Effect of Nanocarbon on the Structural and Mechanical Properties of 6061 Aluminum Composites by Powder Metallurgy

Abstract

:1. Introduction

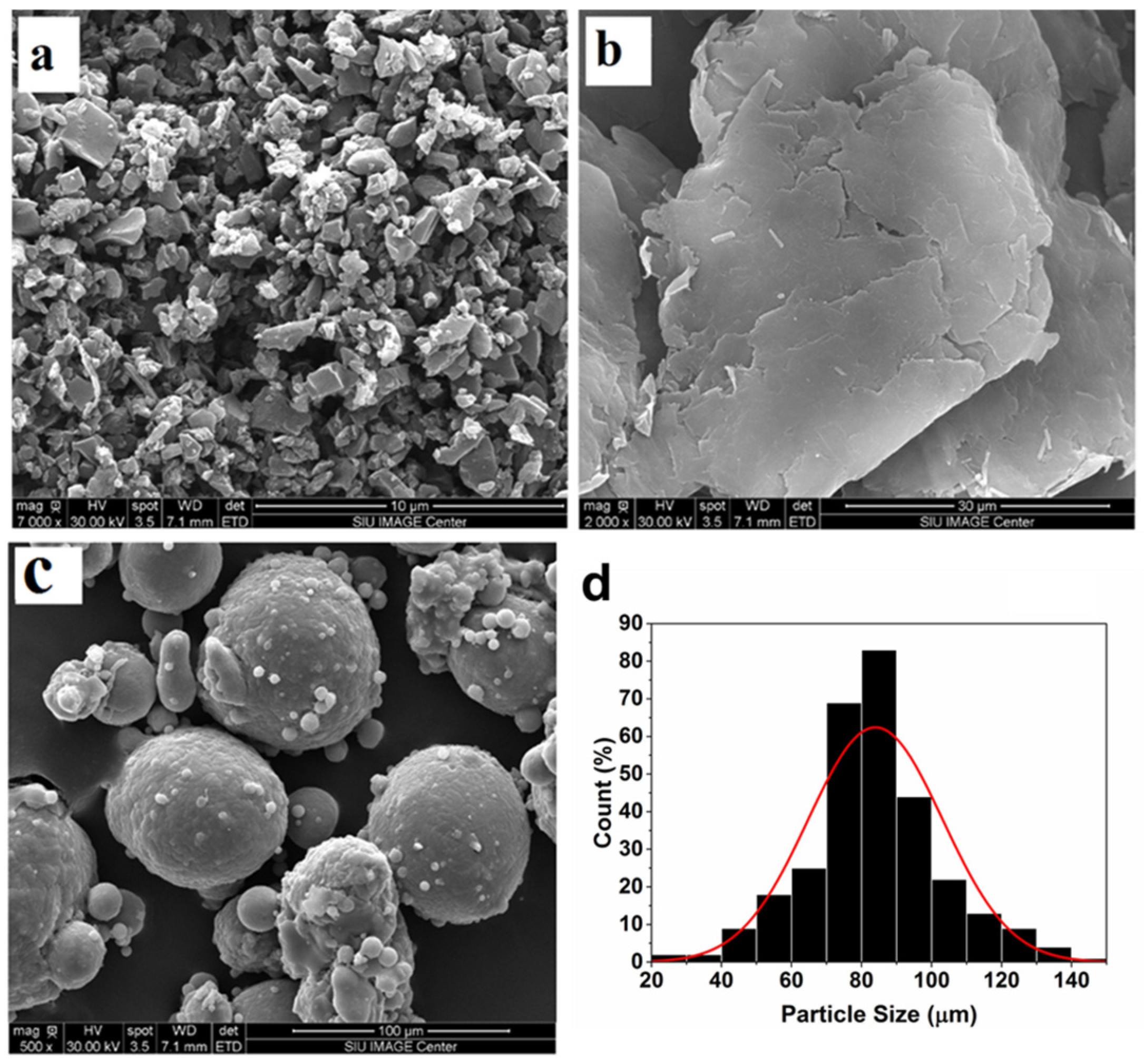

2. Materials and Methods

2.1. Composite Preparation

2.2. Structural Characterization

2.3. Computational Calculations

2.4. Mechanical Testing

3. Results and Discussion

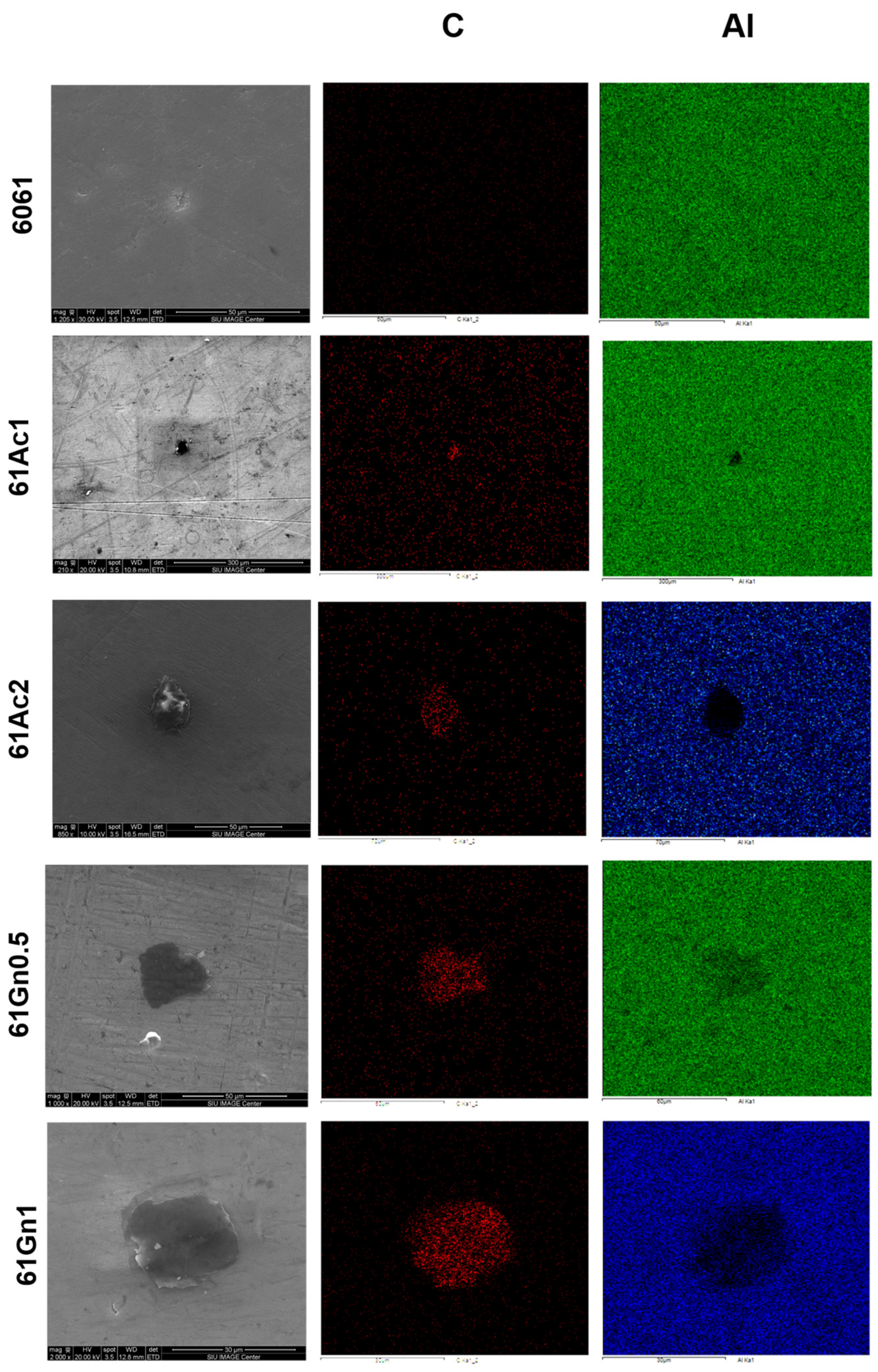

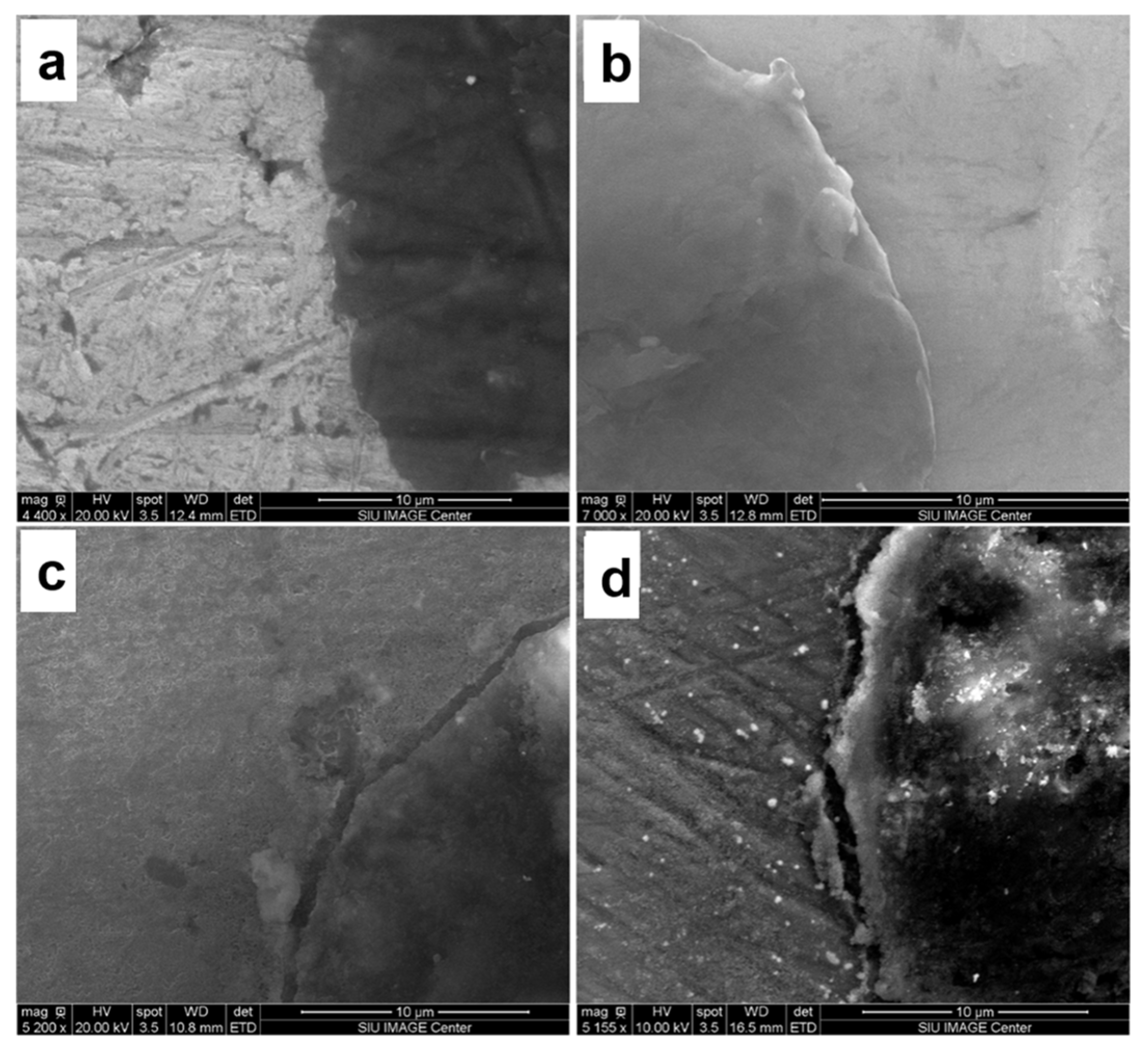

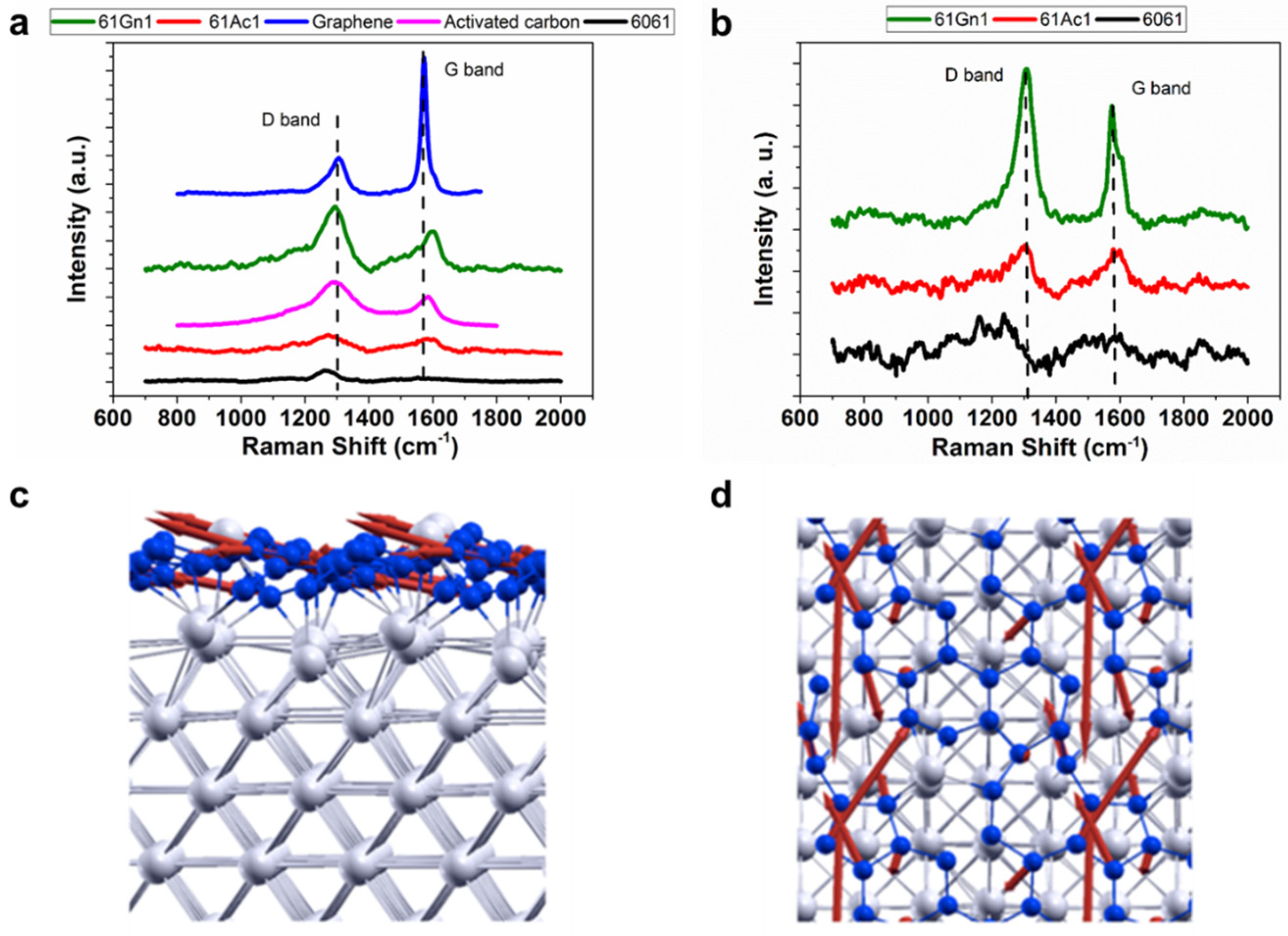

3.1. Structural Characterization

| Graphene Nanoplatelets | Activated Nanocarbon | 61Ac1 | 61Gn1 | ||

|---|---|---|---|---|---|

| Milled | ID/IG ratio | 0.26 | 1.50 | 1.65 | 1.67 |

| Crystallite Size (nm) | 345.47 | 60.43 | 71.64 | 54.94 | |

| Compacted | ID/IG ratio | - | - | 1.11 | 1.33 |

| Crystallite Size (nm) | - | - | 81.84 | 68.46 |

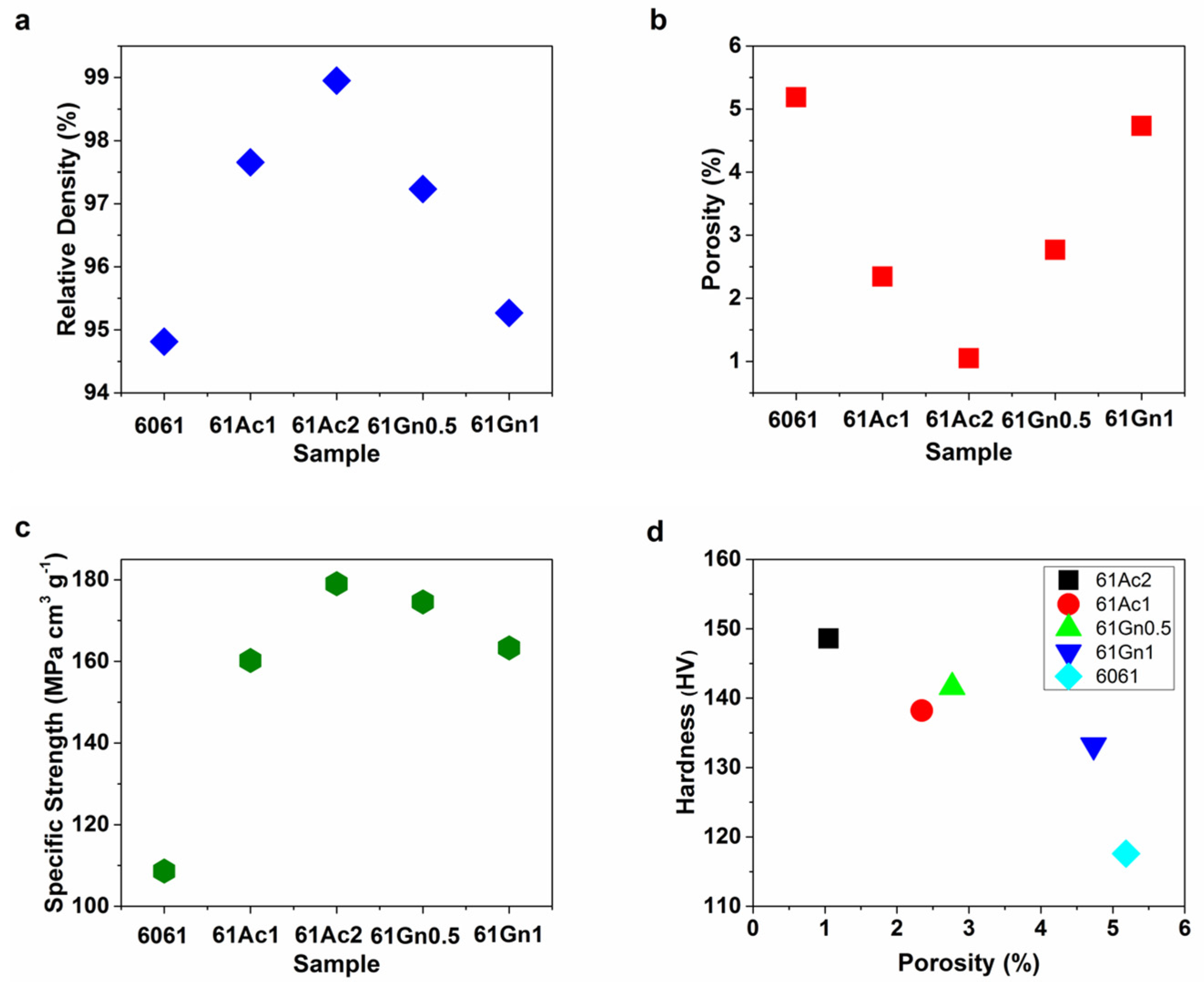

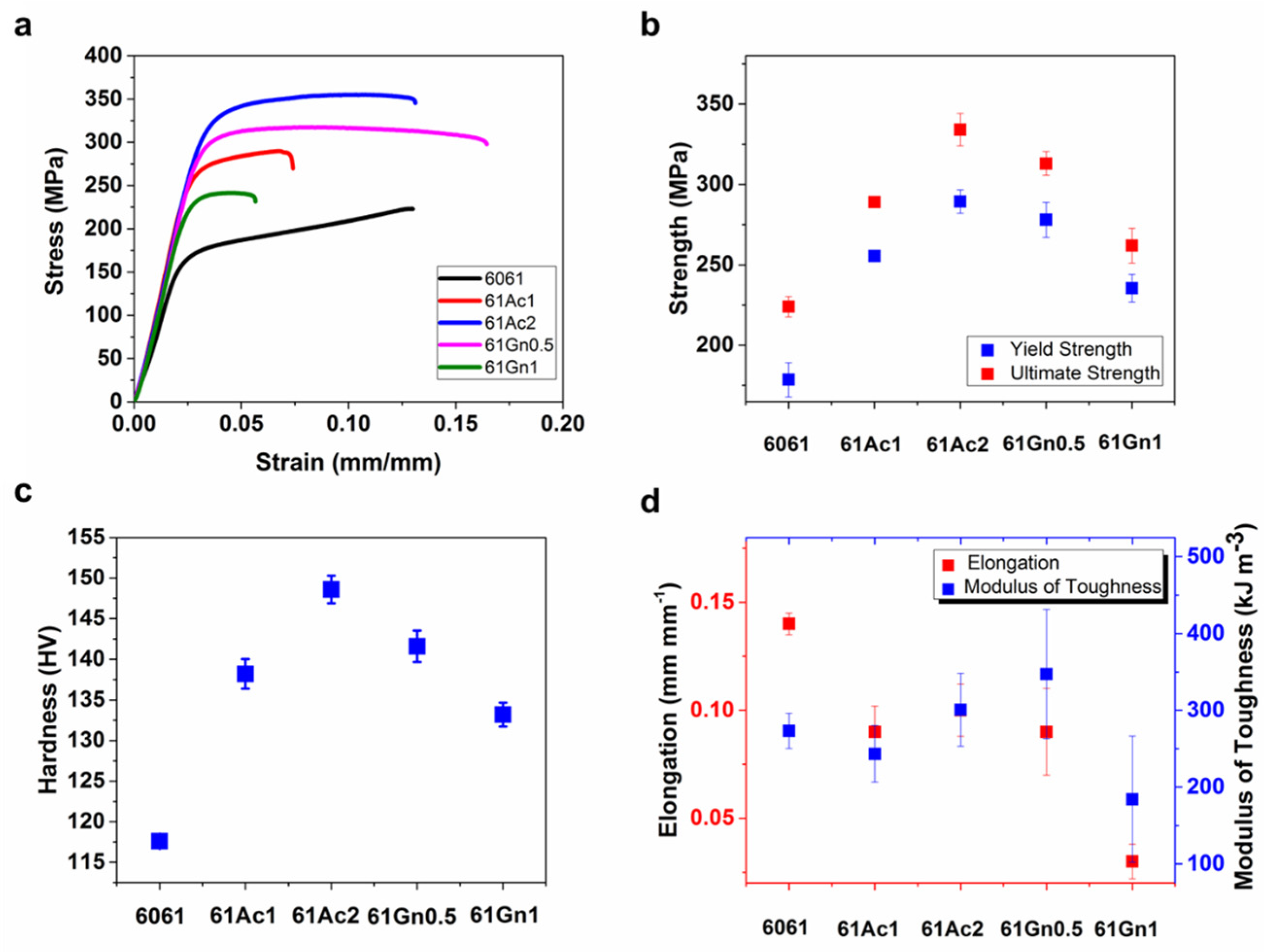

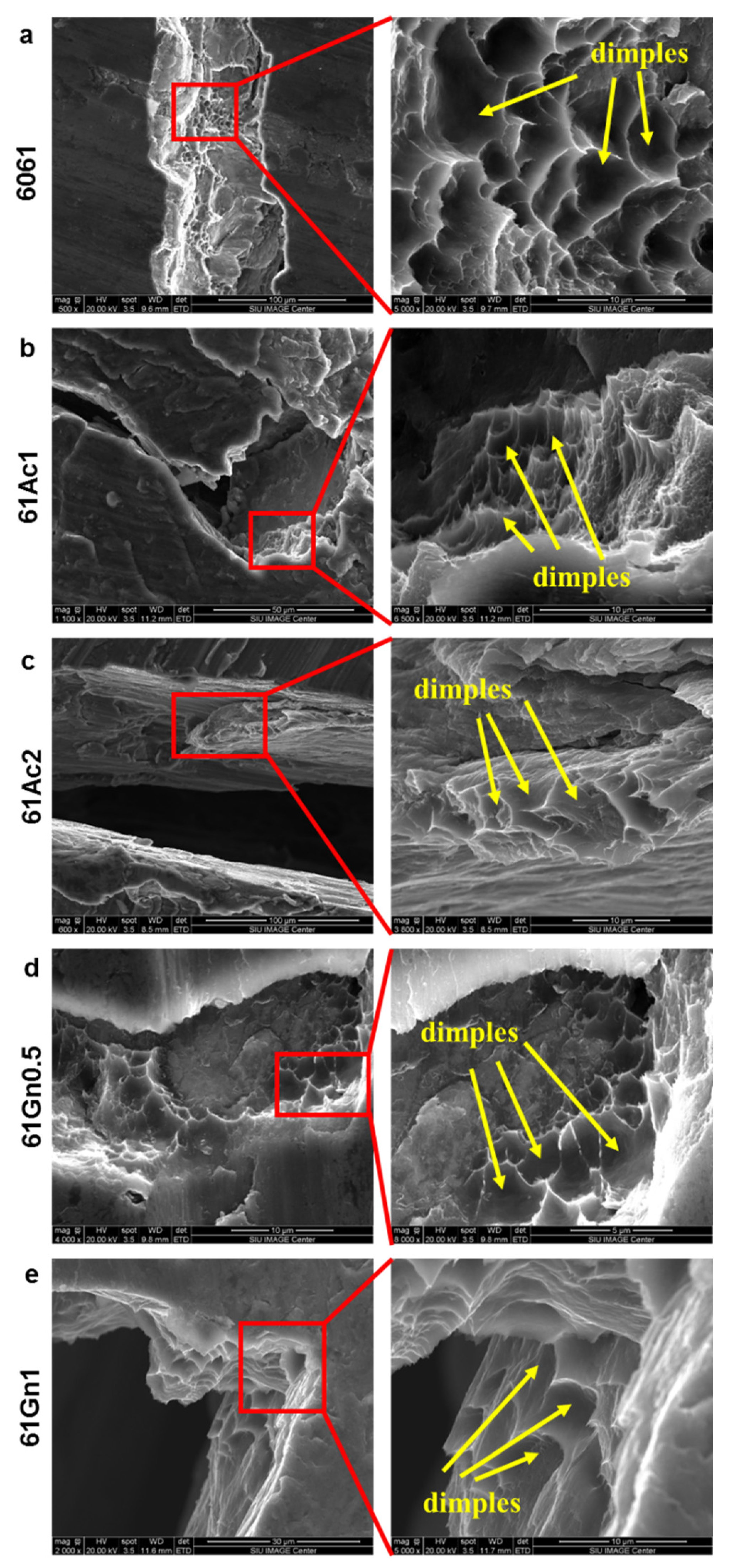

3.2. Mechanical Properties Characterization

| Sample | Hardness (HV) | % of Increment | Yield Strength (MPa) | % of Increment | Ultimate Strength (MPa) | % of Increment | Elongation (mm mm−1) | % of Increment | Modulus of Toughness (kJ m−3) | % of Increment |

|---|---|---|---|---|---|---|---|---|---|---|

| 6061 | 117.6 ± 2 | - | 178.6 ± 10 | - | 224 ± 6 | - | 0.14 ± 0.005 | - | 273.1 ± 23 | - |

| 61Ac1 | 138.2 ± 1 | 17.5 | 255.6 ± 2 | 43.0 | 289 ± 2 | 28.8 | 0.09 ± 0.01 | −33.3 | 243.1 ± 36 | −10.9 |

| 61Ac2 | 148.6 ± 1 | 26.3 | 289.3 ± 7 | 61.9 | 334 ± 10 | 49.1 | 0.10 ± 00.01 | −23.8 | 300.7 ± 47 | 10.11 |

| 61Gn0.5 | 141.6 ± 1 | 20.4 | 278 ± 10 | 55.5 | 313 ± 7 | 39.8 | 0.09 ± 0.02 | −30.9 | 347.2 ± 84 | 27.11 |

| 61Gn1 | 133.2 ± 0.8 | 13.2 | 235.5 ± 8 | 31.8 | 262 ± 10 | 17.1 | 0.03 ± 0.008 | −73.8 | 184.1 ± 82 | −32.5 |

| Sample | |||||

|---|---|---|---|---|---|

| 6061 | 61Ac1 | 61Ac2 | 61Gn0.5 | 61Gn1 | |

| Experimental Density (g cm−3) | 2.56 | 2.61 | 2.62 | 2.62 | 2.56 |

| Theoretical Density (g cm−3) | 2.70 | 2.67 | 2.65 | 2.69 | 2.69 |

| Relative Density (%) | 94.8 | 97.6 | 98.9 | 97.2 | 95.2 |

| Porosity (%) | 5.18 | 2.34 | 1.04 | 2.76 | 4.73 |

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pramanik, A. Effects of reinforcement on wear resistance of aluminum matrix composites. Trans. Nonferrous Met. Soc. China 2016, 26, 348–358. [Google Scholar] [CrossRef]

- Mousavian, R.T.; Khosroshahi, R.A.; Yazdani, S.; Brabazon, D.; Boostani, A.F. Fabrication of aluminum matrix composites reinforced with nano- to micrometer-sized SiC particles. Mater. Des. 2016, 89, 58–70. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xu, S.J.; Xiao, B.L.; Xue, P.; Wang, W.G.; Ma, Z.Y. Effect of ball-milling time on mechanical properties of carbon nanotubes reinforced aluminum matrix composites. Compos. Part A Appl. S. 2012, 43, 2161–2168. [Google Scholar] [CrossRef]

- Guo, B.S.; Song, M.; Yi, J.H.; Ni, S.; Shen, T.; Du, Y. Improving the mechanical properties of carbon nanotubes reinforced pure aluminum matrix composites by achieving non-equilibrium interface. Mater. Des. 2017, 120, 56–65. [Google Scholar] [CrossRef]

- Rativa-Parada, W.; Nilufar, S. Nanocarbon-Infused Metal Matrix Composites: A Review. JOM 2023, 75, 4009–4023. [Google Scholar] [CrossRef]

- Pan, S.H.; Wang, T.L.; Jin, K.Y.; Cai, X.R. Understanding and designing metal matrix nanocomposites with high electrical conductivity: A review. J. Mater. Sci. 2022, 57, 6487–6523. [Google Scholar] [CrossRef]

- Jiang, Y.Y.; Tan, Z.Q.; Xu, R.; Fan, G.L.; Xiong, D.B.; Guo, Q.; Su, Y.S.; Li, Z.Q.; Zhang, D. Tailoring the structure and mechanical properties of graphene nanosheet/aluminum composites by flake powder metallurgy via shift-speed ball milling. Compos. Part A Appl. Sci. Manuf. 2018, 111, 73–82. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Dora, T.L. Application of solid processing routes for the synthesis of graphene-aluminum composites—A review. Mater. Manuf. Process. 2021, 36, 1219–1235. [Google Scholar] [CrossRef]

- Zhang, L.; Hou, G.M.; Zhai, W.; Ai, Q.; Feng, J.K.; Zhang, L.; Si, P.C.; Ci, L.J. Aluminum/graphene composites with enhanced heat-dissipation properties by in-situ reduction of graphene oxide on aluminum particles. J. Alloys Compd. 2018, 748, 854–860. [Google Scholar] [CrossRef]

- Yan, S.J.; Dai, S.L.; Zhang, X.Y.; Yang, C.; Hong, Q.H.; Chen, J.Z.; Lin, Z.M. Investigating aluminum alloy reinforced by graphene nanoflakes. Mat. Sci. Eng. A 2014, 612, 440–444. [Google Scholar] [CrossRef]

- Xiong, B.W.; Liu, K.; Xiong, W.; Wu, X.; Sun, J.Y. Strengthening effect induced by interfacial reaction in graphene nanoplatelets reinforced aluminum matrix composites. J. Alloys Compd. 2020, 845, 156282. [Google Scholar] [CrossRef]

- Zhang, H.P.; Xu, C.; Xiao, W.L.; Ameyama, K.; Ma, C.L. Enhanced mechanical properties of Al5083 alloy with graphene nanoplates prepared by ball milling and hot extrusion. Mater. Sci. Eng. A 2016, 658, 8–15. [Google Scholar] [CrossRef]

- Saboori, A.; Novara, C.; Pavese, M.; Badini, C.; Giorgis, F.; Fino, P. An Investigation on the Sinterability and the Compaction Behavior of Aluminum/Graphene Nanoplatelets (GNPs) Prepared by Powder Metallurgy. J. Mater. Eng. Perform. 2017, 26, 993–999. [Google Scholar] [CrossRef]

- Zare, R.; Sharifi, H.; Saeri, M.R.; Tayebi, M. Investigating the effect of SiC particles on the physical and thermal properties of Al6061/SiCp composite. J. Alloys Compd. 2019, 801, 520–528. [Google Scholar] [CrossRef]

- Jeyasimman, D.; Sivaprasad, K.; Sivasankaran, S.; Ponalagusamy, R.; Narayanasamy, R.; Iyer, V. Microstructural observation, consolidation and mechanical behaviour of AA 6061 nanocomposites reinforced by gamma-Al2O3 nanoparticles. Adv. Powder Technol. 2015, 26, 139–148. [Google Scholar] [CrossRef]

- Zheng, T.Q.; Pan, S.H.; Liu, J.K.; Moodispaw, M.; Luo, A.A.; Taub, A.I.; Li, X.C. Study on nano-treating of Al-Mg-Si-Cu alloys with TiC nanoparticles. J. Alloys Compd. 2023, 947, 169405. [Google Scholar] [CrossRef]

- Fuse, K.; Badheka, V.; Patel, V.; Andersson, J. Dual sided composite formation in Al 6061/B4C using novel bobbin tool friction stir processing. J. Mater. Res. Technol. 2021, 13, 1709–1721. [Google Scholar] [CrossRef]

- Desai, A.M.; Paul, T.R.; Mallik, M. Mechanical properties and wear behavior of fly ash particle reinforced Al matrix composites. Mater. Res. Express 2020, 7, 016595. [Google Scholar] [CrossRef]

- Pazhouhanfar, Y.; Eghbali, B. Microstructural characterization and mechanical properties of TiB2 reinforced Al6061 matrix composites produced using stir casting process. Mater. Sci. Eng. A 2018, 710, 172–180. [Google Scholar] [CrossRef]

- Chamroune, N.; Mereib, D.; Delange, F.; Caillault, N.; Lu, Y.F.; Grosseau-Poussard, J.L.; Silvain, J.F. Effect of flake powder metallurgy on thermal conductivity of graphite flakes reinforced aluminum matrix composites. J. Mater. Sci. 2018, 53, 8180–8192. [Google Scholar] [CrossRef]

- Huang, Y.; Ouyang, Q.B.; Zhang, D.; Zhu, J.; Li, R.X.; Yu, H. Carbon Materials Reinforced Aluminum Composites: A Review. Acta Metall. Sin. Engl. 2014, 27, 775–786. [Google Scholar] [CrossRef]

- Mohammed, S.M.A.K.; Chen, D.L.L. Carbon Nanotube-Reinforced Aluminum Matrix Composites. Adv. Eng. Mater. 2020, 22, 1901176. [Google Scholar] [CrossRef]

- Kumar, P.A.; Namboodiri, V.V.; Joshi, G.; Mehta, K.P. Fabrication and applications of fullerene-based metal nanocomposites: A review. J. Mater. Res. 2021, 36, 114–128. [Google Scholar]

- Su, J.L.; Teng, J. Recent progress in graphene-reinforced aluminum matrix composites. Front. Mater. Sci. 2021, 15, 79–97. [Google Scholar] [CrossRef]

- Akinwande, D.; Brennan, C.J.; Bunch, J.S.; Egberts, P.; Felts, J.R.; Gao, H.J.; Huang, R.; Kim, J.S.; Li, T.; Li, Y.; et al. A review on mechanics and mechanical properties of 2D materials-Graphene and beyond. Extreme Mech. Lett. 2017, 13, 42–77. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Vicarelli, L.; Heerema, S.J.; Dekker, C.; Zandbergen, H.W. Controlling Defects in Graphene for Optimizing the Electrical Properties of Graphene Nanodevices. ACS Nano 2015, 9, 3428–3435. [Google Scholar] [CrossRef]

- Pop, E.; Varshney, V.; Roy, A.K. Thermal properties of graphene: Fundamentals and applications. MRS Bull. 2012, 37, 1273–1281. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Sahoo, S.; Wang, N.; Huczko, A. Graphene research and their outputs: Status and prospect. J. Sci. Adv. Mater. Dev. 2020, 5, 10–29. [Google Scholar] [CrossRef]

- Xie, Y.M.; Meng, X.C.; Mao, D.X.; Qin, Z.W.; Wan, L.; Huang, Y.X. Homogeneously Dispersed Graphene Nanoplatelets as Long-Term Corrosion Inhibitors for Aluminum Matrix Composites. ACS Appl. Mater. Interfaces 2021, 13, 32161–32174. [Google Scholar] [CrossRef]

- Chen, F.; Gupta, N.; Behera, R.K.; Rohatgi, P.K. Graphene-Reinforced Aluminum Matrix Composites: A Review of Synthesis Methods and Properties. JOM 2018, 70, 837–845. [Google Scholar] [CrossRef]

- Fleker, O.; Borenstein, A.; Lavi, R.; Benisvy, L.; Ruthstein, S.; Aurbach, D. Preparation and Properties of Metal Organic Framework/Activated Carbon Composite Materials. Langmuir 2016, 32, 4935–4944. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Lai, M.O.; Yeo, J.L. In situ synthesis of TiC composite for structural application. Compos. Struct. 1999, 47, 613–618. [Google Scholar] [CrossRef]

- Ge, X.; Klingshirn, C.; Morales, M.; Wuttig, M.; Rabin, O.; Zhang, S.; Salamanca-Riba, L.G. Electrical and structural characterization of nano-carbon–aluminum composites fabricated by electro-charging-assisted process. Carbon 2021, 173, 115–125. [Google Scholar] [CrossRef]

- Eisay, A.M.S.; Turkyilmaz, A. Production of Aluminum Matrix Composite Material by Active Carbon Additive. J. Inorg. Organomet. Polym. Mater. 2021, 31, 4025–4032. [Google Scholar] [CrossRef]

- Jaim, H.I.; Isaacs, R.A.; Rashkeev, S.N.; Kuklja, M.; Cole, D.P.; LeMieux, M.C.; Jasiuk, I.; Nilufar, S.; Salamanca-Riba, L.G. Sp2 carbon embedded in Al-6061 and Al-7075 alloys in the form of crystalline graphene nanoribbons. Carbon 2016, 107, 56–66. [Google Scholar] [CrossRef]

- Giannozzi, P.; Baroni, S.; Bonini, N.; Calandra, M.; Car, R.; Cavazzoni, C.; Ceresoli, D.; Chiarotti, G.L.; Cococcioni, M.; Dabo, I.; et al. QUANTUM ESPRESSO: A modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter. 2009, 21, 395502. [Google Scholar] [CrossRef]

- ASTM E384; Standard Test Method for Knoop and Vickers Hardness of Materials. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM E9; Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. ASTM: West Conshohocken, PA, USA, 2018.

- Gao, X.; Yue, H.Y.; Guo, E.J.; Zhang, H.; Lin, X.Y.; Yao, L.H.; Wang, B. Preparation and tensile properties of homogeneously dispersed graphene reinforced aluminum matrix composites. Mater. Des. 2016, 94, 54–60. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Kumar, A.; Omrani, E.; Kim, C.; Rohatgi, P. Synthesis, characterization, and properties of graphene reinforced metal-matrix nanocomposites. Compos. B Eng. 2020, 183, 107664. [Google Scholar] [CrossRef]

- Bisht, A.; Srivastava, M.; Kumar, R.M.; Lahiri, I.; Lahiri, D. Strengthening mechanism in graphene nanoplatelets reinforced aluminum composite fabricated through spark plasma sintering. Mater. Sci. Eng. A 2017, 695, 20–28. [Google Scholar] [CrossRef]

- Hu, Z.R.; Chen, F.; Xu, J.L.; Nian, Q.; Lin, D.; Chen, C.J.; Zhu, X.; Chen, Y.; Zhang, M. 3D printing graphene-aluminum nanocomposites. J. Alloys Compd. 2018, 746, 269–276. [Google Scholar] [CrossRef]

- Popov, M.; Medvedev, V.; Blank, V.; Denisov, V.; Kirichenko, A.; Tat’yanin, E.; Aksenenkov, V.; Perfilov, S.; Lomakin, R.; D’yakov, E.; et al. Fulleride of aluminum nanoclusters. J. Appl. Phys. 2010, 108, 094317. [Google Scholar] [CrossRef]

- Perez-Bustamante, R.; Bolanos-Morales, D.; Bonilla-Martinez, J.; Estrada-Guel, I.; Martinez-Sanchez, R. Microstructural and hardness behavior of graphene-nanoplatelets/aluminum composites synthesized by mechanical alloying. J. Alloys Compd. 2014, 615, S578–S582. [Google Scholar] [CrossRef]

- Bastwros, M.; Kim, G.Y.; Zhu, C.; Zhang, K.; Wang, S.R.; Tang, X.D.; Wang, X.W. Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos. B Eng. 2014, 60, 111–118. [Google Scholar] [CrossRef]

- Cancado, L.G.; Takai, K.; Enoki, T.; Endo, M.; Kim, Y.A.; Mizusaki, H.; Jorio, A.; Coelho, L.N.; Magalhaes-Paniago, R.; Pimenta, M.A. General equation for the determination of the crystallite size L-a of nanographite by Raman spectroscopy. Appl. Phys. Lett. 2006, 88, 163106. [Google Scholar] [CrossRef]

- Sirikumara, H.I.; Rativa-Parada, W.; Karunanithy, R.; Sivakumar, P.; Nilufar, S.; Jayasekera, T. Atomic composition/configuration dependent bulk moduli of Al-C composites. AIP Adv. 2022, 12, 115008. [Google Scholar] [CrossRef]

- Pan, S.H.; Yuan, J.; Zheng, T.Q.; She, Z.Y.; Li, X.C. Interfacial thermal conductance of in situ aluminum-matrix nanocomposites. J. Mater. Sci. 2021, 56, 13646–13658. [Google Scholar] [CrossRef]

- Shin, S.E.; Bae, D.H. Deformation behavior of aluminum alloy matrix composites reinforced with few-layer graphene. Compos. Part A Appl. Sci. Manuf. 2015, 78, 42–47. [Google Scholar] [CrossRef]

- Wang, J.Y.; Li, Z.Q.; Fan, G.L.; Pan, H.H.; Chen, Z.X.; Zhang, D. Reinforcement with graphene nanosheets in aluminum matrix composites. Scr. Mater. 2012, 66, 594–597. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.S.; Tang, A.T.; Asif, M. Effect of Graphene Nanoplatelets addition on mechanical properties of pure aluminum using a semi-powder method. Prog. Nat. Sci. Mater. 2014, 24, 101–108. [Google Scholar] [CrossRef]

- Ramadan, S.; Taha, M.A.; El-Meligy, W.M.; Saudi, H.A.; Zawrah, M.F. Influence of Graphene Content on Sinterability and Physico-Mechanical Characteristics of Al/Graphene Composites Prepared via Powder Metallurgy. Biointerface Res. Appl. Chem. 2023, 13, 192. [Google Scholar]

- Gurbuz, M.; Senel, M.C.; Koc, E. The effect of sintering time, temperature, and graphene addition on the hardness and microstructure of aluminum composites. J. Compos. Mater. 2018, 52, 553–563. [Google Scholar] [CrossRef]

- Huang, C.Y.; Hu, S.P.; Chen, K. Influence of rolling temperature on the interfaces and mechanical performance of graphene-reinforced aluminum-matrix composites. Int. J. Miner. Met. Mater. 2019, 26, 752–759. [Google Scholar] [CrossRef]

- Lazarova, R.; Mourjeva, Y.; Petkov, V.; Anestiev, L.; Marinov, M.; Dimitrova, R.; Shuleva, D. Microstructure and Mechanical Properties of Aluminum: Graphene Composites Produced by Powder Metallurgical Method. J. Mater. Eng. Perform. 2022, 31, 10162–10170. [Google Scholar] [CrossRef]

- Turan, M.E. Investigation of mechanical properties of carbonaceous (MWCNT, GNPs and C60) reinforced hot-extruded aluminum matrix composites. J. Alloys Compd. 2019, 788, 352–360. [Google Scholar] [CrossRef]

- Shin, S.E.; Choi, H.J.; Shin, J.H.; Bae, D.H. Strengthening behavior of few-layered graphene/aluminum composites. Carbon 2015, 82, 143–151. [Google Scholar] [CrossRef]

- Tian, W.-M.; Li, S.-M.; Wang, B.; Chen, X.; Liu, J.-H.; Yu, M. Graphene-reinforced aluminum matrix composites prepared by spark plasma sintering. Int. J. Miner. Metall. Mater. 2016, 23, 723–729. [Google Scholar] [CrossRef]

- El-Ghazaly, A.; Anis, G.; Salem, H.G. Effect of graphene addition on the mechanical and tribological behavior of nanostructured AA2124 self-lubricating metal matrix composite. Compos. Part A Appl. Sci. Manuf. 2017, 95, 325–336. [Google Scholar] [CrossRef]

- Garg, P.; Jamwal, A.; Kumar, D.; Sadasivuni, K.K.; Hussain, C.M.; Gupta, P. Advance research progresses in aluminium matrix composites: Manufacturing & applications. J. Mater. Res. Technol. 2019, 8, 4924–4939. [Google Scholar]

- Zeng, M.; Chen, H.M.; Tao, X.M.; Ouyang, Y.F. Mechanical Property and Corrosion Behavior of Powder-Metallurgy-Processed 3D Graphene-Networks-Reinforced Al Matrix Composites. Crystals 2023, 13, 485. [Google Scholar] [CrossRef]

- Singh, J.; Chauhan, A. Characterization of hybrid aluminum matrix composites for advanced applications—A review. J. Mater. Res. Technol. 2016, 5, 159–169. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shabani, A. Carbon nanotube reinforced aluminum matrix composites produced by spark plasma sintering. J. Mater. Sci. 2017, 52, 8618–8629. [Google Scholar] [CrossRef]

- Zare, H.; Jahedi, M.; Toroghinejad, M.R.; Meratian, M.; Knezevic, M. Microstructure and mechanical properties of carbon nanotubes reinforced aluminum matrix composites synthesized via equal-channel angular pressing. Mater. Sci. Eng. A 2016, 670, 205–216. [Google Scholar] [CrossRef]

- Khan, M.; Amjad, M.; Khan, A.; Ud-Din, R.; Ahmad, I.; Subhani, T. Microstructural evolution, mechanical profile, and fracture morphology of aluminum matrix composites containing graphene nanoplatelets. J. Mater. Res. 2017, 32, 2055–2066. [Google Scholar] [CrossRef]

- El-Daly, A.A.; Abdelhameed, M.; Hashish, M.; Daoush, W.M. Fabrication of silicon carbide reinforced aluminum matrix nanocomposites and characterization of its mechanical properties using non-destructive technique. Mater. Sci. Eng. A 2013, 559, 384–393. [Google Scholar] [CrossRef]

- Kumar, K.R.; Kiran, K.; Sreebalaji, V.S. Micro structural characteristics and mechanical behaviour of aluminium matrix composites reinforced with titanium carbide. J. Alloys Compd. 2017, 723, 795–801. [Google Scholar] [CrossRef]

- Xiong, B.W.; Liu, K.; Yan, Q.S.; Xiong, W.; Wu, X. Microstructure and mechanical properties of graphene nanoplatelets reinforced Al matrix composites fabricated by spark plasma sintering. J. Alloys Compd. 2020, 837, 155495. [Google Scholar] [CrossRef]

- Liu, Q.; Ke, L.M.; Liu, F.C.; Huang, C.P.; Xing, L. Microstructure and mechanical property of multi-walled carbon nanotubes reinforced aluminum matrix composites fabricated by friction stir processing. Mater. Des. 2013, 45, 343–348. [Google Scholar] [CrossRef]

- Lou, S.M.; Li, Y.M.; Cheng, B.J.; Ran, L.W.; Bai, X.F.; Chen, P.; Wang, Q.B. Microstructural and Mechanical Properties of Longitudinal Welds in Porthole Die Extrudates of a 0.5 wt.% GNP/Al Composite. Metals 2023, 13, 522. [Google Scholar] [CrossRef]

- Shin, S.E.; Choi, H.J.; Hwang, J.Y.; Bae, D.H. Strengthening behavior of carbon/metal nanocomposites. Sci. Rep. 2015, 5, 16114. [Google Scholar] [CrossRef]

| Denomination | Description |

|---|---|

| 6061 | 6061 aluminum without any reinforcement |

| 61Ac1 | 6061 aluminum reinforced with 1 vol. % of activated nanocarbon |

| 61Ac2 | 6061 aluminum reinforced with 2 vol. % of activated nanocarbon |

| 61Gn0.5 | 6061 aluminum reinforced with 0.5 vol. % of graphene nanoplatelets |

| 61Gn1 | 6061 aluminum reinforced with 1 vol. % of graphene nanoplatelets |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rativa-Parada, W.; Sirikumara, H.I.; Karunanithy, R.; Sivakumar, P.; Jayasekera, T.; Nilufar, S. Effect of Nanocarbon on the Structural and Mechanical Properties of 6061 Aluminum Composites by Powder Metallurgy. Nanomaterials 2023, 13, 2917. https://doi.org/10.3390/nano13222917

Rativa-Parada W, Sirikumara HI, Karunanithy R, Sivakumar P, Jayasekera T, Nilufar S. Effect of Nanocarbon on the Structural and Mechanical Properties of 6061 Aluminum Composites by Powder Metallurgy. Nanomaterials. 2023; 13(22):2917. https://doi.org/10.3390/nano13222917

Chicago/Turabian StyleRativa-Parada, Wilson, Hansika I. Sirikumara, Robinson Karunanithy, Poopalasingam Sivakumar, Thushari Jayasekera, and Sabrina Nilufar. 2023. "Effect of Nanocarbon on the Structural and Mechanical Properties of 6061 Aluminum Composites by Powder Metallurgy" Nanomaterials 13, no. 22: 2917. https://doi.org/10.3390/nano13222917

APA StyleRativa-Parada, W., Sirikumara, H. I., Karunanithy, R., Sivakumar, P., Jayasekera, T., & Nilufar, S. (2023). Effect of Nanocarbon on the Structural and Mechanical Properties of 6061 Aluminum Composites by Powder Metallurgy. Nanomaterials, 13(22), 2917. https://doi.org/10.3390/nano13222917