Abstract

In swine production, it is broadly recognized that ventilation rates and indoor environmental conditions influence pig productivity. However, sparse scientific data are available on the combined effects and potential interactions of these factors in commercial production systems. This study investigated indoor environmental and management factors influencing wean-to-finish pig mortality in a commercial system. Temperature, relative humidity (RH), and carbon dioxide (CO2) were recorded every 10 min in the front and back of 16 barns across five grow-finish sites in eastern North Carolina for two turns (four barns) or three turns (12 barns) for a total of 44 pig groups. Proportional weekly mortality was modeled using a generalized linear mixed model. Results showed that pigs in environments warmer than the desired room temperature had lower mortality (p < 0.001), suggesting cold stress was more detrimental than heat stress. Elevated RH and CO2 at the back of the barn were linked to increased mortality (p < 0.001), highlighting air exchange rates as a key indicator. Mortality was greatest in pig groups placed during Spring and lowest in Summer (p < 0.05), and mortality declined as pigs aged (p = 0.0134). Surprisingly, greater barn occupancy correlated with lower mortality (p = 0.0012), potentially related to piglet quality at placement. The predictive power of the model varied with the turn of pigs, with R2 averaging 0.24 (ranging from 0.001 to 0.61) and an average RMSE of 0.36% (ranging from 0.17% to 0.77%). Ammonia (NH3) was recorded at the back of six barns, and concentrations were modeled. Greater NH3 concentrations were associated with increased pig age, RH, and CO2, as well as lower deviation from desired room temperature and lower barn occupancy. Collectively, these findings highlight the importance of proper ventilation and management on swine productivity.

1. Introduction

Feed is a significant cost in modern pork production, accounting for 60–70% of total expenses [1]. Optimizing feed efficiency is essential for enhancing the financial sustainability of swine production [2]. However, feed conversion ratios vary between different finishing facilities, even when pigs are sourced from the same sow farm, highlighting the potential for optimization within production systems. Mortality is a strong driver of production efficiency, as it directly reduces the number of pigs reaching market weight, thereby diminishing overall yield and economic return. Each mortality event represents a loss of cumulative inputs, potentially including feed, labor, housing, transportation, and veterinary care, without contributing to output [3]. Furthermore, mortality is a key driver of performance indicators such as average daily weight gain and feed conversion ratios at the group level. Elevated mortality rates in the finishing phase may also reflect underlying deficiencies in health management, nutrition, environmental control, or biosecurity, all of which can compromise the biological and economic efficiency of swine production systems [4,5], making mortality a useful metric for reporting pig productivity.

One effective strategy for improving pig productivity is optimizing the production environment. By refining environmental conditions, it is possible to reduce resource use, streamline pig movements, and minimize waste, all of which contribute to improved feed efficiency [1,6,7]. Mortality and growth efficiency in finishing pigs are influenced by both internal and external factors, such as air temperature, ammonia (NH3) and carbon dioxide (CO2) concentrations, dust levels, feeder space, pig health, stocking density, feed quality, and management practices [1,8,9]. While environmental factors are acknowledged to affect productivity, the extent and mechanisms by which they influence efficiency need further analysis.

Specifically, the objectives of this study were to (1) employ precision sensor technologies to monitor indoor environmental conditions, (2) correlate these factors with finishing pig mortality, and (3) investigate site- and barn-specific differences in common management factors. Results can be used to optimize indoor environment and pig management practices to improve swine production systems.

2. Materials and Methods

2.1. Sites and Barns

A group of finishing barns with historical variation in finishing mortality from a commercially integrated system was selected for study. Wean-to-finish sites were all located in eastern North Carolina, USA, and barns were of comparable age and construction. All sites were managed by the same service technician and veterinarian, and all pigs originated from a single Porcine Reproductive and Respiratory Syndrome (PRRS) positive-stable sow farm in eastern North Carolina. Five of the seven finishing sites that received pigs from the sow farm were selected for observation to capture year-round placement dates of pigs. Each site had its own underground well for water. On each site, a subset of barns was selected for observation with no prior researcher knowledge of individual barn or site performance. In total, there were 16 barns observed from 2021 to 2023, with each barn monitored for two or three turns (placement to marketing) of pig groups (Table 1). Each site utilized dry 5-hole feeders and mechanical tunnel ventilation systems with emergency drop sidewall curtains. Radiant tube heaters provided supplemental heat as needed. All barns were shallow pit, and manure management systems were either pull-plug (manually emptied every 7 days) or flush systems (automatically emptied approximately twice per day). Four sites (A, C, D, and E) had barn design capacity of 880 pigs across 36 pens. Each pen measured 5.61 m × 2.50 m. Site B had a barn design capacity of 1440 pigs across 48 pens. Forty-seven of the pens measured 7.04 m × 2.59 m, while one pen measured 6.22 m × 1.75 m.

Table 1.

Daily mortalities were recorded by farm personnel. Cumulative mortality rates for each turn (unique site, barn, replicate group) of pigs are presented. Site B had 1440 hd design capacity, while all other sites had 880 hd design capacity. All manure systems were shallow pit, pull-plug type, except for Site A Barns 6, 7, 11, and 12, which were shallow pit, flush type.

2.2. Pigs and Husbandry

Pigs were placed in the wean-to-finish facilities at weaning, approximately 21 days of age, aligning with typical USA production practices [10]. Approximately 1600 pigs were weaned each week, resulting in some barns being fully filled in one week while other barns were filled across two weeks to fill the barn (i.e., new pigs were placed in the same barn twice, 7 days apart). Single or multiple placement data were not available for the first replicate, and thus, the number of placements was excluded from analysis. The second and third replicates each had ten barns with one pig placement event and six barns with two placement events. For barns with two pig placement events, the date with the greater number of pigs placed was used as the turn start date. Pigs were generally first marketed in week 18 after placement, with multiple subsequent marketing events occurring as needed to maintain production and harvesting schedules. All pigs were marketed in week 23 or 24 to allow for cleaning and disinfecting before the next turn of pigs.

Pigs were provided with comfort mats and daily mat feeding for the first week after placement. Ventilation protocols prescribed the desired room temperature (DRT) based on the number of weeks after placement (Table 2). Vaccination protocols, health diagnostics, and treatments were conducted under veterinary guidance. Specifically, pigs were to be vaccinated for Mycoplasma hyopneumoniae in weeks 1, 4, and 8. Vaccines for PRRS and circovirus were also administered in weeks 1 and 4. Within 3 days of placement, pigs were vaccinated for Salmonella and Escherichia coli. Precise timing of vaccine administration varied between groups by up to 10 days.

Table 2.

Desired room temperature by number of weeks after placement in the wean-to-finish facilities. Pigs were weaned and placed in the facilities at approximately 21 days of age.

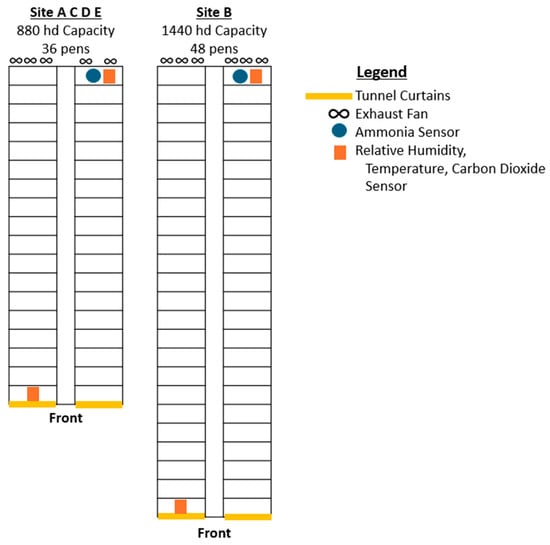

2.3. Sensors

Dry-bulb temperature, relative humidity (RH), and carbon dioxide (CO2) sensors were installed in the front and back of each barn in the first week of pig placement. Sensors were mounted near the ceiling above the first pen (near the tunnel curtain) and last pen (near the fans, opposite end of the barn from the tunnel curtain) to provide consistent measurement locations (Figure 1). The first and last pens were selected for sensor placement as opposed to the middle of the facility to provide information on condition extremes, with the front sensor data being the freshest/lowest concentration conditions and the back sensor data being exhaust/highest concentration conditions. In the first turn, Temco sensors were used exclusively (CO2-W-TH, Temco Controls, Ltd., Spokane, WA, USA); however, the CO2 in the back of the barn was found to occasionally exceed the sensor’s measurement range of 3000 ppm. Beginning in the second turn, sensors with a greater CO2 measurement range (DOL 139, dol-sensors, Aarhus, Denmark) were used in the back of the barns. An ammonia (NH3) sensor (DOL 53, dol-sensors, Aarhus, Denmark) was mounted 1.2 m above the floor of the last pen in six of the barns, with one sensor per site and manure system type. All sensors collected data every 10 min for each turn of pigs from approximately week 1 (placement) to week 23 (one week prior to final closeout). Dataloggers were launched using a cellular-connected device, enabling all timestamps to be synchronized (HOBOconnect, Onset Computer Corporation, Bourne, MA, USA). Sensors were removed before the barns were emptied, cleaned and disinfected, and reinstalled for the subsequent turn of pigs. Analog dataloggers (MX1105, Onset Computer Corporation, Bourne, MA, USA) recorded sensor voltage outputs for post-processing. All sensors were checked for agreement and calibration in a laboratory setting prior to each deployment. Ammonia sensor cartridges were replaced after two turns of pigs.

Figure 1.

Schematic of barn layout and sensor placement for 880 hd design capacity barns (14 study barns) and 1440 hd design capacity barns (2 study barns). Relative humidity, temperature, and carbon dioxide sensors were mounted near the ceiling, while the ammonia sensors were mounted 1.2 m above the floor. Figure not to scale.

Occasional data loss occurred due to power outages, equipment failure, and human error. If only front or back sensor data were unavailable, the recorded data were utilized to predict and backfill the missing data with linear models, using site, barn, location, temperature, RH, and CO2 concentrations to predict the missing values (R2 > 0.68 for all parameters). Backfill data were utilized for 14.5% of front sensor data, 5.6% of back sensor data, and 21.5% of NH3 sensor data.

2.4. Mortality Modeling

Daily mortalities for each barn were recorded by farm personnel. A total of 44 turns of pigs was included in the analysis, and cumulative mortality percentages for each turn are presented in Table 1. Mortality ranged from 3.8% to 13.3% for individual turns with an average of 7.8%. Industry-wide USA wean-to-finish mortality in 2022 was 6.9% on average, ranging from 3.1% for the top 10% (lowest mortality) farms to 12.1% for the bottom 10% (highest mortality) farms, demonstrating that the production system in the present study was industry-representative [10]. A generalized linear mixed-effects model (GLMM) with a binomial distribution was constructed to investigate relationships between weekly mortality and environmental factors. The response was the number of weekly mortalities and was parametrized as a proportion, mortalities/head placed. The data set contained multiple measurements of mortality rates for each barn; therefore, it is plausible that observations within each site/barn were correlated. The model also included random effects for sites and barns (nested within sites) and turn, while explanatory variables were modeled as fixed effects. Prior to modeling, continuous predictors were normalized using min–max scaling to address unit discrepancies and reduce multicollinearity. Fixed effects initially included weeks after placement, waste system type (flush or pull plug), barn position (end vs. inside of row), number of low vitality pigs at placement, season, turn, and PropCapacity (number of pigs/barn design capacity). Seasons were grouped based on average monthly ambient temperatures as reported by nearby weather stations and retrieved post hoc from the National Oceanic and Atmospheric Administration’s Climate Data Online (NOAA CDO) Tool. Season was assigned based on pig placement date, with Winter being placement dates December–February, Spring being March–May, Summer being June–August, and Fall being September–November. Absolute temperature resulted in multicollinearity (GVIF = 5.2); thus, temperature was calculated as deviation from DRT (Table 2) and included as average and standard deviation from front and back sensors. RH and CO2 concentrations were incorporated as weekly averages and standard deviations from both front and back sensors. A manual backward stepwise selection was applied to remove non-significant variables based on p-values, retaining only significant factors (p < 0.05) or significant tendencies (0.05 ≤ p < 0.1).

As the sensors were collecting data at the front and back of the barns, it was expected that there could be some relatedness between the factors. The authors evaluated the potential for correlation between the three environmental factors using variance inflation factor analysis. All GVIFs were <3.7, suggesting that there was some relatedness between factors, but not a cause for concern, as generally <5 is acceptable for datasets of similar size [11,12].

2.5. Ammonia Modeling

Ammonia concentrations were excluded from the mortality model as NH3 sensors were installed in only six of the 16 barns, resulting in limited inference. Instead, a linear mixed-effects model was developed to identify environmental factors influencing NH3 concentrations in wean-to-finish barns. Recorded NH3 levels at 10 min intervals served as the response variable. The model incorporated random effects for barn nested within site and turn to account for the hierarchical structure of the data and repeated measurements. The initial fixed effects included in the model were selected to account for both temporal and environmental factors that could influence the outcome of interest. The fixed effects initially included were Day within the production turn, type of waste management system used (flush or pull-plug), and number of live pigs in the barn on a given day. Environmental variables included measured RH and CO2 at the back of the facility. Temperature was included as the difference between the measured temperature at the back of the barn and DRT, as well as the daily average outdoor temperature retrieved from NOAA CDO databases. Numerical values were scaled, and a manual backward stepwise selection was applied to remove non-significant variables based on p-values, retaining only significant factors (p < 0.05) or significant tendencies (0.05 ≤ p < 0.1). Variance inflation factor analysis indicated no multicollinearity issues (all adjusted GVIFs < 2.6).

3. Results and Discussion

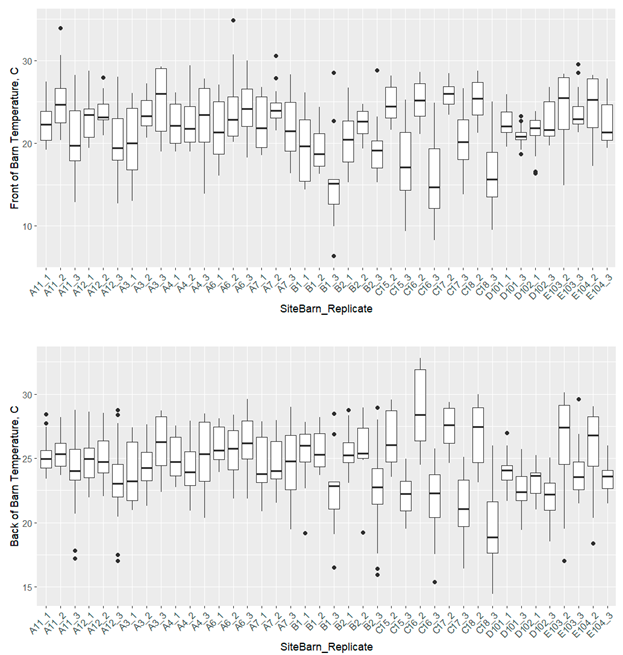

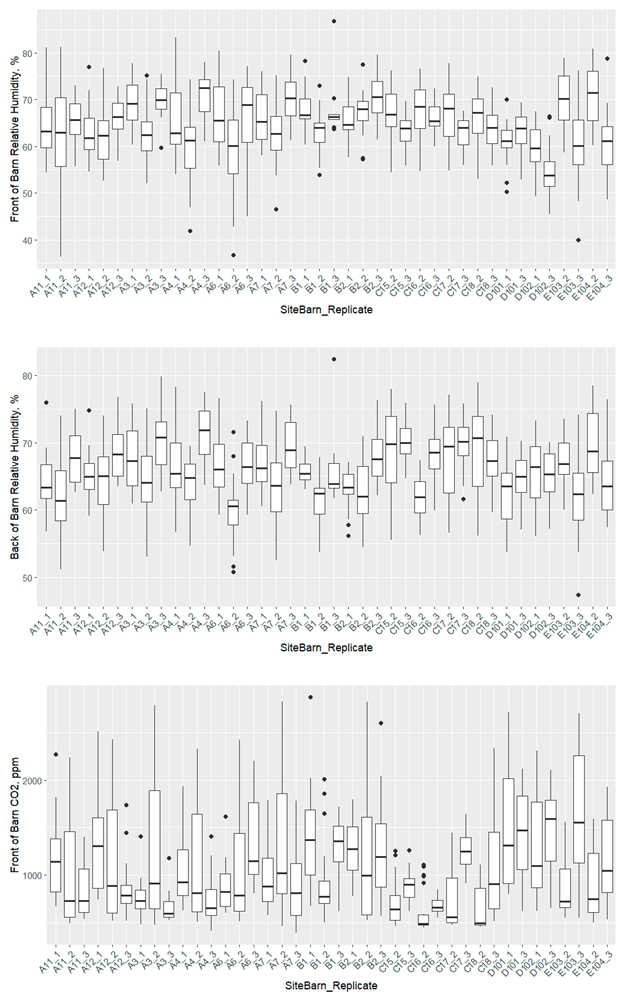

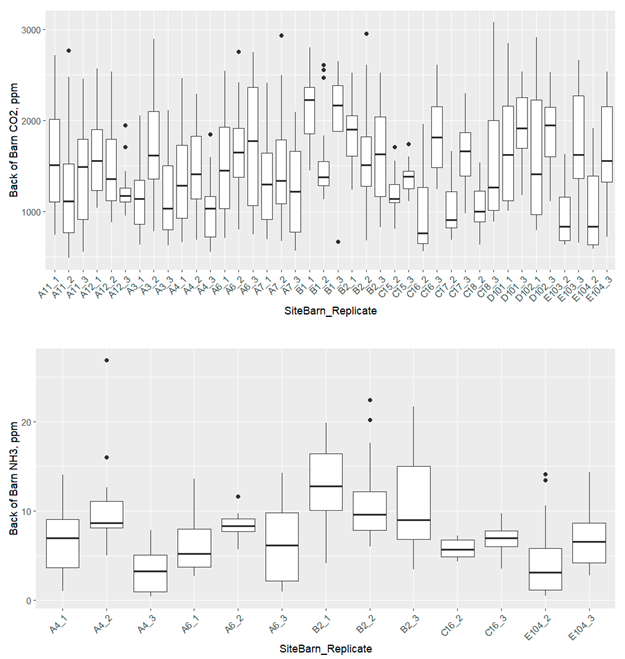

A summary of measured temperature, RH, CO2, and NH3 values is shown in Appendix A.

3.1. Mortality Modeling

The generalized linear mixed model analyzing proportional mortality identified several statistically significant environmental and management predictors (Table 3). The intercept of −4.48 (p < 0.001) represents the baseline log-odds of mortality, or 1.1%, during the fall season when all scaled continuous predictors are set to zero.

Table 3.

Weekly mortality factors, estimates, odds, and p-values as determined with a GLMM and compared to baseline conditions of the Fall season.

Table 3 illustrates the mortality model factors, estimates, and p-values, where Week denotes the number of weeks after placement, PropCapacity represents the percentage of the barn that was filled each week, Spring, Summer, and Winter describe Seasonal effects with Fall as the reference category. RHFrontAvg and RHFrontSD were the average and standard deviation of RH at the front of the barn. TBack_DRTDiff is the difference between the measured temperature at the back of the barn and the DRT. CO2_FrontSD refers to the standard deviation of CO2 concentration at the front of the barn, while CO2_BackAvg and CO2_BackSD refer to the average and standard deviation of CO2 concentration at the back of the barn.

Specifically, TBack_DRTDiff showed a significant association with mortality (p < 0.001), indicating that when the back of barn temperature exceeds the desired room DRT experienced significantly lower mortality. This suggests that cold stress was a greater challenge for pigs than heat stress. Therefore, maintaining temperatures at or above the DRT is better for survival than temperatures falling below. In the tunnel-style barns in this study, fresh air enters at the front curtain or ceiling inlets along the barn and travels toward the exhaust fans at the back, gaining heat as it moves along the length of the barn. This results in the back of the barn being warmer than the front, with a temperature gradient of less than 2 °C from front to back being desirable. Therefore, a back temperature below the DRT suggests that the entire barn is too cold, indicating a greater risk of cold stress. It is important to note that in this study, supplemental heat was provided via radiant tube heaters that function by raising surface (floor, comfort mat, or pig surface) temperatures rather than directly raising the air temperature.

The analysis of air quality parameters involving RH and CO2 on mortality revealed several significant associations. Among the RH variables, RHFront_Avg was significantly associated with mortality (estimate = 1.15, p < 0.001). The RHFront_SD also showed a significant positive effect (estimate = 0.82, p < 0.001), indicating that greater RH values and variability at the front of the barn are linked to greater mortality. Relative humidity variability could be associated with fluctuating environmental conditions, which may hinder the ability of the pig to maintain thermal comfort [13].

This interpretation is further supported by the positive association between CO2_BackAvg and mortality (estimate = 0.38, p = 0.014), meaning that greater CO2 levels in the back zone, the farthest point from ventilation inlets, contribute to greater mortality. Similarly, CO2_BackSD showed a significant positive association with mortality (estimate = 0.59, p < 0.001), indicating that larger fluctuations in CO2 levels at the back zone increase mortality. These results emphasize that inconsistent airflow and poor gas removal elevate the likelihood of mortalities [14].

Conversely, CO2_FrontSD demonstrated a significant negative association with mortality (estimate = −0.38, p = 0.023). When the tunnel curtain is opened, the front end of the barn receives the largest volume of incoming fresh air, containing lower CO2 levels compared to existing barn air. Across the study period, the globally averaged CO2 concentration was 418 ppm [15]. During minimum ventilation stages, ceiling inlets are utilized, and a lower rate of air exchange is prescribed to improve heat retention and manage moisture; thus, variability in CO2 levels at the front of the barn should be minimized by reduced airflow volumes and more uniform distribution. However, during transitional and subsequent tunnel ventilation stages, the tunnel curtain periodically opens to allow an influx of lower CO2 air, increasing variability in CO2 concentrations at the front of the barn. It is expected that transitional ventilation would be more challenging for pigs, as RH results suggest; thus, the negative association between CO2_FrontSD and mortality is surprising and warrants further investigation.

The findings emphasize the importance of maintaining consistent, controlled RH and CO2 levels for reducing pig mortality. Moreover, the greater estimate magnitude for TBack_DRTDiff highlights the influence of temperatures on pig productivity. Effective ventilation is essential to promoting thermal comfort and air quality, both of which are critical to reducing mortality in pigs. Temperature plays a crucial role in pig growth performance, with optimal results achieved within the pig thermoneutral zone [3]. Proper ventilation is needed for maintaining appropriate RH and temperature levels as well. Inadequate ventilation can lead to greater morbidity and mortality, largely due to increased susceptibility to infectious agents, particularly respiratory diseases [16].

Beyond ventilation parameters, seasonal variation was also a significant factor influencing pig mortality. Pairwise seasonal contrasts, adjusted using the Tukey method, revealed several significant differences in mortality risk and are presented in Table 4.

Table 4.

Estimated differences in weekly mortality percentages by season of pig placement dates.

Spring pig placement groups had the greatest mortality rates as compared to the other seasons. Summer had the lowest mortality, significantly lower than Spring and Winter. The difference between Fall and Summer showed a tendency of significance (p = 0.061). Fall and Winter did not differ. These findings suggest that seasonal variations beyond ambient temperature, such as disease pressure, influence mortality rates in pigs. Seasonal variation is known to influence post-weaning pig health, with summer placements into grow-finish facilities typically associated with lower mortality compared to other times of the year [4,17]. This trend is largely driven by challenges in managing barn microenvironments amid daily temperature fluctuations [13] and by seasonal patterns in infectious disease incidence, which tend to rise during colder months [18,19]. Infectious disease incidence also follows a seasonal pattern with increased incidence in colder months of the year, as highlighted by increased reported cases of PRRSV in grow-finish pigs during May 2025 and April 2018 [20]. Other health challenges, including Mycoplasma hyopneumoniae, influenza A virus, and porcine circovirus, also showed elevated or stable prevalence in Spring wean-to-market pigs, reinforcing the seasonal pressure on respiratory and enteric health. The findings underscore the combined effects of environmental stress and infectious disease on pig morbidity and mortality, emphasizing the need for strengthened biosecurity in colder months.

The effect of Week on mortality was found to be significant (estimate = −0.0244, p = 0.0134), indicating a decrease in mortality with increasing pig age. Mortality in pigs decreases with age, largely due to the development of stronger immune systems and a reduced impact of early weaning stress [21]. Young pigs are particularly vulnerable to environmental and physiological challenges immediately after weaning. However, as they grow and adapt to their surroundings, their immunity and ability to regulate body temperature improve, making them more resilient to stressors [21]. In wean-to-finish systems, increasing the weaning age from 12 to 21 days has been shown to improve average daily gain (ADG) and tends to reduce mortality during the first 42 days post-weaning. Moreover, older weaning ages are associated with better finishing ADG, reinforcing the pattern of decreasing mortality and enhanced growth performance over time [21]. National Pork Board (2024) reported 31.9% of total wean-to-finish mortality occurred during weeks 3 to 7 after placement, aligning with the present study results and highlighting this as a critical early period for pig losses in wean-to-finish production [10].

The analysis of PropCapacity revealed a significant negative association with mortality (estimate = −1.514, p = 0.001245), suggesting that greater barn fill capacities are associated with lower mortality. This outcome is unexpected, as overcrowding and increased stocking density are known to increase stress, competition for resources, and mortality rates in pigs [22,23,24]. One possible explanation of this result is that only 3% of weekly PropCapacity observations exceeded barn design capacity. Furthermore, the variation in PropCapacity within the present study was relatively small, ranging from 0.674 to 1.035 for Sites A, C, D, E, with six weekly observations over capacity, while PropCapacity ranged from 0.897 to 1.044 for Site B with 19 weekly observations exceeding capacity. Another possible explanation for this result could be related to the initial health and quality of the pigs at placement. In pig placement groups with high overall health, it is expected that sow farm survivability would be greater and result in more total pigs weaned per week, resulting in more pigs per finishing barn. However, sow farm production data were not available for publication in this manuscript. Instead, the number of low-vitality pigs at placement was used as a potential indicator of pig quality; however, it was not a significant predictor in the final model. A more comprehensive measure of pig quality, including sow farm and weaning data, could be utilized to further improve the model characterization [21,25,26].

The estimated random intercepts at the site level were zero for all sites, indicating an absence of detectable between-site variability in mortality rates after adjusting for the fixed effects. In contrast, the random intercepts at the barn-within-site level resulted in notable variation, suggesting the presence of additional barn-specific factors, such as local management practices or maintenance status, that influence mortality rates. These barn-level differences in mortality cannot be explained by the fixed effects or the broader site-level grouping. Table 5 presents the predicted weekly baseline mortality percentages by barn.

Table 5.

Baseline weekly percentage mortality estimates by barn.

The greatest predicted baseline weekly mortality rate was observed in Site A Barn 3, at 1.75%. Conversely, Site C Barn 16 had the lowest predicted rate of 0.71%, indicating substantial variation in baseline risk attributable to barn-level factors. These findings suggest that beyond air quality, barn-specific characteristics contribute meaningfully to mortality differences and warrant further investigation and targeted management strategies.

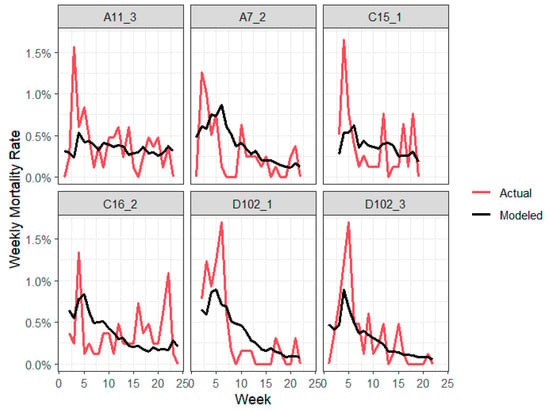

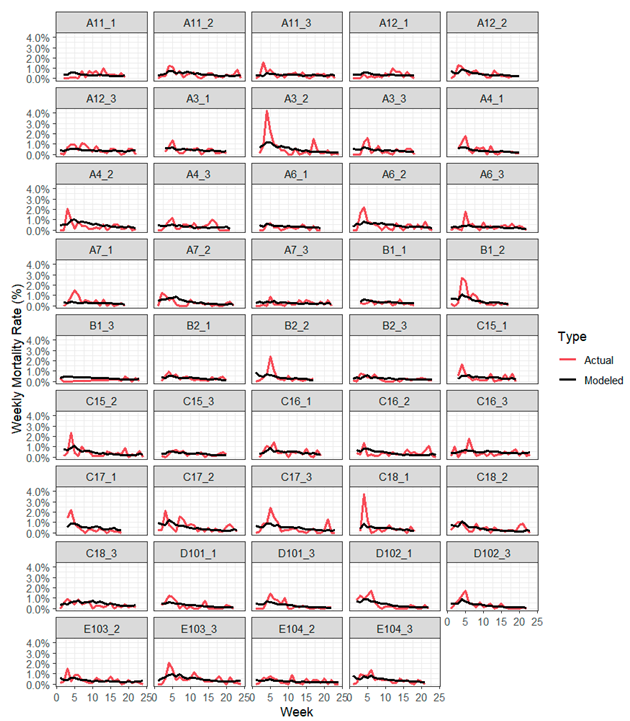

Figure 2 illustrates the comparison of actual vs. predicted cumulative weekly mortality for select turns representing a range of model performance based on RMSE and R2 values. Overall, average R2 = 0.24 and RMSE = 0.36% and all turns are presented in Appendix A. The two greatest R2 turns were D102_3 (RMSE = 0.295%, R2 = 0.612) and D102_1 (RMSE = 0.332%, R2 = 0.611). These results reflect consistent mortality patterns with a typical exponential mortality pattern in early finishing [10].

Figure 2.

Comparison of actual and modeled (predicted) weekly mortality rates for selected barns and turns (SiteBarn_Turn) over the wean-finish period.

Average predictive performing turns, such as A7_2 (RMSE = 0.333%, R2 = 0.192) and C15_1 (RMSE = 0.380%, R2 = 0.177), showed moderate predictive performance. The lowest fit turns were A11_3 (RMSE = 0.345%, R2 = 0.001) and C16_2 (RMSE = 0.367%, R2 = 0.001). These results highlight significant variability in mortality patterns and model performance across different pig groups, underlining the challenges in modeling outcomes where mortality signals may be weak, erratic, or influenced by unaccounted factors such as acute health challenges.

3.2. Ammonia Modeling

The fixed effects from the linear mixed model indicate several significant relationships between environmental and operational factors and NH3 concentration at the back of the barn. Table 6 reports model outcomes with only significant factors reported. Ammonia concentrations were significantly greater later in the production cycle, as shown by a positive estimate for days after placement (1.239). However, there was a negative association with Date (−0.987), suggesting seasonal effects.

Table 6.

Fixed effects estimates for factors influencing ammonia concentrations at the back of the barn.

Increased RH at the back of the barn (RHBackAvg) was associated with increased NH3 levels (estimate = 0.270, p < 0.001). Possible mechanisms include total air exchange rates, or potentially reduced evaporation and increased microbial activity in more humid conditions.

Temperature deviation from DRT (TBack_DRTDiff) had a negative effect (estimate = −0.326, p < 0.001), meaning that as the temperature at the back of the barn exceeded the desired room temperature, NH3 levels declined. Air exchange rates increase when the measured temperature exceeds DRT, increasing dilution of indoor gases. This concept is solidified by the significance of increasing CO2_BackAvg concentration and RHBackAvg with increased NH3 levels.

Interestingly, the proportion of barn capacity occupied (PropCapacity) had a significant negative relationship with NH3 concentration (estimate = −0.079, p < 0.001), indicating that more densely stocked barns were associated with slightly lower NH3.

The random effects in the model account for variability in NH3 concentrations that was not explained by the fixed effects, but rather due to the grouping structure of the data. The variance associated with Site was 1.61 (standard deviation = 1.27), indicating that average NH3 levels differ meaningfully across sites included in the study. Additionally, the Site–Barn grouping (barns nested within sites) had a variance of 0.85 (standard deviation = 0.92), reflecting further variability in NH3 levels among barns within each site. Compared to site and barn level variance, the residual variance is greater at 12.58 (standard deviation = 3.55); thus, while the specified fixed effects and site and barn account for some variability, a substantial portion of NH3 concentration variation remains unexplained.

Ammonia exposure has been shown to negatively impact both growth performance and respiratory health in pigs. Drummond et al. (1980) observed reduced ADG and signs of airway inflammation in pigs exposed to 50–150 ppm NH3, with the most pronounced effects at 100 and 150 ppm [8]. In contrast, Michiels et al. (2015) found no significant effect of NH3 (average 27 ppm) on ADG during the finishing period but reported strong associations between NH3 levels and respiratory issues, including pleurisy and M. hyopneumoniae infection [16]. The present study findings support the relevance of monitoring NH3 levels in pig barns, as even moderate concentrations may contribute to respiratory pathology and coinfections without clearly affecting growth.

4. Conclusions

Temperature (T), relative humidity (RH), and carbon dioxide (CO2) were measured every 10 min at the front and back of 16 tunnel-ventilated wean-finish barns across five production sites in North Carolina, USA. Pigs were sourced from the same sow farm, and all barns had the same service technician and veterinarian. Forty-four groups of pigs were observed, and weekly mortality was modeled using a generalized linear mixed model. For individual groups of pigs, R2 ranged from 0.001 to 0.612, with an overall average R2 = 0.24 and RMSE = 0.36%. The results demonstrated that mortality was lower when T at the back of the barn exceeded the desired room temperature, suggesting cold stress was a greater challenge for pigs than heat stress. Relative humidity average and variability at the front of the barn were positively associated with mortality, while, unexpectedly, variability in front CO2 was negatively associated with mortality. Increasing the back CO2 average and variability also increased mortality. Placement of pig groups in the Spring season had the greatest mortality compared to Fall, Summer, and Winter, and mortality decreased throughout the finishing cycle (weeks after placement). Barn fill capacity was negatively associated with mortality; however, a minority of weeks in this dataset were stocked above capacity, suggesting this metric may be related to pig quality at placement.

Additionally, six barns had an ammonia (NH3) sensor in the back of the barn. NH3 concentrations were described using a linear mixed model. Significant positive relationships were found with days after pig placement, date, average RH, and average CO2 at the back of the barn, while negative relationships were found with back T deviation from desired room temperature, date, and barn fill capacity.

Collectively, these results highlight the importance of maintaining proper, consistent indoor conditions for pig survivability, especially in the early post-wean period. Future research should explore targeted interventions in environmental controls and utility usage to optimize best practices for sustainable and efficient swine production.

Author Contributions

Conceptualization, M.T.K., G.W.A. and S.M.L.; methodology, M.T.K., G.W.A., A.S., L.K., S.W. and S.M.L.; software, O.J.K., A.S., L.K., S.W. and S.M.L.; validation, O.J.K. and S.M.L.; formal analysis, O.J.K., A.S., L.K., S.W. and S.M.L.; investigation, O.J.K., M.T.K., G.W.A. and S.M.L.; resources, M.T.K., G.W.A. and S.M.L.; data curation, O.J.K., A.S., L.K., S.W. and S.M.L.; writing—original draft preparation, O.J.K.; writing—review and editing, O.J.K., M.T.K., G.W.A. and S.M.L.; visualization, O.J.K.; supervision, O.J.K. and S.M.L.; project administration, S.M.L.; funding acquisition, M.T.K., G.W.A. and S.M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Pork Board, grant number PR-005316.

Institutional Review Board Statement

Ethical review and approval were not required for this study due to its observational nature.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

Special thank you to our cooperating industry partners and farms.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| ADG | Average daily gain |

| CO2 | Carbon dioxide |

| NH3 | Ammonia |

| RH | Relative humidity |

Appendix A

All collected temperature, relative humidity, CO2, and NH3 data for each Site, Barn, and Replicate (turn of pigs) are displayed below. Environmental data are followed by predicted vs. actual mortality plots for each turn of pigs.

References

- Patience, J.F.; Rossoni-Serão, M.C.; Gutiérrez, N.A. A review of feed efficiency in swine: Biology and application. J. Anim. Sci. Biotechnol. 2015, 6, 33. [Google Scholar] [CrossRef] [PubMed]

- Pomar, C.; Andretta, I.; Remus, A. Feeding Strategies to Reduce Nutrient Losses and Improve the Sustainability of Growing Pigs. Front. Vet. Sci. 2021, 8, 742220. [Google Scholar] [CrossRef]

- Gebhardt, J.T.; Tokach, M.D.; Dritz, S.S.; DeRouchey, J.M.; Woodworth, J.C.; Goodband, R.D.; Henry, S.C. Postweaning mortality in commercial swine production. I: Review of non-infectious contributing factors. Transl. Anim. Sci. 2020, 4, 462–484. [Google Scholar] [CrossRef] [PubMed]

- Maes, D.; Larriestra, A.; Deen, J.; Morrison, R. A retrospective study of mortality in grow-finish pigs in a multi-site production system. J. Swine Heal. Prod. 2001, 9, 267–273. [Google Scholar] [CrossRef] [PubMed]

- Marchant-Ford, J.N. The Welfare of Pigs; Welfare; Springer: Berlin/Heidelberg, Germany, 2009; Volume 7. [Google Scholar]

- Wiegert, J.; Knauer, M.T.; Shah, S.B. Evaporative pad cooling impacts on barn environment and finishing pig performance. Appl. Eng. Agric. 2022, 38, 351–359. [Google Scholar] [CrossRef]

- Sharpe, K.T.; Reese, M.H.; Buchanan, E.S.; Tallaksen, J.E.; Janni, K.A.; Johnston, L.J. Electrical and thermal energy consumption in Midwest commercial swine facilities. Appl. Eng. Agric. 2018, 34, 857–864. [Google Scholar] [CrossRef]

- Drummond, J.G.; Curtis, S.E.; Simon, J.; Norton, H.W. Effects of Aerial Ammonia on Growth and Health of Young Pigs. J. Anim. Sci. 1980, 50, 1085–1091. [Google Scholar] [CrossRef]

- Baxter, S. Intensive Pig Production: Environmental Management and Design; National Book Network: Blue Ridge Summit, PA, USA, 1984. [Google Scholar]

- National Pork Board; MetaFarms Inc. Production Analysis Summary for U.S. Pork Industry: 2019–2023. 2024. Available online: https://porkcheckoff.org/wp-content/uploads/2024/07/2024-Production-Analysis-Full-Report-1.pdf (accessed on 18 September 2025).

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning with Applications in R, 2nd ed.; Springer: New York, NY, USA, 2021. [Google Scholar]

- Pardoe, I.; Simon, L.; Young, D. Detecting Multicollinearity Using Variance Inflation Factors. 2018. Available online: https://online.stat.psu.edu/stat462/node/180/ (accessed on 26 September 2025).

- Van Huffel, K.; Hansen, M.J.; Bruneel, J.; van Langenhove, H.; Feilberg, A. Extraction efficiency of odorous compounds during a winter and summer period for partial pit ventilation in pig houses with diffuse ceiling inlet and wall inlets. Biosyst. Eng. 2019, 179, 71–79. [Google Scholar] [CrossRef]

- Lee, C.; Giles, L.R.; Bryden, W.L.; Downing, J.L.; Owens, P.C.; Kirby, A.C.; Wynn, P.C. Performance and endocrine responses of group housed weaner pigs exposed to the air quality of a commercial environment. Livest. Prod. Sci. 2005, 93, 255–262. [Google Scholar] [CrossRef]

- Lan, X.; Tans, P.; Thoning, K.W. Trends in Globally-Averaged CO2 Determined from NOAA Global Monitoring Laboratory Measurements; Version 2025-09; Global Monitoring Laboratory: Boulder, CO, USA, 2025. [Google Scholar] [CrossRef]

- Michiels, A.; Piepers, S.; Ulens, T.; Van Ransbeeck, N.; Del Pozo Sacristán, R.; Sierens, A.; Haesebrouck, F.; Demeyer, P.; Maes, D. Impact of particulate matter and ammonia on average daily weight gain, mortality and lung lesions in pigs. Prev. Vet. Med. 2015, 121, 99–107. [Google Scholar] [CrossRef] [PubMed]

- Agostini, P.S.; Gasa, J.; Manzanilla, E.G.; Da Silva, C.A.; de Blas, C. Descriptive study of production factors affecting performance traits in growing-finishing pigs in Spain. Span. J. Agric. Res. 2013, 11, 371–381. [Google Scholar] [CrossRef]

- Tousignant, S.J.; Perez, A.M.; Lowe, J.F.; Yeske, P.E.; Morrison, R.B. Temporal and spatial dynamics of porcine reproductive and respiratory syndrome virus infection in the United States. Am. J. Vet. Res. 2015, 76, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Knutson, T.P.; Rossow, S.; Saif, L.J.; Marthaler, D.G. Decline of transmissible gastroenteritis virus and its complex evolutionary relationship with porcine respiratory coronavirus in the United States. Sci. Rep. 2019, 9, 3953. [Google Scholar] [CrossRef]

- Swine Health Industry Center. Swine Disease Reporting System. 2025, Volume 87, pp. 1–10. Available online: https://www.swinehealth.org/domestic-disease-surveillance-reports/ (accessed on 23 April 2025).

- Main, R.G.; Dritz, S.S.; Tokach, M.D.; Goodband, R.D.; Nelssen, J.L. Increasing weaning age improves pig performance in a multisite production system. J. Anim. Sci. 2004, 82, 1499–1507. [Google Scholar] [CrossRef]

- Chidgey, K.L. Review: Space allowance for growing pigs: Animal welfare, performance and on-farm practicality. Animal 2024, 18, 100890. [Google Scholar] [CrossRef] [PubMed]

- DeDecker, J.M.; Ellis, M.; Wolter, B.F.; Corrigan, B.P.; Curtis, S.E.; Hollis, G.R. Effect of stocking rate on pig performance in a wean-to-finish production system. Can. J. Anim. Sci. 2005, 85, 1–5. [Google Scholar] [CrossRef]

- PIC UK Ltd. PIC Wean to Finish Guidelines; PIC: Basingstoke, UK, 2019. [Google Scholar]

- Magalhaes, E.S.; Zhang, D.; Wang, C.; Thomas, P.; Moura, C.A.A.; Holtkamp, D.J.; Trevisan, G.; Rademacher, C.; Silva, G.S.; Linhares, D.C.L. Field Implementation of Forecasting Models for Predicting Nursery Mortality in a Midwestern US Swine Production System. Animals 2023, 13, 2412. [Google Scholar] [CrossRef] [PubMed]

- Collins, C.L.; Pluske, J.R.; Morrison, R.S.; McDonald, T.N.; Smits, R.J.; Henman, D.J.; Stensland, I.; Dunshea, F.R. Post-weaning and whole-of-life performance of pigs is determined by live weight at weaning and the complexity of the diet fed after weaning. Anim. Nutr. 2017, 3, 372–379. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).