Abstract

This paper shows an optimization study on calculating the optimum replaced wheel diameter in internal grinding of stainless steel. In this work, the effects of the input factors, including the initial diameter, the grinding wheel width, the ratio between the length and the diameter of the work-pieces, the dressing depth of cut, the wheel life and the radial grinding wheel wear per dress on the optimum replaced grinding wheel diameter were considered. Also, the effects of cost components, including the cost of the grinding machine and the wheel cost were examined. Moreover, to estimate the influences of these parameters on the optimum replaced diameter, a simulation experiment was given and conducted by programming. From the results of the study, a regression equation was proposed to calculate the optimum replaced diameter.

1. Introduction

Nowadays, grinding is broadly used in industries. It is reported that about 20–25% of the total mechanical parts are made with the use of grinding machining [1]. Accordingly, studies on optimization of the grinding process have caught much interest from numerous researchers.

Up to now, a number of studies have been done on the optimization of different grinding types. The researches have been carried out on external cylindrical grinding [2,3,4,5], surface grinding [6,7,8] and belt grinding [9]. The studies in this area have been implemented not only on the CNC (Computer Numerical Control) grinding machine [10] but also on the CNC milling machine [11].

Regarding internal grinding process, scientists have paid substantial attention to monitoring and optimizing the grinding process [12], investigating the impact of the wheel dressing on the surface finish [13], online-optimizing the grinding process and the dressing parameters for the reduction of the grinding time [14], and applying adaptive control to increase the efficiency of the grinding process [15]. In addition, to decrease the grinding cost, a cost optimization study on internal grinding process was presented [16]. It was reported that there is an optimum replaced grinding wheel diameter at which the grinding cost is minimum. Moreover, grinding with this optimum replaced diameter can significantly reduce both the time and the cost of the grinding process.

This article presents research on cost optimization of the internal grinding process. The aim of the study is to find the optimum replaced wheel diameter in internal grinding stainless steel. In the study, the effects of the cutting and the cost factors on the optimum replaced diameter were explored. Also, a simulation experiment was created and accomplished by programming for evaluation of the influences of these factors on the optimum replaced diameter. The influences of the cutting factors and the cost elements on the optimum replaced diameter were scientifically weighed. Furthermore, to determine the optimum replaced diameter, a regression equation was proposed.

2. Cost Analysis

The internal grinding cost per part is determined by [16]:

where, Cm,h is the cost of the grinding machine (USD/h), including the wages, the overhead cost, the labor cost etc.; ts is the grinding time which is discussed later in this section; Cgw,p is the wheel cost per part (USD/p) which is calculated by:

In which, Cgw is the cost of a piece of wheel (USD/p); np,w is the entire parts ground per wheel; np,w can be determined as follows [17]:

where, D0 is the initial diameter of wheel (mm); De is the replaced diameter of the wheel (mm); is the radial grinding wheel wear per dress (mm/dress); aed is the dressing depth of cut (mm); np,d is the number of parts per dress which is found by:

wherein, Tw is the wheel life (h); tc is the grinding time (h) which is calculated as follows:

In Equations (5) and (6), vfa and fr,tab can be determined by the following Equations [18]:

and

In the above equations, lw is the length of part (mm); ae,tot is the total depth of cut (mm); vfa is the axial feed speed (mm/min); fr,tab is the tabled radial wheel feed (mm/stroke); fr is the radial wheel feed (mm/ stroke); c1, c2, c3 and c4 are the coefficients for determining the radial wheel feed (Table 1); Wgw is the grinding wheel width; is the work-piece diameter; Srg is the surface roughness grade; is the work-piece speed; As it is grinding stainless steel, can be determined by [18]:

ts is the grinding time, including auxiliary time (h), which is determined by:

Table 1.

Coefficients for determining the radial wheel feed.

In which, tc is the grinding time (h); tsp is the spark-out time (h); td,p is the dressing time per piece (h); tcw is the wheel replacing time (h) and tlu is the loading and unloading work-piece time (h). These time components can be determined by the equations presented in Table 2 in which td is the dressing time (h).

Table 2.

Time components.

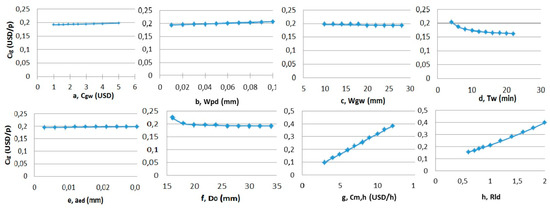

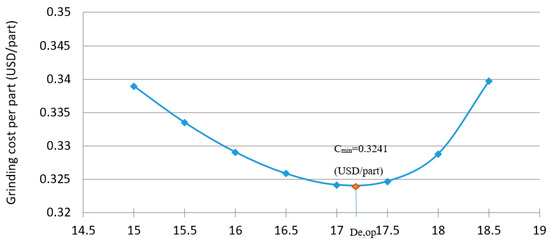

To investigate the influence of input factors on the grinding cost, a program was conducted based on the above cost analysis. From the results of the program, the effects of several input factors on the grinding cost are exhibited in Figure 1. Moreover, the relation between the grinding cost and the replaced wheel diameter is described in Figure 2. This relation was calculated by Equation (1), in which D0 = 20 (mm); Wgw = 25 (mm); aed = 0.12 (mm); Cmh = 5 (USD/h); Cgw = 3 (USD); Tw = 20 (min.); Wpd = 0.02 (mm/dress); Srg = 7; tg = 7; Rld = 2. As it was reported in [16], the grinding cost is powerfully affected by the replaced grinding wheel diameter. In addition, this cost is minimum when the replaced wheel diameter reaches an optimum value (in this case De,op = 17.2 (mm)). Besides, the optimum diameter is considerably bigger than the conventional replaced grinding wheel diameter (about 13 to 14 mm [20]). It is observed from the figures that the grinding cost depends on various factors, such as the initial diameter, the grinding wheel width, the ratio between the length and the diameter of the workpieces, the total depth of dressing cut, the wheel life, the radial grinding wheel wear per dress, the replaced wheel diameter and so on. In addition, among these parameters, the replaced wheel diameter is the unique factor holding an optimum value at which the grinding cost is minimum. Hence, the optimum replaced wheel diameter has been selected to be the objective of the cost optimization problem.

Figure 1.

Grinding cost versus input factors.

Figure 2.

Grinding cost versus replaced wheel diameter.

From the above analyses, the cost optimization problem to determine the optimum replaced wheel diameter De,op is expressed by:

With the following constraint:

Additionally, as reported above, the optimum replaced wheel diameter is affected by a number of parameters. In this study, seven main input factors, including the initial wheel diameter D0, the width of wheel Wgw, the ratio of work-piece length per work-piece diameter Rld, the dressing depth of cut aed, the wheel life Tw, the radial grinding wheel wear per dress Wpd, the cost of the grinding machine Cm,h and the wheel cost Cgw were carefully selected to evaluate their effects on the optimum replaced diameter. Hence, the optimum replaced wheel diameter can be described as follows:

3. Experimental Work

To learn the influences of input parameters on the optimum replaced diameter, a simulation experiment was planned. For the investigation, 8 input parameters, including the initial wheel diameter , the width of wheel, the ratio of length to diameter of the work-piece, the dressing depth of cut , the life of wheel , the radial grinding wheel wear per dress , the cost of the grinding machine and the wheel cost per piece were selected (Table 3). In practice, the cost components (the cost of the grinding machine and the wheel cost per piece) depend on the policies and the location of the company which owns the grinding machine. In addition, they vary from time to time. For example, the grinding machine cost per hour in the USD can be 7 to 10 USD/h while it is only about 4 to 5 USD/h in Vietnam. Therefore, the low and high levels of the cost components were selected based on the above mentioned factors (Table 3).

Table 3.

Experimental input factors.

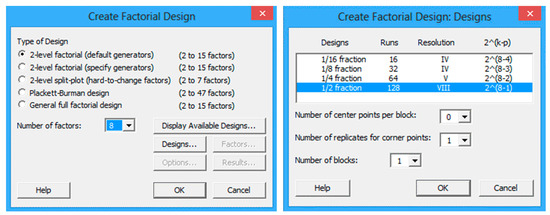

Since this is a simulation experiment, there is no need to reduce the number of experiments. Therefore, the factorial design of experiments was chosen instead of Taguchi’s method. Furthermore, the experimental design with which a 2-level factorial design with ½ fraction was setup with eight mentioned parameters. Therefore, the number of experiments was calculated as (Figure 3). To perform the experiments, based on the cost analysis (see Section 2) a computer program was created. The input factors and the output response (the optimum replaced diameter ) are shown in Table 4.

Figure 3.

Creation of factorial design.

Table 4.

Experimental plans and output response.

4. Results and Discussion

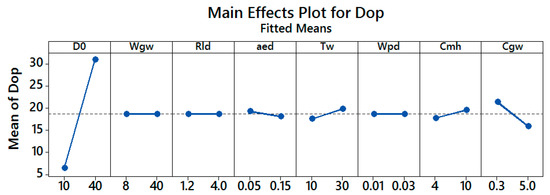

The influences of input parameters on the optimal replaced diameter are illustrated in Figure 4. From this figure, the optimal replaced diameter is powerfully contingent on the original wheel diameter. Also, it depends on the dressing depth of cut , the life of wheel , the cost of the grinding machine and the grinding wheel cost . In addition, is not affected by the width of wheel Wgw, the ratio of the length to the diameter of work-piece Rld and the radial grinding wheel wear per dress Wpd.

Figure 4.

Main effects plot for optimum replaced grinding wheel diameter.

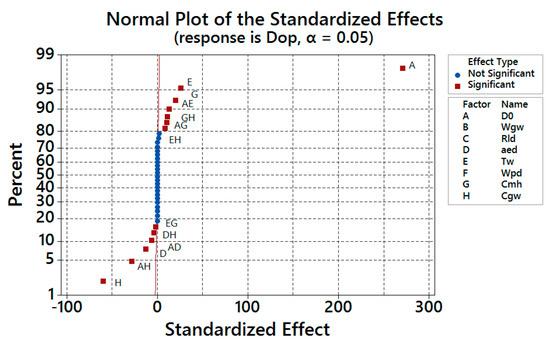

The Normal Plot of the standardized effects is described in Figure 5. From this graph it is known that the initial diameter of grinding wheel (factor A), the life of wheel (factor C), the cost of the grinding machine (factor G) and the interactions AE, GH, AG and EH have positive standardized effects. That means if their values increase, the optimal replaced diameter raises. Also, the cost of the wheel (factor H), the dressing depth of cut (factor D) and the interactions AH, AD, DH and EG have negative standardized effects. If their values grow, the optimum replaced diameter drops.

Figure 5.

Normal Plot for De,op.

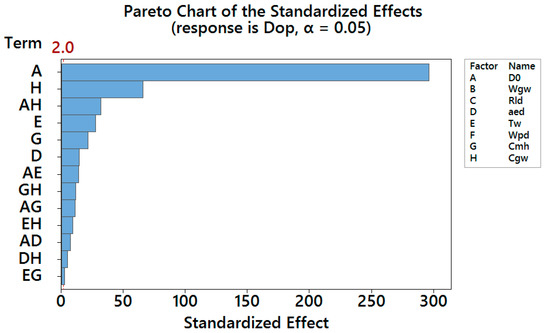

Figure 6 presents the Pareto chart for the optimal replaced diameter. It can be seen from the figure that the reference line crosses characterized factors A (the initial diameter of wheel), H (the cost of the wheel), E (the life of wheel), G (the cost of the grinding machine), D (the dressing depth of cut) and the interactions AH, AE, EF, AE, GH, AG, EH, AD, DH and EG. Therefore, these parameters are significant with the optimum diameter.

Figure 6.

Pareto chart for Dop.

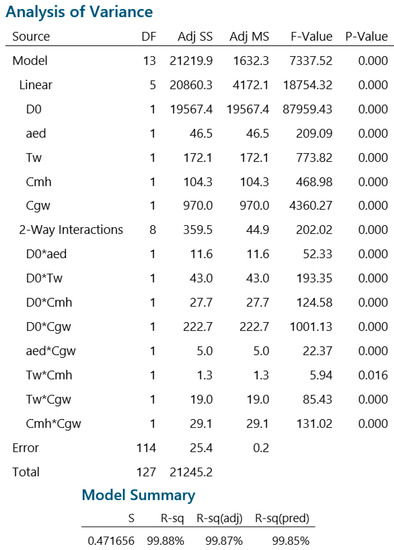

To find the significant effects on the optimum replaced diameter, the insignificant effects which have the P-values higher than 0.05 were ignored. Consequently, it can be found from the figure that the initial diameter of wheel , the dressing depth of cut , the life of wheel , the cost of the grinding machine , the cost of the wheel and the interactions between and , , and ; and ; and and and between and have significant effects on the response (Figure 6). In addition, the following equation was proposed to calculate the optimum replaced wheel diameter:

The regression model (14) fits the experimental data very well because all of the values of adj-R2 and pred-R2 are greater than 99.85% (Figure 7). This model is used to determine the optimum replaced wheel diameter when grinding stainless steel.

Figure 7.

Estimated effects and coefficients for De,op.

5. Conclusions

A cost optimization study on the calculation of the optimal replaced wheel diameter when internal grinding stainless steel was carried out. For doing this, the internal grinding cost was analyzed. Moreover, the influence of many input factors, as well as the cost elements on the optimum replaced diameter were inspected by designing and conducting a simulation experiment computationally. More considerably, an equation for determination of the optimum replaced diameter was presented. As the proposed equation is explicit, the optimum replaced diameter in internal grinding of stainless steel is predicted precisely and effortlessly.

Author Contributions

All authors discussed the original idea. A.-T.L., N.-P.V. and X.-H.L. designed and performed the simulation experiments; N.-P.V. wrote this manuscript with support from Q.-T.N., T.-D.H., T.-H.T., H.-K.L., T.-L.B. and X.-H.L; all authors provided critical feedback and helped shape the research, analysis, and reviewed the manuscript; N.-P.V. supervised this work.

Funding

The work described in this paper was supported by the Thai Nguyen University of Technology for the scientific project No. T2018-B11.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Malkin, S.; Guo, C. Grinding Technology: Theory and Applications of Machining with Abrasives; Industrial Press: New York, NY, USA, 2008. [Google Scholar]

- Li, G.F.; Wang, L.S.; Yang, L.B. Multi-parameter optimization and control of the cylindrical grinding process. J. Mater. Process. Technol. 2002, 129, 232–236. [Google Scholar] [CrossRef]

- Gupta, R.; Shishodia, K.S.; Sekhon, G.S. Optimization of grinding process parameters using enumeration method. J. Mater. Process. Technol. 2001, 112, 63–67. [Google Scholar] [CrossRef]

- Chatterjee, S.; Rudrapati, R.; Kumar pal, P.; Nandi, G. Experiments, analysis and parametric optimization of cylindrical traverse cut grinding of aluminium bronze. Mater. Today: Proc. 2018, 5, 5272–5280. [Google Scholar] [CrossRef]

- Pi, V.N.; The, P.Q.; Khiem, V.H.; Huong, N.N. Cost optimization of external cylindrical grinding. Appl. Mech. Mater. 2013, 312, 982–989. [Google Scholar] [CrossRef]

- Rana, P.; Lalwani, D.I. Parameters optimization of surface grinding process using Modified ε constrained Differential Evolution. Mater. Today: Proc. 2017, 4, 10104–10108. [Google Scholar] [CrossRef]

- Warnecke, G.; Barth, C. Optimization of the Dynamic Behavior of Grinding Wheels for Grinding of Hard and Brittle Materials Using the Finite Element Method. CIRP Ann. Manuf. Technol. 1999, 48, 261–264. [Google Scholar] [CrossRef]

- Pi, V.N.; Tung, L.A.; Hung, L.X.; Ngoc, N.C. Experimental Determination of Optimum Replaced Diameter in Surface Grinding Process. J. Environ. Sci. Eng. 2017, 5, 85–89. [Google Scholar]

- Pandiyan, V.; Caesarendra, W. Tegoeh Tjahjowidodo, and Gunasekaran Praveen, Predictive Modelling and Analysis of Process Parameters on Material Removal Characteristics in Abrasive Belt Grinding Process. Appl. Sci. 2017, 7, 363. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, H.; Yang, Y. Reliability Modeling and Evaluation Method of CNC Grinding Machine Tool. Appl. Sci. 2019, 9, 14. [Google Scholar] [CrossRef]

- Vu, N.P.; Nguyen, O.-X.; Tran, T.-H.; Le, H.-K.; Nguyen, A.-T.; Luu, A.-T.; Nguyen, V.-T.; Le, X.-H. Optimization of Grinding Parameters for Minimum Grinding Time When Grinding Tablet Punches by CBN Wheel on CNC Milling. Appl. Sci. 2019, 9, 957. [Google Scholar] [CrossRef]

- Inasaki, I. Monitoring and Optimization of Internal Grinding Process. CIRP Ann. Manuf. Technol. 1991, 40, 359–362. [Google Scholar] [CrossRef]

- Daneshi, A.; Jandaghi, N.; Tawakoli, T. Effect of Dressing on Internal Cylindrical Grinding. Procedia CIRP 2014, 14, 37–41. [Google Scholar] [CrossRef]

- Xiao, G.; Malkin, S. On-Line Optimization for Internal Plunge Grinding. CIRP Ann. Manuf. Technol. 1996, 45, 287–292. [Google Scholar] [CrossRef]

- Tönshoff, H.K.; Walter, A. Self-tuning fuzzy-controller for process control in internal grinding. Fuzzy Sets Syst. 1994, 63, 359–373. [Google Scholar] [CrossRef]

- Pi, V.N.; Hung, L.X.; Tung, L.N.; Long, B.T. Cost Optimization of Internal Grinding. J. Mater. Sci. Eng. B 2016, 6, 291–296. [Google Scholar]

- Brian Rowe, W. Principle of Modern Grinding Technology; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Long, B.T.; Pi, V.N.; Hung, L.X.; Tung, L.A. Building cutting regime formulas for internal grinding (In Vietnamese). J. Sci. Technol. 2016, 9, 15–18. [Google Scholar]

- Kozuro, L.M.; Panov, A.A.; Remizovski, E.I.; Tristosepdov, P.S. Handbook of Grinding (in Russian); Publish Housing of High-Education: Minsk, Russia, 1981. [Google Scholar]

- Hung, L.X.; Hong, T.T.; Ky, L.H.; Tuan, N.Q.; Tung, L.A.; Long, B.T.; Pi, V.N. A study on calculation of optimum exchanged grinding wheel diameter when internal grinding. In Proceedings of the 9th International Conference on Materials Processing and Characterization, Hyderabad, India, 8–10 March 2019. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).