Design and Simulation of Chinese Cabbage Harvester

Abstract

1. Introduction

2. Physical Characteristic Analysis of Chinese Cabbage

2.1. Collection of Basic Physical Characteristics of Chinese Cabbage

2.2. Measurement of Mechanical Properties in Chinese Cabbage Harvesting

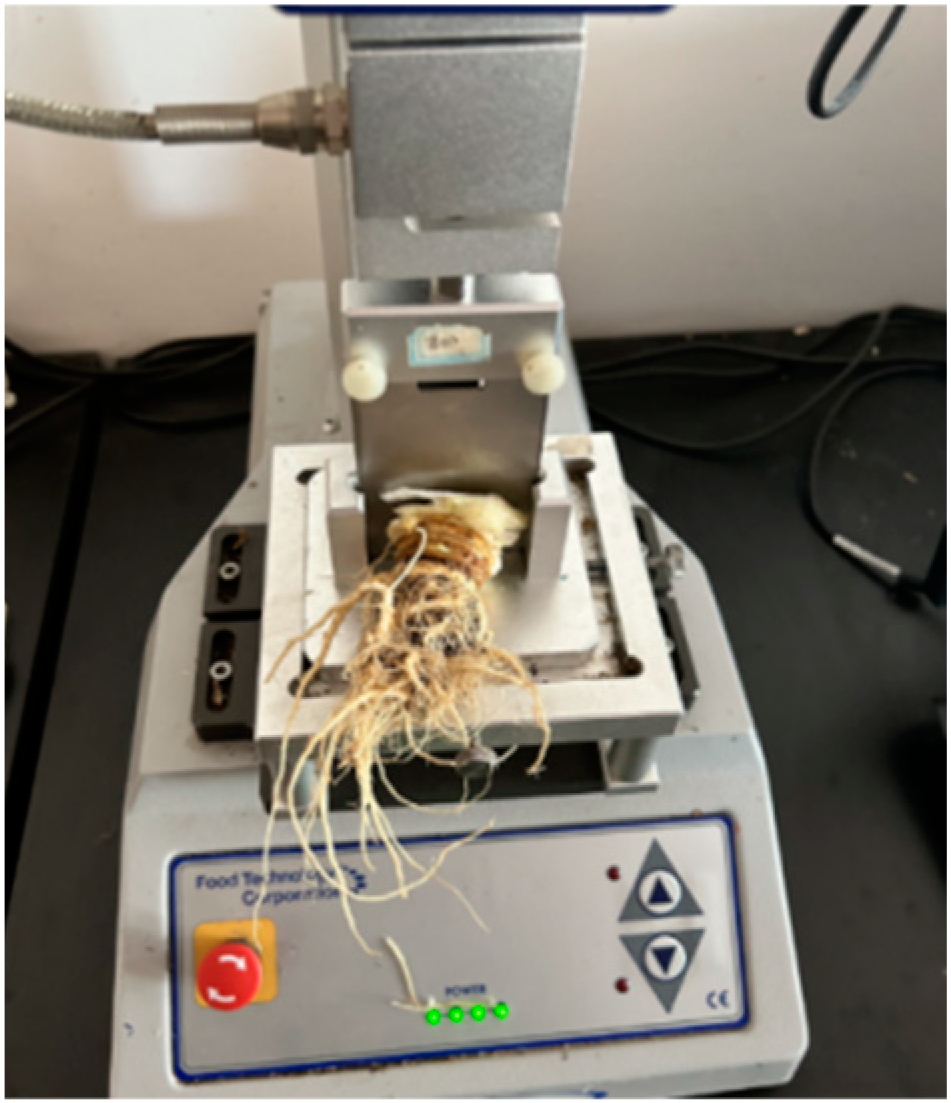

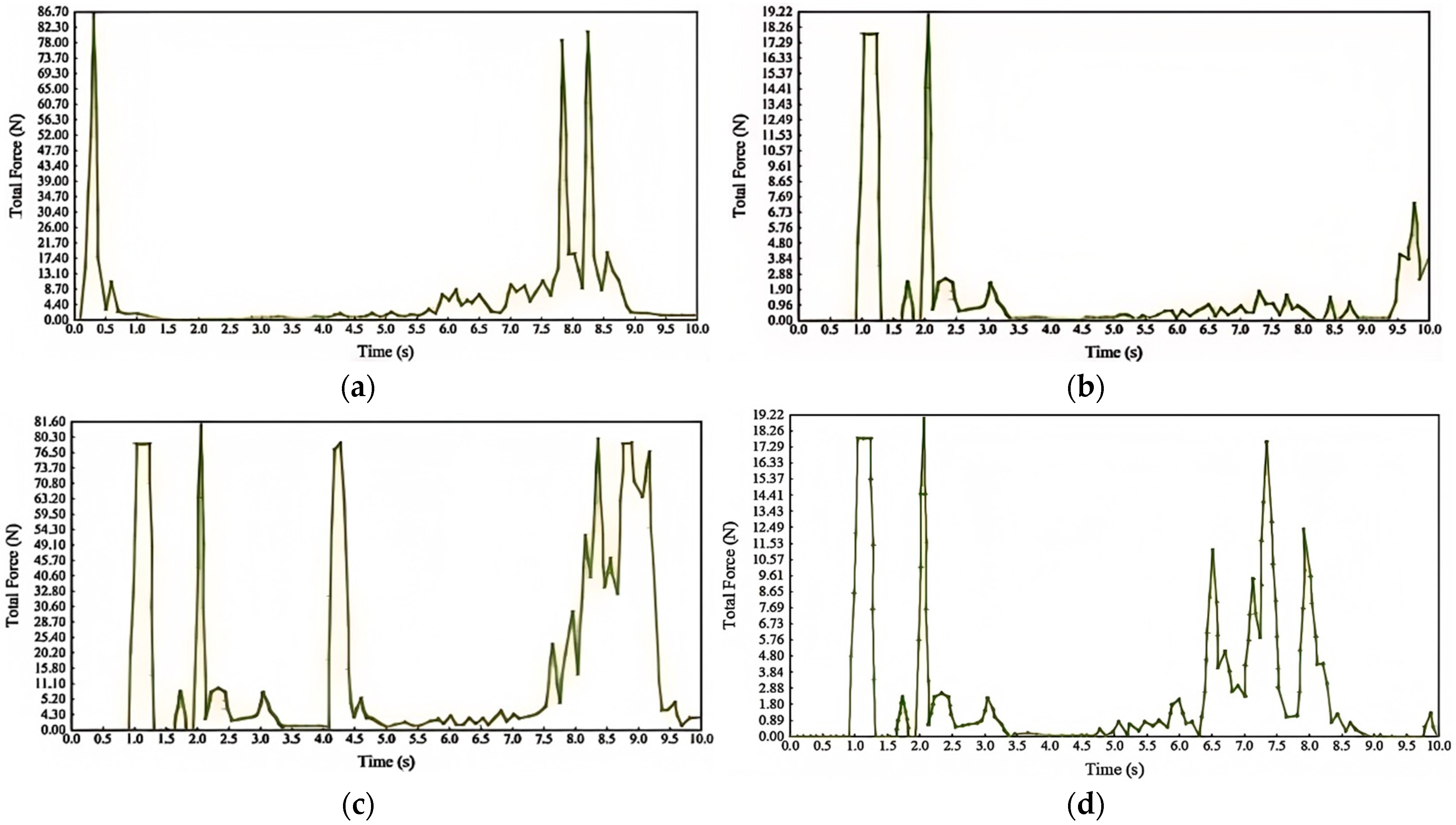

2.2.1. Measurement of the Cabbage Drawing Force

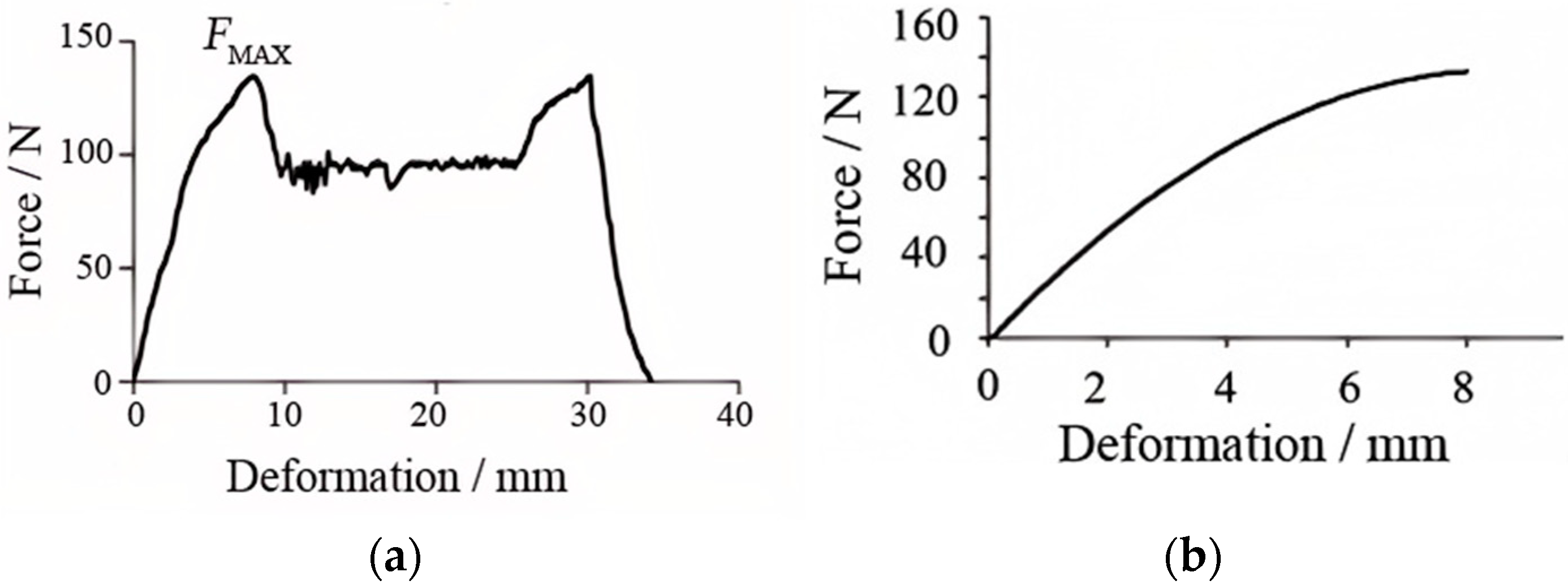

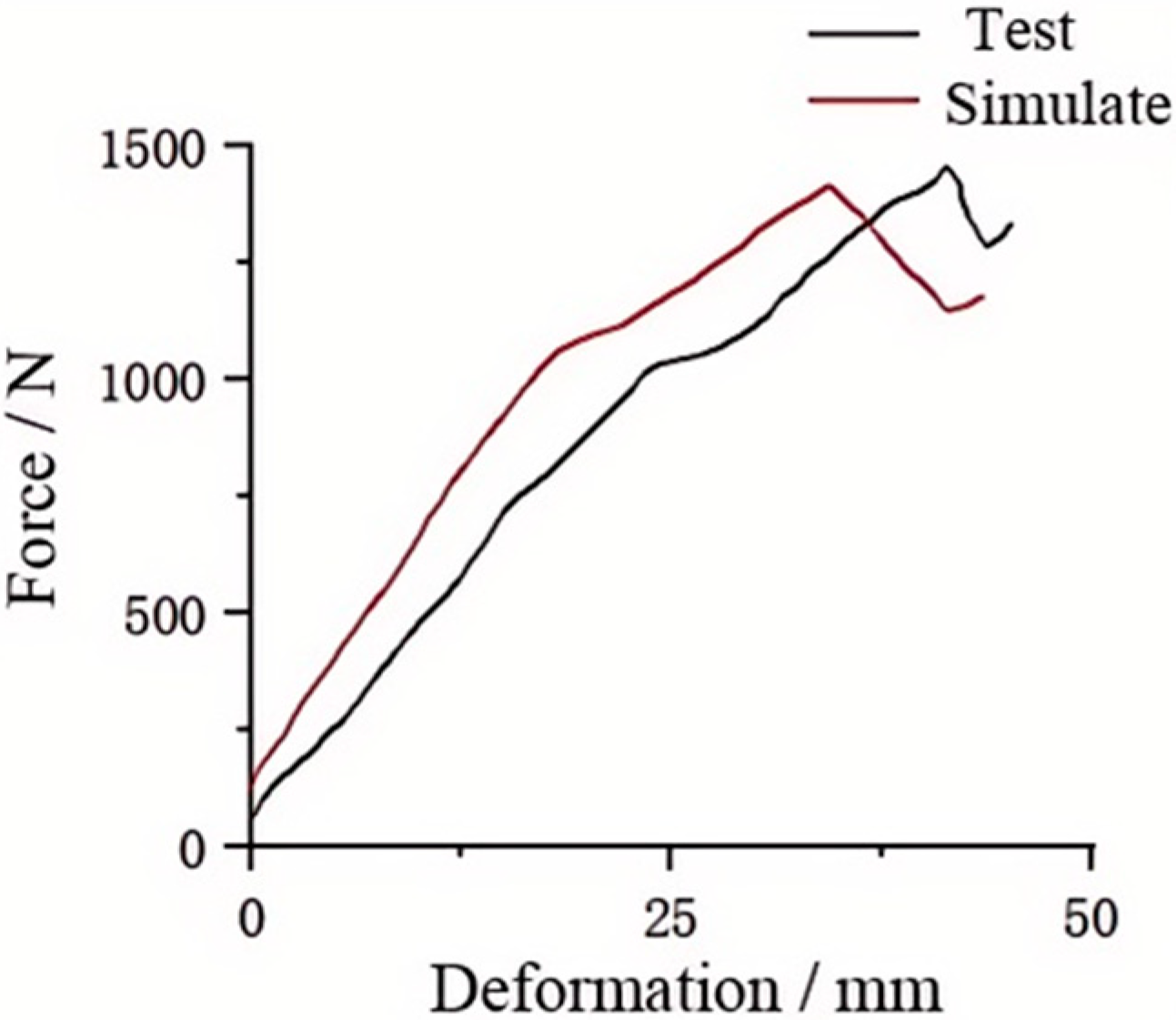

2.2.2. Measurement of the Shear Properties of Chinese Cabbage

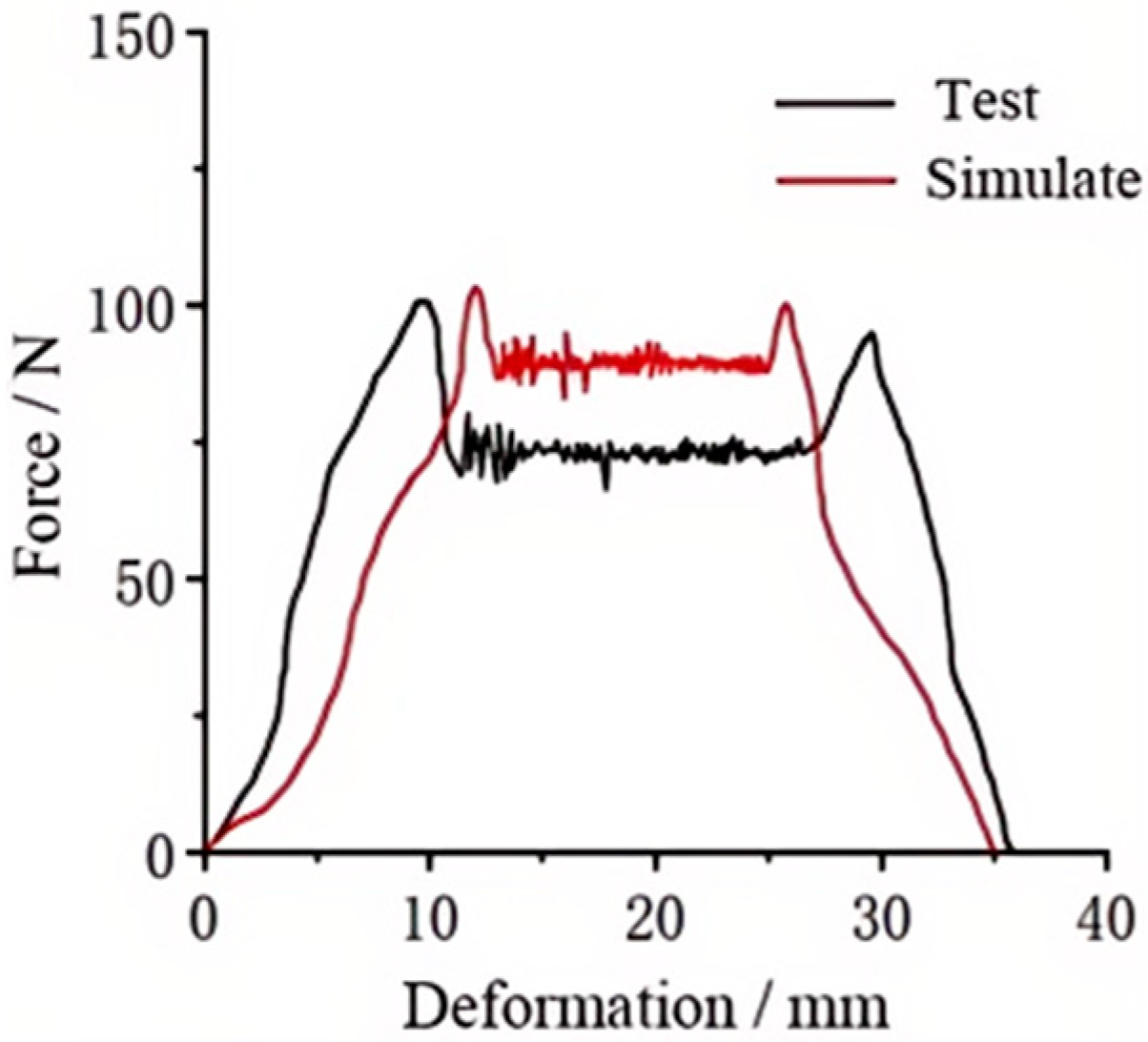

2.2.3. Measurement of Compression Characteristics of Chinese Cabbage

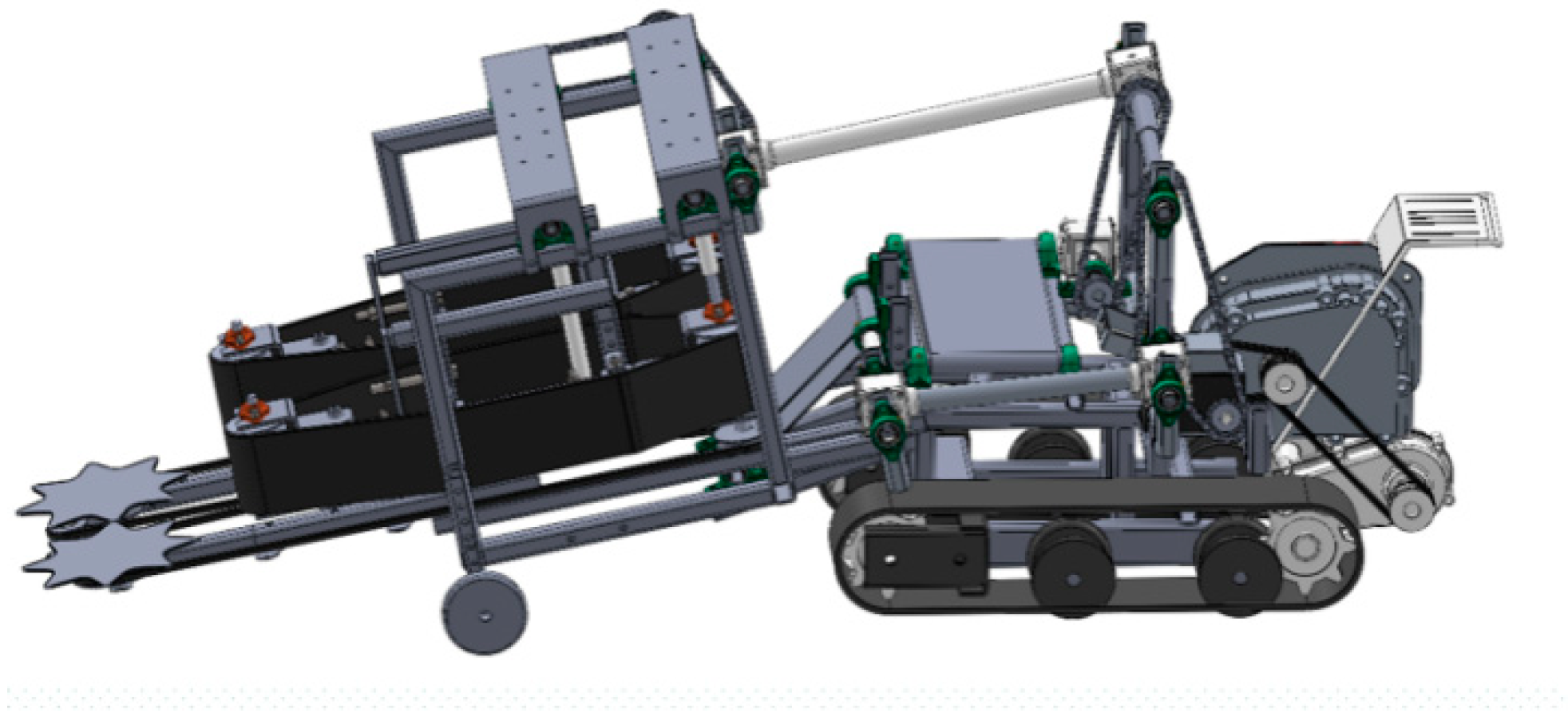

3. Overall Structural Design and Working Principle

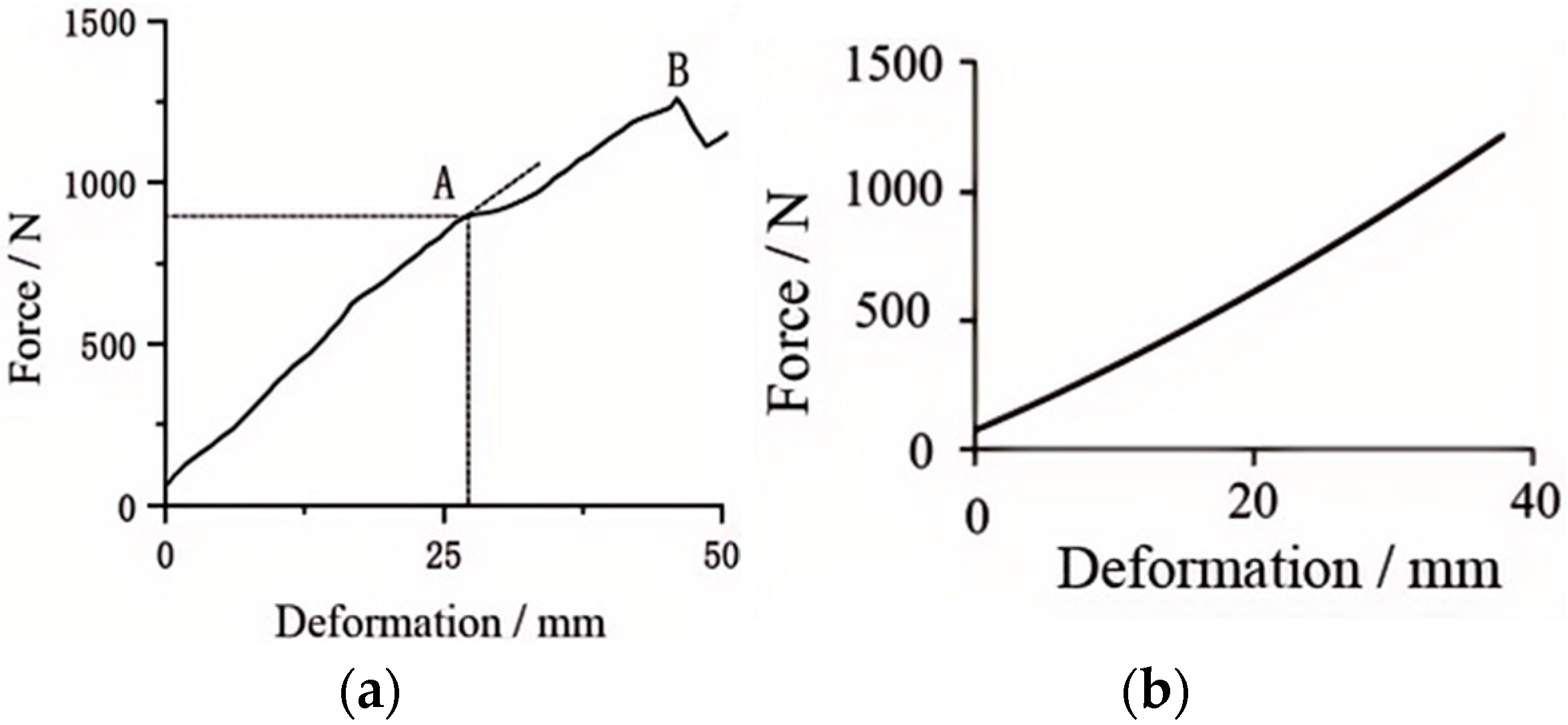

3.1. Overall Structural Design of the Chinese Cabbage Harvester

3.2. Technical Parameters

4. Design and Check of Key Components

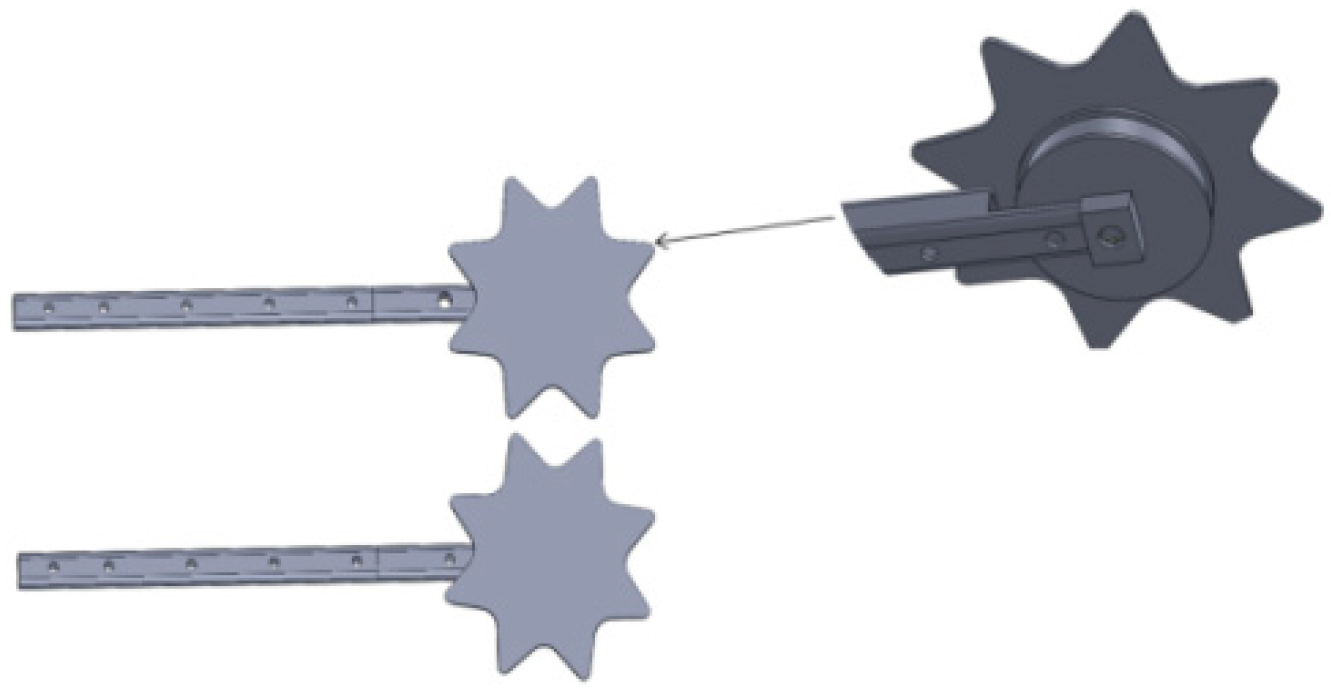

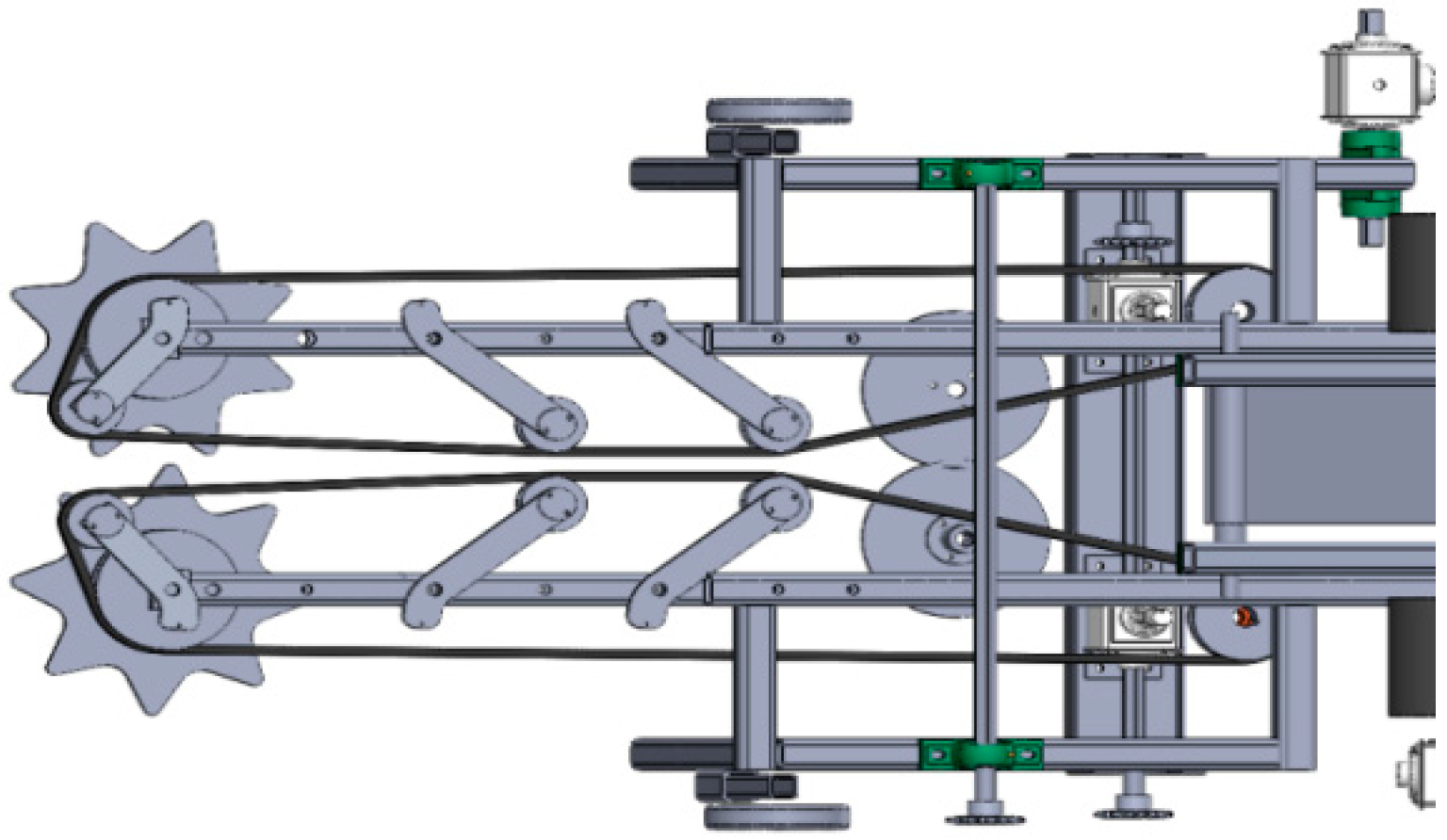

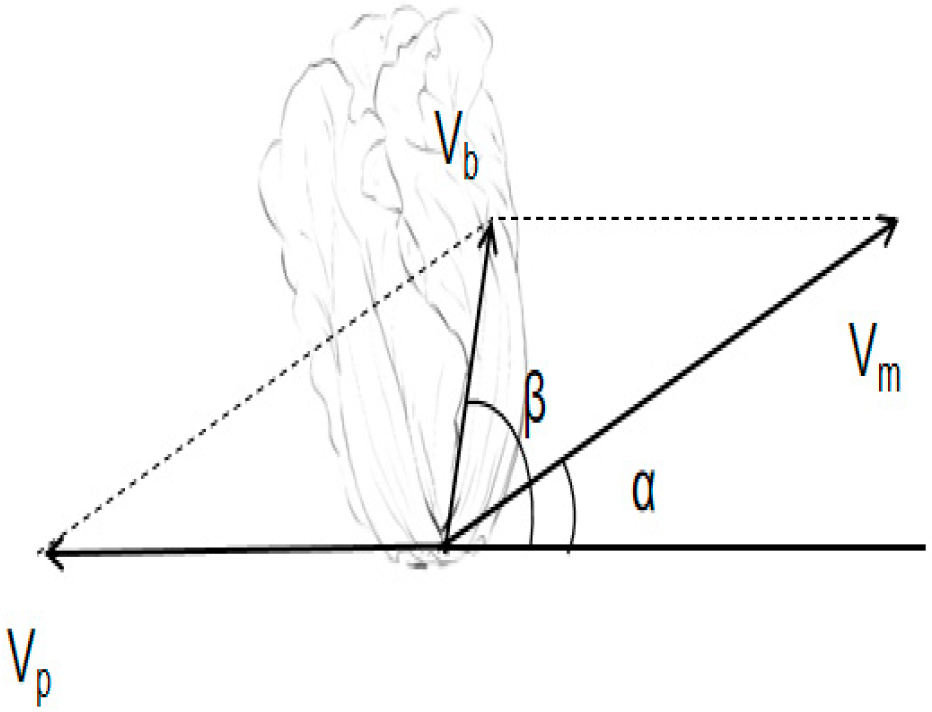

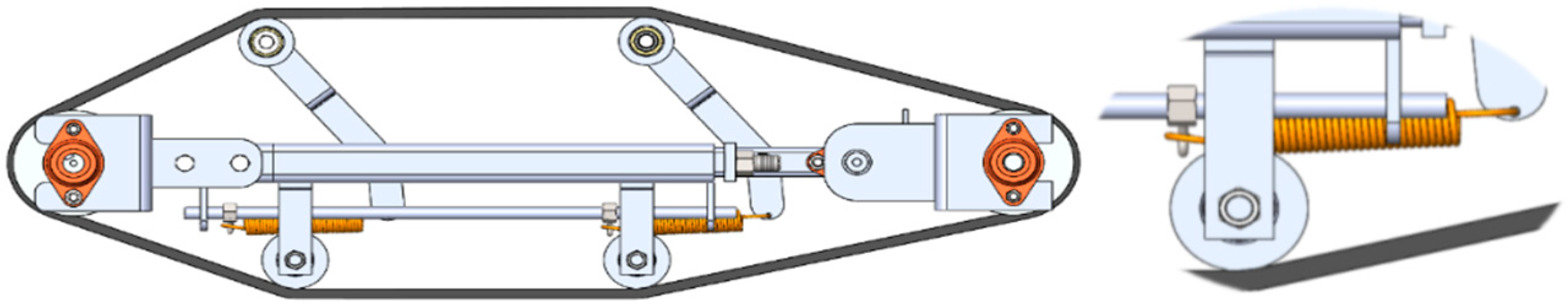

4.1. Design of the Drawing Device

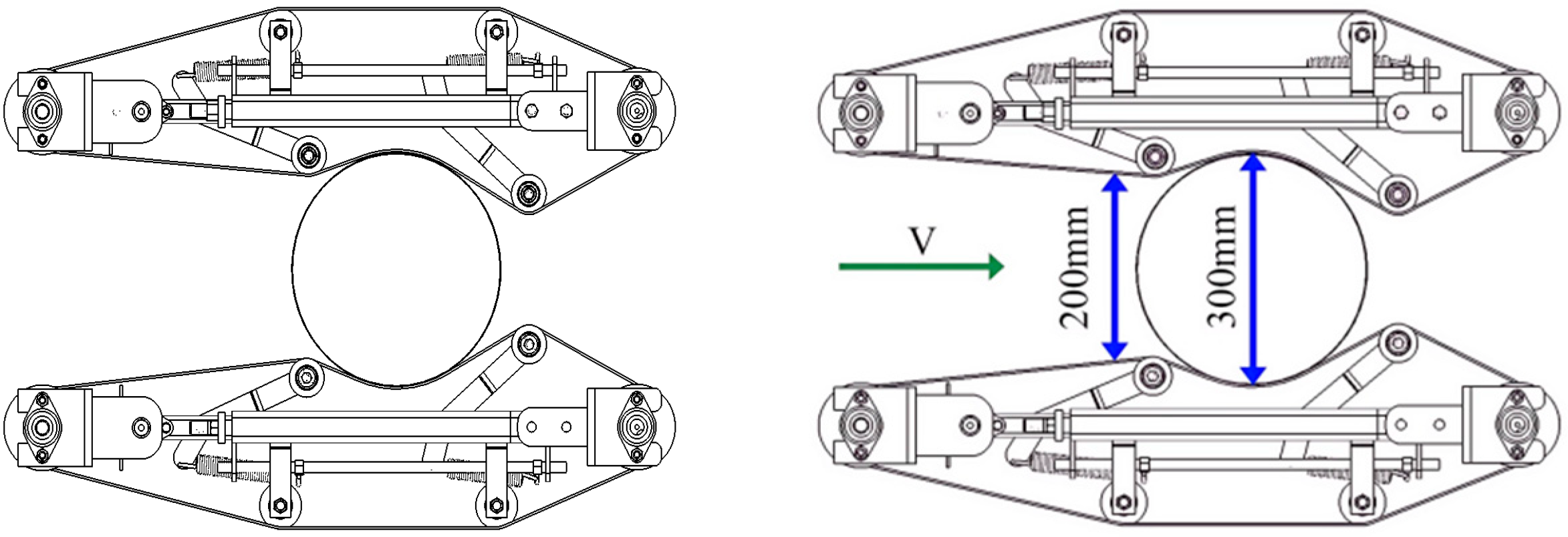

4.2. Design of the Flexible Clamping and Transmission Device

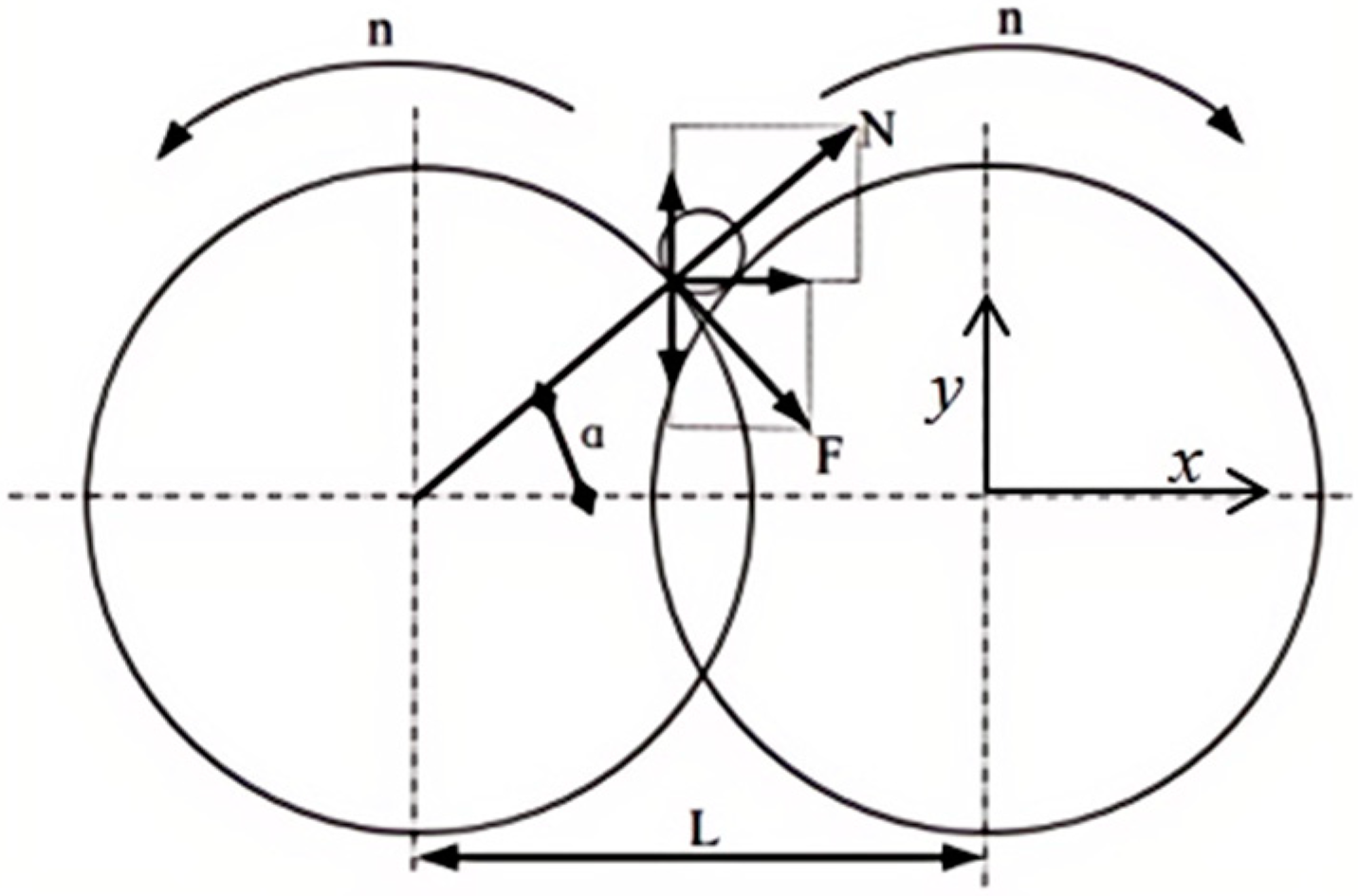

4.3. Design of the Root Cutting Device

5. Simulation Test

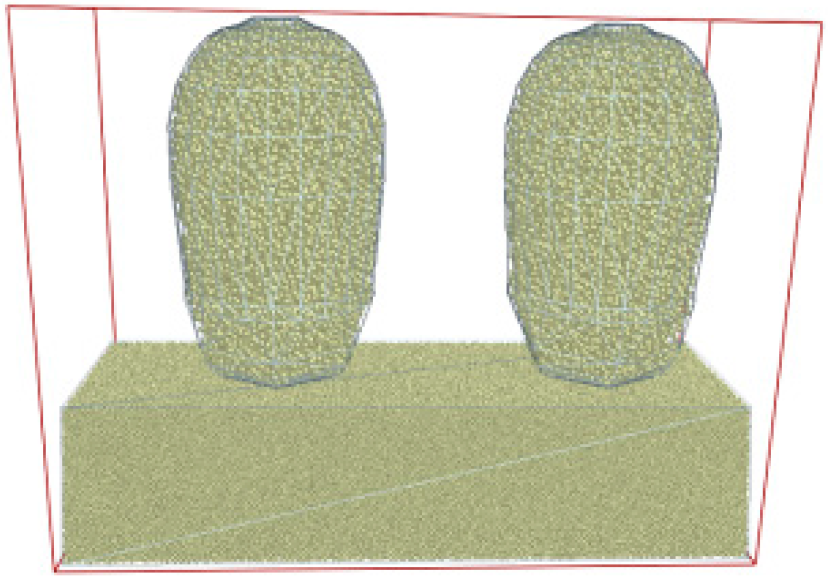

5.1. Model Establishment

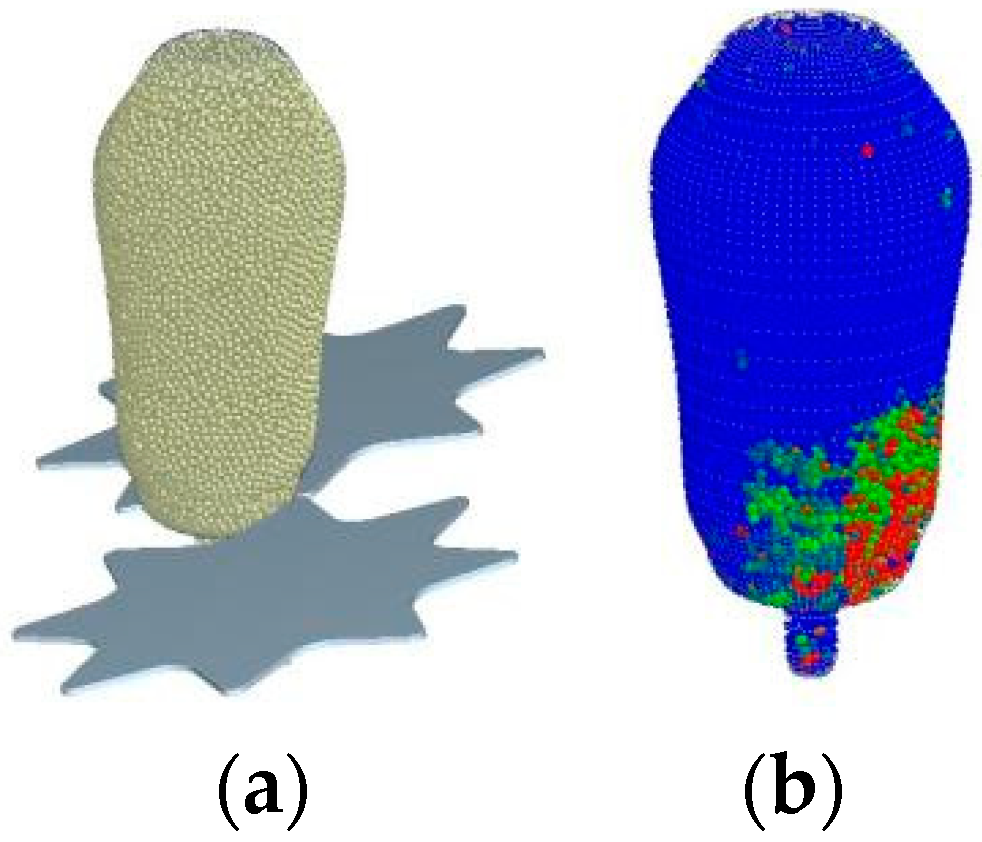

5.1.1. Establishment of the Cabbage Model

5.1.2. Simulation Model Verification

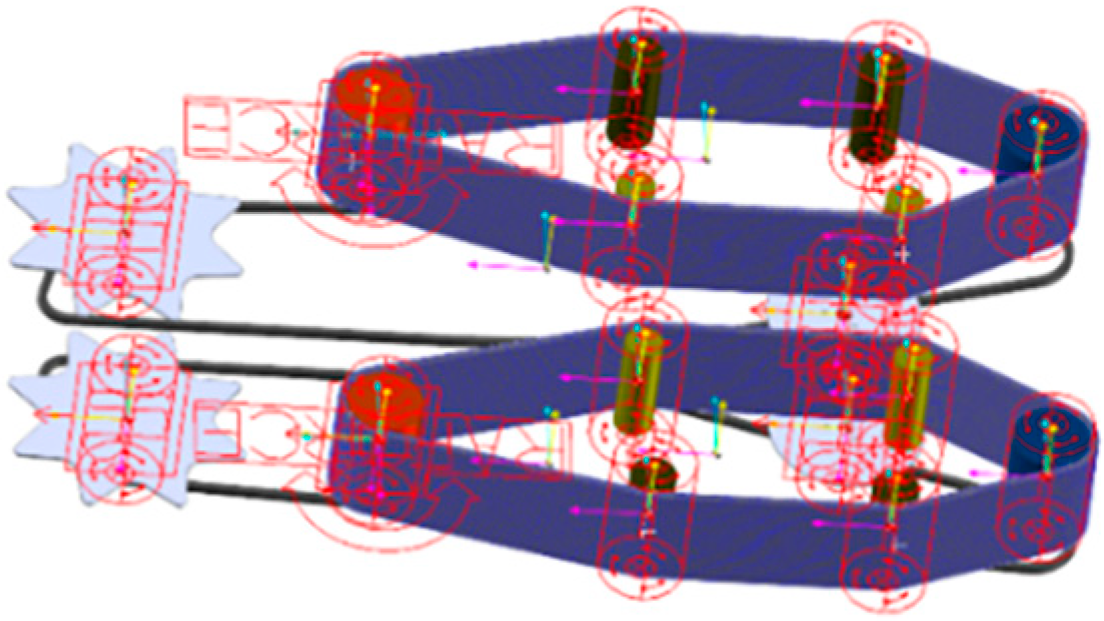

5.1.3. Establishment of the Simulation Model of the Cabbage Harvester

5.2. Test Factors and Indexes

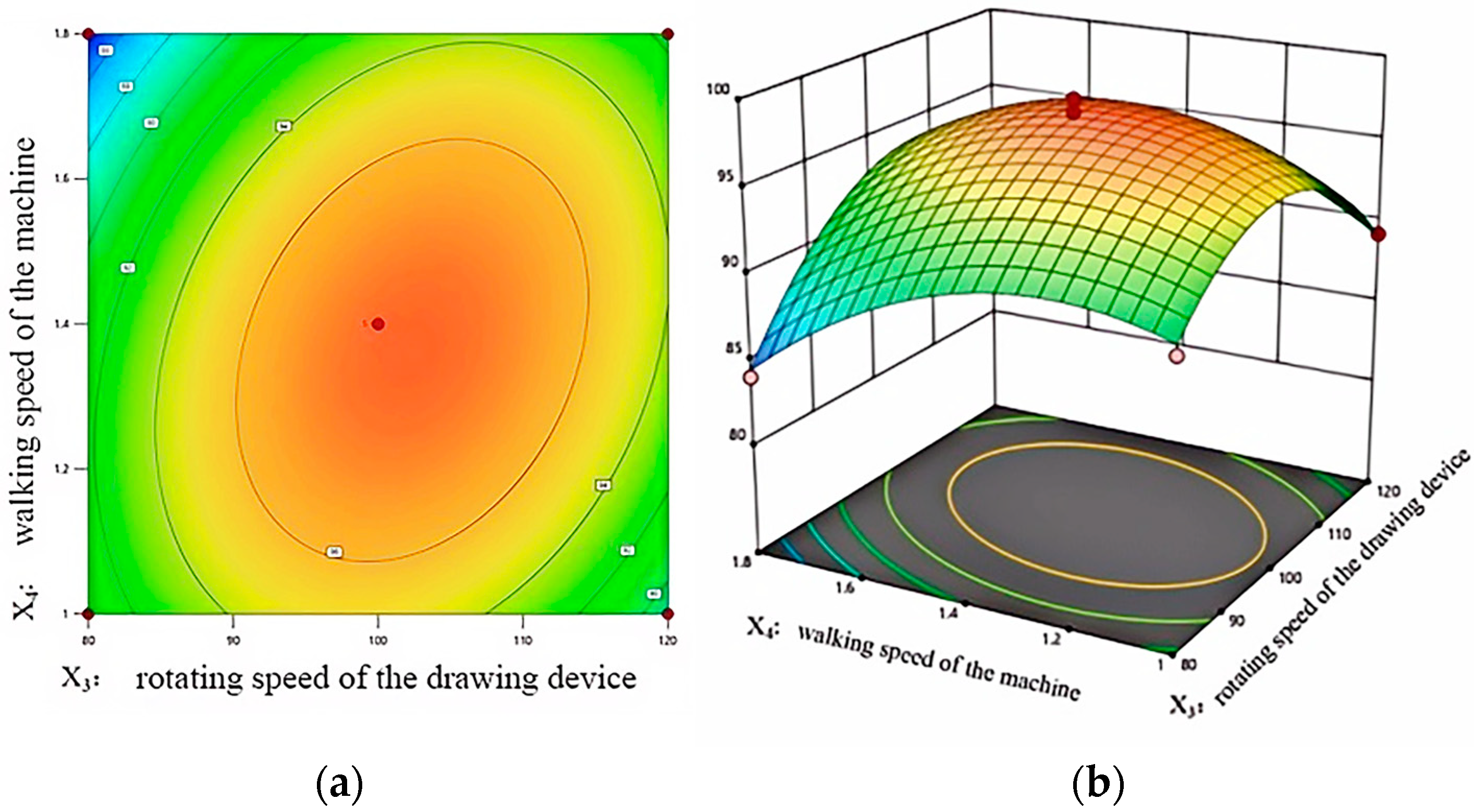

5.3. Results and Analysis

6. Field Test

6.1. Test Conditions and Method

6.1.1. Test Conditions

6.1.2. Test Method

6.2. Test Results and Analysis

7. Conclusions

- (1)

- By taking Chinese cabbage as the test object, the basic physical characteristics and mechanical properties of Chinese cabbage in harvesting were studied, to provide reference to its structural design and simulation analysis;

- (2)

- A hand-held Chinese cabbage harvester with agronomic integration was designed. It is mainly composed of the drawing device, the flexible clamping and transmission device, and the root-cutting device, and force analysis was conducted, showing that the structural design was reasonable and could satisfy the working demand of the Chinese cabbage harvester;

- (3)

- Coupling simulation of the harvesting process for Chinese cabbage was conducted by using the EDEM and RecurDyn software. The optimal parameters combination for the qualified rate of harvesting for the Chinese cabbage harvester were determined as follows: the rotating speed of the root cutting device was 200 r/min, the rotating speed of the flexible clamping device was 160 r/min, the rotating speed of the drawing device was 100 r/min, and the machine walking speed was 1.4 km/h. At this time, the qualified rate of harvesting of Chinese cabbage was 97.91%;

- (4)

- Field verification tests were carried out on the Chinese cabbage harvester based on simulation test results. By considering the qualified rate of harvesting and harvesting efficiency of Chinese cabbage, 1.4 km/h was finally selected as the final walking speed. At this time, the mean value of the qualified rate of harvesting reached 90.5%, which satisfied the demand of Chinese cabbage harvesting and proved to have a good effect in the field verification tests.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ji, G.; Li, Z.; Gao, Z. Planting technology of Chinese cabbage in Jiaozhou. Chin. Veg. 2016, 91, 88–90. [Google Scholar] [CrossRef]

- Cui, S.Y.; Xiao, T.Q.; Chen, Y.S. Analysis of current situation and Restriction factors of vegetable production mechanization in China. Agric. Mech. Res. 2014, 36, 249–251+256. [Google Scholar] [CrossRef]

- Li, Q. Discussion on the influence of Popularization of New Agricultural Machinery on Agricultural Development. Rural Staff Off 2021, 4, 150. [Google Scholar] [CrossRef]

- Jun, C. Analysis of Problems and Solutions in the Technical Promotion of Agricultural Machinery. China Equip. Eng. 2022, 5, 270–271. [Google Scholar] [CrossRef]

- Kanamitsu, M.; Yamamoto, K.; Shibano, Y. Development of a Chinese cabbage harvester(part1). JSAM 1993, 55, 133–140. [Google Scholar] [CrossRef]

- Kim, H.; Yeongsoo, C. Pulling performance of a self-propelled Chinese cabbage harvester and design of apreprocessing unit. J. Agric. Life Sci. 2020, 54, 99–108. [Google Scholar] [CrossRef]

- Li, X.J.; Zhao, D.Y.; Zhang, B.K.; Wang, M.J. Development of Knapsack Cabbage Harvester. Agric. Sci. Technol. Equip. 2017, 10, 25–27. [Google Scholar] [CrossRef]

- Wu, X.; Sun, Y.; Yuan, X. Research on Self-propelled Chinese Cabbage harvester. South Agric. Mach. 2018, 49, 23–24. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Du, D.; Long, S.; Wang, Y.; You, X. Design and Experiment of Crawler Self-propelled Single-row Harvester for Chinese Cabbage. Trans. Chin. Soc. Agric. Mach. 2022, 53, 134–146. [Google Scholar] [CrossRef]

- Xie, J.; Wu, S.; Cao, S. Design and Experiment of cotton straw Pulling device with Gripping roller. Trans. Chin. Soc. Agric. Mach. 2023, 54, 101–111. [Google Scholar] [CrossRef]

- Wang, M.; Zeng, Z.; Zhou, F.; Guo, C. Experimental study on shear characteristics of wheat under static and dynamic loads. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 273–280. [Google Scholar] [CrossRef]

- Sun, F.; Wu, T.; Chen, C.; Sun, Y.; Xie, Q.; Shi, L. Mechanical properties and model construction of compression and stress relaxation of seed cotton. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 53–60. [Google Scholar] [CrossRef]

- Zhang, C.; Kang, J.; Zhang, Z. Design and experiment of seed division plate of flower-gas suction drum cave-planter. Trans. Chin. Soc. Agric. Mach. 2023, 54, 28–37. [Google Scholar] [CrossRef]

- Xin, S.; Zhao, W.; Shi, L. Design and experiment of Gripper Conveying Device for vertical Roller Corn harvesting and cutting Table. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 34–43. [Google Scholar] [CrossRef]

- Geng, A.; Yang, J.; Zhang, J. Analysis of Influencing factors of mechanical damage in maize picking and harvesting. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2016, 32, 56–62. [Google Scholar] [CrossRef]

- Park, S.-J.; Lee, S.-Y.; Park, W.-J.; Yang, K.-W.; Ali, M.; Kim, H.-J. Preliminary tests for chinese cabbage harvesting with harvesting simulator. J. Korea Acad.-Ind. Coop. Soc. 2021, 22, 470–479. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, P.; Zhang, H. Study on discrete element simulation parameter calibration of cotton straw in Xinjiang. Trans. Chin. Soc. Agric. Mach. 2024, 55, 76–84+108. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, X.; Liu, J. Parameter calibration and experiment of banana Straw discrete element simulation bonding model. Trans. Chin. Soc. Agric. Mach. 2023, 54, 121–130. [Google Scholar] [CrossRef]

- Wei, X.; Lei, P.; Ping, J. Establishment and optimization of a discrete element model for the double bond of Canola stem during harvest. Trans. Chin. Soc. Agric. Mach. 2023, 54, 112–120. [Google Scholar] [CrossRef]

- Song, Z.; Li, H.; Yan, Y. Parameter calibration and experiment of discrete element simulation model of soil non-equal diameter particles in Mulberry Garden. Trans. Chin. Soc. Agric. Mach. 2022, 53, 21–33. [Google Scholar] [CrossRef]

- Tao, C.; Jing, M.; Zhang, D. Construction of corn ear discrete element model and simulation verification of threshing. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 33–46. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, L.; Liu, H. Discrete element simulation parameter calibration and experiment of water chestnut. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 41–50. [Google Scholar] [CrossRef]

- Shu, C.; Yang, J.; Wan, X. Parameter calibration and experiment of discrete element simulation of rape extract in combined harvest. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 34–43. [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Chen, F. Simulation optimization and experiment of Fingerclip claw for taking seedling based on EDEM-RecurDyn. Trans. Chin. Soc. Agric. Mach. 2022, 53, 75–85+301. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, C.; Li, Z. Analysis and optimization of Vibration Characteristics of Corn finger clip seed feeder based on EDEM-RecurDyn. J. Agric. Mach. 2023, 54, 36–46. [Google Scholar] [CrossRef]

- Wang, F.; Wen, B.; Xie, X. Operation Mechanism Analysis and Parameter Optimization of Conveying and separating Device of Panax Notoginseng harvester. Trans. Chin. Soc. Agric. Mach. 2023, 54, 201–211+259. [Google Scholar] [CrossRef]

- Li, X.; Du, Y.; Liu, L. Design and experiment of Automatic Control System for Low loss direct grain harvester. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 34–42. [Google Scholar] [CrossRef]

- Wang, J.; Du, D.; Hu, J. Vegetable mechanized harvesting technology and its development. Trans. Chin. Soc. Agric. Mach. 2014, 45, 81–87. [Google Scholar] [CrossRef]

| Parameters | Diameter/mm | Plant Height/mm | Weight/kg | Rhizome Length/mm | Rhizome Diameter/mm |

|---|---|---|---|---|---|

| Mean value | 155 | 164 | 2.77 | 60.55 | 28.36 |

| Maximum value | 162 | 190 | 3.18 | 74.32 | 32.63 |

| Minimum value | 148 | 138 | 2.35 | 50.68 | 42.57 |

| Standard deviation | 7 | 3.41 | 0.42 | 11.87 | 7.29 |

| Coefficient of Variation | 0.05 | 0.07 | 0.15 | 0.20 | 0.26 |

| Parameters | Drawing Force (N) |

|---|---|

| Mean value | 288 |

| Maximum value | 354 |

| Minimum value | 222 |

| Standard deviation | 45.7 |

| Variable coefficient | 0.16 |

| Technical Parameters | Values |

|---|---|

| Matched power/kW | 2.8 |

| Length × width × height/mm | 2700 × 1100 × 1000 |

| Line number | 1 |

| Working width/mm | 700 |

| Suitable row spacing/mm | 500–750 |

| Plant distance/mm | 400 |

| Gear position | Four-speed gear shift: 3-forward + 1 Reverse |

| Operating speed/km·h−1 | 0–1.8 |

| Technical Parameters | Values |

|---|---|

| Track grounding length/mm | 860 |

| Track drive wheel diameter/mm | 180 |

| Track model/mm | 100 × 60 × 45 |

| Track width/mm | 100 |

| Minimum ground clearance/mm | 170 |

| Minimum ground clearance part | Lower supporting crossbar in front of the crawler chassis |

| Drive mode of walking | Mechanical speed change |

| Model Structure | Three-Layer Stacking Model | ||

|---|---|---|---|

| Upper Part | Middle Part | Root | |

| Elasticity modulus/Mpa | 0.135 | 0.284 | 0.469 |

| Density/kg·m−3 | 385.2 | 534.6 | 794.3 |

| Poisson’s ratio | 0.30 | 0.30 | 0.30 |

| Contact Coefficient | |

|---|---|

| Recovery coefficient | 0.29 |

| Static friction coefficient | 0.58 |

| Dynamic friction coefficient | 0.032 |

| Rotating Speed of the Root-Cutting Device /r·min−1 | Rotating Speed of the Flexible Clamping and Conveyor Belt /r·min−1 | Rotating Speed of the Drawing Device /r·min−1 | Walking Speed of the Machine /km·h−1 | |

|---|---|---|---|---|

| +1 | 300 | 200 | 120 | 1.8 |

| 0 | 200 | 160 | 100 | 1.4 |

| −1 | 100 | 120 | 80 | 1.0 |

| No. | /r·min−1 | /r·min−1 | /r·min−1 | /km·h−1 | Qualified Rate of Harvesting y1/% |

|---|---|---|---|---|---|

| 1 | 200 | 160 | 100 | 1.4 | 96.88 |

| 2 | 200 | 160 | 80 | 1 | 91.97 |

| 3 | 300 | 160 | 80 | 1.4 | 88.52 |

| 4 | 200 | 160 | 100 | 1.4 | 96.75 |

| 5 | 100 | 200 | 100 | 1.4 | 90.45 |

| 6 | 200 | 200 | 120 | 1.4 | 89.9 |

| 7 | 300 | 160 | 100 | 1 | 90.37 |

| 8 | 100 | 160 | 100 | 1.8 | 83.54 |

| 9 | 300 | 120 | 100 | 1.4 | 91.12 |

| 10 | 200 | 160 | 100 | 1.4 | 97.98 |

| 11 | 300 | 200 | 100 | 1.4 | 92.37 |

| 12 | 200 | 200 | 100 | 1 | 89.4 |

| 13 | 200 | 160 | 120 | 1.8 | 95.38 |

| 14 | 200 | 160 | 120 | 1 | 89.2 |

| 15 | 200 | 200 | 100 | 1.8 | 90.53 |

| 16 | 300 | 160 | 100 | 1.8 | 91.4 |

| 17 | 100 | 160 | 100 | 1 | 92.74 |

| 18 | 200 | 120 | 100 | 1.8 | 82.69 |

| 19 | 200 | 120 | 80 | 1.4 | 83.75 |

| 20 | 100 | 120 | 100 | 1.4 | 87.16 |

| 21 | 200 | 160 | 100 | 1.4 | 98.71 |

| 22 | 300 | 160 | 120 | 1.4 | 90.86 |

| 23 | 100 | 160 | 80 | 1.4 | 86.19 |

| 24 | 200 | 200 | 80 | 1.4 | 88.58 |

| 25 | 100 | 160 | 120 | 1.4 | 92.65 |

| 26 | 200 | 120 | 100 | 1 | 91.49 |

| 27 | 200 | 160 | 80 | 1.8 | 80.02 |

| 28 | 200 | 160 | 100 | 1.4 | 97.92 |

| 29 | 200 | 120 | 120 | 1.4 | 88.42 |

| Source of Variation | Quadratic Sum | Degree of Freedom | Mean Square | F | p | Significance |

|---|---|---|---|---|---|---|

| Regression model | 456.47 | 14 | 32.61 | 30.32 | <0.0001 | Extremely significant |

| x1 | 8.42 | 1 | 8.42 | 7.83 | 0.0142 | Significant |

| x2 | 32.18 | 1 | 32.18 | 29.92 | <0.0001 | Extremely significant |

| x3 | 24.03 | 1 | 24.03 | 22.34 | 0.0003 | Extremely significant |

| x4 | 9.94 | 1 | 9.94 | 9.24 | 0.0088 | Extremely significant |

| x1 x2 | 4.08 | 1 | 4.08 | 3.79 | 0.0718 | Insignificant |

| x1 x3 | 1.12 | 1 | 1.12 | 1.04 | 0.324 | Insignificant |

| x1 x4 | 1.4 | 1 | 1.4 | 1.31 | 0.2723 | Insignificant |

| x2 x3 | 0.0306 | 1 | 0.0306 | 0.0285 | 0.8684 | Insignificant |

| x2 x4 | 3.76 | 1 | 3.76 | 3.5 | 0.0824 | Insignificant |

| x3 x4 | 19.05 | 1 | 19.05 | 17.72 | 0.0009 | Extremely significant |

| x12 | 94.77 | 1 | 94.77 | 88.13 | <0.0001 | Extremely significant |

| x22 | 188.96 | 1 | 188.96 | 175.72 | <0.0001 | Extremely significant |

| x32 | 170.78 | 1 | 170.78 | 158.81 | <0.0001 | Extremely significant |

| x42 | 82.72 | 1 | 82.72 | 76.92 | <0.0001 | Extremely significant |

| Residue | 15.05 | 14 | 1.08 | |||

| Lack-of-fit | 12.35 | 10 | 1.23 | 1.82 | 0.2953 | Insignificant |

| Errors | 2.71 | 4 | 0.6771 | |||

| Sum | 471.53 | 28 |

| Walking Speed /km·h−1 | No. | Sum/Particles | Damaged Number | Qualified Rate of Harvesting/% | Damage Rate/% |

|---|---|---|---|---|---|

| 1.0 | 1 | 215 | 19 | 91.16 | 8.84 |

| 2 | 234 | 21 | 91.03 | 8.97 | |

| 3 | 219 | 13 | 94.06 | 5.94 | |

| 4 | 223 | 18 | 91.93 | 8.07 | |

| 5 | 217 | 15 | 93.09 | 6.91 | |

| Mean value | 92.25 | 7.75 | |||

| 1.4 | 1 | 275 | 23 | 91.64 | 8.36 |

| 2 | 285 | 26 | 90.88 | 9.12 | |

| 3 | 254 | 25 | 90.16 | 9.84 | |

| 4 | 265 | 25 | 90.57 | 9.43 | |

| 5 | 261 | 28 | 89.27 | 10.73 | |

| Mean value | 90.50 | 9.50 | |||

| 1.8 | 1 | 259 | 43 | 83.40 | 16.60 |

| 2 | 278 | 42 | 84.89 | 15.11 | |

| 3 | 263 | 47 | 82.13 | 17.87 | |

| 4 | 294 | 44 | 85.03 | 14.97 | |

| 5 | 281 | 53 | 81.14 | 18.86 | |

| Mean value | 83.32 | 16.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Yang, X.; Zhang, Z.; Xu, J.; Zhao, P.; Tian, S.; Wei, L.; Ning, X. Design and Simulation of Chinese Cabbage Harvester. Agriculture 2025, 15, 831. https://doi.org/10.3390/agriculture15080831

Liu S, Yang X, Zhang Z, Xu J, Zhao P, Tian S, Wei L, Ning X. Design and Simulation of Chinese Cabbage Harvester. Agriculture. 2025; 15(8):831. https://doi.org/10.3390/agriculture15080831

Chicago/Turabian StyleLiu, Simo, Xuhui Yang, Zhe Zhang, Jianing Xu, Ping Zhao, Subo Tian, Lihua Wei, and Xiaofeng Ning. 2025. "Design and Simulation of Chinese Cabbage Harvester" Agriculture 15, no. 8: 831. https://doi.org/10.3390/agriculture15080831

APA StyleLiu, S., Yang, X., Zhang, Z., Xu, J., Zhao, P., Tian, S., Wei, L., & Ning, X. (2025). Design and Simulation of Chinese Cabbage Harvester. Agriculture, 15(8), 831. https://doi.org/10.3390/agriculture15080831