Abstract

Brown mushrooms are widely consumed globally due to their low calorie content, high nutritional value, and suitability for periodic growth in industrial mushroom houses, offering significant commercial value. Most robotic grippers pick mushrooms based on precise force control, which requires a high-precision force sensor, increasing production costs and potential failure rates. This study presents a fully soft gripper, as the body made of silicon rubber and driven by cable. Its inherent softness, offering a more natural solution for safely picking mushrooms by relying only on simple position control of the servo. Finite element analysis was employed to optimize the cable-driven displacement. Additionally, the gripper can measure mushroom diameters during picking using rough thin-film force sensors and bending sensors attached to the fingers, based on mathematical derivation. Field experiments were conducted with the proposed gripper mounted on a homemade mushroom-harvesting robot to pick medium-sized and large-sized mushrooms. The results demonstrated non-destructive harvesting, an average measurement accuracy of 96.6% for medium mushrooms and 96.1% for large mushrooms, and an average harvesting time of 7.5 s per mushroom. Compared to force-controlled grippers, the proposed cable-driven gripper features a simpler structural design and more efficient control logic, making it highly suitable for industrial applications.

1. Introduction

Brown mushroom, also known as Agaricus bisporus, is one of the most widely cultivated and consumed mushrooms worldwide [1]. Brown mushrooms are rich in nutrients, including dietary fiber, vitamins, steroids, and β-glucans, among others [2,3], highlighting their potential in preventing and treating cardiovascular diseases [4,5]. In 2023, the global mushroom market was valued at USD 25 billion [6], with brown mushrooms accounting for 61.8% of total global edible mushroom production, solidifying their leading position in the market [7].

Fresh markets require mushrooms to be free of scratches [8,9] and have a relatively long shelf life [10]. To minimize damage during harvesting, brown mushrooms are picked manually, which accounts for 50–80% of total production costs [11,12]. Additionally, mushroom harvesting involves repetitive movements and prolonged bending postures, making the process not only time-consuming and physically exhausting but also increasing the risk of work-related musculoskeletal disorders, such as wrist tendinitis and carpal tunnel syndrome [13,14,15]. The availability of labor is further constrained by global population aging.

The application of intelligent and automated technologies is regarded as an effective solution for enhancing harvesting efficiency and improving working conditions. Mechanized and intelligent harvesting equipment can significantly reduce the risk of occupational injuries associated with repetitive motions and prolonged unnatural postures [16]. Consequently, advancing the mechanization and automation of Agaricus bisporus harvesting has become a critical focus for addressing these challenges and promoting sustainable production practices.

Most current end-effectors employ vacuum suction cups, which generate negative pressure to securely grip the mushroom cap from above [17,18,19]. However, excessive suction force can damage the delicate mushroom surface [20,21]. Using a gripper end fabricated with thermoplastic polyurethane (TPU) of flexible 85A hardness as a buffer between the gripper and the mushrooms has been shown to reduce surface damage [22].

Alternative designs include three-finger pneumatic soft grippers for handling brown mushrooms [23] or rigid grippers integrated with soft pads to cushion and protect the mushrooms. For instance, Bikram et al. developed an innovative hybrid three-finger gripper combining rigid and flexible components [6]. The gripper’s textured soft pads outperformed conventional soft pads, reducing applied force by up to 20% and decreasing pick-up time. This design achieved a 100% success rate in picking individual mushrooms and a 64% success rate in cluster picking, demonstrating its effectiveness in delicate harvesting tasks.

Zhao et al. enhanced vacuum suction cups by incorporating granular-filled flexible end-effectors to achieve stable pressure control [24]. Their study found that optimal adsorption performance occurred with a flexible membrane thickness of 0.9 mm and a particle size of 200-mesh quartz. This innovation improved the stability of the adsorption force during the picking system’s operation by 84.71%. Li et al. proposed an “L”-shaped three-finger gripper, designed based on practical gripping experience, and analyzes the mechanical relationships among gripping force, torsional separation torque, and servo output torque [25]. Using the mechanical constitutive model of mushroom stems, the study determines the optimal twisting separation torque and the corresponding servo motor output torque required for the gripper.

Additionally, specialized end-effectors have been developed to penetrate the target brown mushroom and remove it by scooping [26]. While these destructive end-effectors are effective for certain specific tasks, they are unsuitable for the non-destructive requirements of the harvesting process.

Our team has extensive experience in brown mushroom harvesting [27,28]. For example, we previously developed a soft pneumatic gripper [29], which required a heavy and complex pressure supply system for both positive and negative pressure. This is a common challenge faced by end-effectors based on suction cups or pneumatic grippers. Additionally, we developed an under-actuated rigid gripper with a soft glove [11]. It is a classic soft-rigid hybrid structure using precise force control to pick mushrooms without causing damage. However, a fully soft gripper with inherent softness offers a more natural solution for safely picking mushrooms without relying on complex force control. Such a design would not only enhance the picking process but also reduce costs, making it more feasible for widespread use in industrial applications.

In this paper, we present the design of an underactuated cable-driven flexible gripper capable of nondestructive harvesting of brown mushrooms using open loop position control, eliminating the need for precise force control. The key contributions of this work are. (1) the development of a cable-driven flexible gripper integrated with a lifting and rotating mechanism; (2) the ability to measure the mushroom cap diameter during the grasping process, providing a foundation for brown mushroom grading; (3) and the successful demonstration of nondestructive harvesting of 60–90 mm brown mushrooms without force control, enabling a simpler and more efficient control strategy.

2. Materials and Methods

2.1. Mechanism Design

Compared to the pneumatically driven flexible gripper, the cable-driven mechanism offers significant advantages in both structural design and practical application. First, the cable-driven mechanism features a simpler overall structure, eliminating the bulky components of pneumatic systems such as pumps, air tanks, and valves. This not only reduces the system’s size and weight but also simplifies installation and maintenance. Additionally, pneumatic systems often suffer from air leakage issues caused by the aging of silicone components—a problem entirely avoided with the cable-driven design. As a result, the cable-driven mechanism enhances the device’s lifespan and reliability, making it a more robust solution for mushroom harvesting.

Compared to traditional motor-driven systems, the combination of a cable-driven mechanism and a flexible gripper offers distinct advantages. Leveraging the inherent properties of cables and flexible materials, this system provides superior adaptability to the surface shape of target objects. The flexible contact approach eliminates the need for complex sensor systems or precise force control algorithms, greatly simplifying the design and development of the control system. In practical applications, the cable-driven flexible gripper demonstrates excellent adaptability during the gripping process, even without force control, effectively preventing excessive pressure and surface damage to the target object.

The harvesting of brown mushrooms typically requires the gripper to perform gripping, releasing, lifting, lowering, and twisting actions. To perform these actions, the harvesting gripper is composed of three modules: a gripping module, a lifting module, and a rotating module, each driven by an independent motor. For the gripping module, the gripper is made from silicone rubber. This material is fully soft and chemically inert, making it safe for contact with mushrooms and easy to clean when the gripper becomes dirty. Additionally, silicone rubber can be easily cast into complex shapes using molds in the lab, which simplifies the fabrication process. Further details are provided in Section 2.2.

Additionally, since mushroom cap diameter is a key parameter for grading brown mushrooms, the gripper is equipped with a diameter measurement feature that operates during the gripping process. The diameter measurement system integrates a thin-film force sensor and a flexion sensor, both mounted on opposing flexible fingers. When the flexible fingers come into contact with the mushroom, the thin-film force sensor detects the moment of contact while simultaneously capturing data from the flexion sensor. The mushroom diameter is then accurately calculated by combining the input from both sensors, ensuring efficient and precise grading during the harvesting process.

The harvesting workflow of the gripper with the diameter measurement feature is as follows.

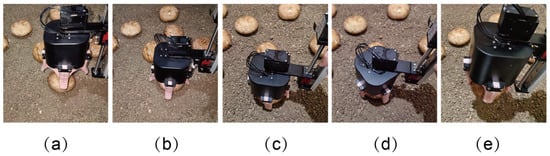

- Positioning: The gripper is positioned directly above the target brown mushroom (Figure 1a).

Figure 1. Steps involved in using a flexible gripper to harvest a brown mushroom. (a) Positioning the gripper above the target mushroom, (b) lowering the gripper, (c) grasping the mushroom and measuring its diameter, (d) rotating the gripper to twist and detach the mushroom stem, and (e) lifting the harvested mushroom.

Figure 1. Steps involved in using a flexible gripper to harvest a brown mushroom. (a) Positioning the gripper above the target mushroom, (b) lowering the gripper, (c) grasping the mushroom and measuring its diameter, (d) rotating the gripper to twist and detach the mushroom stem, and (e) lifting the harvested mushroom. - Lowering: The gripper descends to an appropriate height for gripping (Figure 1b).

- Gripping and Measuring: The gripper grasps the mushroom, the thin-film force sensor detects the impact force, and the flexion sensor records the corresponding data. These readings are used to calculate the mushroom diameter (Figure 1c).

- Twisting and Harvesting: After securely gripping the mushroom, the rotating mechanism twists it off the mushroom bed (Figure 1d).

- Lifting: The gripper ascends, completing the harvesting operation (Figure 1e).

2.2. Fabrication

The cable-driven flexible gripper is shown in Figure 2a. The flexible gripper is integrally cast using silicone rubber (Sil940, Smooth-On, Inc. Macungie, PA, USA). As the temperature and humidity in brown mushroom cultivation environments are typically maintained at approximately 17–18 °C and 85–90%, respectively [30], the silicone rubber used for the soft fingers remains chemically and physically stable. In addition, the cost of replacing the silicone fingers is low, making maintenance convenient and economical. To enhance durability further, an integral molding method was employed.

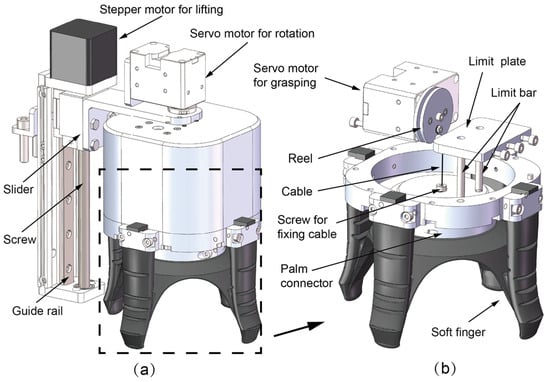

Figure 2.

Three-dimensional model of the rope-driven flexible harvesting gripper. (a) Overall structure with a finger length of 70 mm and an envelope range of 100 mm. (b) Detailed view of the flexible fingers and driving mechanism.

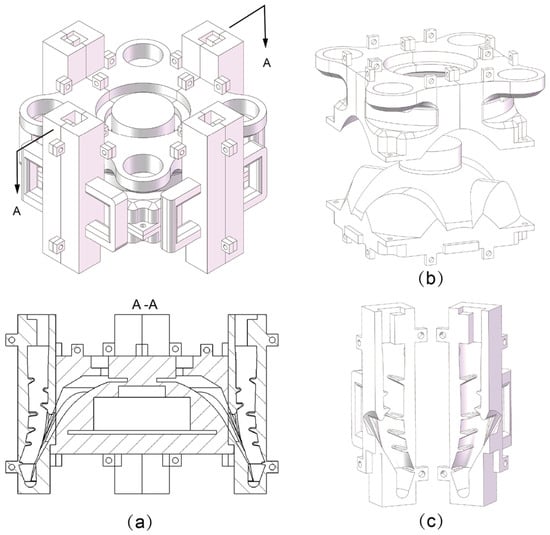

The mold used to cast the gripper with silicone rubber is shown in Figure 3a. The mold consists of different sections, which are 3D-printed by PLA (Polylactic Acid) material. These sections are fixed together using prefixed holes and screws. Figure 3b depicts the palm mold, which features an upper and lower structure, while Figure 3c shows the finger mold with a left and right structure. The finger mold is attached to the palm mold to form a complete assembly.

Figure 3.

Molds for the flexible gripper. (a) Fully assembled mold for the flexible gripper, including a cross-sectional view along plane A-A, with shaded areas indicating solid sections, (b) exploded view of the palm mold, and (c) exploded view of the finger mold.

The Sil940 components were mixed in the specified ratio and stirred thoroughly until uniform. The mixture was then placed in a vacuum chamber at −0.1 bar pressure for 5 min to remove air bubbles. Due to the complex internal curves of the mold, removing the cured silicone posed challenges. To address this, a release agent (Ease Release 200, Smooth-On, Inc. Macungie, PA, USA) was evenly sprayed on the mold’s inner surfaces, spread with a brush, and left to sit for 5 min in a ventilated area. Silicone was injected into the mold using a syringe and cured in a thermostat chamber at 25 °C for 18 h. After curing, the mold was disassembled to extract the flexible gripper.

Figure 2b provides a clearer view of the cable-driven structure. The four fingers are secured to the housing using a snap-fit structure, while the palm is attached to the palm connector. One end of the cable is fixed to a preset hole in the center of the palm connector using a screw, and the other end is secured to the reel. Additionally, a limit bar is mounted on the palm connector to restrict movement, assisted by a limit plate fixed to the shell. With the limit bar constrained by the limit plate, the palm connector is only able to move vertically. As the cable winds to pull the palm upward, the fingers bend to close. The core of the gripper’s actuation is the Dynamixel XM430-W350-R servo motor (ROBOTIS Co., Ltd. Seoul, Republic of Korea), which facilitates both grasping and resetting functions by pulling and releasing the rope. When the servo is activated, the spool rotates to tighten the attached rope, transferring tension through the circular ring to the flexible fingers, causing them to bend inward and complete the grasping motion. Conversely, when the servo rotates in the opposite direction, it loosens the rope, allowing the elastic potential energy of the flexible fingers to restore them to their initial state, preparing for the next operation.

The Dynamixel XM430-W350-R (ROBOTIS Co., Ltd. Seoul, Republic of Korea) servo motor delivers outstanding performance, featuring a stall torque of 4.10 N·m, a maximum speed of 46.0 rpm, an operating voltage of 12.0 V, and compact dimensions of . Weighing only 82.0 g, its lightweight design contributes to efficient system operation. The rotational functionality of the gripper’s palm is driven by an additional Dynamixel servo motor mounted at the top, further enhancing the gripper’s flexibility and versatility.

The lifting module employs a ball screw mechanism from the FUYU brand (model FSK30, specification Tr8 × 4—100 mm Chongqing Fuyu Technology Co., Ltd., Chongqing, China) to perform vertical lifting operations, with a maximum lift height of 100 mm. The Dynamixel servos, configured as bus-type servos, are connected in series via data cables and centrally controlled using a U2D2 control board and power board. This setup simplifies wiring while maintaining the overall neatness and reliability of the rope-driven harvesting gripper system.

2.3. Sensing Method

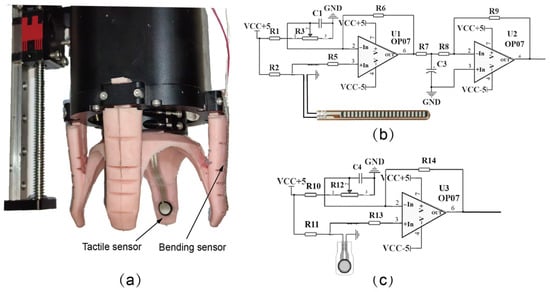

Thin-film force sensors are employed as tactile units to detect the moment the flexible gripper contacts the mushroom, while bend sensors measure the deformation of the gripper, as shown in Figure 4a.

Figure 4.

Flexible gripper with tactile and bending perception. (a) Harvesting gripper equipped with a thin-film force sensor and a bend sensor, (b) conditioning circuit for the bend sensor, and (c) conditioning circuit for the thin-film force sensor.

The bend sensor used, Flex 2.2, has a natural resistance of approximately 190 k measured by a digital multimeter (Fluke 101, Fluke Testing Instruments (Shanghai) Co., Ltd. Shanghai, China) using resistance measurement mode. When bent toward the metal side, the resistance decreases significantly with increasing curvature, reaching a minimum of approximately 40 k, indicating high sensitivity. Conversely, when bent toward the non-metal side, the resistance increases slightly, with a maximum of approximately 220 k measured by the same digital multimeter, demonstrating lower sensitivity. To ensure accurate detection of the bending motion during grasping, the metal side of the bend sensor is adhered to the external surface of the flexible finger, with the non-metal side facing outward.

To accurately measure the resistance change in the bend sensor, an adjustable zero-balanced Wheatstone bridge and a two-stage amplification circuit were designed. The bend sensor, together with resistors and and a potentiometer , forms a single-arm bridge circuit. The potentiometer is adjusted to ensure the bridge output is zero in its initial state. The resistance change signal from the bend sensor is then amplified and filtered using a two-stage amplifier circuit and a T-type filter, as illustrated in Figure 4b.

Since the thin-film force sensor functions solely as a tactile sensor to detect step signals rather than precise force values, a single-stage amplifier suffices for its operation (as shown in Figure 4c). During actual operation, zero adjustment of the thin-film force sensor is not necessary. A sudden increase in the detected contact force signifies that the flexible gripper has touched the mushroom’s surface. At this point, the value from the bend sensor is recorded to calculate the bending angle. Using the corresponding formula, the diameter of the mushroom can then be accurately determined.

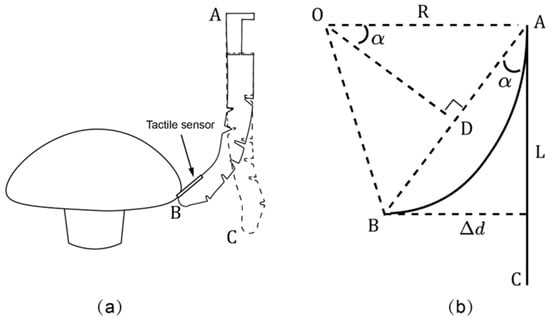

The mathematical derivation for diameter measurement is as follows. As driven by the cable, the flexible finger primarily undergoes bending strain during actuation, with negligible stretching along its length. As the finger-only bending, it is reasonable to assume that the total length of the finger mm remains constant before and after deformation, simplifying the calculations, as shown in Figure 5a.

Figure 5.

Principle of diameter measurement for brown mushrooms by the flexible gripper. (a) Structural diagram of the flexible finger contacting the mushroom cap. (b) Mathematical model for diameter measurement.

The flexible finger is vertically downward in its initial state, represented by the straight line in Figure 5b. Under cable pulling, the finger bends into a curve denoted as . To simplify the analysis, the curve is approximated as a circular arc. Since the base of the flexible finger is fixed to the palm, the initial vertical line serves as the tangent to the circular arc .

By drawing a perpendicular line from point to line and connecting , the perpendicular bisector of line segment intersects line at point . The bending angle is defined as , which represents the degree of the finger’s bending. From the geometric relationships, it can be derived that .

The relationship for the radius of the circular arc is given as

The radial advancement of the fingertip relative to the palm is

Assuming the arc length of the flexible finger remains unchanged before and after deformation, we have

Thus, the can be derived from

Substitute Equation (4) to Equation (2), then

The brown mushroom’s diameter is calculated as

where represents the maximum grasping diameter of the flexible fingers in their initial state (the diameter of the circular region formed by the four fingers).

Calibration is needed to establish a quantitative relationship between the gripper’s true output voltage and the gripping radius before measuring actual mushrooms. To conduct the calibration, the flexible gripper is mounted on an aluminum frame, with a calibration paper marked with bending degrees used as the background. The motor controls the gripper’s positions, ranging from to in increments of . All data are recorded for further fitting.

2.4. Finite Element Analysis Method

The material of the flexible gripper is a hyperelastic elastomer, widely used in applications requiring large deformations. In analyzing the material properties of the flexible gripper, four classic hyperelastic constitutive models are commonly employed: the Neo-Hookean model, Yeoh model, Mooney–Rivlin model, and Arruda–Boyce model [31]. Each model has specific applicable scenarios and accuracy performance, capable of describing the stress–strain relationship of hyperelastic materials under various loading conditions such as uniaxial, biaxial, and shear.

A CMT6104 universal testing machine can be used to measure the uniaxial tensile stress–strain curve of silicone rubber. The experimental data obtained can be fitted using hyperelastic models in the Engineering Data module of ANSYS Workbench 2021 R2. Subsequently, a finite element analysis (FEA) can be conducted using the Static Structural module in ANSYS Workbench to study the deformation behavior of the flexible gripper under an upward pulling force applied via cables.

2.5. Mushroom Size Method

The picking experiments are conducted on the medium-sized brown mushrooms (Portabellini), and large brown mushrooms (Portobello). Given that mushroom caps are not perfectly circular, their diameter is defined as follows: the maximum diameter of the cap is measured, followed by the diameter perpendicular to . The average value is used as the diameter of the brown mushroom.

2.6. Experiment Setup

The proposed gripper is mounted on a homemade mushroom-picking robot developed in our laboratory [32]. This robot is equipped with two independently operating picking arms. Global cameras are mounted on the robot’s body frame to detect target mushrooms using the YOLO v5 algorithm [27]. The visual information guides the robot to align the gripper precisely with the mushroom for the picking process.

The mushroom-picking robot equipped with the proposed gripper was transported to Yangzhou Aojit Biotechnology Co., Ltd., located in Zhenjiang, China, for field testing.

3. Result and Discussion

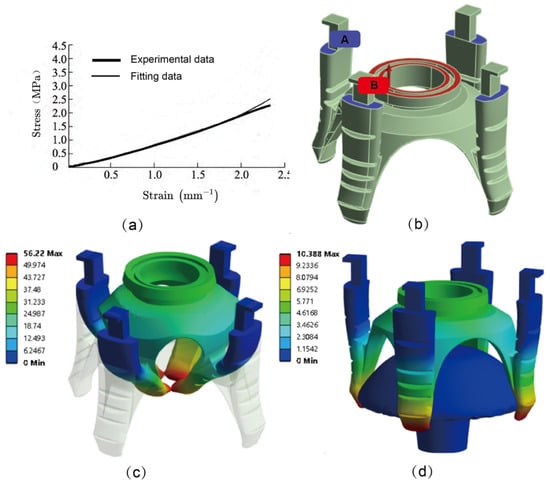

3.1. Finite Element Analysis

In this study, a suitable constitutive model for silicone rubber was selected through experimental measurements and model comparison. It is shown that the second-order Yeoh model provided the best match to the measured stress–strain curve. The strain energy density function for the Yeoh model is expressed as

where and are the first and second deviatoric strain constants, respectively, and is the first invariant of the material.

The resulting stress–strain curve is shown in Figure 6a. The thick line in the graph represents the experimentally measured uniaxial tensile curve, illustrating the material’s actual mechanical response. The fitting results confirm that the Yeoh model accurately describes the stress–strain relationship of silicone rubber under uniaxial tension. This demonstrates that the second-order Yeoh model effectively captures the nonlinear hyperelastic properties of the material, making it a suitable constitutive model for the silicone rubber used in the flexible gripper.

Figure 6.

Static structure simulation. (a) Experimental uniaxial tensile data curve and its fitted curve. (b) ANSYS Workbench parameter settings, where the blue area A represents the fixed surface, while the red area B denotes the force application surface which is pulled upward as indicated by the red arrow. (c) The simulation results of the fully closed flexible gripper, with the semi-transparent shape indicating the initial position and the color bars representing displacement distances. (d) The simulation results of the flexible gripper grasping a mushroom.

As explained in Figure 2b, the cable is fixed to the palm connector and driven by the reel, while the tops of the four fingers are fixed to the housing. When the cable pulls the palm upward, it is equivalent to applying a vertical force on the palm. For the fingers, the tops should remain fixed. In the experimental setup for the cable mechanism, shown in Figure 6b, a vertical force was applied to the palm (indicated by the red area B) to pull it upward, while the upper surfaces of the gripper’s four flexible fingers were fixed (indicated by the blue area A). This simplified equivalent setup was designed to facilitate easier convergence of the finite element analysis.

The simulation results are shown in Figure 6c. As the pulling force is applied, the four flexible fingers bend inward and eventually converge completely, forming a fully closed gripping state. The simulation results indicate that the maximum inward displacement of the fingers is 56.22 mm, while the vertical upward displacement of the center end cap of the gripper is 31.22 mm. These results provide valuable references for the cable-driven stroke and the maximum motion distance of the gripper.

To further validate the gripping capability and contact performance of the gripper, a mushroom model was introduced into the simulation. The design parameters for the mushroom were as follows: the diameter of the mushroom cap was set to 80 mm, representing the mean diameter of medium-sized and large mushrooms; the mechanical properties of the mushroom cap were tested [11]; and considering the gentle gripping force exerted by the proposed cable-driven soft gripper, the entire mushroom was modeled as a solid body. Geometrically, the mushroom cap was aligned with the center of the flexible gripper. Additionally, to avoid penetration between the flexible gripper and the mushroom model during the simulation, a contact surface was defined between the mushroom cap and the flexible fingers to ensure the rationality of the simulation results.

As shown in Figure 6d, the simulation results depict the effect of a cable winding displacement of 30 mm applied to the gripper. The simulation demonstrated that the flexible gripper successfully achieved the mushroom grasping function under the cable driving force. The four flexible fingers conformed effectively to the surface of the mushroom cap, exhibiting a uniform distribution of gripping force without any unreasonable deformations or poor contact issues. These results validate the effectiveness of the flexible gripper’s design and its gripping stability, providing reliable data support for further design optimization and practical applications.

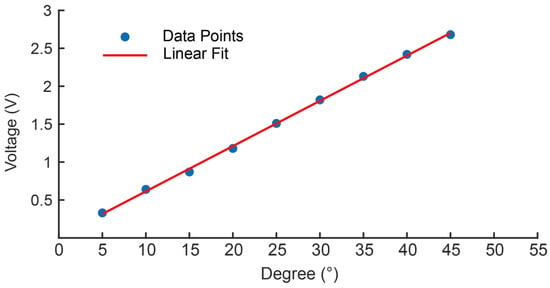

3.2. Sensing Calibration

As shown in Figure 7, the output voltage of the bending sensor, , has a linear relationship with the bending degree, . The corresponding mathematical relationship is given by

.

Figure 7.

Bending sensor calibration results.

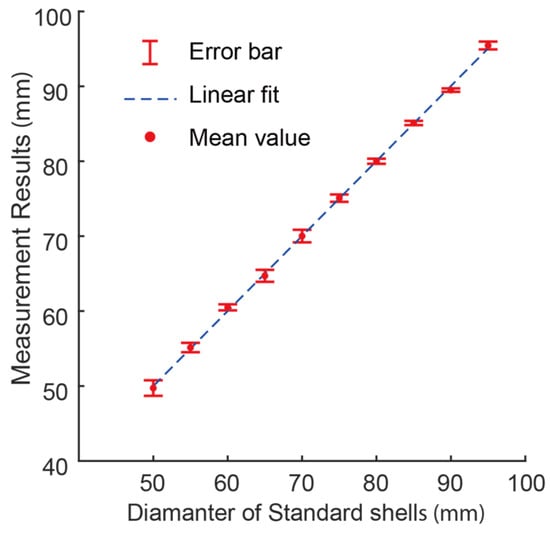

After calibrating the bending sensors, a measurement accuracy experiment was conducted. 3D-printed standard cylindrical shells were used as calibration tools, designed as thin-shell structures with a positioning hole in the center to ensure precise and consistent placement during the experiment. The diameters of the shells ranged from 50 mm to 95 mm, with increments of 5 mm. Before the experiment, the output of the bending sensor was adjusted to zero. During the experiment, the motor drove the gripper to grasp the standard shell, and the computer recorded the bending voltage as the thin-film force sensor provided a step signal indicating contact. The diameter was calculated using Equation (6). The results for the standard shells are shown in Figure 8. The mean errors were less than mm.

Figure 8.

Measurement results for standard cylindrical shells.

3.3. Field Experiments

In actual measurements, when the gripper operated without grasping an object, the achieved cable pulling distance was 30.7 mm, which closely matched the simulation results of 31.22 mm.

For the experiments involving the picking of medium-sized mushrooms, ten medium mushrooms were selected per trial, and the experiment was repeated three times. As Table 1 shown, the mushroom cap width was 69 5.6 for group , 71 6.5 for group , and 67 3.8 for group . As for the experiments involving the picking of large brown mushrooms, ten large mushrooms were picked per trial, and the experiment was repeated three times. The mushroom cap width was 91.5 6.27 for group, 91.1 5.7 for group , and 91.0 7.3 for group . Since medium-sized mushrooms were still in the growth phase, their cap diameter varied more. In contrast, large mushrooms, being at the end of their growth stage, had relatively consistent average sizes. However, because their caps are closer to an elliptical shape, their standard deviation was larger.

Table 1.

Mushroom cap width measurements.

The robot lead the gripper to pick the target position, and then the gripper actively grasped objects under cable actuation and returns to its initial position due to the elastic potential energy of the silicone when the cable was released. During actual harvesting, the servo motor operates in position-control mode, with the cable retraction distance set to 27 mm. This configuration is suitable for picking medium and large brown mushrooms while maintaining sufficient gripping force.

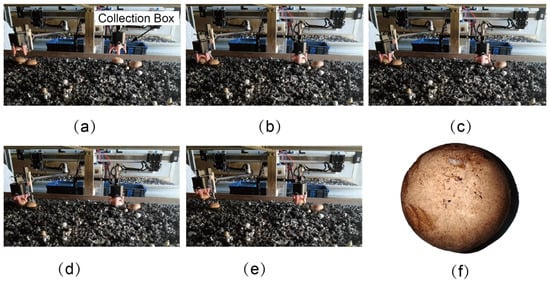

As shown in the Figure 9, the mushroom-picking robot performs a complete harvesting process step by step. First, the cable-driven gripper moves above the target mushroom (Figure 9a), and then the lifting mechanism drives the flexible fingers downward (Figure 9b). Next, the cable-driven flexible gripper closes to grasp the mushroom while the measurement unit determines the mushroom cap diameter. Once the cable is fully retracted (Figure 9c), the rotating mechanism rotates the gripper by 45 degrees [33], which is also consistent with the standard harvesting practice of Yangzhou Aojit Biotechnology Co., Ltd., to separate the stem from the mushroom bed (Figure 9d). Finally, the lifting mechanism raises the gripper (Figure 9e), and the robot arm will move it and drop it into the collection box, completing a full harvesting cycle.

Figure 9.

On-site harvesting experiment images of the brown mushroom-picking robot equipped with the cable-driven flexible gripper. (a–e) Standard steps for brown mushroom harvesting, and the collection boxes indicated by the arrow are used to collect the picked mushrooms. (f) Mushroom cap surface after 72 h.

During the experiments, the mucus on the mushroom’s surface occasionally contaminated the flexible gripper, reducing its frictional force. Therefore, after completing a set of experiments, specifically picking ten medium or large mushrooms, the tips of the flexible fingers were cleaned with water to restore adequate friction.

According to industry standards, the harvested mushrooms were left stationary in the growing room for 72 h [34]. After this period, the mushroom caps were inspected for any peeling or discoloration to assess whether damage occurred during harvesting. Figure 9f shows a picked mushroom stored for 72 h. It is common for the mushroom’s cap to turn a darker brown after being stored for this duration [35]. Additionally, there is was peeling or bruising, which would typically result in softer areas compared to normal organic mushrooms. This indicates that the harvesting process is nondestructive.

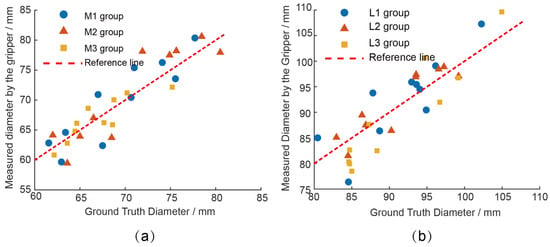

The experimental results indicate that the damage probability for brown mushrooms is 0%, achieving nondestructive harvesting. The diameters of medium-sized and large-sized mushroom samples in Table 1 were calculated using Equation (6) from Section 2.3, and the measurement results are presented in Figure 10. Reference lines indicating the ideal results are intentionally added to clearly illustrate the bias between the measurement results and the ground truth. The specific factors are detailed in Table 2. The diameter measurement accuracies for medium-sized mushrooms in groups M1, M2, and M3 were 96.2%, 95.9%, and 97.6%, respectively, with an average accuracy of 96.6%. For large-sized mushrooms in groups L1, L2, and L3, the diameter measurement accuracies were 95.7%, 97.2%, and 95.4%, respectively, with an average accuracy of 96.1%. The average harvesting time is 7.5 s, which is controlled by the robot program.

Figure 10.

Diameter measurement results by the gripper. (a) Diameter measurement results for medium-sized mushrooms: groups M1, M2, and M3 compared to the ground truth diameter. The dashed reference line highlights the bias between the measurement results and the ideal values. (b) Diameter measurement results for large-sized mushrooms in groups L1, L2, and L3 compared to the ground truth diameter, with a dashed reference line included for reference.

Table 2.

Experimental Results of Brown Mushroom Picking.

4. Discussion

To highlight the novelty of the proposed cable-driven gripper, a comparison with other pneumatic and hybrid grippers is provided in Table 3. The pneumatic gripper [29] previously developed by our team achieved a diameter accuracy of 95%, but it was not applied in situ. The soft-rigid hybrid gripper [11] achieved a diameter accuracy of 97.3% with a low damage rate of 1.67% due to precise force control. Koirala et al. [6,7] developed a soft–rigid hybrid gripper with force control that enabled non-damage picking, while Mbakop et al. [23] developed a pneumatic gripper with bending control that achieved a low damage rate of 2%. Zhao et al. [24] proposed an optimized suction cup design with particle jamming using pressure control, achieving a 2.5% damage rate.

Table 3.

Comparison of the gripper for picking the mushroom.

In contrast, the proposed gripper relies solely on position control using a servo motor, without any sensors for active feedback, which achieves on-damage picking. Thin film force sensors and bending sensors are incorporated to measure the mushroom diameter, achieving a high measurement accuracy of 96.6%.

The results show that this cable-driven flexible gripper can safeguard the surface of brown mushrooms. This gripper offers exceptional flexibility, making it ideal for handling objects with diverse shapes and sizes, especially those that are complex, irregular, or delicate. Its lightweight design and simple structure, facilitated by cable transmission, reduce both mechanical complexity and overall weight. The gripper’s high compliance ensures full surface contact with the object, effectively minimizing localized pressure. Additionally, the use of flexible materials and adjustable gripping forces enhances its suitability for tasks requiring delicate handling, while improving safety during potential collisions.

In the current system, the gripper is cleaned manually to remove mucus accumulated during picking. In future work, we plan to design and integrate an automatic cleaning mechanism into the robot to improve its practicality and enable continuous operation in real harvesting scenarios.

5. Conclusions

A cable-driven gripper made of silicone rubber is proposed to pick mushrooms and simultaneously measure their diameters. The proposed gripper was mounted on a homemade picking robot and tested in field experiments. The key contributions of this work can be summarized as follows.

- (1)

- A compact cable-driven gripper was designed with a gripping module, a lifting module, and a rotating module to pick mushrooms following a five-step process. Static mechanical analysis of the gripper was conducted using ANSYS Workbench to determine the optimal cable retraction distance, which was applied in position control.

- (2)

- An in situ diameter measurement method was proposed. The flexible fingers were equipped with integrated bending sensors on their outer surfaces to monitor bending states, and thin-film tactile sensors were attached to the inner surfaces of the fingertips to capture precise contact information during mushroom gripping. Using the bending and tactile data, a formula for measuring the diameter of brown mushrooms was derived and analyzed in detail.

- (3)

- Field experiments showed that the proposed gripper can achieve non-damaging picking based on position control without requiring force control. Additionally, the average diameter measurement accuracy was 96.6% for medium-sized mushrooms and 96.1% for large mushrooms, with an average harvesting time of approximately 7.5 s per mushroom.

In conclusion, compared to force-controlled picking systems, this design achieves comparable nondestructive harvesting performance with a simpler structure, highlighting its potential for industrial applications.

Author Contributions

Conceptualization, H.S.; methodology, H.S.; investigation, H.S.; writing—original draft preparation, H.S.; writing—review and editing, H.S., G.X., Y.X., W.L., Q.D. and X.C.; visualization, H.S.; supervision, W.L. and Q.D.; funding acquisition, W.L., Q.D. and X.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China (No. 2022YFD2300304) and the Modern Agricultural Machinery Equipment and Technology Demonstration and Promotion Project of Jiangsu Province (No. NJ2021-37).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mleczek, M.; Rzymski, P.; Budka, A.; Siwulski, M.; Jasińska, A.; Kalač, P.; Poniedziałek, B.; Gąsecka, M.; Niedzielski, P. Elemental characteristics of mushroom species cultivated in China and Poland. J. Food Compos. Anal. 2018, 66, 168–178. [Google Scholar] [CrossRef]

- Mwangi, R.W.; Macharia, J.M.; Wagara, I.N.; Bence, R.L. The antioxidant potential of different edible and medicinal mushrooms. Biomed. Pharmacother. 2022, 147, 112621. [Google Scholar] [CrossRef] [PubMed]

- Rizzo, G.; Goggi, S.; Giampieri, F.; Baroni, L. A review of mushrooms in human nutrition and health. Trends Food Sci. Technol. 2021, 117, 60–73. [Google Scholar] [CrossRef]

- Atila, F.; Owaid, M.N.; Shariati, M.A. The nutritional and medical benefits of Agaricus bisporus: A review. J. Microbiol. Biotechnol. Food Sci. 2017, 7, 281–286. [Google Scholar] [CrossRef]

- Iqbal, T.; Sohaib, M.; Iqbal, S.; Rehman, H. Exploring Therapeutic Potential of Pleurotus ostreatus and Agaricus bisporus Mushrooms against Hyperlipidemia and Oxidative Stress Using Animal Model. Foods 2024, 13, 709. [Google Scholar] [CrossRef]

- Koirala, B.; Kafle, A.; Nguyen, H.C.; Kang, J.; Zakeri, A.; Balan, V.; Merchant, F.; Benhaddou, D.; Zhu, W. A Hybrid Three-Finger Gripper for Automated Harvesting of Button Mushrooms. Actuators 2024, 13, 287. [Google Scholar] [CrossRef]

- Koirala, B.; Zakeri, A.; Kang, J.; Kafle, A.; Balan, V.; Merchant, F.A.; Benhaddou, D.; Zhu, W. Robotic Button Mushroom Harvesting Systems: A Review of Design, Mechanism, and Future Directions. Appl. Sci. 2024, 14, 9229. [Google Scholar] [CrossRef]

- Lin, X.; Sun, D.-W. Research advances in browning of button mushroom (Agaricus bisporus): Affecting factors and controlling methods. Trends Food Sci. Technol. 2019, 90, 63–75. [Google Scholar] [CrossRef]

- Wu, X.; Guan, W.; Yan, R.; Lei, J.; Xu, L.; Wang, Z. Effects of UV-C on antioxidant activity, total phenolics and main phenolic compounds of the melanin biosynthesis pathway in different tissues of button mushroom. Postharvest Biol. Technol. 2016, 118, 51–58. [Google Scholar] [CrossRef]

- Mavridis, P.; Mavrikis, N.; Mastrogeorgiou, A.; Chatzakos, P. Low-cost, accurate robotic harvesting system for existing mushroom farms. In Proceedings of the 2023 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Seattle, WA, USA, 28–30 June 2023; pp. 144–149. [Google Scholar]

- Shi, H.; Xu, G.; Lu, W.; Ding, Q.; Chen, X. An Electric Gripper for Picking Brown Mushrooms with Flexible Force and In Situ Measurement. Agriculture 2024, 14, 1181. [Google Scholar] [CrossRef]

- Zied, D.C.; Pardo-Giménez, A. Edible and Medicinal Mushrooms: Technology and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Benos, L.; Tsaopoulos, D.; Bochtis, D. A review on ergonomics in agriculture. Part I: Manual operations. Appl. Sci. 2020, 10, 1905. [Google Scholar] [CrossRef]

- Dianat, I.; Afshari, D.; Sarmasti, N.; Sangdeh, M.S.; Azaddel, R. Work posture, working conditions and musculoskeletal outcomes in agricultural workers. Int. J. Ind. Ergon. 2020, 77, 102941. [Google Scholar] [CrossRef]

- Kirkhorn, S.R.; Earle-Richardson, G.; Banks, R. Ergonomic risks and musculoskeletal disorders in production agriculture: Recommendations for effective research to practice. J. Agromed. 2010, 15, 281–299. [Google Scholar] [CrossRef] [PubMed]

- Anwar, A.; Murugan, A.S.; Recchia, A.; Kim, E.; Urbanic, J. Investigating musculoskeletal risks in manual mushroom harvesting: An ergonomic field study in canadian farms. Soc. Sci. Humanit. Open 2024, 10, 101049. [Google Scholar] [CrossRef]

- Reed, J.; Miles, S.; Butler, J.; Baldwin, M.; Noble, R. AE—Automation and emerging technologies: Automatic mushroom harvester development. J. Agric. Eng. Res. 2001, 78, 15–23. [Google Scholar] [CrossRef]

- Reed, J.; Tillett, R. Initial experiments in robotic mushroom harvesting. Mechatronics 1994, 4, 265–279. [Google Scholar] [CrossRef]

- Yang, S.; Ji, J.; Cai, H.; Chen, H. Modeling and force analysis of a harvesting robot for button mushrooms. IEEE Access 2022, 10, 78519–78526. [Google Scholar] [CrossRef]

- Burton, K. Cultural factors affecting mushroom quality-cause and control of bruising. Mushroom Sci. 2004, 16, 397–402. [Google Scholar]

- Weijn, A.; Tomassen, M.; Bastiaan-Net, S.; Wigham, M.; Boer, E.; Hendrix, E.; Baars, J.; Sonnenberg, A.; Wichers, H.; Mes, J. A new method to apply and quantify bruising sensitivity of button mushrooms. LWT 2012, 47, 308–314. [Google Scholar] [CrossRef]

- Recchia, A.; Strelkova, D.; Urbanic, J.; Kim, E.; Anwar, A.; Murugan, A.S. A prototype pick and place solution for harvesting white button mushrooms using a collaborative robot. Robot. Rep. 2023, 1, 67–81. [Google Scholar] [CrossRef]

- Mbakop, S.; Tagne, G.; Lagache, A.; Youcef-Toumi, K.; Merzouki, R. Integrated design of a bio-inspired soft gripper for mushrooms harvesting. In Proceedings of the 2023 IEEE International Conference on Soft Robotics (RoboSoft), Singapore, 3–7 April 2023; pp. 1–6. [Google Scholar]

- Zhao, K.; Li, H.; Ji, J.; Li, Q.; Li, M.; He, Y.; Li, J.; Xing, S. Pressure-stabilized flexible end-effector for selective picking of agaricus bisporus. Agriculture 2023, 13, 2256. [Google Scholar] [CrossRef]

- Li, J.; Feng, Q.; Ru, M.; Sun, J.; Guo, X.; Zheng, W. Design of Shiitake Mushroom Robotic Picking Grasper: Considering Stipe Compressive Stress Relaxation. Machines 2024, 12, 241. [Google Scholar] [CrossRef]

- Tao, K.; Wang, Z.; Yuan, J.; Liu, X. Design of a novel end-effector for robotic bud thinning of Agaricus bisporus mushrooms. Comput. Electron. Agric. 2023, 210, 107880. [Google Scholar] [CrossRef]

- Lu, W.; Zou, M.; Shi, H.; Wang, L.; Deng, Y. Technology of visual identification—Measuring—Location for brown mushroom picking based on YOLO v5—TL. Trans. Chin. Soc. Agric. Mach. 2022, 53, 341–348. [Google Scholar]

- Ling, W.; Wei, X.; Kaiwei, D.; Wei, L.; Jiahao, Z.; Jun, Z. Portabella mushrooms measurement in situ based on SR300 depth camera. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 13–19+108. [Google Scholar]

- Ji, Q.; Lu, W.; Song, A.; Wang, P.; Ding, Y.; Wang, L. Design of An Intelligent Soft Gripper for On-line Measurement of Fruit Size. Jiangsu J. Agric. Sci. 2020, 36, 8. [Google Scholar]

- den Ouden, M. Mushroom Signals: A Practical Guide to Optimal Mushroom Growing; Roodbont Publishers: Zutphen, The Netherlands, 2016. [Google Scholar]

- Boyce, M.C.; Arruda, E.M. Constitutive models of rubber elasticity: A review. Rubber Chem. Technol. 2000, 73, 504–523. [Google Scholar] [CrossRef]

- Haonan, S. Design of Mobile Robot for Picking Bisporus Mushroom. Master’s Thesis, NJAU, Nanjing, China, 2021. [Google Scholar]

- Huang, M.; Jiang, X.; He, L.; Choi, D.; Pecchia, J. Hand-picking Dynamic Analysis for Robotic Agaricus Mushroom Harvesting. In Proceedings of the 2020 ASABE Annual International Virtual Meeting, Online, 13–15 July 2020; p. 1. [Google Scholar]

- Huang, M.; Jiang, X.; He, L.; Choi, D.; Pecchia, J.; Li, Y. Development of a robotic harvesting mechanism for button mushrooms. Trans. ASABE 2021, 64, 565–575. [Google Scholar] [CrossRef]

- Rai, R.; Arumuganathan, T. Post Harvest Technology of Mushrooms; National Research Centre for Mushroom, Indian Council of Agricultural Research: Solan, India, 2008.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).