Abstract

The high-precision establishment of drive motor models and “pump-motor” system models is crucial for the development of the agricultural machinery powertrain. The research of this paper studied the series combination of electric drive continuously variable transmission devices, hydraulic continuously variable transmission devices, and power shift transmission devices to form a dual continuously variable transmission system. A drive motor efficiency characteristics modeling method combining the improved sine cosine optimization algorithm and BP neural network (ISCA-BPNN) and a hydrostatic transmission device efficiency characteristics modeling method combining the partial least squares method and the idea of sampling without replacement (PLS-SWOR) were proposed. Various binary control strategies for agricultural tractors were designed and compared. The results show that the two proposed modeling methods can effectively establish the efficiency characteristics models of the motor and hydrostatic transmission device. For agricultural machinery equipped with a dual continuously variable transmission system, it is advisable to apply the comprehensive binary control strategy under medium and high loads, and the pure economic binary control strategy under medium and low loads. This study is expected to provide support for the high-level design and intelligent strategy development of continuously variable transmission agricultural machinery in the future.

1. Introduction

Walking agricultural machinery (a typical representative: agricultural tractors) has the ability to travel in scenarios such as fields, slopes, and roads. It is usually required to be able to adapt to the movement needs of different plots [1,2,3,4]. These operating scenarios are complex (mainly reflected in the strong volatility of vehicle load changes), which in turn leads to the need for the drive and power transmission devices of walking agricultural machinery to have high load-bearing capacity and strong speed change capability [5,6,7,8]. In addition, in recent years, humans have paid increasing attention to environmental protection and sustainable development, and energy conservation and emission reduction are also one of the core performances pursued by the drive and power transmission devices of agricultural machinery [9,10,11].

Electric drive continuously variable transmission technology [12,13], hydrostatic transmission technology [14,15,16,17], and power shift technology [18,19,20] are currently a research hotspot in the field of drive and power transmission devices for walking agricultural machinery. Mocera and Martini [21] focused on a hybrid electric tractor with electric continuously variable transmission (equipped with a 56 kW diesel engine and two 30 kW electric motors) and mainly studied its dynamic performance. Fan et al. [22] proposed a targeted energy management control strategy to solve the problem of high-frequency and rapid charge-discharge. The formulation of this energy management strategy involved wavelet transform and fuzzy theory. Zhao et al. [23] proposed a mode switching control method for the dual-motor drive system of electric tractors. This research specifically targeted the working characteristics of wet multi-plate electromagnetic clutches. Zhang et al. [24] adopted the lever topology method to design the hybrid power device of agricultural tractors and conducted targeted research on the energy-saving control strategy of the device. This study specifically applied the mathematical model of the diesel engine and the mathematical model of the motor. JOO [25] targeted an 18 kW tractor and took the low-speed, medium-speed, and high-speed gear stages as operating conditions. This study evaluated and compared the main performance of the vehicle when similar agricultural tractors, respectively, apply “electric drive”, “internal combustion engine + hydrostatic transmission” and “internal combustion engine + mechanical transmission”. Baek et al. [5] conducted research on a power device simulation model with a certain degree of accuracy for a 50 kW tractor (using Romax DESIGNER software). The tractor used in the research was equipped with a hydro-mechanical continuously variable transmission containing a hydrostatic transmission system. The comparison between the measured data and the simulation data took torque, rotational speed, and power transmission efficiency as the main physical quantities. Park et al. [6] established a network model for hydro-mechanical continuously variable transmission tractors and compared it with the simulation results of commercial software. This study emphatically analyzed the power transmission characteristics of the hydro-mechanical continuously variable transmission device. Zhu et al. [26] designed a compound transmission system integrating mechanical, hydraulic, and electric technologies for agricultural tractors based on advanced compound transmission technology. This study analyzed the relevant characteristics of the new device (established a corresponding simulation model using Simulation X software) and formulated the transmission ratio control strategy of the hydraulic mechanical transmission device and the energy management strategy of the hybrid power system. Wang et al. [27] studied various types of control strategies for full power shift transmissions for a 220 kW tractor. This research jointly constructed a simulation model using AMESim and Matlab/Simulink and comprehensively applied mathematical models of various components throughout the entire research process. Bai et al. [28] constructed an engine model based on measured data for a 95 kW power shift tractor and analyzed the relevant factors affecting engine performance.

Agricultural machinery is well-suited for the application of continuously variable transmission technology to meet its higher requirements for power performance and fuel economy. Therefore, research on the efficiency characteristics of electric-driven continuously variable transmission systems and hydrostatic continuously variable transmission devices is particularly crucial. Wang et al. [29] established a closed-loop transfer function model of the hydrostatic transmission system for a specific model of modern agricultural machinery using mathematical modeling methods and constructed a dynamic characteristic simulation model based on AMESim software. They compared the errors between the simulation model and actual tests under several fixed operating conditions. Cheng et al. [30] proposed a semi-empirical full-operating-condition efficiency model for hydraulic pumps and motors of agricultural tractors based on loss mechanisms. This modeling approach requires experimental data to identify the key parameters of the model. Taking fruit-picking machinery during parking operations as an example, Cheng et al. [31] established a system efficiency model based on the mathematical expressions of the mechanism-based efficiency characteristic models of hydraulic pumps and motors. Zhang et al. [32] adopted a numerical modeling method to equate the motor’s output speed, output torque, and efficiency into functional relationships. Regarding the control strategies for continuously variable transmission systems in agricultural machinery, most studies [33,34] use vehicle speed and resistance as inputs for strategy formulation to obtain control parameters of the transmission and engine. However, there is limited research on comprehensive strategies that balance the overall power performance and fuel economy of the vehicle, as well as the effectiveness of strategy formulation when some subsystems of the power unit are missing.

In summary, most researchers have explored the feasibility and advancement of electric drive continuously variable transmission technology, hydrostatic transmission technology, and power shift technology in the field of agricultural machinery. The combined use of these three technologies can meet the requirements of agricultural machinery, such as energy conservation and emission reduction, a wide speed range, and large load-carrying capacity. However, there are few research reports on the comprehensive application of these three technologies at present. In addition, various research contents related to the drive and power transmission devices of agricultural machinery (such as the formulation of speed change control strategies, the optimal design of transmission parameters, and the evaluation of vehicle performance, etc.) are inseparable from the accurate modeling of the transmission characteristics of each component. The characteristics of core components vary greatly in practical engineering applications. Therefore, modeling based on measured calibration data is one of the most effective technical means. However, the interpolation method or polynomial regression method commonly used in practical engineering currently has the problem of limited modeling accuracy. In particular, for the hydrostatic transmission (HST) system composed of hydraulic pumps and motors, the variation in its efficiency characteristics is mainly influenced by the combined effects of multiple factors such as volumetric losses and mechanical losses. This results in a more non-linear variation law of the efficiency characteristics of HST devices. Currently, the modeling methods for various power transmission system characteristic models are gradually transitioning from the traditional mechanism-based models to semi-empirical models and further to data-driven models. In the absence of effective features during modeling, it is difficult to guarantee the accuracy and robustness of the established models. Additionally, the electro-hydraulic hybrid power system involves electric motors, HST devices, and transmissions, all of which require independent control. However, there is a lack of effective top-level control logic for the coordinated control among multiple subsystem actuators under the condition of optimizing multiple vehicle-level objectives.

The research of this paper addressed the above-mentioned issues and proposed a dual continuously variable transmission system with a series combination of “drive motor-hydrostatic transmission device-wet multi-clutch power shift transmission”. Based on the measured sample data of core components (drive motor and hydrostatic transmission device), two targeted high-precision modeling methods (ISCA-BPNN and PLS-SWOR) were proposed, respectively. On this basis, the formulation method of the binary control strategy for agricultural tractors equipped with this new type of transmission device was explored. The research in this paper also provides clear technical support and a theoretical basis for the development of pure electric drive agricultural machinery, oil-electric hybrid electric agricultural machinery, pure hydraulic drive agricultural machinery, and hydraulic-mechanical coupled agricultural machinery.

2. Materials and Methods

2.1. A Novel Dual Continuously Variable Transmission System with Series Combination

The research of this paper is mainly aimed at agricultural machinery, proposing a dual continuously variable transmission system composed of a series combination of “drive motor-hydrostatic transmission device-wet multi-clutch power shift transmission”. The schematic diagram of its configuration scheme is shown in Figure 1.

Figure 1.

The proposed novel dual continuously variable transmission system.

According to Figure 1, the novel dual continuously variable transmission system proposed in this paper mainly consists of an electric drive continuously variable transmission system, a hydraulic continuously variable transmission system, and a power shift transmission. The integral power device adopts the method of power flow series connection. Its power transmission route is as follows: drive motor-front gear pair of the hydraulic variable pump (single-stage gear transmission, whose function is to match the operating speed range of the drive motor with the input speed range of the hydraulic variable pump), hydraulic variable pump, hydraulic constant motor, power shift transmission with multiple wet clutches, and transfer case (if there is a transfer case, the vehicle is four-wheel drive; otherwise, the vehicle is two-wheel drive).

This power device achieves a dual continuously variable transmission function through the coordinated cooperation of the drive motor (which can realize the function of electric drive stepless speed change) and the “variable pump-constant motor” system (which can realize the stepless speed change function of hydraulic transmission). It also takes into account the characteristics of the electromotor, such as low energy consumption, a wide range of suitable economic working areas, low environmental pollution, and low noise, as well as the characteristics of the hydrostatic transmission device (i.e., the “variable pump-constant motor” system), such as strong load-bearing capacity, high power density, and compact structure. The equipped wet multi-clutch power shift transmission, on the one hand, expands the operating condition range of the vehicle by adjusting its own stepped gear ratio changes. On the other hand, it adjusts the working states of the electromotor and the hydrostatic transmission device, increasing the possibility that the two are in their own more optimal working areas. Through the coordinated cooperation among multiple wet clutches (the originally engaged wet clutch disengages, and the next wet clutch to be engaged actuates according to a certain shift timing), the gear shift without power interruption (the vehicle maintains continuous power output and wheel drive during gear shifting or mode switching, with no noticeable jerking or engine speed drop [35,36]) can be achieved.

Based on the series structure of this power unit and the theory of mechanical transmission, the relational expression between the motor output speed and the wheel rotational angular velocity can be derived. Then, the wheel angular velocity is converted into the wheel linear velocity (i.e., the vehicle traveling speed) according to the rolling radius of the driving wheels. The calculation expression for the longitudinal driving speed of the vehicle is as follows:

In the formula, is the longitudinal driving speed of the vehicle (unit: km/h); 0.377 is the unit conversion coefficient; is the output speed of the drive motor (unit: r/min); is the displacement ratio (in this paper, the displacement ratio was defined as the ratio of the current displacement of the variable pump to its rated displacement); is the radius of the driving wheel (unit: m); is the transmission ratio of the front gear pair of the variable pump; is the total transmission ratio of the main reducer and transfer case; and is the transmission ratio of the wet multi-clutch power shift transmission.

2.2. Selection of Core Components and Matching of Main Parameters for Agricultural Tractors

This paper took the mountain agricultural tractor in hilly areas as a specific case for research. The relevant main parameters of this agricultural tractor are shown in Table 1.

Table 1.

Main parameters related to the agricultural tractors used in this paper.

The agricultural tractor adopted a YXVF280M-2 model motor (manufacturer: Anhui Wannan Electric Machinery Co., Ltd., Xuancheng City, China). The working speed range of this motor is 0–4500 r/min, the rated voltage is 380 V, the rated current is 165 A, and the rated power is 90 kW.

To meet the load power requirements of the agricultural tractor, this paper selected the HPV-02 model variable piston pump with a displacement of 55 cm3/rev from Linde and the HMF-02 model constant motor with a displacement of 55 cm3/rev from Linde. The allowable speed of this variable pump is 3300 r/min, the continuous input torque is 218 Nm, the continuous power is 75 kW, and the maximum power is 122 kW. The allowable speed of this constant motor is 4100 r/min, the continuous output torque is 218 Nm, the continuous power is 93 kW, and the maximum power is 157 kW.

The research of this paper adopted the geometric design principle to design the transmission ratios of each gear of the power shift transmission. The transmission ratios of each gear have an approximate common ratio (i.e., the ratio of the transmission ratios of adjacent gears is approximately equal). According to Formula (1), the minimum value of the total transmission ratio of “power shift transmission-transfer case-main reducer” can be calculated to be 12.6401. Taking the common ratio of the geometric design principle to be 1.5, the total transmission ratios of the “power shift transmission (with 3 gears)-transfer case-main reducer” are 28.1585 (when the power shift transmission is in the I gear mode), 18.9601 (when the power shift transmission is in the II gear mode), and 12.6401 (when the power shift transmission is in the III gear mode), respectively. Under the three gears, the speed ranges of the agricultural tractor are 0~13.4667 km/h, 0~20 km/h, and 0~30 km/h, respectively.

To further verify the rationality of the selection of core components and the matching results of main parameters, a method of determining whether the road friction performance is fully utilized was adopted. The maximum friction force of an agricultural tractor when driving on a soft soil road should theoretically be greater than or equal to the maximum driving force generated by the power transmission of the vehicle to the driving wheels. The specific mathematical expression for determination is as follows:

In the formula, is the mass of the agricultural tractor (unit: kg); is the gravity acceleration (in this study, its value was taken as 9.8, unit: m/s2); is the friction coefficient of the soft soil road (in this study, its value was taken as 0.7); is the torque at the output end of the hydraulic motor (unit: Nm); is the transmission ratio of the power shift transmission in the I gear; is the total working efficiency of the vehicle power device (at this stage of estimation, in this study, its value was taken as 80%).

According to Formula (2), it can be calculated that the maximum ground friction force that this agricultural tractor can fully exert is approximately 16,464 N, while the maximum driving force at the wheel end of this agricultural tractor equipped with the existing power device is approximately 16,111.7109 N. The maximum driving force is slightly less than the maximum friction force, and the two are close (with a difference of 2.1398%). Therefore, the selection of the core components and the matching of the main parameters of the power device of the agricultural tractor are reasonable.

2.3. Modeling Method of Drive Motor Efficiency Characteristics Combining Improved Sine Cosine Optimization Algorithm (ISCA) and BP Neural Network

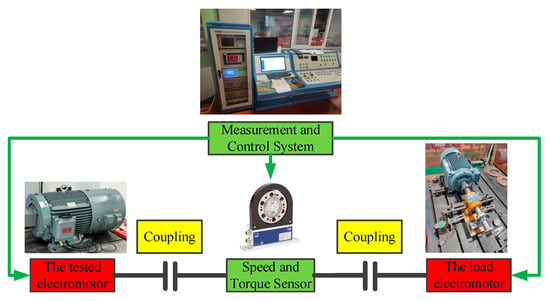

The research of this paper adopted the method of motor back-to-back to test the efficiency characteristics of the YXVF280M-2 model drive motor. The load motor used the YE3-280M-2 model motor (with a rated power of 90 kW). The drive motor consumes electrical energy, outputs torque and rotational speed, and drives the load motor to rotate. The above two motors were directly connected by a coupling, and a K-T40B-001R-MF-S-M-DU2-1-U model HBM torque sensor was set. The torque measurement range of this sensor is 0~1000 Nm, the output signal is 60 kHz ± 30 kHz and ±10 V, and it is equipped with a magnetic rotational speed measuring system (1024 pulses/rev). The schematic diagram of the test platform is shown in Figure 2.

Figure 2.

Schematic diagram of the test platform for motor back-to-back experiments.

The research of this paper adopted the full factorial experimental method. The test range of the working speed of the tested motor was set to be 500~4500 r/min (with an interval step size of 100 r/min, a total of 41 levels), and the test range of the working torque of the tested motor was set to be 45~225 Nm (with an interval step size of 20 Nm, a total of 10 levels). The total number of samples in the full factorial experiment is 41 × 10 = 410. By measuring the input power and output power of the tested motor, and calculating the ratio of the two, the working efficiency of the tested motor under various working conditions can be obtained.

In view of the problems existing in the establishment of the drive motor efficiency characteristics model by the widely used polynomial regression method (limited accuracy in characterizing the variation law, sometimes large model errors, and prone to overfitting, etc.), this paper proposed a drive motor efficiency characteristics modeling method that combines the improved sine cosine optimization algorithm (abbreviated as ISCA) and the BP neural network (abbreviated as BPNN).

The main steps of this method are as follows:

- Step. 1 Import the actual measurement data of the efficiency characteristics of the drive motor, select the part with a larger proportion as the training sample, and the remaining part as the testing sample.

- Step. 2 Initialize the sine cosine optimization algorithm. Set the basic parameters of the sine cosine optimization algorithm, including the population size, the maximum number of iterations, the number of decision variables, the lower boundary of each decision variable, and the upper boundary of each decision variable. In this example, there are four decision variables, which represent the number of neurons in each hidden layer of the deep BPNN.

- Step. 3 Set the objective function. In this study, the comprehensive value of the coefficient of determination of the training set, the mean absolute percentage error of the training set, the coefficient of determination of the testing set, and the mean absolute percentage error of the testing set of the BPNN model was taken as the objective function. The specific calculation expression of this objective function is as follows:

In the formula, is the coefficient of determination of the training set; is the coefficient of determination of the testing set; is the mean absolute percentage error of the training set; is the mean absolute percentage error of the testing set.

- Step. 4 Calculate the fitness values of the initial population of the sine cosine optimization algorithm. Based on the basic principle of BPNN, a deep BPNN with 4 hidden layers is newly constructed. Each individual in the population consists of 4 decision variables, representing the number of neurons in the 4 hidden layers, respectively. Initialize the maximum number of training iterations and the training target error of the BPNN. Initialize the connection weights and bias terms of the BPNN using the random principle. Since there are various random factors in the training process of the BPNN, these factors can cause the network to converge to different parameter combinations (local optimal solutions), ultimately resulting in different prediction effects. Therefore, in this study, the Monte Carlo method is introduced (as the inner loop) in the fitness value calculation process of the sine cosine optimization algorithm. For each individual in the population, a certain number of repetitive BPNN modeling experiments are carried out. Moreover, through comparison, the BPNN model with a lower fitness value is taken as the current optimal model for this individual. The current optimal solution is screened out from the initial population.

- Step. 5 Establish the drive motor efficiency characteristics BPNN model based on the sine cosine optimization algorithm (outer loop) and the Monte Carlo method (inner loop). Use the updated strategy of the sine cosine optimization algorithm to update the position of each individual in the population. The calculation expression of the updated strategy is as follows:

In the formula, is the value of the j-th decision variable of the i-th population individual at the k-th iteration; is the rounding operation; ~ are the position update parameters of the sine cosine algorithm.

Using the original sine cosine optimization algorithm as the outer loop, update the number of neurons in each hidden layer of the deep BPNN through sine search and cosine search. Taking the Monte Carlo method as the inner loop, utilize the randomness of BPNN during modeling to obtain a better BPNN model.

- Step. 6 Take the maximum number of iterations set by the sine cosine optimization algorithm as the termination condition. Count and record the optimal fitness value, the optimal set of decision variables, and the optimal trained BPNN model for each iteration.

The flowchart of the proposed modeling method for the efficiency characteristics of the drive motor is shown in Figure 3.

Figure 3.

Flowchart of the proposed modeling method for the efficiency characteristics of the drive motor.

According to Figure 3, the drive motor efficiency characteristics modeling method proposed in this paper combines the improved sine cosine optimization algorithm with the deep BP neural network. This method utilizes the outer loop (sine cosine optimization algorithm) and the inner loop (Monte Carlo method) to optimize and search for the number of neurons in each hidden layer of the deep BP neural network. At the same time, the randomness of the neural network training process is fully considered. To further compare and verify the effectiveness of the drive motor efficiency characteristics modeling method proposed in this paper, the polynomial regression method was used to model the drive motor efficiency characteristics based on the same training set and testing set. Referring to the objective function proposed in this research, the comprehensive value of the coefficient of determination of the training set, the mean absolute percentage error of the training set, the coefficient of determination of the testing set, and the mean absolute percentage error of the testing set were selected as the indicators to evaluate the effectiveness of the modeling method.

2.4. Modeling Method for the Efficiency Characteristics of Hydrostatic Transmission Devices Combining the Partial Least Squares Method and the Idea of Sampling Without Replacement

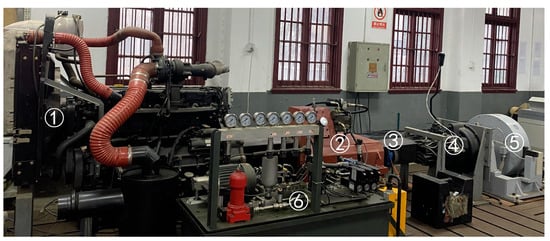

The research of this paper referred to the previous research reports of the research group team on “the Linde HPV-02 model variable piston pump with a displacement of 55 cm3/rev and the Linde HMF-02 model constant motor with a displacement of 55 cm3/rev” [37]. The test bench of “variable pump-constant motor” is shown in Figure 4.

Figure 4.

Test bench for the efficiency characteristics of the “variable pump-constant motor” system. Note: ① Engine (DEUTZ TCD2013L062V); ② The transmission device of the system with the variable pump-constant displacement motor; ③ The speed torque sensor of ZJ-5000 A model; ④ The auxiliary gearbox; ⑤ The electrical eddy current dynamometer of the DW250 model; ⑥ The hydraulic system (realizing lubrication, cooling, and other functions).

The test of the hydrostatic continuously variable transmission system has 3 independent variables (system input speed, system output torque, and the variable pump displacement ratio, with test adjustment ranges of 500~3000 r/min, 50~500 Nm, and 0.17~1.00, respectively) and 1 dependent variable (operating efficiency of the power device). A central composite test method was used to design the test scheme, and a total of 15 sets of sample data were obtained [37].

There are many factors affecting the operating efficiency of variable pumps and constant motors (mainly including component accuracy, oil state, working parameters, etc.). Generally, the transmission efficiency of the hydraulic system is characterized by the product of volumetric efficiency (internal leakage) and mechanical efficiency (mechanical friction). The transmission efficiency of the hydrostatic continuously variable transmission system varies in a relatively large range and has a certain degree of non-linear characteristics. Therefore, this paper proposed a modeling method for the efficiency characteristics of hydrostatic transmission devices that combines the partial least squares method (PLS for short) and the idea of sampling without replacement.

The main steps of this method are as follows:

- Step. 1 Import the efficiency characteristics test data of the hydrostatic transmission device.

- Step. 2 Perform mapping transformation on the original independent variables of the sample data (system input rotational speed, system output torque, and displacement ratio of variable pump). After the mapping transformation, a total of 29 derived independent variables are formed, which are the square terms of the original independent variables, the cube terms of the original independent variables, the square root terms of the original independent variables, the reciprocal terms of the original independent variables, the interaction terms of two of the original independent variables, the interaction terms of three of the original independent variables, the trigonometric function transformation terms of the original independent variables, and the ln function transformation terms of the original independent variables. All 32 independent variables are shown in Table 2.

Table 2. Names and meanings of all independent variables.

Table 2. Names and meanings of all independent variables.

- Step. 3 Randomly select 2 independent variables without replacement from 32 independent variables. Use the partial least squares method to establish a regression model for the efficiency characteristics of the hydrostatic transmission device based on the selected independent variables.

- Step. 4 Continuously increase the number M of independent variables selected without replacement. Repeat Step. 3 until the number M of independent variables selected without replacement reaches 9.

- Step. 5 Analyze the changes in model accuracy under different values of M and study the independent variables that have better explanatory power for the efficiency characteristics of the hydrostatic transmission device.

When M is in the range of 2 to 9, the number of PLS models that need to be established are 496, 4960, 35,960, 201,376, 906,192, 3,365,856, 10,518,300, and 28,048,800, respectively (a total of 43,081,940 efficiency characteristics models of hydrostatic transmission devices are established).

2.5. Binary Speed Change Control Strategy for Agricultural Tractors

The dual continuously variable transmission system with the series combination of “drive motor-hydrostatic transmission device-wet multi-clutch power shift transmission” has 3 adjustable execution components, which are the drive motor, the variable pump, and the automatic transmission, respectively. Both the drive motor and the hydrostatic transmission device can achieve the stepless speed change function. However, the operating efficiency of the drive motor and the hydrostatic transmission device changes when they are under different operating speeds and operating torques. Therefore, the research of this paper adopted the traversal method to solve the binary speed change control strategy for agricultural tractors equipped with the proposed dual continuously variable transmission system. The term “binary” specifically refers to the displacement ratio of the variable pump and the gear of the power shift transmission. The change in the driver’s accelerator pedal opening reflects the load demand of the entire vehicle, thereby replacing the “agricultural machinery resistance” parameter used in most of the literature.

The main steps of this method are as follows:

- Step. 1 Set the range of variation for the driving speed of agricultural tractors (0~30 km/h) and the range of variation for the driver’s accelerator pedal opening (0~100%). Perform discretization processing on the above two parameters.

- Step. 2 Use the traversal method to extract one by one the discretized driving speed of the agricultural tractor and the driver’s accelerator pedal opening (as a set operating condition). Use the traversal method again to select all variable pump displacement ratios and automatic transmission gears that meet the requirements for estimating the comprehensive evaluation indicators of the control strategy.

- Step. 3 Adopt the principle of survival of the fittest to determine the variable pump displacement ratio and automatic transmission gear with the optimal comprehensive evaluation indicator of the control strategy for each set operating condition (i.e., fixed agricultural tractor driving speed and driver’s accelerator pedal opening).

- Step. 4 Statistically record the optimal variable pump displacement ratios and automatic transmission gears under all set operating conditions to form a binary control strategy MAP for agricultural tractors.

The comprehensive evaluation indicators of the control strategy adopted in this study consist of a vehicle economy evaluation indicator and a power performance evaluation indicator. Its specific mathematical expression is as follows:

In the formula, is the comprehensive evaluation indicator of the control strategy; is the operating efficiency of the drive motor; is the operating efficiency of the hydrostatic transmission device; is the maximum torque at the driving wheel end ignoring transmission losses (unit: Nm); is the output torque at the driving wheel end under the current situation considering transmission losses (unit: Nm); and are the weight coefficients of vehicle economy and power performance, respectively (the sum of the two is 100%).

The technical route for formulating the binary speed change control strategy is shown in Figure 5.

Figure 5.

Technical route for formulating binary speed change control strategy.

In terms of modeling, the research of this paper adopted the forward modeling method of vehicle efficiency characteristics (that is, the driver’s accelerator pedal opening is taken as the input of the model, instead of using the load resistance of agricultural tractors as the input of the model). This leads to a mismatch between the input variables of the original hydrostatic transmission efficiency characteristic model and the formulation method of this binary speed change control strategy. It is necessary to convert the input variable (the output torque of the constant motor) into the input torque of the variable pump through the measured efficiency value.

3. Results and Discussion

3.1. Modeling of Drive Motor Efficiency Characteristics

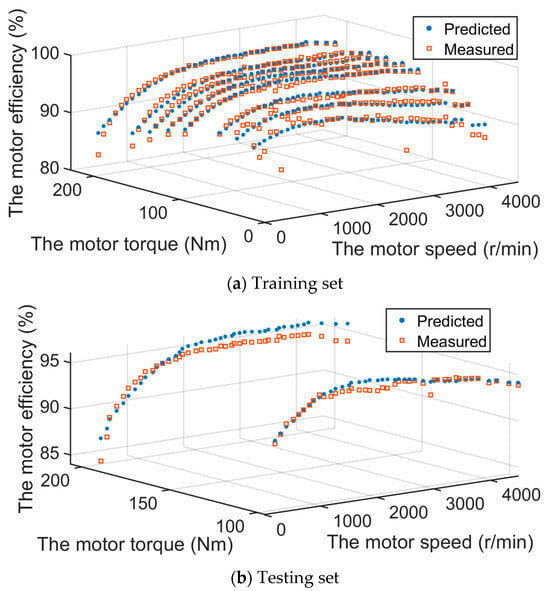

According to the full-factor efficiency characteristics measurement test results of the YXVF280M-2 model motor (a total of 410 groups of sample data), all sample data of the drive motor output torque at 45, 65, 85, 125, 145, 165, 185, and 225 Nm are used as the training set (a total of 328 groups of sample data). All sample data of the drive motor output torque at 105 and 205 Nm are used as the testing set (a total of 82 groups of sample data). The scatter distribution of the sample data in the training set and the testing set is shown in Figure 6.

Figure 6.

Modeling results of the drive motor efficiency characteristics.

According to Figure 6, the efficiency characteristics of this drive motor exhibit non-linear features with respect to changes in its operating speed and torque. As the operating speed of the drive motor increases, the operating efficiency basically shows the law of first increasing and then remaining constant (on the whole, the change rate of the curve becomes smaller and smaller). However, when the drive motor is in the low-torque region, its operating efficiency shows a pattern of first increasing and then decreasing. The minimum efficiency of the drive motor is approximately 81.95%, the maximum efficiency is approximately 96.89%, and the average efficiency is approximately 93.85%. Overall, this drive motor has good economic performance and a wide high-efficiency range.

The modeling results of the drive motor efficiency characteristics using the ISCA-BPNN proposed in this paper are shown in Figure 6.

According to Figure 6, from the perspectives of the training set and the testing set, the established drive motor efficiency characteristics model has high precision and can accurately represent the non-linear variation law of the original data. The coefficient of determination of the established model is approximately 0.9098 (training set) and 0.9507 (testing set), and the mean absolute percentage error is approximately 0.3057% (training set) and 0.3121% (testing set).

The number of neurons in the hidden layers (four layers in total) of the deep BP neural network is 4, 12, 23, and 19, respectively. The efficiency characteristics of the drive motor show a trend of gradient decrease from the central area, which is in the range of relatively high rotational speeds (approximately 3500~4000 r/min) and large torque ranges (150~200 Nm), to the peripheral areas. The high-efficiency range of the drive motor is wide. The proportion of the area with a working efficiency greater than 90% is approximately 93.33%, the proportion of the area with a working efficiency greater than 92% is approximately 85.56%, and the proportion of the area with a working efficiency greater than 95% is approximately 38.00%.

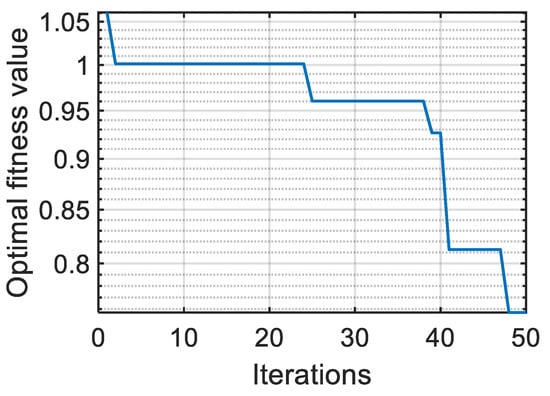

The iterative evolution curve based on the ISCA-BPNN modeling proposed in this paper is shown in Figure 7.

Figure 7.

Iterative evolution curve of the ISCA-BPNN modeling proposed in this paper.

According to Figure 7, the ISCA-BPNN proposed in this paper can continuously optimize the value of the objective function. During the entire iterative evolution process, the initial generation objective function value is 1.0609, and the final generation objective function value is 0.7572, with a relative improvement of 28.63%. Drawing on the analysis idea of orthogonal experiments (range analysis method), the sample data at the same motor speed and motor torque levels are averaged. And the analysis of the degree of influence of factors is carried out based on the average value of efficiency characteristics at different levels. The range value of motor speed is 6.7650%, and the range value of motor torque is 3.4938%. Therefore, the influence degree of motor speed on the efficiency characteristics of the motor is higher than that of motor torque.

To further verify the advancement of the ISCA-BPNN proposed in this paper, the polynomial regression method is used to establish the drive motor efficiency characteristics model with reference to the same training set (a total of 328 groups of sample data) and testing set (a total of 82 groups of sample data). The establishment effect of the polynomial regression model is shown in Figure 8.

Figure 8.

Establishment effect of the polynomial regression model.

According to Figure 8, from the perspective of the training set and testing set, the established polynomial regression model has a certain degree of estimation accuracy. However, there is a certain degree of deviation in characterizing the non-linear variation law of the original data. The coefficient of determination of the polynomial regression model is approximately 0.8740 (training set) and 0.8121 (testing set), and the mean absolute percentage error is approximately 0.4835% (training set) and 0.6909% (testing set). Compared with the ISCA-BPNN proposed in this paper, the coefficient of determination decreases by 4.0961% (training set) and 17.0669% (testing set), respectively, and the mean absolute percentage error increases by 36.7735% (training set) and 54.8270% (testing set), respectively.

3.2. Modeling of Efficiency Characteristics of Hydrostatic Transmission Devices

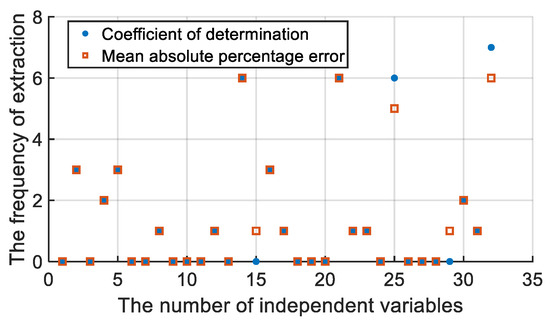

Among 32 independent variables (including three original independent variables and twenty-nine derived independent variables), two to nine independent variables are sampled without replacement, and a model for the efficiency characteristics of the hydrostatic transmission device is established based on the partial least squares method (the number of models required is 496; 4960; 35,960; 201,376; 906,192; 3,365,856; 10,518,300; and 280,488,000, respectively). The statistical results of the model establishment accuracy under various conditions are shown in Figure 9.

Figure 9.

Statistical results of model establishment accuracy under various conditions.

According to Figure 9, as the number of independent variables in sampling without replacement increases, the population accuracy of the PLS modeling improves, and the rate of change in accuracy improvement tends to decrease. In practical engineering applications, it is only necessary to establish a single efficiency characteristics model of the hydrostatic transmission device that meets the granular accuracy requirements. Therefore, the focus is on observing the PLS model with the optimal accuracy under each number of independent variables. When the number of independent variables in sampling without replacement is five, the highest coefficient of determination of the established PLS model is 0.9799 (when the number of independent variables in sampling without replacement is six to nine, respectively, the highest coefficients of determination of the established PLS models increase by 0.1309%, 0.7891%, 1.0554%, and 1.2950%, respectively). The lowest mean absolute percentage error of the established PLS model is 2.4688% (when the number of independent variables in sampling without replacement is six to nine, respectively, the lowest mean absolute percentage errors of the established PLS models decrease by 0.2584%, 0.6254%, 0.8561%, and 1.0884%, respectively). Obviously, with M = 5 as the dividing point, the accuracy change in the PLS model established on the left side of the dividing point is significant, while that on the right side is gentle. Considering that an increase in the number of independent variables may potentially lead to problems such as overfitting, multicollinearity, and the curse of dimensionality (which would instead damage the model performance), this study uses five as the number of independent variables in sampling without replacement to establish the efficiency characteristics model of the hydrostatic transmission device.

To further analyze the influence degree of each independent variable on the efficiency characteristics of the hydrostatic transmission device, the research of this paper selected the model with the highest coefficient of determination and the model with the lowest mean absolute percentage error under the number of independent variables for each sampling without replacement. The occurrence of independent variables in these two types of models was counted. The statistical results of the frequency of each independent variable in the two models are shown in Figure 10.

Figure 10.

Statistical results of the extraction frequency of each independent variable.

According to Figure 10, the independent variables extracted based on the principle of the highest coefficient of determination and the principle of the lowest mean absolute percentage error only differ when M = 3. The independent variable numbers extracted by the former are 14 (T−1out), 25 (ninε2), and 32 (ln(ε)), respectively; the independent variable numbers extracted by the latter are 14 (T−1out), 15 (ε−1), and 29 (sin(ε)), respectively. Therefore, the statistical frequencies of each independent variable under the two principles in Figure 10 are highly consistent (only four independent variables have a fluctuation of ±1). The variables with the highest influence degrees (occurrence frequency probability ≥75%) are variable 14 (T−1out), variable 21 (ninToutε), variable 25 (ninε2), and variable 32 (ln(ε)). The variables with medium influence degrees (occurrence frequency probability ≥25%) are variable 2 (Tout), variable 4 (n2in), variable 16 (ninTout), and variable 30 (ln(nin)).

The mathematical expression of the finally established efficiency characteristics model (five-variable PLS regression model) of the hydrostatic transmission device is as follows:

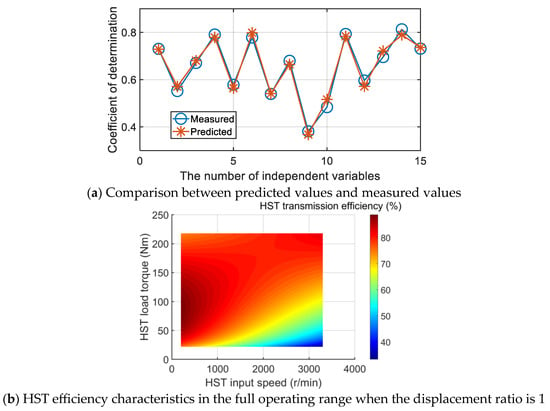

The characterization effect of this five-variable PLS regression model is shown in Figure 11.

Figure 11.

Characterization effect of the five-variable PLS regression model.

According to Figure 11, the coefficient of determination of the finally established five-variable PLS regression model is approximately 0.9799, and the mean absolute percentage error is approximately 2.4688%. The established model has high accuracy. When the variable pump displacement ratio is 1, the working efficiency range of the HST is 33.3197~88.6452%. In this state, the high-efficiency working area of the HST is relatively large. The proportion of areas with working efficiency greater than 70% is approximately 79.8889%, the proportion of areas with working efficiency greater than 80% is approximately 34.2222%, and the proportion of areas with working efficiency greater than 85% is approximately 6.5556%. The HST has low working efficiency under high rotational speed/medium- and low-load conditions, and it is advisable to avoid using it in such working areas.

3.3. Binary Speed Change Control Strategy for Agricultural Tractors

The research settings of this paper are as follows: (1) when the economic weight coefficient is 0.5 and the dynamic weight coefficient is 0.5, the obtained binary speed change control strategy is a comprehensive control strategy; (2) when the economic weight coefficient is 1 and the dynamic weight coefficient is 0, the obtained binary speed change control strategy is an economic control strategy; (3) When the economic weight coefficient is 0 and the dynamic weight coefficient is 1, the obtained binary speed change control strategy is a dynamic control strategy.

This paper further compared the differences in the binary control strategies of agricultural tractors under the conditions of considering the vehicle efficiency characteristics (including the efficiency characteristics of the drive motor and the hydrostatic continuously variable transmission device), only considering the efficiency characteristics of the hydrostatic transmission device, and only considering the efficiency characteristics of the drive motor. This study took the comprehensive control strategy as an example.

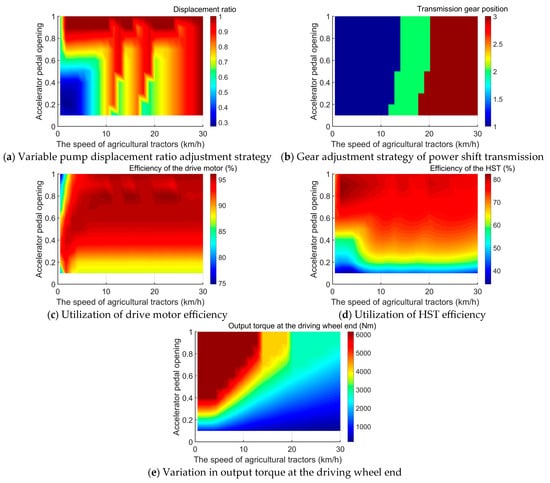

The relevant results of the comprehensive control strategy considering the vehicle efficiency characteristics are shown in Figure 12.

Figure 12.

Results related to comprehensive control strategy considering the vehicle efficiency characteristics.

According to Figure 12, when implementing the comprehensive control strategy, the displacement ratio of the variable pump is adjusted within the range of 0.2727 to 1.0000. Under the heavy-load conditions of agricultural tractors, the displacement ratio of the variable pump is basically around 1.0000. The proportion of the area with a displacement ratio greater than 0.8 is approximately 52.4000%, the proportion of the area with a displacement ratio greater than 0.9 is approximately 31.6000%, and the proportion of the area at the maximum displacement ratio is approximately 18.4000%. The power shift transmission mainly switches gears according to the vehicle speed. As the driver’s accelerator pedal opening increases, there is a lag phenomenon in the shifting timing along the direction of vehicle speed. The working areas of gear I/II/III account for approximately 42.0000%, 19.6000%, and 38.4000%, respectively.

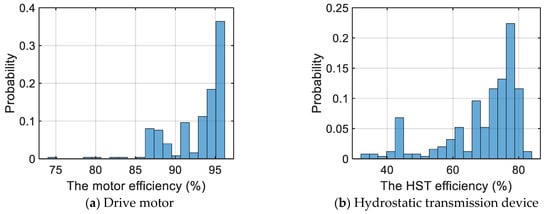

Based on the comprehensive control strategy considering the vehicle efficiency characteristics, the probability statistical histograms of the efficiency utilization of the drive motor and the efficiency utilization of the HST are shown in Figure 13.

Figure 13.

Probability statistical histograms of efficiency utilization.

According to Figure 13, when implementing the comprehensive control strategy, the minimum operating efficiency of the drive motor is approximately 74.7799%, the maximum operating efficiency is approximately 96.0580%, and the average operating efficiency is approximately 92.7807%. The proportion of the area with an operating efficiency greater than 90% is approximately 78.0000%, the proportion of the area with an operating efficiency greater than 92% is approximately 66.8000%, and the proportion of the area with an operating efficiency greater than 95% is approximately 38.8000%. The minimum operating efficiency of the hydrostatic transmission device is approximately 33.9963%, the maximum operating efficiency is approximately 82.2817%, and the average operating efficiency is approximately 69.1320%. The proportion of the area with an operating efficiency greater than 75% is approximately 42.4000%, the proportion of the area with an operating efficiency greater than 78% is approximately 22.0000%, and the proportion of the area with an operating efficiency greater than 95% is approximately 4.4000%. Based on the above, the efficiency utilization of the drive motor and hydrostatic transmission device is good.

Meanwhile, when the agricultural tractor is within 12 km/h, it has the maximum driving force (generally higher than 6000 Nm). This meets the capability requirements for the heavy-load operations of agricultural tractors.

The research of this paper further compared the differences in the vehicle dynamic performance and economic performance under five control strategies. The five control strategies are as follows: a comprehensive control strategy considering the vehicle efficiency characteristics (including the efficiency characteristics of the drive motor and the hydrostatic continuously variable transmission device), a comprehensive control strategy considering only the efficiency characteristics of the hydrostatic transmission device, a comprehensive control strategy considering only the efficiency characteristics of the drive motor, an economic control strategy considering the vehicle efficiency characteristics, and a dynamic control strategy considering the vehicle efficiency characteristics. The comparison results are shown in Table 3.

Table 3.

Comparison of the vehicle-related performance under five control strategies.

According to Table 3, the comprehensive control strategy that ignores the efficiency characteristics of the drive motor (Control Strategy No. 2) and the comprehensive control strategy that considers the efficiency characteristics of the vehicle (Control Strategy No. 1) have similar effects in terms of vehicle performance (the average reduction in vehicle economy is 0.1009%, and the improvement in vehicle dynamic performance is 0.0816%). There is a significant difference between Control Strategy No. 3 and Control Strategy No. 1: the average reduction in vehicle economy is 4.7270%, and the improvement in vehicle dynamic performance is 3.6406%. Therefore, the adjustment strategy of the variable pump displacement ratio has a great impact on vehicle performance. If the efficiency characteristics of the drive motor are similar to those of the motor used in this study, and its high-efficiency operating range is wide, then the influence of the relevant characteristics of the drive motor can be ignored when formulating the speed change control strategy for agricultural tractors.

The pure economic control strategy (Control Strategy No. 4) can effectively improve the vehicle economic performance, with an increase of 8.7734% compared with the comprehensive control strategy. However, the vehicle dynamic performance is reduced by 33.9540%. The pure economic control strategy is suitable for agricultural tractors under medium- and small-load conditions.

The pure dynamic control strategy (Control Strategy No. 5) can enable the vehicle to have good dynamic performance. However, compared with the comprehensive control strategy, the average improvement in vehicle dynamic performance is 0.7179%. Control Strategy No. 5 and Control Strategy No. 1 have similar effects in terms of vehicle dynamic performance. In terms of vehicle economic performance, the effect of Control Strategy No. 5 is 6.5558% lower than that of Control Strategy No. 1. Therefore, this study suggests that the pure dynamic control strategy should not be adopted for agricultural tractors.

The summary of the characteristics of the methods proposed in this paper is presented in Table 4.

Table 4.

Summary of the characteristic comparison of the method proposed in this paper.

4. Conclusions

(1) The research of this paper proposed a dual continuously variable transmission system composed of a series combination of “drive motor-hydrostatic transmission device-wet multi-clutch power shift transmission” for agricultural machinery. The core components in the system were selected, and the main parameters were matched.

(2) A modeling method of the drive motor efficiency characteristics based on ISCA-BPNN was proposed. For 410 groups of motor sample data obtained from full factorial experiments, the proposed method can effectively establish an efficiency characteristic model of the motor within the full operating range. The coefficient of determination of the established model is approximately 0.9098 (training set) and 0.9507 (testing set), and the mean absolute percentage error is approximately 0.3057% (training set) and 0.3121% (testing set). The proposed modeling method is significantly superior to the widely used polynomial modeling method. During the modeling process, the iterative evolution curve shows a continuous stepwise decline. This indicates that the algorithm has the ability to continuously converge to the optimal solution. In terms of motor efficiency characteristics, the influence of motor speed is greater than that of motor torque. For the motor used in this study, the motor operates at the highest efficiency under higher speeds (3000~4000 r/min) and larger load torques (150~200 Nm).

(3) A modeling method for efficiency characteristics of hydrostatic transmission devices based on PLS-SWOR was proposed. When the number of independent variables in sampling without replacement is five, the established model already has high accuracy (the coefficient of determination is approximately 0.9799, and the mean absolute percentage error is approximately 2.4688%) with a moderate number of independent variables. variable 14 (T−1out), variable 21 (ninToutε), variable 25 (ninε2), and variable 32 (ln(ε)) have the greatest influence on modeling.

(4) This paper used the driver’s accelerator pedal opening and vehicle speed as the strategy input signals to adjust the displacement ratio of the variable pump and the gear of the power shift transmission (i.e., the proposed binary speed change control strategy). The efficiency characteristics of the hydrostatic transmission device cannot be ignored in the process of formulating the strategy. If the overall efficiency characteristics of the motor are high and the fluctuation is not obvious (for example, the minimum efficiency of the drive motor used in this case is about 81.95%, the maximum efficiency is about 96.89%, and the average efficiency is about 93.85%), the motor characteristics can be ignored when formulating the strategy. A comprehensive control strategy should be applied under medium and high loads (at this time, agricultural machinery has both high-efficiency characteristics and large output torque), and a pure economic control strategy should be applied under medium and low loads (at this time, agricultural machinery works in its own highest efficiency operating area).

(5) Future research directions mainly include: comparative analysis between the dual continuously variable transmission system with a series configuration of “drive motor–hydrostatic transmission–wet multi-clutch power shift transmission” and other advanced powertrains; highly integrated design of the proposed new power unit; research on the actuation process of the dual-clutch automatic transmission shift actuator under agricultural machinery operating conditions; and improvement of the new powertrain control strategy for agricultural machinery working conditions. In addition, the research in this paper provides a practical theoretical basis and technical methods for tractor manufacturers to conduct high-precision performance evaluation of power systems during the conceptual design phase and the small-batch prototype trial production phase, as well as to develop energy-saving strategies for existing new energy agricultural machinery, design control strategies for power systems with hydraulic transmission, and develop new electro-hydraulic hybrid devices for agricultural machinery at the current stage.

Author Contributions

Methodology, Z.C., J.W. and G.W.; software, Z.C. and J.W.; validation, J.W. and Z.C.; investigation, J.W. and J.L.; resources, J.W. and Z.C.; writing—original draft preparation, J.W. and Z.C.; writing—review and editing, J.W., Z.C. and J.L.; supervision, M.X., Z.L. and G.W.; and project administration, J.W., M.X., Z.L. and G.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R&D Program of China (grant number: 2022YFD2001805), the Jiangsu Province Modern Agricultural Machinery Equipment and Technology Promotion Project (grant number: NJ2025-14), the China Postdoctoral Science Foundation (grant number: 2023T160780), and the National Natural Science Foundation of China (grant number: 52105063).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

We sincerely acknowledge the financial support from the aforementioned funding agencies. We also thank the anonymous reviewers for providing critical comments and suggestions that improved the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xie, D.B.; He, J.X.; Liu, T.; Liu, C.; Zhao, G.; Chen, L.Q. Establishment and validation the DEM-MBD coupling model of flexible straw-Shajiang black soil-walking mechanism interactions. Comput. Electron. Agric. 2024, 224, 109203. [Google Scholar] [CrossRef]

- Chen, Z.W.; Gu, J.L.; Yang, X.F. A novel rigid wheel for agricultural machinery applicable to paddy field with muddy soil. J. Terramechanics 2020, 87, 21–27. [Google Scholar] [CrossRef]

- Mu, H.Y.; Luo, Y.L.; Luo, Y. Electro-Hydraulic Load-Sensitive Simulation Study of Walking Hydraulic System of Electric Agricultural Machinery. Mechanika 2022, 28, 481–489. [Google Scholar] [CrossRef]

- Jiang, Y.Y.; Wang, R.C.; Ding, R.K.; Sun, Z.Y.; Jiang, Y.; Liu, W. Research Review of Agricultural Machinery Power Chassis in Hilly and Mountainous Areas. Agriculture 2025, 15, 1158. [Google Scholar] [CrossRef]

- Baek, S.M.; Kim, W.S.; Kim, Y.S.; Baek, S.Y.; Kim, Y.J. Development of a Simulation Model for HMT of a 50 kW Class Agricultural Tractor. Appl. Sci. 2020, 10, 4064. [Google Scholar] [CrossRef]

- Park, Y.J.; Kim, S.C.; Kim, J.G. Analysis and verification of power transmission characteristics of the hydromechanical transmission for agricultural tractors. J. Mech. Sci. Technol. 2016, 30, 5063–5072. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z.X. System response modeling of HMCVT for tractors and the comparative research on system identification methods. Comput. Electron. Agric. 2022, 202, 107386. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z.X. Research on HMCVT Parameter Design Optimization Based on the Service Characteristics of Agricultural Machinery in the Whole Life Cycle. Machines 2023, 11, 596. [Google Scholar] [CrossRef]

- Liu, W.; Yang, R.; Li, L.; Zhao, C.J.; Li, G.L. Energy and environmental evaluation and comparison of a diesel-electric hybrid tractor, a conventional tractor, and a hillside mini-tiller using the life cycle assessment method. J. Clean. Prod. 2024, 469, 143232. [Google Scholar] [CrossRef]

- Cutini, M.; Brambilla, M.; Pochi, D.; Fanigliulo, R.; Bisaglia, C. A Simplified Approach to the Evaluation of the Influences of Key Factors on Agricultural Tractor Fuel Consumption during Heavy Drawbar Tasks under Field Conditions. Agronomy 2022, 12, 1017. [Google Scholar] [CrossRef]

- Ali, D.; de Castro, R.; Ehsani, R.; Vougioukas, S.; Wei, P. Unlocking the potential of electric and hybrid tractors via sensitivity and techno-economic analysis. Appl. Energy 2025, 377, 124545. [Google Scholar] [CrossRef]

- Liu, H.L.; Shen, C.; Hu, L.L.; Chang, C.; Cao, G.Q. Research progress and development trend of electric agricultural equipments. Trans. Chin. Soc. Agric. Eng. 2024, 40, 39–51. [Google Scholar]

- Zhang, K.; Deng, X.T.; Lu, Z.X.; Wang, T. Research on the Energy Management Strategy of a Hybrid Tractor OS-ECVT Based on a Dynamic Programming Algorithm. Agriculture 2024, 14, 1658. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z.X. Research on Load Disturbance Based Variable Speed PID Control and a Novel Denoising Method Based Effect Evaluation of HST for Agricultural Machinery. Agriculture 2021, 11, 960. [Google Scholar] [CrossRef]

- Lee, D.H. The Direct Voltage Control Scheme of Brushless DC Motor for the Electric Hydrostatic Transmission (HST) System. J. Electr. Eng. Technol. 2025, 20, 4065–4076. [Google Scholar] [CrossRef]

- Jiang, Z.H.; Xia, C.G. Study on Characteristic of Hydrostatic Transmission System of Tractor. J. Agric. Mech. Res. 2021, 43, 249–254. [Google Scholar]

- Chen, J.Q.; Hu, J.K.; Zhang, Z.M. Application research of hydrostatic drive system in high-speed off road fork lift. Mod. Manuf. Eng. 2010, 4, 123–127. [Google Scholar]

- Yang, F.; Teng, L.; Sun, Y.T.; Sun, Y.J.; Jiang, Z.H.; Hou, J.L. Development status and prospect of intelligent chassis of agricultural machinery. J. Chin. Agric. Mech. 2024, 45, 138–147. [Google Scholar]

- Tian, Y.; Ma, Y.F.; Wang, C.Q. Research of the Shift Characteristics of a Tractor Power Shift Transmission. J. Agric. Mech. Res. 2020, 42, 226–230. [Google Scholar]

- Siddique, M.A.; Baek, S.M.; Baek, S.Y.; Kim, Y.J.; Lim, R.G. Development, Validation, and Evaluation of Partial PST Tractor Simulation Model for Different Engine Modes during Field Operations. Agriculture 2023, 13, 44. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V. Numerical Performance Investigation of a Hybrid eCVT Specialized Agricultural Tractor. Appl. Sci. 2022, 12, 2438. [Google Scholar] [CrossRef]

- Fan, Z.G.; Yue, Y.J.; Zhao, H. Optimization of energy management strategies for hybrid tractors. J. Chin. Agric. Mech. 2025, 46, 303–308. [Google Scholar]

- Zhao, Z.H.; Xie, B.; Wen, C.K.; Xing, S.F.; Luo, Z.H.; Feng, R.F. Transient Characteristics and Control Methods of Mode Switching in Electric Tractor Dual Motor Drive System. Trans. Chin. Soc. Agric. Mach. 2025, 56, 532–542. [Google Scholar]

- Zhang, K.; Lu, Z.X.; Wang, L.; Deng, X.T.; Zhang, B.Q.; Sun, X.X. ECVT Configuration Design and Energy-saving Control of Hybrid Tractor Based on Lever Topology Method. Trans. Chin. Soc. Agric. Mach. 2024, 55, 505–518, 538. [Google Scholar]

- Joo, K.Y. Analysis of driving axle and PTO power transmission efficiency of an 18 kW-class single motor electric tractor. Korean J. Agric. Sci. 2024, 51, 921–933. [Google Scholar]

- Zhu, Z.; Yang, Y.P.; Wang, D.Q.; Cai, Y.F.; Lai, L.H. Energy Saving Performance of Agricultural Tractor Equipped with Mechanic-Electronic-Hydraulic Powertrain System. Agriculture 2022, 12, 436. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, X.K.; Xie, T.L.; Guo, H.; Yin, B.F. Automatic Shift Strategy of Ful Power Shift Transmission for Heavy Duty Tractors. Trans. Chin. Soc. Agric. Mach. 2024, 55, 444–455. [Google Scholar]

- Bai, C.S.; Xu, Z.M. Fuel Consumption Simulation for Tractor Engine Load Levels. J. Agric. Mech. Res. 2025, 47, 246–251. [Google Scholar]

- Wang, W.L.; Yan, K.; Wu, L.W.; Liang, R.S.; Wang, Q.X. Research on the Characteristics of Integrated Pump-Motor for Hydrostatic Transmission of Modern Agricultural Machinery. Mach. Tool Hydraul. 2025, 53, 181–187. [Google Scholar]

- Cheng, X.; Peng, Z.X.; Jing, C.B. Efficiency Model of Hydraulic Pump-Motor for Tractor Hydro-Mechanical CVT Under All Operating Conditions. Trans. Beijing Inst. Technol. 2025, 45, 154–164. [Google Scholar]

- Cheng, Z.; Xing, J.; Li, W.J. Efficiency modeling and reducer ratio analysis of hydrostatic transmission system for agricultural and forestry machinery. J. Mech. Electr. Eng. 2024, 41, 99–106. [Google Scholar]

- Zhang, K.; Wang, L.; Deng, X.T.; Lu, Y.; Lu, Z.X.; Xu, X.M.; Cheng, Z.; Zhang, B.Q. Improved Method and Verification of Energy Management Strategy of Hybrid Tractor ECVT Based on Pontryagin’s Minimum Principle. Trans. Chin. Soc. Agric. Mach. 2025, 56, 766–779. [Google Scholar]

- Cao, F.Y.; Li, S.Z.; Zhao, P.F.; Yan, X.H. Economic control strategy of tractor whole machine using HMCVT. Trans. Chin. Soc. Agric. Eng. 2025, 41, 22–28. [Google Scholar]

- Yang, S.J.; Zhang, Z.L.; Chen, Z.Q.; Li, X.L.; Peng, Z.X. Economic control strategy for HMT tractor considering transmission efficiency. Trans. Chin. Soc. Agric. Eng. 2025, 41, 48–56. [Google Scholar]

- Li, W.J.; Cheng, Z.; Yang, M.C. Configurational Comparison of a Binary Logic Transmission Unit Applicable to Agricultural Tractor Hydro-Mechanical Continuously Variable Transmissions and Its Wet Clutch Optimization Design Based on an Improved General Regression Neural Network. Agriculture 2025, 15, 877. [Google Scholar] [CrossRef]

- Xia, G.; Chen, J.S.; Tang, X.W.; Zhao, L.F.; Sun, B.Q. Shift quality optimization control of power shift transmission based on particle swarm optimization-genetic algorithm. Proc. Inst. Mech. Eng. Part D-J. Automob. Eng. 2022, 236, 872–892. [Google Scholar] [CrossRef]

- Huang, X.K.; Lu, Z.X.; Chen, L.; Qian, J.; An, Y.H. Optimization of tractor HMCVT target speed ratio and control simulation based on machine economy. J. Nanjing Agric. Univ. 2022, 45, 777–787. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).