Effects of Frost Damage and Nanomaterials Modification on the Microstructure and Fracture Properties of the Interfacial Transition Zone of Cementitious Materials

Abstract

1. Introduction

2. Experimental

2.1. Materials and Sample Preparation

2.2. Nanoscratch Test

2.3. Nanoindentation Test

2.4. SEM/BSE Test

2.5. Mercury Intrusion Porosimetry (MIP) Test

3. Results and Analysis

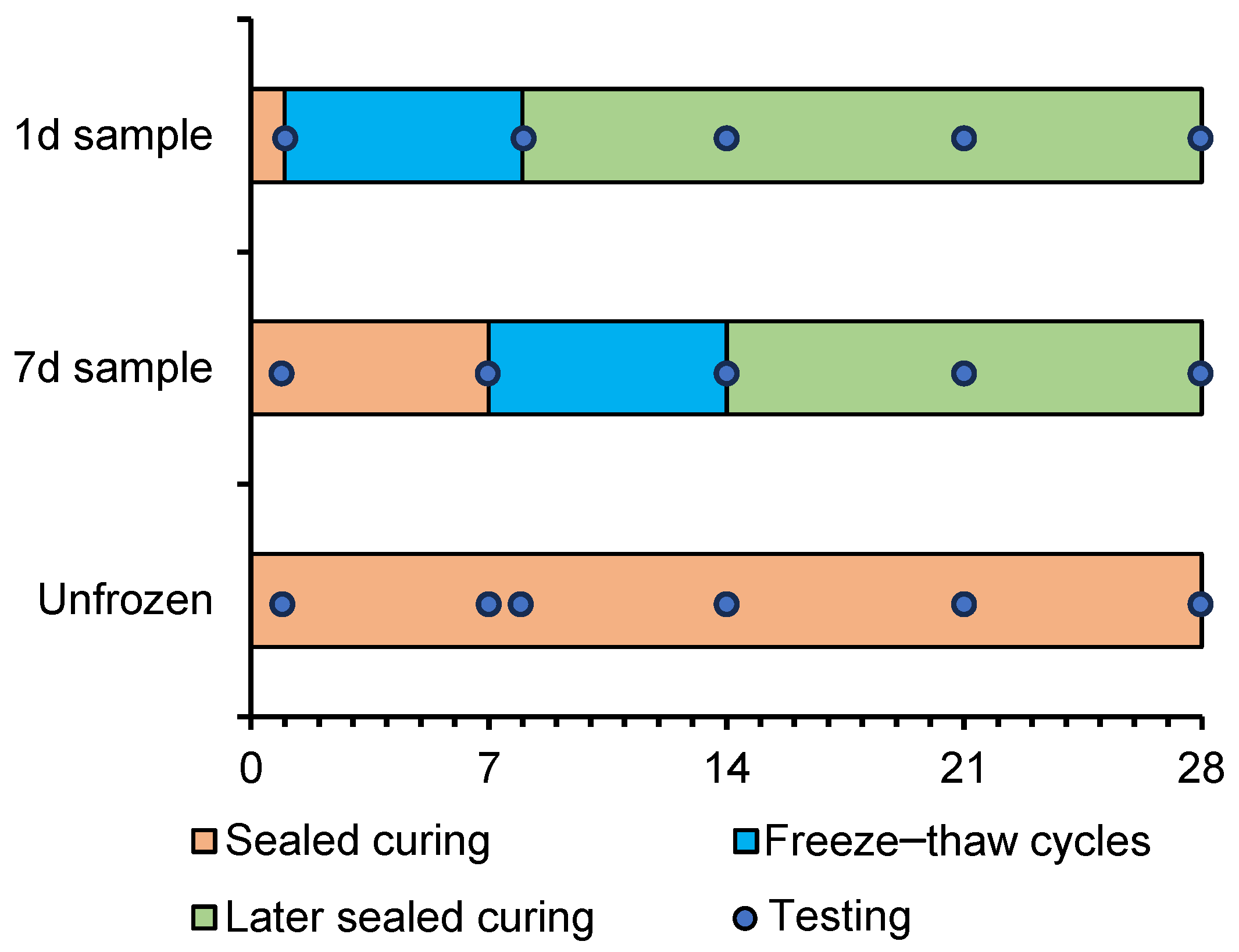

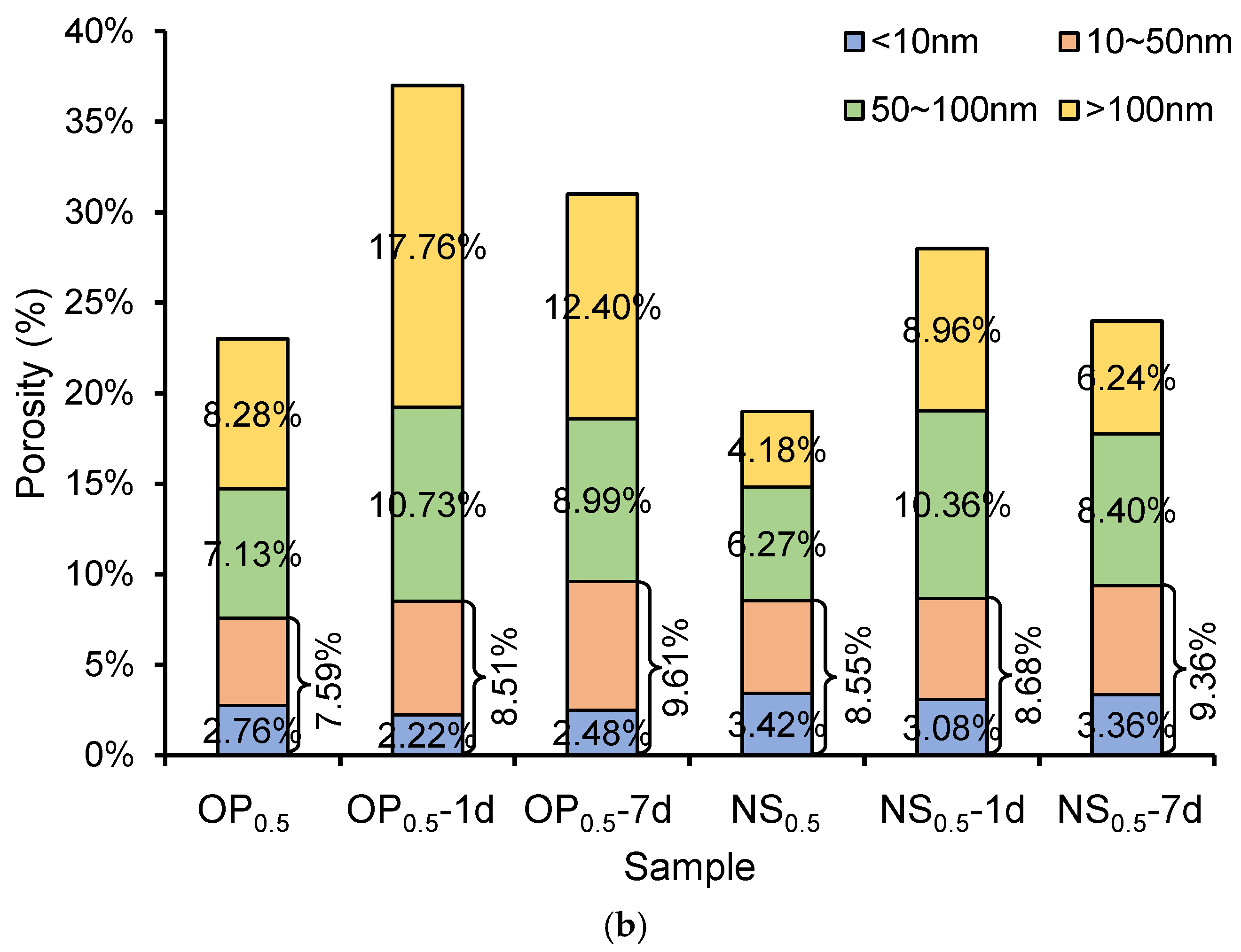

3.1. Effect of Frost Attack on the Porosity of Cement Paste

3.2. Clinker Size Quantification by BSE Imaging

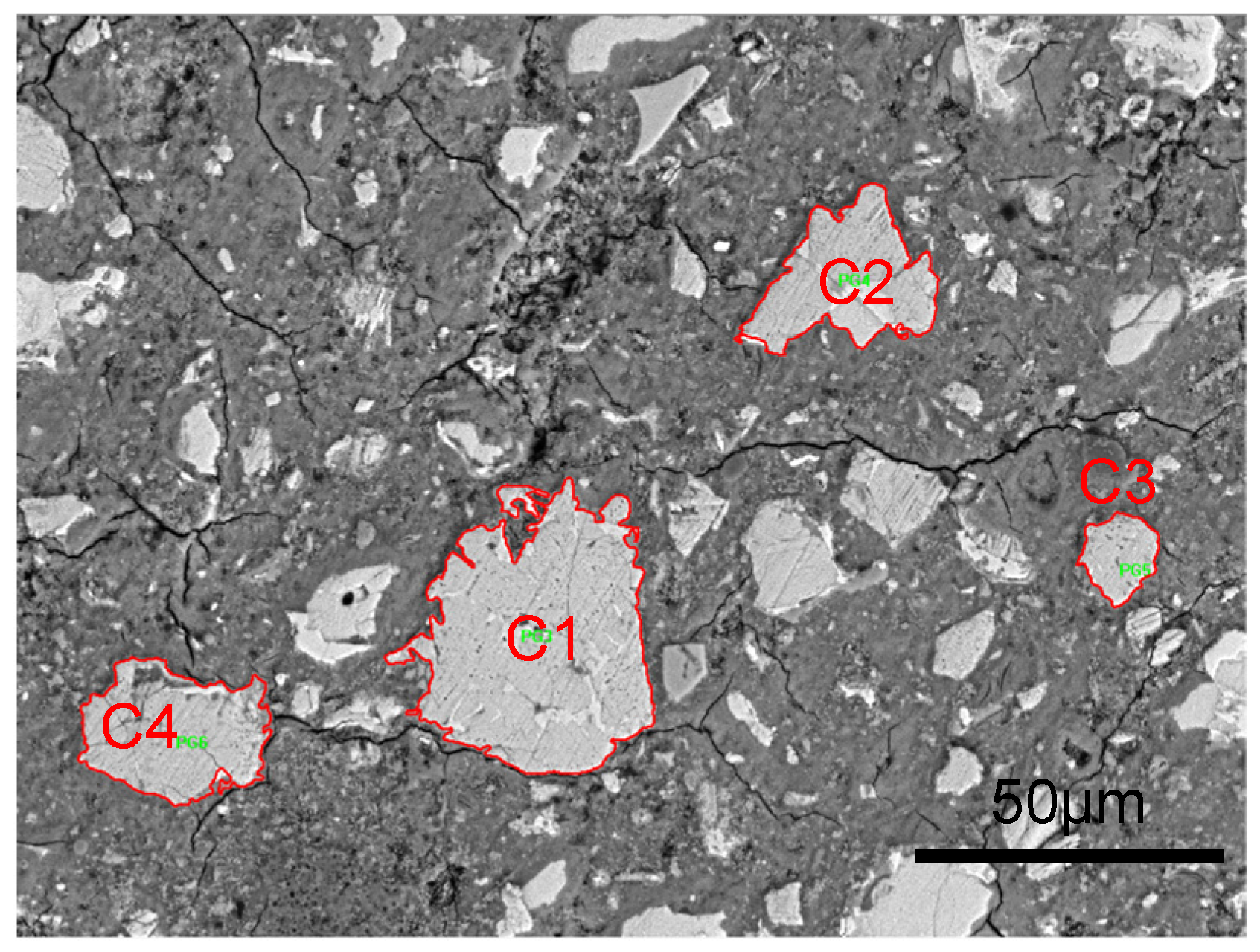

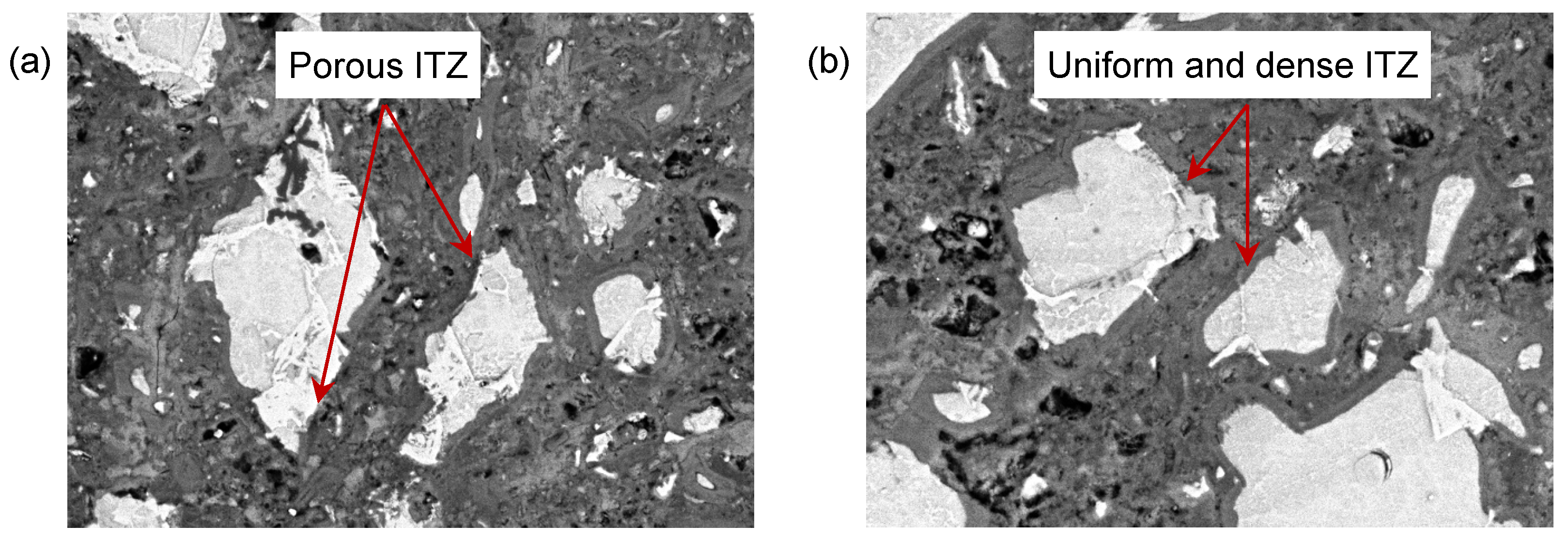

3.3. Phase Identification by Nanoscratch Technique

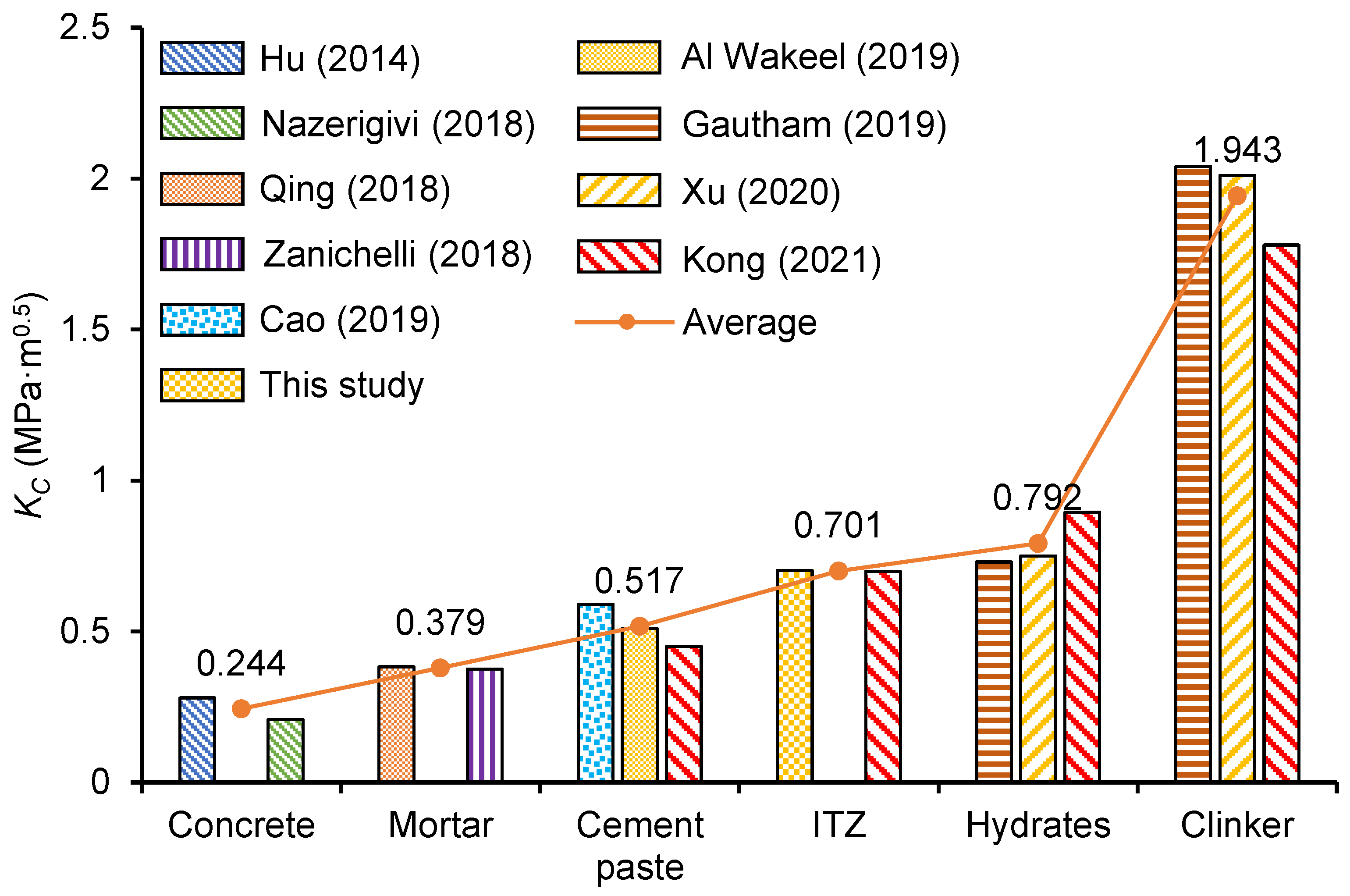

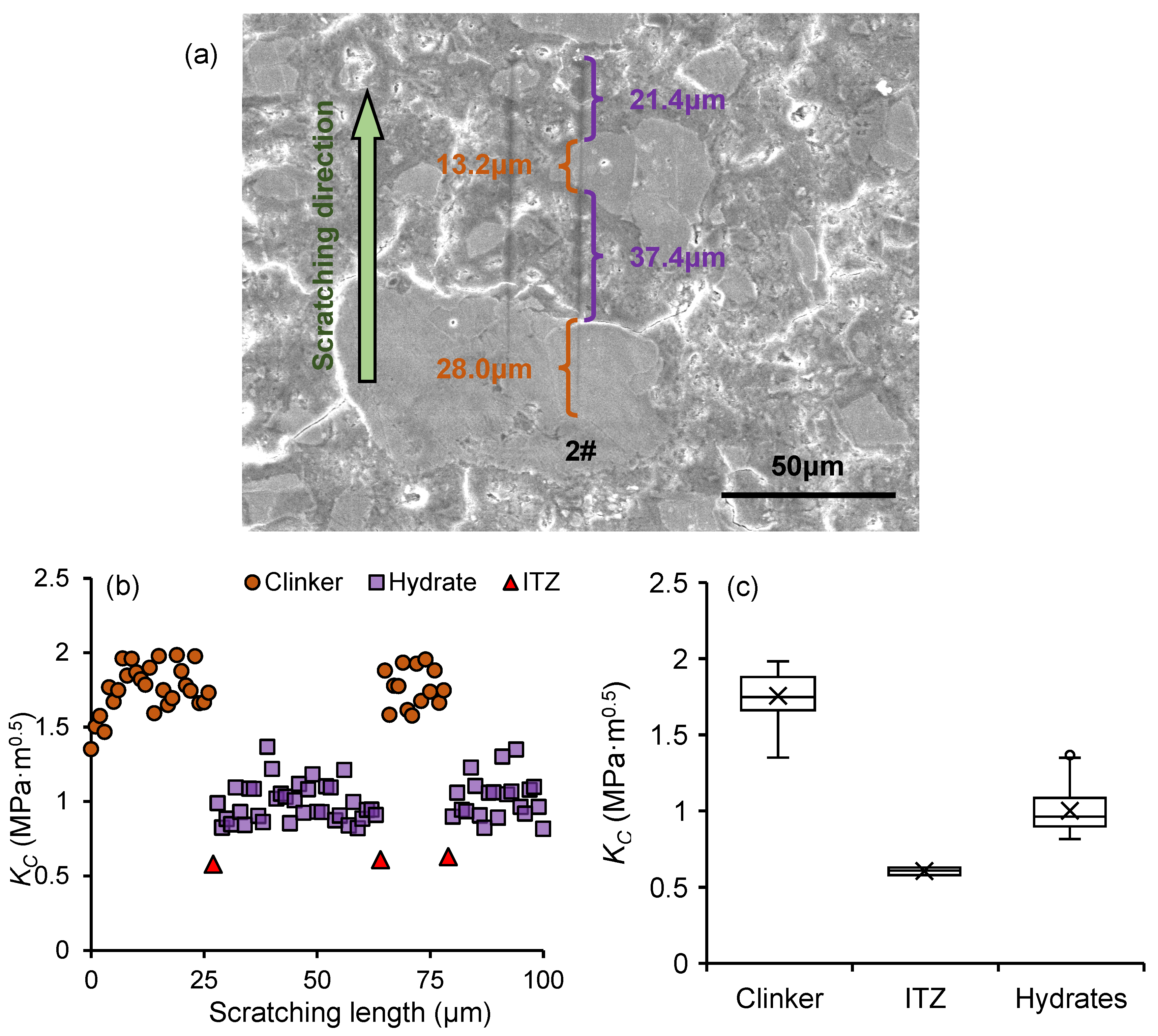

3.3.1. Fracture Toughness of Individual Phase

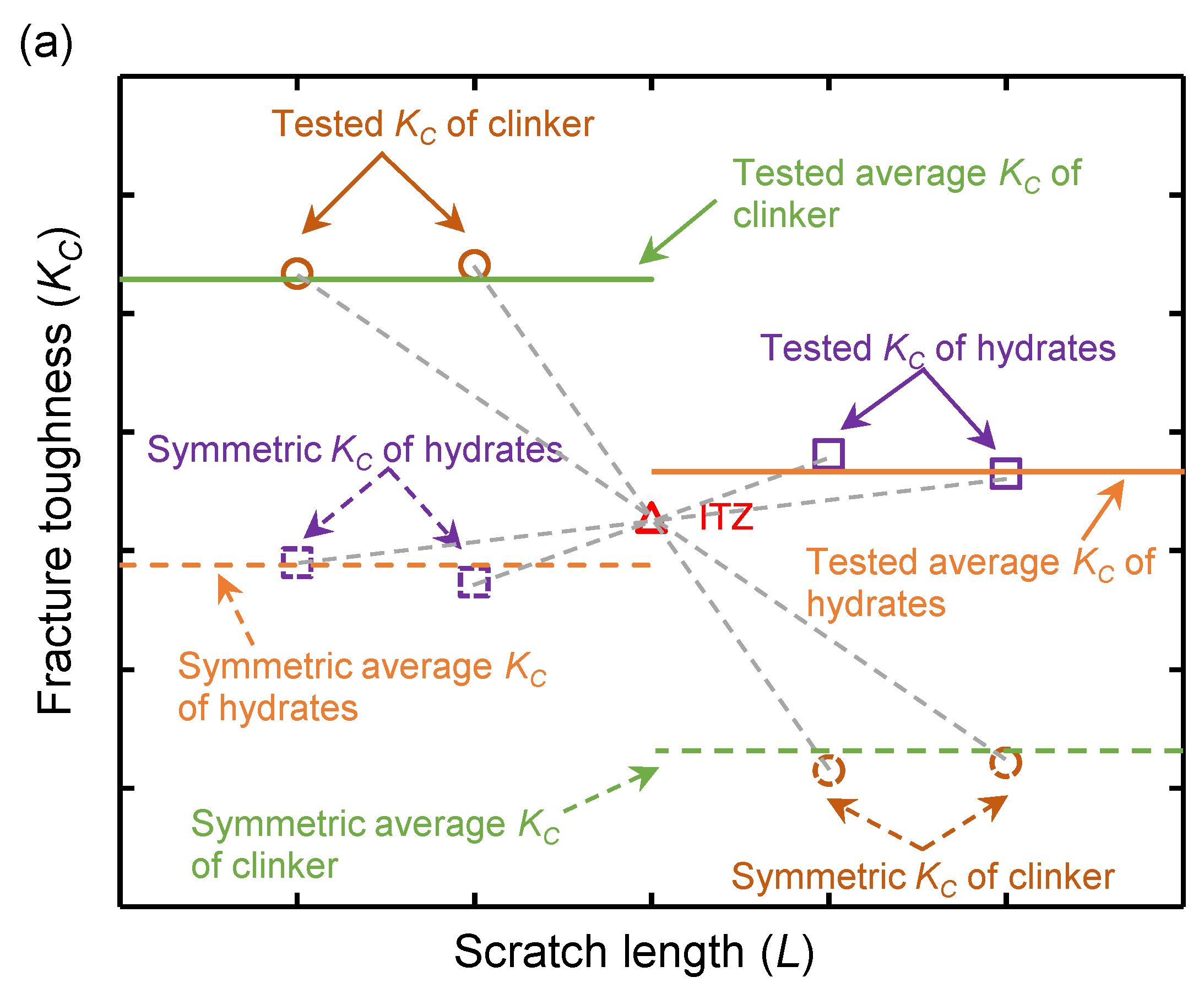

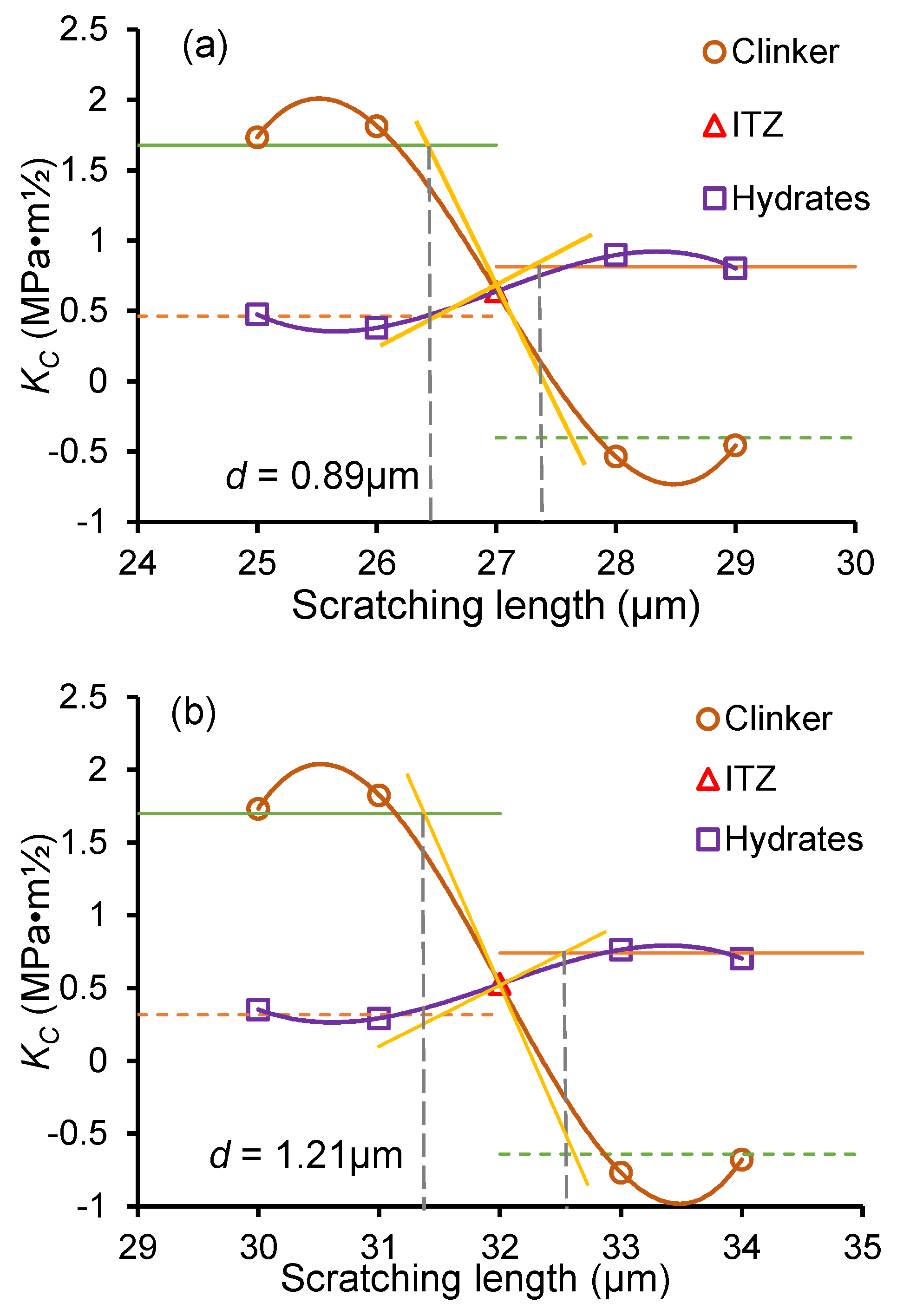

3.3.2. ITZ Thickness Quantification

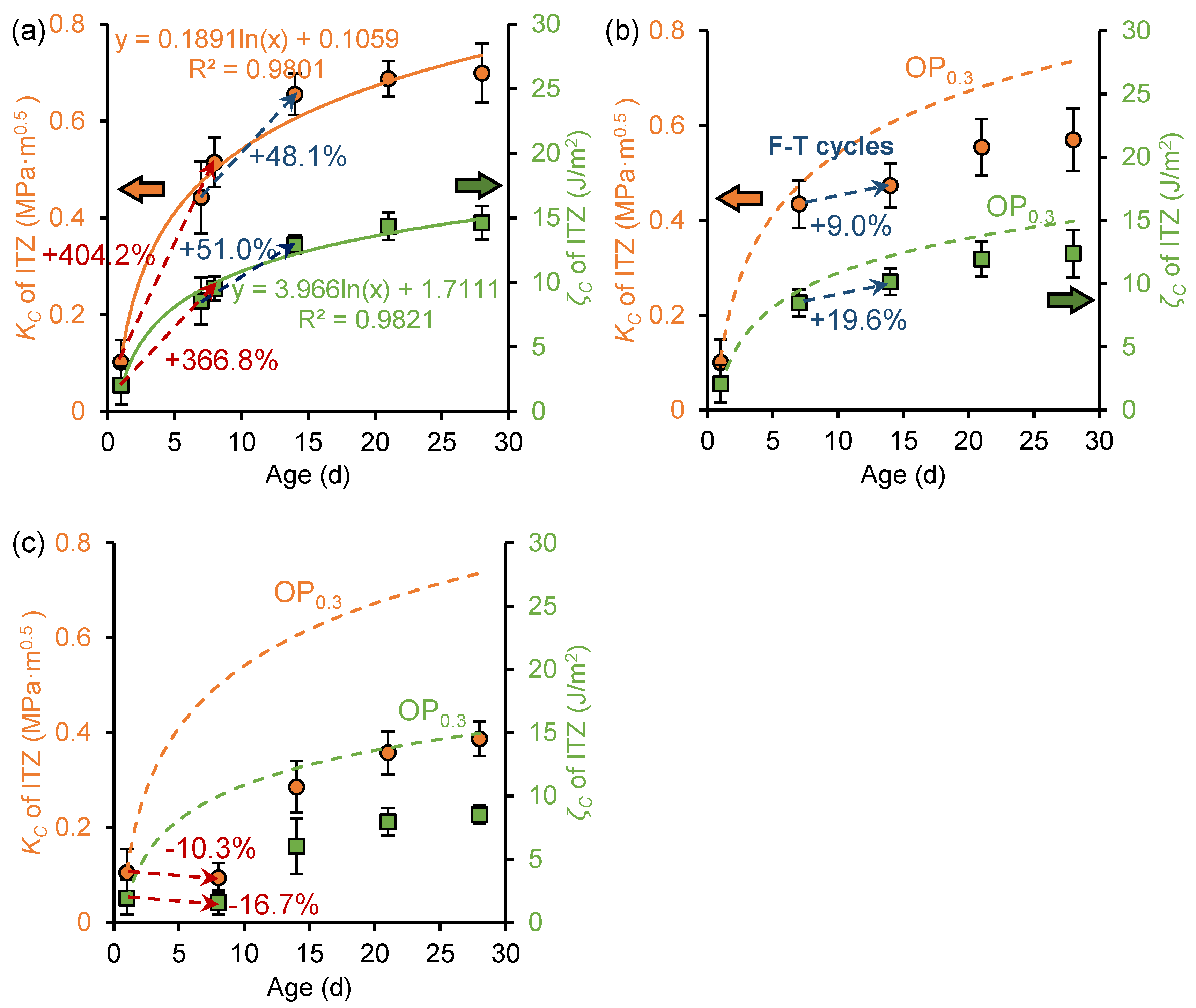

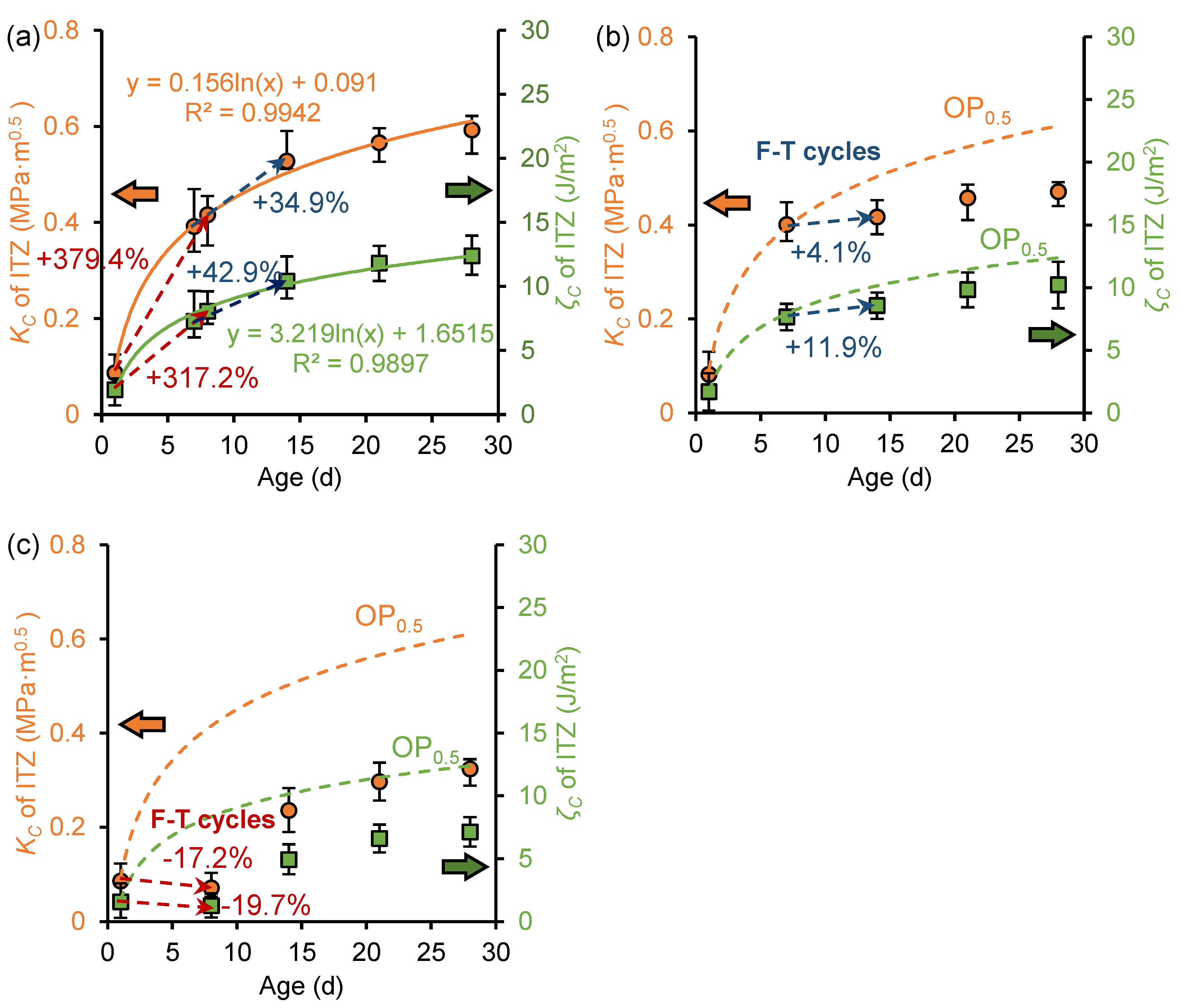

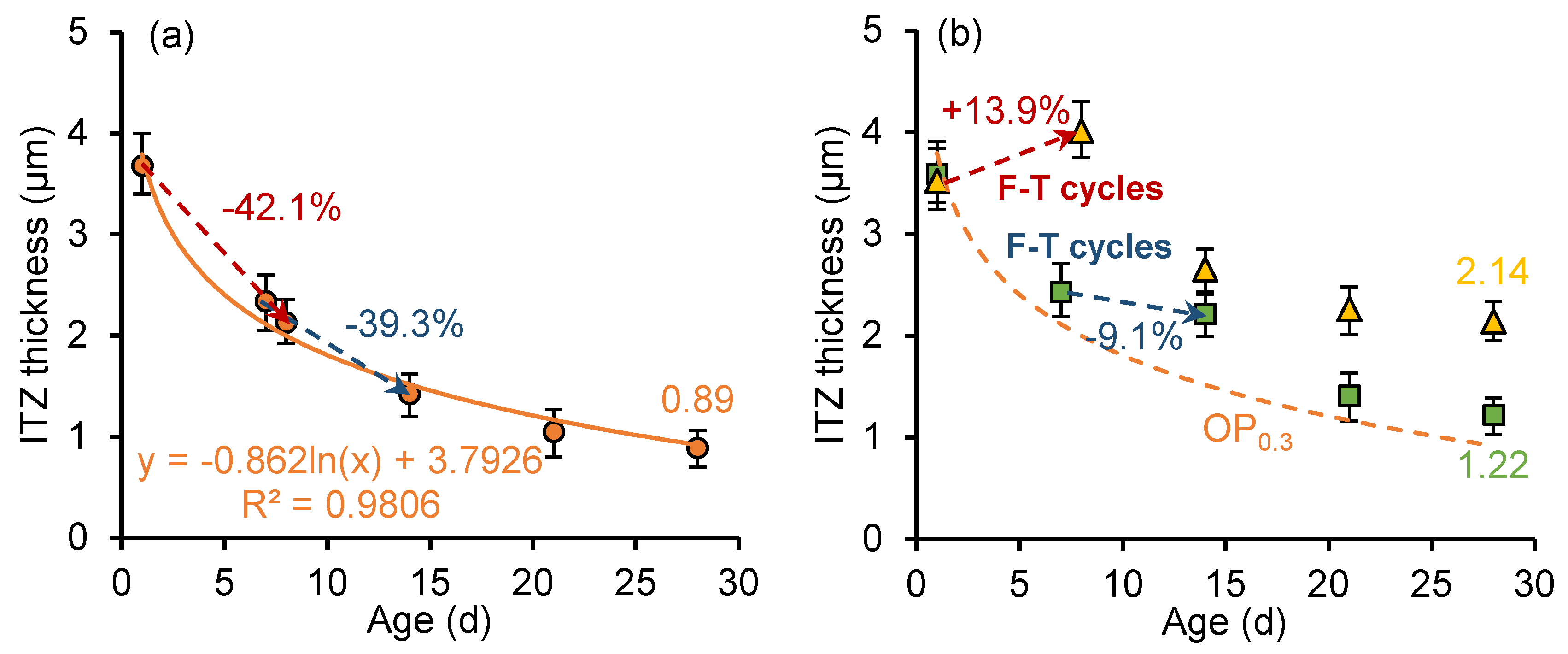

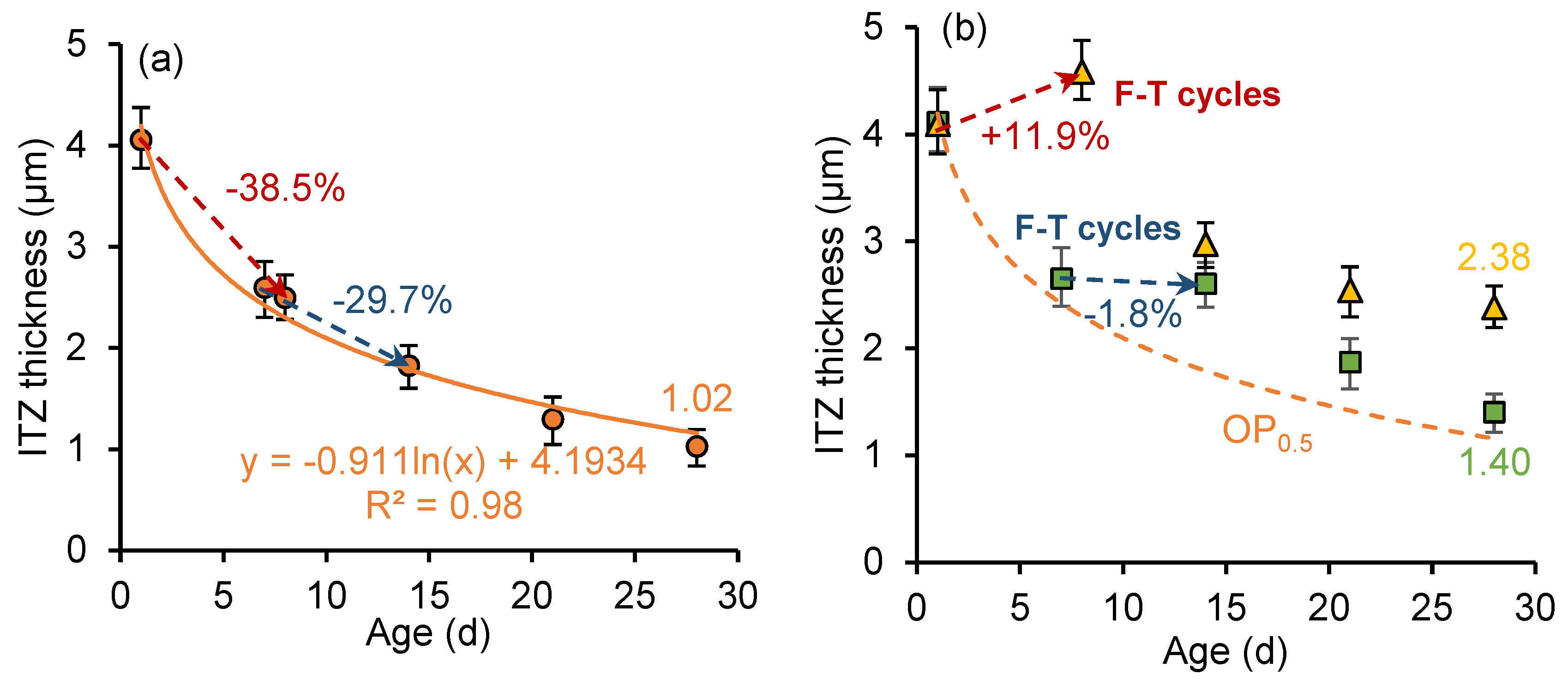

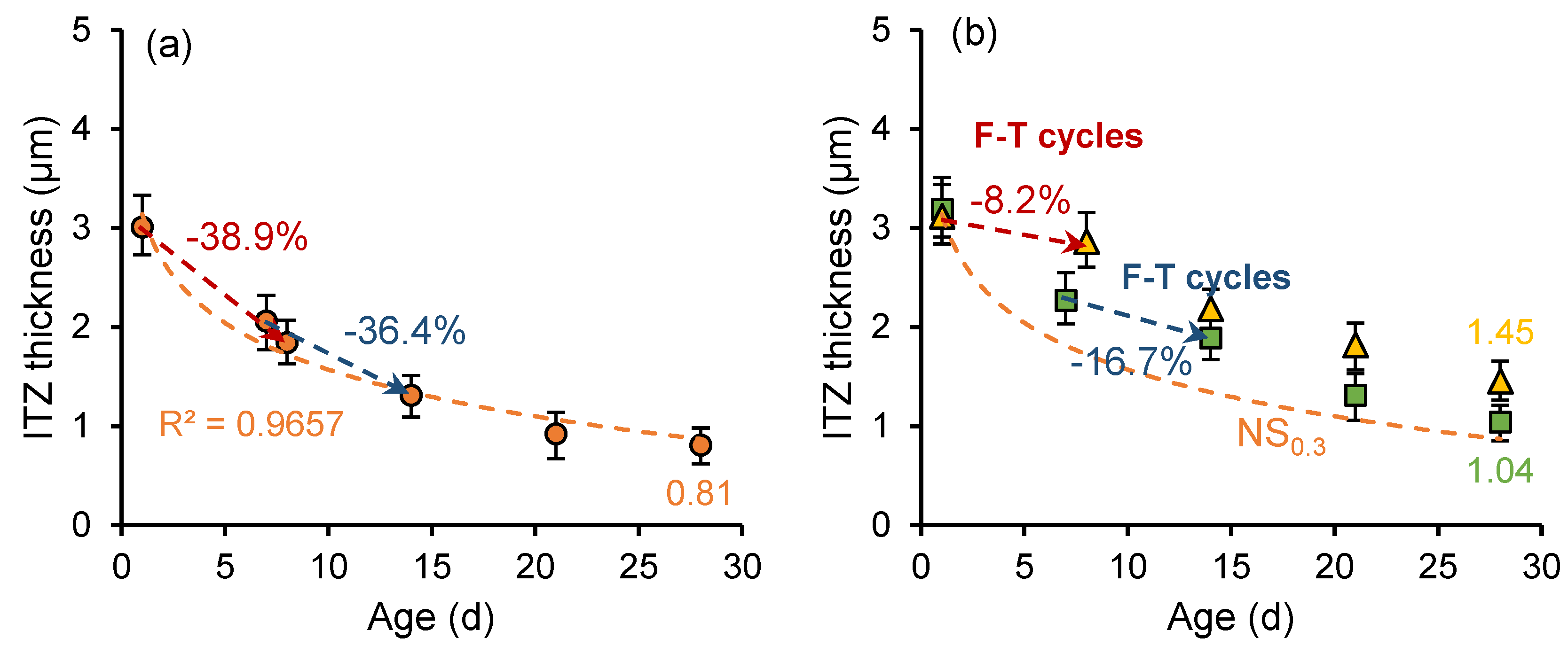

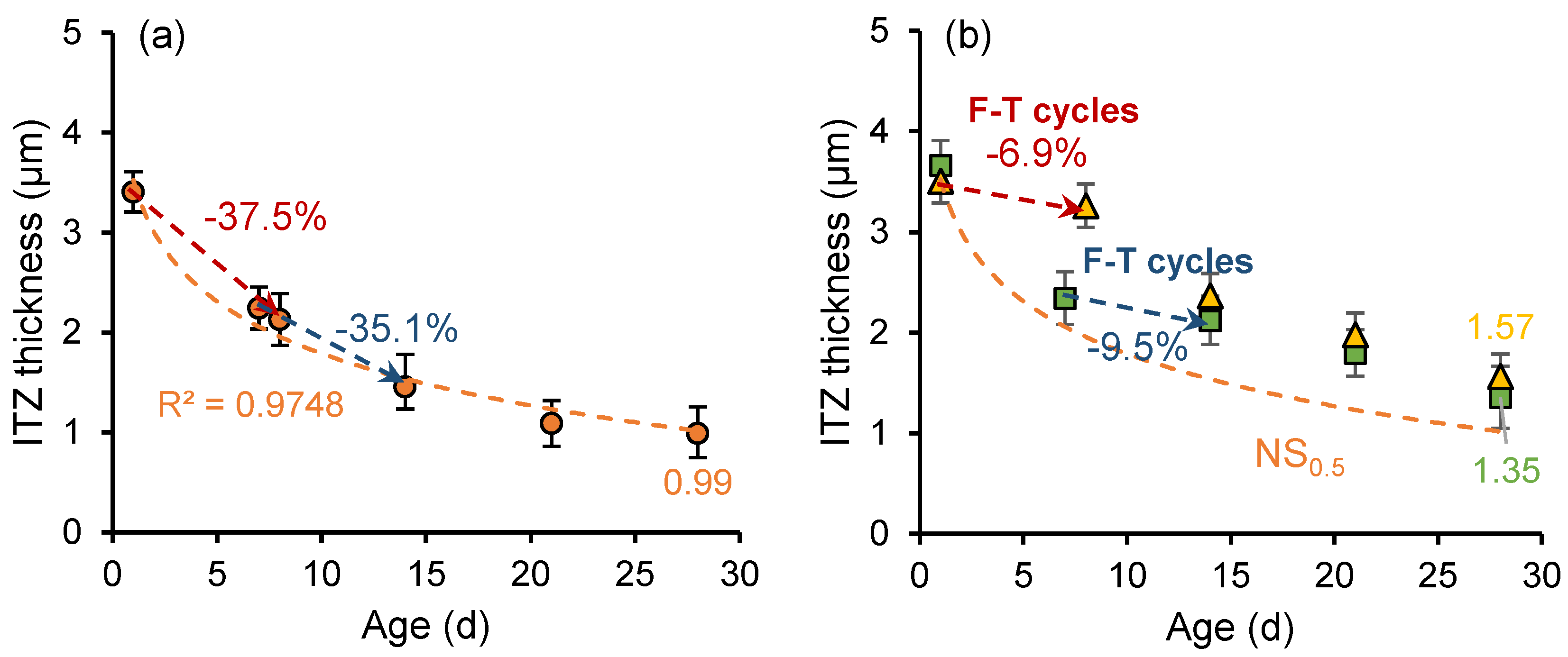

3.4. Effect of Frost Attack on the Fracture Properties and Thickness of ITZ

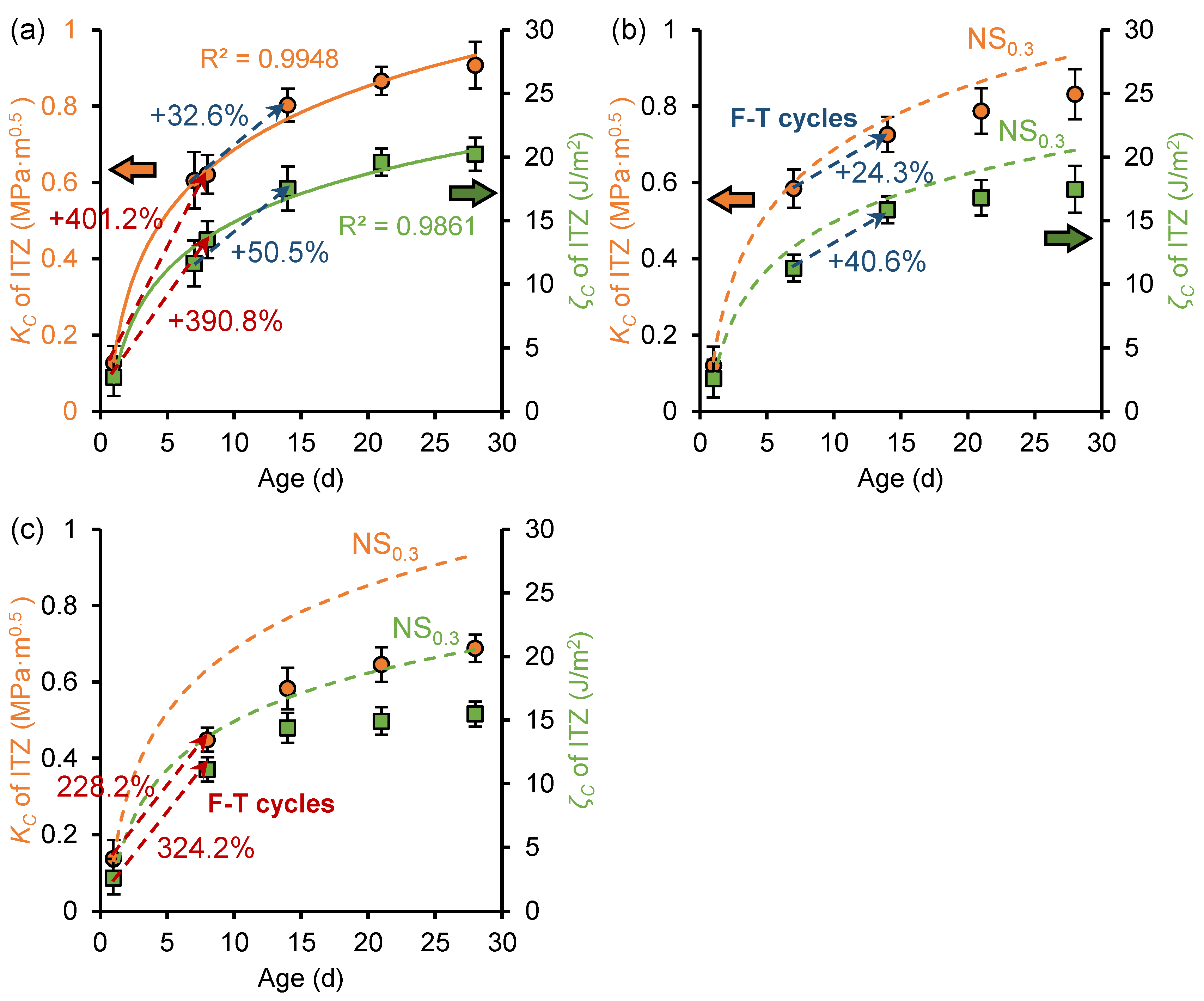

3.5. Effect of Nano-Silica on the Fracture Properties and Thickness of ITZ

4. Discussion

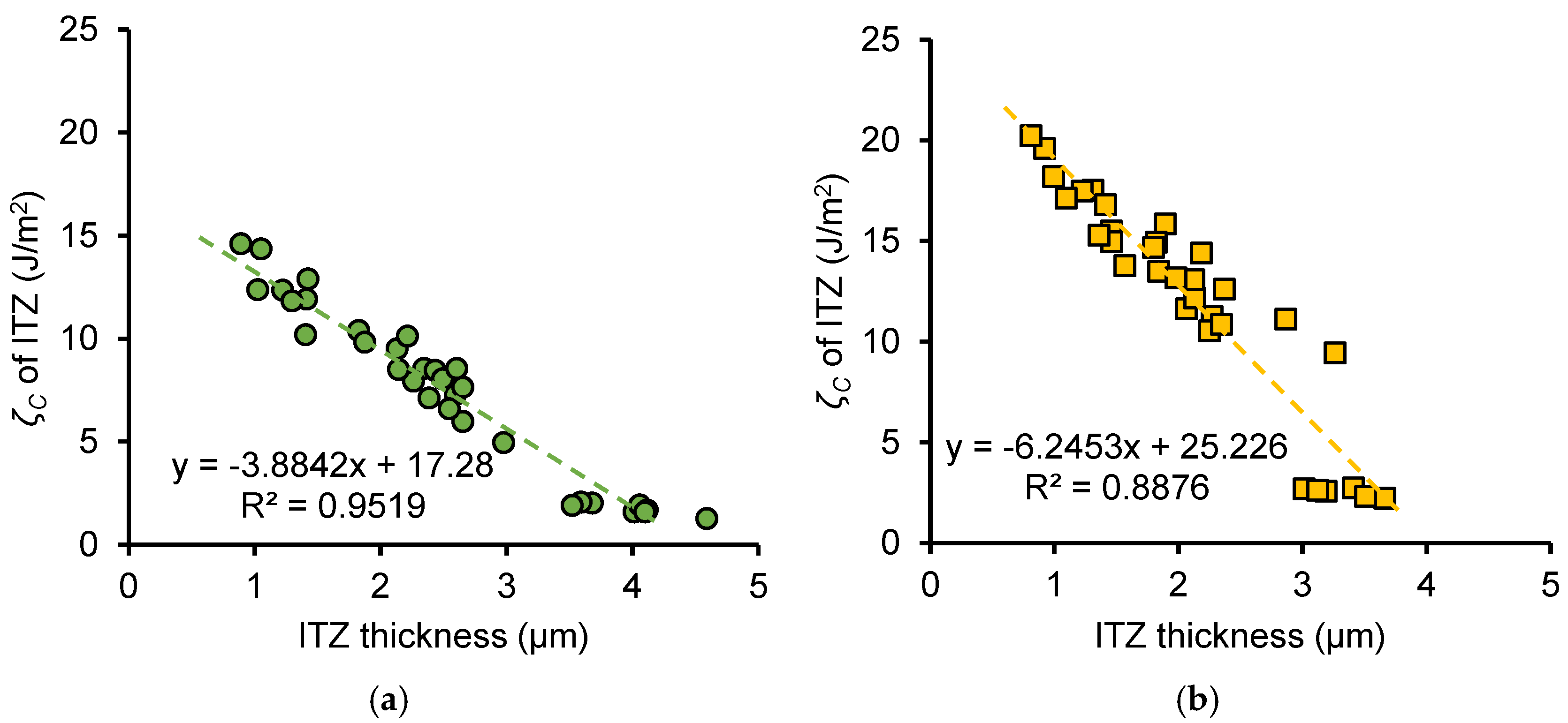

4.1. Relationship Between ITZ Thickness and Fracture Properties

4.2. Relationship Between Clinker Size and ITZ Properties

4.3. Comparison Between Micro and Macrofracture Properties

5. Conclusions

- (1)

- As the weakest phase in cementitious materials, the ITZ is significantly and negatively affected by freeze–thaw cycles in terms of fracture property and microstructural development, and the negative effects are more pronounced for pastes subjected to earlier freezing and with high w/c ratios. For the cement pastes frozen at the age of 1 day, the fracture properties showed a negative growth during the freezing period. Although secondary curing after freezing and thawing will alleviate the frost damage, it is also recommended to impose strict insulation in engineering.

- (2)

- The thickness of ITZ can be significantly reduced and the fracture properties of ITZ can be enhanced by nano-silica. This is attributed to the ability of nano-silica to reduce the number of pores larger than 100 nm through enhanced hydration reactions and its filler effect, which makes the cement paste form a denser structure. The enhancement effect of nano-silica on the frost resistance of cementitious materials is more pronounced in materials with low w/c ratios.

- (3)

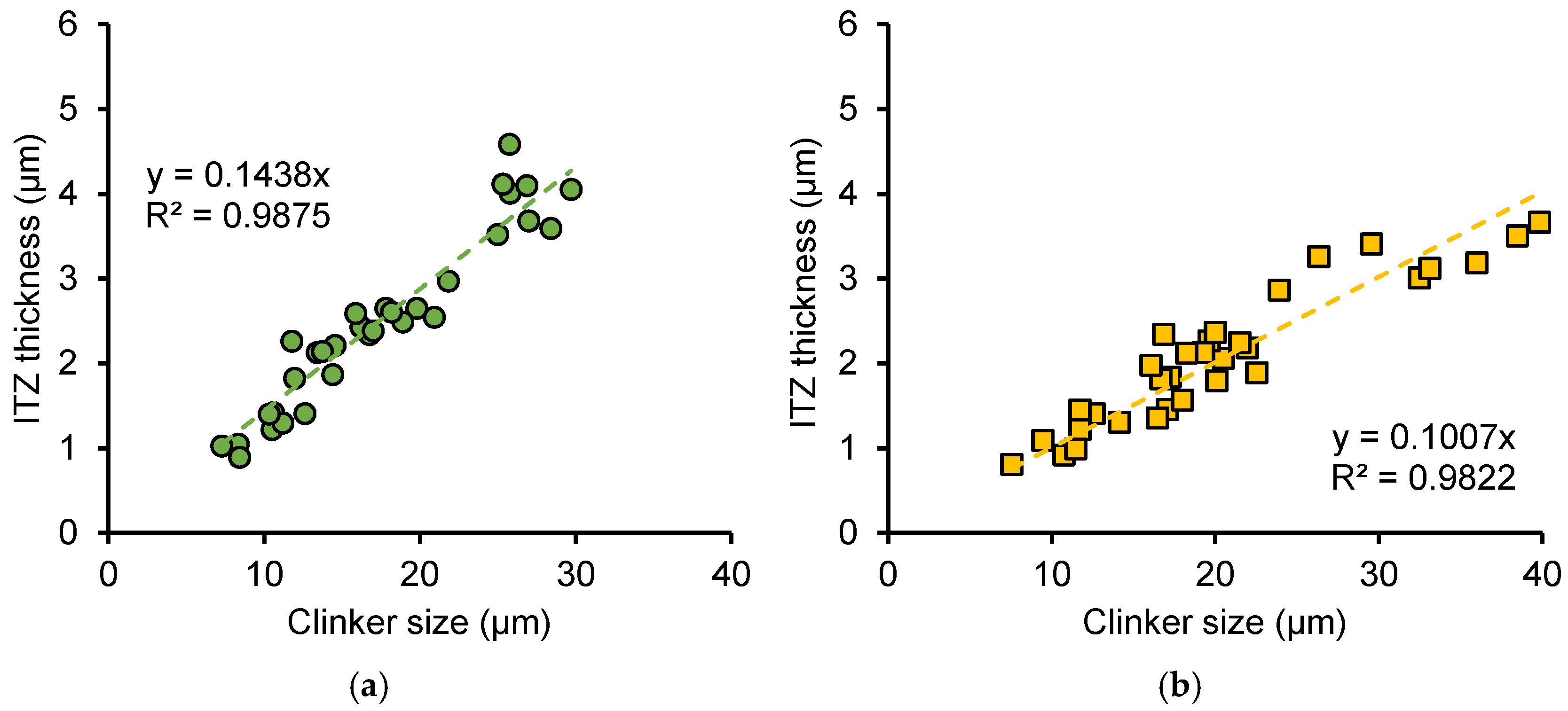

- This is the first time to characterize the relationship between clinker particle size and thickness and fracture properties of ITZ using a combination of nanoscratch and SEM techniques. A significant negative correlation was observed between ITZ thickness and fracture properties, with thicker ITZs exhibiting lower fracture toughness and fracture energy. Moreover, clinker size also showed a linear relationship with both ITZ thickness and fracture properties. Larger clinker particles are associated with greater ITZ thickness and reduced fracture properties. For a given cement paste, neither the w/c ratio nor early age freeze–thaw cycles alter the linear relationship between clinker size and ITZ properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pigeon, M.; Marchand, J.; Pleau, R. Frost resistant concrete. Constr. Build. Mater. 1996, 10, 339–348. [Google Scholar] [CrossRef]

- Šelih, J. Performance of concrete exposed to freezing and thawing in different saline environments. J. Civ. Eng. Manag. 2010, 16, 306–311. [Google Scholar] [CrossRef]

- Hasan, M.; Ueda, T.; Sato, Y. Stress-strain relationship of frost-damaged concrete subjected to fatigue loading. J. Mater. Civ. Eng. 2008, 20, 37–45. [Google Scholar] [CrossRef]

- Kosior-Kazberuk, M. Variations in fracture energy of concrete subjected to cyclic freezing and thawing. Arch. Civ. Mech. Eng. 2013, 13, 254–259. [Google Scholar] [CrossRef]

- Ma, Z.; Zhao, T.; Yang, J. Fracture behavior of concrete exposed to the freeze-thaw environment. J. Mater. Civ. Eng. 2017, 29, 04017071. [Google Scholar] [CrossRef]

- Li, Q.; Cai, L.; Fu, Y.; Wang, H.; Zou, Y. Fracture properties and response surface methodology model of alkali-slag concrete under freeze–thaw cycles. Constr. Build. Mater. 2015, 93, 620–626. [Google Scholar] [CrossRef]

- Cai, W.; Cen, G.; Wang, H. Fracture Surface Fractal Characteristics of Alkali-Slag Concrete under Freeze-Thaw Cycles. Adv. Mater. Sci. Eng. 2017, 2017, 1689893. [Google Scholar] [CrossRef]

- Dong, Y.; Su, C.; Qiao, P.; Sun, L. Microstructural damage evolution and its effect on fracture behavior of concrete subjected to freeze-thaw cycles. Int. J. Damage Mech. 2018, 27, 1272–1288. [Google Scholar] [CrossRef]

- Li, J.; Wang, F.; Yi, F.; Ma, J.; Lin, Z. Fractal analysis of the fracture evolution of freeze-thaw damage to asphalt concrete. Materials 2019, 12, 2288. [Google Scholar] [CrossRef]

- Jenq, Y.-S.; Shah, S.P. Features of mechanics of quasi-brittle crack propagation in concrete. Int. J. Fract. 1991, 51, 103–120. [Google Scholar] [CrossRef]

- Lyu, K.; She, W.; Chang, H.; Gu, Y. Effect of fine aggregate size on the overlapping of interfacial transition zone (ITZ) in mortars. Constr. Build. Mater. 2020, 248, 118559. [Google Scholar] [CrossRef]

- Gao, Y.; De Schutter, G.; Ye, G.; Tan, Z.; Wu, K. The ITZ microstructure, thickness and porosity in blended cementitious composite: Effects of curing age, water to binder ratio and aggregate content. Compos. Part B Eng. 2014, 60, 1–13. [Google Scholar] [CrossRef]

- Elsharief, A.; Cohen, M.D.; Olek, J. Influence of aggregate size, water cement ratio and age on the microstructure of the interfacial transition zone. Cem. Concr. Res. 2003, 33, 1837–1849. [Google Scholar] [CrossRef]

- Prokopski, G.; Langier, B. Effect of water/cement ratio and silica fume addition on the fracture toughness and morphology of fractured surfaces of gravel concretes. Cem. Concr. Res. 2000, 30, 1427–1433. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Effect of aggregate on the fracture behavior of high strength concrete. Constr. Build. Mater. 2004, 18, 585–590. [Google Scholar] [CrossRef]

- Carrasquillo, R.L.; Nilson, A.H.; Slate, F.O. Microcracking and behavior of high strength concrete subject to short-term loading. J. Proc. 1981, 78, 179–186. [Google Scholar]

- Hoover, C.G.; Ulm, F.-J. Experimental chemo-mechanics of early-age fracture properties of cement paste. Cem. Concr. Res. 2015, 75, 42–52. [Google Scholar] [CrossRef]

- Akono, A.-T.; Ulm, F.-J. Microscopic toughness of viscous solids via scratching: From amorphous polymers to gas shale. J. Nanomechanics Micromechanics 2017, 7, 04017009. [Google Scholar] [CrossRef]

- Kabir, P.; Ulm, F.-J.; Akono, A.-T. Rate-independent fracture toughness of gray and black kerogen-rich shales. Acta Geotech. 2017, 12, 1207–1227. [Google Scholar] [CrossRef]

- Anderson, K.; Akono, A.-T. Microstructure–toughness relationships in calcium aluminate cement–polymer composites using instrumented scratch testing. J. Mater. Sci. 2017, 52, 13120–13132. [Google Scholar] [CrossRef]

- Kong, W.; Wei, Y.; Wang, Y.; Sha, A. Development of micro and macro fracture properties of cementitious materials exposed to freeze-thaw environment at early ages. Constr. Build. Mater. 2021, 271, 121502. [Google Scholar] [CrossRef]

- Johnson, C.V.; Chen, J.; Hasparyk, N.P.; Monteiro, P.J.; Akono, A.T. Fracture properties of the alkali silicate gel using microscopic scratch testing. Cem. Concr. Compos. 2017, 79, 71–75. [Google Scholar] [CrossRef]

- Wei, Y.; Kong, W.; Wang, Y.; Sha, A. Multifunctional application of nanoscratch technique to characterize cementitious materials. Cem. Concr. Res. 2021, 140, 106318. [Google Scholar] [CrossRef]

- Gonzalez, M.; Tighe, S.L.; Hui, K.; Rahman, S.; de Oliveira Lima, A. Evaluation of freeze/thaw and scaling response of nanoconcrete for Portland Cement Concrete (PCC) pavements. Constr. Build. Mater. 2016, 120, 465–472. [Google Scholar] [CrossRef]

- Cheng, Y.; Shi, Z. Experimental Study on Nano-SiO2 Improving Concrete Durability of Bridge Deck Pavement in Cold Regions. Adv. Civ. Eng. 2019, 2019, 5284913. [Google Scholar] [CrossRef]

- Wang, B.; Wang, L.; Lai, F. Freezing resistance of HPC with nano-SiO2. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2008, 23, 85–88. [Google Scholar] [CrossRef]

- Zhao, Z.R.; Kong, J.; Yang, H.X. Study on frost resistance of nano SiO2 cement concrete. Appl. Mech. Mater. 2012, 198, 48–51. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Seo, J.-W.T.; Konsta-Gdoutos, M.S.; Hersam, M.C.; Shah, S.P. Highly concentrated carbon nanotube admixture for nano-fiber reinforced cementitious materials. Cem. Concr. Compos. 2012, 34, 612–617. [Google Scholar] [CrossRef]

- Wang, B.; Han, Y.; Liu, S. Effect of highly dispersed carbon nanotubes on the flexural toughness of cement-based composites. Constr. Build. Mater. 2013, 46, 8–12. [Google Scholar] [CrossRef]

- Wei, Y.; Kong, W.; Wang, Y. Strengthening mechanism of fracture properties by nano materials for cementitious materials subject to early-age frost attack. Cem. Concr. Compos. 2021, 119, 104025. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, Z.; Yao, X.; Gao, X. Quantifying effect of later curing on pores of paste subject to early-age freeze-thaw cycles by different techniques. J. Mater. Civ. Eng. 2019, 31, 04019153. [Google Scholar] [CrossRef]

- Wei, Y.; Guo, W.; Wu, Z.; Gao, X. Computed permeability for cement paste subject to freeze-thaw cycles at early ages. Constr. Build. Mater. 2020, 244, 118298. [Google Scholar] [CrossRef]

- Wei, Y.; Liang, S.; Kong, W. Mechanical Properties of Cementitious Materials at Microscale; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Akono, A.-T.; Randall, N.X.; Ulm, F.-J. Experimental determination of the fracture toughness via microscratch tests: Application to polymers, ceramics, and metals. J. Mater. Res. 2012, 27, 485–493. [Google Scholar] [CrossRef]

- Xu, J.; Corr, D.J.; Shah, S.P. Nanomechanical properties of CSH gel/cement grain interface by using nanoindentation and modulus mapping. J. Zhejiang Univ.-Sci. A 2015, 16, 38–46. [Google Scholar] [CrossRef]

- Xu, J.; Corr, D.J.; Shah, S.P. Nanomechanical investigation of the effects of nanoSiO2 on C–S–H gel/cement grain interfaces. Cem. Concr. Compos. 2015, 61, 7–17. [Google Scholar] [CrossRef]

- Durst, K.; Göken, M.; Vehoff, H. Finite element study for nanoindentation measurements on two-phase materials. J. Mater. Res. 2004, 19, 85–93. [Google Scholar] [CrossRef]

- Wei, Y.; Gao, X.; Liang, S. Nanoindentation-based study of the micro-mechanical properties, structure, and hydration degree of slag-blended cementitious materials. J. Mater. Sci. 2016, 51, 3349–3361. [Google Scholar] [CrossRef]

- Constantinides, G.; Ulm, F.-J. The effect of two types of CSH on the elasticity of cement-based materials: Results from nanoindentation and micromechanical modeling. Cem. Concr. Res. 2004, 34, 67–80. [Google Scholar] [CrossRef]

- Wong, H.; Head, M.; Buenfeld, N. Pore segmentation of cement-based materials from backscattered electron images. Cem. Concr. Res. 2006, 36, 1083–1090. [Google Scholar] [CrossRef]

- Xu, J.; Corr, D.J.; Shah, S.P. Nanoscratch Study of the Modification Effects of NanoSiO2 on C–S–H Gel/Cement Grain Interfaces. J. Mater. Civ. Eng. 2017, 29, 04017093. [Google Scholar] [CrossRef]

- Jo, B.W.; Kim, C.H.; Lim, J.H. Investigations on the development of powder concrete with nano-SiO2 particles. KSCE J. Civ. Eng. 2007, 11, 37–42. [Google Scholar] [CrossRef]

- Quercia, G.; Brouwers, H. Application of nano-silica (nS) in concrete mixtures. In Proceedings of the 8th fib International Ph. D. Symposium in Civil Engineering, Lyngby, Denmark, 20–23 June 2010. [Google Scholar]

- Bernard, O.; Ulm, F.-J.; Lemarchand, E. A multiscale micromechanics-hydration model for the early-age elastic properties of cement-based materials. Cem. Concr. Res. 2003, 33, 1293–1309. [Google Scholar] [CrossRef]

- Liang, S.; Wei, Y.; Wu, Z. Multiscale modeling elastic properties of cement-based materials considering imperfect interface effect. Constr. Build. Mater. 2017, 154, 567–579. [Google Scholar] [CrossRef]

- Hu, Y.; Luo, D.; Li, P.; Li, Q.; Sun, G. Fracture toughness enhancement of cement paste with multi-walled carbon nanotubes. Constr. Build. Mater. 2014, 70, 332–338. [Google Scholar] [CrossRef]

- Nazerigivi, A.; Nejati, H.R.; Ghazvinian, A.; Najigivi, A. Effects of SiO2 nanoparticles dispersion on concrete fracture toughness. Constr. Build. Mater. 2018, 171, 672–679. [Google Scholar] [CrossRef]

- Qing, L.; Dong, M.; Guan, J. Determining initial fracture toughness of concrete for split-tension specimens based on the extreme theory. Eng. Fract. Mech. 2018, 189, 427–438. [Google Scholar] [CrossRef]

- Zanichelli, A.; Carpinteri, A.; Fortese, G.; Ronchei, C.; Scorza, D.; Vantadori, S. Contribution of date-palm fibres reinforcement to mortar fracture toughness. Procedia Struct. Integr. 2018, 13, 542–547. [Google Scholar] [CrossRef]

- Cao, M.; Xie, C.; Guan, J. Fracture behavior of cement mortar reinforced by hybrid composite fiber consisting of CaCO3 whiskers and PVA-steel hybrid fibers. Compos. Part A Appl. Sci. Manuf. 2019, 120, 172–187. [Google Scholar] [CrossRef]

- Al Wakeel, S.; Němeček, J.; Li, L.; Xi, Y.; Hubler, M. The effect of introducing nanoparticles on the fracture toughness of well cement paste. Int. J. Greenh. Gas Control 2019, 84, 147–153. [Google Scholar] [CrossRef]

- Gautham, S.; Sasmal, S. Determination of fracture toughness of nano-scale cement composites using simulated nanoindentation technique. Theor. Appl. Fract. Mech. 2019, 103, 102275. [Google Scholar] [CrossRef]

- Xu, S.; Feng, Y.; Liu, J.; Zeng, Q. Micro indentation fracture of cement paste assessed by energy-based method: The method improvement and affecting factors. Constr. Build. Mater. 2020, 231, 117136. [Google Scholar] [CrossRef]

| Materials | Mass Fraction/% | Specific Gravity | Specific Surface Area/(m2 kg−1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | LOI | |||

| Cement | 20.55 | 4.59 | 3.27 | 62.59 | 2.61 | 2.93 | 0.53 | 0.83 | 1.77 | 3.14 | 350 |

| Nanomaterials | Diameter | Specific surface area | Purity | Bulk density | PH value | ||||||

| Nano-silica | 15 nm | 250 m2/g | 99.9% | 0.1–0.15 g/cm3 | 5–7 | ||||||

| Sample | Cement | Water | Nano-Silica | Content by Weight | w/c | Frozen Age |

|---|---|---|---|---|---|---|

| OP0.3 | 1400 | 420 | 0 | 0 | 0.3 | — |

| OP0.3-1d | 1 day | |||||

| OP0.3-7d | 7 days | |||||

| OP0.5 | 1400 | 700 | 0 | 0 | 0.5 | — |

| OP0.5-1d | 1 day | |||||

| OP0.5-7d | 7 days | |||||

| NS0.3 | 1372 | 420 | 28 | 2% | 0.3 | — |

| NS0.3-1d | 1 day | |||||

| NS0.3-7d | 7 days | |||||

| NS0.5 | 1372 | 700 | 28 | 2% | 0.5 | — |

| NS0.5-1d | 1 day | |||||

| NS0.5-7d | 7 days |

| Tested Phase | Maximum Load (mN) | Loading Rate (mN/s) | Holding Time (s) | Unloading Rate (mN/s) |

|---|---|---|---|---|

| Clinker | 4 | 0.4 | 5 | 0.4 |

| Hydrates | 4 | 0.4 | 5 | 0.4 |

| ITZ | 1 | 0.1 | 5 | 0.1 |

| Clinker Number | Gray Level Range | Pixel Number | Equivalent Diameter D (μm) |

|---|---|---|---|

| C1 | 156~255 | 34,530 | 37.7 |

| C2 | 148~255 | 12,595 | 22.8 |

| C3 | 161~255 | 3515 | 12.1 |

| C4 | 152~255 | 12,786 | 23.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Zhou, X.; Kong, W. Effects of Frost Damage and Nanomaterials Modification on the Microstructure and Fracture Properties of the Interfacial Transition Zone of Cementitious Materials. Nanomaterials 2025, 15, 1670. https://doi.org/10.3390/nano15211670

Zhou X, Zhou X, Kong W. Effects of Frost Damage and Nanomaterials Modification on the Microstructure and Fracture Properties of the Interfacial Transition Zone of Cementitious Materials. Nanomaterials. 2025; 15(21):1670. https://doi.org/10.3390/nano15211670

Chicago/Turabian StyleZhou, Xiangong, Xiancheng Zhou, and Weikang Kong. 2025. "Effects of Frost Damage and Nanomaterials Modification on the Microstructure and Fracture Properties of the Interfacial Transition Zone of Cementitious Materials" Nanomaterials 15, no. 21: 1670. https://doi.org/10.3390/nano15211670

APA StyleZhou, X., Zhou, X., & Kong, W. (2025). Effects of Frost Damage and Nanomaterials Modification on the Microstructure and Fracture Properties of the Interfacial Transition Zone of Cementitious Materials. Nanomaterials, 15(21), 1670. https://doi.org/10.3390/nano15211670