Design and Experimental Validation of the Profiling Cutting Platform for Tea Harvesting

Abstract

1. Introduction

2. Materials and Methods

2.1. Overall Design of the Profiling Cutting Platform

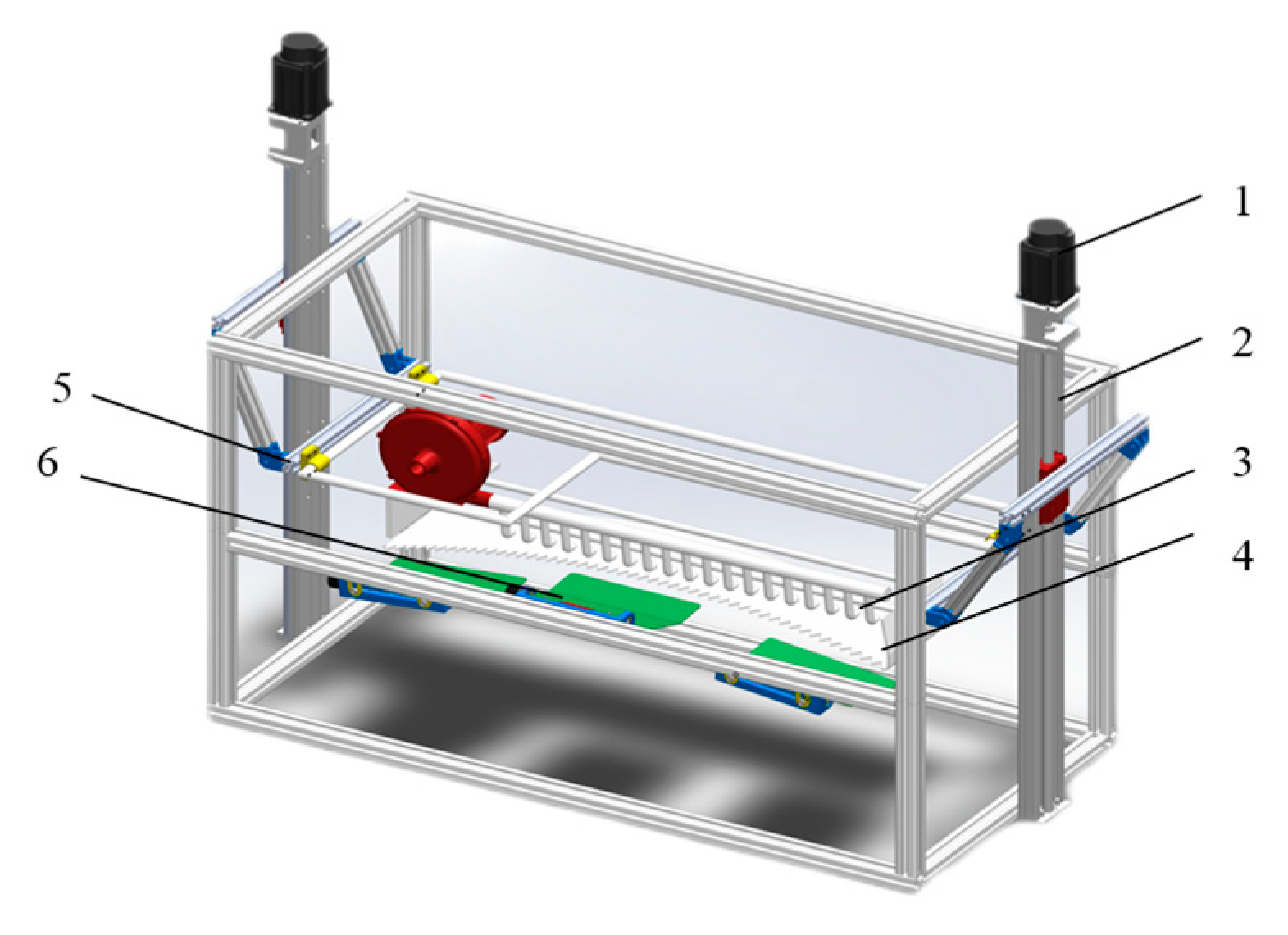

2.1.1. Overall Structure of the Profiling Cutting Platform

2.1.2. Control System Principle

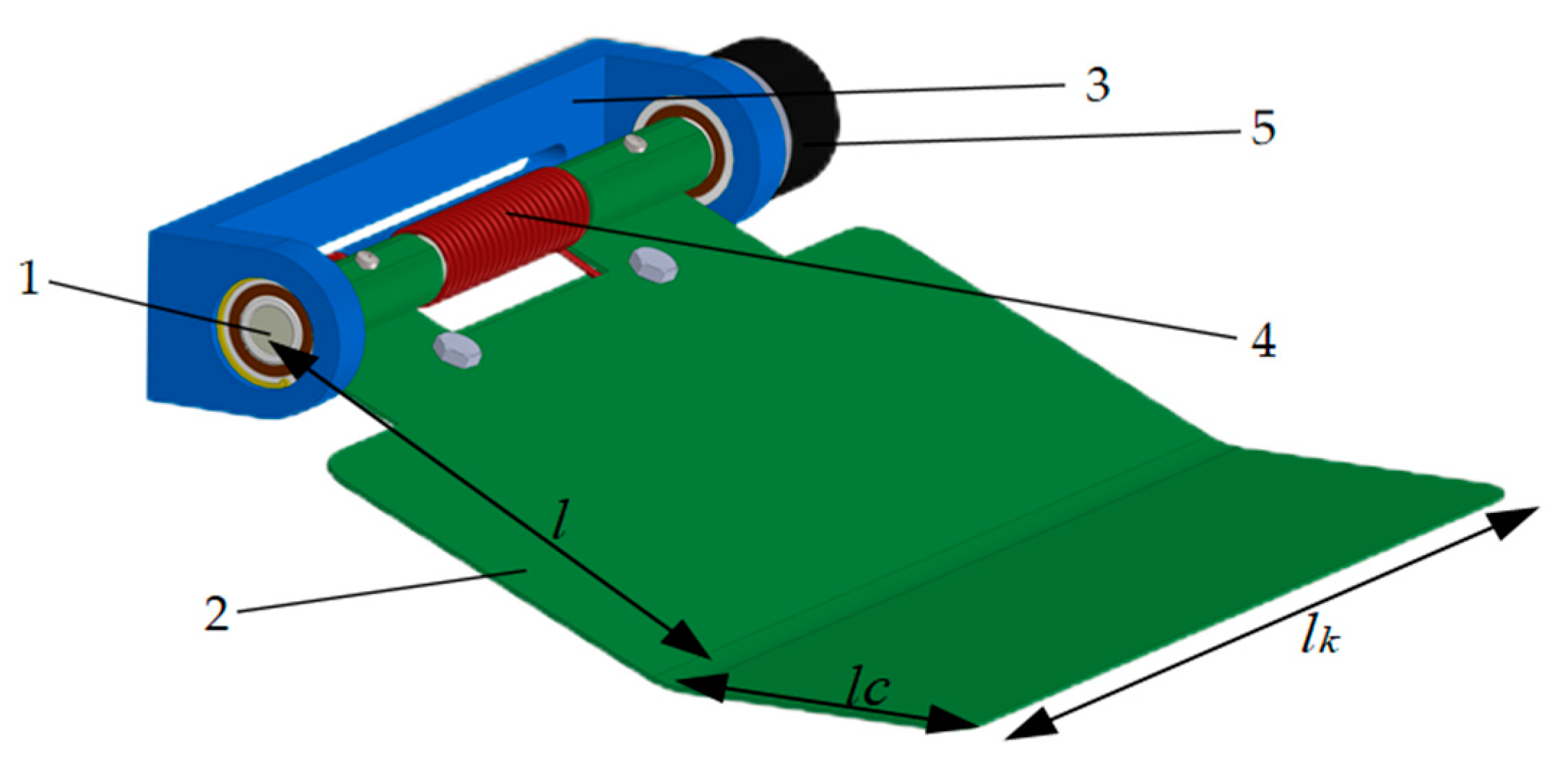

2.2. Design of Key Components of the Profiling Mechanism

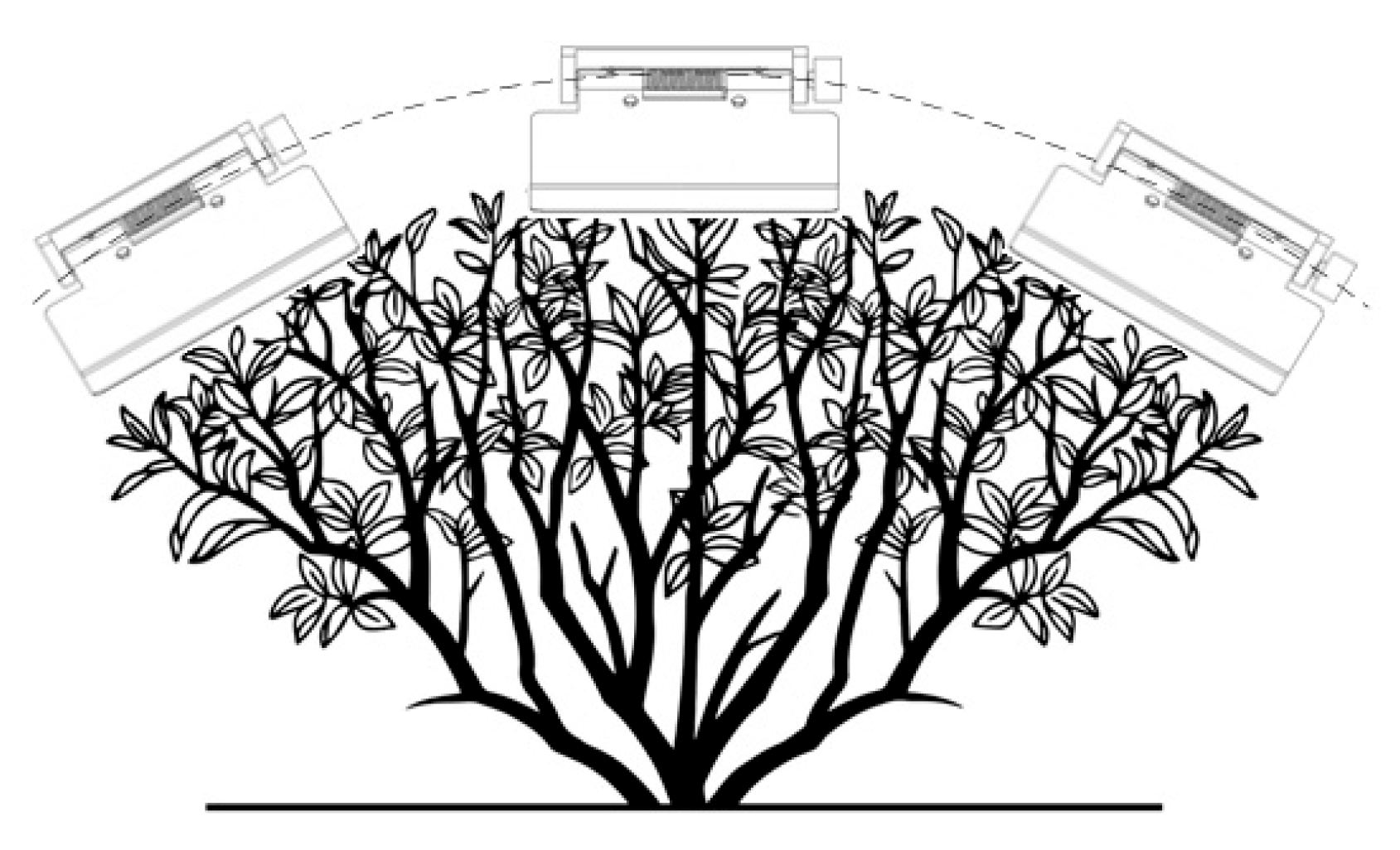

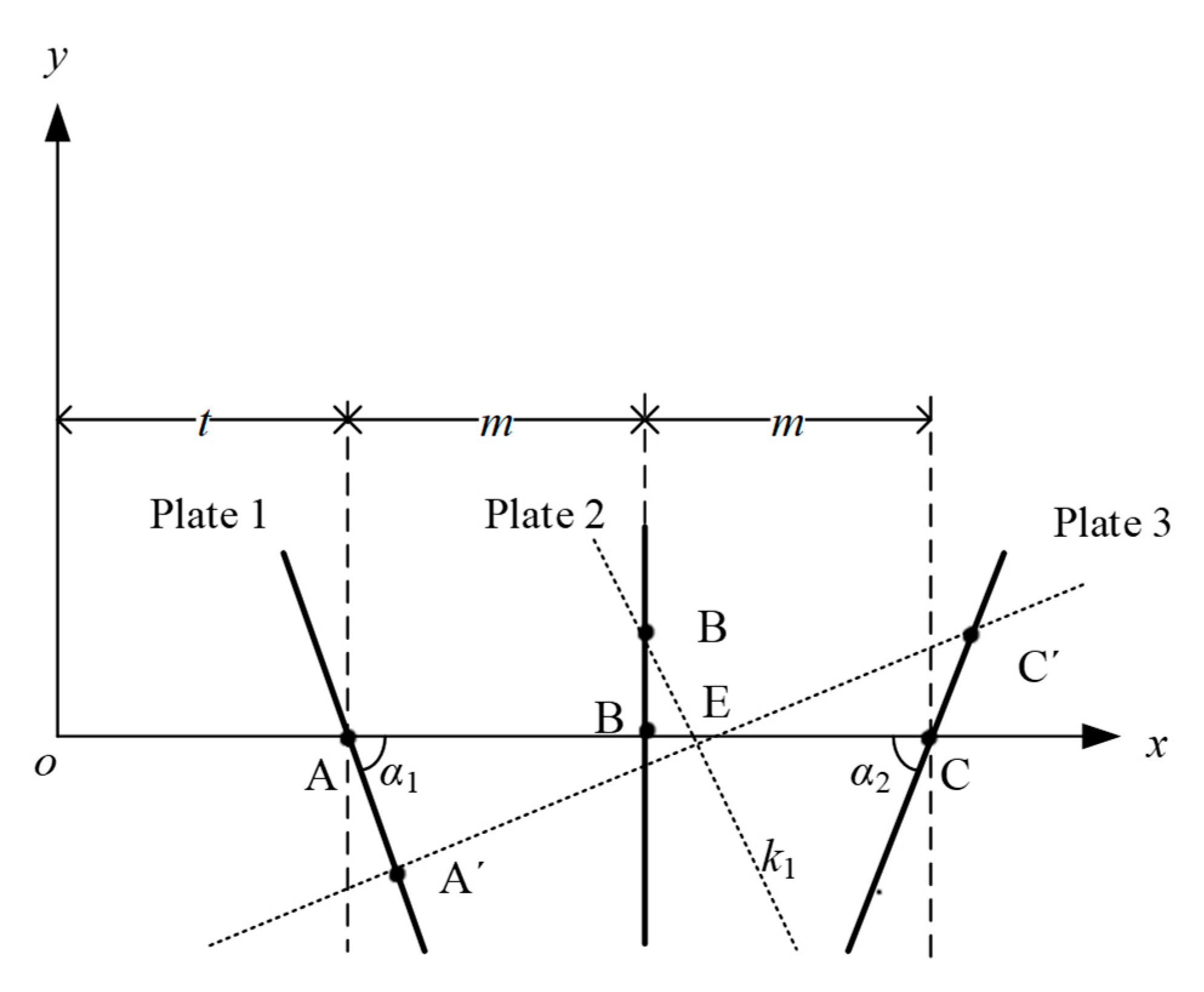

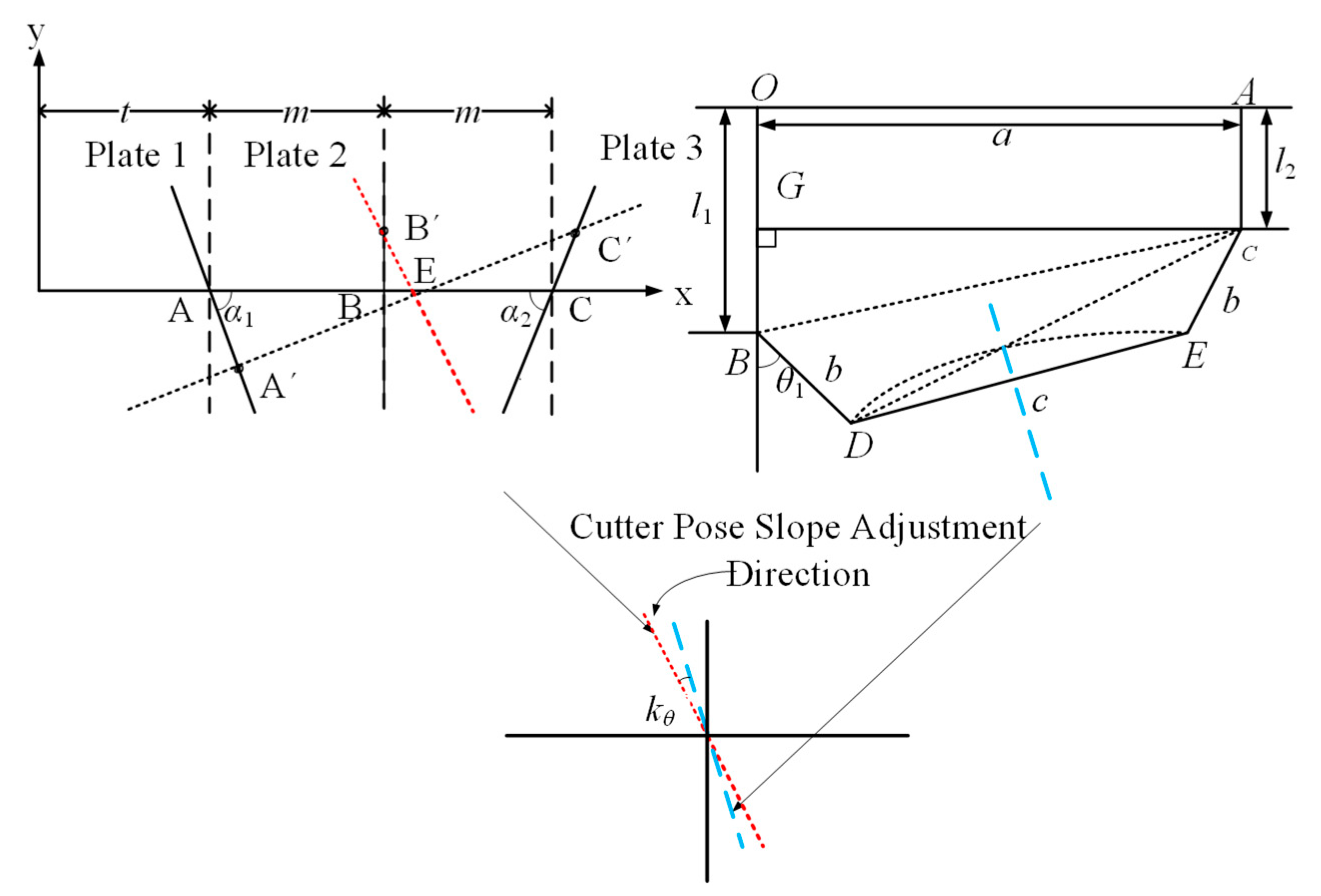

2.2.1. Design of the Tea Canopy Surface

2.2.2. Design of the Torsion Spring

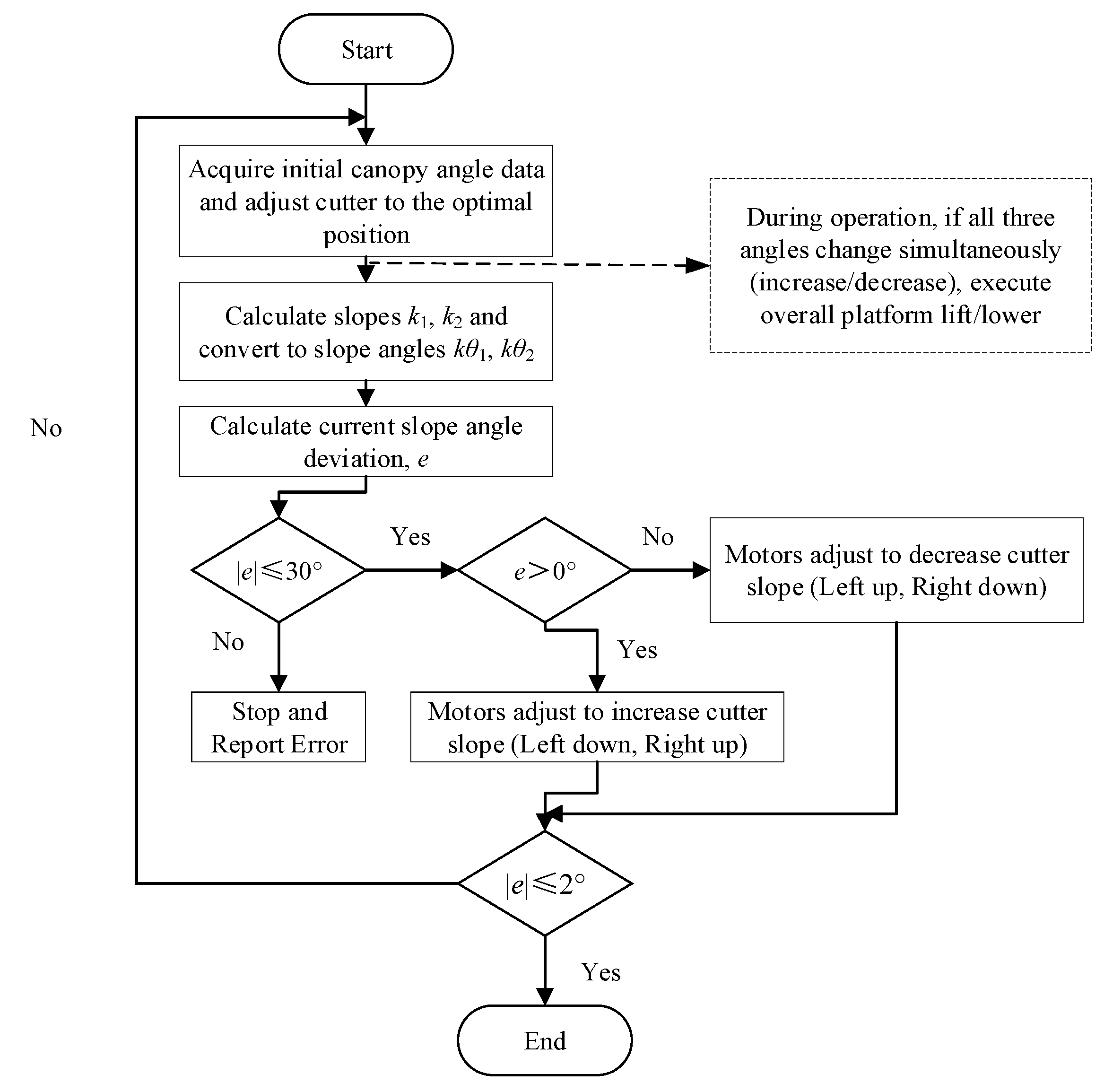

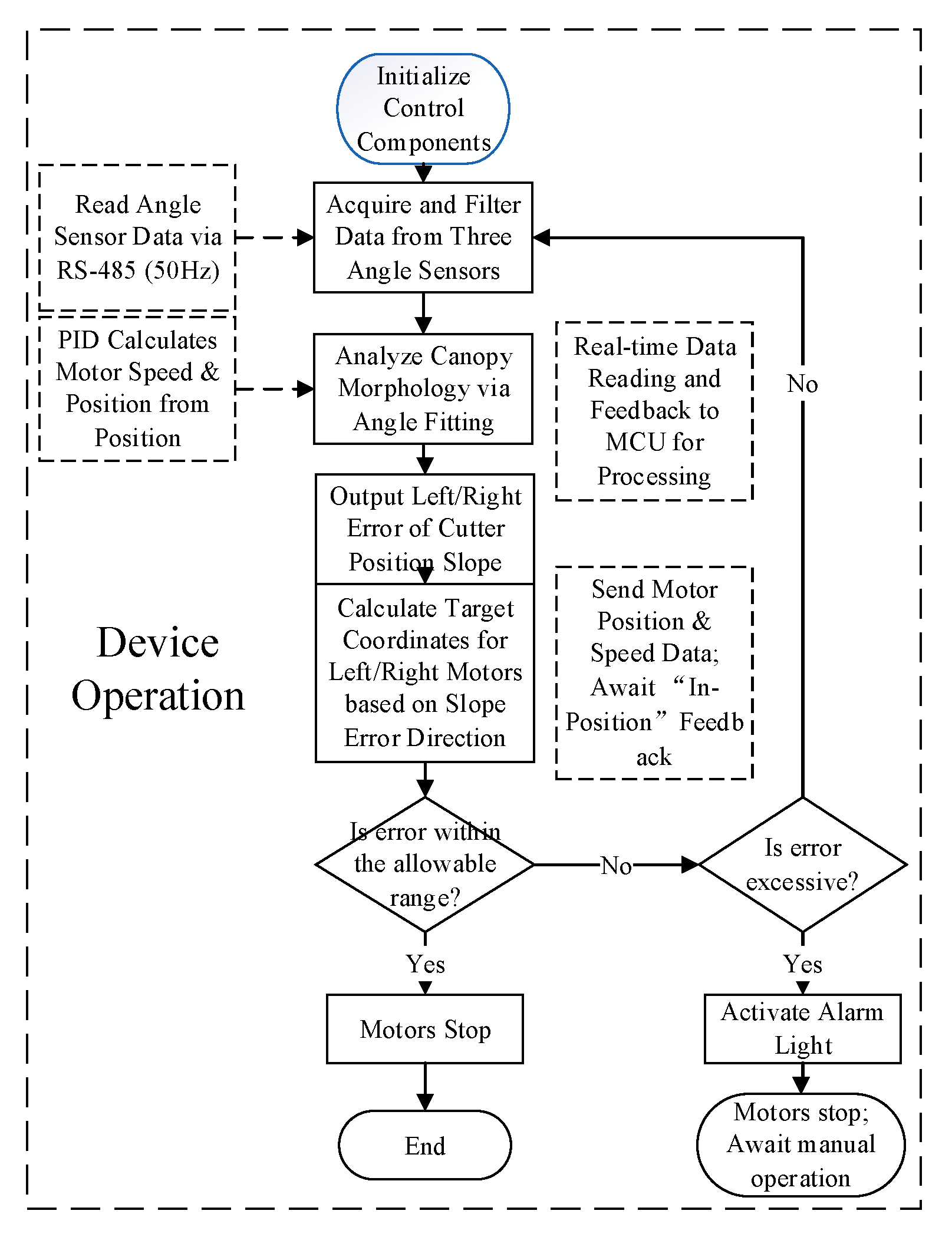

2.3. Software Design of the Profiling Cutting Platform Control System

2.3.1. Acquisition Profiling Control Strategy for the Header

Acquisition of Tea Canopy Pose Information

Acquisition of Header Pose Information

Deviation Between Tea Canopy and Header Pose Information

2.3.2. Design of Control System Program

3. Experimental Validation and Results

3.1. Experimental Verification with a Physical Prototype

Experimental Conditions

3.2. Experimental Method

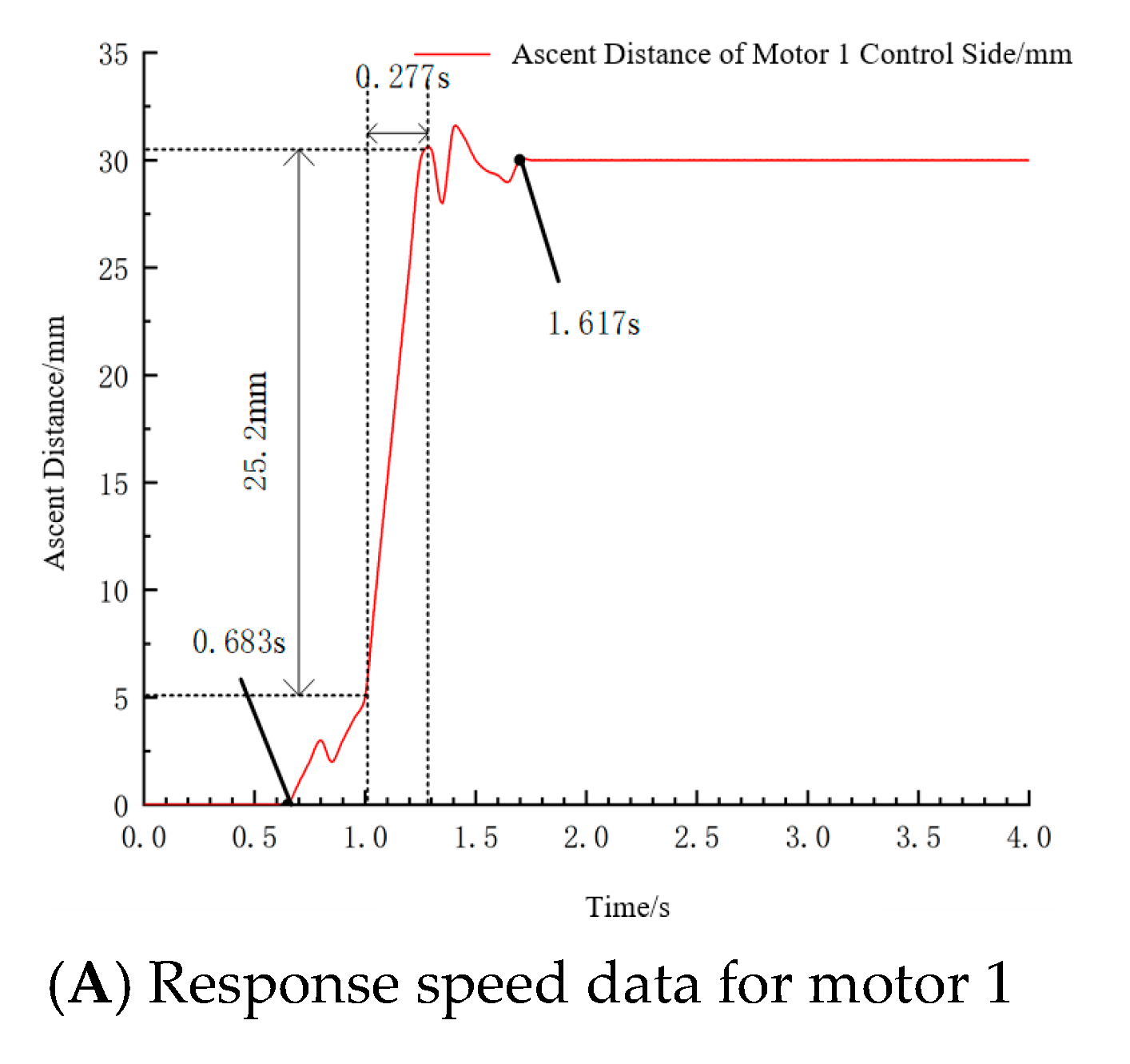

3.2.1. Response Speed and Precision Tests of the Profiling Header Control System

3.2.2. Harvesting Performance Test of the Profiling Cutting Platform

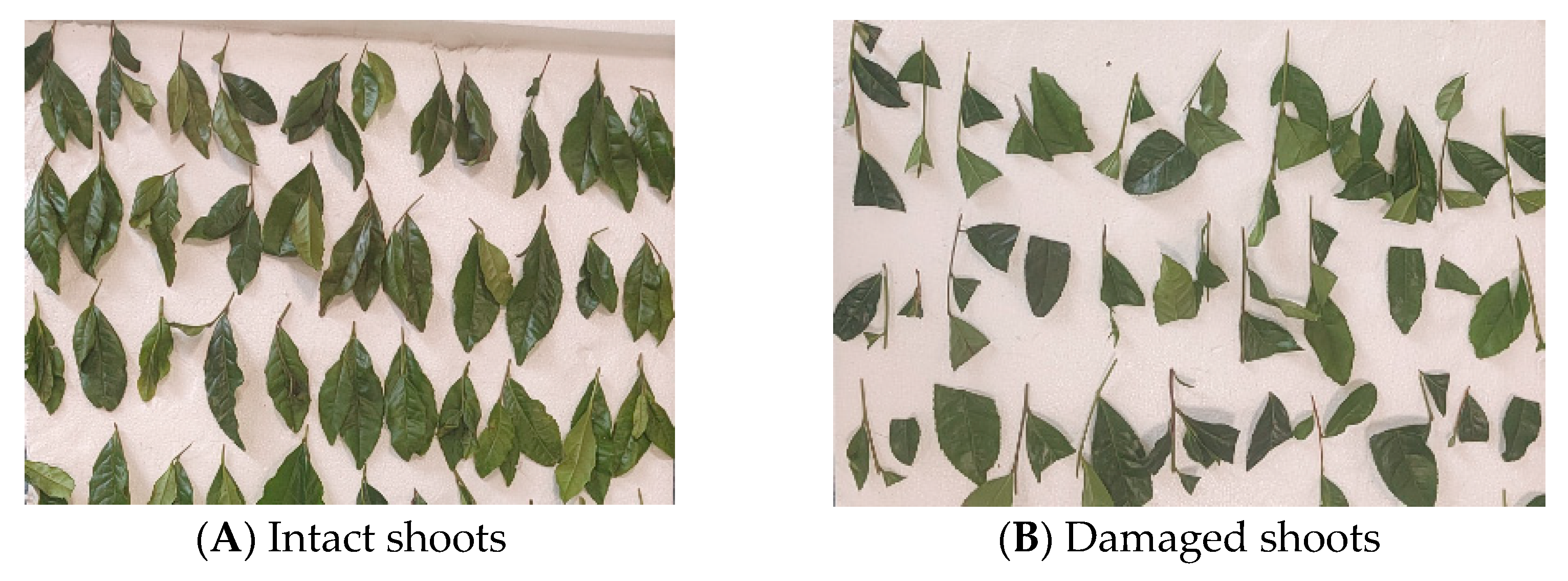

3.3. Experimental Results and Analysis

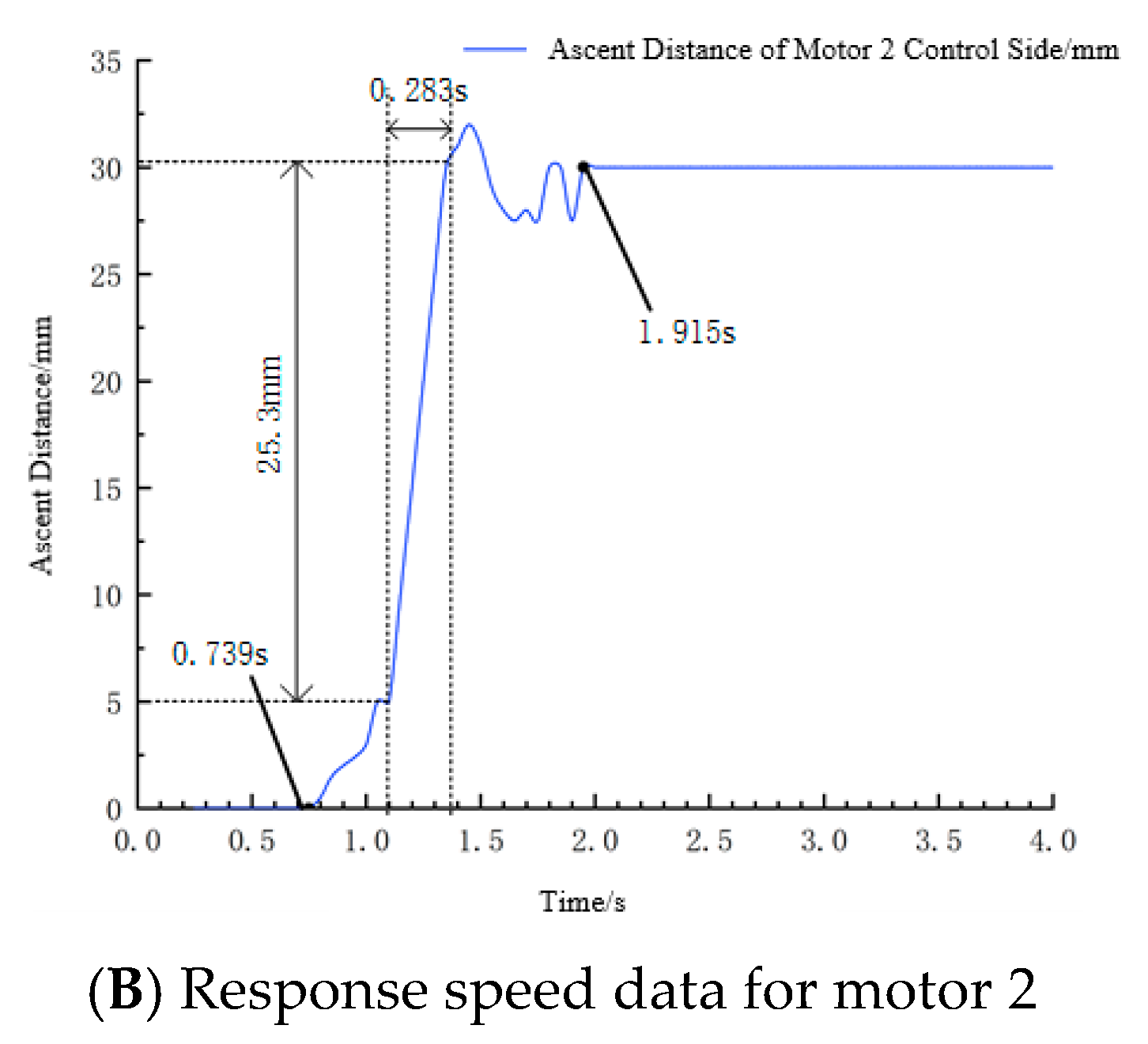

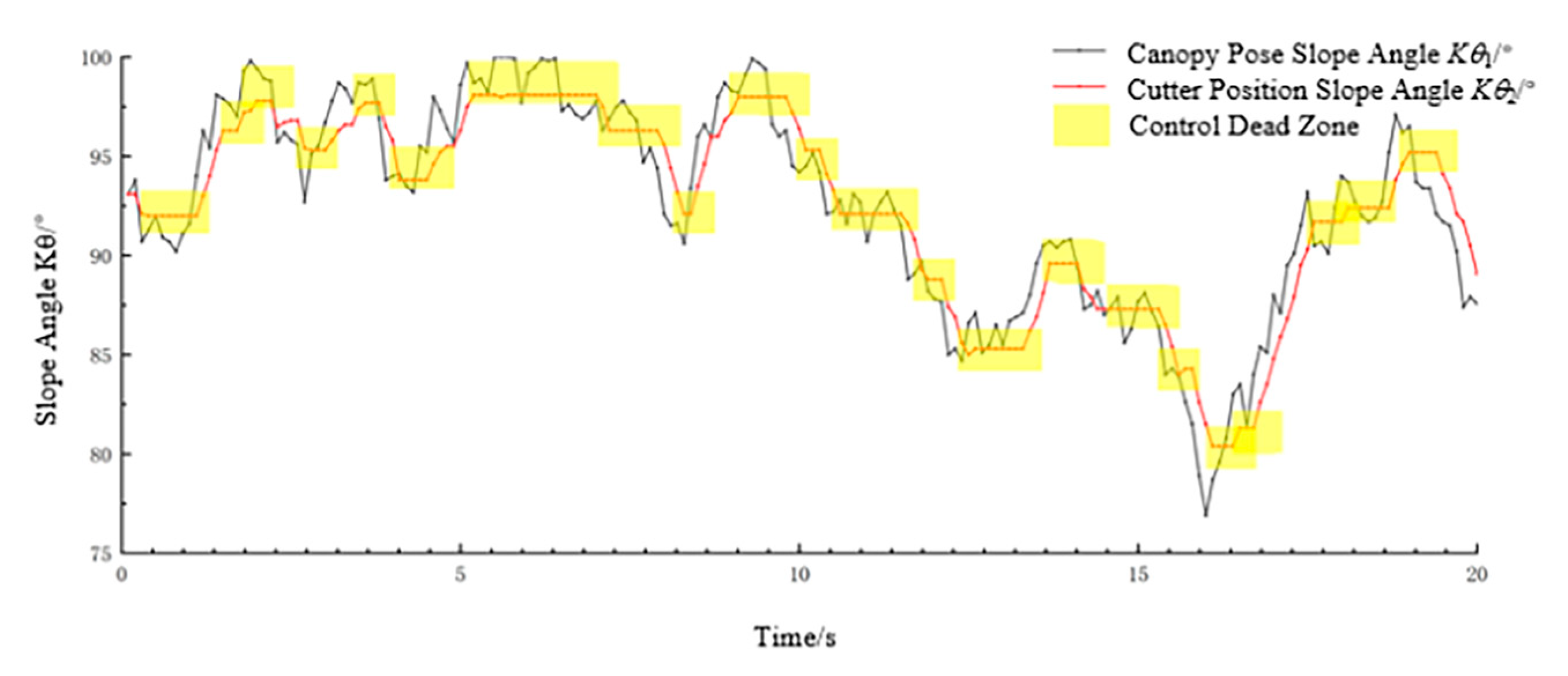

3.3.1. Response Speed Test of the Profiling Cutting Platform Control System

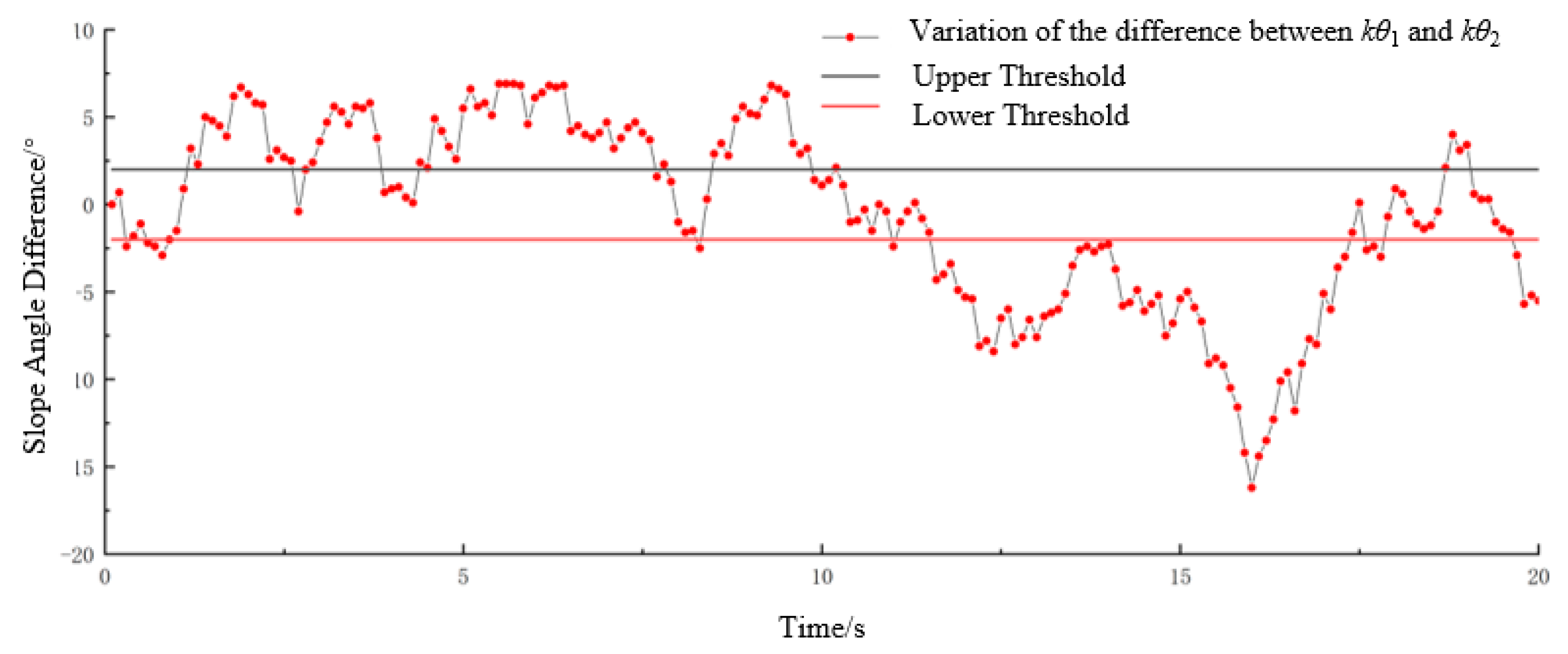

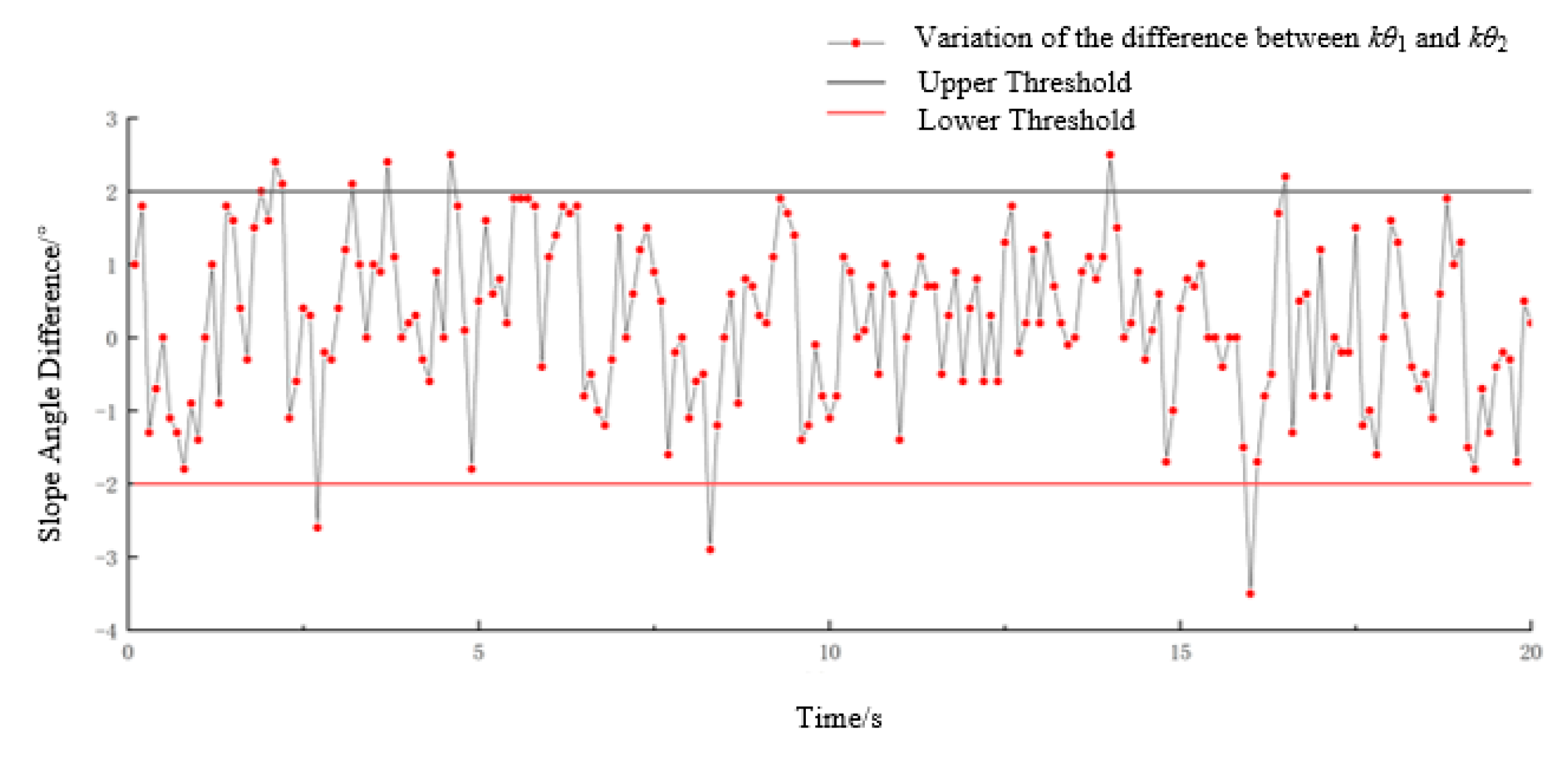

3.3.2. Response Accuracy Test of the Profiling Cutting Platform Control System

3.3.3. Harvesting Performance Test of the Profiling Cutting Platform Control System

4. Conclusions

- (1)

- A novel contact-based profiling mechanism and its associated control method were proposed to address the challenge of poor mechanized harvesting quality on the irregular canopy morphology found in hilly tea gardens in China. This system automatically adjusts the picking header’s pose, effectively resolving the problem of the inconsistent harvesting performance.

- (2)

- A mathematical model was established to correlate the tea canopy’s pose with sensor signals. Based on this theoretical analysis, a parametric design was conducted for key components of the system, determining the optimal structural dimensions for the profiling plate and the selection parameters for the torsion spring.

- (3)

- The software and hardware for the header’s servo-control system were developed, and a functional prototype was established. Subsequent experimental validation clearly demonstrated the system’s excellent dynamic performance and harvesting effectiveness. The key quantitative results were twofold: the time the cutter spent in an optimal cutting position improved dramatically from 26.5% without profiling to 95.0% with profiling, and the integrity rate of the harvested shoots increased from 50.7% to 74.6%, a 47.1% improvement, demonstrating the system’s ability to significantly enhance harvest quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mei, Y.; Zhang, S. Analysis of China’s Tea Production and Domestic Sales in 2022. China Tea 2023, 45, 25–30. [Google Scholar]

- Mei, Y.; Liang, X. Analysis of China’s Tea Production and Domestic Sales in 2021. China Tea 2022, 44, 17–22. [Google Scholar]

- Weng, W. An Overview of China’s Tea Market in 2020 and First Half of 2021. China Tea 2021, 43, 74–76. [Google Scholar]

- Yan, J.; Hu, D.; Liu, Q.; Yu, L.; Liu, S. Research Progress and Development Trend of Tea Stripping Technology and Machinery. J. Chin. Agric. Mech. 2022, 43, 75–83. [Google Scholar]

- Zheng, H.; Fu, T.; Xue, X.; Ye, Y.; Yu, G. Research Status and Prospect of Tea Mechanized Picking Technology. J. Chin. Agric. Mech. 2023, 44, 28–35. [Google Scholar]

- Wang, Q. A Brief Discussion on Tea Picking Technology in Agricultural Technology Promotion. Friends Farmers Get Rich 2019, 66. [Google Scholar]

- Han, Y.; Xiao, H.; Qin, G.; Song, Z.; Din, W.; Mei, S. Studies on Develop Situations of Tea-Leaf Pickers Both at Home and Abroad. J. Chin. Agric. Mech. 2014, 35, 20–24. [Google Scholar]

- Li, Y. Recommended Tea Garden Management Machine for Hilly Terrain—Model 3TG-1500 High-clearance Field Management Machine. Agric. Knowl. 2015, 3. [Google Scholar]

- Tan, J.; Sui, S.; Gao, X.; Li, G.; Wan, X.; Jiang, J.; Luo, G.; Wei, D.; Chen, X.; Zhang, J. Mechanization Status and Development Suggestions for Tea Gardens in Hilly and Mountainous Areas. Sichuan Agric. Sci. Technol. 2023, 75–78. [Google Scholar]

- Dong, C.; Li, Y.; Chen, J.; Wang, M.; Jia, J.; Zhang, R.; Wang, M.; Liu, Z. A Bionic Tea Picking Cutter, Tea Picking Device and Tea Picking Method. Chinese Patent CN114009214A, 8 February 2022. [Google Scholar]

- Li, Y. Research on Visual Detection and Positioning Technology of Tea Picking Robot. Ph.D. Thesis, Zhejiang Sci-Tech University, Hangzhou, China, 2022. [Google Scholar]

- Tang, Y.; Han, W.; Hu, A.; Wang, W. Design and Experiment of Intelligent Tea-plucking Machine for Human Riding Based on Machine Vision. Trans. Chin. Soc. Agric. Mach. 2016, 47, 15–20. [Google Scholar]

- Zhao, R.; Bian, X.; Chen, J.; Dong, C.; Wu, C.; Jia, J.; Mao, M.; Xiong, Y. Development and Test for Distributed Control Prototype of the Riding Profiling Tea Harvester. J. Tea Sci. 2022, 42, 263–276. [Google Scholar]

- Wu, M.; Huan, X.; Chen, J.; Dong, C.; Shao, B.; Bian, X.; Fan, G. Research and Experiment on Profiling Method of Tea Picker Based on Fusion of 2D-LiDAR and Attitude and Heading Reference System. J. Tea Sci. 2023, 43, 135–145. [Google Scholar]

- Yan, J. Optimal Design of Profiling Tea Harvester and Its Coordination with Tea Garden Management. Ph.D. Thesis, Anhui Agricultural University, Hefei, China, 2019. [Google Scholar]

- Hu, J.; Chen, W.; Chen, B. Tea Harvester (SV100 Arc-Shaped Two-Person). Chinese Patent CN306011996S, 25 August 2020. [Google Scholar]

- Geng, A.; Zhang, M.; Zhang, J.; Zhang, Z.; Gao, A.; Zhang, J. Design and Experiment of Automatic Control System for Corn Header Height. Trans. Chin. Soc. Agric. Mach. 2020, 51, 118–125. [Google Scholar]

- Peng, Q.; Ma, J.; Song, H.; Lv, A. Research on Cotton Height Profiling Device. Jiangsu Agric. Sci. 2016, 44, 356–358. [Google Scholar]

- Tang, X.; Liu, T.; Huang, M. Calculation and Experimental Study on Torsional Stiffness of Torsion Spring. J. Nanchang Univ. (Eng. Technol.) 2020, 42, 249–253. [Google Scholar]

- Jiang, X.; Huang, Z.; Mu, Y. Influence of Ovality of Cylindrical Helical Torsion Spring Coil on Stress and Stiffness. Mach. Build. Autom. 2022, 51, 9–12. [Google Scholar]

- Wang, Q.; Lin, H.; Liao, P. Shearing Mechanical Properties of Tea Stem. J. Fujian Agric. For. Univ. (Nat. Sci. Ed.) 2022, 51, 428–432. [Google Scholar] [CrossRef]

- Han, Y.; Song, Z.; Chen, Q. Design and Experiment of 4CJ-1200F Intelligent Tea Plucking Machine. J. Intell. Agric. Mech. 2022, 3, 1–6. [Google Scholar]

| Trial No. | Motor | Platform Ascent Distance/mm | Settling Time/s | Adjustment Speed/(mm·s−1) |

|---|---|---|---|---|

| 1 | 1 | 30 | 0.934 | 90.97 |

| 2 | 30 | 1.176 | 89.40 | |

| 2 | 1 | 50 | 0.991 | 91.31 |

| 2 | 50 | 1.124 | 90.30 |

| Trial No. | Without Profiling | With Profiling | ||||

|---|---|---|---|---|---|---|

| Sample Weight/kg | Intact Shoots/kg | Integrity Rate/% | Sample Weight/kg | Intact Shoots/kg | Integrity Rate/% | |

| 1 | 0.065 | 0.036 | 53.6% | 0.06 | 0.044 | 73.3% |

| 2 | 0.072 | 0.035 | 48.8% | 0.069 | 0.053 | 76.5% |

| 3 | 0.076 | 0.038 | 50.6% | 0.073 | 0.052 | 71.5% |

| Average | 0.071 | 0.036 | 50.7% | 0.067 | 0.050 | 74.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, H.; Ren, N.; Fu, T.; Chen, B.; Hu, Z.; Yu, G. Design and Experimental Validation of the Profiling Cutting Platform for Tea Harvesting. Agriculture 2025, 15, 1866. https://doi.org/10.3390/agriculture15171866

Zheng H, Ren N, Fu T, Chen B, Hu Z, Yu G. Design and Experimental Validation of the Profiling Cutting Platform for Tea Harvesting. Agriculture. 2025; 15(17):1866. https://doi.org/10.3390/agriculture15171866

Chicago/Turabian StyleZheng, Hang, Ning Ren, Tong Fu, Bin Chen, Zhaowei Hu, and Guohong Yu. 2025. "Design and Experimental Validation of the Profiling Cutting Platform for Tea Harvesting" Agriculture 15, no. 17: 1866. https://doi.org/10.3390/agriculture15171866

APA StyleZheng, H., Ren, N., Fu, T., Chen, B., Hu, Z., & Yu, G. (2025). Design and Experimental Validation of the Profiling Cutting Platform for Tea Harvesting. Agriculture, 15(17), 1866. https://doi.org/10.3390/agriculture15171866