Printed Ag Mesh Electrodes with Enhanced Adhesion on Diverse Substrates for Transparent Heater Applications

Abstract

1. Introduction

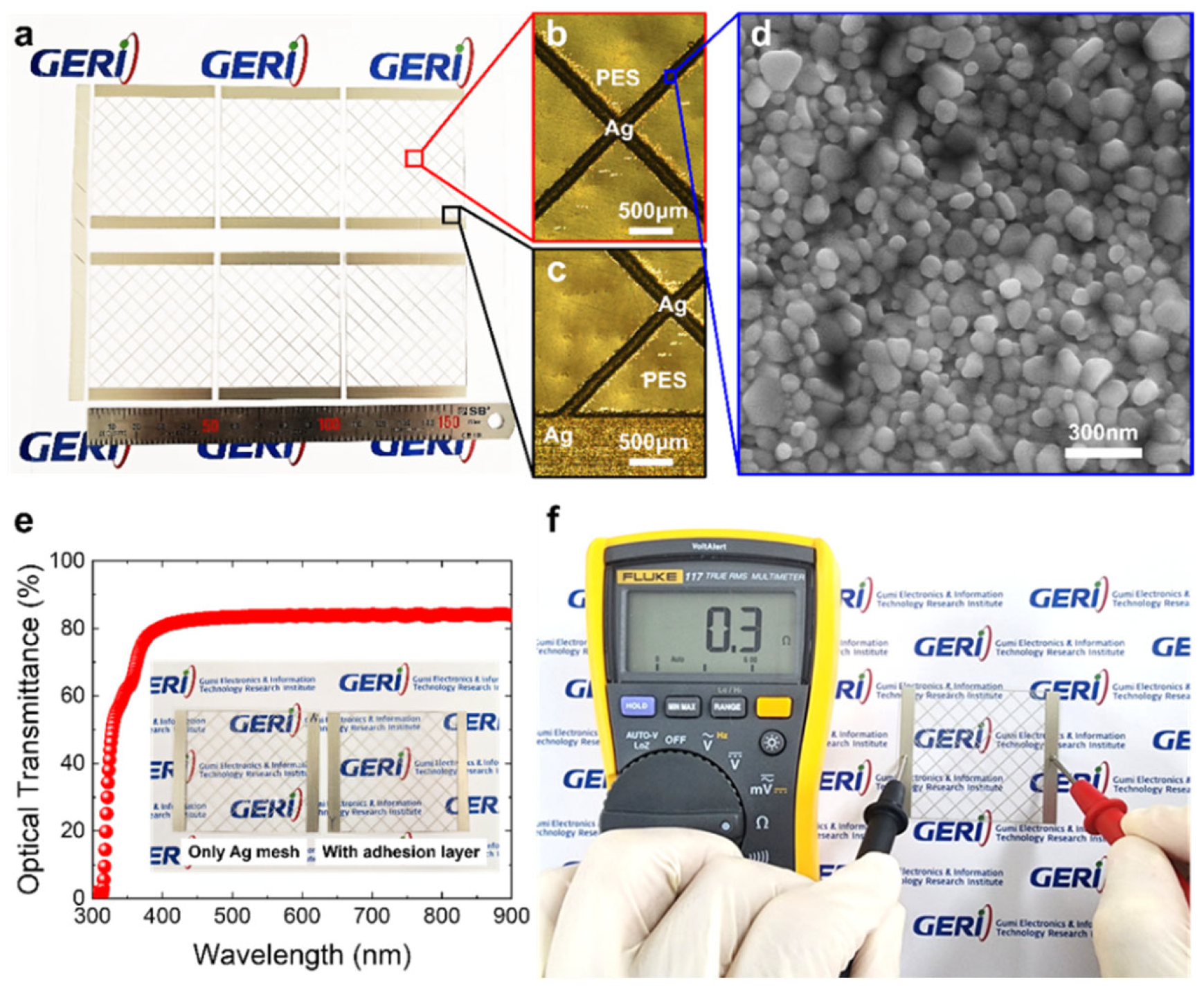

2. Materials and Methods

2.1. Fabrication of Heaters via Printing Processes

2.2. Structural, Optical, and Electrical Evaluation of Inkjet-Printed Heaters

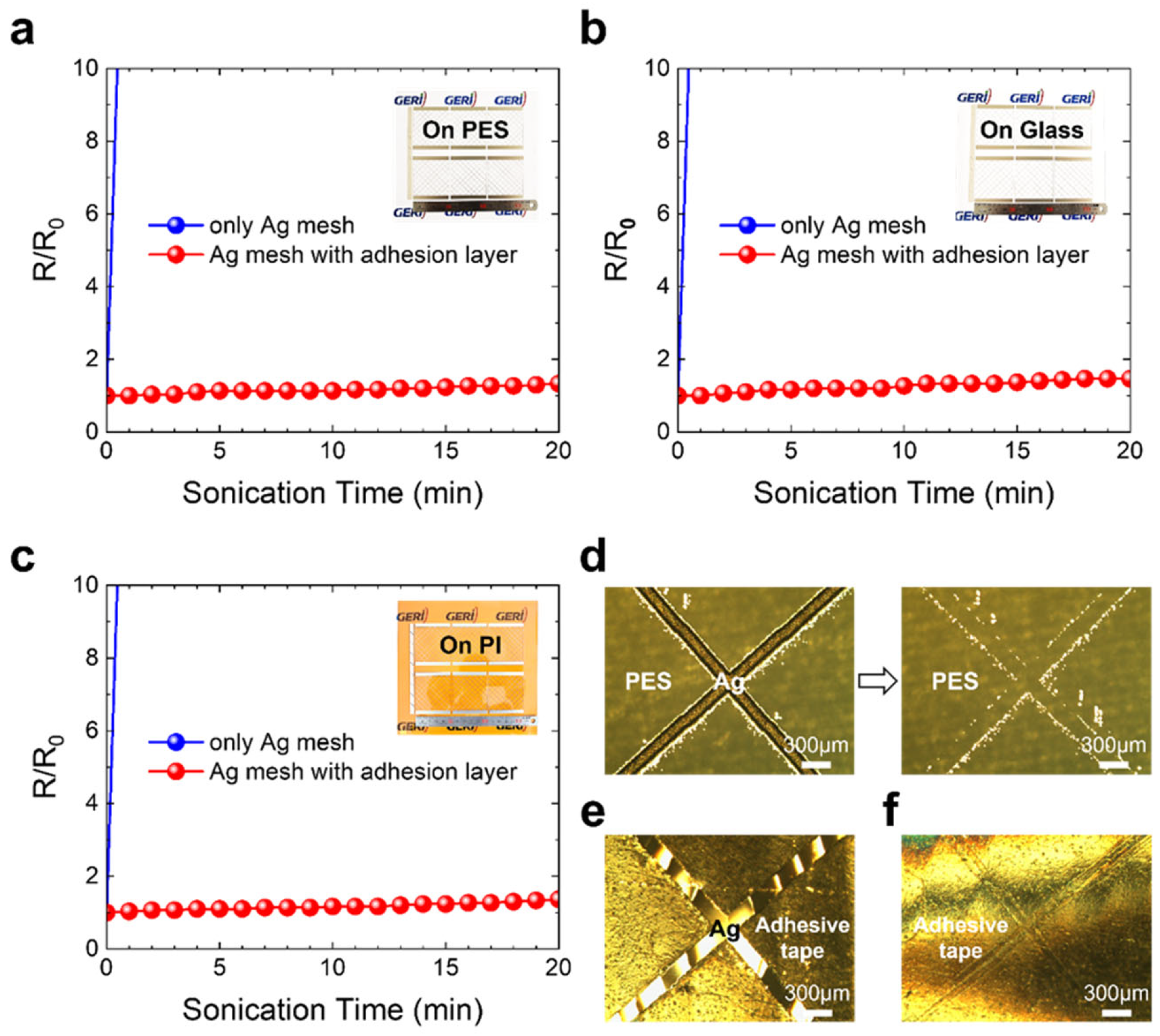

2.3. Adhesion Test of Inkjet-Printed Ag Mesh Structures on Various Substrates

2.4. Performance Evaluation of the Printed Heater

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DI | Deionized |

| FE-SEM | Field-emission scanning electron microscopy |

| IR | Infrared |

| LED | Light-emitting diode |

| OM | Optical microscopy |

| PES | Polyethersulfone |

| PI | Polyimide |

| UV | Ultraviolet |

References

- Chandrasekaran, S.; Jayakumar, A.; Velu, R. A Comprehensive Review on Printed Electronics: A Technology Drift towards a Sustainable Future. Nanomaterials 2022, 12, 4251. [Google Scholar] [CrossRef]

- Wiklund, J.; Karakoç, A.; Palko, T.; Yiğitler, H.; Ruttik, K.; Jäntti, R.; Paltakari, J. A Review on Printed Electronics: Fabrication Methods, Inks, Substrates, Applications and Environmental Impacts. J. Manuf. Mater. Process. 2021, 5, 89. [Google Scholar] [CrossRef]

- Chen, K.-Y.; Kachhadiya, J.; Muhtasim, S.; Cai, S.; Huang, J.; Andrews, J. Underground Ink: Printed Electronics Enabling Electrochemical Sensing in Soil. Micromachines 2024, 15, 625. [Google Scholar] [CrossRef]

- Chen, J.; Yuan, Y.; Wang, Q.; Wang, H.; Advincula, R.C. Bridging Additive Manufacturing and Electronics Printing in the Age of AI. Nanomaterials 2025, 15, 843. [Google Scholar] [CrossRef]

- Beedasy, V.; Smith, P.J. Printed Electronics as Prepared by Inkjet Printing. Materials 2020, 13, 704. [Google Scholar] [CrossRef]

- Martins, P.; Pereira, N.; Lima, A.C.; Garcia, A.; Mendes-Filipe, C.; Policia, R.; Correia, V.; Lanceros-Mendez, S. Advances in Printing and Electronics: From Engagement to Commitment. Adv. Funct. Mater. 2023, 33, 2213744. [Google Scholar] [CrossRef]

- Grillo, A.; Parvez, K.; Wang, J.; Peng, Z.; Pelella, A.; Dun, C.; Urban, J.J.; Bartolomeo, A.D.; Casiraghi, C. All 2D Material Printed Diodes and Circuits on Paper for Sustainable Electronics. ACS Nano 2025, 19, 30833–30843. [Google Scholar] [CrossRef] [PubMed]

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A New Frontier of Printed Electronics: Flexible Hybrid Electronics. Adv. Mater. 2019, 32, 1905279. [Google Scholar] [CrossRef]

- Kell, A.J.; Wagner, K.; Liu, X.; Lessard, B.H.; Paquet, C. Advanced Applications of Metal–Organic Decomposition Inks in Printed Electronics. ACS Appl. Electron. Mater. 2024, 6, 1–23. [Google Scholar] [CrossRef]

- Cyu, R.-H.; Wang, C.-H.; Manikandan, A.; Wu, S.-C.; Tang, S.-Y.; Horng, R.-H.; Chueh, Y.-L. Printable Two-Dimensional Nanomaterials: Approaching Low-Cost Electrodes for High-Efficiency Li/Na-Ion Batteries and Photodetectors. ACS Appl. Nano Mater. 2025, 8, 8133–8143. [Google Scholar] [CrossRef]

- Kwon, Y.-T.; Kim, Y.-S.; Lee, Y.; Kwon, S.; Lim, M.; Song, Y.; Choa, Y.-H.; Yeo, W.-H. Ultrahigh Conductivity and Superior Interfacial Adhesion of a Nanostructured, Photonic-Sintered Copper Membrane for Printed Flexible Hybrid Electronics. ACS Appl. Mater. Interfaces 2018, 10, 44071–44079. [Google Scholar] [CrossRef]

- Li, C.-Y.; Liao, Y.-C. Adhesive Stretchable Printed Conductive Thin Film Patterns on PDMS Surface with an Atmospheric Plasma Treatment. ACS Appl. Mater. Interfaces 2016, 8, 11868–11874. [Google Scholar] [CrossRef] [PubMed]

- Azim, N.; Orrico, J.F.; Appavoo, D.; Zhai, L.; Rajaraman, S. Polydopamine Surface Functionalization of 3D Printed Resin Material for Enhanced Polystyrene Adhesion Towards Insulation Layers for 3D Microelectrode Arrays (3D MEAs). RSC Adv. 2022, 12, 25605–25616. [Google Scholar] [CrossRef]

- Kim, H.-J.; Park, S.Y.; Park, J.; Ko, Y.; Park, S.E.; Kim, Y.; Kim, J. Improved Adhesion of Printed Ag Electrodes for Flexible Transparent Display Applications. Mater. Adv. 2025, 6, 547–551. [Google Scholar] [CrossRef]

- Su, M.; Huang, J.; Gong, H.; Zhu, Z.; Li, P.; Wang, H.; Zhao, P.; Wang, J.; Zhang, J. Additive–Subtractive Manufacturing Based on Water-Soluble Sacrificial Layer: High-Adhesion Metal Patterning via Inkjet Printing. Micromachines 2025, 16, 706. [Google Scholar] [CrossRef] [PubMed]

- Htwe, Y.Z.N.; Mariatti, M. Printed Graphene and Hybrid Conductive Inks for Flexible, Stretchable, and Wearable Electronics: Progress, Opportunities, and Challenges. J. Sci. Adv. Mater. Devices 2022, 7, 100435. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, C.; Zhang, H.; Han, M. Multilayer Flexible Electronics: Manufacturing Approaches and Applications. Mater. Today Phys. 2022, 23, 100647. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Z.; Zhao, T.; Wang, Y.; Liu, J.; Chen, J.; Hu, Q.; Li, Z.-M.; Yang, G.; Zhong, G.-J. Investigation of Surface Changes of Biaxially Oriented Polypropylene Films by Multiple Organic/Inorganic Nanocomposite Coatings for Enhanced Water-based Ink Printing. Surf. Interfaces 2025, 64, 106364. [Google Scholar] [CrossRef]

- Utsch, D.; Sippel, M.; Voigt, C.; Häußler, F.; Franke, J. Assessment and Improvement of Adhesion of Printed Silver-Based Inks on Alumina Produced by Fused Filament Fabrication. Power Electron. Devices Compon. 2024, 8, 100067. [Google Scholar] [CrossRef]

- Viviani, P.; Gibertini, E.; Fontana, P.; Lissandrello, F.; Gogotsi, Y.; Magagnin, L. Flexible Inkjet-Printed Lithium-Ion Batteries with Ti3C2Tx Current Collector. J. Power Sources 2024, 601, 234287. [Google Scholar] [CrossRef]

- Wen, S.; Zhang, R.; Zhao, Y.; Xu, X.; Ji, S. Patterning Adhesive Layers for Array Electrodes via Electrochemically Grafted Polymers. ACS Omega 2025, 10, 3190–3198. [Google Scholar] [CrossRef]

- Hehn, T.; Zimmer, F.; Klein, M.; Holtmannspötter, J. An Optimized Additive Manufacturing Strategy for Low-Impedance Electronics. Electronics 2025, 14, 695. [Google Scholar] [CrossRef]

- Samaitis, V.; Merfeldas, A.; Jankauskas, A.; Raišutis, R.; Jasiūnienė, E. From Print to Performance: A Comparative Study of Conductive and Radiated Emissions in FR-4 PCB Technology versus Dragonfly IV Additively Manufactured Electronics. ACS Appl. Electron. Mater. 2025, 7, 1381–1391. [Google Scholar] [CrossRef]

- Li, M.; Cai, J.; Deng, L.; Li, X.; Iacopi, F.; Yang, Y. Additively Manufactured Conductive and Dielectric 3D Metasurfaces for Independent Manipulation of Broadband Orbital Angular Momentum. Mater. Des. 2025, 249, 113500. [Google Scholar] [CrossRef]

- Li, L.; Jiang, C.; Li, L. A Comparative Study on the Effect of Substrate Structure on Electrochemical Performance and Stability of Electrodeposited Platinum and Iridium Oxide Coatings for Neural Electrodes. Micromachines 2024, 15, 70. [Google Scholar] [CrossRef] [PubMed]

- Song, M.; Kim, H.-J.; Kim, C.S.; Jeong, J.-H.; Cho, C.; Lee, J.-Y.; Jin, S.-H.; Choi, D.-G.; Kim, D.-H. ITO-free highly bendable and efficient organic solar cells with Ag nanomesh/ZnO hybrid electrodes. J. Mater. Chem. A 2015, 3, 65–70. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, S.-H.; Lee, J.; Lee, E.-S.; Choi, J.-H.; Jung, J.-H.; Choi, D.-G. High-Durable AgNi Nanomesh Film for a Transparent Conducting Electrode. Small 2014, 10, 3767–3774. [Google Scholar] [CrossRef]

- Yuan, S.; Fan, Z.; Wang, G.; Chai, Z.; Wang, T.; Zhao, D.; Busnaina, A.A.; Lu, X. Fabrication of Flexible and Transparent Metal Mesh Electrodes Using Surface Energy-Directed Assembly Process for Touch Screen Panels and Heaters. Adv. Sci. 2023, 10, 2304990. [Google Scholar] [CrossRef] [PubMed]

- Zarei, M.; Mohammadi, K.; Mahmood, A.A.; Li, M.; Leu, P.W. Flexible Embedded Metal Meshes by Nanosphere Lithography for Very Low Sheet Resistance Transparent Electrodes, Joule Heating, and Electromagnetic Interference Shielding. ACS Appl. Electron. Mater. 2025, 7, 4266–4278. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Guo, W.; Xie, L.; Wei, C.; Zhuang, J.; Su, W.; Cui, Z. Embedded Ag/Ni Metal-Mesh with Low Surface Roughness As Transparent Conductive Electrode for Optoelectronic Applications. ACS Appl. Mater. Interfaces 2017, 9, 37048–37054. [Google Scholar] [CrossRef]

- Papanastasiou, D.T.; Schultheiss, A.; Muñoz-Rojas, D.; Celle, C.; Carella, A.; Simonato, J.-P.; Bellet, D. Transparent Heaters: A Review. Adv. Funct. Mater. 2020, 30, 1910225. [Google Scholar] [CrossRef]

- Wang, T.; Lu, K.; Xu, Z.; Lin, Z.; Ning, H.; Qiu, T.; Yang, Z.; Zheng, H.; Yao, R.; Peng, J. Recent Developments in Flexible Transparent Electrode. Crystals 2021, 11, 511. [Google Scholar] [CrossRef]

- An, B.W.; Gwak, E.-J.; Kim, K.; Kim, Y.-C.; Jang, J.; Kim, J.-Y.; Park, J.-U. Stretchable, Transparent Electrodes as Wearable Heaters Using Nanotrough Networks of Metallic Glasses with Superior Mechanical Properties and Thermal Stability. Nano Lett. 2016, 16, 471–478. [Google Scholar] [CrossRef]

- Bak, Y.; Kim, S.; Kwon, J.H.; Shin, Y.J.; Kim, Y.W.; Lee, T.-Y.; Jeong, S.Y.; Jeong, J.-Y.; Kwon, S.J.; Cho, E.-S.; et al. Highly Reliable Textile-Based Stretchable Photo-Heating Platform: Wearable OLEDs with Kirigami-Patterned Transferable Transparent Stretchable Electronics. Chem. Eng. J. 2025, 522, 167217. [Google Scholar] [CrossRef]

- Osawa, Y.; Kinbara, Y.; Kageoka, M.; Lida, K.; Kheddar, A. Soft Robotic Shell with Active Thermal Display. Sci. Rep. 2021, 11, 20070. [Google Scholar] [CrossRef]

- Yang, J.; Zi, D.; Zhu, X.; Li, H.; Li, Z.; Sun, L.; Zhang, G.; Wang, F.; Peng, Z.; Lan, H. Printed Flexible Transparent Electrodes for Harsh Environments. Adv. Mater. Technol. 2022, 7, 2101087. [Google Scholar] [CrossRef]

- Kramar, V.; Kabanov, A.; Kramar, O.; Fateev, S.; Karapetian, V. Detection and Recognition of the Underwater Object with Designated Features Using the Technical Stereo Vision System. Fluids 2023, 8, 92. [Google Scholar] [CrossRef]

- Patel, M.; Nguyen, T.T.; Park, H.-H.; Cho, S.; Yun, S.; Kumar, N.; Ghosh, S.; Kim, J. Transparent Underwater Power Windows: Enhanced Light Management and Harvesting with Water-Embedded Wide-Bandgap Heterojunction Photovoltaics for Sustainable Energy. Nano Energy 2025, 142, 111239. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-J.; Park, S.Y.; Park, J.; Ko, Y.; Shin, C.; Man, D.-W.; Kim, Y. Printed Ag Mesh Electrodes with Enhanced Adhesion on Diverse Substrates for Transparent Heater Applications. Nanomaterials 2025, 15, 1681. https://doi.org/10.3390/nano15211681

Kim H-J, Park SY, Park J, Ko Y, Shin C, Man D-W, Kim Y. Printed Ag Mesh Electrodes with Enhanced Adhesion on Diverse Substrates for Transparent Heater Applications. Nanomaterials. 2025; 15(21):1681. https://doi.org/10.3390/nano15211681

Chicago/Turabian StyleKim, Han-Jung, Se Yong Park, Jeongmin Park, Yohan Ko, Changjoo Shin, Dong-Woo Man, and Yoonkap Kim. 2025. "Printed Ag Mesh Electrodes with Enhanced Adhesion on Diverse Substrates for Transparent Heater Applications" Nanomaterials 15, no. 21: 1681. https://doi.org/10.3390/nano15211681

APA StyleKim, H.-J., Park, S. Y., Park, J., Ko, Y., Shin, C., Man, D.-W., & Kim, Y. (2025). Printed Ag Mesh Electrodes with Enhanced Adhesion on Diverse Substrates for Transparent Heater Applications. Nanomaterials, 15(21), 1681. https://doi.org/10.3390/nano15211681