Abstract

Hydrogen is widely regarded as a promising carbon-free alternative fuel. However, the development of low-emission marine gas turbine combustion systems has been hindered by the associated risks of combustion instability, also termed as thermoacoustic oscillations. Although there is sufficient literature on hydrogen fuel and combustion instability, systematic reviews addressing the manifestations and mechanisms of these instabilities remain limited. The present study aims to provide a comprehensive review of combustion instabilities in hydrogen-enriched marine gas turbines, with a particular focus on elucidating the characteristics and underlying mechanisms. The review begins with a concise overview of recent progress in understanding the fundamental combustion properties of hydrogen, and then details various instability phenomena in hydrogen-enriched methane flames. The mechanisms by which hydrogen enrichment affects combustion instabilities are extensively discussed, particularly in relation to the feedback loop in thermoacoustic combustion systems. The paper concludes with a summary of the key combustion instability challenges associated with hydrogen addition to methane flames and offers prospects for future research. In summary, the review highlights the interaction between hydrogen-enriched methane flames and thermoacoustic phenomena, providing a foundation for the development of stable, low-emission combustion systems in industrial marine applications incorporating hydrogen enrichment.

1. Introduction

1.1. Growing Concern for Adding Hydrogen into Conventional Combustion

With the increasing emphasis on climate protection, hydrogen (H2) has gained significant attention due to its clean and sustainable properties, positioning it as a promising fuel substitute for power generation in gas turbine combustion systems. Hydrogen offers clear advantages in terms of CO2-free emissions compared to more commonly used fuels, offering a potential pathway for environmental protection in marine applications. Recent studies [1,2] have listed hydrogen-enriched liquefied natural gas (LNG) as a mid-term solution to mitigate greenhouse gas emissions from shipping.

Unlike conventional natural gas (primarily methane, CH4), hydrogen possesses several favorable combustion characteristics, including high combustion efficiency, a wide flammability range, short ignition times, and superior thermal diffusivity [3,4,5]. Table 1 presents a comparison of the fundamental properties of hydrogen and methane as fuels. Given that hydrogen and methane have similar Wobbe Index values (WI, an indicator of fuel interchangeability mostly used in gas turbines), the heat load remains constant when hydrogen is introduced into the combustion chamber under the same pressure conditions. Consequently, hydrogen demonstrates high fuel interchangeability in gas turbine applications [6,7].

Table 1.

Comparison on fuel elementary features between hydrogen and methane at 300 K and 1 atm (Computed using GRI-Mech 3.0 [8]).

Burning high contents of hydrogen poses notable challenges to gas turbines. The non-premixed combustors can burn pure hydrogen to avoid flashback and auto-ignition [9,10,11]. However, the significant increase in nitrogen oxide (NOx) emissions and reduced combustion efficiency have hindered the development of non-premixed combustors. Currently, the most widely adopted lean premixed (LPM) gas turbine combustors are limited to burning hydrogen at a volume content of up to 30% [12]. The potential for flashback and autoignition due to hydrogen enrichments can disrupt normal combustion and, in some cases, lead to overheating and engine damage [11]. Low-emission combustion systems are often operated near the lean blowout (LBO) limits, where combustion instability [13] is likely to occur, leading to combustion failure. As a result, burning high concentrations of hydrogen presents significant challenges for conventional combustors.

1.2. Industrial Burners Developed for High Hydrogen Combustion

In response to equipment retrofitting demands, gas turbine manufacturers worldwide are focused on enabling high hydrogen combustion in heavy-duty gas turbines. Siemens Energy & Power Transmission Group aims to have 100% hydrogen-fueled gas turbines available by 2030 [14,15]. Details on the progress of the joint GE (General Electric) and U.S. Department of Energy (DOE) High Hydrogen Turbine Program can be found in Ref. [16]. Mitsubishi Power has been involved in hydrogen/ammonia-firing Gas Turbine Combined Cycle (GTCC) projects [17]. With support from Japan’s New Energy and Industrial Technology Development Organization (NEDO), a gas turbine combustor capable of operating with a mixture of natural gas and up to 30% hydrogen by volume has been proposed for large-scale gas turbines [18].

As one of the world’s major energy consumers, China has implemented numerous energy policies to promote hydrogen energy. In pursuit of its Carbon Peak and Carbon Neutrality goals—also known as the Dual Carbon Goals [19]—China’s National Development and Reform Commission and the National Energy Administration released the Medium- and Long-Term Plans for the Development of the Hydrogen Energy Industry (2021–2025) [20]. Pure hydrogen gas turbines are attracting increased attention in research and development for sustainable combustion. China’s first demonstration project featuring hydrogen-enriched combustion was conducted on F-class gas turbines in Hubei Province by China United Heavy-Duty Gas Turbine Technology Co., Ltd. (Shanghai, China) [21]. Additionally, PetroChina and Huatian Aeropower Combustion Engine Co., Ltd., Wuxi, China, recently achieved successful testing of a 2 MW pure hydrogen gas turbine using a non-premixed combustion chamber [22]. The development of high-efficiency hydrogen gas turbine combustion chambers in China is now approaching completion.

In addition to China [22,23], the USA [24,25], Japan [26,27], and Germany [28] are leading the development of burners for high-hydrogen combustion. While China has committed to achieving carbon neutrality by 2060 [19], Japan aims to reach this goal by 2050 [17].

Most gas turbine combustion chambers employ Dry Low Emissions (DLE) techniques and micromix methods to accommodate high hydrogen content [12]. In DLE combustion, fuel is fully mixed with excess air using a swirler, which significantly lowers flame temperatures and, in turn, reduces NOx emissions. The recirculation zones created by the swirler also contribute to stable combustion [29]. While DLE techniques are widely applied in gas turbines [30], the presence of flashback and auto-ignition, along with the significant increase in NOx emissions due to hydrogen enrichment, negatively impacts performance. To address these challenges, DLE combustors need to be adapted for non-premixed combustion and equipped with multiple NOx reduction strategies, such as dilution or air/fuel staging. However, these methods introduce other potential issues. For instance, while CO2 dilution effectively lowers flame temperatures, NOx emissions can be triggered via the NH2 pathways [31]. Similarly, fuel-staged combustion reduces NOx but increases CO emissions [32]. Thus, although DLE combustors are primarily used in conventional gas turbine systems, they may prove unsuitable for burning high hydrogen concentrations.

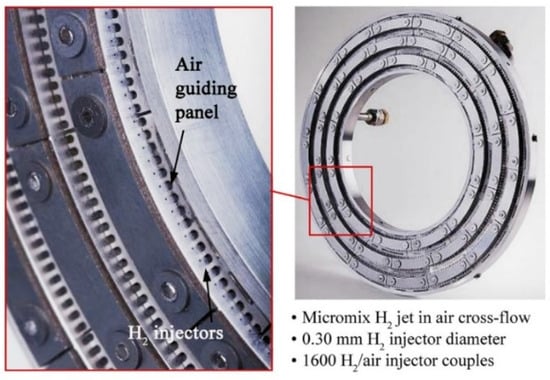

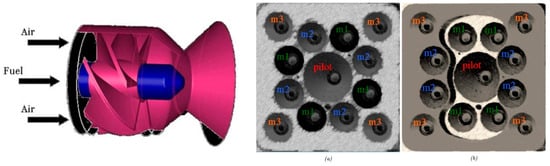

To burn pure hydrogen while avoiding common issues such as auto-ignition and flashback, dry-low-NOx Micromix (MMX) combustors are preferred. Originally proposed by Prof. Funke at Aachen University of Applied Sciences (AcUAS), micromix combustors have been researched for over three decades [10,33,34,35,36,37,38,39]. These combustors utilize a large number of jet-in-crossflow (JICF) and air-guiding panels (AGP) to create distributed, small, compact flames with minimal recirculation zones. The rapid mixing of reactants and shortened residence time help achieve low NOx emissions, while the non-premixed configuration ensures stable combustion, preventing flashback. Figure 1 demonstrates a typical micromix combustor for a gas turbine, Honeywell/Garrett GTCP 36-300 Haj Ayed, Kusterer, Funke, Keinz, Striegan and Bohn [35]. A nozzle diameter of 0.84 mm was tested at atmospheric pressure under various operating conditions. The combustion system achieved over 99% combustion efficiency, with no flashback observed. At the design condition of 1.6 MW, the micromix combustor maintained NOx emissions below 2.5 ppm, corrected to 15 Vol% O2. Across the entire operating range, NOx emissions remained under 4 ppm at atmospheric conditions. Since 2014, AcUAS and Kawasaki Heavy Industries Ltd. Japan (KHI) [34,36] on micromix combustor research for a 2 MW class industrial gas turbine. Supported by the Hydrogen Technologies and Utilization Project of the New Energy and Industrial Technology Development Organization (NEDO) in 2016 [40,41], a micromix combustor for can-case integration in the Kawasaki M1A gas turbine was developed. As shown in Figure 2, hydrogen fuel staging was incorporated into the micromix combustor design to ensure low-emission, stable combustion. The M1A micromix burner emitted NOx emissions below 35 ppm at 16% O2 across all operating conditions, while the latest M1A-17 gas turbine produced NOx emissions of 65 ppm at 15% O2 at full load [26].

Figure 1.

A typical micromix combustor for 1.6 MW gas turbine, Honeywell/Garrett Auxiliary Power Unit APU GTCP 36-300 [35].

Figure 2.

Micromix combustor used in Kawasaki M1A gas turbine with 0.80 mm hydrogen injectors. (a) the prototype of the micromix combustor. (b) the fuel staging concept during startup, low load, and high load conditions. Reproduced from Ref. [42].

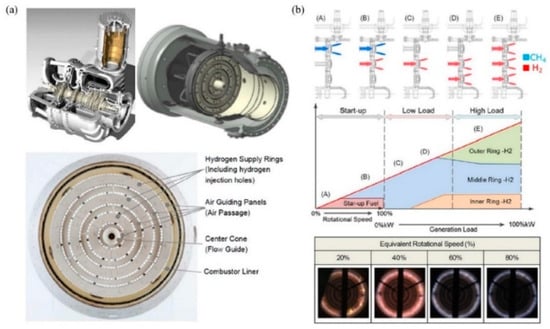

Based on the design principles of micromix combustors, Kawasaki proposed a novel fuel injector for enhancing the fuel flexibility [43]. The principle drawing of novel fuel injector for micromix flames is shown in Figure 3. Low-speed vortex fetch is formed in the back area of the jet, and the mixing degree is higher. The new geometry protects the fuel jet from crossflow and creates a low velocity zone behind the jet that promotes flame anchoring at the trailing edge of the fuel chamber.

Figure 3.

Principle drawing of novel fuel injector for micromix flames [43].

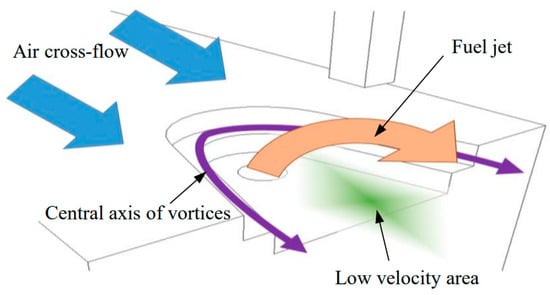

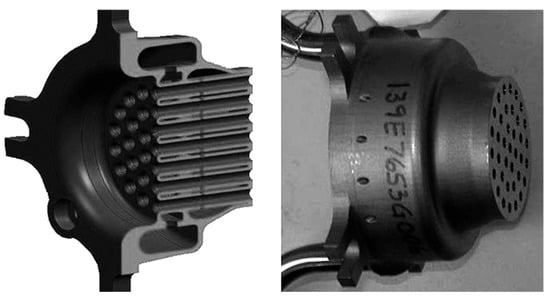

The US National Aeronautics and Space Administration (NASA) investigated the combustion performance of low emission hydrogen combustors for gas turbines using lean direct injection (LDI) [44] in 2015. Several designs of injectors were tested, as shown in Figure 4. All of the LDI configurations resulted in low levels of NOx. No flashback or autoignition were encountered. The configuration C4 performed the best for NOx emissions and durability criteria. Cooling is a critical problem with hydrogen combustors. In 2014, NASA tested a second-generation swirl-venturi lean direct injection combustion (SV-LDI) concept [45], as shown in Figure 5. The second-generation configurations had better low power operability than the original design. The 5-recess configuration generally had lower NOx emissions than the flat dome configuration.

Figure 4.

The LDI injectors tested by NASA. Left: the combustor assembly. Right: the four injector configurations. (a) NASA N1 injector; (b) Configuration C1; (c) Configuration C2; (d) Configuration C3 and Mod C4. Reproduced from Ref. [44].

Figure 5.

The second-generation swirl-venturi lean direct injection by NASA. (Left) a single SV-LDI fuel/air mixer. (Right) the second-generation SV_LDI hardware. (a) flame dome and (b) 5-recess configurations. Reproduced from Ref. [45].

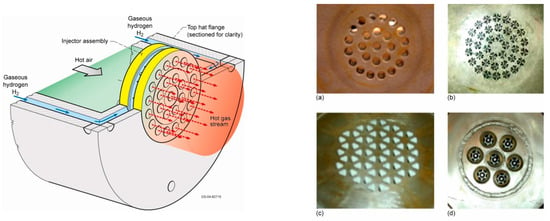

General Electric Company (GE) developed a low NOx hydrogen combustion system for heavy-duty gas turbines. As shown in Figure 6, the concept relies on small-scale jet-in-crossflow mixing that is a departure from traditional swirl-based premixing concepts. The newly designed fuel injector concept has been incorporated into a full-scale, multi-nozzle combustor can with an energy conversion rate of more than 10 MW at F-class conditions. The test results showed that the small-scale fuel-air mixing can lead to low-NOx hydrogen combustion in advanced gas turbines.

Figure 6.

The multitube miser for high-hydrogen fuel from GE [46]. (Left) the structure; (Right) the physical object.

Building on the principles of micromix combustors, numerous ongoing studies worldwide are examining the flame dynamics and combustion characteristics of burning high hydrogen content in these systems. However, recent research has highlighted some of their limitations. Ruiz et al. [33] used numerical simulations to investigate hydrogen-enriched combustion in industrial micromix systems. At an energy density of 14 MW/m2 bar, flames with 90% hydrogen generated low NOx emissions (12–85 ppm). However, CO concentrations significantly increased, ranging from 448 to 4970 ppm with varying hydrogen content. Chen et al. [10] studied the mixing performance of a novel micromix nozzle and found that, due to the millimeter-scale configurations of micromix combustors, increasing the premixed distance did not enhance the mixing uniformity of the reactants from the non-premixed injectors. As a result, achieving complete mixing of fuel and air remains a significant challenge [10,33]. Additionally, common issues in gas turbine combustion systems, such as combustion instability [38,47,48,49,50,51,52], have also been observed in micromix combustors.

1.3. Combustion Instability of Hydrogen-Enriched Methane Flames

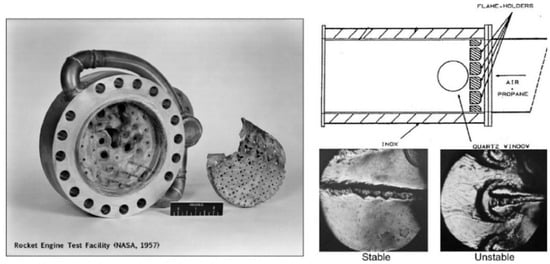

Combustion instability (CI), also known as thermoacoustic instability [12], has been widely reported in low-emission gas turbine combustion systems, particularly in DLE combustors. These pressure oscillations can reach high amplitudes, disrupting normal operation and potentially leading to system failures [53,54], as illustrated in Figure 7.

Figure 7.

Combustion instability damaging hardware. (Left) a rocket engine suffered from combustion instability; (Right) comparison of a laboratory burner of stable and unstable conditions [53,54].

Although most commonly observed in lean premixed combustion, combustion instabilities are not confined to a single combustion mode and are prevalent across various combustor types. For instance, combustion instabilities have been reported in partially premixed swirl combustors [55,56], non-premixed swirling combustors [57,58], heavy oil-fired boiler with NOx-reduction treatments [59] and a 350-kW boiler with flue gas recirculation [60,61]. The widespread occurrence of CI suggests that many conventional combustors are susceptible to such pressure fluctuations [62]. A widely accepted condition for the onset of combustion instability, based on the Rayleigh Criterion [63], is that instability occurs when the phase difference between heat release oscillations and pressure fluctuations is less than 90°.

where and separately present pressure and heat release rate fluctuations.

The prevalence of combustion instability is primarily attributed to two factors: the confined space in combustion chambers, which is insufficient to dissipate thermoacoustic oscillations, and the fact that only a small fraction of the heat generated by chemical reactions is required to induce these oscillations. Additionally, reductive outlet nozzles are prone to triggering combustion instabilities [64]. The complexity of energy transfer within combustion systems complicates intrinsic analysis [65], while the nonlinear responses of flames to acoustic excitations [66] render such oscillations unpredictable and difficult to control. Various methods have been proposed to manage combustion instabilities, including feedback control [67] and passive control [68,69] such as Helmholtz resonators, perforated liners [70,71,72], and electrical heaters [73].

The risk of oscillations is further exacerbated by hydrogen enrichment. First, hydrogen addition raises uncertainty about whether combustion instability in a given combustor can be controlled, as hydrogen enrichment may either trigger [74,75] or suppress [76,77] instabilities, depending on combustor design and operating conditions. Second, hydrogen enrichment tends to alter the nature of fluctuations, affecting oscillation frequency and amplitude [78,79], shifting operating conditions for instability [80,81], and leading to frequency shifts, mode switching [82,83,84,85], and other nonlinear flame behaviors [86,87,88]. Finally, combustion instability has been reported in most low-emission combustion modes of hydrogen-enriched flames. In addition to the common lean premixed combustion [89], pressure oscillations have been observed in hydrogen-rich Moderate or Intense Low-oxygen Dilution (MILD) combustion [90], fuel/air staging combustion [49,82], and even in pure hydrogen micromix combustors [91]. These pervasive combustion oscillations present significant obstacles to the development of hydrogen-enriched combustors and hinder the potential application of burning high hydrogen contents.

Extensive studies have investigated the effects of hydrogen addition on combustion instability, driven by the potential for widespread future use of hydrogen energy [12]. Hydrogen addition accelerates flame motion and reduces flame convection distances due to hydrogen’s high reactivity. As the hydrogen content increases, the centroid of flame heat release shifts upstream toward the nozzle. These changes alter the flame’s response to external excitations [92,93,94,95], thereby modifying the phase difference between heat release and pressure oscillations, which influences the resulting fluctuations. In thermoacoustic systems, the heat release from chemical reactions acts as a constant energy source [96], while flow disturbances can both trigger [97] and influence [98] thermoacoustic oscillations. The complex interactions within combustion systems make these processes difficult to unravel. For instance, the acoustically forced dynamics of swirl flames [99,100,101] lead to macro-scale changes in hydrogen-rich flame shapes. On a micro-scale, mechanical effects such as local flame front deformations and equivalence ratio fluctuations [102] can induce mode shifting. Furthermore, the nonlinear response of flames to acoustic excitations [66] contributes to the unpredictability and uncontrollability of such oscillations. High hydrogen combustion is particularly sensitive to low-frequency oscillations (<1000 Hz) due to the flame’s low-pass filter behavior [103] and the nonlinear combustion dynamics of hydrogen-rich flames [104,105,106]. Despite significant efforts to understand the underlying mechanisms, there remain unresolved areas, particularly in the intermediate interactions between hydrogen addition and combustion instability. These include variations in heat release distribution with different hydrogen fractions, the vortex dynamics influenced by hydrogen addition, and its interaction with nearby chemical reactions, as well as the thresholds of hydrogen content that lead to significant behavioral changes. These phenomena vary across different combustor and nozzle configurations and under varying operating conditions.

1.4. Purpuse and Scope of This Review

Combustion instabilities are considered a significant risk in gas turbine combustion systems [107], and the increasing emphasis on hydrogen energy applications introduces additional complexities compared to the instability behavior of conventional methane flames. As a research hotspot, numerous reviews have explored the connections between hydrogen-enriched methane flames and combustion instability. A summary of key studies and their conclusions is provided in Table 2.

Table 2.

Previous reviews that introduce the dynamics and stability of hydrogen-enriched flames.

Previous research has primarily focused on describing the oscillation behavior of hydrogen-rich methane flames and the instability of high-hydrogen combustion [11,74]. However, there remains a lack of comprehensive understanding regarding the effects of hydrogen addition on combustion instability, particularly concerning the characteristics and underlying mechanisms of these phenomena. Thus, it is essential to conduct an in-depth review of the phenomena and mechanisms related to hydrogen combustion that have emerged in recent years.

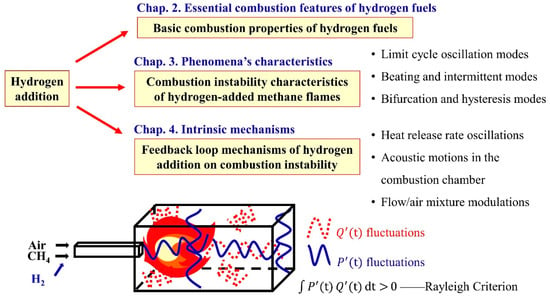

This review aims to summarize recent literature on the combustion instability of hydrogen-enriched methane flames while clarifying the characteristics and underlying mechanisms. The related studies are divided into three parts, including essential combustion features, instability manifestations, and mechanisms, as illustrated in Figure 8. The structure of this paper is organized into six sections as follows:

Figure 8.

The recent relative studies divided into three sections, as the afterward three chapters in this review. The formula of Rayleigh Criterion is adopted from Ref. [63].

- Section 2: A brief introduction to the essential combustion features of hydrogen fuels.

- Section 3: A discussion of the instability manifestations in hydrogen-enriched methane flames.

- Section 4: An analysis of the underlying mechanisms by which hydrogen addition affects combustion instability.

- Section 5: A review of the current research status and prospects for future work.

- Section 6: Conclusions of the present review.

2. Basic Combustion Properties of Hydrogen Fuels

Hydrogen exhibits distinct combustion characteristics that set it apart from conventional fuels such as natural gas, the primary component of which is methane, comprising approximately 85% [110]. Understanding the fundamental differences between hydrogen and methane combustion is crucial for gas turbine applications.

Hydrogen addition influences the thermo-physical properties of turbulent reacting flows, thereby affecting flame behavior and combustion dynamics. As a result, hydrogen-enriched methane flames differ from conventional flames across various scales. The following section provides a detailed overview of the primary combustion features of hydrogen fuels. As illustrated in Figure 9, a three-step approach is presented. First, the thermophysical properties of hydrogen fuels are discussed at the microscopic level. Next, the fundamental properties of hydrogen-enriched methane flames are examined. Finally, the dynamics and stability of hydrogen-enriched combustion are summarized. While combustor geometries and operating conditions impact macro-scale performance, the microscopic-level characteristics are primarily determined by the properties of hydrogen itself. This section serves as a foundation for the subsequent discussion on the phenomena and underlying mechanisms of combustion instability due to hydrogen addition.

Figure 9.

Schematic representation of basic combustion properties of hydrogen fuels.

2.1. Thermophysical Properties of Hydrogen

The thermophysical properties of fuels encompass both chemical reactions and transport phenomena. While hydrogen exhibits high reactivity in chemical processes [111], in turbulent reacting flows, transport properties play a crucial role in influencing flame behavior and nonlinear combustion dynamics. Therefore, the focus here is on transport properties. Hydrogen demonstrates highly active transport properties, most notably in its strong molecular diffusivity. Key transport parameters, such as thermal diffusivity, mass diffusivity, and the Lewis number (Le)—a non-dimensional ratio—are summarized in Table 3 for both methane and hydrogen. A comparison of mass diffusivity reveals that hydrogen molecules diffuse approximately four times faster than methane in air.

Table 3.

Comparison of molecular diffusivities between hydrogen and methane at 300 K and 1 atm (Computed using GRI-Mech 3.0 [8], the adiabatic flame temperature equals 1660 K).

It is worth noting that in numerical simulations, the Lewis number of fuel mixtures is often assumed to be one to improve the computational efficiency of Direct Numerical Simulation (DNS) and Large Eddy Simulation (LES) [112]. As shown in Table 3, this assumption is feasible for methane combustion; however, for hydrogen combustion, it is essential to compare appropriate combustion models and apply precise reaction mechanisms due to hydrogen’s distinct properties.

Hydrogen’s strong diffusivity makes laminar hydrogen flames more sensitive to stretch [113], resulting in unstable flame fronts [114]. A recent study [115] found that the exceptionally low Lewis number of hydrogen amplifies small perturbations at the flame front, leading to highly wrinkled flame structures, significantly increased flame velocity, and substantial changes in reaction rates.

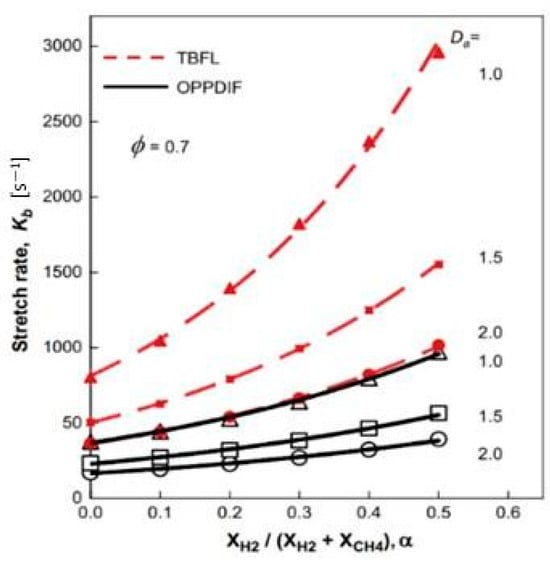

Strain rates, denoted as Kb (also referred to as local stretch rates), are used to quantify the rate of flame surface variations. Strain rate characterizes the combined effects of hydrodynamic flame stretch and flame front curvature [24,113]. As shown in Figure 10, flames exhibit higher strain rates as hydrogen content increases, indicating that hydrogen enrichment makes the flames more sensitive to flow disturbances.

where presents the flame surface area.

Figure 10.

Strain rate (stretch rate) with hydrogen addition [116]. OPPDIF stands for opposed-flow planar flame, while TBFL means tubular flame. Da means the Damkholler number.

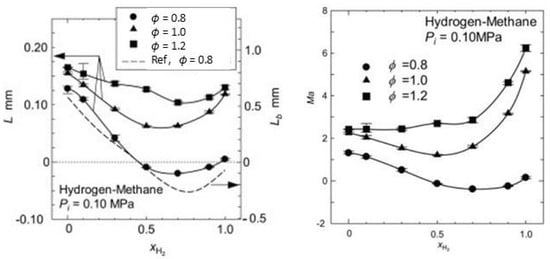

In addition to the higher strain rates observed in hydrogen-enriched flames, studies on Markstein length (also referred to as Markstein number) indicate that hydrogen-enriched flames exhibit greater sensitivity in their laminar burning rates to flame stretch. The Markstein length and Markstein number are used to characterize the flame’s response to burning velocity under the influence of stretch, including both strain and curvature effects. The Markstein number relates to the surface of the reaction zone, while the Markstein length is of the same order of magnitude as, and proportional to, the laminar flame thickness .

where and separately present the laminar stretched and unstretched burning velocity, means the flame thickness of unstretched flame, can be derived by one-dimensional temperature gradients of planar premixed flames. , presents unburnt.

The results in Figure 11 [114] show that a negative Markstein length appears in hydrogen fractions between 0.5 and 0.9, indicating flame instability. The changing sign of the Markstein length suggests a more pronounced response of the mixture to flame stretch. Given hydrogen’s higher laminar burning velocity, the addition of hydrogen increases flame instability, making the combustion process more difficult to control.

Figure 11.

Markstein length (left) and Markstein number (right) of different hydrogen contents [114]. The means Markstein length .

2.2. Hydrogen-Enriched Methane Flame Fundamental Characteristics

Since the definition of laminar burning velocity is not applicable to turbulent flows, the turbulent consumption speed () has been introduced to compare turbulent “flow velocity”. represents the fuel consumption rate in the internal shear layer and depends on turbulent intensity. Similarly, the turbulent flame speed (), defined as the global fuel consumption per unit time, is taken equivalent to the turbulent consumption speed ().

where denotes the volumetric heat release rate, is the heat value of the mixture, is the positive axis of the flame, means the unburned mixture density, and correspond to the temperature of the unburnt and burnt mixture.

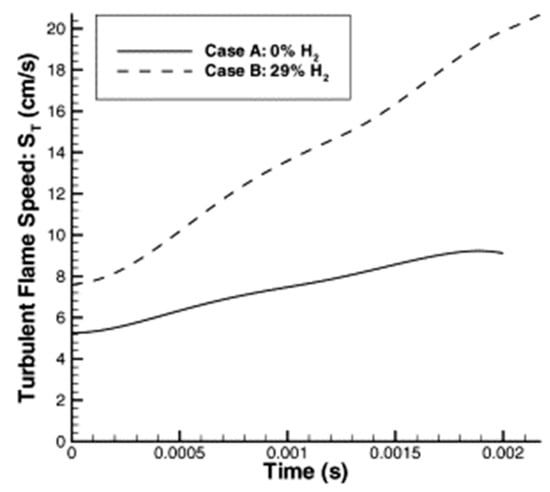

A DNS study [117] comparing the turbulent consumption speed of lean premixed flames with varying hydrogen fractions, as shown in Figure 12, reveals that hydrogen-fueled flames exhibit higher velocities than pure methane flames. After 2 ms (two vortex transition turnover cycles), the velocity difference can be as much as twofold. The higher turbulent consumption speed enhances the flame’s resistance to flashback and promotes stable combustion. Hydrogen enrichment leads to increased turbulence intensity.

Figure 12.

Turbulent flame speed for a single hydrogen fraction (29% H2) and CH4 [117].

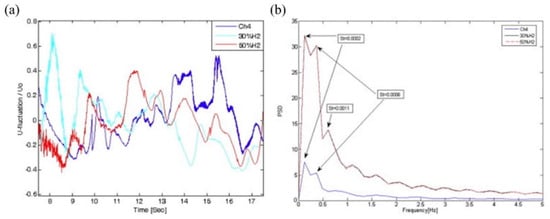

The increase in turbulence intensity with hydrogen enrichment has a significant impact on the dynamic flame characteristics within the combustion chamber. In addition to producing a more compact flame shape, hydrogen addition intensifies the velocity fluctuations at the flame front. A LES study [118] used axial velocity fluctuations at the wrinkled flame front to represent these fluctuations, as shown in Figure 13. The hydrogen-enriched mixture exhibits pronounced fluctuations, whereas the pure methane flame remains relatively stable.

Figure 13.

Axial velocity fluctuations in the wrinkled flame location: (a) fluctuations, (b) spectra (12.5–17.5 s). means inlet velocity. . Replotted from Ref. [118].

The increased flame temperature in hydrogen-enriched methane flames has been widely documented in Refs. [119,120]. At an equivalence ratio of 0.5, increasing the hydrogen content from 20% to 80% raises the adiabatic flame temperature from 1670 K to 1745 K [24]. Similarly, in a turbulent non-premixed diffusion model combustor [121], the overall flame temperature increases from 1125 K in methane combustion to 1372 K in hydrogen combustion.

2.3. Dynamics and Stability of Hydrogen-Enriched Combustion

This section briefly introduces the combustion dynamics and stability characteristics of hydrogen-enriched flames, which arise from hydrogen’s thermophysical and fundamental flame properties. These include phenomena such as auto-ignition and flashback [120], more NOx emissions [12,122], and varying combustion instability behavior [12,90,123,124].

Due to its shorter ignition delay time, hydrogen is prone to spontaneous ignition in the premixed section without an external ignition source [125,126]. This can occur across a wide range of operating pressures, making premixed combustors unsuitable for high hydrogen combustion for safety reasons.

Flashback refers to the undesirable movement of the flame front from the main reaction zone back into the combustor’s injection section, leading to overheating and combustion failure. The turbulent flame speed of hydrogen-enriched methane flames is significantly higher than the flow velocity of the reactants, making flashback a common issue in hydrogen combustion [127]. Recent studies using the flamelet generated manifolds (FGM) approach have accurately predicted flashback limits for laminar premixed hydrogen flames, showing good agreement with experimental data [128].

The increased NOx emissions associated with hydrogen-enriched methane flames present further challenges. In a turbulent non-premixed diffusion combustor model [121], NOx emissions rise significantly to 549 ppm in hydrogen flames compared to 57 ppm in methane flames. It is important to note that, beyond thermal NOx, hydrogen addition also promotes the NNH pathway, which has recently been identified as a dominant route for NOx formation [129].

Given that combustion instability in hydrogen-enriched methane flames is the primary focus of the present study, this topic will be discussed in detail in the following sections.

3. Combustion Instability Characteristics of Hydrogen-Added Methane Flames

Combustion instability refers specifically to combustion processes characterized by periodic pressure oscillations with well-defined frequencies. While pressure fluctuations are common in turbulent reacting flow systems, even during stable combustion, combustion is considered stable if the amplitude of these fluctuations remains within 5% of the mean chamber pressure for certain combustors [130]. In contrast, combustion instability is marked by large-amplitude periodic pressure oscillations.

The impact of hydrogen addition is evident in the shift in oscillation operating conditions, such as changes in stability maps [76,131]. The transition of unstable regions toward lower equivalence ratios [76,124,132] is attributed to the faster reaction rates and shorter convective time scales associated with higher hydrogen content. In addition to this shift in equivalence ratios, hydrogen-enriched flames exhibit an extended lean blowout (LBO) limit compared to pure methane flames, owing to hydrogen’s higher resistance to strain [12,90,123,124].

Combustion instability, as a nonlinear combustion dynamics phenomenon, manifests in various forms. According to dynamical system theory [133], these nonlinear processes are typically classified into several modes, including limit cycle oscillations, beating and intermittent oscillations, and bifurcation and hysteresis oscillations. Some oscillation types, such as limit cycles, are directly triggered by hydrogen enrichment [86]. Other instability types, like bifurcation and hysteresis, are generally considered independent of fuel interchangeability [134]; yet these manifestations have been observed in hydrogen-enriched methane flames.

3.1. Limit Cycle Oscillation Modes

Limit cycle oscillations are the most common form of self-sustained combustion instabilities. These oscillations are typically characterized by continuous, periodic fluctuations with fixed frequency and amplitude [135]. The addition of hydrogen affects both the frequency and amplitude of these limit cycle oscillations.

The effects of hydrogen addition on oscillation frequency can vary. In some articles on lean premixed (LPM) combustion with low hydrogen content (<20%) [79,82,136], hydrogen-enriched methane flames exhibit similar oscillation frequencies to those of pure methane flames, with hydrogen enrichment primarily influencing the amplitude of oscillations. However, as hydrogen content increases to around 40%, a slight rise in oscillation frequency is observed. For example, a 10% increase in hydrogen by volume induces a frequency shift to higher modes, within 5% of the original frequency [78]. This slight frequency shift is attributed to the reduced convection time caused by hydrogen addition.

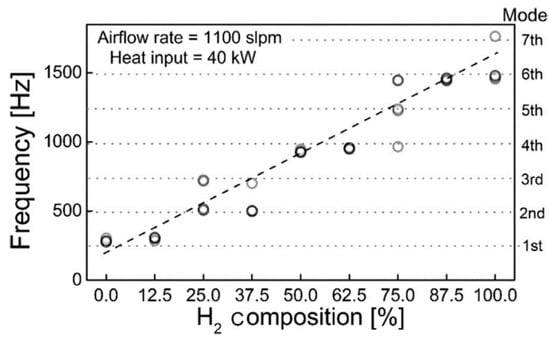

At higher hydrogen concentrations, mode switching between acoustic resonant frequencies occurs, a phenomenon widely reported by researchers in Korea [52,106,137,138,139,140]. As shown in Table 4, high hydrogen contents tend to trigger a shift in fluctuation frequency from a lower mode to a higher one, with peak frequencies reaching up to seven times the original frequency. This phenomenon, known as frequency/mode switching (FMS) [82,83], is a common result of significant hydrogen enrichment.

Table 4.

The frequency switching caused by hydrogen enrichments.

A typical correlation between oscillation frequency and hydrogen fractions is illustrated in Figure 14 [139]. The oscillation frequencies increase almost linearly, progressing from the 1st to the 7th acoustic resonant frequency of the combustor as hydrogen content gradually rises. The dominant characteristic time scale in premixed combustion—convection time—shortens with hydrogen enrichment, which is the key factor driving frequency/mode switching (FMS).

Figure 14.

The FMS tendency with different hydrogen contents [139].

While most studies focus on hydrogen addition in DLE burners, several published articles have highlighted the instability of hydrogen-rich combustion in micromix combustors [33,141,142], where high-frequency fluctuations are more likely to occur.

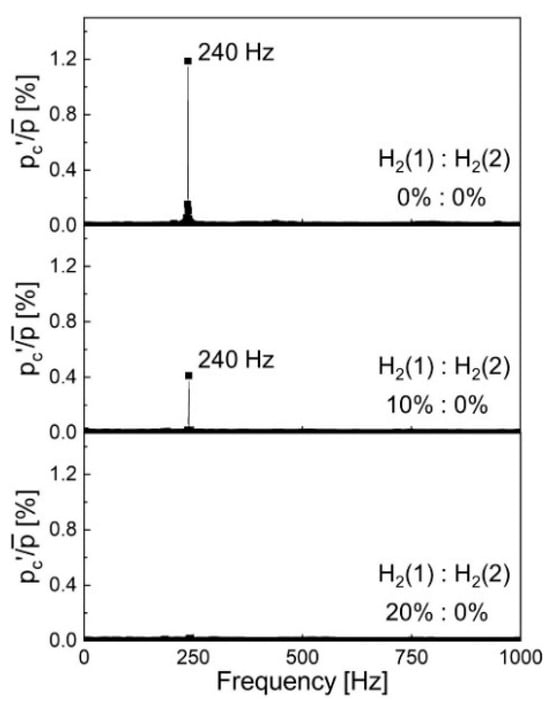

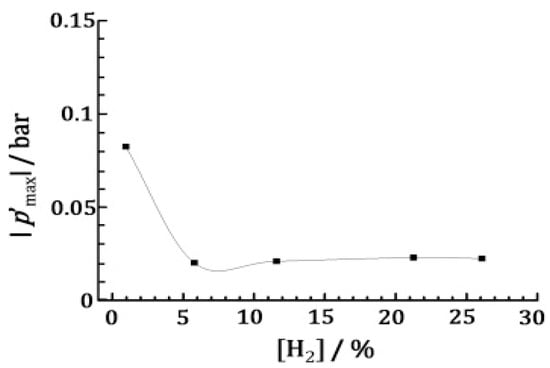

In contrast to frequency, oscillation amplitude does not exhibit a clear trend with increasing hydrogen content. Interestingly, small fractions (<5%) of hydrogen addition can reduce oscillation amplitudes. Since oscillation amplitude reflects fluctuation intensity [89], hydrogen enrichment is thought to influence the distribution of fluctuation energy.

In the experimental work of Ge et al. [79], self-excited combustion instabilities were tested in a swirling premixed radially staged DLE burner with hydrogen content varying from 0% to 26%. The peak pressure fluctuation amplitude, as shown in Figure 15, reveals that adding hydrogen to pure methane causes a sharp decrease in peak amplitude. However, as the hydrogen percentage increases beyond 5%, no significant effects on amplitude are observed.

Figure 15.

Changes in oscillation amplitudes with growing fractions of hydrogen [79].

In addition to single-nozzle gas turbine combustors, the reduction in oscillation amplitudes due to hydrogen enrichment has also been observed in fuel-staged dual-nozzle gas turbine combustors [82]. In these dual-nozzle systems, asymmetric fuel compositions are used to implement fuel staging, and the combustion instability phenomena are analyzed. As shown in Figure 16, increasing the hydrogen content in one of the dual-nozzle combustors weakens the combustion instability, which eventually almost disappears. The asymmetric hydrogen distribution attenuates combustion instability by disrupting the thermo-acoustic coupling, as the imbalance in flame position between the dual nozzles helps eliminate the instability.

Figure 16.

Reduction in oscillation amplitudes in one nozzle in a dual-nozzle gas turbine combustor with different hydrogen contents [82].

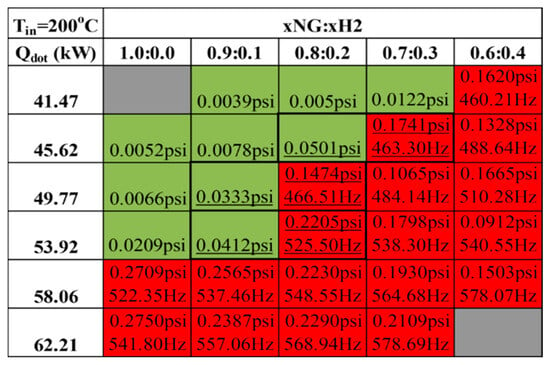

The reduction in oscillation amplitudes is primarily observed in low hydrogen combustion, with no clear trends emerging in high hydrogen combustion. Strollo et al. [78] conducted experimental studies to examine the effects of hydrogen addition on combustion instability in a single-nozzle swirling premixed combustor. As shown in Figure 17, increasing the hydrogen content from 20% to 40% at a heat load of 49.77 kW resulted in higher oscillation amplitudes. However, at a heat load of 62.21 kW, hydrogen enrichment reduced the oscillation amplitudes when the hydrogen content was below 20%.

Figure 17.

The stability map in a single-nozzle swirling premixed combustor [78].

3.2. Beating and Intermittent Oscillation Modes

Beating and intermittent modes are two common manifestations of combustion instability, differing from limit cycles primarily in their oscillation characteristics within the time domain [143,144]. Unlike limit cycles, which exhibit constant oscillation amplitude over continuous periods, beating refers to oscillations where the amplitude first increases to a maximum and then decreases to a lower value within a single cycle. Intermittent modes, on the other hand, display periodic oscillations with varying amplitudes that are not fixed.

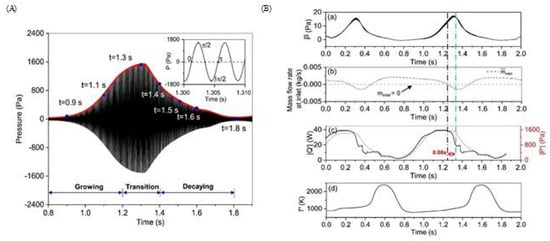

Recent studies have reported the effects of hydrogen addition on beating. Zhao et al. [143] used URANS (unsteady Reynolds-Averaged Navier–Stokes) simulations on a standing-wave combustor to investigate the impact of hydrogen content, as shown in Figure 18. The findings reveal significant effects of hydrogen enrichment on the thermodynamic properties of flames. Building on this work, Song et al. [144] conducted numerical simulations of pure hydrogen combustion and observed the presence of beating. The study found that beating instabilities occurred at equivalence ratios of 1.1 and 1.0 in the premixed gas. A typical beating mode, as depicted in Figure 19a, can be divided into three stages: the growing stage (0.8–1.2 s), the transition stage (1.2–1.4 s), and the decaying stage (1.4–1.8 s). The heat reactions, flame structures, temperature, and velocity fields all undergo similar changes across these stages. Pressure oscillations increase from 64 Pa to 1200 Pa during the growing stage, with peak fluctuations reaching 1540 Pa in the transition stage. An ultra-low oscillation frequency of 1 Hz is also noted as a characteristic feature of beating instabilities. The negative bulk inlet velocity during the growing stage, as shown in Figure 19b, suggests that backflow near the flame and changes in oxygen concentration may contribute to the occurrence of beating [144].

Figure 18.

The turbulent reaction rate with different hydrogen contents [143]. (a) hydrogen mass flow rate equals 1.0 × 10−6 kg/s; (b) hydrogen mass flow rate equals 5.0 × 10−6 kg/s; (c) hydrogen mass flow rate equals 1.0 × 10−5 kg/s.

Figure 19.

Beating in pure hydrogen combustion. (A) a beating oscillation cycle in the time domain; (B) the changes in key parameters in the time domain. The variations of (a) mean pressure; (b) mass flow rate at inlet; (c) heat release rate; (d) temperature as time passes. Reproduced from Ref. [144].

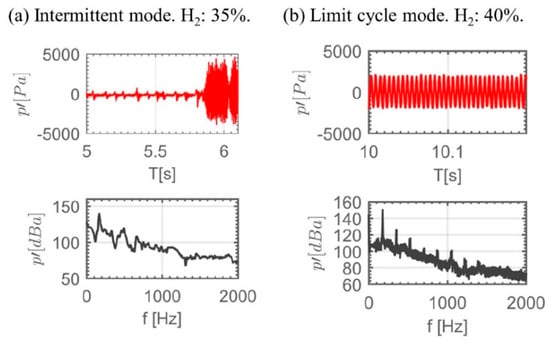

There are varying interpretations of intermittent modes. Some scholars consider them to represent an oscillatory phenomenon distinct from limit cycles [145,146], while others view them as an intermittent process during the transition between two limit cycles [147,148]. Regardless of the interpretation, intermittent modes are often considered precursors to impending combustion instability [148]. Karlis et al. [136] studied intermittent modes in a lean premixed swirl model gas turbine combustor with hydrogen fractions ranging from 0 to 40% and different equivalence ratios, maintaining a constant Reynolds number of 19,000. Limit cycles were observed at all hydrogen contents for equivalence ratios of 0.70, whereas intermittent states appeared at equivalence ratios of 0.55. With constant heat load and equivalence ratios, intermittent states were triggered when the hydrogen content ranged between 30% and 37.5%, with a limit cycle achieved at 40% H2. A comparison of the oscillation characteristics is shown in Figure 20. The authors [136] conducted theoretical calculations on the relative extinction strain rates ) of hydrogen-fueled natural gas. The increased enhances the coupling between the flame and swirling flows, leading to intermittent bursts of heat release rates.

Figure 20.

Comparison of the dynamic states of pressure between intermittent modes and limit cycle modes. Rearranged from Ref. [136].

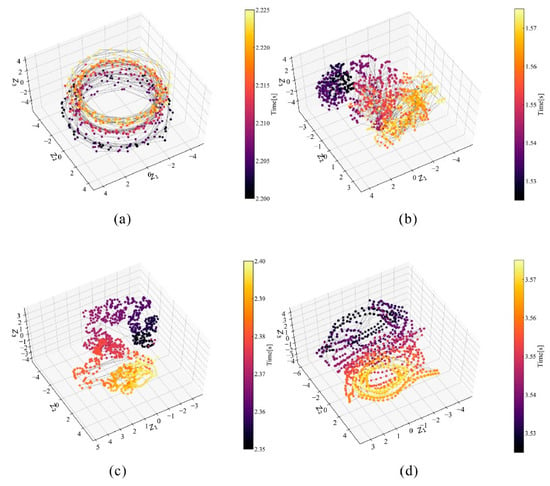

Intermittent modes have also been reported during the transition from vortex-dominated to thermoacoustic states. Nakaya et al. [149] experimentally investigated combustion instabilities under varying hydrogen flow rates in non-premixed hydrogen-rich combustion using a bluff body in a model afterburner. Combustion instability was observed under fuel-rich conditions with overall equivalence ratios of approximately 2.4 and 2.7. Mode transitions occurred at an equivalence ratio of 2.4. After hydrogen injection, the pressure frequencies and amplitudes exhibited spontaneous variations over different time periods. At 0 s, there was a slight increase in pressure. By approximately 2.4 s, the peak of the flame-vortex interaction at 2300 Hz became dominant. Subsequently, this peak weakened, while the first longitudinal mode strengthened. Eventually, harmonic modes of combustion instability appeared, indicating the presence of a limit cycle. Figure 21 illustrates the evolution of latent variables (attractors) in a three-dimensional latent space, analyzed using the Gaussian process latent variable method (GP-LVM) [150], following hydrogen injection. The limit cycle of the flame-vortex interaction is shown in Figure 21a. The transition to intermittent modes is depicted in Figure 21b, where there are no clear indications of thermoacoustic instability. Weak and strong harmonic modes are observed in Figure 21c and Figure 21d, respectively.

Figure 21.

Evolution of the latent variables in the coupling of the flame-vortex interaction to the thermoacoustic mode via GP-LVM after hydrogen was injected at the overall equivalence ratio of 2.4 [149]. (a) limit cycle of the flame-vortex interaction; (b) weak transition from the vortex to the thermoacoustic; (c) strong transition from the vortex to the thermoacoustic; (d) limit cycle of the combustion instability.

3.3. Bifurcation and Hysteresis Oscillation Modes

Bifurcation and hysteresis are indicative of nonlinear flame behavior in combustion systems [108]. In turbulent reacting flows within a combustion chamber, operating parameters can cause significant changes when passing through a critical threshold. A bifurcation point represents the specific moment when this shift occurs. In other words, bifurcation points mark the transition from a stable state (or low-amplitude oscillation) to unstable behavior, corresponding to critical values of the governing parameters. Due to hysteresis, the reverse transition may not occur at the same parameter value. Hysteresis, defined as the phenomenon where energy is lost after repeated loadings [134], further characterizes the nonlinear behavior in the system. Thus, bifurcation and hysteresis are closely linked to nonlinear combustion dynamics.

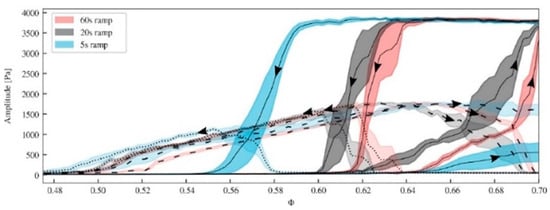

Bifurcation- and hysteresis-related combustion dynamics are typically associated with variations in equivalence ratios or mean inlet velocities. However, relatively few studies have explored these dynamics in relation to varying hydrogen content. Indlekkofer et al. [151], for instance, reported hysteresis phenomena in a laboratory-scale annular combustor with 70% hydrogen power fractions. Different types of hysteresis were observed between the upward and downward ramps, affecting both oscillation amplitudes and stable operating conditions, as shown in Figure 22. The hysteresis phenomena significantly rely on the working conditions of ramping speed, direction, and the thermal power. A potential cause for the various responses to ramping directions is the various initial conditions. The joint PDFs (probability distribution function) in Figure 23 shows a repetitive but slightly asymmetric pattern of the quasi-periodically switching spinning mode leading to beating through the acoustic signal amplitude.

Figure 22.

The hysteresis effects presented by the transition in the bifurcation points [151] (Power = 6 kW). The dashed and dotted lines mean increasing and decreasing equivalence ratios, respectively.

Figure 23.

Comparison of the joint PDFs of the nature (left) and orientation angle (right) at Power = 4 kW [151]. The region where the amplitude is below 100 Pa is marked.

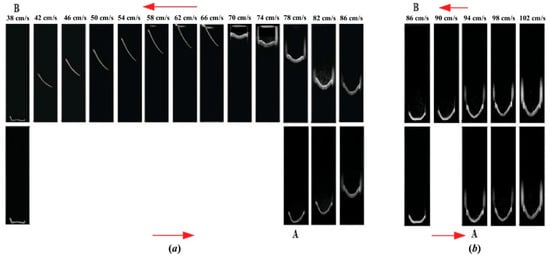

Aguilar et al. [86] experimentally studied the bifurcation of flame structures in a perfectly premixed combustor. As hydrogen power fractions increased, the original pure methane flame transitioned from a lifted flame attached to the wall to a bluff-body anchored flame, and eventually to a bluff-body anchored flame detached from the wall. At a constant hydrogen power fraction of 0.23, two distinct flame shapes and structures were observed, as shown in Figure 24. This study identified flame structure bifurcation under different hydrogen power contents, extending the understanding of bifurcation phenomena from varying typical operating conditions to changes in hydrogen content. These findings suggest that hydrogen enrichment adds complexity to bifurcations.

Figure 24.

Flames share different shapes at the same condition of equals 0.23 [86].

Bifurcation and hysteresis are frequently reported under varying equivalence ratios, but there is limited information on how these phenomena behave under different hydrogen contents. However, bifurcation and hysteresis affected by hydrogen enrichment have been observed in other combustion types, beyond lean premixed combustion in gas turbine systems. Agreda et al. [152] conducted a bifurcation analysis on the effects of hydrogen addition in pre-vaporized ethanol combustion, with hydrogen content ranging from 0 to 0.02464 molar fractions. Using well-stirred reactor (WSR) simulations, they found that as hydrogen content increased, oscillation amplitudes gradually diminished, leading to a steady, stable solution. This suggests that hydrogen enrichment reduces oscillation intensity. Tang et al. [153] studied the effects of hydrogen enrichment on hysteresis in propane combustion in a micro-planar combustor. Their findings indicated that hydrogen addition expands the velocity range of stable states and mitigates flame instability. Adding 10% hydrogen inhibited the transformation of flame structure from U-shaped to inclined flames, thereby improving flame stability. The flame position and thickness increase with inlet velocity were found to be independent of hydrogen addition. Furthermore, hydrogen enrichment extended the inlet velocity range for U-shaped flames, helping to overcome the inlet velocity inertia caused by hysteresis. As shown in Figure 25 [153], flame structure transitions with changing flow rates at two different hydrogen contents. The red arrows represent the direction of variation in inlet velocity, whether increasing or decreasing. Points A and B mark the onset of flame structure transformation. The results demonstrate that hydrogen-rich flames are more effective at suppressing hysteresis compared to pure propane flames. In pure propane combustion, inlet velocity inertia leads to hysteresis and triggers combustion instability. However, the high-temperature range induced by hydrogen enrichment reduces these effects, increasing the peak curvature radius while also negatively affecting the minimum curvature.

Figure 25.

The hysteresis with and without hydrogen addition in propane combustion at the equivalence ratio 0.9 [153]. (a) no hydrogen; (b) with hydrogen addition 10%.

4. Feedback Loop Mechanisms of Hydrogen Addition on Combustion Instability

Combustion instability is a coupling phenomenon between resonant combustor acoustics and heat release rate fluctuations. The heat release from chemical reactions serves as the dominant energy source in combustion systems [154]. Under the combined influence of acoustics, fluid dynamics, and flame reactions, combustion instability manifests through various characteristics, which are summarized within the feedback loop process [155]. Heat release oscillations generate acoustic oscillations, while pressure and velocity fluctuations propagate through the flow, affecting flame propagation. The resulting vortical structures and equivalence ratio oscillations feed back into heat release oscillations, thereby closing the feedback loop. The feedback loop mechanism for thermoacoustic instabilities is critical, as the complex interactions between oscillatory flows, unsteady heat release, and combustion chamber structures play a decisive role in the onset, manifestation, and progression of combustion instability.

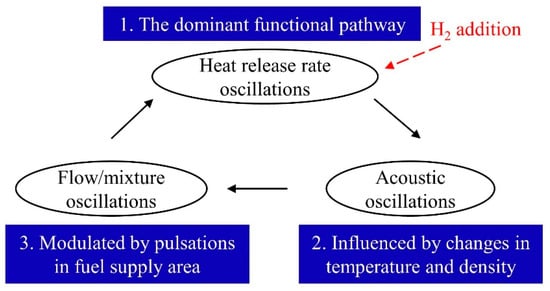

Hydrogen enrichment can influence each aspect of the feedback loop mechanism, as illustrated in Figure 26. Fuel interchangeability directly affects heat release oscillations due to differences in reaction rates and turbulence intensities. As a primary impact mechanism, hydrogen addition affects heat release oscillations in three key areas: movement of the heat release centroid, changes in flame shape, and alterations in the flame’s dynamic response to external disturbances. The second section examines the effects of hydrogen enrichment on acoustic oscillations. While fuel flexibility may have limited influence on the acoustic properties of specific combustors, hydrogen enrichment—through changes in temperature and density—can impact the acoustic resonant frequencies of the combustion system. The third section addresses flow/mixture oscillations, where variations in fuel composition lead to pulsations in the fuel supply, causing changes in the turbulent flow fields.

Figure 26.

The effects of hydrogen addition on combustion instability. The feedback loop mechanisms are adopted in Ref. [155].

4.1. Heat Release Rate Oscillations

The heat release from the chemical reactions of the flames is sufficient to sustain periodic instability oscillations, making flames generally regarded as the primary heat source of combustion instabilities [156]. Since the length and time scales of reaction zones and flame brushes are significantly smaller than the combustor size and acoustic wavelength, flames shorter than the acoustic wavelength are considered “acoustically compact” [155]. These acoustically compact flames are typically approximated as point or line sources, representing the “center of heat release”. This assumption is usually valid for lean premixed combustion, where the spatially integrated unsteady heat release is a key factor.

Hydrogen addition directly affects the spatial distribution of heat release and shifts the “center of heat release” due to the increased flame speed. As a result, the convection time scale [139], which represents the characteristic time for reactants to be transported from the injection point to the main reaction zones by convection, is reduced. These changes play a crucial role in determining the phase relationship between heat release and pressure oscillations, significantly impacting instability characteristics.

Moreover, several studies [86,136,157] have demonstrated the correlation between flame shape variations and combustion instabilities triggered by hydrogen enrichment. For instance, increased extinction strain rates due to hydrogen’s high diffusivity can lead to transitions from V-shaped to M-shaped flames [136].

In addition to changes in flame heat release, the flame’s response to external excitations, such as forced oscillations [87,158,159], is also affected by hydrogen incorporation. These variations influence the intrinsic relationships between turbulence, flame dynamics, and acoustic processes in the development of combustion instabilities.

4.1.1. Movement of Flame Positions

There is no universally accepted criterion or well-defined conditions to determine the flame’s “center of heat release”. Based on the assumption of “acoustically compact” flames [155], the heat release is typically integrated over the combustor cross section to produce a one-dimensional mean axial distribution. The time-averaged “center of heat release” [157] and flame length [86] are expressed in the following forms.

where is the axial position, means the combustor cross-section area.

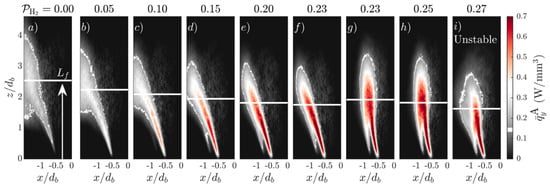

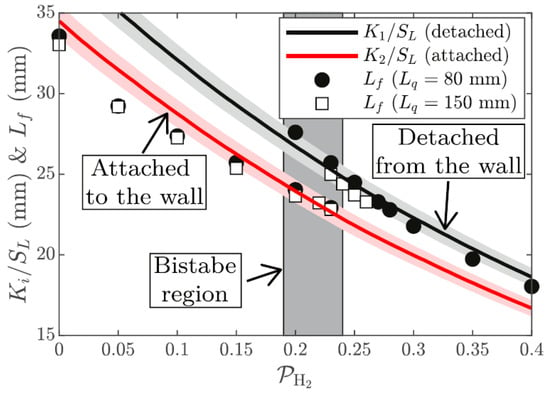

Due to higher reaction rates, hydrogen enrichment can significantly shift the centroid of heat release upstream of the burner or shorten the flame length. Hydrogen addition moves the center of heat release upstream of the nozzle, with variations in hydrogen content directly affecting flame shape [86]. As hydrogen enrichment increases, the flame gradually detaches from the wall and moves upstream toward the injection point. A sudden change in flame shape occurs at a hydrogen power fraction of = 0.23, after which further increases in lead to a continuous reduction in flame length (). The combustion system becomes unstable when > 0.27, with high-amplitude limit cycle oscillations forming at > 0.27. The flame lengths () are clearly associated with hydrogen fractions. A characteristic flame length as a function of hydrogen content has been proposed [86], as illustrated in Figure 27. The laminar flame speed and two curve constants are applied for comparison. It is suggested that the reduction in flame length is related to an increase in laminar flame speed. Thus, hydrogen can be applied to present the characteristic flame length, which is further used as an input for the flame transfer function.

Figure 27.

A characteristic flame length as a function of hydrogen content [86]. Two different flame shapes observed at = 0.23, the gray shaded area.

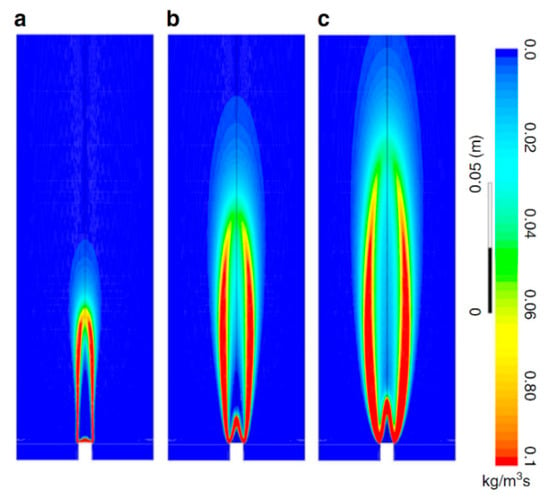

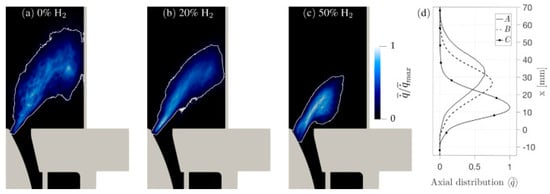

In addition to experimental observations, numerical simulations also reveal the relationship between flame length and hydrogen enrichment. Agostinelli et al. [157] used LES to analyze the effects of hydrogen addition on flame structure in a lean, partially premixed swirling flame. Hydrogen volume fractions were set at 0%, 20%, and 50%. The results, shown in Figure 28, demonstrate a reduction in flame length due to hydrogen enrichment. At 50% H2, a bi-modal thermoacoustic oscillation was triggered, with two dominant frequencies at 310 Hz and 470 Hz.

Figure 28.

Normalized time-averaged heat release rate for different hydrogen contents [157]. White iso-contours stand for 10% of . (a) 0%H2, (b) 20%H2, (c) 50%H2, and (d) the normalized heat release rates along the axial distributions.

Nam et al. [160] conducted Large Eddy Simulations (LES) on a scaled-down partially premixed combustor, calculating flame length by measuring the intensity-weighted centroid of OH radicals. As the hydrogen fraction increased from 50% to 100%, the combustion dynamics transitioned from unstable to stable, and the flame length decreased, causing the flame to shift upstream. Additionally, higher hydrogen enrichment was observed to result in more compact flames.

The aforementioned studies [155,157,160] have demonstrated that the “center of heat release” shifts upstream of the nozzle with hydrogen enrichment, significantly influencing combustion system dynamics. Hydrogen-enriched flames, being more compact, are more likely to trigger higher-frequency combustion instabilities compared to pure methane flames.

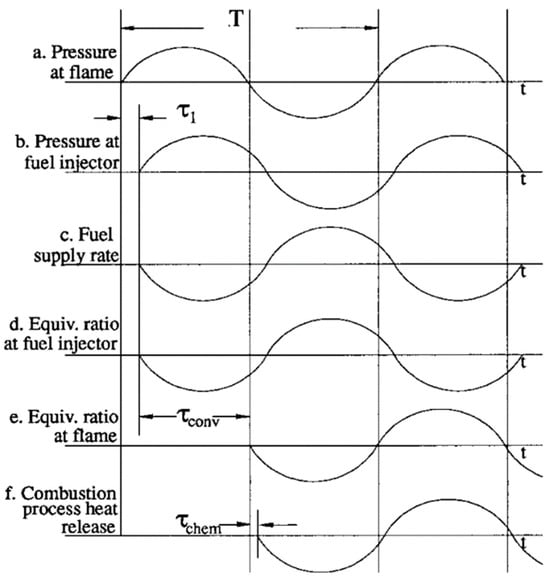

Consequently, increasing hydrogen content is believed to shorten the convection time (), a characteristic time scale that measures the convective flow from the nozzle to the main reaction zone. The convection time theory originated from time lag theory [102,161]. In early 1998, Lieuwen et al. [162] observed that the degree of reactant mixing played a crucial role in driving combustion instabilities in lean premixed gas turbine (LNGT) combustors. The distribution of several characteristic time scales in combustion instability, based on equivalence ratio perturbations [102], is shown in Figure 29. The occurrence of instabilities in combustion systems can be attributed to time lags in combustion—i.e., reactants injected from the nozzle at one instant are converted into burnt flue gases at a later time [163]. Convection time accounts for 69.9% and 83.4% of the total characteristic time scales for the 3rd and 4th modes, respectively, in a model gas turbine combustor with hydrogen addition [161].

Figure 29.

The source of convection time in driving combustion instability [102].

The convection time [139] is usually derived from flame lengths and convection velocity of reactants . The convection velocity is represented by the nozzle exit velocity for simple nozzles such as LPM combustors [106,137].

where stands for flame lengths, means the convection velocity of reactants, represented by the nozzle exit velocity.

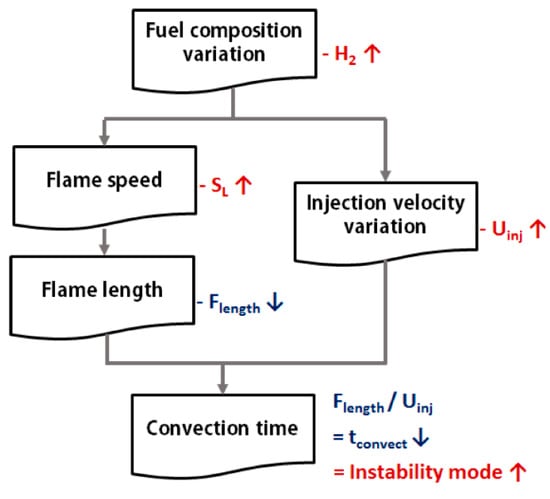

Hydrogen enrichment shortens flame length and increases nozzle velocity, thereby reducing convection time and influencing the instability characteristics of the combustion system. Yoon et al. [164] provided a qualitative description of how hydrogen addition affects convection time and its connection to instability modes, as shown in Figure 30. The reduced convection time alters the phase relationships between heat release and pressure fluctuations, leading to a transition to higher-frequency oscillation modes.

Figure 30.

A qualitative description of the hydrogen addition on convection time [164].

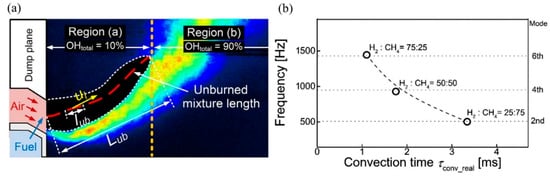

The shortened convection time due to hydrogen enrichment has been identified as a key parameter in combustion instability frequency/mode shifting (FMS) in premixed combustion [106,137,139,140,164,165,166]. Yoon et al. [139] investigated the effects of hydrogen addition in a partially premixed gas turbine, finding that increasing hydrogen content triggered FMS from the fundamental mode (≈250 Hz) to the 7th harmonic mode (≈1750 Hz) of the combustor. The authors also optimized the calculation of convection time and introduced the concept of real convection time [139]. A segmentation process of flame length was applied, and the exact unburned mixture velocity was determined using particle-image velocimetry (PIV). A clear inverse correlation between global convection time () and combustion instability frequency with varying hydrogen content is shown in Figure 31.

where is the equally divided local length along the mixture trajectory, and is the local velocity at each local distance.

Figure 31.

The relationships between convection time and oscillation frequency with different hydrogen contents. (a) the calculation progress of the . (b) the corresponding relationships between and CI Reproduced from Ref. [139].

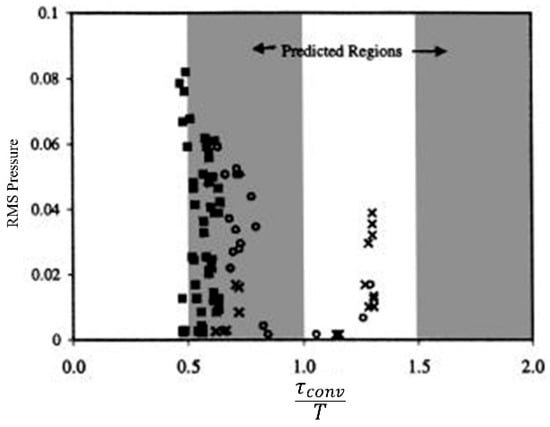

The relationships between convection time and oscillation frequency at different hydrogen levels highlight the critical role of convection time in combustion instability phenomena. Lieuwen et al. [167] analyzed the application of the time lag theory for several combustors and compared the measured convection time and predicted instability regions. As shown in Figure 32, regions of instability were expected to occur where . The corresponding relationships between them suggested the importance of convection time in all characteristics time scales in lean premixed instabilities.

where is a constant that depends on the combustor configuration, is a coefficient and a function of the flame Strouhal number, and , respectively, stand for the flame length and convection length.

Figure 32.

Pressure amplitudes measured in a lean premixed combustor and predicted linear stability limits as a function of convective time lag. Rearranged from Ref. [167].

4.1.2. Transitions of Flame Shapes

Several studies have highlighted the relationship between hydrogen-enriched flame shapes and the presence of combustion instability. Many studies [168,169,170] have observed that hydrogen addition leads to a transition in flame shape from V-shape to M-shape, accompanied by the onset of self-excited combustion instabilities. However, Lantz et al. [171] found that this flame shape transition with hydrogen addition inhibited the occurrence of combustion instability. Other studies [78,168] reported no significant variations in flame shape with low hydrogen content (typically less than 20% by volume), though instability states were still altered. While flame shape variations from hydrogen enrichment can influence stability conditions, the underlying mechanisms remain unclear.

Some studies [124,168,172] have identified hydrogen-enriched flame shapes as critical in triggering combustion instability. Taamallah et al. [124] and Shanbhogue et al. [168] linked the onset of thermoacoustic oscillations to flame shape variations caused by hydrogen enrichment. When flame shapes transition into the outer recirculation zone (ORZ), unstable combustion states emerge. The high extinction strain rates associated with hydrogen enrichment are thought to be the source of flame shape changes and the mechanism enabling combustion instability.

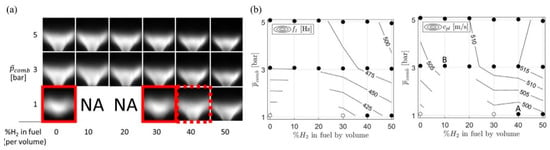

Chterev et al. [172] presented contrasting findings, where increasing hydrogen content caused flame shapes to transition from M-shape to V-shape, leading to high-frequency oscillations. As shown in Figure 33, increasing hydrogen fractions at 1 bar shifted the flame shape from M-flame to V-flame. The rise in oscillation frequency and amplitude demonstrates the intensified fluctuations due to hydrogen addition.

Figure 33.

The flame shapes, oscillation frequency and amplitudes for different hydrogen contents. (a) flame shapes transited from M-shape to V-shape by increasing hydrogen contents. Solid lines present the M-shape flames, while the dashed lines illustrate the V-shape flames. (b) the increased oscillation frequencies and amplitudes by hydrogen addition. Rearranged from Ref. [173].

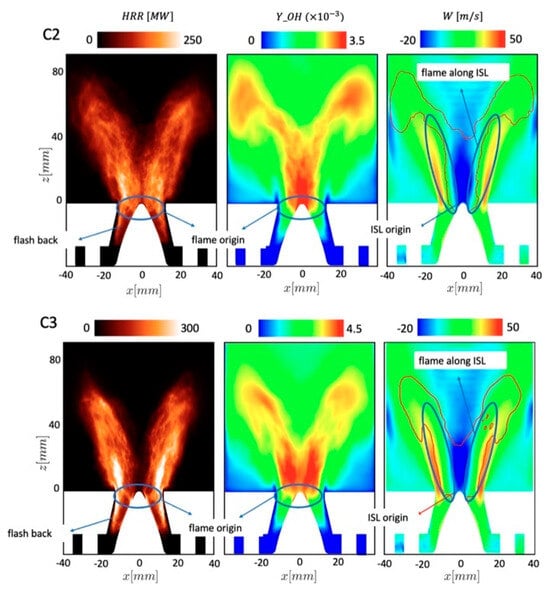

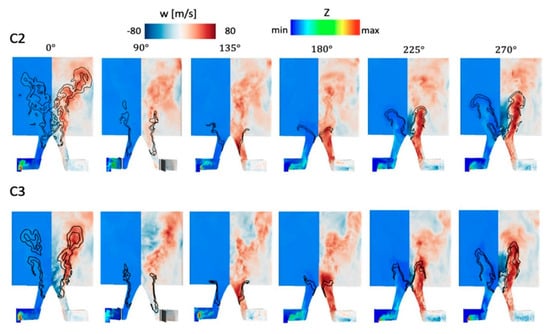

In contrast to the above studies [124,168,172] that suggest a connection between flame shapes and instability with hydrogen enrichment, other work [131,174] has reported that changes in instability manifestations may not be related to flame shape transitions induced by hydrogen. Figura et al. [131] was among the first to investigate the effects of hydrogen addition on the relationship between flame structure and self-induced thermoacoustic oscillations. They found that adding 25% hydrogen in a premixed combustor shifted unstable conditions to lower equivalence ratios while maintaining similar flame structures and oscillation frequencies, albeit with lower amplitude. More recently, Gong et al. [174] conducted Large Eddy Simulations on combustion instability in swirling flames using the PRECCINSTA burner with hydrogen addition. Instability occurred in the pure methane case (C2), whereas flames with 38% H2 addition (C3) maintained stable combustion, as shown in Figure 34. The flame shapes between the two cases—C2 and C3—were clearly visible: the pure methane combustion (C2) exhibited an unstable V-shaped flame, while the hydrogen-enriched flames (C3) showed a similar V-shaped but stable flame. These findings suggest that combustion instability may not necessarily be linked to flame shape.

Figure 34.

Comparison of heat release, flame shapes and velocity with hydrogen addition. C2 presents the pure methane case, while C3 means the flames with 38% H2 addition. ISL: inner shear layer. Replotted from Ref. [174].

4.1.3. Changes in Flame Dynamic Response to External Excitations

Many studies [87,158,159] have explored the forced response of hydrogen-enriched flames in contrast to self-excited combustion instability. The dynamic response of the flame to external perturbations helps to illustrate the interactions between flow and heat release fluctuations, corresponding to the feedback loop mechanisms shown in Figure 26.

Flame transfer function (FTF) [86,170,175,176] is a widely used linear analysis method to describe the response of unsteady heat release rates to velocity fluctuations in the dump plane [156,177]. These results can be incorporated into low-order thermoacoustic network models [86] or three-dimensional Helmholtz acoustic models [178] o predict the onset of combustion instability or to analyze flame instability within the system [170,175]. While FTF is useful, most manifestations of combustion instabilities exhibit nonlinear behavior. In response, nonlinear analysis methods such as the flame describing function (FDF) have been developed, which assume that the gain and phase depend on the amplitude level of the input. Additionally, the interaction between the flame and vortices can be observed through flame front wrinkling—small-scale fluctuations that affect the flame surface and interact with the flame front [147].

where the superscript and respectively represent the instantaneous fluctuations and average values of heat release rate, and the same with and for velocity in the dump plane.

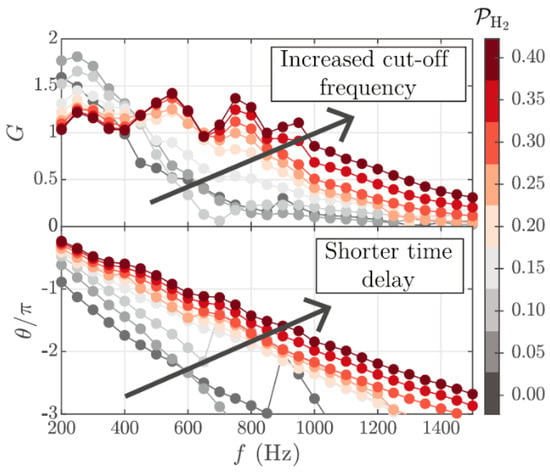

Aguilar et al. [86] experimentally compared the linear flame response to external disturbances with varying hydrogen power fractions. Two key features are observed in Figure 35 as hydrogen enrichment increases: an increase in the cut-off frequency and a reduction in time delay. The former amplifies fluctuations in the gain and phase of the FTF, indicating stronger fluctuations in the flame response. The latter is associated with a reduced phase difference gradient, which is attributed to the increased laminar flame velocity due to hydrogen addition.

Figure 35.

The flame transfer function (FTF) with hydrogen power fractions [86].

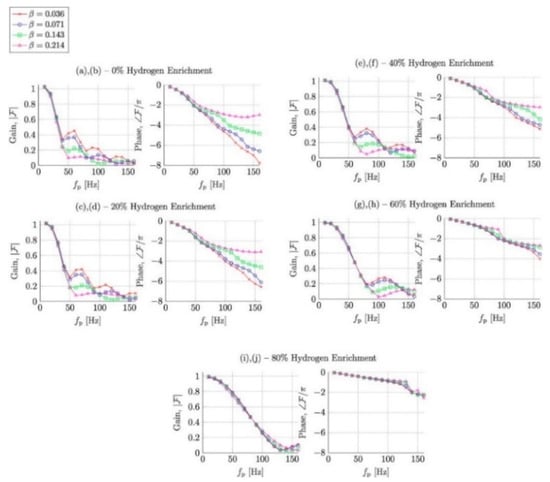

In recent years, the study of Flame Describing Functions (FDF), a nonlinear analysis method, has gained increased attention in hydrogen addition research, providing deeper insights into hydrogen-fueled flames [86,87,88]. Lim et al. [87] conducted numerical simulations on hydrogen-enriched premixed combustion and generated FDFs to map the response of perturbed flames at varying hydrogen levels. The FDF results with different hydrogen fractions [87] showed that hydrogen enrichment led to an increase in the threshold frequency for gain drop-off and a global reduction in phase lag, as illustrated in Figure 36. Three key findings emerged regarding hydrogen addition: (1) the increase in cut-off frequency indicated a higher potential for combustion instability; (2) the decrease in phase difference was linked to shorter hydrogen-enriched flames and reduced convection time; and (3) a reduction in nonlinearity was observed. However, for different perturbation amplitudes, the solution trends shifted from convergence to divergence, suggesting that nonlinearity may not be entirely suppressed.

Figure 36.

The flame describing function (FDF) with hydrogen fractions [87].

The flame-vortex interactions excited by hydrogen addition have been widely studied [89,160,179]. Agostinelli et al. [105] used LES to analyze a partially premixed swirling flame under different pressure conditions, comparing flame stabilization with 40% hydrogen enrichment. In contrast to the reference case (natural gas), which exhibited a lifted M-shaped flame with a strong precessing vortex core (PVC), the 40% hydrogen-enriched flame transitioned into a V-shape and weakened the PVC, resulting in the excitation of the first acoustic mode of oscillations. The instantaneous fields for these hydrogen-fueled cases are shown in Figure 37, where the white iso-contour highlights the distortion of the flame front due to the PVC; the PVC caused the flame to move downstream. Further computations of the system’s acoustic modes revealed that the different thermoacoustic responses induced by hydrogen addition were due to changes in flame shape, specifically the increased resistance to strain-induced extinction in the hydrogen-enriched flames.

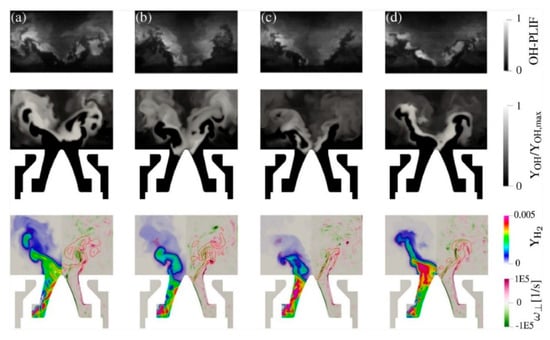

Figure 37.

Instantaneous fields of an oscillatory cycle by different measurements [105]. (Top) experimentally measured OH-PLIF signal. (Middle) the LES-predicted OH mass. (Bottom, left) hydrogen mass fraction. (Bottom, right) flow vorticity normal to the plane. Red iso-contour means the heat release at 10% of the peak . Instants (a) and (c) correspond respectively to the maximum and the minimum of OH∗ chemiluminescence and heat release rate signals while instants (b) and (d) correspond to a phase difference of π/2.

4.2. Acoustic Motions in the Combustion Chamber

In gas turbine combustors, acoustically coupled oscillations within the closed acoustic environment are driven by the heat released from chemical reactions. Acoustic waves propagating throughout the combustion chamber interact with both flow motion and the combustion process. The wave equation, expressed in terms of flow variables as the sum of mean and fluctuating components, can be derived to describe thermoacoustic phenomena in combustion systems. The frequency domain form of the Helmholtz equation [180] is presented as follows.

where and represent the pressure fluctuation and heat release oscillations per unit volume, respectively; stands for the mean density; represents the acoustic resonant frequency of the combustor. In . stands for the growth rate of the eigenfrequency.

Hydrogen enrichment affects both source term distributions and flow fields. More importantly, the increased temperature associated with hydrogen enrichment can influence the density distribution of the reactants. However, variations in temperature and density distributions with hydrogen enrichment have not been widely reported.

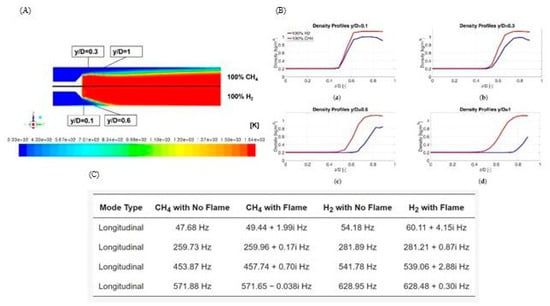

There is limited information on the direct analysis of the eigenmodes of the combustor with hydrogen addition. Ceglie et al. [75] highlighted the connections between temperature, density, and the eigenmodes of the combustor. They conducted numerical simulations using Reynolds-Averaged Navier–Stokes (RANS) and Finite Element Method (FEM) approaches to investigate fluid dynamics and thermoacoustic behavior in a premixed burner. As shown in Figure 38, pure hydrogen flames exhibit larger high-temperature zones and lower density distributions along both axial and radial positions. The acoustic modes of the burner shift to higher frequencies with hydrogen flames. The increased reaction rate and reduced time delay in hydrogen flames alter the phase relationships between pressure and heat release fluctuations.

Figure 38.

The combustion characteristics comparison of pure methane and hydrogen flames. (A) the temperature distributions; (B) the density distributions; (C) the eigenmodes. Rearranged from Ref. [75].

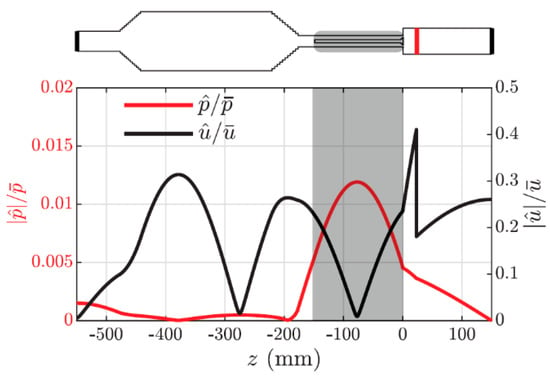

Most studies use FTF and low-order networks to predict combustion instabilities [86,181]. However, articles examining the effects of hydrogen addition on combustion instability in specific combustors often do not provide sufficient information to analyze the flame’s interaction with acoustic motions in the combustion chamber. A common approach involves first deriving flame interactions with flow modulations (e.g., the flame transfer function) and then applying a reduced-order network model that includes acoustic elements to predict system stability. As shown in Figure 39 from Aguilar et al. [86], acoustic motions in the combustion chamber—potentially influenced by temperature and density changes due to hydrogen enrichment—are typically not accounted for. Nonetheless, these variations generally do not cause significant changes in the prediction results, allowing such methods to achieve satisfactory outcomes. Their findings successfully capture the bifurcation point caused by increased hydrogen content.

Figure 39.

The network model to analyze the instability in a combustion chamber [86].

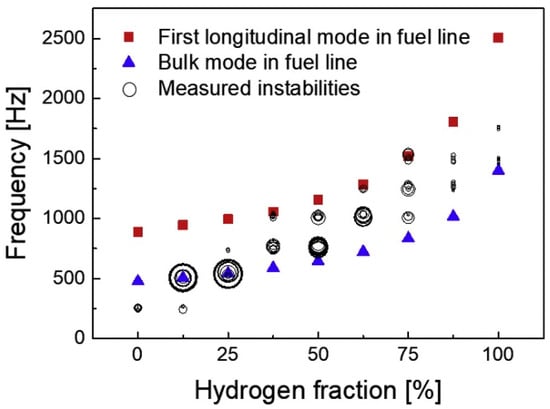

The network model method is one of the most commonly used tools for capturing acoustic motions in the combustion chamber, typically calculated using reduced models through FEM. Similar approaches have been adopted in hydrogen studies, yielding high accuracy, particularly from research groups in Korea [52,182,183]. Kim et al. [182] developed an in-house Helmholtz solver to simulate combustion instability in hydrogen-enriched natural gas flames within a lean premixed gas turbine combustor, utilizing FEM and shift-invert methods. Kim et al. [52] applied this method to study the effects of fuel line acoustics on mode transitions under hydrogen enrichment. The results were validated against experimental data, as shown in Figure 40. The fuel line bulk mode frequencies matched the longitudinal resonance of the combustor in low-hydrogen combustion, while the longitudinal mode in the fuel line strongly coupled with the harmonic frequencies of the combustor.

Figure 40.

Corresponding relationships between bulk modes and measured instabilities with different hydrogen contents [52].

4.3. Flow/Air Mixture Modulations

The injector in gas turbine engines plays a critical role in determining flow oscillations due to its intrinsic unsteadiness [108]. Hydrogen enrichment can lead to incomplete mixing of fuel and air, or fluctuations in the mass flow rates of both at the nozzle injection point. Equivalence ratio oscillations may occur because the space and time for complete mixing are constrained. These fluctuations in equivalence ratio are a key driver of combustion instability [108]. Given hydrogen’s higher diffusivity and increased reaction rates, hydrogen-enriched flames are particularly susceptible to local mass flow rate and equivalence ratio fluctuations. Such pulsations in the fuel supply region influence the development of combustion instabilities [184,185], and in some cases, intensified pulsations due to hydrogen enrichment may even suppress them.

Many studies [74,76,159] have acknowledged the effects of hydrogen addition on flow and mixture modulations, though few have directly explored these phenomena. In the LES study by Gong et al. [174] on combustion instability in swirling flames using the PRECCINSTA burner, the combined effects of mass flow rate and equivalence ratio fluctuations with hydrogen addition were examined. As shown in Figure 41, when the flame flashes back to 90°, the unstable pure methane flame extends halfway into the center body, while the stable hydrogen-rich flame shifts further upstream. The flame lift-off is related to the hydrodynamic structure of the flow, which is influenced by hydrogen enrichment.

Figure 41.

Periodic evolution of the flow at six phases with hydrogen addition. C2 presents the pure methane case, while C3 means the flames with 38% H2 addition. (Left) mixture fraction. (Right) instantaneous axial velocity. Replotted from Ref. [174].

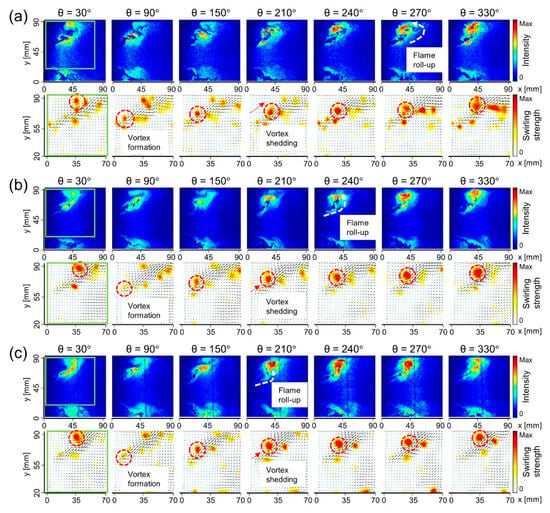

Kwak et al. [82] conducted experiments to investigate a fuel-staged dual-nozzle gas turbine combustor with asymmetric hydrogen addition. Phase-synchronized flame images captured by OH-PLIF (planar laser-induced fluorescence) and flow fields obtained via PIV (particle image velocimetry) are shown in Figure 42, with the first row displaying flame images and the second row illustrating flow fields. The results indicate that asymmetric hydrogen addition disrupts the in-phase behavior between the two main reaction zones in the dual-nozzle combustor. As hydrogen content increases, the flame begins to roll up earlier in the phase, shifting from = 270 to = 240 and = 210. This demonstrates that the interaction between flame and vortex is intensified with hydrogen addition. However, due to the asymmetry of hydrogen addition in one of the dual nozzles, these stronger interactions dampened the oscillations.

Figure 42.

The phase-synchronized flame images and flow fields of forced flames for different hydrogen conditions [82]. First row: OH-PLIF. Second row: PIV results. (a) pure methane flames; (b) 20% hydrogen addition; (c) 40% hydrogen addition.

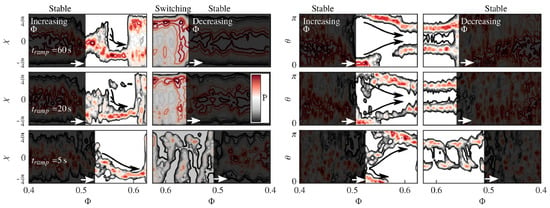

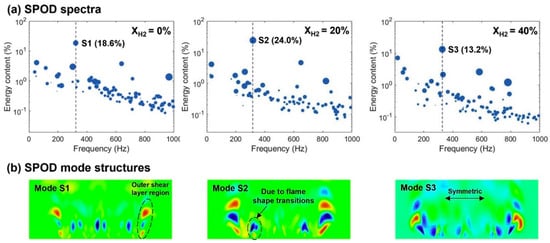

In a study examining the effects of hydrogen addition on meso-scale burner array flame stability under acoustic perturbations [186], spectral proper orthogonal decomposition (SPOD) was applied to OH-PLIF images for flame stability analysis. The S1 mode structure (with 0% hydrogen fraction) shown in Figure 43 reveals thin repeating structures in the shear layers around the main flame. In contrast, for the S2 mode structure (with 20% hydrogen fraction), significant oscillatory regions were observed in the external zone of the shear layer. Another oscillatory structure was identified in the flame-vortex interaction zone, where transitions in flame shape occurred. In the stable case (S3 mode structure, with 40% hydrogen fraction), no significant oscillatory geometries were detected, and no flame shape transitions were observed. The SPOD results demonstrate the correlations between the various modes and acoustic wave propagation under different hydrogen fractions.

Figure 43.

The SPOD spectra of axial-perturbed flame arrays with different hydrogen contents [186]. (a) SPOD spectra; (b) dominant SPOD mode structures of such flame arrays.

5. Discussions

5.1. Status

The addition of hydrogen to conventional methane flames has recently garnered significant attention. At the same time, combustion instability issues in marine gas turbine systems have hindered the development of low-emission combustors. Numerous studies have emerged linking hydrogen-enriched methane flames with combustion instability. Given the distinct combustion characteristics of hydrogen and methane, hydrogen-enriched methane flames can exhibit various instability features. Therefore, understanding the instability manifestations and elucidating the underlying mechanisms of hydrogen addition on combustion instability is crucial for industrial marine applications.