Abstract

To mitigate the high stubble rates (root residue rates) and plant damage associated with the current mechanized harvesting of Shanghai Green (Brassica rapa subsp. chinensis), this study developed and optimized a novel soil loosening and root lifting device. A theoretical dynamic model was first established to analyze the device’s operational principles. Subsequently, a coupled multi-body dynamics and discrete element method (RecurDyn-EDEM) model was established to simulate the complex interactions between the device, soil, and plant roots. Response surface methodology was employed to optimize key operational parameters: walking speed, loosening depth, and vibration frequency. The simulation-based optimization was validated by field tests. The optimal parameters were identified as a walking speed of 0.137 m/s, a loosening depth of 34.5 mm, and a vibration frequency of 1.34 Hz, under which the Shanghai Green pulling force was 35.41 N, yielding optimal extraction performance. Field tests conducted under these optimal conditions demonstrated excellent performance, achieving a qualified plant posture rate of 87.5% and a low damage rate of 7.5%. This research provides a robust design and validated operational parameters, offering significant technical support for the development of low-loss harvesting equipment for leafy vegetables.

1. Introduction

Shanghai Green (Brassica rapa subsp. chinensis), a member of the Brassicaceae family, constitutes one of the most prevalent vegetable crops in China. Its cultivation is primarily concentrated in the middle and lower reaches of the Yangtze River. With the expansion of Shanghai Green production [1,2,3,4], escalating labor costs and the inherent inefficiencies of traditional manual harvesting methods have become increasingly inadequate to satisfy the demands of large-scale cultivation [5].

Under large-scale cultivation, achieving the continuous cropping of Shanghai Green is key to improving the overall yield. The conventional harvesting method—cutting the plant at or near the soil surface and transporting it via a conveyor—while efficient, leaves root systems in the soil [6,7,8,9]. This necessitates manual tillage before replanting and increases the risk of soil-borne pests and diseases, thereby hindering sustainable consecutive cultivation. In contrast, a root-inclusive harvesting approach, involving uprooting followed by root separation (“pull first, then cut”), streamlines the harvesting process, reduces labor, facilitates rapid crop rotation, improves soil fertility utilization, and enhances economic returns [10,11].

In the context of harvesting research for root and tuber crops, traditional efforts have primarily concentrated on the design of soil loosening implements such as digging blades. In contrast, the domain of leafy vegetable harvesting has witnessed the development of advanced, albeit costly, robotic solutions that incorporate precise gripping technologies [12]. To address the limited centripetal enclosure and low gripping success rates of conventional mechanical grippers in leafy vegetable harvesting, Zhen et al. [13] introduced a variable-position gripping approach featuring rotating claws, which enhanced adaptability to plant morphology and position. Through multi-body dynamic simulation and dimensional modeling, the optimal parameters for hydroponic green mustard harvesting were established; however, the high cost and limited efficiency of robotic systems restrict their scalability for commercial applications. In contrast, root vegetable harvesters typically utilize a loosening shovel to disturb the soil before extracting crops [14,15]. For example, a carrot harvester developed by Jin et al. employs a rotating grainer for collection, a guiding bar, and subsequent loosening and pulling operations [16]. Zhou et al. designed a pentagonal shovel to reduce soil adhesion when harvesting radishes [17], while Du et al. developed a self-propelled kale harvester with a guided pulling mechanism [18]. Additionally, Zou et al. proposed an integrated scheme for spinach harvesting that includes a vibration shovel, variable-stiffness clamping, and a conveying system [19,20].

Nevertheless, both the current market and academic literature lack a cost-effective and efficient mechanical system specifically tailored for the whole-plant extraction of densely planted leafy vegetables like Shanghai Green. This study seeks to address this gap by integrating soil loosening and root pulling techniques, employing modern simulation methods to optimize the proposed system.

The operation of the soil loosening and root lifting device for Shanghai Green is inherently complex, as both the soil and the vegetable itself comprise particles that are prone to deformation and fragmentation. A notable strength of this study is its demonstration of the practical value of the combined EDEM-RecurDyn simulation platform [21,22]. Conventional multi-body dynamics often cannot capture the detailed granular behavior of soil, while using discrete element modeling alone struggles to represent the complex real-world movements and linkages of agricultural machinery [23,24,25]. Traditional simulation methods—whether employing solely discrete element modeling or multi-body dynamics analysis—are insufficient to accurately capture the multifaceted interactions among the soil loosening and root lifting device, soil particles, and Shanghai Green [23,24,25,26,27,28,29,30,31]. To address this challenge, this study constructs a virtual prototype of the device within the RecurDyn environment and models both soil and Shanghai Green in EDEM [32,33]. This study utilizes coupled EDEM-RecurDyn simulations to build a robust theoretical foundation, thereby enhancing the efficiency and quality of Shanghai Green harvesting operations [34].

This study aims to develop and optimize a mechanical harvesting system tailored for the whole-plant extraction of Shanghai Green under large-scale cultivation conditions. By integrating soil loosening and root extraction techniques, this research seeks to address the limitations of the traditional manual harvesting and inefficient mechanical systems currently available for densely planted leafy vegetables. Utilizing a coupled EDEM-RecurDyn simulation approach, this work systematically investigates the influence of key operational parameters—including walking speed, loosening shovel depth, vibration frequency, and root lifting mechanism depth—on machine performance. The ultimate goal is to determine the optimal configuration of the harvesting device, thereby providing a robust theoretical foundation for improving the efficiency and quality of Shanghai Green harvesting operations while supporting sustainable and continuous cropping practices.

2. Design of Critical Components of the Soil Loosening and Root Lifting Device

2.1. Structural Design and Operating Principle of the Soil Loosening and Root Lifting Device

The primary function of the soil loosening and root lifting device is to facilitate the extraction of Shanghai Green by loosening the soil around its roots with a dedicated loosening component. This process reduces the resistance encountered during pulling, while a separate pulling component ensures that the Shanghai Green can be fully removed from the soil for subsequent transportation and collection. The soil loosening mechanism must effectively loosen the soil surrounding the roots to minimize extraction resistance and prevent difficulties caused by soil compaction. Additionally, the depth and force applied by the loosening component must be carefully controlled to avoid disrupting the soil structure, altering the orientation of the Shanghai Green, or causing mechanical damage to the stems and leaves. During the root lifting operation, it is essential to extract the Shanghai Green intact, maintaining the appropriate pulling force to minimize damage to the aboveground parts of the plant, thereby ensuring product quality [35,36,37,38].

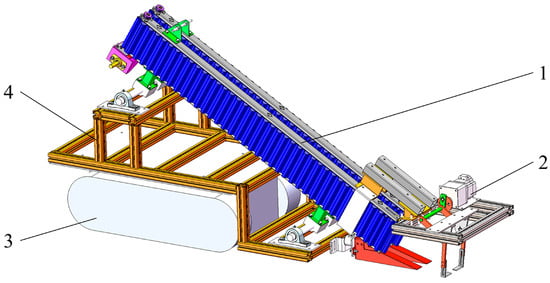

To meet the aforementioned requirements, an eccentric wheel-driven soil loosening and root lifting device for Shanghai Green was developed. As depicted in Figure 1, the device is integrated into a single-row Shanghai Green harvesting test machine and is positioned at the front end of the harvester in the direction of travel. The soil loosening and root lifting device comprises two primary components: the soil loosening mechanism and the root lifting mechanism.

Figure 1.

Structural diagram of a single-row Shanghai Green harvester. 1. Conveyor mechanism. 2. Soil loosening and root lifting mechanism. 3. Track chassis. 4. Mounting frame.

The soil loosening mechanism consists of a frame, motor, eccentric wheel, connecting rod, soil loosening blade mounting rod, and soil loosening blade, all powered by the motor. The operating principle involves the motor driving the eccentric wheel to rotate, which subsequently actuates the connecting rod at the end hinged to a short shaft. This motion induces the oscillation of the soil loosening blade mounting rod about its hinge with the frame, causing the attached soil loosening blade to vibrate and cut into the soil surrounding the roots. One complete rotation of the eccentric wheel results in a single reciprocating cutting motion of the soil loosening blade. The blade itself is fastened to the mounting rod with bolts, and the depth of operation can be finely adjusted by varying the alignment of the blade’s slot with the corresponding hole on the mounting rod.

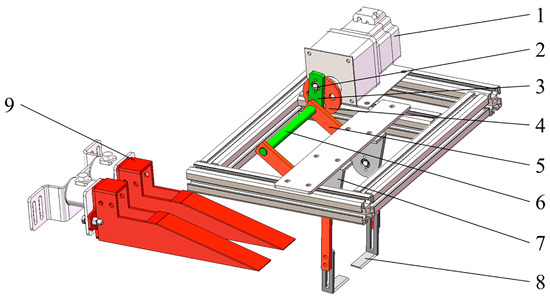

The root lifting mechanism is mounted on the frame above the chassis to enable the efficient extraction of the plant. The structural details of the soil loosening and root lifting device are illustrated in Figure 2.

Figure 2.

Structural diagram of soil loosening and root lifting device. 1. Motor. 2. Short shaft. 3. Connecting rod. 4. Eccentric wheel. 5. Soil loosening shovel mounting rod. 6. Long shaft. 7. Frame. 8. Soil loosening shovel. 9. Root lifting mechanism.

During actual soil loosening and root lifting operations, the loosening shovel operates at the front end of the root lifting mechanism to loosen the soil adjacent to the roots of Shanghai Green. This process effectively reduces the adhesive force between the plant roots and the surrounding soil while preserving the relative position of the Shanghai Green within the soil matrix. As the front end of the root lifting mechanism advances to the location of the plant, the roots of Shanghai Green are guided between the root lifting components on either side. As the base of the Shanghai Green stem gradually ascends along the upper surface of the root lifting mechanism, the plant is lifted and extracted from the soil in a controlled manner.

2.2. Critical Component Design

- (1)

- Establishment of soil loosening mechanism movement model

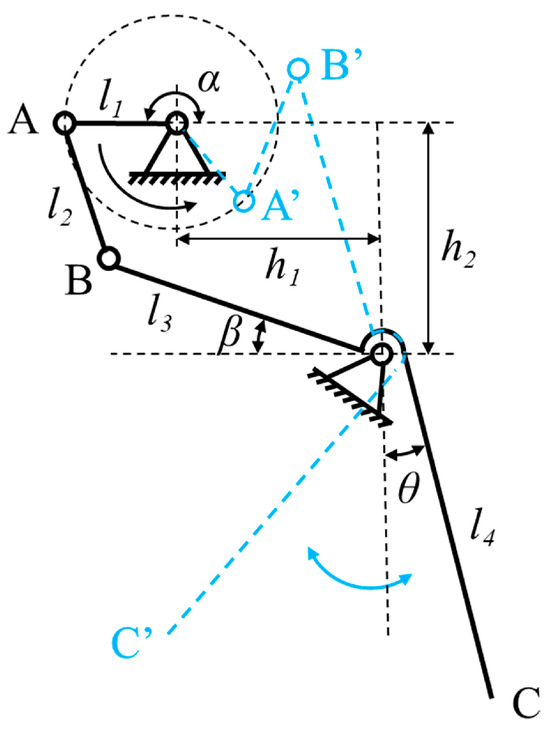

Based on the structural design and operating principle of the soil loosening mechanism, a mechanical motion mathematical model can be established. A schematic diagram of the soil loosening mechanism is presented in Figure 3.

Figure 3.

Working principle diagram of soil loosening mechanism.

In this diagram, l1 represents the distance between the eccentric wheel shaft center and the short shaft center; l2 denotes the distance between the short shaft center and the long shaft center; l3 corresponds to the distance between the hinge point of the soil loosening blade mounting rod and the long shaft, and the hinge point between the mounting rod and the frame; l4 indicates the distance from the hinge point of the mounting rod and the frame to the bottom edge of the soil loosening blade; and α represents the angular displacement of the short shaft.

Taking the center of the eccentric wheel as the origin, let AB represent the connecting rod, and let point C denote the end of the soil loosening shovel. The positional relationships among these points are defined as follows:

From this, we can derive the expression for the coordinates of point C in terms of the operating time and the short shaft’s angular velocity:

In the equation, ω represents the angular velocity of the short shaft; t represents the operating time of the device; β represents the angle between the soil loosening shovel mounting rods and the ground; θ represents the angle between the lower part of the soil loosening shovel mounting rod and the vertical direction; and (, ), (, ), and (, ) represent the coordinates of points A, B, and C, respectively.

- (2)

- Design of root lifting device

In this study, mature Shanghai Green plants were selected as the research subjects. To determine the design objectives and key parameters of the device, preliminary physical tests were conducted in this study. The results showed that the average pulling force required to completely uproot a mature Shanghai Green plant was 41.94 N, as shown in Figure 4.

Figure 4.

Shanghai Green pulling force test.

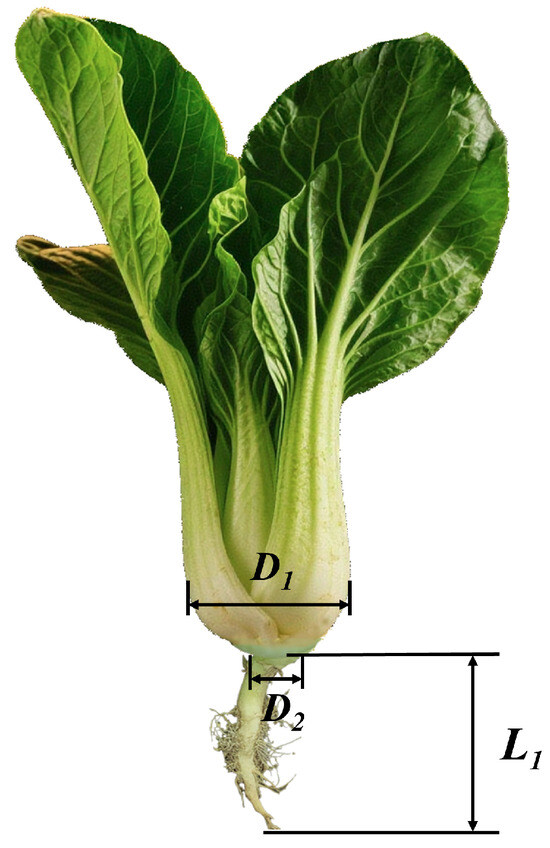

As shown in Figure 5 and Table 1, the average petiole diameter of Shanghai Green is 36.75 mm, the average rhizome diameter is 21.75 mm, and the average root length is 53.35 mm. During the root lifting process, the contact position between the Shanghai Green plant and the root lifting device is critical in ensuring successful extraction. Accordingly, the front end of the root lifting device must be positioned lower than the base of the plant’s stem leaves. Furthermore, the spacing between the two sides of the root lifting device must be greater than the diameter of the Shanghai Green rhizome but less than that of the petiole. Therefore, the spacing between the root lifting devices was set to 25 mm. Based on the root length, the height of the root lifting device was determined to be 50 mm. Since a greater working depth of the root lifting device leads to increased soil resistance and, consequently, higher power consumption, minimizing the device’s penetration depth can help reduce the overall energy use of the soil loosening and root lifting operations.

Figure 5.

Shanghai Green geometric parameter diagram. D1: average petiole diameter of Shanghai Green; D2: average rhizome diameter of Shanghai Green; L1: average root length of Shanghai Green.

Table 1.

Geometric parameters of Shanghai Green.

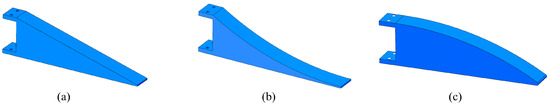

The sloped surface of the root lifting device is a critical area where the device makes contact with the Shanghai Green plant and carries out the root lifting operation. Optimizing the shape of this sloped surface can reduce the pulling force required to extract Shanghai Green and enhance the overall efficiency of the pulling process. During operation, due to the unevenness of the actual field surface where Shanghai Green is cultivated, the root lifting device frequently enters the soil, making it essential to take into account the forward resistance encountered as the device penetrates the soil. Consequently, research on the root lifting device primarily focuses on the design of the sloped surface. As shown in Figure 6, common sloped surface configurations include a straight ramp, a concave surface, and a convex surface.

Figure 6.

Three different types of root lifting devices: (a) ramp type; (b) concave type; (c) convex type.

3. Coupling Simulation Experiment of Soil Loosening and Root Lifting Device

3.1. Experimental Factors and Methods

3.1.1. Determination of Experimental Parameters

This study adopts a two-stage simulation strategy. In the first stage, single-factor experiments are conducted to minimize both the pulling force and forward resistance, thereby selecting the optimal root lifting device configuration from among the sloped, concave, and convex designs. In the second stage, response surface methodology (RSM) is employed to optimize the key operational parameters of the selected configuration. According to existing research, the operating speed of leafy vegetable harvesters generally ranges from 0.1 m/s to 0.18 m/s. Therefore, five speed gradient parameters are selected for this study: 0.1 m/s, 0.12 m/s, 0.14 m/s, 0.16 m/s, and 0.18 m/s. Considering that the root length of Shanghai Green varies between 47 mm and 66 mm, three soil penetration depth gradients for the loosening shovel are determined: 25 mm, 30 mm, and 35 mm. Additionally, three loosening frequency gradients are established: 0.5 Hz, 1.5 Hz, and 2.5 Hz. For the simulation tests, the maximum pulling force experienced by the Shanghai Green and the forward resistance of the harvester during operation are selected as the output variables.

3.1.2. Experimental Methods

We adopt a two-step experimental strategy. Initially, single-factor experiments are conducted to identify the primary effects of key variables. Subsequently, response surface methodology (RSM) is employed to analyze interactive effects and determine the optimal parameter combination. The rationale for this two-stage experimental strategy is to first establish a foundational understanding of the main effects before proceeding to a more complex optimization. The initial single-factor experiments serve as a crucial preliminary screening step. By systematically varying one parameter at a time (walking speed and penetration depth), we can effectively determine the influential range for each factor and identify the most promising basic device geometry (concave, ramp, or convex) based on its individual performance. This approach provides clear, interpretable data on the direct impact of each variable and establishes a viable operating window. Building upon these initial findings, the subsequent response surface methodology is employed to investigate the more complex interactive effects between multiple factors and to mathematically model the system for precise optimization. This sequential design ensures that the more resource-intensive RSM is focused on the most relevant parameter ranges, thereby enhancing the efficiency and robustness of the overall optimization process.

- (1)

- Single-factor experimental method

For the three types of root lifting devices (ramp, concave, and convex), the effects of two factors—walking speed and the depth of the root lifting device—were analyzed, with each factor examined at five levels. The combination of three device types and two factors resulted in six experimental groups, and each group underwent five tests, yielding a total of thirty tests [39].

The levels of the experimental factors are presented in Table 2 and Table 3. By systematically varying the same parameters across the three device shapes, a comprehensive comparison was conducted to identify which external shape of the root lifting device required the lowest pull-out force and forward resistance.

Table 2.

Level table of walking speed test parameters.

Table 3.

Level table of embedded depth test parameters.

- (2)

- Interactive factor response surface experiment method

To investigate the interactions among the harvester walking speed, the shape of the root lifting device, the depth of soil loosening shovel penetration, and vibration frequency on the performance of the soil loosening and root lifting device, a comprehensive experimental study was conducted. The key performance indicator considered was the Shanghai Green pulling force. A quadratic multiple regression equation was established for each test factor to facilitate the analysis. Design-Expert 13 software was utilized to design a four-factor, single-level, quadratic orthogonal rotation combination experimental plan. Based on the experimental data, the optimal structural and operational parameter combinations for the soil loosening and root lifting device were determined. Additionally, significance analysis was performed to identify the main factors influencing each performance indicator.

- (3)

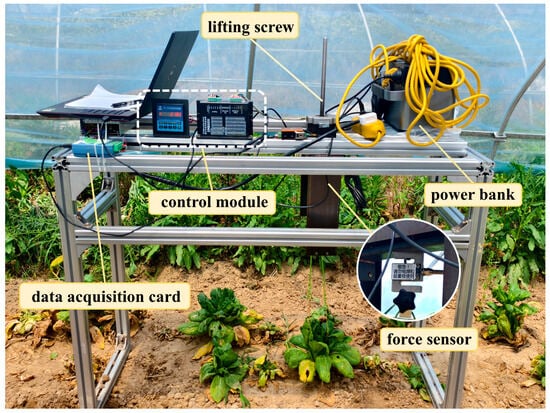

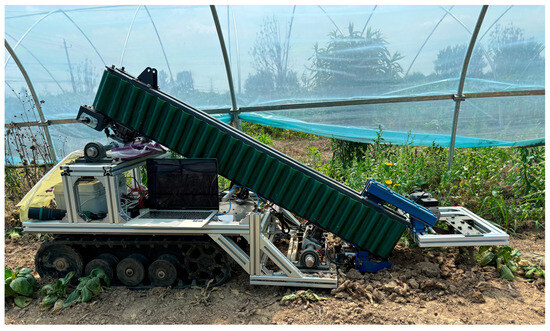

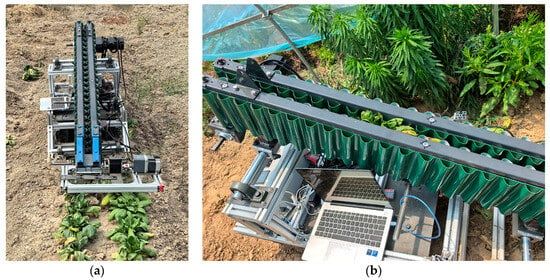

- Purpose and design of the field test

To verify the accuracy of the simulation results, a Shanghai Green harvesting test was conducted in Bailu Town, Dantu District, Zhenjiang City, China. The Shanghai Green vegetable field is depicted in Figure 7. Based on the results of the orthogonal simulation tests, the root lifting device—including a ramp-type root lifting device—was structurally optimized and fabricated before being mounted on a self-developed single-row leafy vegetable harvester, as shown in Figure 8, for use in the field test. During the test, the consistency of the pulling effect with the simulation results was verified by varying the machine’s forward speed, soil loosening shovel depth, and vibration frequency. Additionally, the damage rate and harvest success rate of Shanghai Green after the operation were evaluated.

Figure 7.

Shanghai Green vegetable field during harvest season.

Figure 8.

Shanghai Green single-row harvester.

The test apparatus comprises a single-row Shanghai Green harvester, a root lifting device, a JN-DN1 torque sensor, an LZ-DZL1 three-dimensional force sensor, a data acquisition card, and a computer. The flange plate at the upper end of the three-dimensional force sensor is secured to the machine frame by a mounting plate, while the lower end is attached to the root lifting device through another mounting plate. The sensor is connected to a transmitter, with each transmitter outputting three voltage signals corresponding to the forces in the x, y, and z directions. The six signal lines generated by the two three-dimensional force sensors are connected to ports AIN1 to AIN6 on the data acquisition card. The shafts on both sides of the torque sensor are linked to the motor via a coupling at one end and to an eccentric wheel at the other end. Signal output is achieved using a 24 V-powered transmitter, which provides two voltage signals representing torque and rotational speed. These two signal lines from the torque sensor are connected to ports AIN7 and AIN8 of the data acquisition card. The data acquisition card transmits the collected voltage signals to the computer for processing. The sensor arrangement is illustrated in Figure 9 and Figure 10.

Figure 9.

Schematic diagram of the installation position of the three-dimensional force sensor.

Figure 10.

Schematic diagram of torque sensor installation location.

This harvesting test was designed to verify the effects of different root lifting device depths and tilling frequencies on harvesting performance at a fixed forward speed. During the test, the forward speed of the harvester was set to 0.1 m/s, 0.14 m/s, and 0.18 m/s. The depth of the root lifting device was set to 25 mm, 30 mm, and 35 mm by adjusting its position. The tilling motor speed was modified via the display panel to achieve three tilling frequencies: 0.5 Hz, 1.5 Hz, and 2.5 Hz. Data collected from the three-dimensional force sensor and the torque sensor following each harvesting operation were processed and calculated, and error analysis was performed by comparing the experimental results to the coupled simulation data.

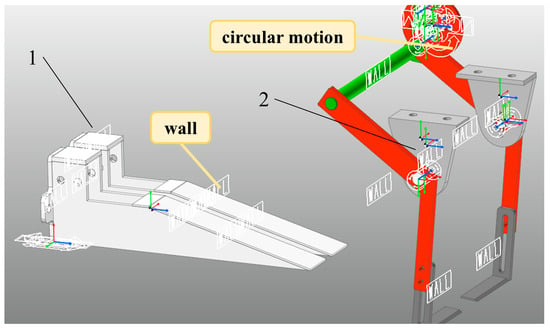

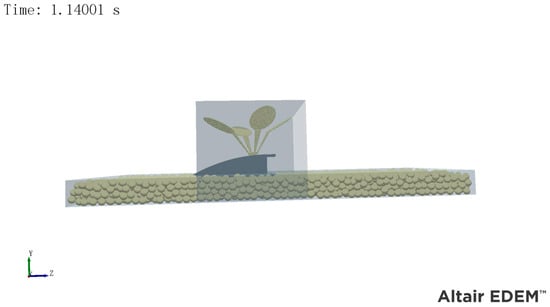

3.2. Motion Model of Root Lifting Device

The three-dimensional model of the root lifting device was imported into RecurDyn (Version 2023) software, where relevant constraints and drivers were applied, as illustrated in Figure 11.

Figure 11.

Constraints and drive of root lifting device. 1. Root lifting mechanism. 2. Soil loosening mechanism.

The following motion constraints were added to the components of the root lifting device: (1) a RevJoint (revolute pair) between the eccentric wheel and the ground; (2) a fixed joint between the eccentric wheel and the short shaft; (3) a RevJoint between the short shaft and connecting rod 1; (4) a fixed joint between the long shaft and connecting rod 2; (5) a RevJoint between connecting rod 2 and connecting rod 1; (6) a fixed joint between the frame and the ground; and (7) a RevJoint between connecting rod 2 and the frame. Motion was applied to the rotating joint between the eccentric wheel and the ground and set to circular motion.

Additionally, uniform linear motion was assigned to the root lifting device. Subsequently, a separate dynamic simulation was conducted to verify the correctness of the dynamic model of the root lifting device. Upon successful simulation, a wall was added to all necessary components that required coupling within the root lifting device, following the designated sequence, and the components were exported in the wall format.

3.3. Establishment of Discrete Element Models

- (1)

- Establishment of soil particle and Shanghai Green particle models

In Bailu Town, Dantu District, Zhenjiang City, China, the soil compaction and moisture content in the field cultivating mature Shanghai Green were measured during its maturity stage, and the results are presented in Table 4. For the purpose of simulation, the soil model was simplified by representing the soil as spherical particles with sizes corresponding to those observed under actual field conditions.

Table 4.

Soil compactness and moisture content during the mature stage of Shanghai Green cultivation.

Density, elastic modulus, and Poisson’s ratio are the fundamental parameters required for a discrete element method (DEM)-based simulation of Shanghai Green during harvesting. The density reflects the mass distribution and inertial properties of the plant structure. The elastic modulus determines the mechanical response of Shanghai Green to applied stress, while Poisson’s ratio quantifies the extent of lateral deformation under tensile loading.

Together, these parameters characterize the physical and mechanical properties of Shanghai Green. As shown in Table 5, the material properties of Shanghai Green particles were established based on existing research and related sources [40].

Table 5.

Table of discrete element model parameters for Shanghai Green.

- (2)

- Setting of Shanghai Qing model and parameters

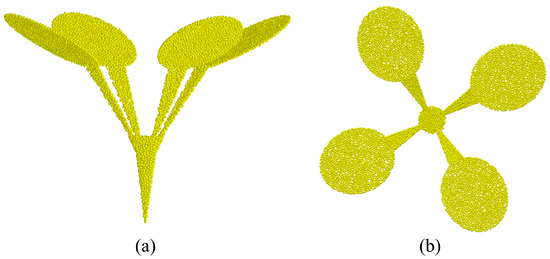

During the soil loosening and root lifting process, the primary plant component involved is the root of Shanghai Green. Although Shanghai Green possesses numerous lateral roots and root hairs, these structures are brittle, prone to breakage, and have minimal impact on the overall extraction process. Therefore, in this study, the stem and leaves of Shanghai Green were simplified, and the root model was represented as a circular cone. According to the collected data, the length of the main root of mature Shanghai Green ranges from 43 mm to 66 mm, with an average length of 52.25 mm. For modeling purposes, the root was approximated as a circular cone with an upper diameter of 15 mm, a lower diameter of 2 mm, and a length of 52 mm.

The “virtual object–physical entity combination method” was employed to establish a discrete element model of Shanghai Green using EDEM (EDEM™ discrete element method, Version 2023) software. First, the geometric model of Shanghai Green was imported into EDEM and set to virtual mode, allowing particles to pass through it without obstruction. Next, a bounding box was created to completely enclose the geometric model, and a particle factory was used to generate Shanghai Green particles within this space. Once the box was fully filled with particles, the simulation deck was exported.

In the following step, the exported file was opened, the bounding box was deleted, and the status of the Shanghai Green geometric model was switched to solid. The simulation was then restarted, resulting in a filled Shanghai Green model. The geometric coordinates of all particles were exported and subsequently used to directly reconstruct the Shanghai Green model in further simulations, as illustrated in Figure 12. To position the Shanghai Green model appropriately, a particle factory was utilized; when the model reached the desired location, the simulation was paused, the simulation deck was exported again, and the simulation time was reset to zero.

Figure 12.

Shanghai Green’s discrete element model: (a) front view of the discrete element model of Shanghai Green; (b) top view of the discrete element model of Shanghai Green.

- (3)

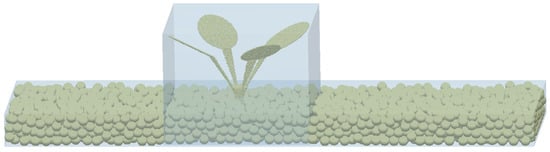

- Establishment and parameterization of the soil trench model

As shown in Figure 13, to avoid model overlap, the simulation file containing the Shanghai Green model was opened. A soil trough was constructed with dimensions of 800 mm in length, 240 mm in width, and 60 mm in height. The soil particle properties were defined, and a particle factory was used to fill the soil trough with soil particles. The Bonding V2 model was selected to represent the bonding interactions both between the soil particles and between the Shanghai Green particles. After configuring the necessary simulation parameters in the Creator (pre-processing) and Simulator modules, the soil trough was filled completely with particles. Finally, in EDEM post-processing, the simulation deck file was exported, and the simulation time was reset to zero to prepare for subsequent analyses.

Figure 13.

Single Shanghai Green soil trough model.

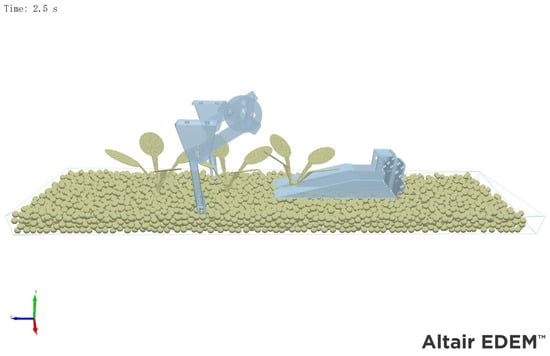

3.4. Coupling Simulation

All components of the geometric model were carefully inspected to ensure that the designated movable components functioned correctly. Subsequently, the coupling interface was activated to set EDEM into coupling mode. The “connect” feature was then initiated in RecurDyn, and the simulation step size in RecurDyn was set as an integer multiple of that in EDEM to ensure synchronization. Once these preparations were complete, the co-simulation was started. The simulation process is illustrated in Figure 14. During the simulation, the root lifting device operated in the soil in the vicinity of the Shanghai Green root and then extracted the Shanghai Green plant from the soil.

Figure 14.

Coupling simulation of soil loosening and root lifting device.

Using the EDEM post-processing module, the forward resistance of the root lifting device and the extraction force exerted on Shanghai Green under stable operating conditions within the virtual soil trough were continuously recorded. Based on these data, the power consumption of the root lifting device was calculated. All other parameters were maintained constant throughout the tests, and the average values obtained from data processing were used as the final test results.

4. Result and Discussion

4.1. Analysis of Simulation Results

- (1)

- Selection of root lifting device

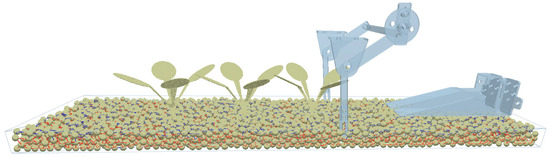

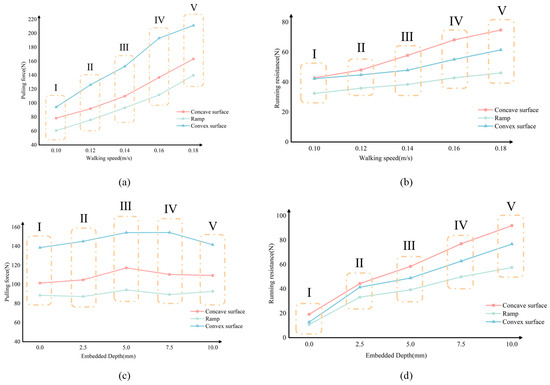

Initially, a single-factor experimental approach was adopted to assess two experimental variables: walking speed and the soil penetration depth of the root lifting device. Coupled simulation tests were then performed for three types of root lifting devices, while all other experimental parameters were held constant. The simulation tests are shown in Figure 15.

Figure 15.

Single-factor experiment on the outline of the root lifting device.

The maximum values of the pulling force of the root lifting device and the forward resistance of the root lifting device on Shanghai Green were obtained, as shown in Table 6 and Table 7.

Table 6.

Experimental data at various travelling speeds.

Table 7.

Experimental data at various depths of entry of the root lifting device.

For the three different root lifting devices, the pulling force required to extract Shanghai Green at various walking speeds and the resistance encountered when both sides of the device operate simultaneously are shown in Figure 16a,b. The results indicate that, as the walking speed increased, both the pulling force necessary to lift Shanghai Green and the soil resistance experienced by the root lifting device also increased. Five lifting experiments were conducted for each of the three root lifting device shapes. The results demonstrate that, across all tested speeds, the ramp-type root lifting device consistently required the lowest pulling force and forward resistance to extract Shanghai Green.

Figure 16.

Effects of different factors on the pulling force and resistance of root lifting device: (a) effect of single-factor walking speed on the pulling force of Shanghai Green; (b) effect of single-factor walking speed on the running resistance of root lifting device; (c) effect of single-factor embedded depth on the pulling force of Shanghai Green; (d) effect of single-factor embedded depth on the running resistance of root lifting device. I–V represent five groups of comparative tests involving three different geometries of the root-lifting device under varying experimental conditions.

To further examine the significance of the root lifting device penetration depth on both forward resistance and pulling force and to validate the conclusion that the ramp-type root lifting mechanism exhibits superior performance in terms of reduced pulling force and resistance, a two-factor response surface analysis should be conducted.

For the three different shapes of root lifting devices, the pulling force required to extract Shanghai Green at various soil penetration depths and the changes in resistance encountered when both sides of the root lifting device operate simultaneously are shown in Figure 16c,d. The results indicate that the pulling force required for Shanghai Green is not significantly affected by the soil penetration depth of the root lifting device. However, the soil resistance encountered by the root lifting device increases as the penetration depth increases. This is primarily because deeper penetration increases the contact area between the root lifting device tip and the soil, leading to greater friction. The experimental results also show that, within the 0–10 mm depth range, the ramp-type root lifting device requires the lowest pulling force and forward resistance to extract Shanghai Green.

To further verify the significance of the effect of penetration depth on forward resistance and to confirm whether the ramp-type root lifting mechanism indeed exhibits lower resistance, a two-factor response surface analysis is required.

For all three configurations, the pulling force increases with advancing speed. This is mainly because higher speeds lead to an increased soil strain rate, thereby enhancing the soil’s shear strength and resistance to displacement. Under all speed conditions, the sloped device consistently requires the lowest pulling force, which may be attributed to its smooth and gradual lifting process that minimizes abrupt soil disturbance.

- (2)

- Analysis of the influence of interaction factors

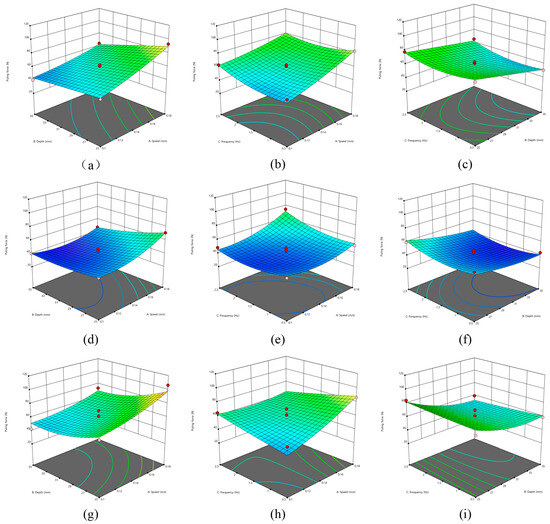

The simulation experiment of the interaction factor response surface is illustrated in Figure 17. Simulation data were recorded using Design-Expert software. The detailed experimental design and corresponding results are presented in Table 8.

Figure 17.

Soil loosening and root lifting device coupled simulation with Shanghai Green and soil.

Table 8.

Results of the interaction factor response surface experiment.

The pulling force required by the root lifting device to extract Shanghai Green ranged from 35.64 N to 106.36 N. This indicates that factors such as the forward speed of the machine, the depth of the soil loosening shovel, and the soil loosening frequency all significantly affect the efficiency and effectiveness of the extraction process. To gain deeper insights into the influence of these factors on Shanghai Green extraction and to identify the optimal combination of parameters, regression analysis and analysis of variance (ANOVA) were performed on the test data using Design Expert(Version 10) software. The results of these analyses, including those of the response surface analysis, are presented in Table 9 and Figure 18.

Table 9.

Variance analysis of regression model.

Figure 18.

Response surfaces of different interacting factors to evaluation indicators. (a) Response surface of the pulling force of the concave-type root lifting device as affected by soil loosening shovel depth and forward speed. (b) Response surface of the pulling force of the concave-type root lifting device as affected by soil loosening frequency and forward speed. (c) Response surface of the pulling force of the concave-type root lifting device as affected by soil loosening frequency and shovel depth. (d) Response surface of the pulling force of the ramp-type root lifting device as affected by soil loosening shovel depth and forward speed. (e) Response surface of the pulling force of the ramp-type root lifting device as affected by soil loosening frequency and forward speed. (f) Response surface of the pulling force of the ramp-type root lifting device as affected by soil loosening frequency and shovel depth. (g) Response surface of the pulling force of the convex-type root lifting device as affected by soil loosening shovel depth and forward speed. (h) Response surface of the pulling force of the convex-type root lifting device as affected by soil loosening frequency and forward speed. (i) Response surface of the pulling force of the convex-type root lifting device as affected by soil loosening frequency and shovel depth.

4.2. Optimization of Test Result Targets

The pulling force required to extract Shanghai Green and the forward resistance of the machine are critical indicators for assessing the effectiveness of soil loosening and root lifting operations. To determine the optimal combination of operational parameters within the given constraints and to provide performance benchmarks for further testing of the soil loosening and root lifting device, parameter optimization was performed using Design-Expert software. The optimal settings identified were a machine walking speed of 0.137 m/s, a loosening shovel penetration depth of 34.50 mm, and a vibration frequency of 1.34 Hz, under which the Shanghai Green pulling force was 35.41 N, and the pull-out effect for Shanghai Green was maximized.

4.3. Field Test

Field harvesting tests were conducted to validate the simulation test plan for the 17 groups of the ramp-type root lifting device. The distance travelled to collect data for each field experiment was 4 m. Multiple repeated tests were performed in ascending order according to the test numbers in Table 8. The average values of the collected data after each test were calculated and compared with the simulation results.

Data processing and calculation were carried out for evaluation indicators related to the harvesting effectiveness of Shanghai Green following the harvesting operations. The field harvesting process during the test is illustrated in Figure 19.

Figure 19.

Harvesting process of the field test. (a) Front view of the whole machine. (b) Operation diagram of the clamping and conveying device.

The data collected from the field tests are presented in Table 10. Comparative analysis revealed that the results from the field tests and the simulation tests exhibited the same general trends. Specifically, when the machine’s forward speed was 0.18 m/s, the soil loosening shovel depth was 25 mm, and the vibration frequency was 1.5 Hz, the maximum observed difference in the Shanghai Green pulling force was 74.21 N, representing a deviation of 4.61% from the simulated value. All other measurement errors were below 5%.

Table 10.

Results of field harvesting tests.

A statistical evaluation of model performance indicated a high level of agreement between the simulated and measured field data. The coefficient of determination (R2) was calculated as 0.981, suggesting that the simulation results explained 98.1% of the variability observed in the experimental measurements. The root mean square error (RMSE) and mean absolute error (MAE) were 1.528 and 1.552, respectively, reflecting a low overall prediction error. Variance analysis further demonstrated that the residual sum of squares (SSE = 39.62) was substantially smaller than the total sum of squares (SST = 2092.07), indicating that the vast majority of the variation in the observed values was captured by the simulation model. These results confirm that the developed model possesses a strong predictive capability and reliability for application in agricultural engineering simulations.

The primary source of error was attributed to variations in the physical properties of the soil during actual operation, such as those caused by rotary tillage and ridge formation, which result in discrepancies between actual parameters and simulated values. Nonetheless, the resistance trends observed in both the simulation and field tests were largely consistent, and the deviations remained within the acceptable error range, thereby validating the accuracy of the Shanghai Green soil loosening and root extraction model.

4.4. Discussion

This research makes full use of the EDEM-RecurDyn co-simulation technique to guide the improvement and real-world testing of a soil loosening and root lifting mechanism for the mechanized harvesting of Shanghai Green (Brassica rapa subsp. chinensis). The outcomes highlight how integrating the discrete element method (DEM) with multi-body dynamics (MBD) can bring new insight and accuracy to studying the complicated soil–machine–plant mechanical interactions found in root vegetable harvesting.

In this study, Application Programming Interface (API) tools were employed to automate simulation workflows and improve modeling reliability. The API environment enabled the batch execution of parameter sweeps and design of experiments (DoE) without manual intervention, ensuring consistent procedures and reducing human error. This framework also facilitated the integration of iterative optimization methods, such as gradient descent, to refine model parameters efficiently based on the results of preceding runs. As a result, the modeling process in our agricultural engineering simulations became more adaptive, robust, and computationally efficient.

By comparing simulation and physical test results—especially for outcomes like traction resistance and root lifting performance—this work shows that this co-simulation method can reliably predict the interactions between soil, equipment, and crops. It also confirms that the simulation accurately reflects how essential operational settings (depth, angle, and travel speed) affect core performance metrics, which makes it a valuable reference for design optimization.

Through multi-criterion optimization, focusing specifically on reducing traction forces and root lifting effort, this project identified parameter settings that bring substantial real-world benefits. The optimal mix of depth, angle, and speed resulted in clear gains over traditional set-ups. Amidst the usual challenges of mechanical Shanghai Green harvest—such as lowering energy use, reducing soil resistance, and curbing plant damage—these improvements are significant. The observed decreases in resistance, supported by both simulation and practical results, are particularly relevant for developing compact harvesters and achieving better energy efficiency. Moreover, decreasing the required lifting force noticeably helps to minimize bruising, breakage, and high rates of stubble, as post-harvest assessments confirm.

The optimized device developed here shows real promise for wider use in leafy vegetable harvesting technology. Historically, issues like leftover stubble and crop injury have hindered mechanization from protecting product value and farm productivity [see Section 1]. The findings indicate that carefully controlled lifting trajectories and meticulously managed force, tailored according to soil mechanics, could greatly reduce such obstacles. Furthermore, field-measured compaction data underscore the importance of adaptable devices that can perform well under different soil conditions. Although the mechanization of leafy vegetable harvest is now being explored in some studies [17,19,20,30], there remains limited work that digs deep into the soil loosening and root extraction phase for crops like Shanghai Green, especially that making use of advanced co-simulation tools. Most existing research focuses on seeding, transplanting, or other root crop harvest methods, leaving a noticeable gap that the present study seeks to address in the context of intensive vegetable production.

Although the results are encouraging, several caveats must be acknowledged. One limitation arises from the simplification needed in modeling the Shanghai Green plant and surrounding soil: even with calibration, such discrete element models inevitably smooth over plant and soil complexity. Refining the digital modeling potentially by including more flexible structures or using bonded particle methods could make future simulations more realistic in terms of root detachment and damage. Also, soil moisture and density were only examined under specific conditions here; operational performance across broader field and seasonal variation should be studied further. Another point for further investigation is the influence of the subsequent transport and handling stages after root lifting, which likely impact overall crop integrity and thus deserve system-level consideration. Finally, while this study’s validation centered on force measurements, longer-term tests and broader soil conditions, including those with higher moisture levels, remain important for confirming the robustness and everyday practicality of the optimized design.

5. Conclusions

- (1)

- According to the requirements for Shanghai Green harvesting, a soil loosening and root lifting device was designed to address the serious stubble issues associated with current mechanized harvesting methods. Through an analysis of the device’s structure and operating principles, a dynamic model was constructed to verify its feasibility. Comparative analyses of the pulling force and forward resistance experienced by leafy vegetables during harvesting were conducted under varying machine travel speeds and root lifting device penetration depths, using three different root lifting device designs. As a result, the root lifting device, as a key component, was optimized.

- (2)

- The coupled RecurDyn-EDEM simulation method was employed to examine the influence of three key experimental factors—machine walking speed, root lifting device penetration depth, and root lifting frequency—on the harvesting efficiency of Shanghai Green. Test factors and levels were appropriately defined, and a quadratic orthogonal rotation center combination test was designed. A regression model was established, and response surface and variance analyses were performed. The results indicate that, in terms of impact on harvesting efficiency, the order from greatest to least was walking speed, root lifting device shape, loosening shovel penetration depth, and vibration frequency. Interactions between these factors were also observed. Optimization of the regression equation obtained from the orthogonal test determined that the optimal conditions were as follows: a root lifting device with a ramp shape, a machine walking speed of 0.137 m/s, a loosening shovel penetration depth of 34.50 mm, and a vibration frequency of 1.34 Hz, under which the Shanghai Green pulling force was 35.41 N, yielding optimal extraction performance.

- (3)

- Based on the simulation results, a root extraction device for Shanghai Green was developed in this study, and the simulation findings were validated through field harvesting tests. The field tests confirmed the accuracy of the simulation predictions, with a prediction error of less than 5%. Ultimately, the prototype demonstrated a damage rate of 7.5% and a posture qualification rate of 87.5% for harvested Shanghai Green, thereby confirming the effectiveness of the device design and the reliability of the research methodology.

Author Contributions

Conceptualization, Q.D. and Z.Z.; methodology, Z.Z. and Q.D.; software, Z.Z. and Y.F.; validation, Q.Z.; investigation, Q.D., Q.Z., S.Z., and Y.F.; resources, Z.Z.; data curation, Q.D. and Q.Z.; writing—original draft preparation, Q.D.; writing—review and editing, Z.Z. and Q.D.; visualization, Q.D.; supervision, Z.Z. and H.M.; project administration, Z.Z.; funding acquisition, Z.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the earmarked fund for the China Agriculture Research System (CARS-23-D03), the General Program of Basic Science (Natural Science) Research in Higher Education Institutions of Jiangsu Province (23KJB210004), and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD-2023-87).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liao, Y.; Chen, L.; Pan, S.; He, J.; Yang, W.; Wu, Y. Status and Development of Mechanized Harvesting Technology and Equipment for Leaf Vegetables. Acta Agric. Jiangxi 2019, 31, 77–81. [Google Scholar] [CrossRef]

- Lu, H.; Lv, J.; Jin, W.; Zhang, P.; Wu, Z.; Chen, Y. The Current Situation of the Mechanized Harvesting Technology Development of Leaf Vegetable in China. J. Chin. Agric. Machanization 2018, 40, 261–268. [Google Scholar] [CrossRef]

- Wang, J.; Du, D.; Hu, J.; Zhu, J. Vegetable Mechanized Harvesting Technology and Its Development. Trans. Chin. Soc. Agric. Mach. 2014, 45, 81–87. [Google Scholar]

- Liang, S.; Liu, L.; Liu, F.; Cui, W.; Zhang, X.; Gao, J. Development status of mechanized harvesting technology and equipment for leafy vegetables. J. Chin. Agric. Mech. 2025, 46, 346–352. [Google Scholar] [CrossRef]

- Zuo, Z.; Gao, S.; Peng, H.; Xue, Y.; Han, L.; Ma, G.; Mao, H. Lightweight Detection of Broccoli Heads in Complex Field Environments Based on LBDC-YOLO. Agronomy 2024, 14, 2359. [Google Scholar] [CrossRef]

- Miao, P.; Zuo, Z.; Mao, H.; Han, L.; Wang, T.; Wei, F.; Shi, X. Research on Automatic Alignment Control System of Electric Leaf Vegetable Harvester. J. Agric. Mech. Res. 2022, 44, 84–89. [Google Scholar] [CrossRef]

- Li, H.; Jang, T.; Guan, Z.; Mu, S.; Wu, C.; Zhang, M. Design and Experiment of Row-following Rapeseed Stalks Orderly Harvester. Trans. Chin. Soc. Agric. Mach. 2023, 54, 92–101. [Google Scholar]

- Zhang, T.; Li, Y.; Song, S.; Pang, Y.; Shao, W.; Tang, X. Design and Experiment of Tumorous Stem Mustard Harvester Based on Flexible Gripping. Trans. Chin. Soc. Agric. Mach. 2020, 51, 162–169+190. [Google Scholar]

- Wu, W.; Hu, L.; Wang, G.; Wang, Y.; Huang, Y.; Xu, J. Design and simulation optimization of cutting mechanism of electric leaf vegetable multifunctional harvester. J. Chin. Agric. Machanization 2023, 44, 7–16+24. [Google Scholar] [CrossRef]

- Peng, H.; Zuo, Z.; Ma, G.; Han, L.; Liu, Z.; Mao, H. Design and experiment of a ridge-surface based cutting height active adjustment system for a leafy vegetable harvester. Biosyst. Eng. 2025, 257, 104196. [Google Scholar] [CrossRef]

- Peng, H.; Mao, H.; Taha, M.F.; Han, L.; Zuo, Z.; Ma, G. Effects of structure and soil parameters on the detection performance of a contact soil surface height detection device. Comput. Electron. Agric. 2025, 234, 110242. [Google Scholar] [CrossRef]

- Sergii Hrushetskyi, I.C. Review of the current state of mechanization of the potato harvesting process. Int. Sci. J. Eng. Agric. 2024, 3, 47–66. [Google Scholar]

- Zhen, W.; Feng, J.; Dong, Z.; Li, L.; He, Z.; Deng, C.; Xia, H. Centering grabbing with variable orientation envelope for hydroponic leafy vegetables cultivated in pipeline. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 46–54. [Google Scholar]

- Liu, Z.; Wang, E.; Mao, H.; Zuo, Z.; Peng, H.; Zhao, M.; Yu, Y.; Li, Z. Design and Testing of an Electric Side-Mounted Cabbage Harvester. Agriculture 2024, 14, 1741. [Google Scholar] [CrossRef]

- Liu, Z.; Mao, H.; Wang, Y.; Jiang, T.; Zuo, Z.; Chai, J.; Liu, C.; Shen, L.; Wei, S.; Ma, G. Design and Experiment of a Universal Harvesting Platform for Cabbage and Chinese Cabbage. Agriculture 2025, 15, 935. [Google Scholar] [CrossRef]

- Jin, X.; Du, X.; Wang, S.; Ji, J.; Dong, X.; Wang, D. Design and Experiment of Stems Cutting Device for Carrot Harvester. Trans. Chin. Soc. Agric. Mach. 2016, 47, 82–89. [Google Scholar]

- Zhou, G.; Zhang, J.; Wang, H.; Gu, X.; Yang, J.; Liu, L. Radish Harvester Design and Finite Element Analysis of Digging Shovel. J. Agric. Mech. Res. 2016, 38, 94–98. [Google Scholar] [CrossRef]

- Du, D.; Fei, G.; Wang, J.; Huang, J.; You, X. Development and experiment of self-propelled cabbage harvester. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2015, 31, 16–23. [Google Scholar]

- Zou, L. Research on the Key Technologies of Low Damage and Orderly Harvest for Spinach with Root. Ph.D. Dissertation, Shandong Agricultural University, Taian, China, 2022. [Google Scholar]

- Zou, L.; Yuan, J.; Liu, X.; Li, J.; Zhang, P.; Niu, Z. Burgers viscoelastic model-based variable stiffness design of compliant clamping mechanism for leafy greens harvesting. Biosyst. Eng. 2021, 208, 1–15. [Google Scholar] [CrossRef]

- Ou, M.; Wang, G.; Lu, Y.; Zhang, Z.; Pan, H.; Jia, W.; Dong, X. Structure Optimization and Performance Simulation of a Double-Disc Fertilizer Spreader Based on EDEM-CFD. Agronomy 2025, 15, 1025. [Google Scholar] [CrossRef]

- Yuan, H.; Liang, S.; Wang, J.; Lu, Y. Numerical Simulation and Analysis of Vibrating Rice Filling Based on EDEM Software. Agriculture 2022, 12, 2013. [Google Scholar] [CrossRef]

- Hou, J.; Liu, L.; Zhao, G.; Li, Y.; Xin, L.; Hou, R. Optimization and Test of Garlic Variable Stiffness Flexible Clamping Conveyor Device Based on EDEM-MFBD. Trans. Chin. Soc. Agric. Mach. 2025, 56, 362–373. [Google Scholar]

- Hou, J.; Zhang, E.; Zhang, K.; Li, Y. Optimization Design and Test of Seedling Picking and Throwing Device of Plug Seeding Transplanter Based on DEM—MFBD. Trans. Chin. Soc. Agric. Mach. 2023, 54, 46–57+87. [Google Scholar]

- Hu, J.; Pan, J.; Chen, F.; Yue, R.; Yao, M.; Li, J. Simulation Optimization and Experiment of Finger-clamping Seedling Picking Claw Based on EDEM RecurDyn. Trans. Chin. Soc. Agric. Mach. 2022, 53, 75–85+301. [Google Scholar]

- Li, H.; Gao, J.; Wang, Y.; Zhang, Q.; Lv, D.; Fu, J. Design and Test of Chain-spoon Type Precision Seed-metering Device for Garlic Based on DEM-MBD Coupling. Trans. Chin. Soc. Agric. Mach. 2024, 55, 147–159. [Google Scholar]

- Li, W.; Zhao, W.; Zhu, H.; Zhai, L.; He, X. Design and Experiment of Variable Pitch Potato Grading Devices Based on DEM -MBD Coupling. Trans. Chin. Soc. Agric. Mach. 2025, 56, 94–104. [Google Scholar]

- Yu, Y.; Li, P.; Lai, Q.; Tan, Y.; Zhao, Q.; Chen, Y. Simulation and Experiment of Coffea Picking Process Based on DEM-MBD Coupling. Trans. Chin. Soc. Agric. Mach. 2024, 55, 157–167. [Google Scholar]

- Zhang, H.; Zhang, C.; Li, Z.; Ding, L.; Zhu, C.; Zhang, J. Simulation Analysis and Optimization of Vibration Characteristics of Corn Finger Clip Seeding Device Based on EDEM-RecurDyn Coupling. Trans. Chin. Soc. Agric. Mach. 2023, 54, 36–46. [Google Scholar]

- Yang, X.; Zhang, Y.; Gong, L.; Zhou, H.; Peng, X.; Wang, J. Design and Experiment of Spinach Harvester with Root Cutting and Gathering under Soil. Trans. Chin. Soc. Agric. Mach. 2025, 56, 384–393. [Google Scholar]

- Gao, G.; Xie, H.; Wang, T. EDEM simulation and experiment of pullout force of protected vegetable harvester. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 24–31. [Google Scholar]

- Wei, M.; Hu, J.; Liu, W.; Zeng, T.; Tan, R.; Zhang, Y.; Xu, H. Optimization of Hole Punching Mechanism for Strawberry Transplanter Based on RecurDyn-EDEM. J. Chin. Agric. Machanization 2025, 47, 146–154. [Google Scholar] [CrossRef]

- Jin, Y.; Hu, J.; Lv, J.; Yao, M.; Liu, W.; Zeng, T. Design and Experiment of Multi-blade Duck Bill Planting Mechanism for Automatic Vegetable Transplanter. Trans. Chin. Soc. Agric. Mach. 2024, 55, 217–229. [Google Scholar]

- Yue, R.; Yao, M.; Zhang, T.; Shi, J.; Zhou, J.; Hu, J. Design and Experiment of Dual-Row Seedling Pick-Up Device for High-Speed Automatic Transplanting Machine. Agriculture 2024, 14, 942. [Google Scholar] [CrossRef]

- Xu, G.; Fang, H.; Song, Y.; Du, W. Optimal Design and Analysis of Cavitating Law for Well-Cellar Cavitating Mechanism Based on MBD-DEM Bidirectional Coupling Model. Agriculture 2023, 13, 142. [Google Scholar] [CrossRef]

- Ji, X.; Yan, J.; Xie, S. Design and Experimental Testing of Potato Drip Irrigation Tape Recycling Machine. Agriculture 2024, 14, 1432. [Google Scholar] [CrossRef]

- Liu, S.; Yang, X.; Zhang, Z.; Xu, J.; Zhao, P.; Tian, S.; Wei, L.; Ning, X. Design and Simulation of Chinese Cabbage Harvester. Agriculture 2025, 15, 831. [Google Scholar] [CrossRef]

- Li, X.; Salem, A.; Liu, Y.; Sun, B.; Shi, G.; He, X.; Wang, D.; Chang, Z. Design and Experiment of a Dual-Disc Potato Pickup and Harvesting Device. AgriEngineering 2025, 7, 148. [Google Scholar] [CrossRef]

- Shi, J.; Hu, J.; Liu, W.; Lv, J.; Jin, Y.; Yao, M.; Wang, C. The Design and Experiment of a Motion Control System for the Whole-Row Reciprocating Seedling Picking Mechanism of an Automatic Transplanter. Agriculture 2025, 15, 1423. [Google Scholar] [CrossRef]

- Gao, F. Design and Experimental Study on Key Components of Leaf Vegetable Harvester. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).