Abstract

The advancement of floating offshore wind energy demands innovative and robust mooring and shared infrastructure solutions to enable scalable, cost-effective deployment of future wind farms. This review provides a comprehensive overview of shared mooring systems for floating offshore wind applications, with a focus on system configurations, environmental load considerations, modelling methods and mooring cost estimations. Existing concepts of shared mooring and shared anchoring are summarized and discussed. Drawing on insights from numerical studies, industrial practices, and academic research, the paper identifies key technical challenges and gaps in current design methodologies, validation requirements, and regulatory frameworks. Recommendations are proposed to guide future research aimed at improving system reliability, optimizing mooring layouts, and lowering the levelized cost of energy for large-scale floating wind projects.

1. Introduction

Offshore wind energy has experienced significant growth in recent years, driven by increasing installed capacity and technological advancements. By 2023, global offshore wind capacity had reached 68,258 MW, distributed across 319 operational projects and more than 13,096 turbines. This represented a 10.2% increase compared to the previous year, alongside a substantial expansion of projects under construction, which grew by 64% compared to 2022. Within this landscape, floating offshore wind turbines (FOWTs) still account for a small share of the installed capacity, with a total of 234 MW operational in 2023. However, this represents a 91% increase compared to 2022 [1], boosted by pilot projects such as the 88-MW Hywind Tampen in Norway [2], the 50-MW Kincardine Offshore Wind Farm in Scotland, and the 25-MW WindFloat Atlantic project in Portugal [3]. The approximately 110 MW installed throughout 2023 represents just 1.75% of the total new capacity added that year, highlighting the need for further advancements to accelerate the adoption of this technology.

Despite the current relatively low share of FOWTs, the trend toward expanding into deeper waters is evident in the large number of projects in the pipeline. An estimated 240 GW of offshore wind capacity is planned for installation in the coming years, with approximately 37% corresponding to floating systems. By 2029, cumulative installed FOWT capacity could reach 14,186 MW, according to developer-announced timelines [1]. However, technical and economic challenges still hinder the large-scale commercialization of this technology, particularly due to high capital (CAPEX) and operational (OPEX) expenditures. Currently, the levelized cost of energy (LCOE) for floating wind turbines is more than twice that of fixed-bottom structures, reaching approximately 290 USD/MWh compared to 133 USD/MWh [4]. These factors underscore the need for engineering advancements and cost reductions to make floating offshore wind energy competitive on a large scale.

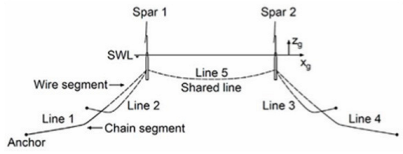

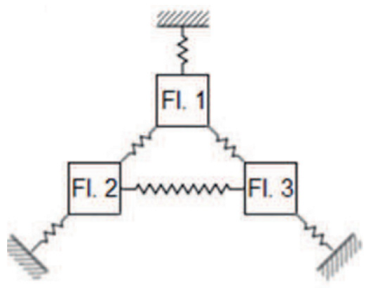

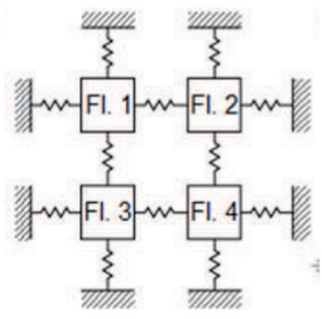

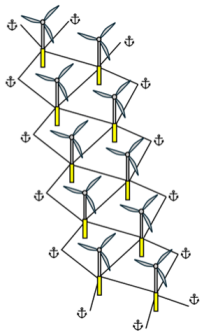

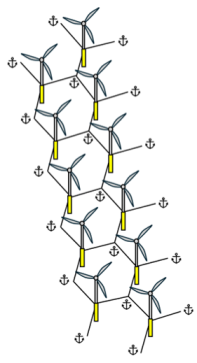

One innovative approach gaining attention is the use of shared mooring lines. This system connects multiple turbines using a common set of mooring lines, optimizing load distribution and reducing the number of required anchors and lines. The shared configuration not only reduces installation and maintenance costs but also improves overall system efficiency. Additionally, this setup can enhance the redundancy of the system, providing increased reliability in the event of a line failure.

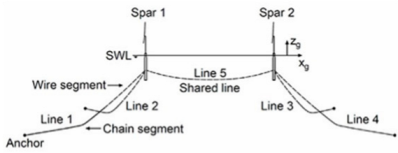

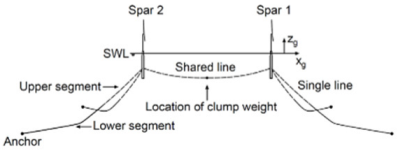

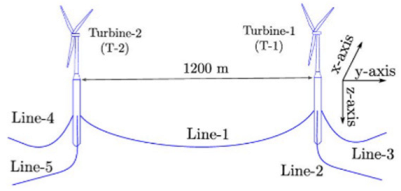

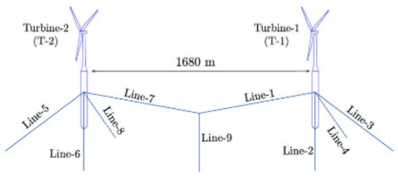

However, the use of shared mooring introduces complexity to the system’s dynamics by creating couplings between turbines, requiring research to develop efficient and safe configurations. Several studies have explored both the design and dynamic behaviour of shared mooring systems for floating offshore wind farms (FOWFs). Goldschmidt and Muskulus [5] analyzed different array layouts, including linear, triangular, and rectangular configurations, while Connolly and Hall [6] used a quasi-static model to assess cost savings across varying water depths, finding significant benefits beyond 400 m. Liang et al. [7] conducted a static analysis for the shared mooring system for a dual-spar configuration, employing the elastic catenary theory for cable structures. Regarding system dynamics, Liang et al. [8] studied a dual-spar configuration with a shared mooring line, revealing increased horizontal motions and load fluctuations, including sudden tension spikes that could compromise structural integrity, while more recent work has expanded to comparisons of different shared mooring systems and various wind farm layouts by Biroli et al. [9,10]. Zhang and Liu [11] performed coupled dynamic analyses on floating wind farms with shared mooring under complex conditions, considering hydrodynamic and structural coupling. The dynamic responses after the failure of mooring lines were investigated as well. Experimental tests by Lopez-Olocco et al. [12] validated these numerical analyses. Later, Liang et al. [13] demonstrated that implementing clump weights reduced oscillations and mitigated high-tension events. Gözcü et al. [14] examined shared line length effects in spar platforms with vertical lines and buoys, showing that proper adjustments could allow turbines to perform similarly to single-turbine systems. Sauder [15] conducted a frequency-domain analysis of a square floating wind farm, highlighting the need to carefully assess damping and resonance effects to avoid inaccurate load estimations and potential resonances. Regarding larger farms, Lozon and Hall [16] investigated the dynamics and potential failures of a wind farm consisting of two rows with five 10 MW Spar-type platforms, using shared lines and anchors. The results showed that the system was not at risk of cascading failures, demonstrating favourable characteristics compared to conventional designs.

Regarding shared anchor, despite the potential benefits, they introduce additional challenges related to the multidirectional and cyclic loads experienced by mooring anchors, as highlighted in studies by Lovera et al. [17] and Coughlan et al. [18]. B. D. Diaz et al. [19] showed that axially symmetric anchors, such as driven piles and suction caissons, can be adapted for multiline moorings, whereas plate-type anchors require intermediate load rings to distribute forces. Pile-driven and dynamically installed anchors offer versatility across different soil conditions, while drag embedded anchors are limited to horizontal loads, restricting their use in taut or shared-anchor setups. Complementing these findings, Stevenson [20] highlighted that suction buckets, driven and grouted piles, torpedo anchors, as well as newer solutions like Helical Anchors and JAVELIN, can sustain loads in multiple directions, making them suitable for complex shared mooring layouts.

The implementation of shared anchor systems in floating offshore wind farms remains limited. Hywind Tampen, developed by Equinor in Norway, is the world’s first floating wind farm designed to supply electricity to offshore oil and gas facilities. Located in the North Sea, approximately 140 km off the Norwegian coast, it consists of 11 spar platforms with a shared anchor system, where the turbines are interconnected through a common mooring arrangement [2]. The COREWIND project [21] explored shared mooring and anchor concepts for FOWFs at two sites. Shared mooring lines demonstrated significant cost reductions, while shared anchors lowered anchor costs but, in some configurations, increased overall expenses or tensions on mooring lines.

There have been a few reviews on the shared mooring/anchor systems for offshore renewable energy systems [22,23,24,25]. Xu et al. [22] reviewed the shared mooring wind farm layout and optimization method, focusing on the dynamic analysis method and the bearing characteristics of shared anchors. Jiang [23] focused on the design of mooring systems for floating wind turbines, addressing key aspects such as floater-mooring interactions, material and component selection, design methods and guidelines. Saincher et al. [24] presents a comprehensive review of shared moorings/anchors within the floating offshore renewable energy (FORE) sector, including the floating wind, solar and wave energy sectors. While the review of Paduano [25] put emphasis on anchor-soil interactions and nonlinearity in mooring system design.

The ESOMOOR project aims to significantly advance the mooring technologies for large-scale FOWFs, substantially lower the Levelized Cost of Energy (LCOE) of FOWTs while optimizing energy conversion efficiency [26] by considering innovative shared mooring design with synthetic ropes. To support the identification of suitable floaters, mooring configurations and materials, this paper reviews key design aspects relevant to shared-mooring concepts. It summarizes relevant shared-mooring concepts and applications, outlining major design parameters such as platform type, mooring layout and materials, loading conditions and modelling tools. Finally, a cost analysis highlights strategies for reducing mooring-system capital costs and identifies the key cost drivers in shared-mooring configurations.

4. Modelling Methods and Simplifications

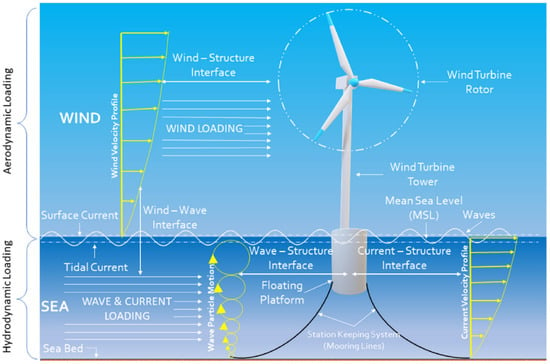

The modelling of floating offshore wind turbines involves a wide range of coupled aero-hydro-servo-elastic phenomena. These include the interaction between the rotor–nacelle assembly and the floating substructure, as well as, in multi-unit configurations, the dynamic coupling among turbines connected through a shared mooring network [22]. Numerical tools play a crucial role in analyzing these mechanisms, and the literature offers a variety of modelling approaches, from simplified low-fidelity schemes in frequency domain, mid-fidelity tools, to fully coupled high-fidelity simulations for FOWTs. Table 3 summarizes the fidelity levels of some commonly employed methods.

Table 3.

Fidelity of common methods used in floating wind turbine analysis. Reproduced from [56].

Low-fidelity models are mainly used in the earliest design stages, when fast evaluations of system behaviour, parameter sensitivity, and feasibility are required. They often rely on linearized or quasi-static representations of the mooring system, in which the line is assumed to instantaneously reach a new equilibrium as the floater moves. Quasi-static approaches employ catenary equations to update line geometry, capturing geometric nonlinearity while neglecting inertia and damping. This method, commonly implemented in tools such as MoorPy, is computationally efficient and suitable for early optimization. However, it cannot represent key dynamic effects such as damping, inertia forces, or snap loads, and its applicability is limited in energetic seas or highly nonlinear conditions [56,57]. To bridge this gap, quasi-dynamic formulations introduce drag and inertia forces in an approximate manner, often through reduced-order or Morison models, offering improved physical realism with modest computational cost [57].

As the design advances, mid-fidelity engineering tools become the preferred option. Software such as OpenFAST, HAWC2, SIMA, Bladed, SIMPACK, Orcaflex, and Flexcom enables time-domain simulations of the fully coupled aero-hydro-servo-elastic response of FOWTs, capturing nonlinear interactions with reasonable computational efficiency [22,56,58]. These tools combine aerodynamic solvers, structural models, hydrodynamic modules based on potential-flow or Morison-type formulations, and mooring solvers. They typically require hydrodynamic coefficients precomputed from frequency-domain radiation–diffraction analyses [56]. Mid-fidelity tools are widely used for operational and extreme-load simulations, fatigue assessment, and evaluation of turbine–platform interaction effects.

Methods based on potential flow and BEM often fail to capture nonlinear interactions among these forces. This has driven the adoption of high-fidelity CFD and FEM frameworks, which can resolve the coupled aero-hydro-structural physics with more accuracy [59]. These tools usually refer to CFD and structural FEM codes including OpenFOAM, STAR-CCM+, ANSYS, and Abaqus, which can represent strongly nonlinear and fully dynamic behaviour with high spatial and temporal resolution [56,60]. However, their computational cost is high, particularly for multi-floater or large farm simulations, which limits their use to final design verification, failure-mode analyses, or calibrating lower-fidelity models. When it comes to the shared mooring system, the modelling is more complex and time consuming.

Studies focusing specifically on shared mooring configurations adopt modelling approaches that differ substantially in scope and fidelity. Reference [5] models the dynamic behaviour of shared-moored floaters using rigid-body equations of motion. In the frequency domain, the mooring system is represented by a linearized stiffness matrix. In the time domain, a quasi-static catenary mooring model is coupled to the hydrodynamic solver. First-order wave loads are evaluated using the Morison equation, while diffraction effects are approximated with the McCamy–Fuchs method. Second-order mean and slow-drift forces are computed using Newman’s approximation, with transfer functions derived from fixed-cylinder data. Pan et al. [61] developed a simplified floating wind-farm framework composed of a low-order rigid-body module, a quasi-static mooring module and a Gaussian wake module, with all array-level simulations executed in Simulink to capture interactions between upstream and downstream turbines connected through shared arrangements.

Arramounet et al. [62] employed OrcaFlex, combined with HAWC2, to investigate the economic implications of shared mooring and shared anchor systems through time-domain simulations, focusing on resulting cost structures and load trends. Reference [8,9] also adopted a consistent software environment, using SIMA, modelling spar floaters as six-DOF rigid bodies in SIMO and representing shared mooring lines as nonlinear slender elements in RIFLEX, thereby resolving fully coupled turbine–mooring dynamics. Hydrodynamic properties of the floater are computed in the frequency domain using WADAM, providing added mass, radiation damping, first-order wave forces, and second-order mean drift forces. Reference [14] used HAWC2 as in part of [62] but modelled shared-mooring configurations through a multibody Timoshenko-beam formulation, Morison or WAMIT-based hydrodynamic loading. Aerodynamic loads were computed using blade-element momentum theory, the turbine controller was implemented through an external dynamic link library (DLL), and mooring-line dynamics were calculated in a separate DTU-developed DLL.

Zhong et al. [63] constructed a shared-mooring-ready hydrodynamic and structural model by generating platform meshes in ANSYS, computing first- and second-order wave loads, added mass, damping and stiffness in OrcaWave, and importing these outputs into OrcaFlex to obtain a modified semi-submersible representation. Hall et al. [64] proposed a methodology beginning with a linearized analysis of array layout options, followed by quasi-static optimization of each mooring line using MoorPy, and finalized through fully coupled time-domain simulations of the entire shared-mooring array in OpenFAST. Hall et al. [65] also expanded the RAFT frequency-domain model based on FAST tool, to simulate full arrays by assembling system matrices at the array level, applying phase-consistent wave excitation to each platform, and using MoorPy to linearize the mooring stiffness. This approach enables the prediction of tensions in shared mooring lines and was validated through comparisons with FAST.Farm. Coupled dynamic analysis of the shared mooring system was conducted by [16] using FAST.Farm, an extension to OpenFAST which was used for aero-hydro-servo-elastic dynamics of each floating wind turbine. Two new capabilities were included in FAST.Farm to properly simulate shared-mooring arrays: the dynamic coupling between wind turbines from shared mooring lines and the accurate representation of the timing of wave loads across the array.

In summary, as in conventional FOWT systems, low-, mid-, and high-fidelity methods play complementary roles within a multi-fidelity design workflow. Early-stage screening relies on simplified models, engineering-level simulations support load analysis, control development, and operational studies, and high-fidelity solvers provide the level of detail required for final design, certification, and failure assessment. Integrated software ecosystems are essential for coupled simulations and continue to advance toward supporting farm-scale layouts, multi-body interactions, and shared-mooring configurations.

The literature on modelling approaches for FOWTs with shared moorings shows that mid-fidelity tools remain the most commonly used option. In these frameworks, hydrodynamic coefficients are typically derived in the frequency domain and then assigned to each unit within a multi-body system. However, hydrodynamic coupling effects, especially the contribution of nonlinear wave forces to platform motion, are still crucial for ensuring overall stability [66], and their importance increases when platforms are interconnected through shared moorings. In the aerodynamic domain, accurately representing the unsteady flow around turbine blades, including turbulence, wake evolution, and their impact on efficiency and structural loading, continues to pose significant challenges. Despite progress on both fronts, the combined influence of turbine–turbine interactions and the nonlinear behaviour introduced by shared mooring systems has yet to be fully addressed. Structural deformation of the substructures and the flexible response of turbine blades introduce additional complexity into the wake behaviour of FOWTs [67]. Therefore, a fully coupled aero-hydro-servo-elastic framework that integrates CFD, FEM, and open-source tools for mooring dynamics is regarded as the most accurate approach, as it can also account for interactions among multiple floaters and turbines.

For addressing computational challenges while maintaining high accuracy, the Reduced Order Models (ROMs) have emerged as a viable solution, which showed the effectiveness in enabling large-scale wind farm simulations, reducing computational costs, and improving real-time operational efficiency [68,69]. Machine learning (ML) has also become an increasingly relevant tool in FOWT modelling, with promising benefits for prediction accuracy, operational optimization, and fault identification. However, Masoum [70] demonstrated the challenges remain in fully integrating ML-driven models into existing simulation frameworks. Future applications of these techniques to FOWTs with shared moorings could be strengthened by coupling them with mooring dynamics tools, while further research should focus on improving predictive accuracy and adaptability through experimental validation.

5. Mooring Costs Estimation

Floating Offshore Wind Farms represent a promising solution for harnessing wind energy in deep waters, where traditional fixed-bottom turbines are not viable. However, their widespread implementation faces significant challenges, primarily related to high capital expenditures, operational expenditures, and complex installation logistics. The mooring system, essential for station-keeping, contributes substantially to these costs, making its optimization crucial for improving economic feasibility. To enhance competitiveness and accelerate large-scale deployment, minimizing costs through innovative design strategies, shared anchoring solutions, and advanced procurement models has become a key focus of research and industry efforts.

Beiter et al. [71] and DTOcean+ [72] developed studies focused on the cost analysis of offshore wind energy components, providing important frameworks for economic assessment. While Beiter et al. [71] proposed a model tailored to the United States context, DTOcean+ concentrated on European conditions. These work established methodological approaches to estimate procurement and system costs, forming the basis for evaluating the economic potential of offshore wind energy. Their models have since been adopted and adapted in subsequent research, serving as reference tools for comparative cost assessments and techno-economic evaluations in different geographic and technological contexts.

In general, the cost estimation of mooring components is derived from the quantity of material required and the minimum breaking load of the material. Among these components, chains and lines typically represent the largest share of the overall mooring cost, accounting for approximately 50–70% of the total [73]. For most conventional materials, empirical relationships between these parameters and cost are well established in the literature. However, nylon has only recently emerged as an alternative for mooring lines, and corresponding cost relationships are not yet widely available.

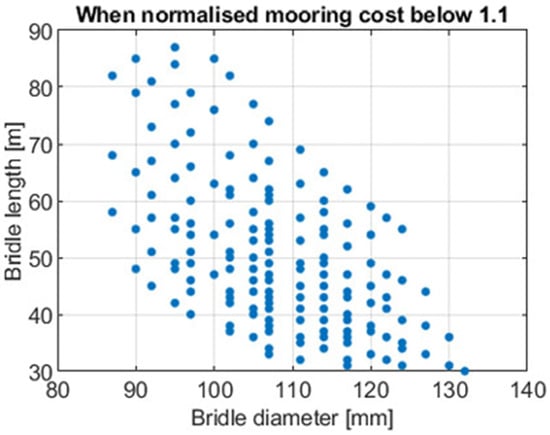

Building on the procurement cost model in [50], Pan and Cheng [74] conducted a parametric study on bridles for a 15 MW spar-type floating offshore wind turbine in catenary configuration using chain lines at a moderate water depth site. The study identifies that chain diameter, grade, and line length are critical parameters influencing mooring costs. A set of over 100 cost-effective bridle configurations was produced and their relationships between bridle length and diameter are shown in Figure 2.

Figure 2.

Relationship between the bridle’s length and diameter obtained from the effective solutions. Reproduced from [74].

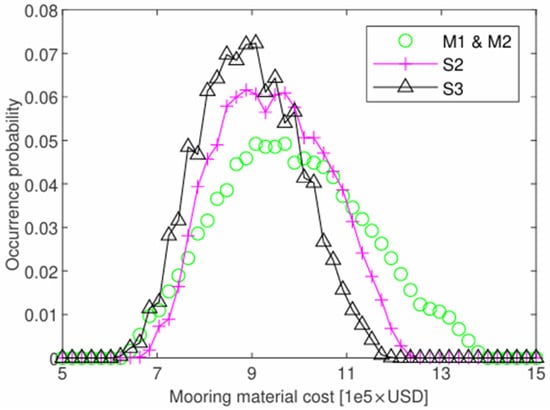

Expanding on this approach, Pan et al. [75] developed a comprehensive design methodology for shared mooring line configurations at a moderate water depth site, demonstrating that shared lines can significantly reduce procurement costs. The methodology generated many different conventional configurations for single turbine and shared mooring configurations for two- and three-turbine arrays. Chain mooring lines were once again considered in the analysis. The cost distribution based on the generated models is presented in Figure 3. For shared mooring designs, the cost distribution is skewed toward lower costs and with higher probabilities of occurrence compared to conventional moorings, with the cost-saving benefits increasing as the number of shared lines rises.

Figure 3.

Distribution of mooring material costs. Reproduced from [75].

Using the cost estimation model from DTOcean+ [73], Chemineau et al. [76] investigated the cost implications of different mooring strategies for floating offshore wind turbines, focusing on single-turbine, shared-anchor, and shared-line configurations applied to semi-submersible platforms at sites of moderate and deep water depth. Their analysis highlighted that the shared-anchor layout delivered only limited economic benefits, since reductions in anchor costs were counterbalanced by the increased length and expense of the mooring lines required. In contrast, the shared-line configuration demonstrated clear potential for significant cost savings, primarily because the horizontal inter-platform connections enhanced yaw stiffness and eliminated the need for supplementary buoys, which had been necessary in the conventional design. Beyond the financial advantages, the study also emphasized practical considerations: while shared-line systems can substantially lower procurement costs, they introduce operational challenges associated with surface cables, particularly regarding navigability and long-term maintenance. This dual perspective underscores the need to balance economic optimization with operational feasibility in the design of shared mooring systems. The applied correlations for chain, polyester lines, and drag-embedded anchors were defined as follows:

where is the minimum breaking load (in kN), is the mooring length (in m), is the mass of the anchor (in kg), is the material cost of the anchor (in €/kg), and CF is a complexity factor that varies depending on the type of anchor employed.

Housner and Hernando [77] conducted a comprehensive assessment of the economic implications of adopting shared-anchor systems for floating offshore wind farms at deep-water conditions. Using open-source tools to account for installation logistics, operations and maintenance, and energy production, the study compared pilot-scale and gigawatt-scale projects based on a semi-submersible platform with polyester taut moorings and suction pile anchors. Among the cost evaluations reviewed, installation expenses, vessel requirements and their spatial constraints, installation and transit time, as well as operational and maintenance costs were considered. These encompassed repair and replacement expenses, annual failure rates for different mooring lines and anchors, and the costs associated with moorings, anchors, power cables, turbines, substations, substructures, and other components. Additionally, an estimate of the Annual Energy Production (AEP) was obtained to calculate the LCOE. Results indicated that shared anchors can reduce LCOE at smaller scales, largely through lower operational costs, but these benefits diminish at larger scales due to higher anchor failure rates and associated maintenance expenses.

Weller et al. [78] developed a multi-objective optimization framework for the design of mooring systems for a 15 MW semi-submersible floating offshore wind turbine, considering platform horizontal excursion, characteristic line tension, and mooring system CAPEX with equal weighting. The analysis evaluated moderate- and deep-water conditions, employing cost factors derived from publicly available data and internal databases for chains, polyester ropes, and connectors. Different mooring configurations, including chain catenary, semi-taut with chain and polyester, and taut with only polyester, were assessed, revealing that taut systems exhibit lower component costs due to reduced line lengths, although installation costs were not considered. Semi-taut configurations occasionally require larger chain sizes to limit platform motions, resulting in CAPEX values comparable to chain catenary systems. The study further indicated that increasing the number of mooring lines can enable the use of smaller-diameter lines, thereby reducing the overall CAPEX of the mooring system.

6. Summary and Conclusions

This study summarizes key findings on shared mooring configurations for FOWTs, and strategies for improving performance and reliability. A review of existing shared mooring and anchor concepts for FOWTs shows that mooring systems are generally classified into catenary, taut-leg, or semi-taut configurations, all of which are suitable for water depths between 200 and 850 metres, typical of most current designs. The most commonly used mooring materials for FOWTs with shared moorings and anchors are chain and polyester. Chain provides high durability and weight, contributing to platform stability, while polyester offers flexibility and a high strength-to-weight ratio, making it particularly suitable for deeper waters.

The selection of mooring materials depends on site-specific conditions and project requirements. One key challenge in shared mooring lines is the occurrence of snap loads. To mitigate excessive tensions and prevent potential failures, clump weights and stiffer mooring lines can be strategically implemented. Adding weights at specific points along the mooring line helps reduce dynamic tension fluctuations, while increasing line stiffness improves energy absorption and limits excessive platform motions under extreme conditions. Shared mooring lines present opportunities and challenges, requiring careful analysis of excitation modes and redundancy mechanisms to ensure operational stability. By incorporating clump weights, stiffer lines, and site-specific sea state analysis, developers can optimize mooring performance and minimize risks associated with extreme conditions.

In the modelling method, mid-fidelity tools such as OrcaFlex and SIMA remain widely used for platform and shared mooring dynamics, providing a balance between accuracy and computational efficiency. However, accurately capturing hydrodynamic coupling effects and the complex aerodynamic interaction among multiple turbines remains challenging, making it difficult to fully assess and ensure overall system stability. High-fidelity coupled CFD-FEM frameworks allow for detailed aero-hydro-servo-elastic simulations, capturing nonlinear interactions between turbines, shared mooring systems, and platform motions. Combining these modelling approaches with mooring dynamics tools can enhance predictive accuracy, optimize shared mooring performance, and support the development of more reliable and economically feasible floating wind farms. Reduced Order Models (ROMs) have emerged as effective tools for enabling large-scale wind farm simulations while reducing computational costs and supporting real-time operational decisions. Machine learning (ML) techniques offer further opportunities for predictive accuracy, operational optimization, and fault detection, although integrating ML-driven models into existing simulation frameworks remains a challenge.

On the other hand, the cost analysis highlights several strategies for reducing the capital cost of mooring systems. In some cases, increasing the number of mooring lines can lower overall CAPEX, particularly when taut configurations are adopted. Taut moorings generally reduce expenditures because they require shorter line lengths, making them attractive for projects where material optimization is a priority. Nonetheless, their installation is often more complex and demands specialized procedures and equipment, which must be considered in the cost assessment. Load direction is another critical factor influencing cost. Upwind lines typically carry higher tensions than downwind ones, allowing for differentiated specifications. Using lines with lower minimum breaking loads and smaller diameters in downwind positions, while maintaining stronger lines upwind, can reduce costs without compromising safety or stability.

With respect to anchor strategies, the advantages of shared anchors are less clear. Although they reduce the number of anchor units, they may require additional mooring lines and introduce higher risks of failure, potentially increasing both capital and operational costs. In contrast, shared mooring lines show greater promise: by reducing the number of components such as buoys, weights, and anchors, they can significantly decrease installation and maintenance expenses while maintaining structural integrity.

Overall, cost optimization in floating offshore wind mooring systems can be achieved through careful consideration of taut configurations, directional load effects, and shared line arrangements. However, shared anchors do not consistently yield financial benefits and should be evaluated cautiously within the broader mooring strategy.

Author Contributions

Conceptualization, Y.S. and S.W.; investigation, R.S., H.J. and S.W.; resources, R.S., H.J., M.V.B., Y.S. and S.W.; data curation, R.S., H.J., M.V.B., Y.S. and S.W.; writing—original draft preparation, R.S., H.J., M.V.B., Y.S. and S.W.; writing—review and editing, R.S., H.J., M.V.B., Y.S. and S.W.; visualization, R.S., H.J. and S.W.; supervision, Y.S. and S.W.; project administration, Y.S. and S.W.; funding acquisition, Y.S. and S.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been supported by the project “Enhancing shared mooring system design for floating offshore wind farms (ESOMOOR)”, funded by the Portuguese Foundation for Science and Technology (Fundação para a Ciência e Tecnologia—FCT), Innovation Fund Denmark (3170-00020B) and co-funded by the European Union, with the project reference CETP-2023-00145. However, the views and opinions expressed are those of the author(s) only and do not necessarily reflect those of the European Union or the CETPartnership. Neither the European Union nor the granting authority can be held responsible for them. This work contributes to the Strategic Research Plan of the Centre for Marine Technology and Ocean Engineering (CENTEC), which is financed by the Portuguese Foundation for Science and Technology (Fundação para a Ciência e Tecnologia—FCT) under contract UID-00134-2025.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- McCoy, A.; Musial, W.; Hammond, R.; Hernando, D.M.; Duffy, P.; Beiter, P.; Pérez, P.; Baranowski, R.; Reber, G.; Spitsen, P. Offshore Wind Market Report; Report for National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2024. Available online: https://www.nrel.gov/docs/fy24osti/90525.pdf (accessed on 2 September 2025).

- Equinor. Hywind Tampen. Available online: https://www.equinor.com/energy/hywind-tampen (accessed on 2 September 2025).

- Principle Power. Projects. Available online: https://www.principlepower.com/projects (accessed on 21 October 2025).

- DNV. Energy Transition Outlook. 2024. Available online: https://www.dnv.com/energy-transition-outlook/download/ (accessed on 9 October 2024).

- Goldschmidt, M.; Muskulus, M. Coupled Mooring Systems for Floating Wind Farms. Energy Procedia 2015, 80, 255–262. [Google Scholar] [CrossRef]

- Connolly, P.; Hall, M. Comparison of Pilot-Scale Floating Offshore Wind Farms with Shared Moorings. Ocean Eng. 2019, 171, 172–180. [Google Scholar] [CrossRef]

- Liang, G.; Merz, K.; Jiang, Z. Modeling of a Shared Mooring System for a Dual-Spar Configuration. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Fort Lauderdale, FL, USA, 28 June–3 July 2020; American Society of Mechanical Engineers: New York, NY, USA, 2020; Volume 84416, p. V009T09A057. [Google Scholar]

- Liang, G.; Jiang, Z.; Merz, K. Dynamic Analysis of a Dual-Spar Floating Offshore Wind Farm with Shared Moorings in Extreme Environmental Conditions. Mar. Struct. 2023, 90, 103441. [Google Scholar] [CrossRef]

- Biroli, M.V.; Wang, S.; Soares, C.G. Dynamic Analysis Comparison of Shared Mooring System for Offshore Wind Turbine Platforms. In Innovations in Renewable Energies Offshore; CRC Press: Boca Raton, FL, USA, 2024; pp. 369–378. [Google Scholar]

- Biroli, M.V.; Vidal, F.J.; Desiderati, J.; Wang, S.; Soares, C.G. Dynamic Analysis of Shared Moorings in Different Wind Farm Layouts. Mar. Energy Res. 2025, 2, 10012. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H. Coupled Dynamic Analysis on Floating Wind Farms with Shared Mooring under Complex Conditions. Ocean Eng. 2023, 267, 113323. [Google Scholar] [CrossRef]

- Lopez-Olocco, T.; Liang, G.; Medina-Manuel, A.; Ynocente, L.S.; Jiang, Z.; Souto-Iglesias, A. Experimental Comparison of a Dual-Spar Floating Wind Farm with Shared Mooring against a Single Floating Wind Turbine under Wave Conditions. Eng. Struct. 2023, 292, 116475. [Google Scholar] [CrossRef]

- Liang, G.; Lopez-Olocco, T.; Medina-Manuel, A.; Saavedra-Ynocente, L.A.; Souto-Iglesias, A.; Jiang, Z. Experimental Investigation of Two Shared Mooring Configurations for a Dual-Spar Floating Offshore Wind Farm in Irregular Waves. Mar. Struct. 2024, 95, 103579. [Google Scholar] [CrossRef]

- Gözcü, O.; Kontos, S.; Bredmose, H. Dynamics of Two Floating Wind Turbines with Shared Anchor and Mooring Lines. J. Phys. Conf. Ser. 2022, 2265, 042026. [Google Scholar] [CrossRef]

- Sauder, T. Second-Order Wave Loads on Floating Wind Parks with Shared Mooring. J. Phys. Conf. Ser. 2023, 2626, 012038. [Google Scholar] [CrossRef]

- Lozon, E.; Hall, M. Coupled Loads Analysis of a Novel Shared-Mooring Floating Wind Farm. Appl. Energy 2023, 332, 120513. [Google Scholar] [CrossRef]

- Lovera, A.; Coquio, T.; Peyrard, C. Analysis of Loads Applied on Floating Wind Turbines Shared Anchors. Ocean Eng. 2025, 324, 120627. [Google Scholar] [CrossRef]

- Coughlan, K.; Davis, M.; Westgate, Z.; Lee, J.; Arwade, S.; Martin, B.; DeGroot, D. Design and Analysis of Shared Anchor Layouts for Floating Wind Farms in Deep Waters. Ocean Eng. 2025, 320, 120208. [Google Scholar] [CrossRef]

- Diaz, B.D.; Rasulo, M.; Aubeny, C.P.; Fontana, C.M.; Arwade, S.R.; DeGroot, D.J.; Landon, M. Multiline Anchors for Floating Offshore Wind Towers. In Proceedings of the OCEANS 2016 MTS/IEEE Monterey, Monterey, CA, USA, 19–23 September 2016; pp. 1–9. [Google Scholar]

- Stevenson, L. Floating Offshore Wind Anchor Review. Available online: https://fowcoe.co.uk/wp-content/uploads/2024/03/FOWCoE-Report-Anchor-Review-PN000585-RPT-005-MA03.pdf (accessed on 7 December 2025).

- Ikhennicheu, M.; Lynch, M.; Doole, S.; Borisade, F.; Matha, D.; Dominguez, J.L.; Vicente, R.D.; Habekost, T.; Ramirez, L.; Potestio, S. Corewind: D2. 1 Review of the State of the Art of Mooring and Anchoring Designs, Technical Challenges and Identification of Relevant DLCs. Report, H2020-Grant Agreement, No. 815083. 2020. Available online: https://corewind.eu/wp-content/uploads/files/publications/COREWIND-D2.1-Review-of-the-state-of-the-art-of-mooring-and-anchoring-designs.pdf (accessed on 7 December 2025).

- Xu, H.; Rui, S.; Shen, K.; Jiang, L.; Zhang, H.; Teng, L. Shared Mooring Systems for Offshore Floating Wind Farms: A Review. Energy Rev. 2024, 3, 100063. [Google Scholar] [CrossRef]

- Jiang, Z. Mooring Design for Floating Wind Turbines: A Review. Renew. Sustain. Energy Rev. 2025, 212, 115231. [Google Scholar] [CrossRef]

- Saincher, S.; Sriram, V.; Stoesser, T. Shared Moorings for Floating Offshore Renewable Energy Technologies: A Review. Renew. Sustain. Energy Rev. 2025, 224, 116064. [Google Scholar] [CrossRef]

- Paduano, B. Current Status and Perspectives on Shared Moorings for Offshore Floating Renewable Energy Systems: A Review. Renew. Sustain. Energy Rev. 2026, 226, 116350. [Google Scholar] [CrossRef]

- Home—ESOMOOR. Available online: https://www.esomoor.eu/ (accessed on 19 November 2025).

- Sloan, C.; Hall, M.; Housner, S.; Lozon, E.; Sirnivas, S. Shared Mooring Systems for Deep-Water Floating Wind Farms; Technical Report for New York State Energy Research and Development Authority (NYSERDA): Albany, NY, USA, 2022. [Google Scholar]

- Xu, S.; Wang, S.; Soares, C.G. Review of Mooring Design for Floating Wave Energy Converters. Renew. Sustain. Energy Rev. 2019, 111, 595–621. [Google Scholar] [CrossRef]

- Xu, S.; Wang, S.; Liu, H.; Zhang, Y.; Li, L.; Soares, C.G. Experimental Evaluation of the Dynamic Stiffness of Synthetic Fibre Mooring Ropes. Appl. Ocean. Res. 2021, 112, 102709. [Google Scholar] [CrossRef]

- Lian, Y.; Zhang, Y.; Zheng, J.; Zhang, J.; Chen, W.; Chen, S.; Wu, X.; Xie, Y.; Ma, J.; Liu, H. Experimental Inves-tigation on Dynamic Stiffness of Full-Scale Polyester Mooring Ropes. Ocean. Eng. 2025, 332, 121403. [Google Scholar] [CrossRef]

- Sørum, S.H.; Fonseca, N.; Kent, M.; Faria, R.P. Assessment of Nylon versus Polyester Ropes for Mooring of Floating Wind Turbines. Ocean. Eng. 2023, 278, 114339. [Google Scholar] [CrossRef]

- Lian, Y.; Liu, H.; Zhang, Y.; Li, L. An Experimental Investigation on Fatigue Behaviors of HMPE Ropes. Ocean. Eng. 2017, 139, 237–249. [Google Scholar] [CrossRef]

- Xu, S.; Wang, S.; Soares, C.G. Experimental Study of the Influence of the Rope Material on Mooring Fatigue Damage and Point Absorber Response. Ocean. Eng. 2021, 232, 108667. [Google Scholar] [CrossRef]

- Francois, M.; Davies, P. Fibre Rope Deep Water Mooring: A Practical Model for the Analysis of Polyester Mooring Systems. In Proceeding of the Rio Oil and Gas Expo and Conference 2000, Rio de Janeiro, Brazil, 16–19 October 2000. [Google Scholar]

- Falkenberg, E.; Åhjem, V.; Yang, L. Best Practice for Analysis of Polyester Rope Mooring Systems. In Proceedings of the Offshore Technology Conference 2017, Houston, TX, USA, 1–4 May 2017. D031S034R006. [Google Scholar]

- Sørum, S.H.; Fonseca, N.; Kent, M.; Faria, R.P. Modelling of Synthetic Fibre Rope Mooring for Floating Offshore Wind Turbines. J. Mar. Sci. Eng. 2023, 11, 193. [Google Scholar] [CrossRef]

- Lee, C.F.; Fjermedal, S.; Ong, M.C. Design and Analysis of Taut Mooring Systems for a Combined Floating Offshore Wind and Wave Energy System at Intermediate Water Depth. Ocean. Eng. 2024, 312, 119174. [Google Scholar] [CrossRef]

- Lian, Y.; Zhong, F.; Zheng, J.; Chen, W.; Ma, G.; Wang, S.; Yim, S.C. Effects of Mooring Line with Different Ma-terials on the Dynamic Response of Offshore Floating Wind Turbine. J. Mar. Sci. Eng. 2023, 11, 2302. [Google Scholar] [CrossRef]

- Depalo, F.; Wang, S.; Xu, S.; Soares, C.G.; Yang, S.-H.; Ringsberg, J.W. Effects of Dynamic Axial Stiffness of Elastic Moorings for a Wave Energy Converter. Ocean. Eng. 2022, 251, 111132. [Google Scholar] [CrossRef]

- Vidal, F.J.; Wang, S.; Soares, C.G. Dynamic Modelling of Synthetic Moorings for a Wave Energy Converter. In Innovations in Renewable Energies Offshore; CRC Press: Boca Raton, FL, USA, 2024; pp. 437–445. [Google Scholar]

- Yang, S.-H.; Ringsberg, J.W.; Johnson, E.; Hu, Z.; Palm, J. A Comparison of Coupled and De-Coupled Simula-tion Procedures for the Fatigue Analysis of Wave Energy Converter Mooring Lines. Ocean. Eng. 2016, 117, 332–345. [Google Scholar] [CrossRef]

- Yang, S.-H.; Ringsberg, J.W.; Johnson, E. Wave Energy Converters in Array Configurations—Influence of In-teraction Effects on the Power Performance and Fatigue of Mooring Lines. Ocean. Eng. 2020, 211, 107294. [Google Scholar] [CrossRef]

- Hall, M.; Lozon, E.; Devoy McAuliffe, F.; Baudino Bessone, M.; Bayati, I.; Bowie, M.; Bozonnet, P.; Castagné, M.; Feng, J.; Housner, S.; et al. The IEA Wind Task 49 Reference Floating Wind Array Design Basis; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2024.

- Clement, C.; Kosleck, S.; Lie, T. Investigation of Viscous Damping Effect on the Coupled Dynamic Response of a Hybrid Floating Platform Concept for Offshore Wind Turbines. Ocean. Eng. 2021, 225, 108836. [Google Scholar] [CrossRef]

- DNVGL. Recommended Practice—C205: Environmental Conditions and Environmental Loads; DNVGL: Høvik, Norway, 2017. [Google Scholar]

- Jonkman, J.M. Dynamics Modeling and Loads Analysis of an Offshore Floating Wind Turbine; National Renewable Energy Laboratory: Golden, CO, USA, 2007.

- Bertollucci Colherinhas, G.; Petrini, F.; de Morais, M.V.G.; Bontempi, F. Optimal Design of Passive-Adaptive Pendulum Tuned Mass Damper for the Global Vibration Control of Offshore Wind Turbines. Wind. Energy 2021, 24, 573–595. [Google Scholar] [CrossRef]

- Bashetty, S.; Ozcelik, S. Review on Dynamics of Offshore Floating Wind Turbine Platforms. Energies 2021, 14, 6026. [Google Scholar] [CrossRef]

- Head, M.; Shokouhian, M.; Schaffer, W. MOWER 14-01: Foundation Anchorages for Offshore Wind Turbines in Deep Water Using Composite Materials. 2016. Available online: https://www.researchgate.net/profile/Monique-Head/publication/311442219_Foundation_Anchorages_for_Offshore_Wind_Turbines_in_Deep_Water_Using_Composite_Materials/links/5859a75c08ae64cb3d494421/Foundation-Anchorages-for-Offshore-Wind-Turbines-in-Deep-Water-Using-Composite-Materials.pdf (accessed on 7 December 2025).

- Shields, M.; Cooperman, A.; Kreider, M.; Oteri, F.; Hemez, Z.; Gill, L.; Sharma, A.; Fan, K.; Musial, W.; Trowbridge, M. The Impacts of Developing a Port Network for Floating Offshore Wind Energy on the West Coast of the United States; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2023.

- van den Berg, D.; De Tavernier, D.; van Wingerden, J.-W. The Dynamic Coupling between the Pulse Wake Mixing Strategy and Floating Wind Turbines. Wind. Energy Sci. 2023, 8, 849–864. [Google Scholar] [CrossRef]

- Sandal, K.; Norman, N. Honeymooring. Available online: https://www.sintef.no/globalassets/project/eera-deepwind-2025/presentasjoner/6b_substructures_kasper_sandal_6b.pdf?utm_source=chatgpt.com%E3%80%81 (accessed on 19 November 2025).

- Installation_wickman-Hanssen. Available online: https://www.sintef.no/globalassets/project/eera-deepwind-2022/posters/installation_wickman-hanssen.pdf?utm_source=chatgpt.com (accessed on 19 November 2025).

- Honeymooring. Available online: https://www.semar.no/honeymooring (accessed on 19 November 2025).

- Valsø-Jørgensen, T. A game-changing dynamic mooring solution for floating wind-farms. In Proceedings of the WindEurope’s Annual on- and Offshore Wind Energy Event, Copenhagen, Denmark, 23–25 November 2021. [Google Scholar]

- Otter, A.; Murphy, J.; Pakrashi, V.; Robertson, A.; Desmond, C. A Review of Modelling Techniques for Floating Offshore Wind Turbines. Wind. Energy 2022, 25, 831–857. [Google Scholar] [CrossRef]

- Cecilia, S. Quasi-Dynamic Modelling of Shared Mooring Lines for Floating Wind Turbines. Master’s Thesis, NTNU, Trondheim, Norway, 2022. [Google Scholar]

- Berdugo-Parada, I.; Servan-Camas, B.; Garcia-Espinosa, J. Numerical Framework for the Coupled Analysis of Floating Offshore Multi-Wind Turbines. J. Mar. Sci. Eng. 2023, 12, 85. [Google Scholar] [CrossRef]

- Zhang, W.; Calderon-Sanchez, J.; Duque, D.; Souto-Iglesias, A. Computational Fluid Dynamics (CFD) Applica-tions in Floating Offshore Wind Turbine (FOWT) Dynamics: A Review. Appl. Ocean. Res. 2024, 150, 104075. [Google Scholar] [CrossRef]

- Rogne, Ø.Y. Faster Simulations of Floating Wind Turbines with Shared Mooring. SINTEF Blog, 16 May 2024. [Google Scholar]

- Pan, Q.; Yu, W.; Cheng, P.W. Simplified Modeling of Floating Offshore Wind Farms with Shared Mooring Line Configurations. Ocean. Eng. 2025, 327, 121018. [Google Scholar] [CrossRef]

- Arramounet, V. Design Practices and Guidelines for Mooring, Anchoring System Design. Available online: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://corewind.eu/wp-content/uploads/files/delivery-docs/D2.4.pdf&ved=2ahUKEwiLxeyBwq-RAxUHrlYBHUSpIG4QFnoECBoQAQ&usg=AOvVaw0ps3YVOtENiJLpai7_hhoe (accessed on 7 December 2025).

- Zhong, F.; Lian, Y.; Zheng, J.; Chen, W.; Ma, G.; Yim, S. Effects of Shared Lines with Different Materials on Mooring Response of the Floating Offshore Wind Turbine Farm. Chin. J. Ship Res. 2024, 19, 59–70. [Google Scholar]

- Hall, M.; Lozon, E.; Housner, S.; Sirnivas, S. Design and Analysis of a Ten-Turbine Floating Wind Farm with Shared Mooring Lines. J. Phys.: Conf. Ser. 2022, 2362, 012016. [Google Scholar] [CrossRef]

- Hall, M.; Carmo, L.; Lozon, E. Frequency-Domain Modeling of Floating Wind Arrays with Shared Mooring Lines. Wind. Energy Sci. Discuss. 2025, 1–25. [Google Scholar] [CrossRef]

- Evro, S.; Veith, J.; Akinwale, A.; Tomomewo, O.S. Enhancing Floating Offshore Wind Turbine Systems through Multi-Scale Coupled Modeling. Sustain. Energy Technol. Assess. 2025, 77, 104299. [Google Scholar] [CrossRef]

- Yang, L.; Liao, K.; Ma, Q.; Khayyer, A.; Sun, H. Coupled Aero-Servo-Elastic Method for Floating Offshore Wind Turbine Wake Analysis. Ocean. Eng. 2024, 307, 118108. [Google Scholar] [CrossRef]

- Lin, Z.; Cevasco, D.; Collu, M. Progress on the Development of a Holistic Coupled Model of Dynamics for Off-shore Wind Farms: Phase I—Aero-Hydro-Servo-Elastic Model, With Drive Train Model, for a Single Wind Turbine. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Madrid, Spain, 17–22 June 2018; Volume 51319, p. V010T09A060. [Google Scholar]

- Liang, J.; Kato, B.; Wang, Y. Constructing Simplified Models for Dynamic Analysis of Monopile-Supported Offshore Wind Turbines. Ocean. Eng. 2023, 271, 113785. [Google Scholar] [CrossRef]

- Masoumi, M. Machine Learning Solutions for Offshore Wind Farms: A Review of Applications and Impacts. J. Mar. Sci. Eng. 2023, 11, 1855. [Google Scholar] [CrossRef]

- Beiter, P.; Musial, W.; Smith, A.; Kilcher, L.; Damiani, R.; Maness, M.; Sirnivas, S.; Stehly, T.; Gevorgian, V.; Mooney, M.; et al. A Spatial-Economic Cost-Reduction Pathway Analysis for U.S. Offshore Wind Energy Development from 2015–2030. p. NREL/TP–6A20-66579, 1324526. 2016. Available online: https://research-hub.nrel.gov/en/publications/a-spatial-economic-cost-reduction-pathway-analysis-for-us-offshor/ (accessed on 7 December 2025).

- Marines, F.E. Deliverable 4.6: Framework for the Prediction of the Reliability, Economic and Environmental Criteria and Assessment Methodologies for Moorings and Foundations. 2015. Available online: https://www.france-energies-marines.org/wp-content/uploads/2023/07/DTO_WP4_ECD_D4.6.pdf (accessed on 7 December 2025).

- Laurie, C. Exploring Offshore Wind Energy Opportunities in the Great Lakes. NREL. Available online: https://www.nrel.gov/news/detail/program/2023/exploring-offshore-wind-energy-opportunities-in-the-great-lakes (accessed on 2 September 2025).

- Pan, Q.; Cheng, P.W. Cost-Based Mooring Designs and a Parametric Study of Bridles for a 15 MW Spar-Type Floating Offshore Wind Turbine. J. Phys. Conf. Ser. 2022, 2265, 042013. [Google Scholar] [CrossRef]

- Pan, Q.; Liu, D.; Guo, F.; Cheng, P.W. A Comprehensive Design Methodology of Shared Mooring Line Configurations for Assessing Mooring Costs and Performances of Floating Offshore Wind Turbines. Wind Energy Sci. Discuss. 2024, 2024, 1–32. [Google Scholar]

- Chemineau, M.; Castillo, F.; Mechinaud, L.; Arramounet, V.; Gilloteaux, J.C. Design and Costs Benefits of Shared Anchors and Shared Mooring Lines of Floating Wind Turbines at Farm Level. J. Phys. Conf. Ser. 2023, 2626, 012048. [Google Scholar] [CrossRef]

- Housner, S.; Hernando, D.M. Levelized Cost of Energy Comparison of Floating Wind Farms With and Without Shared Anchors; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2024. [Google Scholar]

- Gaertner, E.; Rinker, J.; Sethuraman, L.; Zahle, F.; Anderson, B.; Barter, G.; Abbas, N.; Meng, F.; Bortolotti, P.; Skrzypinski, W. Definition of the IEA 15-Megawatt Offshore Reference Wind Turbine. 2020. Available online: https://docs.nrel.gov/docs/fy20osti/75698.pdf (accessed on 7 December 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).