Abstract

The transesterification of waste frying oil (WFO) with methanol in the presence of potassium hydroxide catalyst supported on Jatropha curcas fruit shell activated carbon (KOH/JS) was studied. The catalyst systems were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM) and the Brunauer–Emmett–Teller (BET) method. The effects of reaction variables such as residence time, reaction temperature, methanol/oil molar ratio and catalyst bed height in packed bed reactor (PBR) on the yield of biodiesel were investigated. SEM images showed that KOH was well distributed on the catalyst support. The optimum conditions for achieving the conversion yield of 86.7% consisted of a residence time of 2 h, reaction temperature of 60 °C, methanol/oil molar ratio of 16 and catalyst bed height of 250 mm. KOH/JS could be used repeatedly five times without any activation treatment, and no significant activity loss was observed. The results confirmed that KOH/JS catalyst had a great potential to be used for industrial application in the transesterification of WFO. The fuel properties of biodiesel were also determined.

1. Introduction

Due to an increase in crude oil price, environmental concern for vehicle exhaust emission, and the demand for the reduction of greenhouse gas emission, the development of renewable energies has grown dramatically over the past years. Among the applicable renewable energies, biodiesel has recently attracted extensive attention because it is biodegradable, non-toxic, and environmentally friendly [1,2,3]. Biodiesel is defined as fatty acid methyl ester (FAME) or fatty acid ethyl ester (FAEE) from vegetable oils or animal fats. The significant advantages of biodiesel over conventional fossil-based diesel fuels include cleaner engine emissions, its status as a renewable energy source and superior lubricating property, making it an excellent alternative fuel [4].

In general, transesterification of triglyceride (TG) to diglyceride (DG), monoglyceride (MG), methyl ester (ME) and glyceride (GL) can be catalyzed by bases, acids, and enzymes [5,6]. In many production processes for biodiesel, alkaline catalysts are typically used. The commonly used homogenous base catalysts are potassium hydroxide (KOH), sodium hydroxide (NaOH), and the corresponding potassium or sodium methoxide [7,8]. However, the use of homogeneous alkaline catalysts in the production of biodiesel requires acid neutralization and a washing step to remove the catalyst and salt from the ester phase, which generates a large amount of wastewater. In addition, it is difficult to separate the homogeneous catalyst from the glycerol phase [9]. In order to overcome these problems, the use of heterogeneous catalysts as a potential solution is preferred [10].

The heterogeneous catalyst process has recently become attractive as an effective biodiesel production process [11]. Due to their facile separation and recycled use, solid catalysts, such as zeolites, alkali earth oxides, alkali metals or alkali earth salts loaded on metal oxide, metallic complexes, and silica-alumina, have been explored as promising alternatives [12]. More recently, there has been an increasing development of heterogeneous catalysts, such as NaOH, KOH and a series of potassium catalysts supported on alumina, alkali-doped metal oxide, zeolite and activated carbon. The activity of these solid bases generally increases with base strength. Besides being more active than metal compounds, the use of solid bases requires catalytic reactions to occur under milder conditions than acids [13]. However, the small pore size and low surface area of these catalysts have limited their use in biodiesel synthesis [14]. Due to its unique properties, it is now well established that activated carbon can be used as a highly effective catalyst support in liquid and vapor phase reactions such as transesterification reactions. Not only can activated carbon be produced from a variety of raw materials [15], but also it has the large surface area, which allows that catalyst to be highly dispersed in an effective manner.

With regard to concerns about recycling and utilization of agricultural biomass resources [16], the effective uses of agricultural waste biomass for the production of activated carbons by thermo-chemical conversion has gained much attention over the last decade [17]. Jatropha curcas fruit shell (JS) is a promising biomass waste that can be utilized as a precursor for activated carbon. Their seeds also contain high oil levels and have been widely used for biodiesel production in several Asian countries. However, the solid residues that remain after the seed-pressing process are typically regarded as mere waste. Accumulation of these wastes for a long period of time often creates environmental problems due to its unpleasant odor. Since the fixed carbon content in JS is quite high, the utilization of this waste as activated carbon can minimize the environmental problem [18]. The main objective of this work was to optimize the continuous process for biodiesel production from waste frying oil (WFO) using potassium hydroxide supported on Jatropha curcas fruit shell activated carbon (KOH/JS). The effects of residence time, reaction temperature, methanol/oil molar ratio, catalyst bed height and reusability of catalyst were systematically investigated.

2. Experimental Section

2.1. Materials and Reagents

The activated carbon used in this work was prepared from JS by a chemical activation process. WFO samples were collected in university cafeterias without further treatment. The numerous fractions were blended in order to obtain waste oil. Filter papers with an average pore size of 5 µm were used to remove any non-oil components or impurities in WFO before used. The basic properties of waste oil feedstock are shown in Table 1. It was observed that the acid value (AV) of WFO was 1.91, which did not exceed the standard values for the transesterification process. The reaction process can, therefore, be achieved by using a heterogeneous base catalyst [19]. All other chemicals were analytical grade reagents (Merck, >99% purity) and were used as received.

Table 1.

Physicochemical properties of waste oil feedstock.

| Properties | Waste Oil Feedstock |

|---|---|

| Density (g/mL @ 15 °C) | 0.892 |

| Molecular weight (g/g mole) | 912.4 |

| Saponification value (mg KOH/g oil) | 188.76 |

| Acid value (mg KOH/g oil) | 1.91 |

| Water content (wt%) | 0.10 |

2.2. Activated Carbon Preparation

The JS was first cleaned with water to remove fines and dirt, and dried at 100 °C for 12 h. The dried sample was crushed with a grinder and sieved to a particle size of 1.8–2.8 mm. It was then soaked in phosphoric acid (H3PO4) solution with the impregnation ratio of 1.7 for 24 h at ambient temperature [20]. After that, it was dried in an oven at 100 °C for 12 h. The resultant sample was further activated in a horizontal automatic tubular furnace at 500 °C for 24 h under nitrogen atmosphere [21]. After cooling, the activated carbon was washed several times with distilled water until the pH became neutral. The washed sample was then dried at 110 °C for 12 h to obtain activated carbon as the final product, cooled in a desiccator and stored in glass containers.

2.3. Catalyst Preparation

A potassium-containing solution was prepared by dissolving KOH in distilled water. Activated carbon was divided in 50 g portions and placed in a beaker. 750 mL of KOH solution with initial concentration of 0.40 g/mL was added. Activated carbon suspended in KOH solutions was then agitated at ambient temperature for 24 h. The amount of adsorbed KOH was measured by a gravimetrical method [22].

2.4. Characterization of Activated Carbon and Catalyst

The X-ray diffraction (XRD) characterization of the activated carbon and KOH/JS catalyst was performed on a Philips Analytical PW 3710 based generator X-ray diffractometer using Cu Kα radiation over a 2θ range from 5° to 100° with a step size of 0.04° at a scanning speed of 3°/min.

To evaluate the surface area, mean pore diameter and pore volume, adsorption–desorption of nitrogen (N2) at 77 K was carried out by a Quantachrome instrument (Autosorb-1 Model No. ASIMP.VP4). Before taking adsorption data, degassing at 120 °C and a residual pressure of 300 μm Hg for 24 h was performed using the degas port. The surface area was calculated using the Brunauer–Emmett–Teller (BET) equation and the mean pore diameter and pore volume was obtained by applying the Barret–Joyner–Halenda (BJH) method on the desorption branch [23].

The microstructures of the materials were observed by a scanning electron microscope (SEM). The SEM images of the representative sample were obtained from a Camscan-MX 2000 equipped with an energy dispersive spectroscope (EDS).

2.5. Instrumentation and Catalytic Reaction Procedure

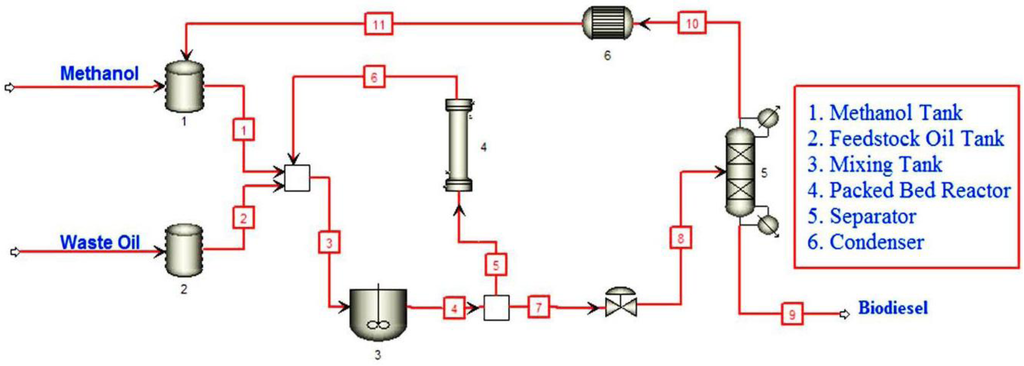

The continuous transesterification was performed in a packed bed reactor (PBR). The scheme of the PBR was shown in Figure 1.

Figure 1.

Schematic diagram of packed bed reactor (PBR) for continuous process for biodiesel production.

Figure 1.

Schematic diagram of packed bed reactor (PBR) for continuous process for biodiesel production.

The reactor was composed of a water-jacketed stainless steel column with an external diameter of 60 mm and a height of 345 mm. The column was packed with KOH/JS solid-base catalyst. WFO and methanol were charged into the system using two separate raw material pumps. The reactants were mixed and preheated in a mixing tank. The mixture was fed to the inlet of reactor using a pump (1–3 mL/min). The reaction temperature was controlled by a heater to keep constant temperature with an error of ±1.0 °C. The temperature difference between the inlet and the outlet was below 1.0 °C during all the runs. Temperature and pressure of the system were monitored by a temperature indicator and pressure gauges. The sample obtained was purified by reduced pressure distillation to remove the excess methanol and water generated during reaction. A methanol recovery unit, which is based on continuous distillation, consists of a condenser and a heater. The permeate stream containing biodiesel, methanol and glycerol was collected in the separator. Since the low-melting point methanol phase could be simply separated and recovered for reuse by evaporation and distillation, respectively, most biodiesel production process uses excess methanol to get high yield. Excess un-reacted methanol can then be separated and recycled easily by vaporization after reaction.

The continuous production of biodiesel from WFO and methanol was carried out in a PBR at atmospheric pressure. The effects of residence time (1 to 3 h), reaction temperature (50 to 70 °C), methanol/oil molar ratio (10 to 20), catalyst bed height (150 to 300 mm) and reusability of catalyst (1 to 5 times) on the conversion to FAME were studied. After a certain period of time, a known amount of sample was taken out from the reactor for analysis. All experiments were repeated 3 times and the standard deviation was never higher than 7% for any point.

2.6. Analysis of Final Product

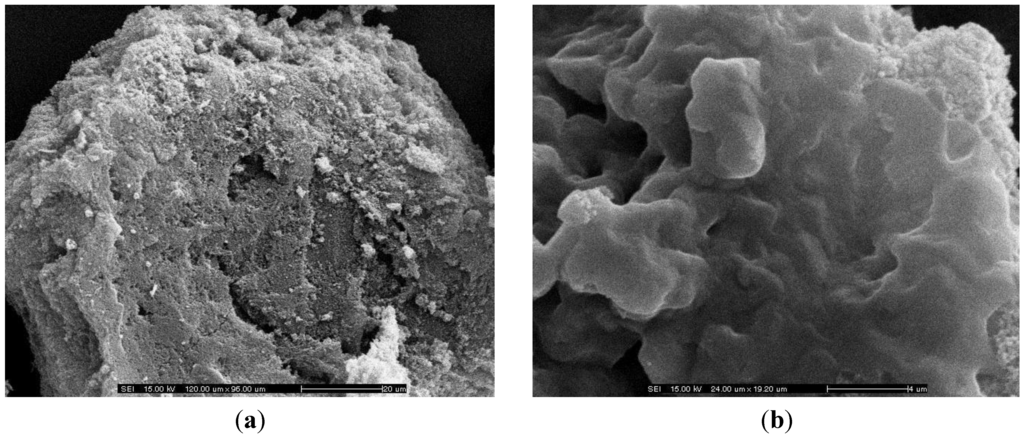

Composition of the FAME was analyzed with gas chromatograph-mass spectrometry (GC-MS QP2010 Plus, Shimadzu Corporation, Japan) equipped with a flame ionization detector (FID) and a capillary column 30 m × 0.32 mm × 0.25 µm (DB-WAX, Carbowax 20M). Yield of biodiesel was calculated by Equation (1):

where mi is the mass of internal standard added to the sample, Ai is the peak area of internal standard, mb is the mass of the biodiesel sample and Ab is the peak area of the biodiesel sample [24]. The physical and chemical properties of biodiesel including kinematic viscosity, density, flash point, cloud point, pour point, acid value and water content were analyzed according to ASTM methods.

3. Results and Discussion

3.1. Characterization of KOH/JS Catalyst

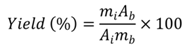

Figure 2 shows XRD patterns of activated carbon derived from Jatropha curcas fruit shell and KOH/JS catalyst. It is observed that pure activated carbon exhibits broad peaks with an absence of sharp peaks. This reveals an amorphous nature of material, which is advantageous for well-defined adsorbents. The occurrence of broad peaks around 26° and 43° indicates an alignment of carbon layer planes [21,25]. For the KOH/JS catalyst, the existence of diffraction peaks at 2θ = 30°, 32°, 34°, 38°, 39° and 41° refers to the potassium hydroxide phase. These results implied that the catalyst contained KOH as expected. It was hypothesized that KOH was coated within the highly porous structure of the activated carbon. The formation of the KOH phase contributes to higher basicity and catalytic activity for the transesterification reaction in comparison to activated carbon. The amount of adsorbed KOH was measured by a gravimetrical method. The total loading content of the potassium salts was 31.3 wt% based on the weight of activated carbon.

Figure 2.

XRD patterns of activated carbon and Jatropha curcas fruit shell activated carbon (KOH/JS) catalyst.

Figure 2.

XRD patterns of activated carbon and Jatropha curcas fruit shell activated carbon (KOH/JS) catalyst.

The physical properties of activated carbon and KOH/JS catalyst are summarized in Table 2. The Jatropha curcas fruit shell activated carbon had a BET surface area of 927.85 m2/g and a pore volume of 0.923 cm3/g. The KOH/JS catalyst, on the other hand, exhibits lower specific surface area (275.83 m2/g) and pore volume (0.209 cm3/g), compared to activated carbon. The significant reduction in BET surface area of 33.3 wt% KOH/JS catalyst indicates the filling of KOH molecules into the activated carbon pores, supporting the above hypothesis [15]. In addition, it can be seen that the catalyst resulted in a strong increase in the active sites. This assumption is supported by the SEM images.

Table 2.

The physical properties of activated carbon and KOH/AC (AC = Activated Carbon) catalyst.

| Physical Property | Material | |

|---|---|---|

| Activated Carbon | KOH/JS Catalyst | |

| BET surface area (m2/g) | 927.85 | 275.83 |

| Pore volume (m3/g) | 0.923 | 0.209 |

| Mean pore diameter (A°) | 44.86 | 93.71 |

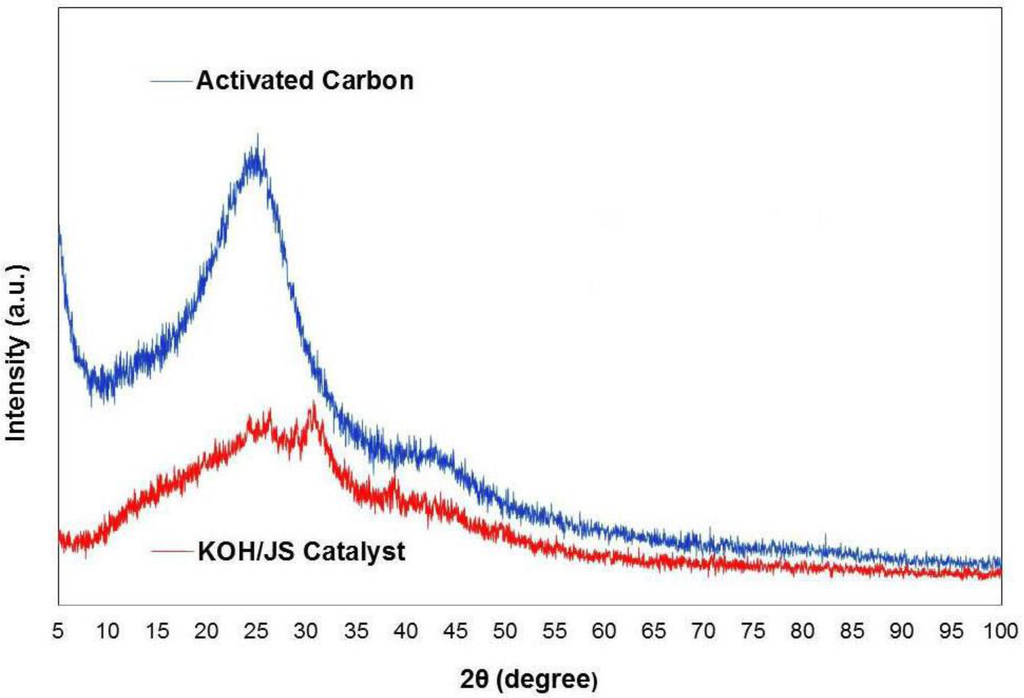

The porous nature of activated carbon and KOH/JS catalyst is illustrated by SEM images, as shown in Figure 3. The results showed that the metal loading affected the partial metal coverage on the activated carbon surface [26]. Figure 3(b) shows a good dispersion of potassium species on the entire surface of activated carbon. Based on previous research, good catalytic activity is enabled by preservation of the support material after catalyst preparation. In addition, the metal species must be highly distributed upon the surface of the support [22].

Figure 3.

(a) SEM micrograph of activated carbon; (b) SEM micrograph of KOH/JS catalyst.

Figure 3.

(a) SEM micrograph of activated carbon; (b) SEM micrograph of KOH/JS catalyst.

3.2. Influence of Various Parameters on the Yield of Biodiesel

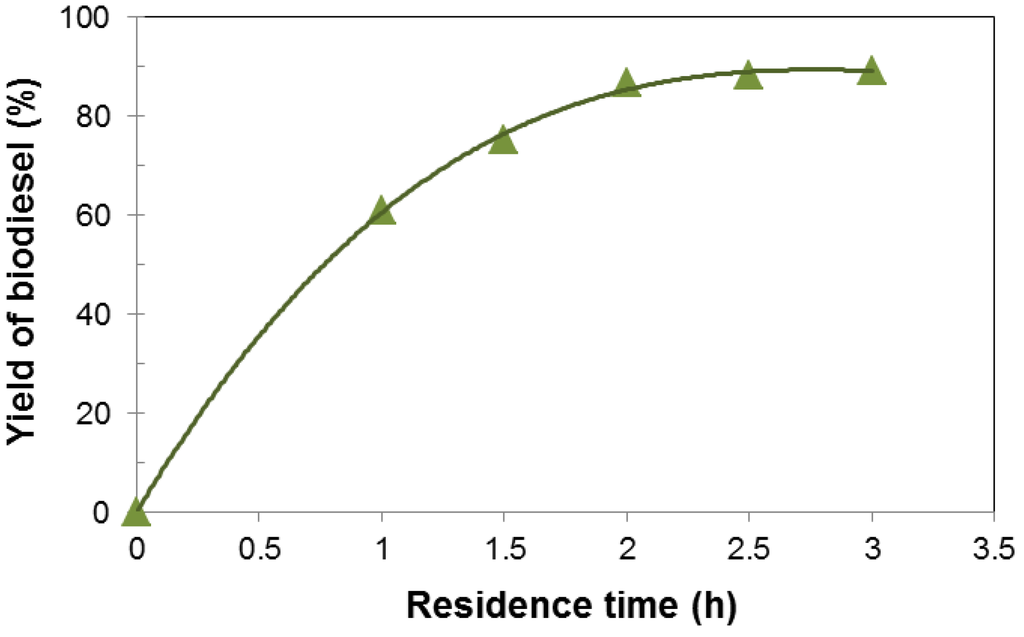

The conditions used for the preparation of biodiesel in the continuous reactor were a reaction temperature of 60 °C, methanol/oil molar ratio of 16, catalyst bed height of 250 mm and pressure of 1 atm. The impurities and non-oil components of WFO were removed by filtration before use. Flow rate of reactant is one of the key parameters during the continuous transesterification carried out in the PBR. Residence time was controlled by changing the flow rate of the feedstock chemical [27]. The corresponding yield of biodiesel with the residence time is shown in Figure 4. The yield of methyl ester increased from 61.1 to 86.7% with an increase of residence time from 1 to 2 h. However, a slight increase in the yield was observed for an increase in residence time from 2 to 3 h. This might be because when the residence time is too long, the transesterification reaction between WFO and methanol could be reversible. The hydrolysis reaction of FAME can then be strengthened to generate more free fatty acid (FFA) and alcohol. From an economical point of view, it is therefore not necessary to spend a long time to increase the conversion of waste oil, when the yield of FAME has been nearly optimized to avoid saponification and hydrolysis reaction in transesterification reaction [28].

Figure 4.

Effect of residence time on the yield of biodiesel in PBR.

Figure 4.

Effect of residence time on the yield of biodiesel in PBR.

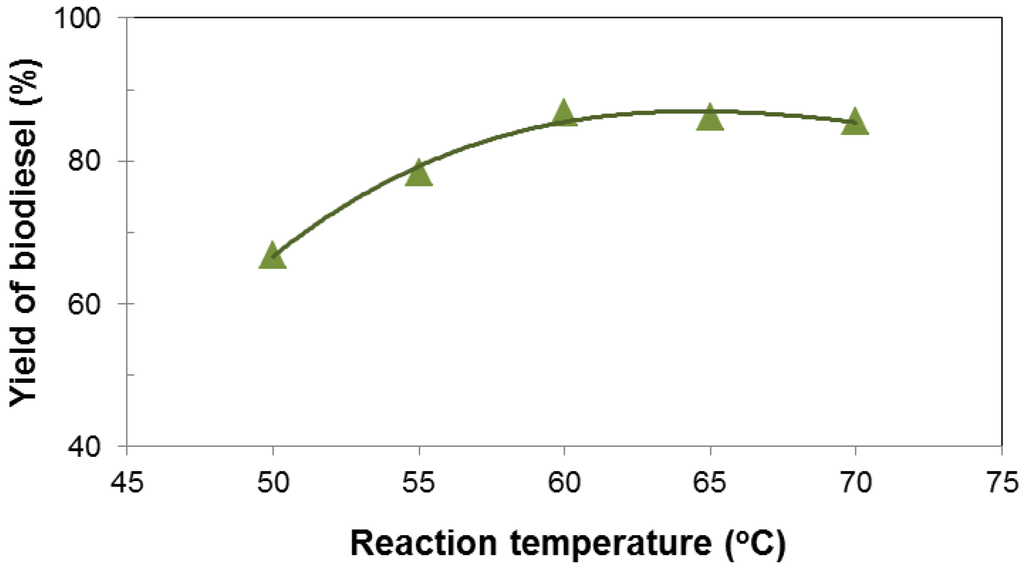

The catalytic effect of reaction temperature on transesterification was investigated from the percentage of WFO conversion to methyl ester. From Figure 5, the yield of biodiesel was obviously raised from 66.8 to 85.6% with an increase in reaction temperature from 50 to 70 °C. The effect of reaction temperature on promoting transesterification can be explained by endothermic reaction aspects, in which higher temperature would lead to higher reaction rate [29,30]. The highest yield rate was obtained at the reaction temperature of 60 °C. However, when the reaction temperature continued to increase over 60 °C or above the boiling point of methanol, the conversion was decreased. Due to the fact that the evaporation of methanol leads to the reduced ratio of methanol/oil in the reaction, the result is a decline in the transesterification activity [31]. In general, the transesterification reaction temperature should be below the boiling point of alcohol in order to prevent the alcohol evaporation. The range of optimal reaction temperature may vary from 50 to 60 °C, depending upon the oils or fats used.

Figure 5.

Effect of reaction temperature on the yield of biodiesel in PBR.

Figure 5.

Effect of reaction temperature on the yield of biodiesel in PBR.

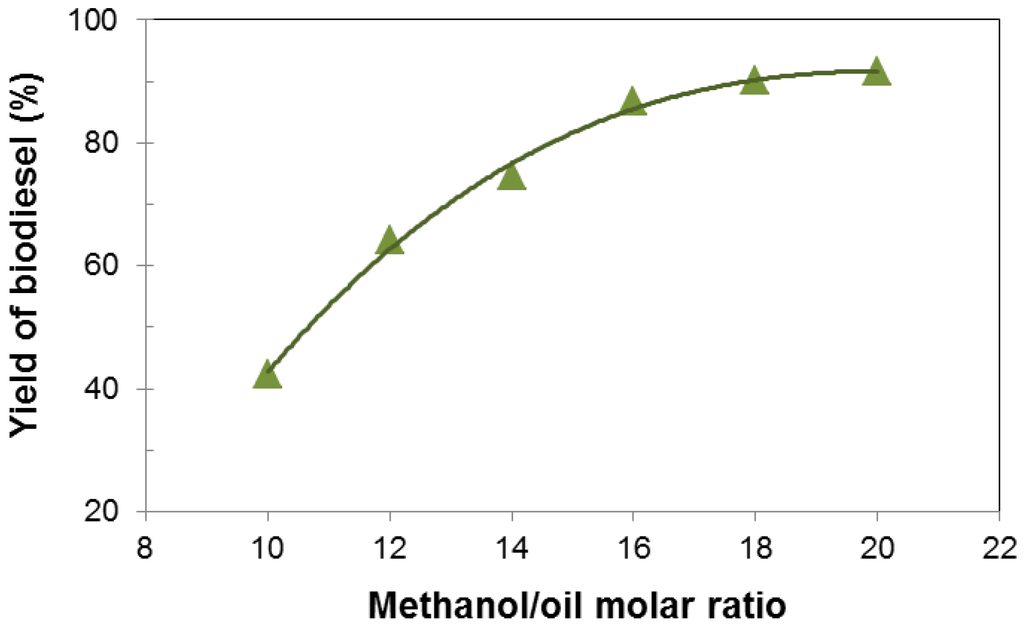

Figure 6.

Effect of methanol/oil molar ratio on the yield of biodiesel in PBR.

Figure 6.

Effect of methanol/oil molar ratio on the yield of biodiesel in PBR.

The effect of methanol/oil molar ratio was investigated from 10 to 20. It is shown that the yield of biodiesel rapidly increases with increasing molar ratio of methanol/oil (Figure 6). Since biodiesel production by transesterification is a reversible reaction, the production yield could be elevated by introducing an excess amount of the reactant methanol to change the equilibrium. When the ratio is less than 16, the molar ratio of methanol/oil has a significant effect on the catalytic activity. According to the Le Chatelier’s principle, when the methanol amount is increased, the backward reaction is less favored over the forward reaction, and therefore higher product yield is observed [32]. The increase in transesterification became slower upon further increase in methanol/oil molar ratio to 18 and 20. Moreover, a higher molar ratio of methanol/oil could cause a separation problem during recycling [33]. Therefore, the optimal molar ratio of methanol/waste oil of 16 is preferable.

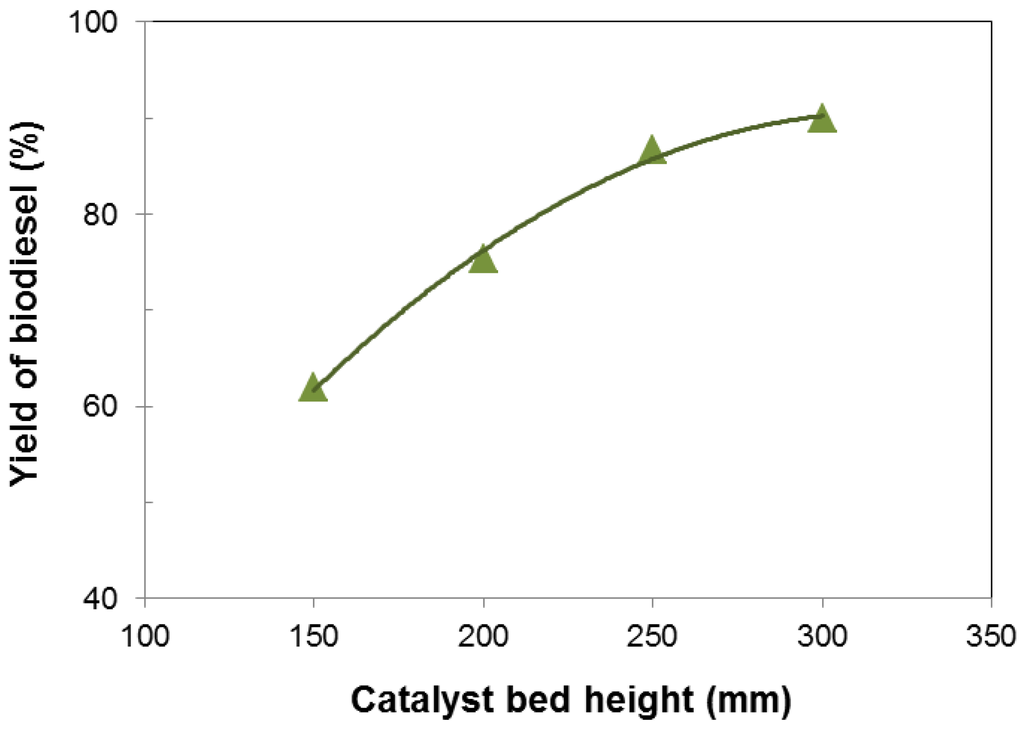

The catalyst bed height in the PBR is associated with the residence time during continuous transesterification. The influence of catalyst amount on the conversion is illustrated in Figure 7. The yield of FAME was greatly dependent on the amount of catalyst applied. The yield increased rapidly from 62.0% to 89.9% with the increase of the catalyst bed height from 150 to 300 mm. It demonstrates that a high catalyst bed height provides a longer reaction time and more active sites to promote the reaction between waste oil and methanol at a given flow rate [27]. However, when the catalyst bed height exceeded 250 mm, the rate of reaction increased slightly. Therefore, the optimum catalyst bed height for biodiesel production in this research is found to be 250 mm.

Figure 7.

Effect of catalyst bed height on the yield of biodiesel in PBR.

Figure 7.

Effect of catalyst bed height on the yield of biodiesel in PBR.

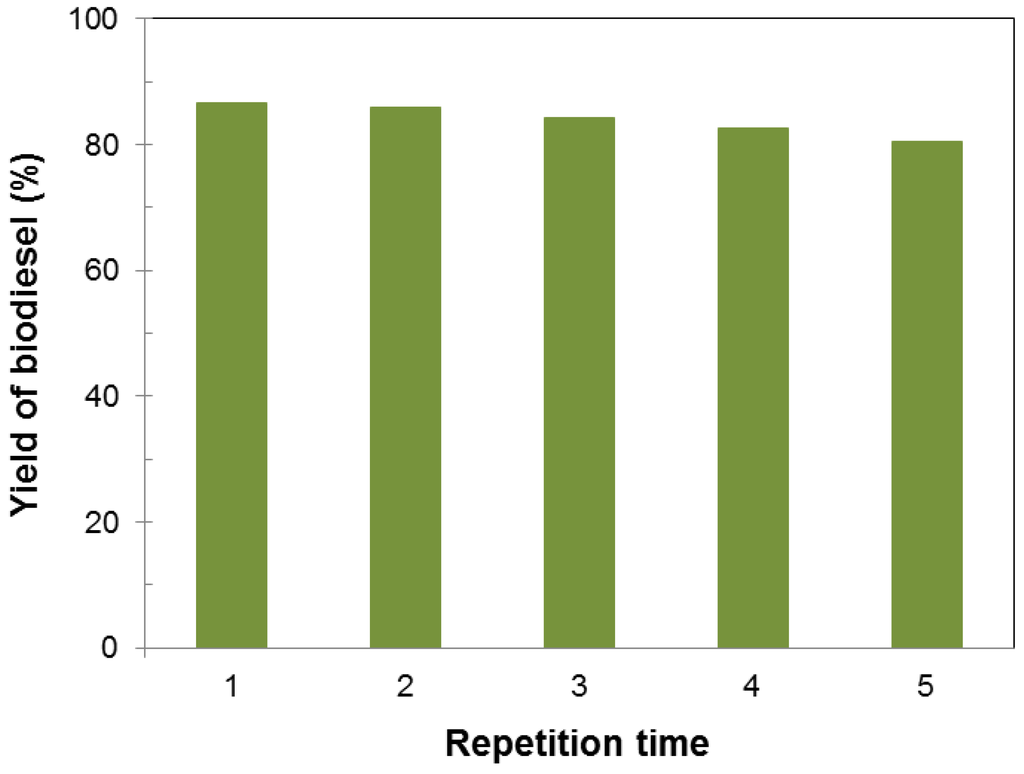

Reusability is very important for the economical application of KOH/JS as a heterogeneous catalyst for biodiesel synthesis. It is important to ensure that the active species are not leached from the solid support of the catalyst. If the leaching of the active species is too high, the active species could act as a homogeneous catalyst, and thus, the process advantages of the heterogeneous catalyst could be lost [13]. The reusability was checked by using the catalyst without any further purification and activation. KOH/JS catalyst was collected after adding the reaction and fresh reactants. The yield of FAME, determined after each catalyst collection, was employed to evaluate the reusability. The optimal operating conditions: a residence time of 2 h, reaction temperature of 60 °C, methanol/oil molar ratio of 16 and catalyst bed height of 250 mm, were determined by the operational parameters employed in the PBR. Under these conditions, a high yield of biodiesel was obtained (Figure 8). WFO conversions exhibited no apparent decrease and exceeded 80% in each of 5 consecutive runs. The contents of KOH on JS after the reaction of biodiesel production were 29.2 wt%. This heterogeneous catalyst showed high stability and reusability for transesterification without loss of its catalytic activity during reaction. Small loss of the catalyst is an important factor for good catalyst reusability [24].

Figure 8.

Effect of repetition time on the yield of biodiesel in PBR.

Figure 8.

Effect of repetition time on the yield of biodiesel in PBR.

3.3. Characterization and Fuel Properties of Biodiesel

The fuel properties of biodiesel obtained in this work are summarized in Table 3. It can be seen that most of its properties are in the range of fuel properties as described in the latest standards for biodiesel [34,35,36].

Table 3.

The fuel properties of biodiesel derived from waste frying oil (WFO).

| Fuel Properties | Biodiesel in This Work |

|---|---|

| Kinematic viscosity (mm2/s @ 40 °C) | 4.9 |

| Density (g/mL @ 15 °C) | 0.874 |

| Flash Point (°C) | 166 |

| Cloud Point (°C) | 11 |

| Pour Point (°C) | 7 |

| Acid value (mg KOH/g oil) | 0.80 |

| Water content (%) | 0.03 |

4. Conclusions

In this study, agricultural waste biomass can be utilized as a catalyst support for the continuous process of biodiesel production. KOH/JS heterogeneous catalyst was successfully used in the transesterification reaction of WFO into FAME. The optimum conditions, which yielded a conversion of WFO of nearly 87%, were residence time of 2 h, reaction temperature of 60 °C, methanol/oil molar ratio of 16 and catalyst bed height of 250 mm with pressure of 1 atm in PBR. The experimental results showed that KOH/JS had excellent activity and stability during transesterification. The catalyst was used five times, and no apparent activity loss was observed. However, this catalyst can cause saponification of the feedstock with high FFA. The obtained fuel properties of the biodiesel meet all biodiesel standards. As a solid catalyst, KOH/JS can decrease the cost of biodiesel and the steps of purification. It has potential for industrial application in the transesterification of WFO to FAME.

Acknowledgments

This work is supported by Silpakorn University Research and Development Institute (SURDI 52/02/06.01-53/02/04.01). The authors acknowledge sincerely the Department of Materials Science and Engineering (MSE), Faculty of Engineering and Industrial Technology, Silpakorn University (SU) and National Center of Excellence for Petroleum, Petrochemicals, and Advanced Materials (PPAM), Chulalongkorn University (CU) for supporting and encouraging this investigation. We would like to give special thanks to Matthew Hall, Associate Professor of Biomaterials and Glass Science, Director of Center for Advanced Ceramic Technology (CACT), Kazuo Inamori School of Engineering at Alfred University (USA) for proofreading and English editing of this manuscript.

References

- Jiang, J.J.; Tan, C.S. Biodiesel production from coconut oil in supercritical methanol in the presence of cosolvent. J. Taiwan Inst. Chem. Eng. 2012, 43, 102–107. [Google Scholar] [CrossRef]

- Manh, D.V.; Chen, Y.H.; Chang, C.C.; Chang, M.C.; Chang, C.Y. Biodiesel production from Tung oil and blended oil via ultrasonic transesterification process. J. Taiwan Inst. Chem. Eng. 2011, 42, 640–644. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, C.; Wang, W.; Wu, Y.; Yu, F.; Chi, R.; Zhang, J. Continuous production of biodiesel from soybean oil using supercritical methanol in a vertical tubular reactor: I. Phase holdup and distribution of intermediate product along the axial direction. Chin. J. Chem. Eng. 2010, 18, 626–629. [Google Scholar]

- Gan, M.; Pan, D.; Ma, L.; Yue, E.; Hong, J. The kinetics of the esterification of free fatty acids in waste cooking oil using Fe2(SO4)3/C catalyst. Chin. J. Chem. Eng. 2009, 17, 83–87. [Google Scholar] [CrossRef]

- Du, W.; Xu, Y.; Liu, D.; Zhang, J. Comparative study on lipase-catalyzed transformation of soybean oil for biodiesel production with different acyl acceptors. J. Mol. Catal. 2004, 30, 125–129. [Google Scholar] [CrossRef]

- Simasatitkul, L.; Siricharnsakunchai, P.; Patcharavorachot, Y.; Assabumrungrat, S.; Arpornwichanop, A. Reactive distillation for biodiesel production from soybean oil. Korean J. Chem. Eng. 2011, 28, 649–655. [Google Scholar]

- Vicente, G.; Martinez, M.; Aracil, J. Integrated biodiesel production: A comparison of different homogeneous catalysts systems. Bioresour. Technol. 2004, 92, 297–305. [Google Scholar] [CrossRef]

- Furuta, S.; Matsuhashi, H.; Arata, K. Biodiesel fuel production with solid amorphous-zirconia catalysis in fixed bed reactor. Biomass Bioenerg. 2006, 30, 870–873. [Google Scholar] [CrossRef]

- Chen, Y.H.; Huang, Y.H.; Lin, R.H.; Shang, N.C.; Chang, C.Y.; Chia-Chi Chang, C.C.; Chiang, P.C.; Hud, C.Y. Biodiesel production in a rotating packed bed using K/γ-Al2O3 solid catalyst. J. Taiwan Inst. Chem. Eng. 2011, 42, 937–944. [Google Scholar] [CrossRef]

- Bournay, L.; Casanave, D.; Delfort, B.; Hillion, G.; Chodorge, J.A. New heterogeneous process for biodiesel production: A way to improve the quality and the value of the crude glycerin produced by biodiesel plants. Catal. Today 2005, 106, 190–192. [Google Scholar]

- Hameed, B.H.; Goh, C.S.; Chin, L.H. Process optimization for methyl ester production from waste cooking oil using activated carbon supported potassium fluoride. Fuel Process. Technol. 2009, 90, 1532–1537. [Google Scholar]

- Wang, J.; Chen, K.; Chen, C. Biodiesel production from soybean oil catalyzed by K2SiO3/C. Chin. J. Catal. 2011, 32, 1592–1596. [Google Scholar] [CrossRef]

- Noiroj, K.; Intarapong, P.; Luengnaruemitchai, A.; Jai-In, S. A comparative study of KOH/Al2O3 and KOH/NaY catalysts for biodiesel production via transesterification from palm oil. Renew Energy 2009, 34, 1145–1150. [Google Scholar]

- Fang, L.; Zhang, K.; Li, X.; Wu, H.; Wu, P. Preparation of a carbon-silica mesoporous composite functionalized with sulfonic acid groups and its application to the production of biodiesel. Chin. J. Catal. 2012, 33, 114–122. [Google Scholar] [CrossRef]

- Baroutian, S.; Aroua, M.K.; Raman, A.A.A.; Sulaiman, N.M.N. Potassium hydroxide catalyst supported on palm shell activated carbon for transesterification of palm oil. Fuel Process. Technol. 2010, 91, 1378–1385. [Google Scholar]

- Foo, K.Y.; Hameed, B.H. Utilization of biodiesel waste as a renewable resource for activated carbon: Application to environmental problems. Renew. Sustain. Energy Rev. 2009, 13, 2495–2504. [Google Scholar] [CrossRef]

- Nunes, A.A.; Franca, A.S.; Oliveira, L.S. Activated carbons from waste biomass: An alternative use for biodiesel production solid residues. Bioresour. Technol. 2009, 100, 1786–1792. [Google Scholar] [CrossRef]

- Kurniawan, A.; Ismadji, S. Potential utilization of Jatropha curcas L. press-cake residue as new precursor for activated carbon preparation: Application in methylene blue removal from aqueous solution. J. Taiwan Inst. Chem. Eng. 2011, 42, 826–836. [Google Scholar] [CrossRef]

- Saka, S.; Kusdiana, D. Biodiesel fuel from rapeseed oil as prepared in supercritical methanol. Fuel 2001, 80, 225–231. [Google Scholar] [CrossRef]

- Gratuito, M.K.B.; Panyathanmaporn, T.; Chumnanklang, R.A.; Sirinuntawittaya, N.; Dutta, A. Production of activated carbon from coconut shell: Optimization using response surface methodology. Bioresour. Technol. 2008, 99, 4887–4895. [Google Scholar]

- Tongpoothorn, W.; Sriuttha, M.; Homchan, P.; Chanthai, S.; Ruangviriyachai, C. Preparation of activated carbon derived from Jatropha curcas fruit shell by simple thermo-chemical activation and characterization of their physico-chemical properties. Chem. Eng. Res. Des. 2011, 89, 335–340. [Google Scholar] [CrossRef]

- Baroutian, S.; Aroua, M.K.; Raman, A.A.A.; Sulaiman, N.M.N. A packed bed membrane reactor for production of biodiesel using activated carbon supported catalyst. Bioresour. Technol. 2011, 102, 1095–1102. [Google Scholar]

- Alba-Rubio, A.C.; Vila, F.; Alonso, D.M.; Ojeda, M.; Mariscal, R.; Granados, M.L. Deactivation of organosulfonic acid functionalized silica catalysts during biodiesel synthesis. Appl. Catal. Environ. 2010, 95, 279–287. [Google Scholar] [CrossRef]

- Jiang, S.T.; Zhang, F.J.; Pan, L.J. Sodium phosphate as a solid catalyst for biodiesel preparation. Braz. J. Chem. Eng. 2010, 27, 137–144. [Google Scholar]

- Pechyen, C.; Atong, D.; Ahtong, D.; Sricharoenchaikul, V. Investigation of pyrolyzed chars from physic nut waste for the preparation of activated carbon. J. Solid Mech. Mater. Eng. 2007, 1, 498–507. [Google Scholar] [CrossRef]

- Buasri, A.; Chaiyut, N.; Nakweang, C. Preparing activated carbon from palm shell for biodiesel fuel production. Chiang Mai J. Sci. 2011, 38, 572–578. [Google Scholar]

- Feng, Y.; Zhang, A.; Li, J.; He, B. A continuous process for biodiesel production in a fixed bed reactor packed with cation-exchange resin as heterogeneous catalyst. Bioresour. Technol. 2011, 102, 3607–3609. [Google Scholar]

- Lu, P.; Yuan, Z.; Li, L.; Wang, Z.; Luo, W. Biodiesel from different oil using fixed-bed and plug-flow reactors. Renew Energy 2010, 35, 283–287. [Google Scholar]

- Samart, C.; Sreetongkittikul, P.; Sookman, C. Heterogeneous catalysis of transesterification of soybean oil using KI/mesoporous silica. Fuel Process. Technol. 2009, 90, 922–925. [Google Scholar] [CrossRef]

- Marchetti, J.M.; Miguel, V.U.; Errazu, A.F. Heterogeneous esterification of oil with high amount of free fatty acids. Fuel 2007, 86, 906–910. [Google Scholar] [CrossRef]

- Bo, X.; Guomin, X.; Lingfeng, C.; Ruiping, W.; Lijing, G. Transesterification of palm oil with methanol to biodiesel over a KF/Al2O3 heterogeneous base catalyst. Energy Fuels 2007, 21, 3109–3112. [Google Scholar]

- Wan, T.; Yu, P.; Gong, S.; Li, Q.; Luo, Y. Application of KF/MgO as a heterogeneous catalyst in the production of biodiesel from rapeseed oil. Korean J. Chem. Eng. 2008, 25, 998–1003. [Google Scholar] [CrossRef]

- Long, T.; Deng, Y.; Gan, S.; Chen, J. Application of choline chloride·xZnCl2 ionic liquids for preparation of biodiesel. Chin. J. Chem. Eng. 2010, 18, 322–327. [Google Scholar]

- Buasri, A.; Chaiyut, N.; Loryuenyong, V.; Pin-Ngern, K.; Tonprasert, N.; Dangnuan, S. Production of fatty acid methyl ester by esterification of waste frying oil with methanol using acidified silica as heterogeneous. J. Biobased Mater. Bioenerg. 2012, in press. [Google Scholar]

- Buasri, A.; Ksapabutr, B.; Panapoy, M.; Chaiyut, N. Synthesis of biofuel from palm stearin using an activated carbon supported catalyst in packed column reactor. Adv. Sci. Lett. 2012, in press. [Google Scholar]

- Buasri, A.; Ksapabutr, B.; Panapoy, M.; Chaiyut, N. Biodiesel production from waste cooking palm oil using calcium oxide supported on activated carbon as catalyst in a fixed bed reactor. Korean J. Chem. Eng. 2012, 29, pp. 1–5. Available online: http://www.springer.com/chemistry/journal/11814 (accessed on 24 May 2012).

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).