Impact Characteristic Analysis of Tower Foundation Under Concealed Conductive Paths with Grounding Grid Based on a Scaled Model

Abstract

1. Introduction

2. Finite-Element Model Setup

3. Derivation and Validation of Scaling Relations for the Foundation

3.1. Derivation of Scaling Relations

3.2. Correction of the Scaling Relations

3.3. Validation of the Scaling Relations

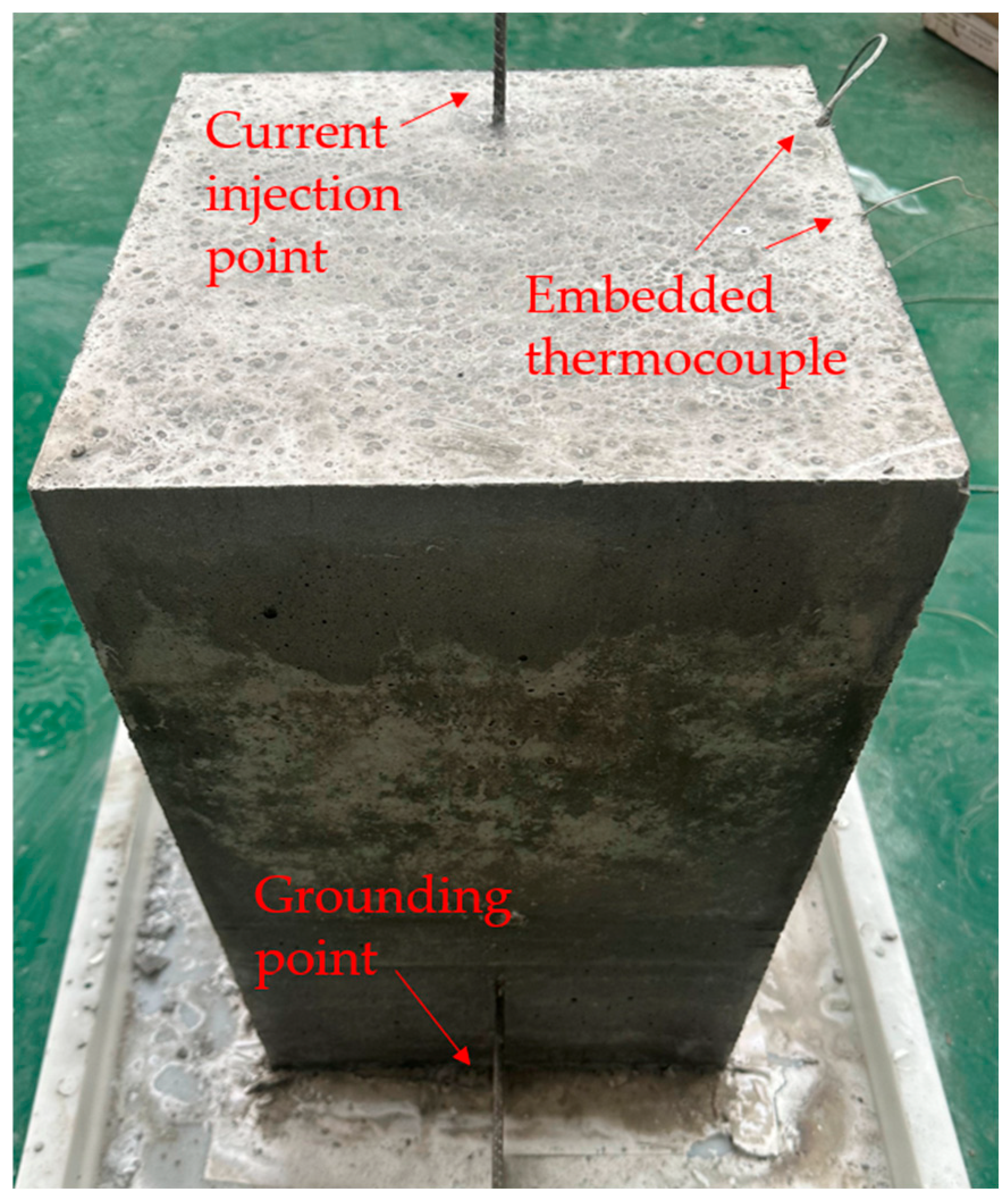

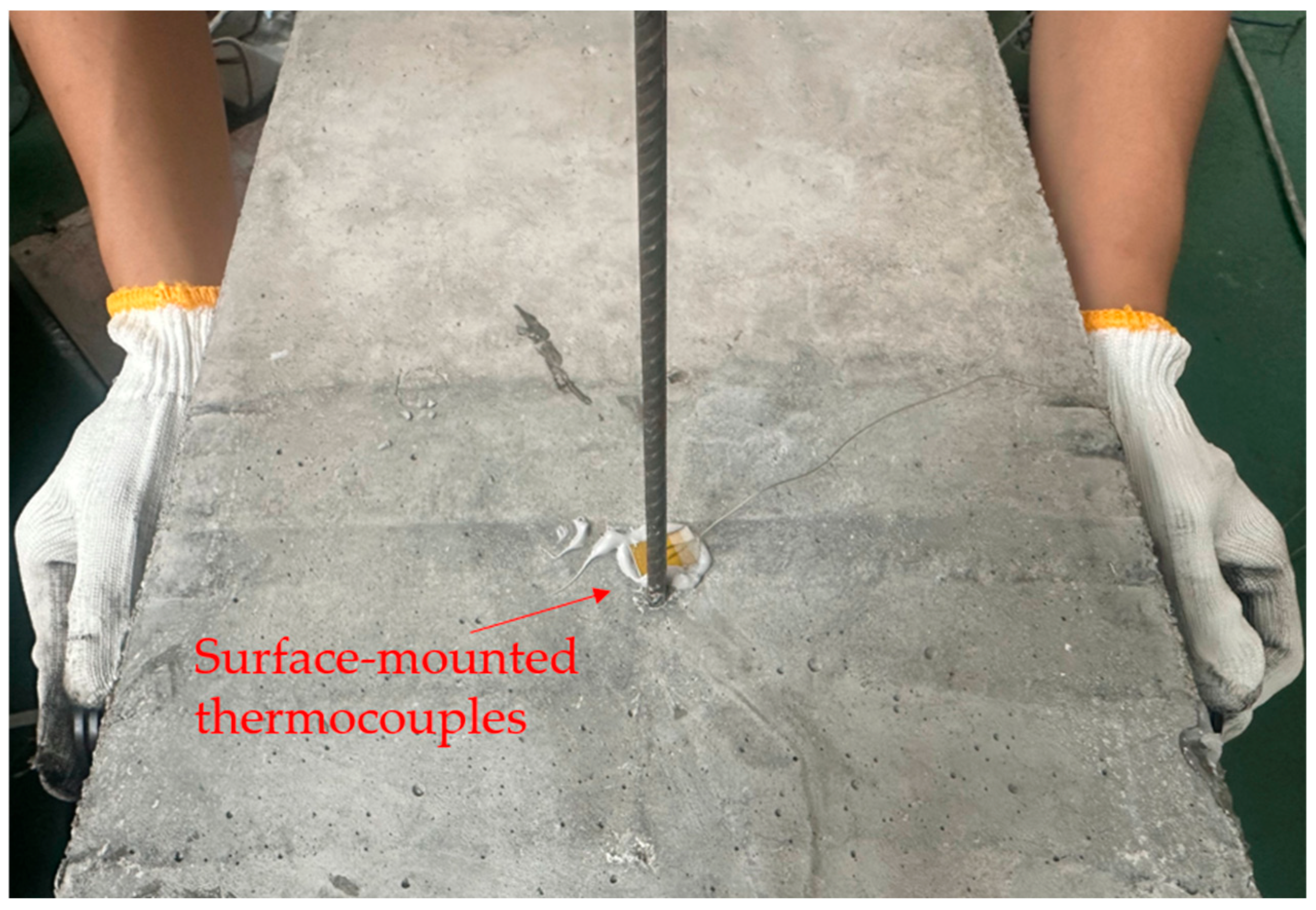

4. Scaled-Model Fabrication and Testing

4.1. Scaled-Model Fabrication

4.2. Experimental Results and Analysis

5. Conclusions

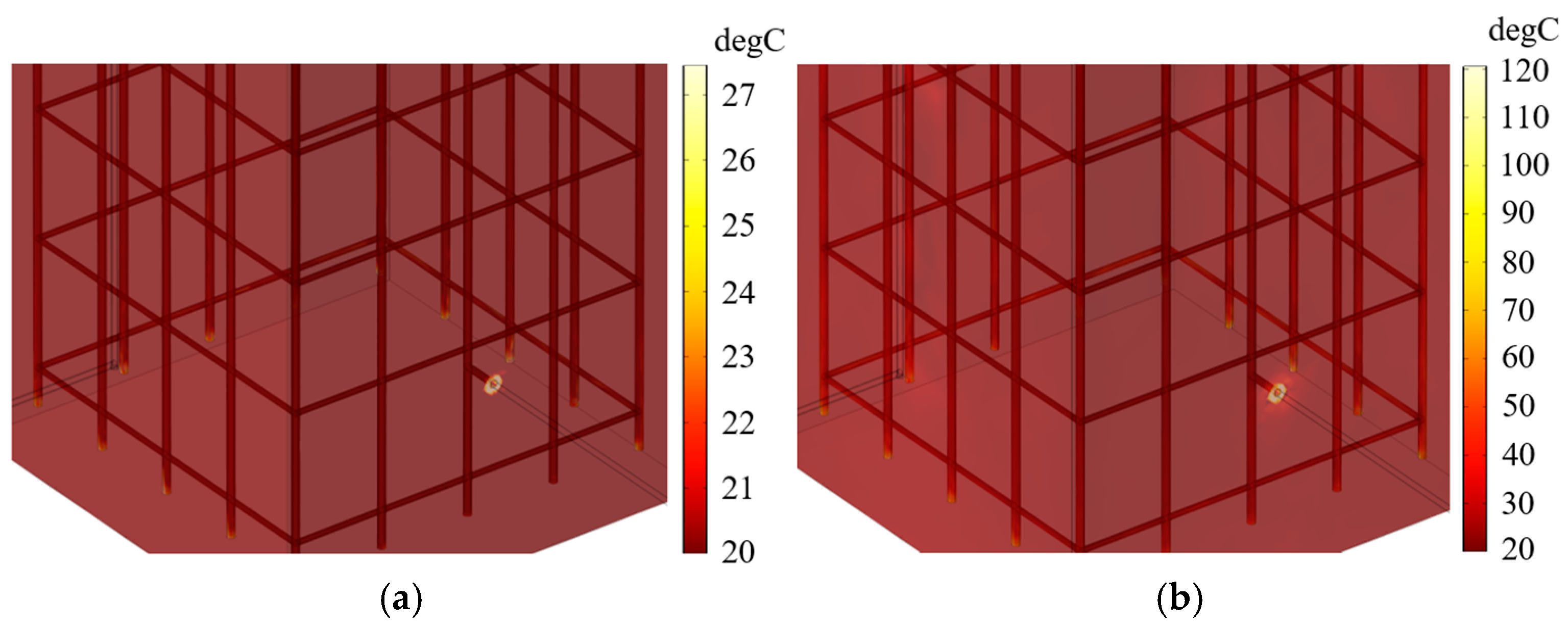

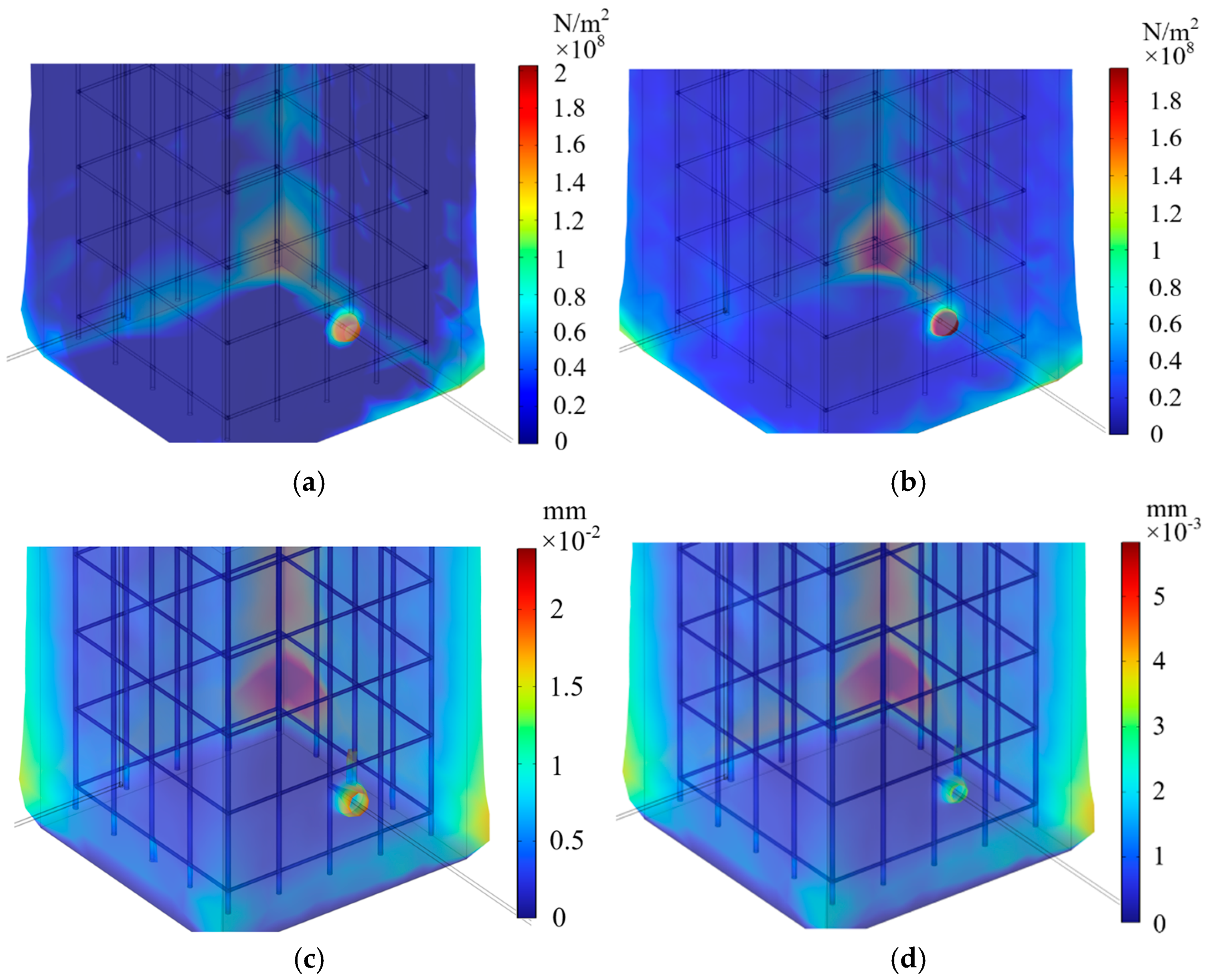

- The electro-thermal-mechanical distribution characteristics of the tower foundation under lightning current and power-frequency follow current shocks are generally consistent. Simulation results indicate that at the concealed conduction locations, the maximum stresses and displacements under power-frequency continuing current are approximately 13 times those induced by lightning impulses. The damage caused by power-frequency follow current is significantly greater than that induced by lightning current. Although the lightning current exhibits a higher peak amplitude, its extremely short duration results in minimal temperature rise, making it unlikely to cause further damage to the tower foundation. In contrast, the prolonged duration of the power-frequency follow current, coupled with the limited current dispersion paths within the foundation, leads to substantial heat accumulation. This process generates steep temperature gradients, which in turn induce thermal damage to the foundation structure.

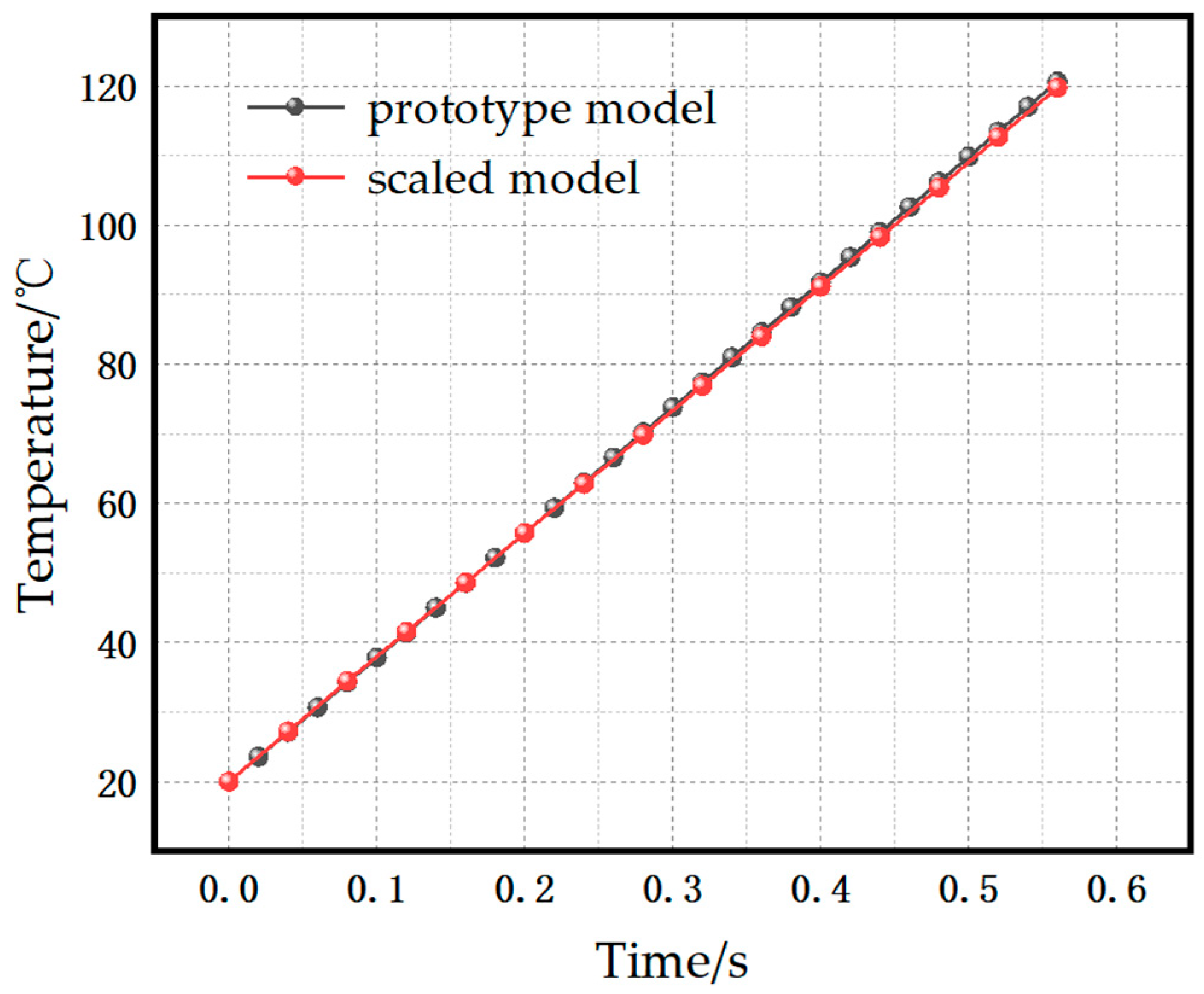

- Scaling relations for the tower foundation under power-frequency follow current were derived, and, considering that intrinsic electrical and thermal material parameters cannot be freely adjusted according to geometric scaling, a parameter-correction method based on similarity criteria was proposed. Using a 1/4-scale model as an example, simulation comparisons indicate that the key parameters between the scaled model and the prototype are reduced to within 3%, and that the corrected scaling approach can reliably reproduce the prototype’s electro-thermal behavior under continuing current.

- An experimental platform was established, and a 1/4-scale model of the tower foundation was designed and fabricated. Under the action of power-frequency follow current, the maximum temperature at the concealed conduction site reached 124 °C; this peak has a relative error of 2.83% compared with the prototype simulation and 3.58% compared with the scaled-model simulation. The maximum temperature measured at the concrete surface was 97.2 °C. After 20 power-frequency follow current impacts, ultrasonic inspection shows that the wave speed at the concealed conduction center decreased from 3.797 km/s before testing to 3.571 km/s, a reduction of approximately 5.95%. The reduction in wave velocity indicates a loss of structural integrity, suggesting the possible occurrence of microcracks or interfacial defects that scatter and attenuate the ultrasonic waves. The corresponding waveform distortion, including amplitude reduction and the appearance of secondary peaks, further confirms the formation of internal reflection interfaces caused by material degradation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, B.; He, J.; Zeng, R. State of art and prospect of grounding technology in power system. High Volt. Eng. 2015, 41, 2569–2582. [Google Scholar]

- Fu, Z.; Wang, X.; Wang, Q.; Xu, X.; Fu, N.; Qin, S. Advances and Challenges of Corrosion and Topology Detection of Grounding Grid. Appl. Sci. 2019, 9, 2290. [Google Scholar] [CrossRef]

- Saleh, S.A.; Jewett, D.; Panetta, S.A. The analysis, modeling, and capabilities of grounding system designs. IEEE Trans. Ind. Appl. 2022, 58, 5908–5920. [Google Scholar] [CrossRef]

- Abirami, M.; Ganesan, S.; Subramanian, S.; Anandhakumar, R. Source and transmission line maintenance outage scheduling in a power system using teaching learning based optimization algorithm. Appl. Soft Comput. 2014, 21, 72–83. [Google Scholar] [CrossRef]

- Fan, R.; Zeng, W.; Ming, Z.; Zhang, W.; Huang, R.; Liu, J. Risk Reliability Assessment of Transmission Lines under Multiple Natural Disasters in Modern Power Systems. Energies 2023, 16, 6548. [Google Scholar] [CrossRef]

- Zeng, R.; He, J.; Gao, Y.; Zou, J.; Guan, Z. Grounding resistance measurement analysis of grounding system in vertical-layered soil. IEEE Trans. Power Deliv. 2004, 19, 1553–1559. [Google Scholar] [CrossRef]

- Liu, W.; Hu, Y.; Tian, H.; Jiang, Z.; Su, X.; Xiong, J.; Su, W.; Wang, Y. Research on Lightning Overvoltage Protection of Line-Adjacent Pipelines Based on Solid-State Decoupling. Appl. Sci. 2023, 13, 12529. [Google Scholar] [CrossRef]

- Ren, H.; Li, T.; Ning, J.; Song, S. Analysis of damage characteristics of steel fiber-reinforced concrete based on acoustic emission. Eng. Fail. Anal. 2023, 148, 107166. [Google Scholar] [CrossRef]

- Xian, W.; Chen, W.; Hao, H.; Wang, W.D.; Wang, R. Investigation on the lateral impact responses of circular concrete-filled double-tube (CFDT) members. Compos. Struct. 2021, 255, 54–65. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Nimityongskul, P.; Mindess, S. Effect of loading rate on damage of concrete. Cem. Concr. Res. 2004, 34, 2127–2134. [Google Scholar] [CrossRef]

- Saqif, M.A.; El-Tawil, S. Uniaxial behavior of UHPC under cyclic compression: Experimental investigation and constitutive model. Constr. Build. Mater. 2024, 426, 136132. [Google Scholar] [CrossRef]

- Liu, J.; Huimin, H.; Renbo, Z.; Xiuli, D. Meso-scale simulations on dynamic splitting tensile behaviors of concrete at elevated temperatures. Explos. Shock. Waves 2020, 40, 106979. [Google Scholar]

- Cui, D.; Wang, L.; Zhang, C.; Xue, H.; Gao, D.; Chen, F. Dynamic Splitting Performance and Energy Dissipation of Fiber-Reinforced Concrete under Impact Loading. Materials 2024, 17, 421. [Google Scholar] [CrossRef]

- Nie, P.; Liu, H.; Wang, Y.; Han, S. Seismic Response and Collapse Analysis of a Transmission Tower Structure: Assessing the Impact of the Damage Accumulation Effect. Buildings 2024, 14, 2243. [Google Scholar] [CrossRef]

- Gidrão, G.D.M.S.; Krahl, P.A.; Bosse, R.M.; Silvestro, L.; Ribeiro, R.S.; Lima, G.T.D.S.; Carrazedo, R. Internal Damping Ratio of Normal- and High-Strength Concrete Considering Mechanical Damage Evolution. Buildings 2024, 14, 2446. [Google Scholar] [CrossRef]

- Krentowski, J.R. Assessment of Destructive Impact of Different Factors on Concrete Structures Durability. Materials 2022, 15, 225. [Google Scholar] [CrossRef] [PubMed]

- Dixit, A.; Bhalla, S. Prognosis of fatigue and impact induced damage in concrete using embedded piezo-transducers. Sens. Actuators A Phys. 2018, 274, 116–131. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Jiang, C.; Zhang, J.; Li, T.; Zhang, H.; Wang, Q. Research on Concrete Installation Grounding Scattering Characteristics and External Application Resistance Reduction Strategy. In Proceedings of the International Symposium on Insulation and Discharge Computation for Power Equipment, Wuhan, China, 26–28 May 2023; pp. 735–744. [Google Scholar]

- Zhang, M.; Feng, Z.; Tang, X.; Zhou, L. Thermal effect analysis of tower conductive concrete foundation under ontinuous lightning strike. J. Electr. Power Sci. Technol. 2024, 39, 249–254. [Google Scholar]

- Tian, X.; Pei, F.; Liu, X.; Jia, L.; Deng, C.; Lan, F.; Cheng, H. Analysis of electrothermal characteristics of conductive concrete foundation of power tower. IOP Conf. Ser. Earth Environ. Sci. 2020, 571, 012057. [Google Scholar] [CrossRef]

- Mao, H.; Tian, H.; Hu, Y.; Gao, T.; Chen, Y.; Mu, M. Study on Temperature Rise Characteristics of Tower Grounding Electrode Under Lightning Strike and Power Frequency Short-Circuit Conditions. In Proceedings of the International Symposium on Insulation and Discharge Computation for Power Equipment, Wuhan, China, 26–28 May 2023; pp. 703–711. [Google Scholar]

- Liu, Y.; Lei, C.; Tang, L.; Feng, Z.; Zhou, L. Impulse grounding resistance analysis of typical tower grounding device under continuous lightning impulse. J. Electr. Power Sci. Technol. 2023, 38, 243–248. [Google Scholar]

- Wang, H.; Zhang, L.; Sun, Y.; Zhang, Z.; Wang, D. Modeling and Modification of Converter Transformer Similarity Model Based on Finite Element And Similarity Theory. In Proceedings of the 2022 4th International Conference on Smart Power & Internet Energy Systems (SPIES), Beijing, China, 9–12 December 2022; pp. 395–401. [Google Scholar]

- Takami, J.; Tsuboi, T.; Yamamoto, K.; Okabe, S.; Baba, Y. Lightning surge characteristics on inclined incoming line to substation based on reduced-scale model experiment. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 739–746. [Google Scholar] [CrossRef]

- Hong, S.; Chen, D.; Dong, B. Numerical simulation and mechanism analysis of GPR-based reinforcement corrosion detection. Constr. Build. Mater. 2022, 317, 125913. [Google Scholar] [CrossRef]

- Bu, J.; Guo, Z.; Zhang, J.; Zhang, Y. Experimental Study on the Damage Mechanism of Reinforced Concrete Beams Based on Acoustic Emission Technique. Appl. Sci. 2023, 13, 9207. [Google Scholar] [CrossRef]

- Yan, L.; Jun, W.; Jun, C. Experimental study on the detection of internal damage of concrete by impact-echo method. Chin. J. Appl. Mech. 2020, 37, 149–154. [Google Scholar]

- Wronkowicz, A.; Dragan, K.; Lis, K. Assessment of uncertainty in damage evaluation by ultrasonic testing of composite structures. Compos. Struct. 2018, 203, 71–84. [Google Scholar] [CrossRef]

- Concu, G.; Trulli, N. Concrete Defects Sizing by Means of Ultrasonic Velocity Maps. Buildings 2018, 8, 176. [Google Scholar] [CrossRef]

- Camara, L.A.; Wons, M.; Esteves, I.C.A.; Medeiros-Junior, R.A. Monitoring the Self-healing of Concrete from the Ultrasonic Pulse Velocity. J. Compos. Sci. 2019, 3, 16. [Google Scholar] [CrossRef]

| Material | Electrical Conductivity (S/m) | Density (kg/m3) | Thermal Conductivity (W·m−1·K−1) | Coefficient of Thermal Expansion (K−1) |

|---|---|---|---|---|

| Concrete | 1.0 × 10−4 | 2400 | 1.28 | 1.0 × 10−6 |

| steel | 1.0 × 107 | 7850 | 44.5 | 1.23 × 10−5 |

| Grounding grid | 3.08 × 104 | 2000 | 127 | 1.7 × 10−5 |

| Current Type | Temperature (°C) | Stress (N/m2) | Displacement (mm) |

|---|---|---|---|

| Lighting current | 27.45 | 1.55 × 107 | 1.85 × 10−3 |

| Power-frequency follow current | 120.59 | 2.03 × 108 | 2.40 × 10−2 |

| M | L | T | θ | I | |

|---|---|---|---|---|---|

| M | 1 | 0 | 0 | 0 | 0 |

| L | 0 | 1 | 0 | 0 | 0 |

| T | 0 | 0 | 1 | 0 | 0 |

| θ | 0 | 0 | 0 | 1 | 0 |

| I | 0 | 0 | 0 | 0 | 1 |

| α | 0 | 0 | 0 | −1 | 0 |

| ρ | 1 | −3 | 0 | 0 | 0 |

| k | 1 | 1 | −3 | −1 | 0 |

| CP | 0 | 2 | −2 | −1 | 0 |

| σe | −1 | −3 | 3 | 0 | 2 |

| E | 1 | −1 | −2 | 0 | 0 |

| f | 0 | 0 | −1 | 0 | 0 |

| σ | 1 | −1 | −2 | 0 | 0 |

| ΔT | 0 | 0 | 0 | 1 | 0 |

| δ | 0 | 1 | 0 | 0 | 0 |

| Physical Quantity | Similarity Ratio |

|---|---|

| Thermal expansion coefficient | |

| Thermal conductivity | |

| Electrical conductivity | |

| Frequency | |

| Stress | |

| Temperature rise | |

| Displacement |

| Material | Dosage(kg/m3) |

|---|---|

| Cement | 380 |

| Water | 190 |

| Sand | 680 |

| Gravel | 1200 |

| Water Reducer | 7.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pu, Z.; Qin, R.; Li, P.; Wu, T. Impact Characteristic Analysis of Tower Foundation Under Concealed Conductive Paths with Grounding Grid Based on a Scaled Model. Appl. Sci. 2025, 15, 12143. https://doi.org/10.3390/app152212143

Pu Z, Qin R, Li P, Wu T. Impact Characteristic Analysis of Tower Foundation Under Concealed Conductive Paths with Grounding Grid Based on a Scaled Model. Applied Sciences. 2025; 15(22):12143. https://doi.org/10.3390/app152212143

Chicago/Turabian StylePu, Ziheng, Ruize Qin, Peng Li, and Tian Wu. 2025. "Impact Characteristic Analysis of Tower Foundation Under Concealed Conductive Paths with Grounding Grid Based on a Scaled Model" Applied Sciences 15, no. 22: 12143. https://doi.org/10.3390/app152212143

APA StylePu, Z., Qin, R., Li, P., & Wu, T. (2025). Impact Characteristic Analysis of Tower Foundation Under Concealed Conductive Paths with Grounding Grid Based on a Scaled Model. Applied Sciences, 15(22), 12143. https://doi.org/10.3390/app152212143