region is wider, i.e.,

,

, and

, the domain could evolve to a triangular shape, as shown in

Figure 12. Similarly, the outer and inner regions are of AB and BA stacking order, correspondingly, as shown in

Figure 12a, where the transition region is significantly wider than the case in

Figure 11a. Once the dynamics start, both the AB and BA regions grow gradually towards each other and finally meet in the middle, before a structured pattern emerges independently in the transition region (this does happen if the transition region is too wide, i.e.,

), as shown in

Figure 11b. On the other hand, the growing speed is not uniform along the ring. We find three parts where both the outer and inner regions grow slightly slower. Furthermore, those parts are at the positions where the defects that involve one couple of 5 and 7 rings finally emerge. Also note that at those positions, the direction of the transition region (depicted by red arrows) is parallel to the direction of nearby empty holes in the phase-field, as shown in

Figure 11f.

As the AB and BA regions grow, they will meet each other and form the transition boundary with defected points, as shown in

Figure 12c. Then, the width of the transition boundary increases, as shown in

Figure 11d. Finally, the simulation reaches an equilibrium where the BA stacking order region is of triangular shape, as shown in

Figure 12e. Similarly as the previous case, the defects that involve a couple of 5 and 7 rings are certainly seen, as shown in

Figure 12f, where we zoom in on the boxed patch from

Figure 12e.

3.5.2. Shrinking Inner Region with Uniform Transition

Finally we simulate a case that the center grain does shrink and finally goes away. The initial condition is specifically generated that the direction of the shifting displacement in the transition region is vertical uniformly. We use a linear transition for simplicity. Suppose

for the outer structure, and

for the inner structure. Let

r be the distance from

to the center of the box,

the inner radius of the boundary region, and

the outer radius of the boundary region. In the phase-field, we set

by

In

Figure 13, we present a sample case, with

and

.

Figure 13a shows the initial condition. Note that it takes a short period for the phase domain to evolve to a state with a ’natural’ transition region; thus, we only use data points after

. As shown by

Figure 13b–e, the center keeps shrinking. On the other hand, the center grain does not stay circular as it shrinks. In

Figure 13c–e, the BA region is elliptical, and its aspect ratio grows. This actually agrees with previous results: the transition width

W for

is the smallest, i.e., the left and right parts of the central ellipse.

W increases as

increases, and reaches the maximum when

, i.e., the top and bottom parts.

In

Figure 13f, we plot the area of the central grain as a function of time. Here, we use two methods to measure the area. By the first method, we simply count the numbers of atoms with

, that each atoms occupies an area of

. Since only one group of atoms on the bottom layer are counted, we multiply the value by 2 to represent the total area for convienence. By the second method, we measure the width

H from the left vertex to the right vertex of the central region, i.e., the length of the short axis of the ellipse. As shown in

Figure 13f, for the first case, the area shrinks slower at the beginning and then faster. For the second case, the area as a function of time is linear, which is the expected behavior if the boundary motion is governed by a constant mobility. It could be a good sign for the possibility of using the method for at least qualitative dynamics.

We further test the case that and and find that the center grain still shrinks, although it shrinks much more slowly than the above case because of the lower curvature of the boundary.

4. Conclusions

In this work, we have developed a phase-field crystal model tailored for bilayer graphene by extending the structural PFC methodology. A central feature of our model is the incorporation of an external potential, derived from first-principles calculations of the generalized stacking fault energy, to represent the influence of a fixed bottom graphene layer. This approach allows the PFC free energy functional to accurately capture the energetics of different stacking orders and the transitions between them.

One accomplishment of this study is the quantitative calibration of the model parameter, , which scales the strength of the interlayer interaction potential. By simulating the width of the transition regions (stacking fault boundaries) between AB and BA domains for various dislocation characters and comparing these results with molecular dynamics simulations, we determined an optimal value of . This calibration ensures that our PFC model reproduces interface widths consistent with atomistic simulations, thereby bridging the gap between the coarse-grained PFC description and more detailed atomic-scale methods.

Our simulations successfully demonstrate the model’s capability to capture complex microstructural evolution in bilayer graphene. Notably, we observed that an initially circular domain of one stacking order embedded in the other can evolve into stable, non-circular shapes (triangular or hexagonal) bounded by dislocation networks featuring 5–7 carbon rings. The stability of these shapes is attributed to the pinning of the boundary at these defect vertices. Conversely, when initialized with a smooth, uniform transition, the central domain shrinks at a rate governed by boundary curvature, indicating the model’s potential for studying domain growth kinetics.

In summary, this work establishes a quantitatively calibrated phase-field crystal framework for investigating stacking phenomena and defect dynamics in bilayer graphene. The model efficiently simulates processes at diffusive time scales that are challenging for atomistic methods, while retaining essential atomic-level structural information. This makes it a valuable tool for exploring microstructure evolution in bilayer graphene systems, with potential applications in understanding defect engineering and stability in twisted bilayers or other two-dimensional heterostructures.