3. Results and Discussion

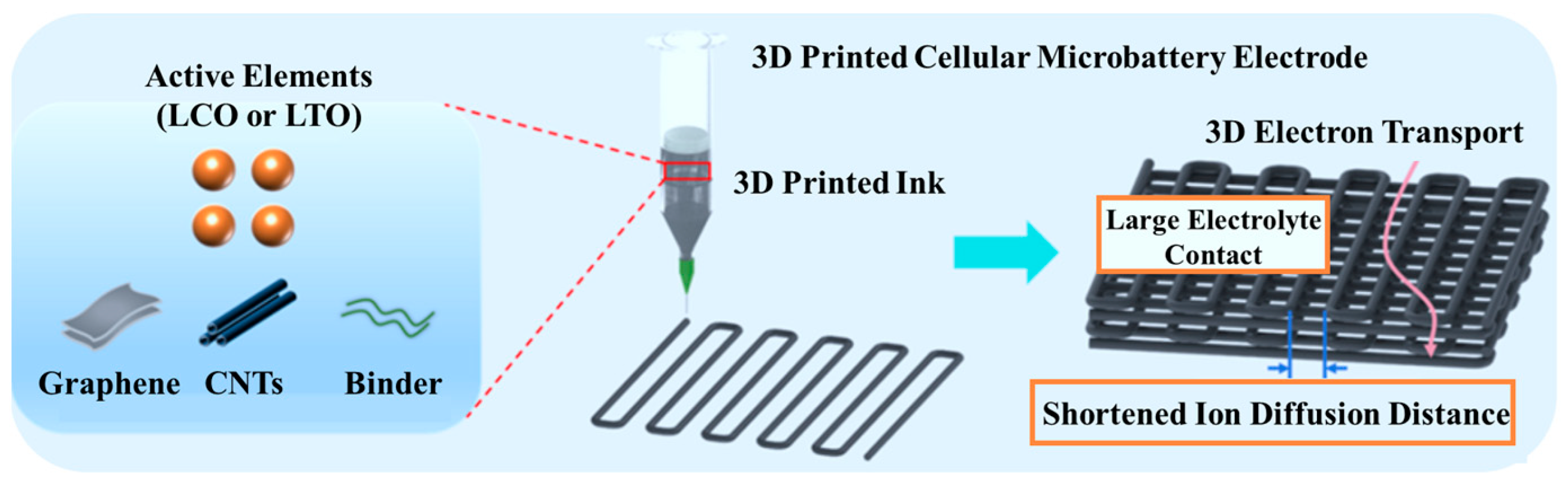

Figure 1 schematically depicts the design rationale for 3D-printed hierarchically porous electrodes used in this work. The fabrication workflow centers on three coupled stages: formulation of printable functional inks, precision DIW of periodic lattice architectures, and subsequent cell assembly. Such a workflow shifts the electrode design paradigm from passive, planar coatings toward actively engineered 3D geometries in which pore topology, strut spacing and layer stacking are digitally prescribed. This transition enables tunable electrolyte accessibility and controlled mass loading within a fixed footprint, prerequisites for translating intrinsic material capacity into practical areal energy density in compact devices. Beyond geometry, the electrode composition critically modulates charge-carrier transport. Here we designed composite inks that combine LCO active particles with an interconnected conductive scaffold built from rGO and CNTs, together with conventional binders. The hybrid rGO-CNTs framework serves two complementary roles: rGO provides broad-area, low-tortuosity planar sheets that promote lithium-ion accessibility and lateral electron delocalization, while CNTs form one-dimensional tubular bridges that reinforce pathways and mechanical integrity. When patterned into a periodic 3D lattice, these constituents generate a multiscale network that couples macroscale electrolyte channels with nanoscale electronic conduits. From the ion-transport perspective, the deliberate introduction of hierarchical porosity shortens effective diffusion distances and reduces tortuosity. The lattice provides large electrolyte-electrode interfacial area and rapid through-thickness pathways; concurrently, rGO sheets form accessible interstices at the particle scale that further facilitate Li

+ ingress and homogenize local concentration gradients. Reduced tortuosity and increased electrolyte uptake are thus expected to suppress concentration polarization during high-rate operation and to narrow Warburg-type diffusion impedance observed in impedance spectroscopy.

Concerning electronic conduction, the hybrid rGO-CNTs network optimizes both long-range carrier mobility and interparticle contact resistance. The extended π-conjugation within rGO sheets facilitates in-plane electron transport across printed struts, while CNTs bridge inter-sheet gaps under mechanical deformation. As a result, printed electrodes exhibit lower charge-transfer resistance and improved rate capability compared with their particulate-only counterparts. The synergy between the two conductive motifs is particularly important for printed geometries where electronic pathways must traverse both printed filaments and interfilament voids.

Building on the design rationale in

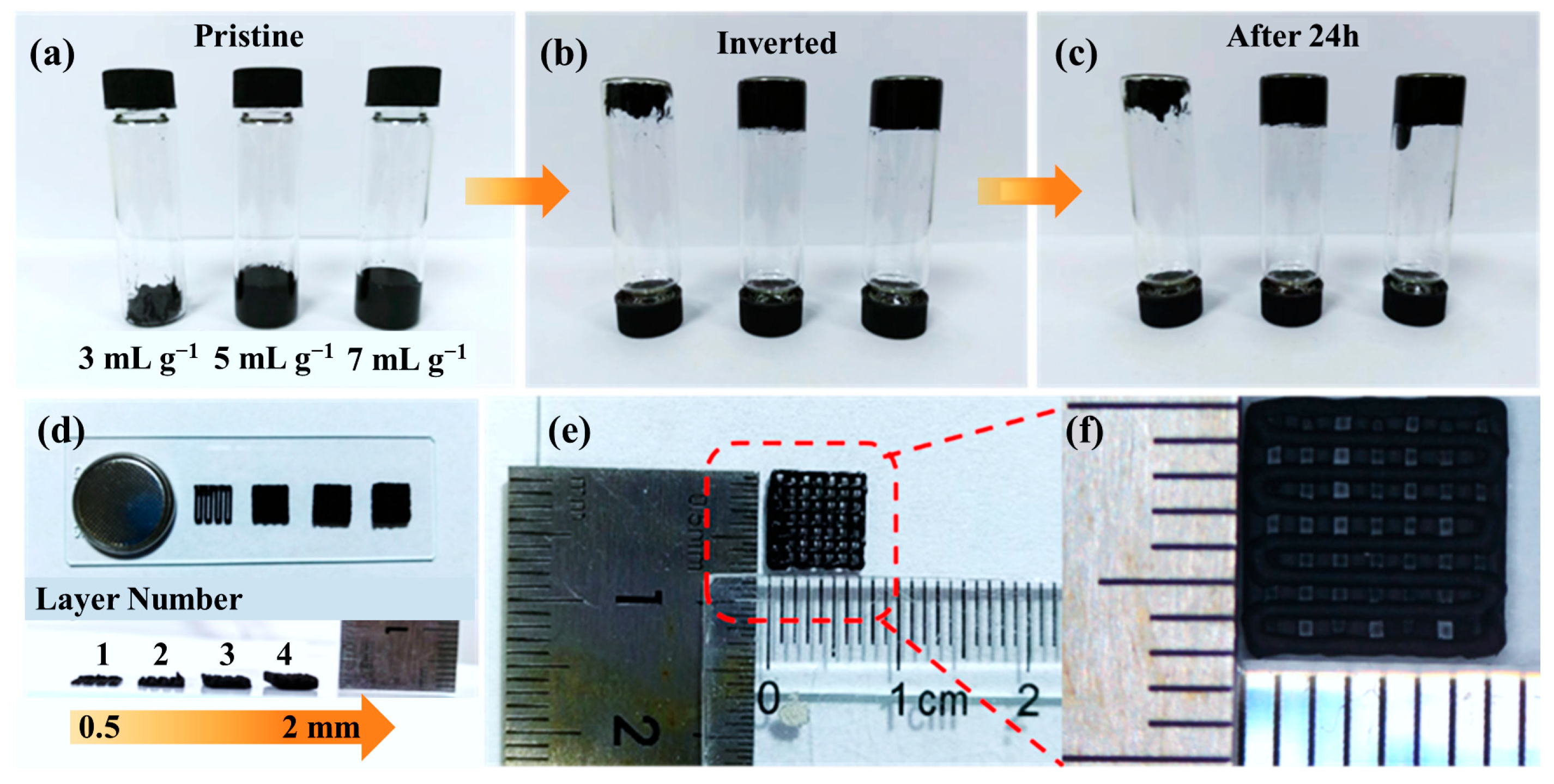

Figure 1, where digitally programmed lattices shorten ion paths and establish 3D electron percolation, the inks are verified reliable towards a stable written filament that is suitable for DIW. As shown in

Figure 2a–c, inversion tests on inks with solvent-to-solid ratios of 3, 5, and 7 mL g

−1 exhibited no phase separation at rest and no dripping upon inversion, indicating finite yield stress and rapid thixotropic recovery. Among these, the 5 mL g

−1 formulation provided the best balance between extrudability and shape fidelity: 3 mL g

−1 was overly viscous and interrupted flow, whereas 7 mL g

−1 sagged and lost resolution. After 24 h the inks remained anti-sedimented, confirming storage stability and ensuring that the nozzle experiences the intended rheology. Consequently, the 5 mL g

−1 ink was adopted for subsequent prints so that the programmed lattice could be rendered as a stable, hierarchically porous electrode. With rheology secured, we then assessed vertical build fidelity to guarantee that the targeted multiscale porosity is preserved during layer-by-layer deposition.

As displayed in

Figure 2d, the printed filament thickness increases almost linearly from 0.5 mm to 2 mm as the number of printed layers increases, while the filament boundaries remain sharp with negligible lateral spreading. This vertical fidelity is critical for maintaining the designed pore-solid ratio, which governs both ionic diffusion and electronic transport. The preserved architecture ensures low tortuosity pathways for ion movement and uninterrupted 3D networks for electrons, fulfilling the dual-transport principle outlined earlier. To validate scalability, centimeter-scale lattices were further patterned as shown in

Figure 2e,f. The deposited filaments exhibit highly uniform width and consistent spacing across the full print area, confirming high-resolution deposition and limited die-swell effects. This centimeter-level structural coherence coupled with sub-millimeter feature control establishes a robust framework for multiscale transport: large-area electrolyte contact promotes ionic accessibility, while the interconnected rGO-CNTs network supports rapid electron conductivity across micro- and macroscale domains. These geometric and structural foundations are essential for the subsequent evaluation of electrochemical responses in both half-cell and full-cell systems.

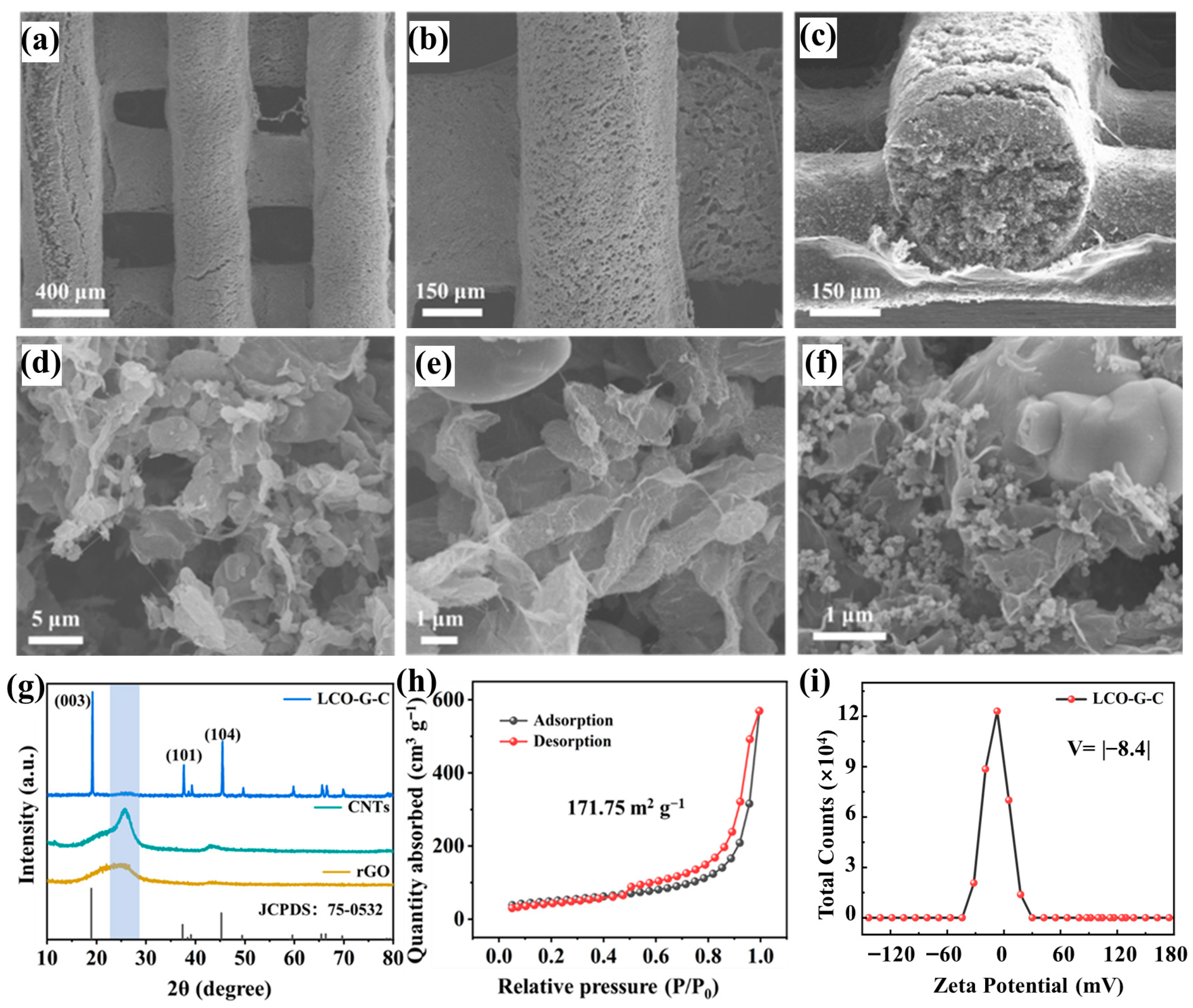

Building upon the established 3D-printed lattice architecture, which ensures both geometric precision and microstructural continuity, further insights into the printed electrodes were gained through detailed morphological and compositional characterization. Low-magnification scanning electron microscope images reveal that the printed filaments form a highly ordered and well-registered lattice with uniform strand spacing (

Figure 3a), and the smooth, ripple-free sidewalls (

Figure 3b) indicate the rapid thixotropic recovery and high printing fidelity of the optimized 5 mL g

−1 ink. The cross-sectional view (

Figure 3c) shows each filament possessing a dense cylindrical core wrapped by a thin compact shell, while the inter-filament voids remain open. These interconnected channels penetrate vertically through the electrode, providing continuous diffusion pathways that effectively shorten ion transport distances and enhance electrolyte accessibility throughout the printed network. At higher magnification, the LCO-graphene-CNTs (LCO-G-C) electrode exhibits a hierarchically interwoven microstructure (

Figure 3d,e). Wrinkled rGO sheets conformally coat LCO particles, forming lamellar conductive planes that promote in-plane electron transfer. Simultaneously, CNTs bridge adjacent grains and rGO domains, establishing long-range networks that maintain electrical continuity even under deformation. This multiscale conductive framework ensures rapid charge transport and uniform current distribution, mitigating polarization effects during cycling. In contrast, the LCO-graphene-Super-P (LCO-G-S) electrode displays evident carbon domain agglomeration and fewer conductive bridges (

Figure 3f), resulting in discontinuous electron pathways and higher interfacial resistance. These structural distinctions demonstrate how the combination of rGO and CNTs yields a synergistic conductive network, integrating the planar conductivity of rGO with the one-dimensional percolation of CNTs to simultaneously facilitate ionic infiltration and electronic conduction. The resulting hierarchical porous architecture not only enhances the electrochemical kinetics but also underpins the superior transport behavior of the 3D-printed electrodes in subsequent performance evaluations.

X-ray diffraction (XRD) further validates that the 3D printing process maintains the intrinsic crystallinity of the active material. As shown in

Figure 3g, the diffraction peaks of the printed LCO-G-C electrode correspond precisely to the layered LiCoO

2 reference (JCPDS 75-0532), featuring distinct reflections at (003), (101), and (104) without the emergence of any secondary phases. This indicates that the DIW process followed by freeze-drying and curing does not induce lattice distortion or impurity formation, thereby preserving the cathode layered structure. A similar result is observed for the Super-P-based electrode (

Figure S1), whose diffraction pattern aligns with the standard layered LiCoO

2 structure, confirming that the integrity of the crystal framework is retained regardless of the type of carbon additive employed. To probe the pore characteristics crucial for mass transport, nitrogen adsorption–desorption measurements were conducted. The LCO-G-C electrode exhibits a type-IV isotherm with an H3-type hysteresis loop (

Figure 3h), characteristic of mesoporous materials. The Brunauer–Emmett–Teller specific surface area reaches 171.75 m

2 g

−1, suggesting the presence of abundant mesopores originating from the rGO-CNTs conductive scaffold and the inter-filament voids of the 3D printed lattice. These mesopores not only provide additional electrolyte reservoirs but also serve as channels that homogenize ion flux and mitigate concentration gradients during high-rate cycling, collectively lowering the effective tortuosity of the electrode. In contrast, the LCO-G-S electrode (

Figure S2) shows a similar type-IV isotherm but a markedly smaller BET surface area of approximately 57.25 m

2 g

−1 roughly one-third of that of LCO-G-C. This substantial difference underscores the superior structural accessibility and hierarchical porosity enabled by the rGO-CNTs hybrid framework, which enhances both electrolyte infiltration and ion diffusion kinetics. These findings reveal that the rationally designed multiscale porous network of the LCO-G-C electrode effectively bridges micro- and macro-scale transport, thereby laying a solid foundation for its enhanced electrochemical performance.

The reduced accessible surface area of the LCO-G-S electrode indicates a scarcity of mesoporous reservoirs and a correspondingly higher effective tortuosity for ion transport. This observation aligns well with the carbon agglomeration and discontinuous pore morphology revealed by SEM in

Figure 3f. In contrast, the LCO-G-C electrode exhibits a more favorable colloidal behavior during ink preparation and extrusion, as evidenced by its zeta potential distribution centered at approximately −8.4 mV (

Figure 3i). The moderately negative surface charge provides a balance between sufficient dispersibility and rapid gelation during the DIW process, ensuring structural uniformity upon deposition. This electrostatic condition, together with the steric hindrance imparted by the wrinkled rGO nanosheets, effectively prevents large-scale flocculation while enabling rapid recovery of a yield-bearing network after shear release. Such behavior guarantees consistent filament extrusion and smooth surface morphology, as previously observed in the SEM images. Conversely, the Super-P-based slurry displays a nearly neutral zeta potential (

Figure S3), indicating weak electrostatic repulsion and a strong tendency toward particle aggregation during mixing and printing. This colloidal instability compromises the formation of a continuous conductive network and results in nonuniform pore structures after drying, thereby impeding both ionic and electronic transport. Collectively, these electrokinetic and morphological results emphasize that a well-balanced surface potential, aided by rGO-induced steric stabilization, is critical for constructing robust, homogeneous, and hierarchically conductive 3D-printed electrodes.

The supplementary characterization provides compelling evidence for why the rGO and CNTs hybrid network outperforms the super-P counterpart in the 3D-printed lattice electrodes. The LCO-G-C ink maintains a uniform dispersion and exhibits rapid recovery of a yield-bearing structure after shear release, which translates into a hierarchically porous, low-tortuosity framework once printed. This architecture verified by the high BET surface area and the interconnected pores visible in SEM and CT reconstructions facilitates fast electrolyte infiltration and establishes efficient, continuous pathways for both ion and electron transport. In comparison, the LCO-G-S electrode, though retaining an intact LiCoO2 crystal structure, presents a far smaller accessible surface area and less effective conductive percolation. The restricted porosity and discontinuous carbon domains result in higher charge-transfer resistance and hindered ionic diffusion, as corroborated by electrochemical impedance and rate-performance analyses. Collectively, these findings underscore that the multiscale interconnected carbon framework formed by rGO sheets serving as planar highways and CNTs bridging across neighboring grains within the DIW-printed lattice-is essential for achieving concurrent ion-electron transport. This synergistic configuration ensures rapid charge carrier mobility and structural robustness under high-rate cycling, thereby enabling superior stability and performance in 3D-printed full-cell systems.

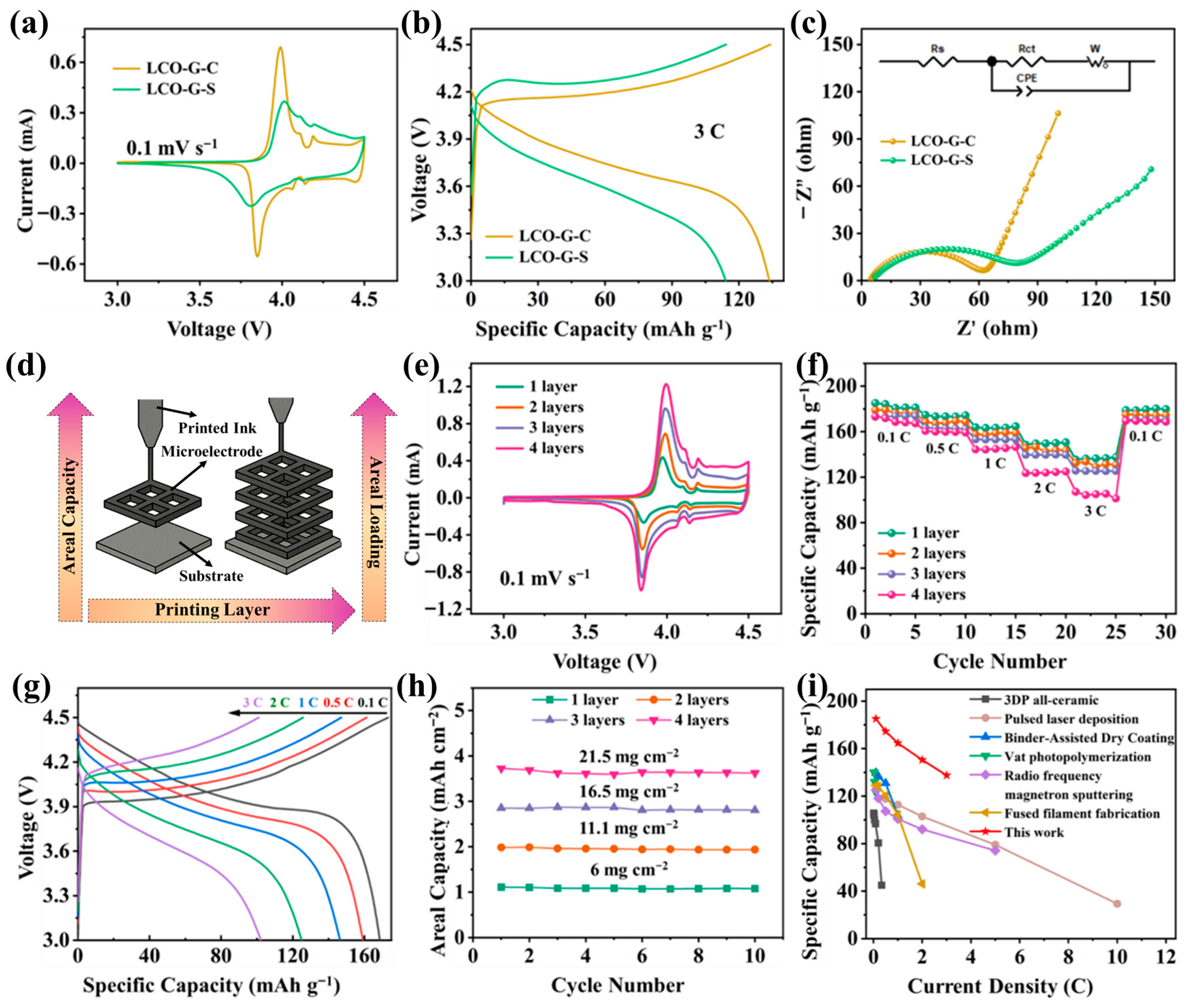

As illustrated in

Figure 4a, both LCO-G-C and LCO-G-S electrodes exhibit the characteristic Co

3+/Co

4+ redox pair near 3.9–4.2 V, indicating that the intrinsic electrochemical nature of LCO remains intact after DIW. Nevertheless, the LCO-G-C electrode demonstrates distinctly sharper and more symmetrical redox peaks with a reduced potential separation, signifying faster charge-transfer kinetics and lower polarization losses. This improvement arises from the interconnected rGO-CNTs framework, which enhances interparticle electrical continuity and accelerates Li

+ intercalation/deintercalation dynamics. At a higher current density of 3 C (

Figure 4b), the galvanostatic charge–discharge profiles further confirm these advantages. The LCO-G-C electrode maintains a stable and flat voltage plateau with minimal hysteresis, whereas LCO-G-S displays a pronounced IR drop and premature capacity decay, suggesting sluggish ion diffusion and poorer electrical contact. Electrochemical impedance spectroscopy (

Figure 4c) quantitatively supports this observation: the Nyquist plots reveal a significantly smaller semicircle for LCO-G-C, indicating a lower charge-transfer resistance, and a steeper low-frequency slope, corresponding to a reduced Warburg diffusion impedance. These kinetic enhancements directly reflect the synergy between the hierarchically porous 3D lattice and the continuous rGO-CNTs conductive network, which together provide efficient and balanced transport channels for both ions and electrons.

Figure S4 further highlights the rate capability differences between the two carbon architectures. When subjected to a stepwise current sequence from 0.1 C to 3 C and then returned to 0.1 C, the LCO-G-C electrode consistently delivers higher specific capacities with a notably smaller capacity decay compared to LCO-G-S. Upon reverting to 0.1 C, the LCO-G-C nearly recovers its initial capacity, indicating minimal kinetic hysteresis and excellent structural reversibility. This superior rate stability arises from the synergistic effects of the hierarchical porous lattice and the rGO-CNTs network, which provide efficient ion diffusion channels and uninterrupted electron transport pathways. Cycling tests (

Figure S5) further confirm the structural and electrochemical robustness of 3D-printed LCO-G-C electrodes. At a constant current density, it maintains nearly 100% coulombic efficiency and retains 86.6% of its initial capacity after 5000 cycles, while the LCO-G-S electrode degrades significantly to 68.2%. After cycles, the 4-layer 3D-printed LCO-G-C electrode retains an intact macroscopic structure (

Figure S6), and its hierarchical 3D porous framework together with the rGO-CNTs conductive network is preserved (

Figure S7). This outstanding long-term cycling stability highlights the critical role of the multiscale conductive network, which simultaneously facilitates efficient ionic access and uninterrupted electron transport. The hierarchical 3D framework composed of interconnected rGO sheets and CNTs bridges, establishes a balanced dual-transport pathway that minimizes charge-transfer resistance and diffusion polarization. Such structural and electronic integrity enables 3D-printed electrodes to sustain high performance over extended operation, demonstrating their promise for durable and high-power energy storage systems.

The superior durability of the LCO-G-C electrode arises from two synergistic mechanisms. First, the 3D-printed lattice effectively alleviates concentration gradients and mechanical stress accumulation within thick electrodes, maintaining uniform ion flux and structural stability during extended cycling. Second, the rGO-CNTs conductive framework forms a robust, low-resistance interface that stabilizes the electrode-electrolyte boundary, suppressing parasitic side reactions and preventing repeated SEI reconstruction. The galvanostatic profiles after 5000 cycles at 3 C (

Figure S8) vividly illustrate these effects. The LCO-G-C electrode retains a long and flat Co

3+/Co

4+ redox plateau with a narrow voltage gap, reflecting efficient charge-transfer kinetics and excellent capacity retention. In contrast, the LCO-G-S electrode exhibits an early voltage decline and a shortened plateau, indicative of higher polarization and structural degradation. The preserved plateau and reduced hysteresis of the LCO-G-C electrode are consistent with its lower charge-transfer resistance and weaker diffusion impedance, validating the multiscale transport design principle. Together, the hierarchical porous lattice and the interconnected carbon network enable simultaneous optimization of ionic diffusion and electronic conduction, thereby sustaining both power capability and cycling stability in 3D-printed full batteries.

Following the DIW-based structural blueprint (schematic in

Figure 4d), the printing process was tuned to incrementally increase the number of layers while preserving the lattice geometry. This modular stacking strategy allowed a controlled enhancement of areal mass loading without compromising mechanical stability or diffusion efficiency. As shown in

Figure 4e, cyclic voltammograms of the LCO-G-C electrodes with 1 to 4 layers retain distinct Co

3+/Co

4+ redox peaks, with only slight broadening as thickness increases. This behavior confirms that even at higher loadings, the 3D lattice efficiently facilitates ion transport and mitigates polarization. The corresponding rate performance (

Figure 4f) further validates the structural integrity of the printed electrodes. Across current densities from 0.1 C to 3 C, all samples deliver stable capacities with minimal degradation, and upon returning to 0.1 C, the specific capacities nearly recover to their initial values-demonstrating outstanding reversibility and diffusion uniformity. Representative GCD profiles of the 4-layer electrode (

Figure 4g) exhibit long, flat voltage plateaus, revealing excellent electrochemical kinetics and fast Li

+ intercalation even under high loading conditions. Quantitatively, the areal loading can be tuned from 6 to 21.5 mg cm

−2 (

Figure 4h), accompanied by nearly linear gains in areal capacity, highlighting effective utilization of the additional active mass and the high structural fidelity of the printed framework. More importantly, the coexistence of macropores between filaments and the embedded mesoporous rGO-CNTs network ensures low tortuosity and continuous ion/electron pathways, thus preventing the severe rate decay commonly observed in thick LCO electrodes. When benchmarked against other fabrication techniques (

Figure 4i), including all-ceramic 3D printing [

41], Pulsed Laser Deposition [

42], Binder-Assisted Dry Coating [

43], photopolymerization [

44], sputtering [

45], and Fused Filament Fabrication [

46], the 3D-printed electrodes occupy a superior region of the Ragone-type plot. They simultaneously achieve high gravimetric energy and power densities, underscoring the advantage of the multiscale transport mechanism enabled by the interconnected rGO-CNTs network and the digitally engineered porous architecture.

Building upon the optimized ink formulation and hierarchical microstructure engineering discussed above, the practical applicability of this 3D-printed architecture was evaluated through the assembly of a fully printed LCO//LTO full cell. Commercial Li

4Ti

5O

12 (LTO) powder was incorporated with rGO and CNTs to develop a percolated conductive framework, forming a printable LTO-G-C ink via direct ink writing. When paired with the LCO-G-C cathode, the resulting LCO//LTO configuration offers well-matched electrochemical characteristics, making it an ideal platform to evaluate ion-electron transport within hierarchically porous electrodes. The full battery assembly is schematically illustrated in

Figure S9. In this process, both the LCO- and LTO-based inks were directly printed into ordered 3D structures, followed by the placement of a separator between the two electrodes. The electrolyte was then introduced. The stacked assembly was encapsulated using compatible shells to complete the integrated full cell. This 3D configuration significantly enhances the electrode-electrolyte contact area, shortens Li

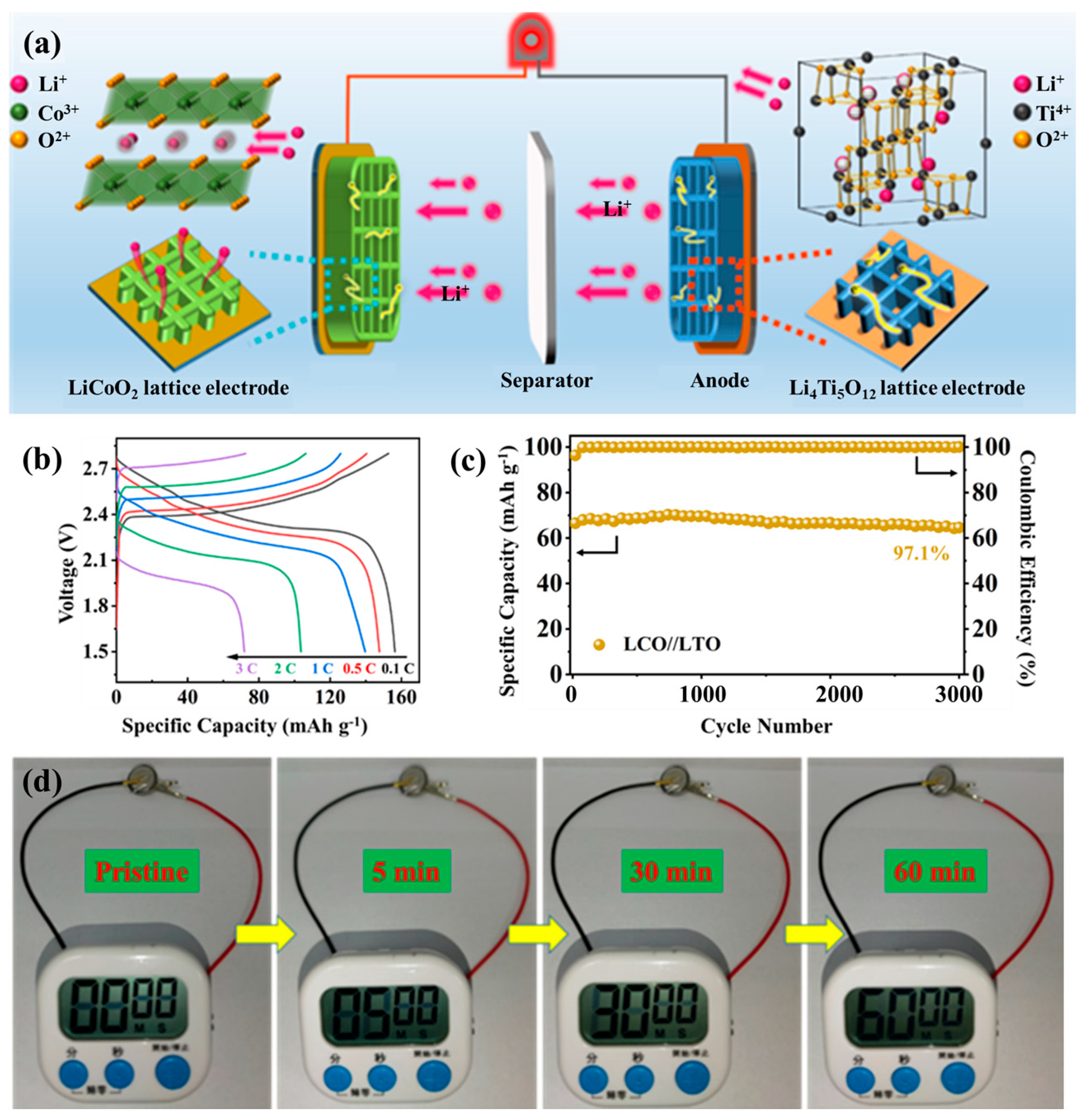

+ transport pathways, and ensures continuous 3D electronic connectivity through the rGO-CNTs conductive framework. Such a design successfully translates the multiscale ion-electron transport strategy from the material to the device level. As depicted in

Figure 5a, the working principle of the 3D-printed LCO//LTO cell relies on the synergy between structural hierarchy and compositional design. The LCO cathode lattice provides abundant electrolyte-accessible surfaces and ultrashort Li

+ diffusion distances, while the integrated rGO-CNTs framework ensures rapid and uniform electron conduction across the printed filaments. On the anode side, the printed LTO lattice enables highly reversible Li

+ insertion and extraction, maintaining structural stability throughout cycling. Coupled via a separator and fully infiltrated by electrolyte, the two electrodes establish a continuous multiscale transport network, where ions migrate efficiently through open macropores, and electrons percolate seamlessly through the conductive carbon skeleton.

A two-layer 3D-printed LCO-G-C cathode was paired with a two-layer LTO-G-C anode to construct a full cell operating within 1.5–2.8 V. The cyclic voltammetry curve at 0.1 mV s

−1 (

Figure S10) shows distinct lithiation and delithiation peaks with minimal potential separation, signifying highly reversible redox behavior and stable interfacial kinetics. The galvanostatic charge–discharge profiles (

Figure 5b) further demonstrate the kinetic superiority of the hierarchical 3D architecture. The cell exhibits flat and symmetric voltage plateaus across 0.1–3 C, while the voltage hysteresis grows only slightly with increasing current density, confirming reduced tortuosity and low interfacial impedance in the printed lattice network. As illustrated in the rate performance tests (

Figure S11), the full cell delivers specific capacities of 151.4, 148.9, 139.6, 105.2, and 72.9 mAh g

−1 at 0.1, 0.5, 1, 2, and 3 C, respectively, and the capacity nearly fully recovers when the rate returns to 0.1 C, reflecting the mechanical robustness and structural integrity of the printed lattice. Electrochemical impedance spectroscopy (

Figure S12) reveals a low charge-transfer resistance of 14.68 Ω and a steep low-frequency tail, which correspond to fast Li

+ diffusion through the interconnected porous channels and continuous electron conduction along the rGO-CNTs framework. Collectively, these results confirm that the fully 3D-printed system achieves efficient ion-electron transport and excellent high-rate performance. Long-term cycling tests (

Figure 5c) further demonstrate outstanding durability. After 3000 cycles, the LCO//LTO full cell retains 97.1% of its initial capacity with a nearly constant Coulombic efficiency, underscoring the mechanical resilience of the 3D lattice and the zero-strain nature of the LTO anode. The lattice-based structure prevents interfacial delamination and electrolyte depletion, ensuring continuous ionic and electronic pathways throughout extended cycling. This stability highlights the capability of the 3D-printed multiscale framework to sustain high-rate operation and long-term reliability in practical energy-storage devices.

To demonstrate device-level applicability, the assembled 3D-printed LCO//LTO full cell was utilized to power a digital stopwatch, as shown in

Figure 5d. The stopwatch showed instantaneous activation and consistent operation for extended durations, captured at 5, 30, and 60 min. This demonstrates the strong power output and stable voltage delivery of the 3D-printed full cell. This successful demonstration bridges the gap between material-level optimization and practical device functionality, illustrating how the multiscale ion-electron transport network effectively translates into sustained, real-world performance. In conjunction with the preceding rate and cycling analyses, this result confirms that the designed hierarchically porous and electronically continuous structure not only supports efficient charge transport under laboratory conditions but also maintains reliability during continuous operation. The seamless synergy between the 3D-printed lattice architecture and the rGO-CNTs interconnected framework validates the proposed strategy as a universal and scalable pathway for the on-demand fabrication of all-3D-printed high-performance full batteries.

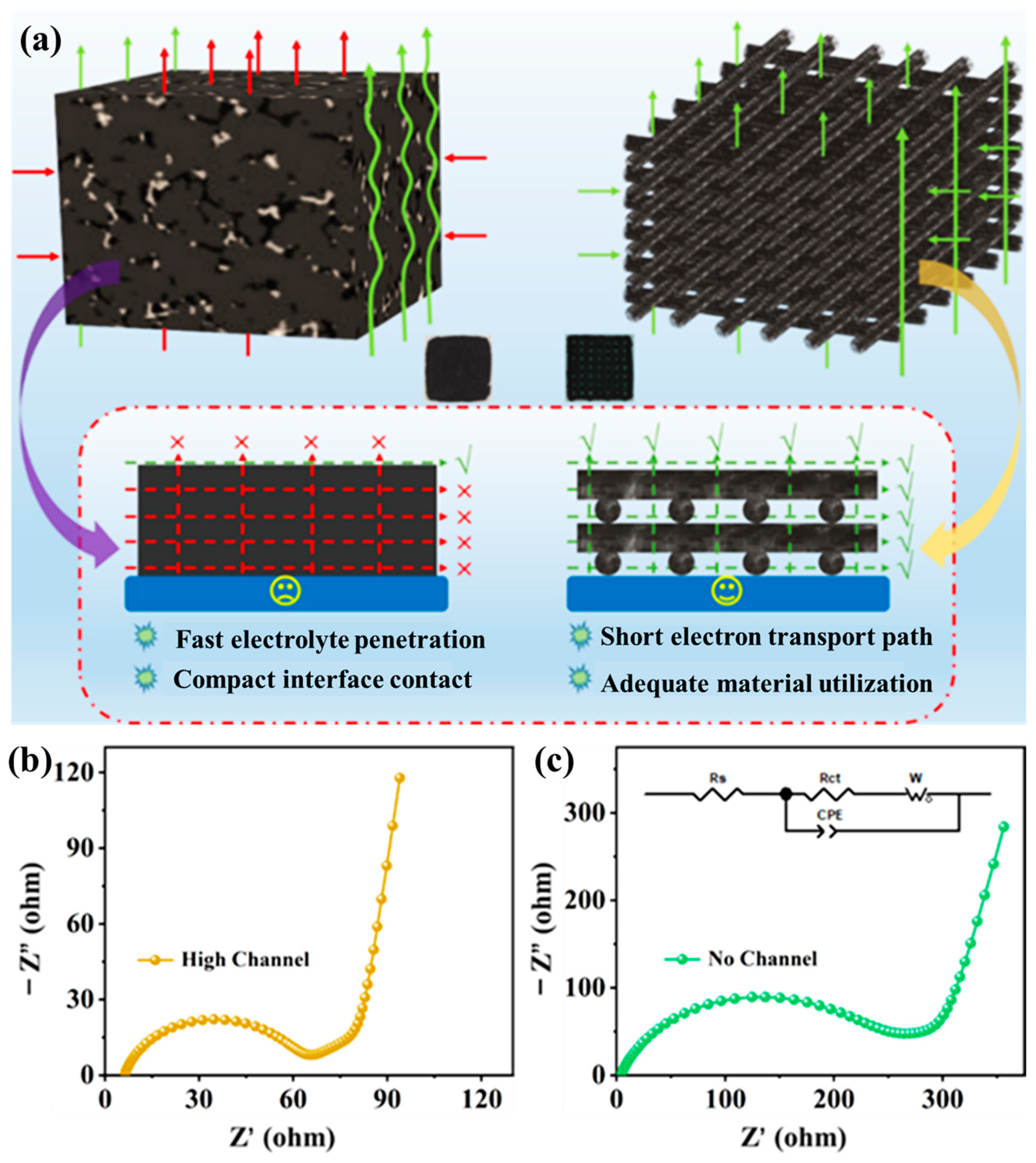

Figure 6a provides a direct comparison between charge carrier transport in a conventional slurry-cast thick electrode and that in the 3D-printed high-loading LCO lattice. In the printed configuration, rGO sheets intertwined with CNTs form a hierarchically porous, percolated framework. Micron-scale surface pores on each filament accelerate electrolyte infiltration, while the interconnected through-plane lattice channels reduce Li

+ diffusion distances and expose abundant active sites. Simultaneously, the carbon network ensures continuous 3D electron pathways, promoting compact electrode-electrolyte contact and high active-material utilization. In contrast, the conventional slurry-cast thick electrode lacks ordered channels, resulting in hindered electrolyte penetration and increased tortuosity, which lead to sluggish ion transport and uneven reaction fronts.

These distinct structural features are reflected in the electrochemical impedance spectra. As shown in

Figure 6b, the Nyquist plot of the 3D-printed four-layer electrode exhibits a significantly lower charge-transfer resistance (Rct ≈ 55.35 Ω) and a reduced low-frequency Warburg slope, indicating enhanced Li

+ diffusion and faster interfacial kinetics within the lattice framework. Conversely, the slurry-cast thick electrode (

Figure 6c) presents a much higher Rct (237.9 Ω) and a pronounced diffusion tail, consistent with longer ion diffusion paths and limited electrolyte access. These findings confirm that the hierarchically porous, electronically interconnected structure effectively mitigates polarization by coupling rapid ionic infiltration with short and continuous electronic pathways. Consequently, the high-loading 3D-printed LCO electrodes maintain efficient charge transport even at increased thickness, establishing the foundation for high-areal-capacity and durable full-cell systems.