Abstract

The collision restitution coefficient (CRC) is the essential parameter of the discrete element method (DEM) to study the interaction mechanism between corn seed and soil. The accuracy of its measurement results is the criticalness to ensuring simulation accuracy. In the current study, the CRC between corn seed and soil is mainly measured by the method of corn seed colliding with soil. However, since the soil is a granular body, the essence of the collision of corn seed with soil is the collision between one corn seed and a quantity of soil particles, resulting in inaccurate measurement results soil particles. Therefore, based on the collision dynamics theory of mass point and fixed surface, this paper proposed a measurement method of CRC to study the interaction mechanism between corn seed and soil. This paper analyzed the influence of mass point selection on the measurement results of CRC in the collision process. The measurement method was determined by taking soil particle as mass point and corn seed as fixed surface. To verify the feasibility of this method, a CRC measurement system was established based on high-speed camera technology. The soil particle was dropped at the heights of 10, 15, 20, and 25 cm to collide with the corn seed. The separation velocity and approaching velocity of the soil particle was measured to obtain the CRC between the corn seed and soil. Taking the CRC as the essential parameter of discrete element simulation, the discrete element simulation experiment (DESE) and the soil bin experiment (SBE)of corn seed free fall impact on soil were carried out, and the experiment results were compared and analyzed. In the experiment, the falling height (40, 50, 60, 70 cm) of corn seed and the touching position of the corn seed (positions a, b, c, d) were taken as the influencing factors. The movement state of corn seed and the separation approaching velocity ratio (SAVR) ξ during the collision were taken as the indexes. The results showed that when the positions of corn seed touched the soil was the same, with the increase of the falling height, the SAVR ξ obtained from the DESE and the SBE showed a downward trend. When the falling height was the same, and the corn seed touched the soil at positions b, c, and d, the motion state in the DESE was basically the same as that in the SBE. The relative error of the SAVR between the DESE and the SBE was less than 10%, which proves the feasibility of the method proposed in this paper. The measurement method of the CRC between corn seed and soil proposed in this study provided a theoretical research basis for clarifying the interaction mechanism between corn seed and soil and solving the seed bouncing in high-speed precision sowing.

1. Introduction

The mechanization level of corn sowing has reached 90%. During the sowing operation, corn seeds are discharged from the seed metering device and fall into the seedbed through the seed guide pipe. During the implantation process, the corn seeds collide with the soil and bounce on the seedbed, resulting in a high variation coefficient of sowing depth and a obviously difference in seed implantation position, which seriously affects the operation quality of the corn planter [1]. Studying the movement state of seed after collided with soil and clarifying the mechanism of seed-soil interaction is exceedingly essential to solve the seed bouncing on the seedbed and improve the quality of precision planting.

Currently, the primary methods to study the mechanism of corn seed and soil interaction are field experiments and SBE. Limited by the observation technology, operating environment, and the instantaneous completion of seed colliding with soil during seed dropping, it is tough to obtain the movement change process caused by seed colliding with soil during field experiments [2]. The SBE can’t effectively obtain the force change and energy change when the seed collide with the soil, and it’s complicated to analyze the seed soil interaction mechanism [3]. The DEM is widely used in particle motion analysis. It can obtain the movement velocity, force, energy loss, and other information of the working object at each movement time. It is an effective means to study the mechanism of seed-soil interaction. When using the DEM, the appropriate parameter setting is the basis for studying the interaction between materials, materials, and mechanical devices [4], which is of great significance for accurately simulating the actual physical behavior of macro granular materials [5]. Among them, the CRC, as the essential parameter for studying the problem of seed impacting soil, is of great significance for analyzing the mechanism of seed-soil interaction [6,7].

The CRC is a parameter reflecting the deformation recovery ability of objects during a collision. At present, scholars have carried out a lot of research on the CRC of agricultural materials. The existing research usually uses the impact experiment to measure CRC [8]. Feng et al. [9] measured and analyzed the CRC of potato when it collided with 65Mn steel, rubber, soil block, and other materials for potato tubers during harvest. Wang et al. [10] measured the elastic properties of processed tomato seeds when they collided with rubber, plexiglass, Q235, and other materials. Lu et al. [11] measured and analyzed the CRC of peanut pods when they collided with Q235, aluminum alloy, plexiglass, rubber, white sand (moisture content is 17.5%). Huang et al. [12] measured and analyzed the CRC of rape seeds when they collided with Q235, aluminum alloy, plexiglass, rubber, and other materials. Liu et al. [13] measured and analyzed the CRC between micro potato and steel plate. Zhou et al. [14] measured the CRC between three different shapes of corn seed and the galvanized wall, and analyzed the influence of corn seed’s varying collision positions, collision velocity, and collision angles on the CRC. Sui et al. [15] analyzed the collision process between soybean and soil through high-speed camera technology, corrected the CRC between soybean seed and soil by comparing the experiment and discrete element simulation results, and calibrated the contact parameters between soybean and soil.

The above analysis shows that most of the research on the CRC of agricultural materials focuses on the measurement of the CRC between crop seeds with a regular shape (processing tomato seeds, peanut pods, micro potatoes, soybeans, etc.) and agricultural machinery equipment materials (Q235, aluminum alloy, plexiglass, rubber, etc.) with large volume and relatively flat surface. There are few studies on collision between soil and other particulate matter. In the study of the CRC between corn seed and soil, it is mainly measured by the method of corn seed colliding with soil. However, since the soil is a granular body, the essence of the collision of corn seed with soil is the collision between one corn seed and a quantity of soil particles, resulting in inaccurate measurement results soil particles. To this end, this paper proposes a method for measuring the CRC between corn seed and soil during collision based on the mass point fixed surface collision kinetics theory. Through the analysis of the collision process, the mass point and the fixed surface in the collision process of corn seed and soil were determined, and the measurement method of the CRC was clarified. In the cause of providing a theoretical research basis for defining the interaction mechanism between corn seed and soil and solving the problem of seed bouncing, we compare the results of DESE and SBE to analyze its feasibility.

2. Theoretical Analysis of CRC

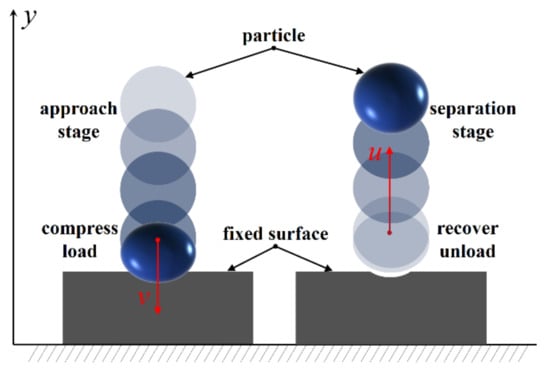

According to the collision kinetics theory of mass point and fixed surface, the two interaction objects that collide with each other can be regarded as mass point and fixed surface, respectively. The mass point collides with the fixed surface at a certain velocity. According to the relative position relationship between the mass point and the fixed surface, the collision process can be divided into the approach stage and the separation stage, as shown in Figure 1.

Figure 1.

Analysis of collision process.

In the approach stage, the distance between the mass point and the fixed surface is continuously reduced, and the mass point contacts the fixed surface with the velocity v, which compresses and loads the fixed surface. The mass point is subjected to the reverse force of the fixed surface, and the velocity rapidly decreases to zero. At this stage, the kinetic energy of the mass point is loaded into the mass point fixed surface system, which is absorbed and converted into elastic strain energy and plastic strain energy.

In the separation stage, the distance between the mass point and the fixed surface gradually increases, and the mass point and the fixed surface begin to recover elastic deformation. The elastic strain energy is unloaded and converted into the kinetic energy of the mass point. The mass point velocity increases rapidly from zero and reaches the maximum value u when it comes out of contact with the fixed surface. The plastic strain energy generated by the kinetic energy loading of the mass point in the approach stage is absorbed and converted into internal energy by the mass point and the fixed surface in the separation stage, resulting in plastic deformation [16,17,18].

The CRC is the primary parameter representing the energy change when the mass point collides with the fixed surface. It is only related to the material characteristics of the collision object. It reflects the ability of the object to recover the deformation during the collision. The more significant the CRC, the lower the energy loss, and the easier it is to recover to the initial state. At present, the CRC is mainly obtained by measuring the ratio of velocity (Newton measurement method), impulse (Poisson measurement method), and energy (strong measurement method) at the time of separation and approach [19]. Since it is difficult to directly obtain the change of impulse and energy in the actual measurement experiment, the Newton measurement method is adopted in this paper. In other words, the CRC is obtained by measuring the separation velocity and approach velocity of the mass point and calculating the SAVR.

3. Measurement Method of CRC between Corn Seed and Soil

Based on the kinetics theory of mass point fixed surface collision, the Newton method was used to measure the CRC between corn seed and soil. The criticalness lay in the selection of mass points and fixed surfaces. Therefore, the collision processes of corn seed and soil particles were analyzed, respectively, to obtain the optimal measurement method of the CRC of corn seed and soil.

3.1. Analysis of Collision Process when Taking Corn Seed as Mass Point

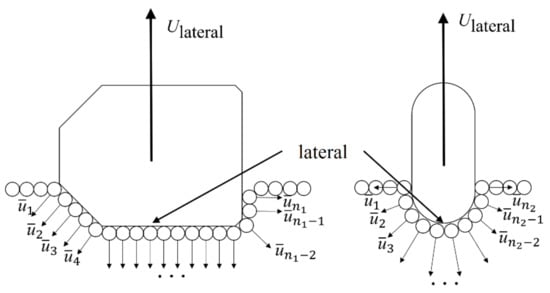

According to the above theoretical analysis of the collision process, the collision model between corn seed and soil was established using corn seed as the mass point and the soil as the fixed surface. The soil was a granular system composed of n soil particles. There was a small cohesion between the particles, and the particles would be separated under the action of external forces. The macroscopic performance was the plastic deformation of the soil [20,21,22]. Considering that the shape of corn seed was complex, and irregular compared with that of wheat, soybean, peanut, and other crops, there were also obviously differences in the shape of corn seed of different varieties. The maximum average sphericity of Yuyu 30 was 76.01%, while the maximum average sphericity of Yudan 9953 was only 65.73% [23,24,25]. In this paper, only the bottom surface (opposite to the basal fruit stalk) and the side surface of the corn seed touching the soil were taken as examples for analysis, as shown in Figure 2 and Figure 3.

Figure 2.

Instantaneous impulse Analysis when the side of corn seed touches soil.

Figure 3.

Instantaneous impulse Analysis when the bottom of corn seed touches soil.

According to the impulse theorem, the impact impulse acting on the ith soil particle is divided into external impact impulse and internal impact impulse , then:

For the particle system composes of n soil particles, there were:

where mi is the mass of the ith soil particle; is the velocity of the center of mass at the end of collision of the ith soil particle; is the velocity of the center of mass of the ith soil particle at the beginning of collision, and the soil is stationary at the beginning of the collision, = 0; is the external impact impulse on the ith soil particle; is the internal impact impulse on the ith soil particle.

Since the internal impact impulse appeared as a pair, . Let the total mass of soil particles moving after collision be M, and is the average velocity of soil particle centroid at the end of collision and at the beginning of collision, where , obtained from the theorem of mass center motion and impulse theorem:

The simultaneous solution shows that:

where S is the total impulse of the system; S1 is the impulse absorbed by soil particles; S2 is the impulse of corn seed collision and separation stage; N is the quality of corn seed; V is the maximum velocity before the corn seed contacts the soil; U is the maximum velocity of corn seed separated from the soil.

When measuring the CRC, it was found that if the corn seed was taken as the mass point, the corn seed collides with the soil, which was essentially the contact collision between the corn seed and multiple soil particles. In the actual experiment, it was complicated to analyze the interaction between a single soil particle and corn seed during the collision process, and the obtained corn seed approach velocity v and separation velocity u could not be applied to the measurement of CRC [26].

Moreover, the movement state of corn seed in the separation stage is completed by the joint action of multiple soil particles. As shown in Figure 2 and Figure 3, the number and velocity of soil particles are different at the side and bottom when they collide with the soil. The impulse of soil particles’ absorption and transformation is different, and the movement state of corn seed in the separation stage is different, resulting in the difference in the measured SAVR. In addition, the CRC obtained according to the Newton measurement method is different.

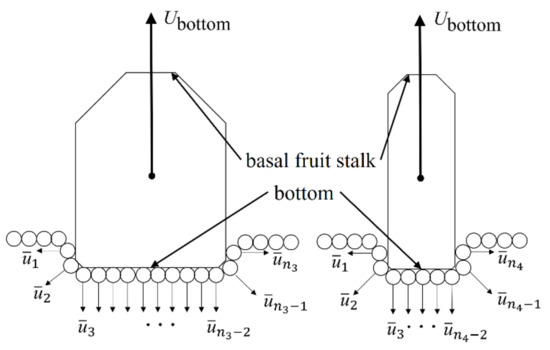

3.2. Analysis of Collision Process when Taking Soil Particles as Mass Point

As shown in Figure 4, the collision model takes soil particles as mass points and corn seed as fixed surfaces. According to the conservation of momentum and the conservation of mechanical energy in the collision process system, the kinetic energy changes in the two stages are showed in Equations (5) and (6).

Figure 4.

Process analysis of soil particle colliding with corn.

Equation (7) is obtained according to the momentum conservation of the collision system.

Equation (8) is obtained.

where ΔE1 is kinetic energy change value in compression stage; ΔE2 is kinetic energy change value in the recovery stage, J; m1 is the mass of the mass point, g; m2 is the mass of the fixed surface, g; v10 is the velocity before particle collision, m/s; v20 is the velocity of the fixed surface before the collision, m/s; v1t is the velocity of the particle after the collision, m/s; v2t is the velocity of fixed surface after the collision, m/s; v11 is the velocity of mass point when separation, m/s; v22 is the velocity of fixed surface when separation, m/s.

where v20, v2t, v22 both are 0 and m2 is much larger than m1. Accordingly:

According to the definition of CRC, then:

According to the above analysis, taking soil particles as mass point could effectively avoid the simultaneous contact between corn seed and multiple soil particles and realized the contact between single collision objects, which meets the mass point fixed surface collision kinetics theory requirements. According to the above analysis, the CRC could be obtained by measuring the separation velocity v1t and the approaching velocity v10 of the mass point.

3.3. Measurement Method

According to the above analysis, the paper adopted the method of measuring the CRC with soil particle as mass point and corn seed as fixed surface. In the cause of obtaining the CRC between corn seed and soil, a CRC measurement system was built based on high-speed camera technology to measure the separation velocity and approach velocity of soil particles. To ensure the accuracy of the experiment system, the following requirements shall be met:

- (1)

- The experiment was conducted in a relatively closed environment to avoid the influence of the airflow field in the experiment space on the measurement results.

- (2)

- To obtain the CRC between corn seed and soil, improve the contrast and ensure the shooting effect, a simple CRC experiment bench was built with a white background plate.

- (3)

- The white background plate was vertically placed on the desktop to obtain the actual distance of soil particle movement. The vertical distance between the high-speed camera and the soil particle movement plane in all experiments should be kept consistent.

- (4)

- Drawn a straight line parallel to the desktop on the white background plate to facilitate the experiment and subsequent high-speed camera data analysis.The main experiment equipment was the revealer 5f01 high-speed camera produced by Hefei Fuhuang Junda high tech Information Technology Co., Ltd. (Hefei, China), with a shooting frame rate of 1000 fps and an exposure time of 998 μs, using high-speed video target tracking measurement software to process image data.

The specific operation steps during the experiment were:

- (1)

- Fix the corn seed on the tabletop of the experiment bench, and the side is close to the background plate so that the surface is relatively smooth and flat, and the large plane with uniform distribution of horny endosperm is upward as the fixing surface.

- (2)

- Open the high-speed camera control software to make the high-speed camera ready for shooting. Adjust the focus, exposure rate, white balance and other parameters of the high-speed camera according to the images collected by the control software. Make the white background plate and corn seed in the center of the video acquisition area, and ensure the best definition of the picture. Adjust the position of the lighting device to ensure that shadows do not cover the movement range of soil particles.

- (3)

- To avoid the influence of sweat and grease secreted by fingers on the properties of soil particles, during the experiment, the soil particles were clamped with tweezers, and the tweezers were loosened at the straight positions of different heights to make them fall naturally and collide with corn seed. In the cause of capturing the complete falling process, trigger the high-speed camera shooting command before releasing the tweezers.

The collision separation and approach velocity of soil particles were analyzed and obtained by the high-speed video target tracking measurement software. After the shooting, the specific methods for processing the obtained video files were as follows:

- (1)

- Coordinate system is set at the starting point of soil particle falling;

- (2)

- Calibrate the size in the drawing, measure the scale in the drawing, and calculate the corresponding ratio between the actual size and the picture size: LActual:LFigure = k:1 is used for conversion of experiment data. If the camera position changes during the experiment, it needs to be recalibrated;

- (3)

- After the calibration is completed, the soil particle is set as the tracking target, and the target tracking module is used to obtain the movement trajectory of the soil particles, the separation velocity v1t of the soil particles after the collision, and the approaching velocity v10 of the soil particles before the collision. The CRC is obtained from Equation (10).

4. Experiment Verification

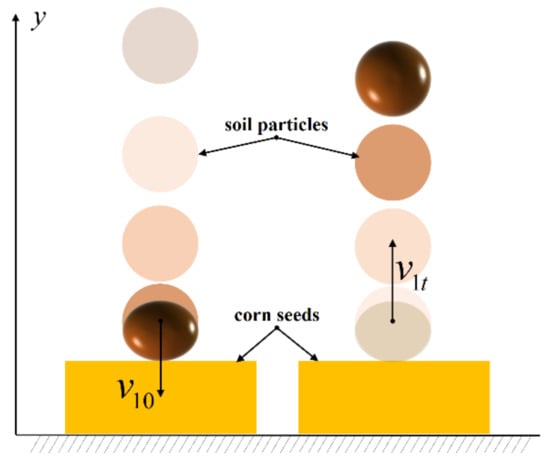

To verify the feasibility of the method proposed in this paper, taking soil particle as mass point to collide with corn seed, measured the CRC between soil particle and corn seed. The DESE and the SBE were carried out with the corn seed as the mass point and the soil bin as the fixed surface, compared the movement state and SAVR of the corn seed.

4.1. Measurement of CRC

The experiment was carried out to measure the CRC between corn seed and soil. The moisture content of corn seed was 12.8%, the weight of a thousand seeds was 351 g, the average density was 1.197 kg/m3, the shape was complete, and the surface was flat. To reduce the influence of corn seed’ uneven surface on CRC measurement results, the large surface with a uniform and flat distribution of horny endosperm was used as the fixed surface. During the experiment, the soil was first treated with a sieve. After natural air drying, the soil particles were taken as the mass points. The soil bulk density was 1346 kg/m3, and the particle size range was 2–3 mm. It should be noted that according to the mass point fixed surface collision kinetics theory, the CRC is independent of the weight of the mass point. However, in the actual measurement, multiple particles were bonded together due to the little cohesion between soil particles in the natural state. Soil particles with large size were formed by the bonding of several small particles with little cohesion between them. In actual measurements, dispersion occurred after collision, which was inconsistent with the particle-fixed surface collision dynamics theory. Soil particles with small size, whose motion process was affected by air resistance close to its own gravity, greatly influence the motion state, and could not be used to measure the CRC. Therefore, the diameter of soil particles should not be too large or too small.

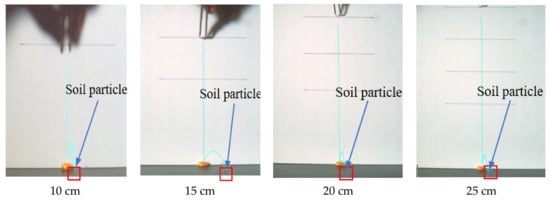

Using the measurement method of the CRC proposed above, the soil particles are clamped to fall freely at the heights of 10, 15, 20, and 25 cm to collide with corn particles, as shown in Figure 5. The experiment was repeated several times. The high-speed camera recorded the collision process, and the approaching velocity v10 and separation velocity v1t were analyzed. Since the surface of corn seed is not an ideal plane, the direction of soil particles and corn will have a divergent shift after the collision, resulting in the measured separation velocity being smaller than the ideal state. In this paper, the maximum SAVR in the normal direction of the contact was taken as the CRC. Sorted out the experiment data, measured the collision approaching velocity and separation velocity of soil particles, calculated the SAVR, and took the maximum value as the corn seed soil CRC = 0.607.

Figure 5.

Image analysis of high-speed photography.

4.2. Verification of Measurement Results

Based on the CRC measured in the previous paper, we carried out the DESE and SBE of the seed soil interaction mechanism. We compared and analyzed the movement state of corn seed falling at different heights and touching the soil at different positions, as well as the SAVR ξ of corn seed colliding the soil bin, to verify the accuracy of the CRC measured by the measurement method proposed in the article.

4.2.1. Seed Impact Soil DESE

Measure the size of corn seed used in the experiment, established a three-dimensional model of corn seed, as shown in Figure 6, and save as Step format was imported into EDEM2018 software as a template. Considering the influence of calculation speed and accuracy, we establish a multi-ball model of corn seed with 11 particles, as shown in Figure 7.

Figure 6.

Three-dimensional model of corn seed.

Figure 7.

Discrete element simulation model.

A cylindrical soil bin with a diameter of 60 mm and a height of 10 mm was established to generate soil particles in the soil bin. The soil particle diameter was set to 1 mm to improve the accuracy and ensure the calculation speed. A polygon plate with a diameter of 60 mm was charged at the top of the soil bin, and linear motion is added. The plate motion compresses the soil bin downward by 2 mm, and the compression rate of the discrete element soil model is 20%. The contact model of soil particles was the Hertz-Mindlin non-sliding contact model. The contact model between corn seed and soil was linear spring model [27,28,29]. The values of characteristic velocity were showed in Table 1. The discrete element simulation model parameters of corn seed and soil were shown in Table 2, and the discrete element simulation contact parameters of corn seed and soil were shown in Table 3.

Table 1.

Values of Characteristic Velocity.

Table 2.

Discrete element simulation model parameters of corn seed and soil.

Table 3.

Discrete element simulation contact parameters of corn seed and soil.

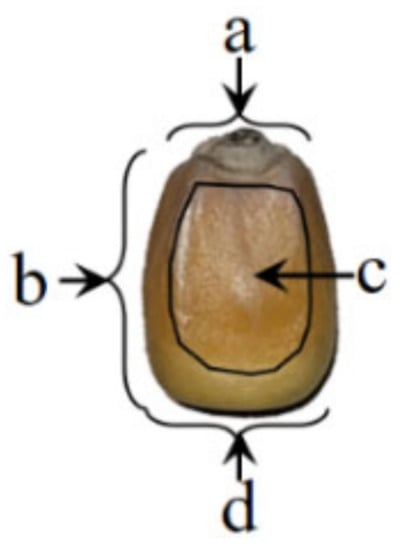

Two factor and four level experiments were carried out. The factor levels were shown in Table 4. The positions of corn seed touched the soil are divided into four positions according to the shape characteristics of corn seed, that is, basal fruit stalk a, lateral surface b, large plane c, and bottom surface d, as shown in Figure 8.

Table 4.

Experiment factor level.

Figure 8.

The position of seed touching the soil.

We set a particle factory at the height of 400, 500, 600, and 700 mm from the soil model to make the seed fall in free fall motion, and saved the movement state data of corn seed. The corn seed approaching velocity V0 and separation velocity Vt were saved and the SAVR was calculated automatically, the calculation equation is shown in Equation (11). Each group of experiments was repeated five times to obtain the mean value.

4.2.2. Soil Bin Experiment

We built a collision experiment platform to make corn seed fall into the soil. The corn seed used had the same variety and moisture content as the corn seed used in measurement the CRC. The soil used was taken from the same plot as the soil particles used to measure the CRC.

Over the aluminum soil bin, the soil was screened with a 2 mm aperture sieve so that the soil particles fell vertically into the aluminum soil bin. The soil particles above the top edge of the soil bin were scraped so that the soil surface was flush with the bin edge. The universal material machine compresses the soil in the soil bin, and the compression height is 20% of the height of the soil bin so that the compression ratio of the actual soil bin was consistent with that of the discrete element model. Placed the prepared soil bin on the support platform to make the corn seed fall freely at the positions of 400, 500, 600, and 700 mm from the soil bin’s soil surface, and conducted the experiment that corn seed collide soil. We used the high-speed camera of revealer 5f01 to capture the moments when the corn seed collide, approach, touch the soil and collide and separate. We analyzed the movement process of the corn seed through the high-speed video target tracking measurement software, obtained the approach velocity v0 and separation velocity vt of the corn seed when the contact positions are a, b, c, d, and calculated the SAVR , the calculation equation is shown in Equation (12).

4.2.3. Comparison and Analysis of Experiment Results

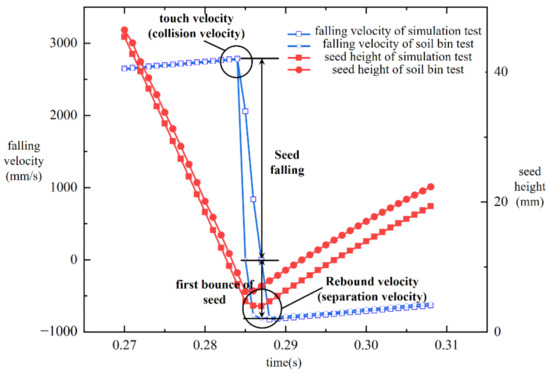

- (1)

- Comparative Analysis of the Movement State of Corn Seed

Aiming at the process of collision, approaching, and separation between corn seed and soil bin, the SBE and DESE under the same experiment conditions were selected to analyze the movement state of corn seed. The experiment conditions were 400 mm height drop and soil contact at position c. We compared and analyzed the movement state of corn seed and drawn the curve of seed velocity and height with time, as shown in Figure 9. The positive value of velocity represents the direction of seed falling close to the soil. The negative value of velocity represents the direction of seed rebound and soil separation. The corn seed starts to fall at 0 s and reach the maximum velocity of falling at about 0.283 s. The collision approaches velocity v0, and collides with the soil. The movement state changes, causing a sudden change in velocity. After the corn seed moves to the lowest point, it starts to rebound, the elastic deformation between particles recovers, and the elastic strain energy is converted into the potential energy of particles. The velocity of corn seed begins to increase and reaches the maximum value vt when it separated from soil particles, that is, the collision separation velocity is vt.

Figure 9.

Velocity and height of single seed in the DESE and the SBE.

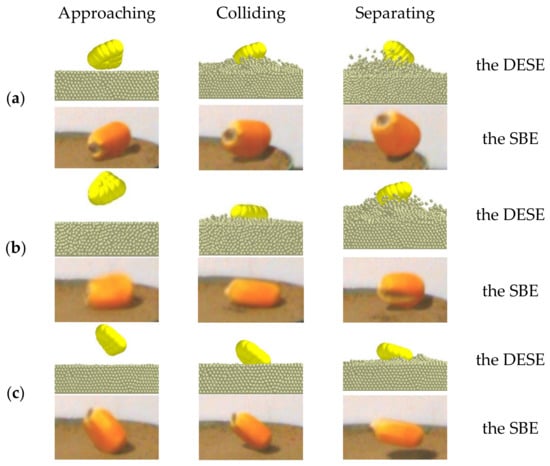

When the falling height and contact position of corn seeds in the DESE and the SBE are the same, the movement state of seed is compared. The movement state of seeds in the free fall stage is consistent, and the movement state of seeds after collision and separation is slightly different, but the difference is seldom. The separated corn seed showed a compound motion state of rotating motion with the contact side as the axis and parabola motion with the contact point as the starting point. The motion state of three groups (a, b, c) of simulation and real soil bin comparison experiments arbitrarily selected are shown in Figure 10.

Figure 10.

Comparison of movement status. (a–c) represent three groups of comparative tests, in each group of tests the falling height and contact position of corn seeds in the DESE and the SBE are the same, to compare the movement state of seeds in the DESE and the SBE.

- (2)

- Comparative Analysis of SAVR ξ

The SAVR ξ of the DESE and the SBE are shown in Table 5. The comparative analysis shows that the SAVR ξ decreases with the increase of the falling height. The reason was that, according to the impulse theorem, with the drop height increase, the corn seeds’ movement velocity before the collision contact increased. The increase of collision velocity led to the increase of collision impulse and collision force, and the deformation of contact position. The increase of deformation at the contact position leads to the increase of the contact area between corn seed and soil and energy loss due to contact friction. The energy loss led to the relative increase of the energy lost by the system, the reduction of the strain energy released in the unloading stage, the change of the corn seed movement state, and the relative reduction of the collision separation velocity. Therefore, the SAVR decreased with the increase of height, the SAVR ξ decreased with the increase of height. Except for position a, the relative error between the SBE and the DESE was within 10%, which confirms the reliability of the proposed method. As for the reason of the obviously error in position a, it was that the material properties of corn seed in the simulation experiment are all horny endosperms. In contrast, the characteristics of the basal fruit stalk materials of actual corn seed are different from those of horny endosperm materials. Therefore, there is an obviously difference in the SAVR between the SBE and the DESE in the simulation and the actual experiment. In the future research, the CRC between position A, and soil should be accurately measured, and different CRC should be used according to different materials in the EDEM to improve the accuracy of the simulation.

Table 5.

Comparison of results of the SBE and the DESE.

5. Conclusions

(1) Through the analysis of the collision process of corn seed colliding with soil, it was found that when using corn seed colliding with soil to measure the CRC, it was essentially a collision of one surface and multiple points. A large number of soil particles determined the movement state of corn seed after collision and separation. It was complicated to obtain the interaction relationship between a single soil particle and corn seed, and it could not be applied to measurement the CRC.

(2) A method for measuring the CRC by taking soil particles as the mass point and taking corn seed as the fixed surface was proposed. The analysis of the impact process shown that the contact between corn seed and multiple soil particles could be avoided, and the CRC of corn seed and soil could be obtained intuitively. Using soil particles to fall and collide with corn seed, the CRC between corn and soil was 0.607.

(3) The results of the verification experiment shown that the movement state of corn seed in the DESE and the SBE were basically the same when they fall at the same height and touch the soil at the same position; In the DESE and the SBE, the error of the SAVR was within 10% except for the position a, which verifies the accuracy of the proposed method.

Author Contributions

Conceptualization, Z.G. and C.L.; methodology, Z.G. and S.H.; software, Z.G., S.H. and Y.L.; writing—original draft preparation, Z.G. and C.L.; writing—review and editing, Z.G., C.L., H.L., J.H., Q.W. and H.Z.; funding acquisition, C.L. and H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the China Agriculture Research System of MOF and MARA: CARS-03; the 2115 Talent Development Program of China Agricultural University and Chinese Universities Scientific Fund: 2021TC105.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Horabik, J.; Beczek, M.; Mazur, R.; Parafiniuk, P.; Ryżak, M.; Molenda, M. Determination of the restitution coefficient of seeds and coefficients of visco-elastic Hertz contact models for DEM simulations. Biosyst. Eng. 2017, 161, 106–119. [Google Scholar] [CrossRef]

- Badua, S.A. Control System Response for Seed Placement Accuracy on Row Crop Planters. Ph.D. Thesis, Kansas State University, Manhattan, KS, USA, 2020. [Google Scholar]

- Yan, B.; Wu, G.; Fu, W.; Gao, N.; Meng, Z.; Zhu, P. Influencing factors of corn implantation distribution for high-height planting based on EDEM. Trans. Chin. Soc. Agric. Mach. 2020, 51, 47–54. [Google Scholar] [CrossRef]

- Han, S.; Qi, J.; Kan, Z.; Li, Y.; Meng, H. Parameters calibration of discrete element for deep application of bulk manure in Xinjiang orchard. Trans. Chin. Soc. Agric. Mach. 2021, 52, 101–108. [Google Scholar] [CrossRef]

- Zeng, Z.; Ma, X.; Cao, X.; Li, Z.; Wang, X. Critical review of applications of discrete element method in agricultural engineering. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Q.; Ma, L.; Li, L. Cottonseed particle motion law in 3-DOF hybrid vibration screen surface. Trans. Chin. Soc. Agric. Eng. 2015, 31, 49–56. [Google Scholar] [CrossRef]

- Müller, G.T.; Huang, K. Influence of the liquid film thickness on the coefficient of restitution for wet particles. Phys. Rev. E 2016, 93, 429–437. [Google Scholar] [CrossRef] [PubMed]

- Hastie, D.B. Experimental measurement of the coefficient of restitution of irregular shaped particles impacting on horizontal surfaces. Chem. Eng. Sci. 2013, 101, 828–836. [Google Scholar] [CrossRef]

- Feng, B.; Sun, W.; Shi, L.; Sun, B.; Zhang, T.; Wu, J. Determination of restitution coefficient of potato tubers collision in harvest and analysis of its influence factors. Trans. Chin. Soc. Agric. Eng. 2017, 33, 50–57. [Google Scholar] [CrossRef]

- Wang, L.; Ran, B.; Kan, Z.; Kan, Z. Experiment of restitution coefficient of processing tomato seeds in collision models. J. Jiangsu Univ. 2015, 36, 48–52. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, N.; Wang, B.; Yu, Z.; Lin, D.; Hu, Z. Measurement and analysis of peanuts’ restitution coefficient in point-to-plate collision mode. J. China Agric. Univ. 2016, 21, 111–118. [Google Scholar] [CrossRef]

- Huang, X.; Zha, X.; Pan, H.; Zong, W.; Chen, H. Measurement and analysis of rapeseeds’ restitution coefficient in point-to-plate collision model. Trans. Chin. Soc. Agric. Eng. 2014, 30, 22–29. [Google Scholar] [CrossRef]

- Liu, W.; He, J.; Li, H.; Li, X.; Zheng, K.; Wei, Z. Calibration of simulation parameters for potato minituber based on EDEM. Trans. Chin. Soc. Agric. Mach. 2018, 49, 125–135, 142 . [Google Scholar] [CrossRef]

- Zhou, W. The Physical and Mechanical Properties Research of Corn Grain. Ph.D. Thesis, Northeast Agricultural University, Harbin, China, 2015. [Google Scholar]

- Sui, J. Research on Experiment and Simulation Analysis of Soybean Collision with Soil. Ph.D. Thesis, Jilin University, Changchun, China, 2016. [Google Scholar]

- Zhang, G.; Xiang, X.; Tang, H. Field test and numerical calculation of restitution coefficient of rockfall collision. Chin. J. Rock Mech. Eng. 2011, 30, 1266–1273. [Google Scholar]

- Yu, X.; Cui, Y.; Chen, F.; Hu, G. Measurement of coefficient of restitution and gravitational acceleration by using bouncing ball. Coll. Phys. 2010, 29, 35–36. [Google Scholar] [CrossRef]

- Qin, Z.; Lu, Q. Analysis of impact process model based on restitution coefficient. J. Dyn. Control 2006, 4, 294–298. [Google Scholar]

- Liu, Y.; Zong, W.; Ma, L.; Huang, X.; Li, M.; Tang, C. Determination of three-dimensional collision restitution coefficient of oil sunflower grain by high-speed photography. Trans. Chin. Soc. Agric. Eng. 2020, 36, 44–53. [Google Scholar] [CrossRef]

- Li, G. Advanced Soil Mechanics; Tsinghua University Press: Beijing, China, 2013. [Google Scholar]

- Ren, L. Soil Adhesion Mechanics; China Machine Press: Beijing, China, 2011. [Google Scholar]

- Zeng, D. Mechanical Soil Dynamics; Beijing Science and Technology Press: Beijing, China, 1990. [Google Scholar]

- Zhang, F.; Zhao, W.; Han, Z.; Liu, J.; Yang, X.; Dai, F. Experimental researches on mechanical properties of corn kernels. Chin. Agric. Mech. 2010, 3, 75–78. [Google Scholar] [CrossRef]

- Shi, Z.; Cheng, H.; Li, J.; Feng, J. Characteristic parameters to identify varieties of corn seeds by image processing. Trans. Chin. Soc. Agric. Eng. 2008, 24, 193–195. [Google Scholar]

- Hao, J.; Yang, J.; Du, T. A study on basic morphologic information and classification of maize cultivars based on seed image process. Sci. Agric. Sin. 2008, 41, 994–1002. [Google Scholar]

- Peter, E.; Hu, B. Eberhard Modern Contact Dynamics; Southeast University Press: Shanghai, China, 2003. [Google Scholar]

- Xie, F.; Wu, Z.; Wang, X.; Liu, D.; Wu, B.; Zhang, Z. Calibration of discrete element parameters of soils based on unconfined compressive strength test. Trans. Chin. Soc. Agric. Eng. 2020, 36, 39–47. [Google Scholar] [CrossRef]

- Wang, X. Study on the Evaluation of Soil Compaction by Agricultural Tire and Combination Shovel Loose Soil Technology. Ph.D. Thesis, China Agricultural University, Beijing, China, 2018. [Google Scholar]

- Wang, Y.; Liang, Z.; Zhang, D.; Cui, D.; Shi, S.; Li, K.; Yang, L. Calibration method of contact characteristic parameters for corn seeds based on EDEM. Trans. Chin. Soc. Agric. Eng. 2016, 32, 36–42. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).