The Influence of Holes and Beam Sleeves on the Compressive Mechanical Properties of Reinforced Concrete Beam Segments

Abstract

1. Introduction

2. Materials and Methods

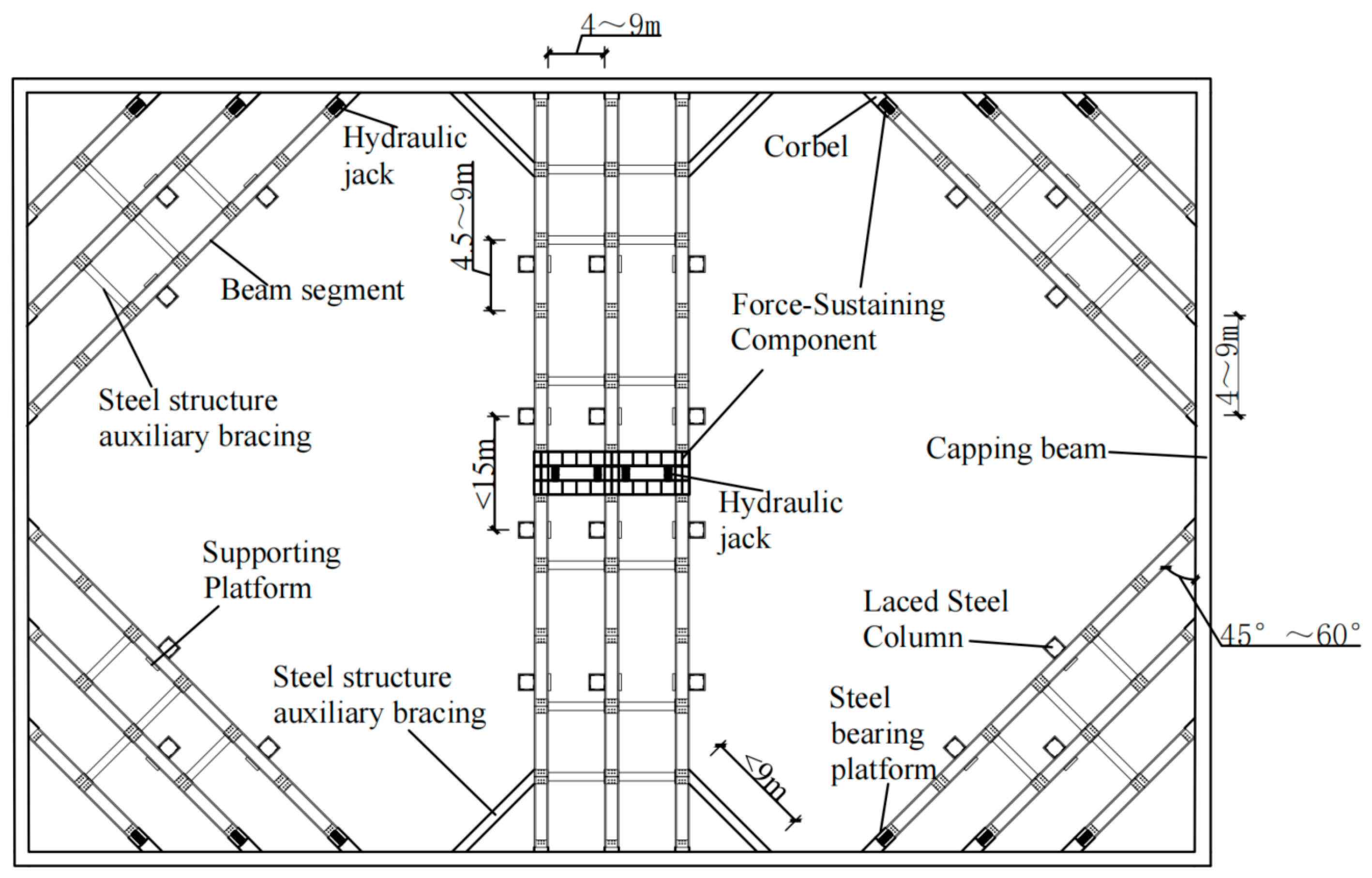

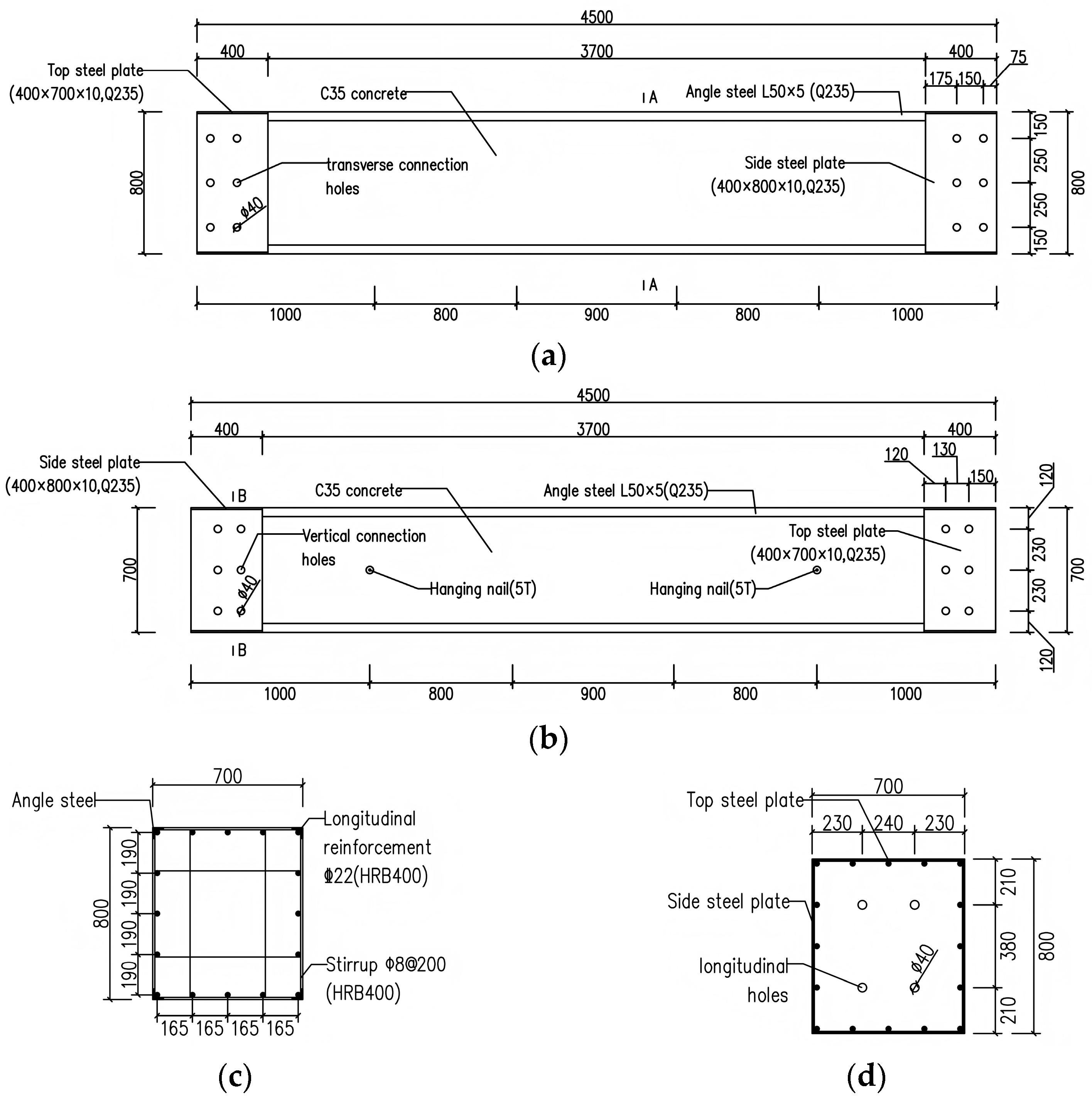

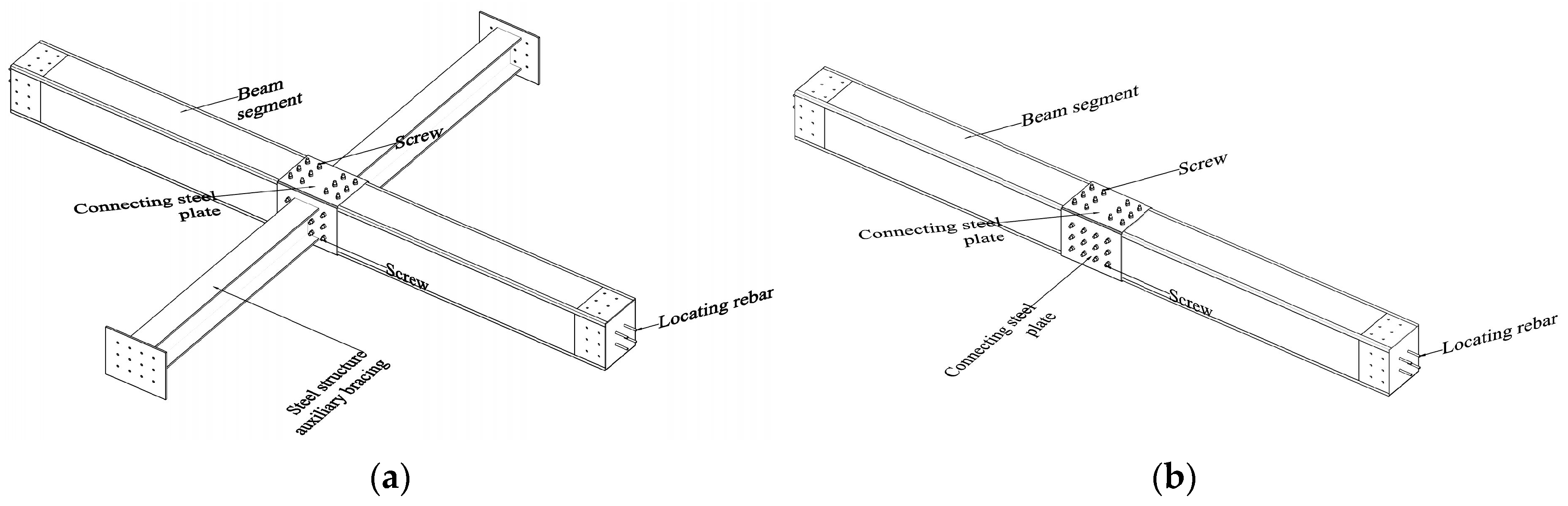

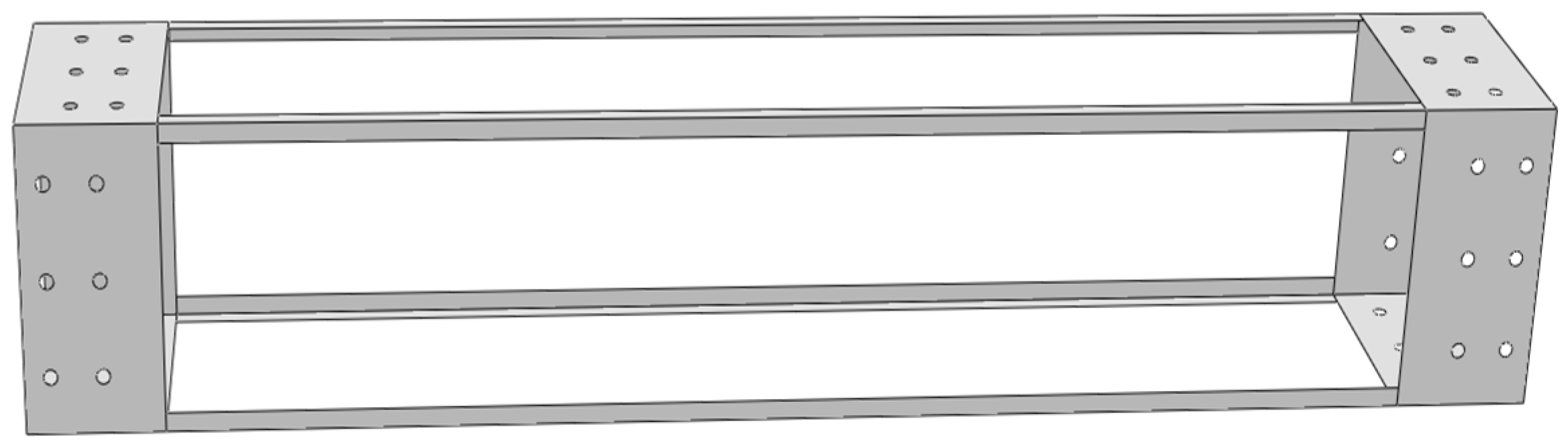

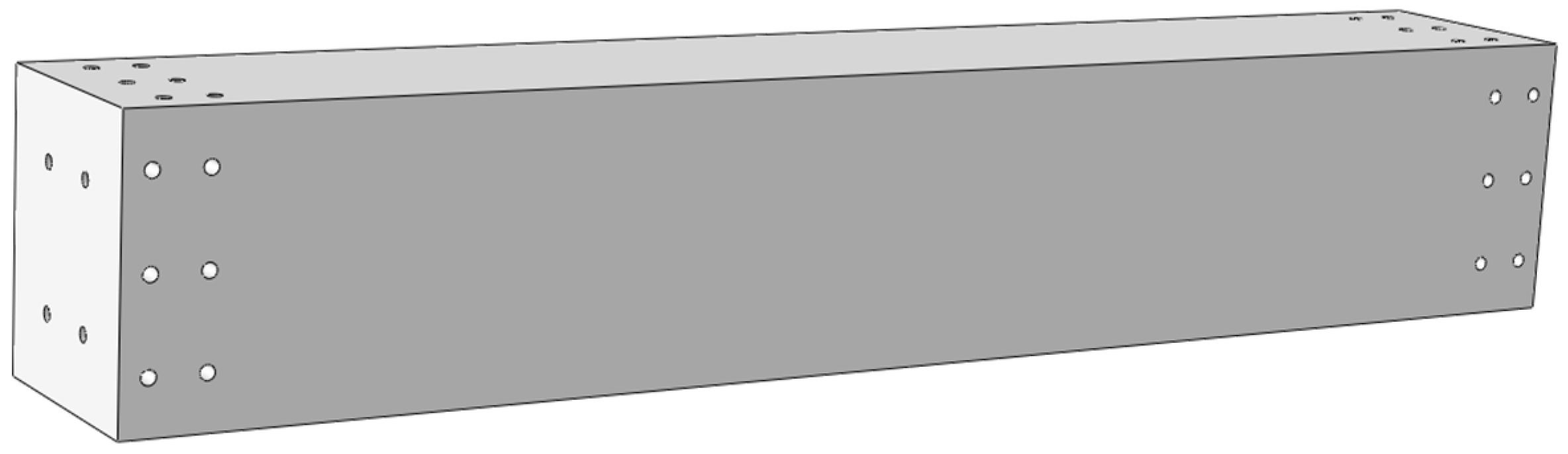

2.1. Source and Characteristics of Research Subject

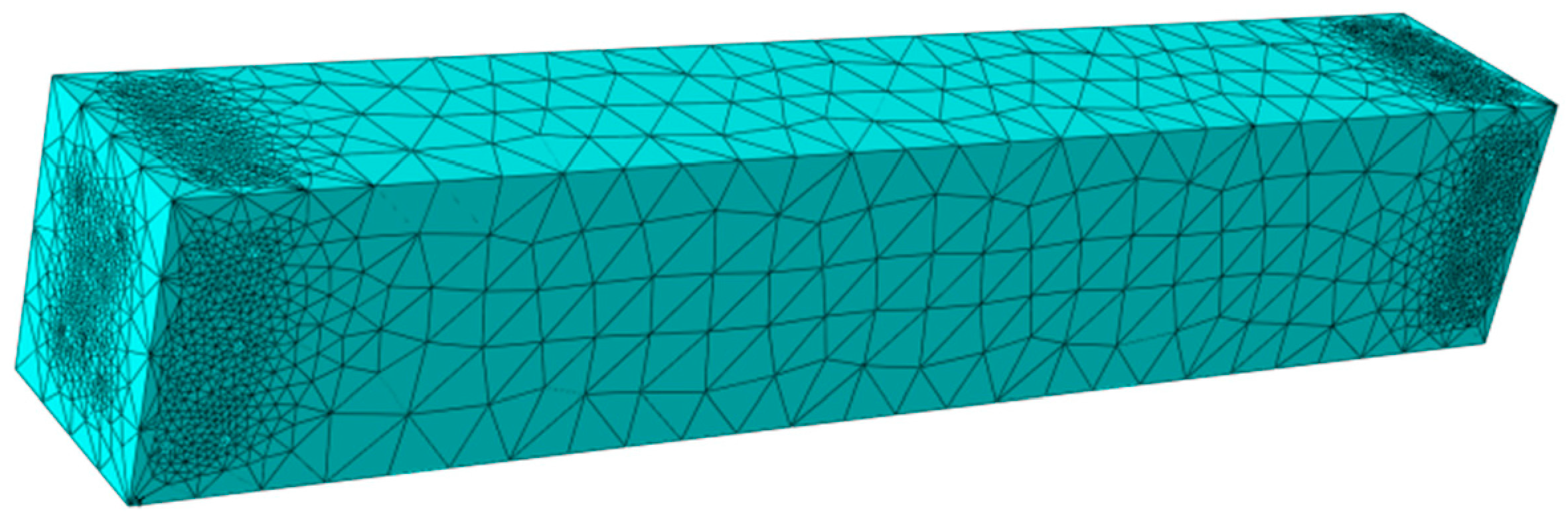

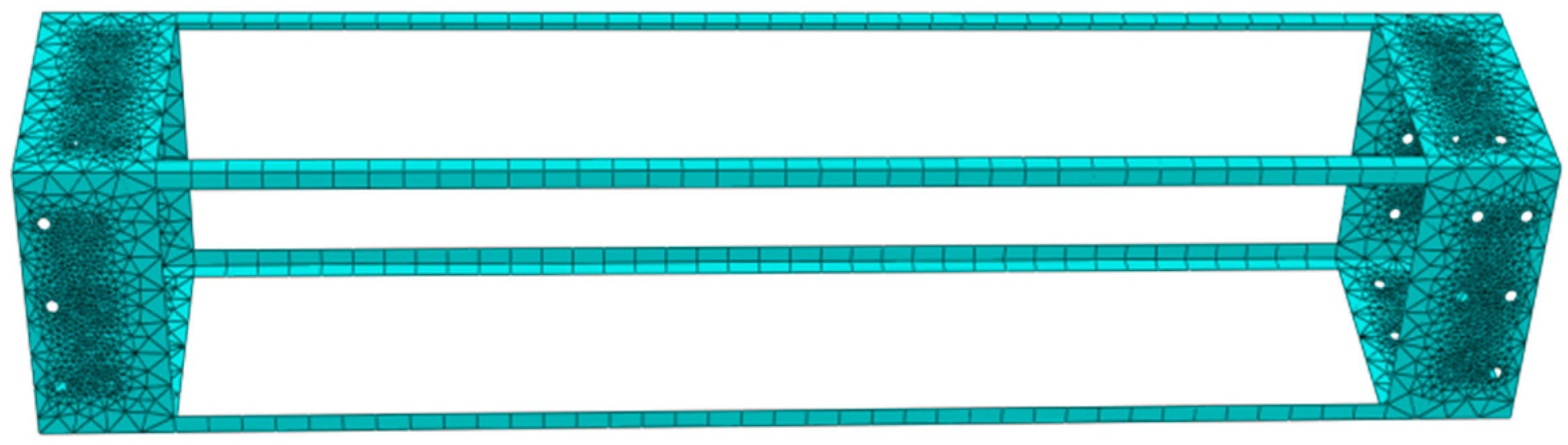

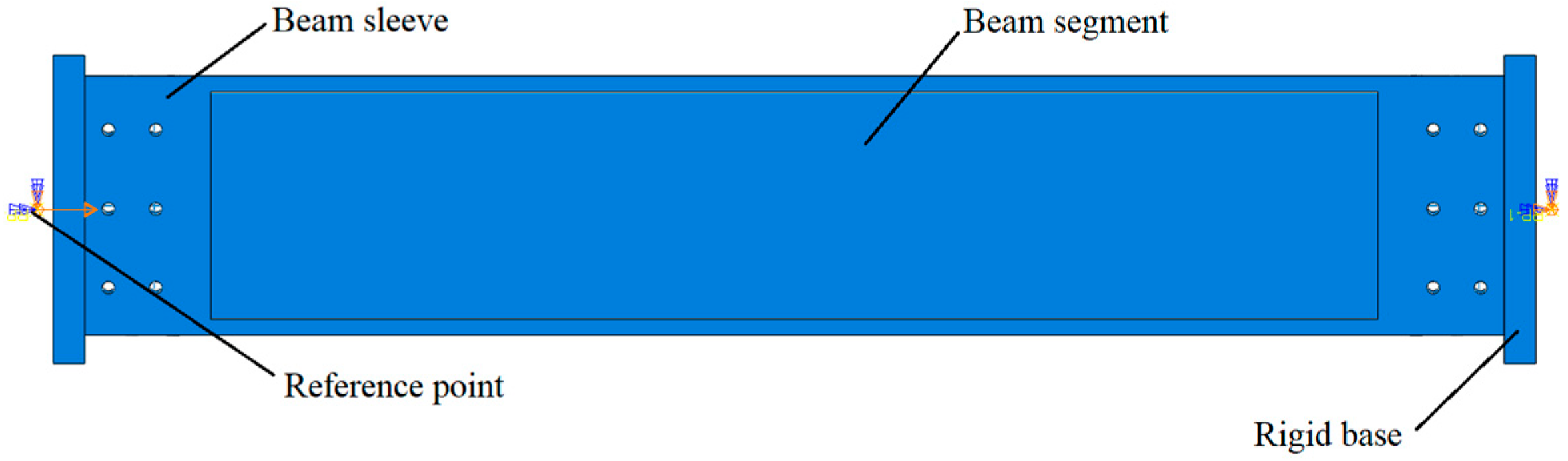

2.2. Finite Element Modeling of Beam Segments and Model Parameter Configuration

2.2.1. Module Division

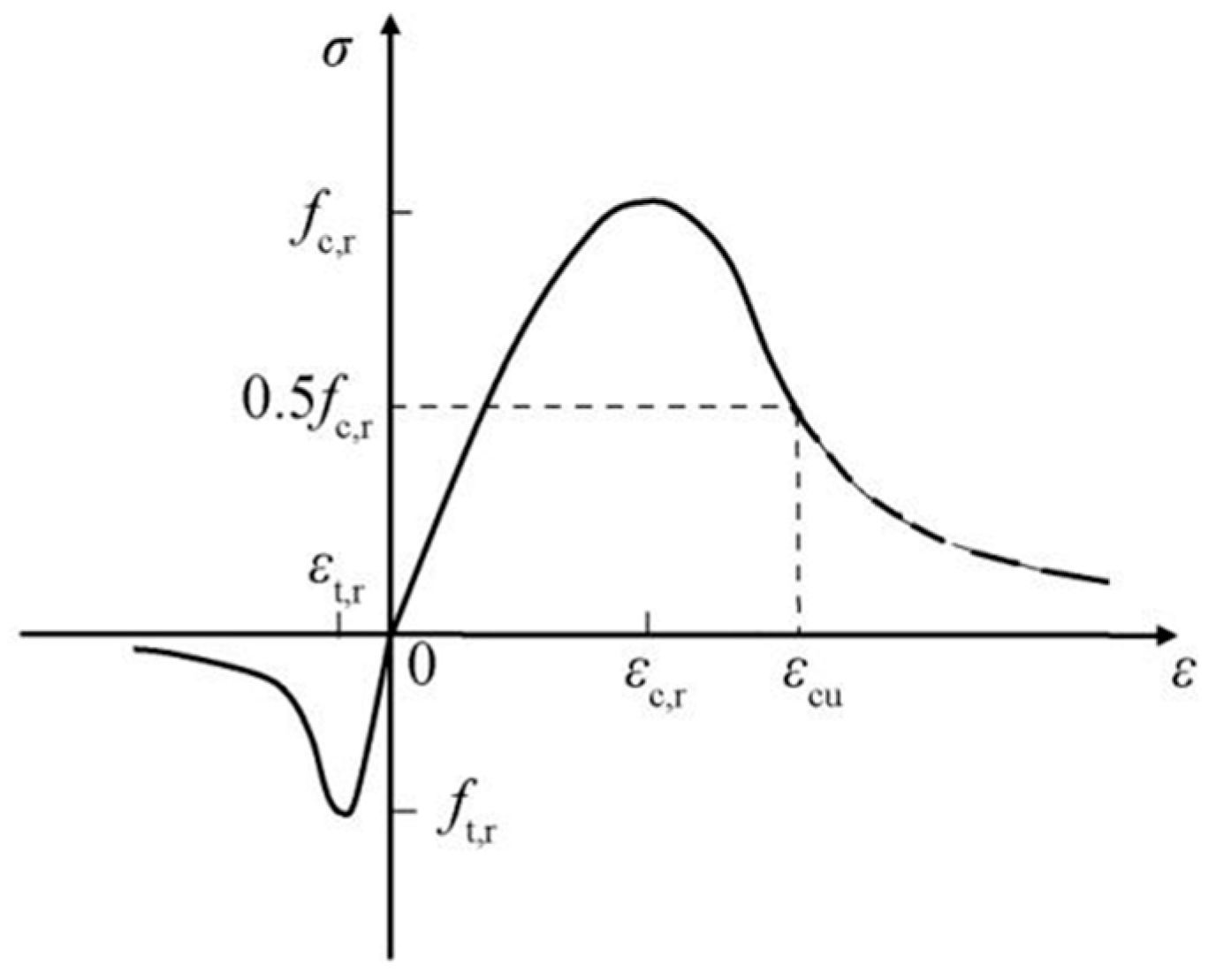

2.2.2. Concrete CDP Principal Modeling

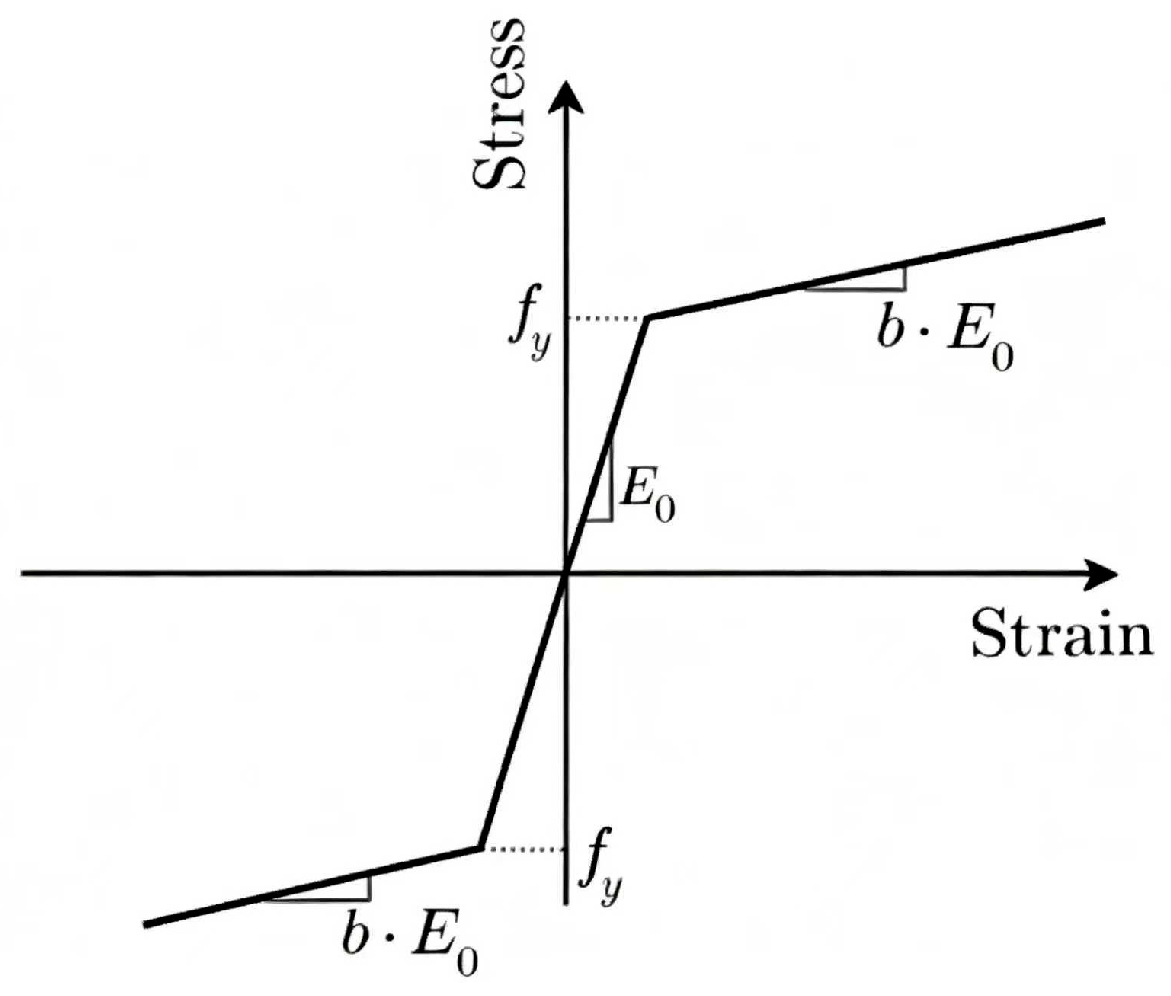

2.2.3. Reinforcing Steel Principal Structure

2.3. Experimental Design

3. Results and Discussion

3.1. Model Validation

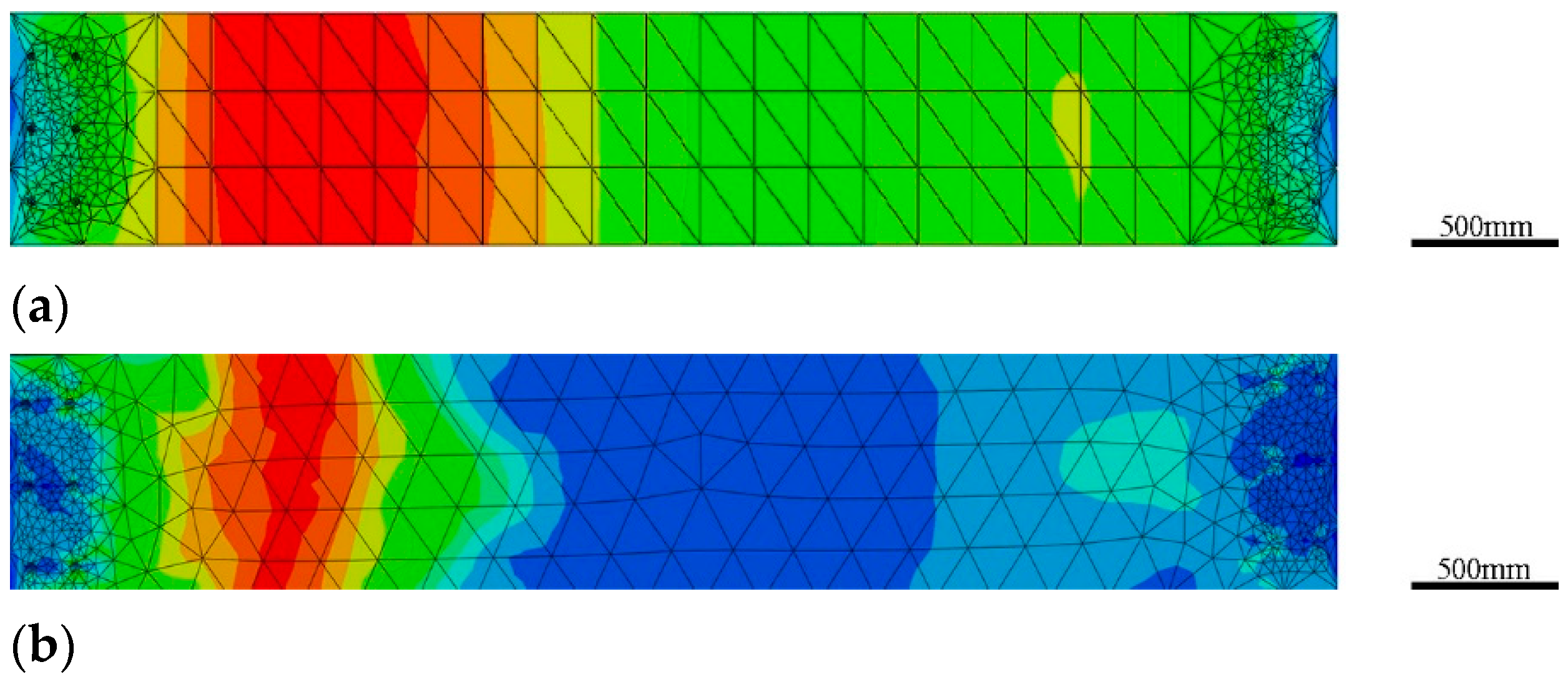

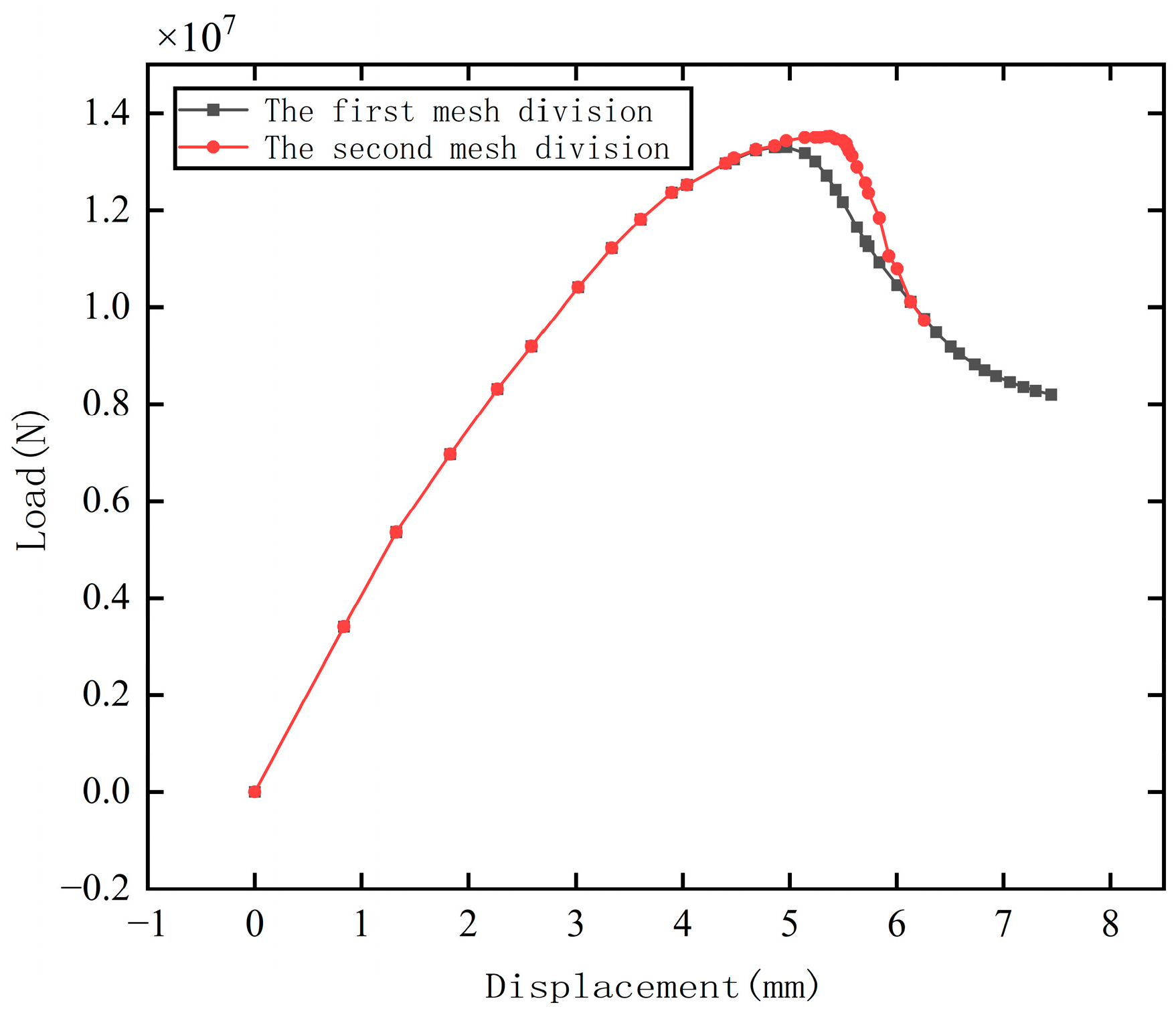

3.2. Mesh Division Validation

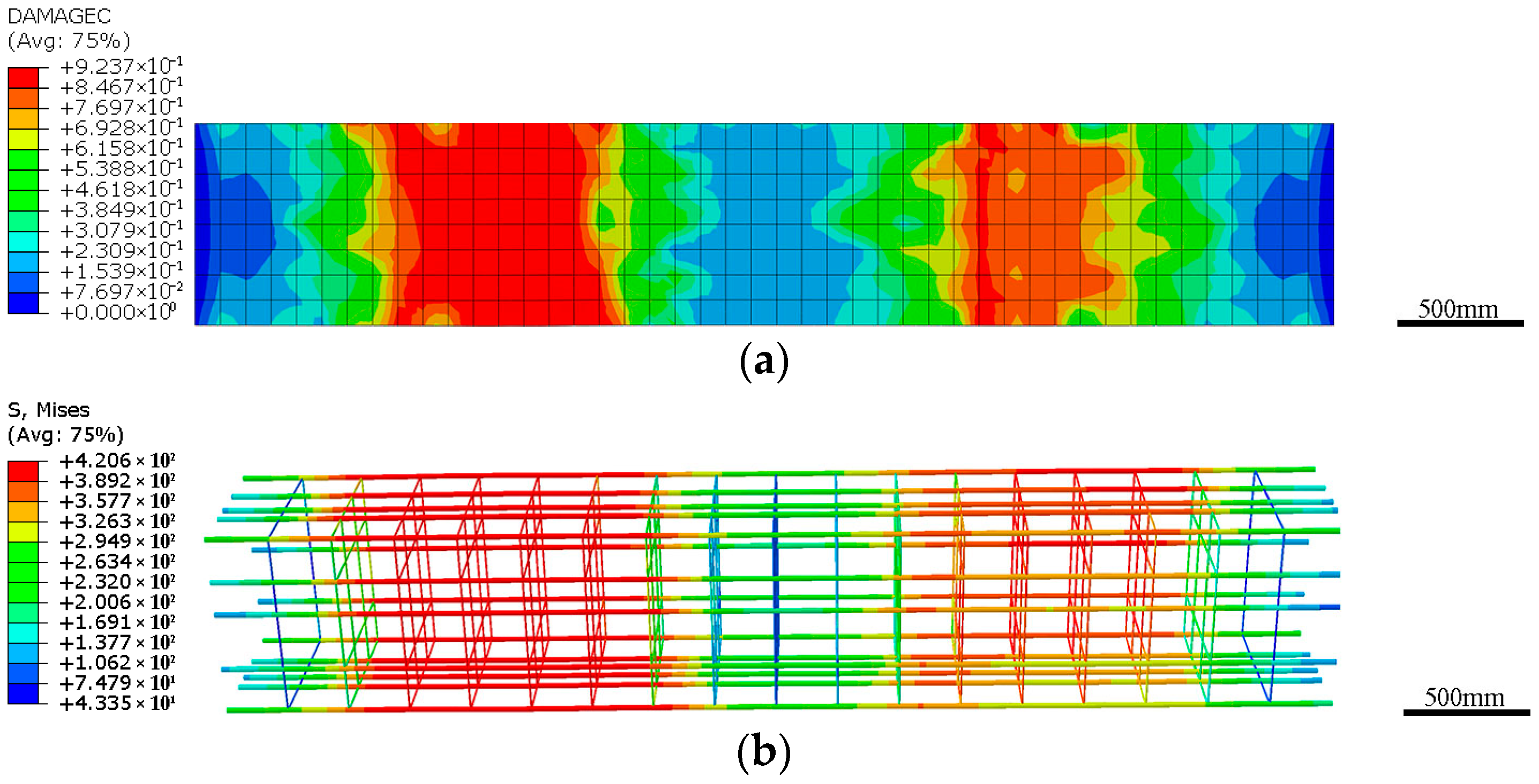

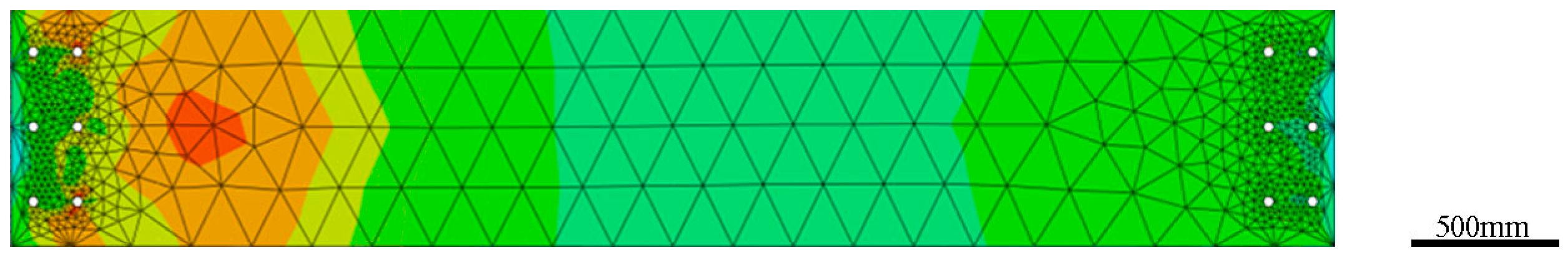

3.3. Analysis of Axial Compression of Specimen When the Boundary Is a Rigid Body Section

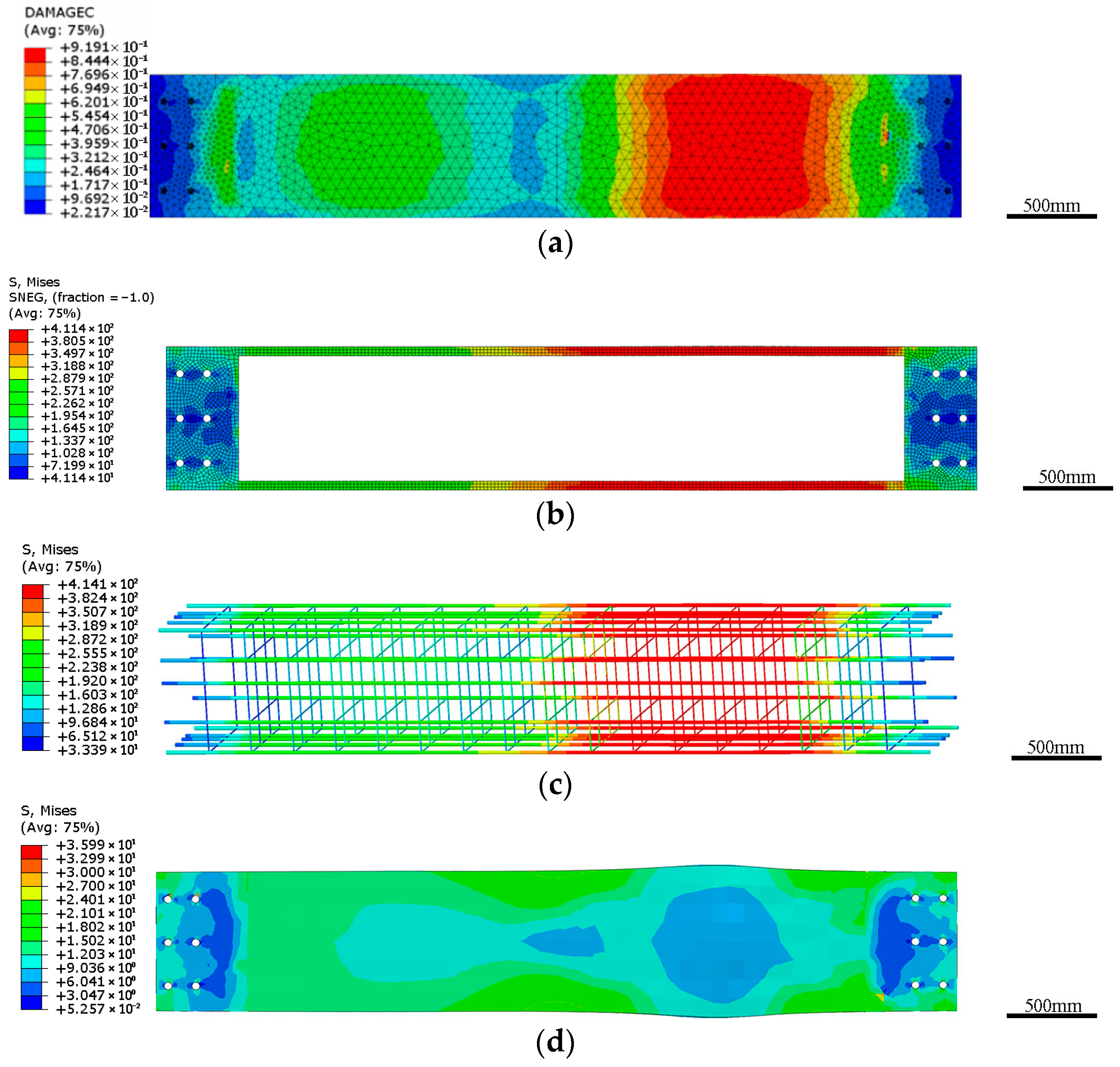

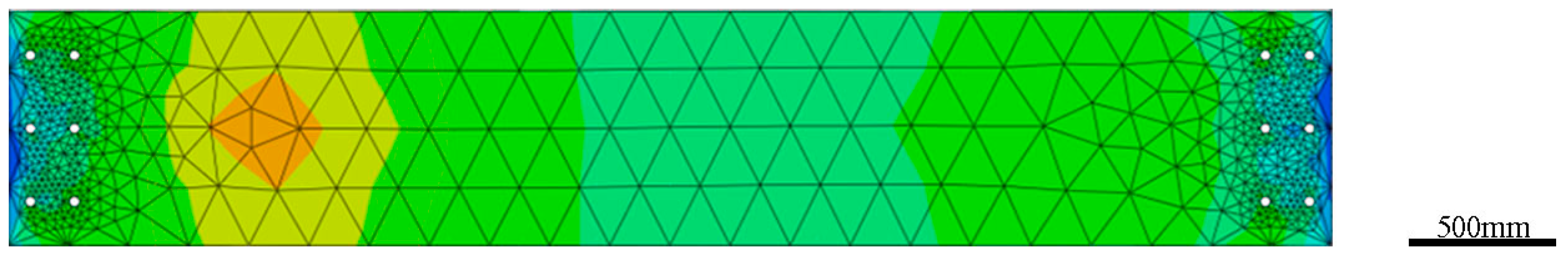

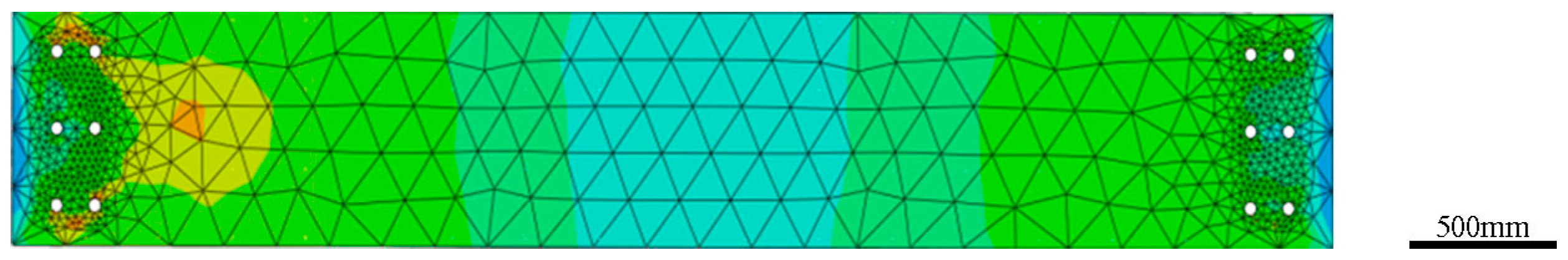

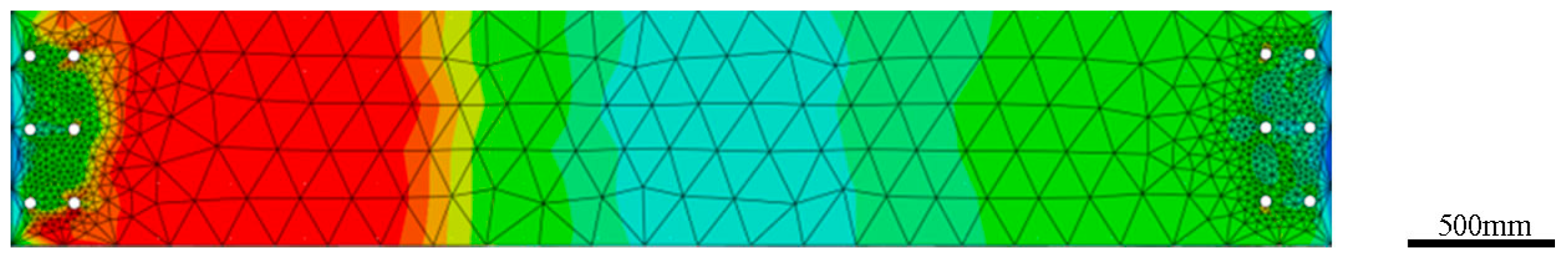

3.4. Analysis of the Effect of End Friction Constraints on the Axial Compressive Mechanical Properties of Specimens with Holes

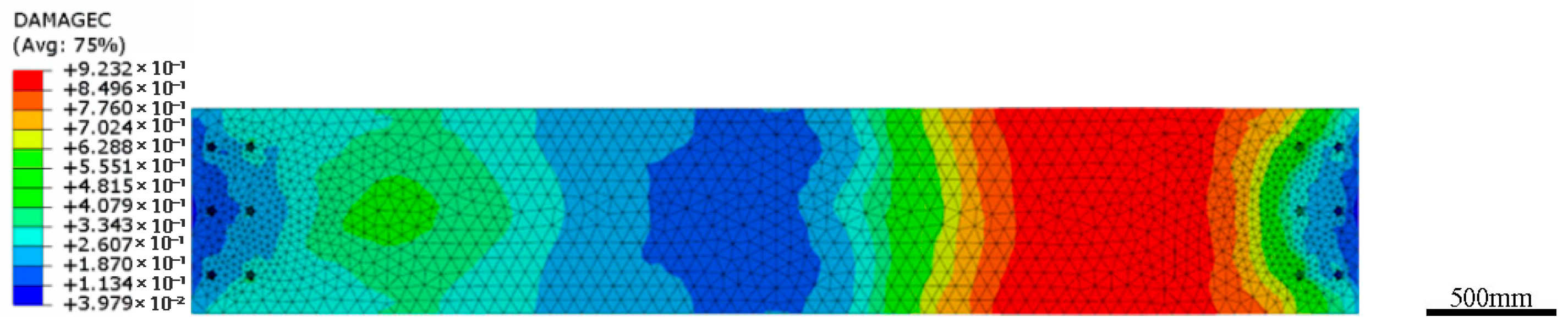

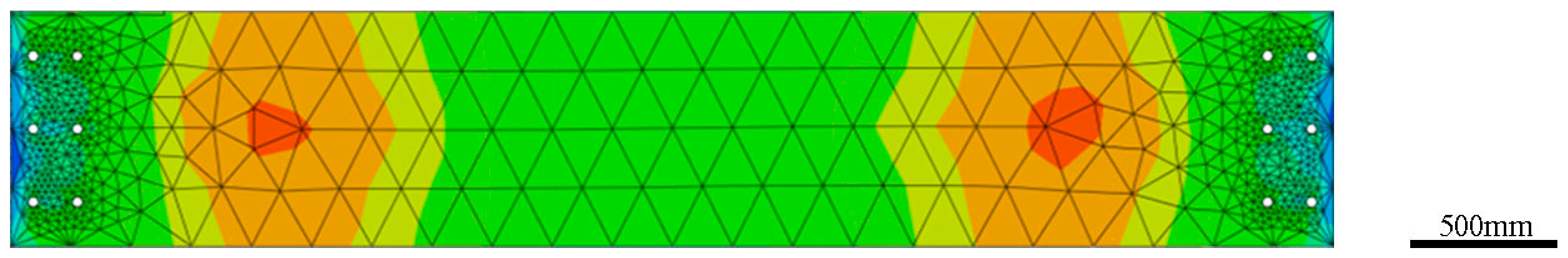

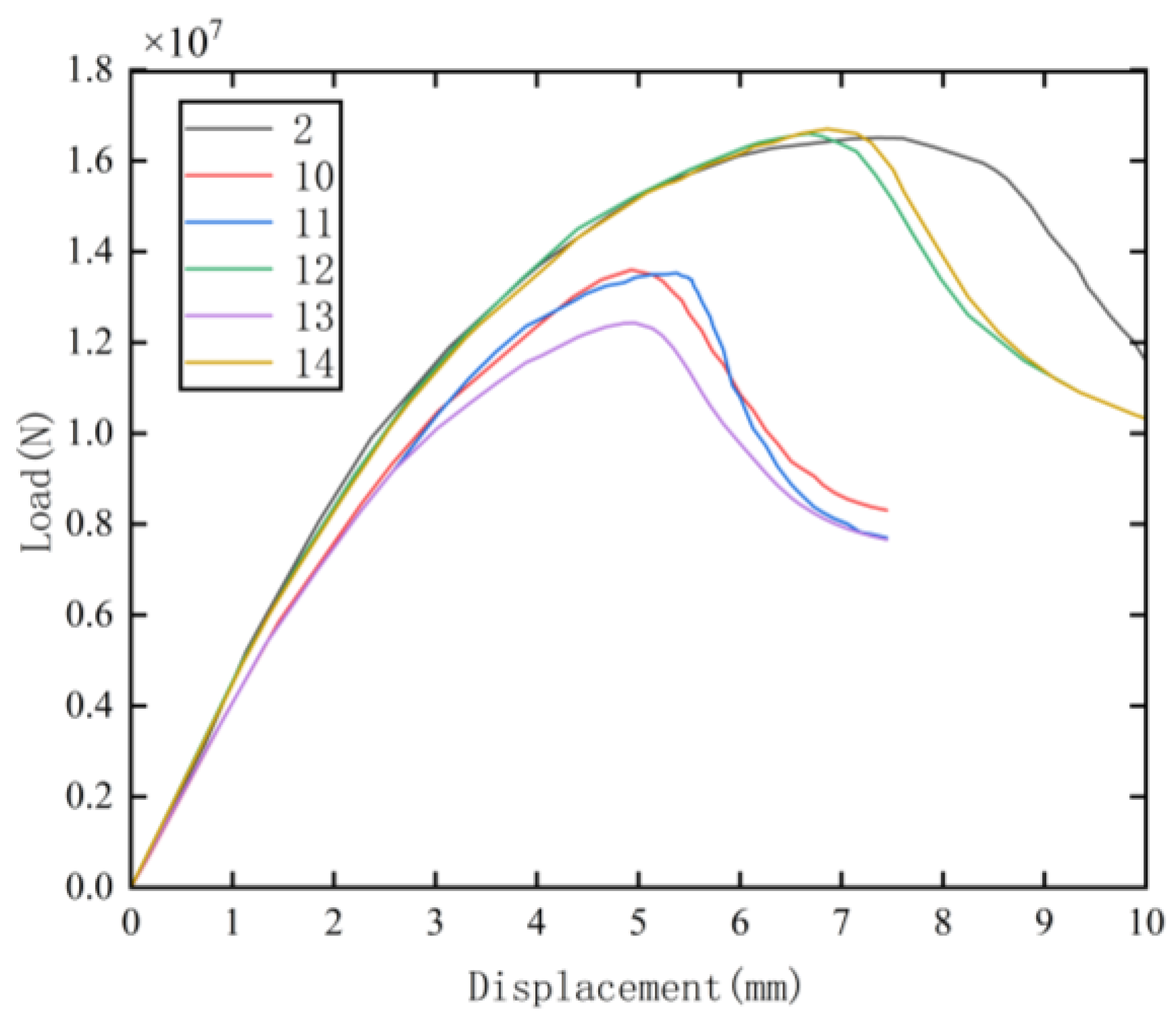

3.5. Influence of Hole Diameter on the Axial Compressive Mechanical Properties of Specimen Concrete

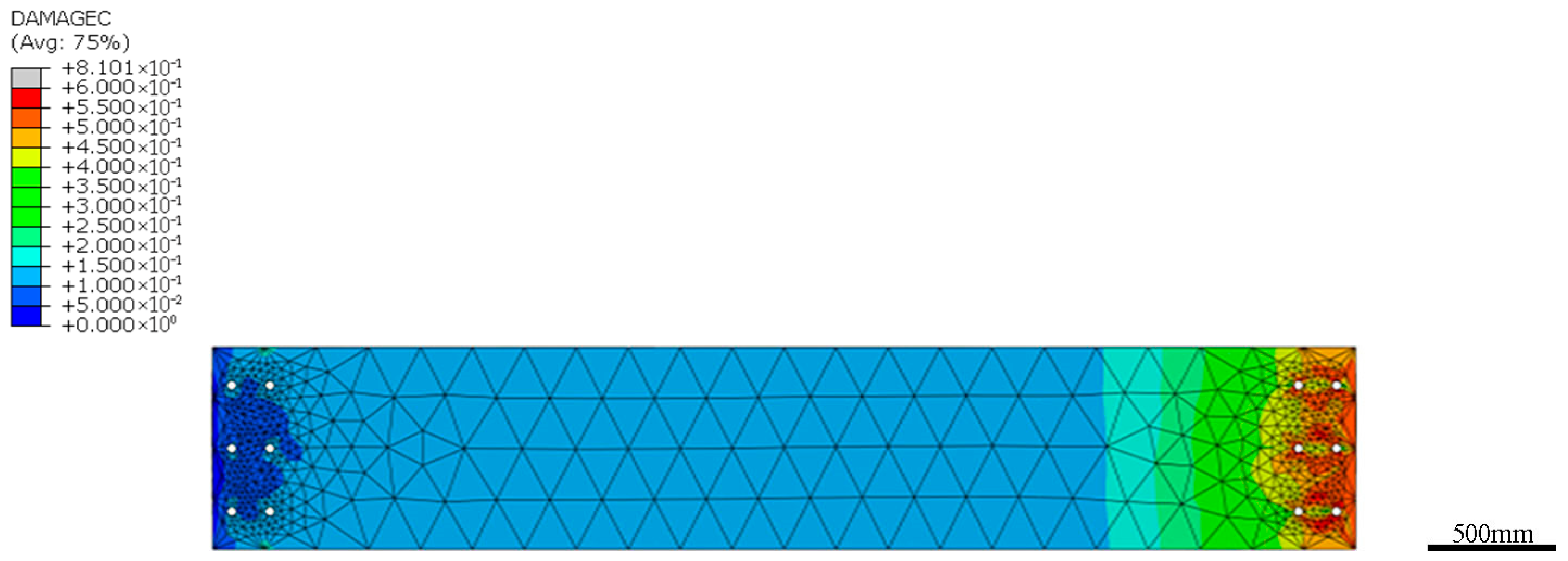

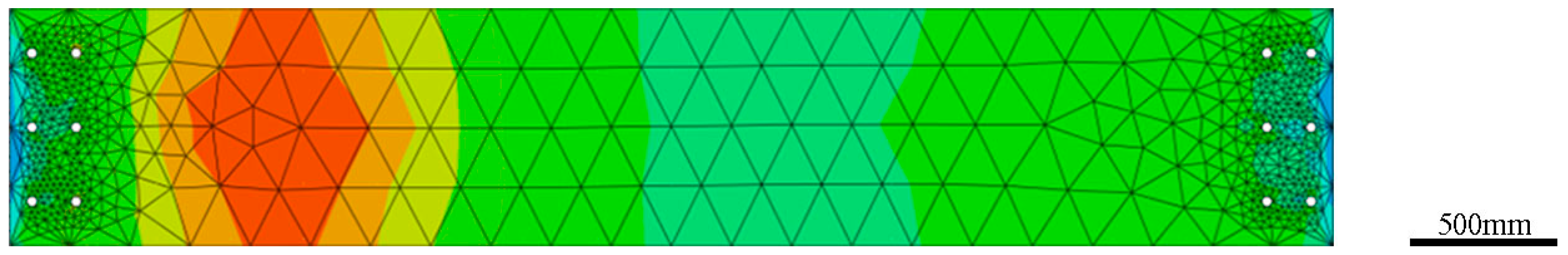

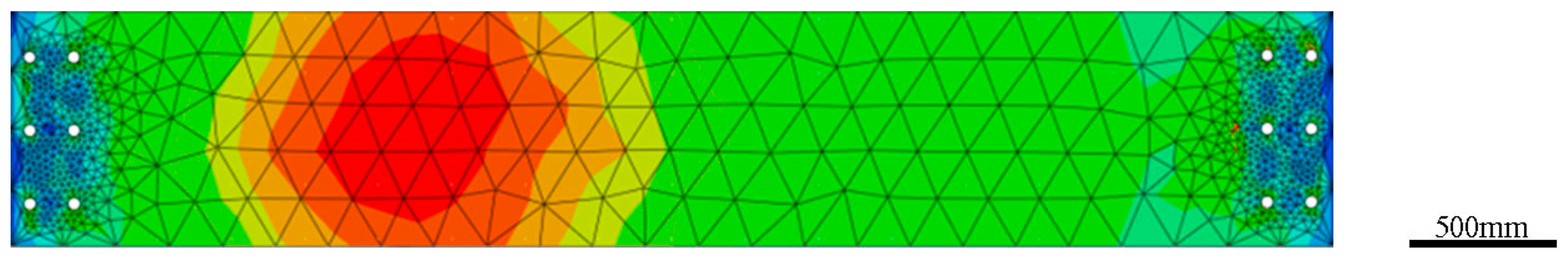

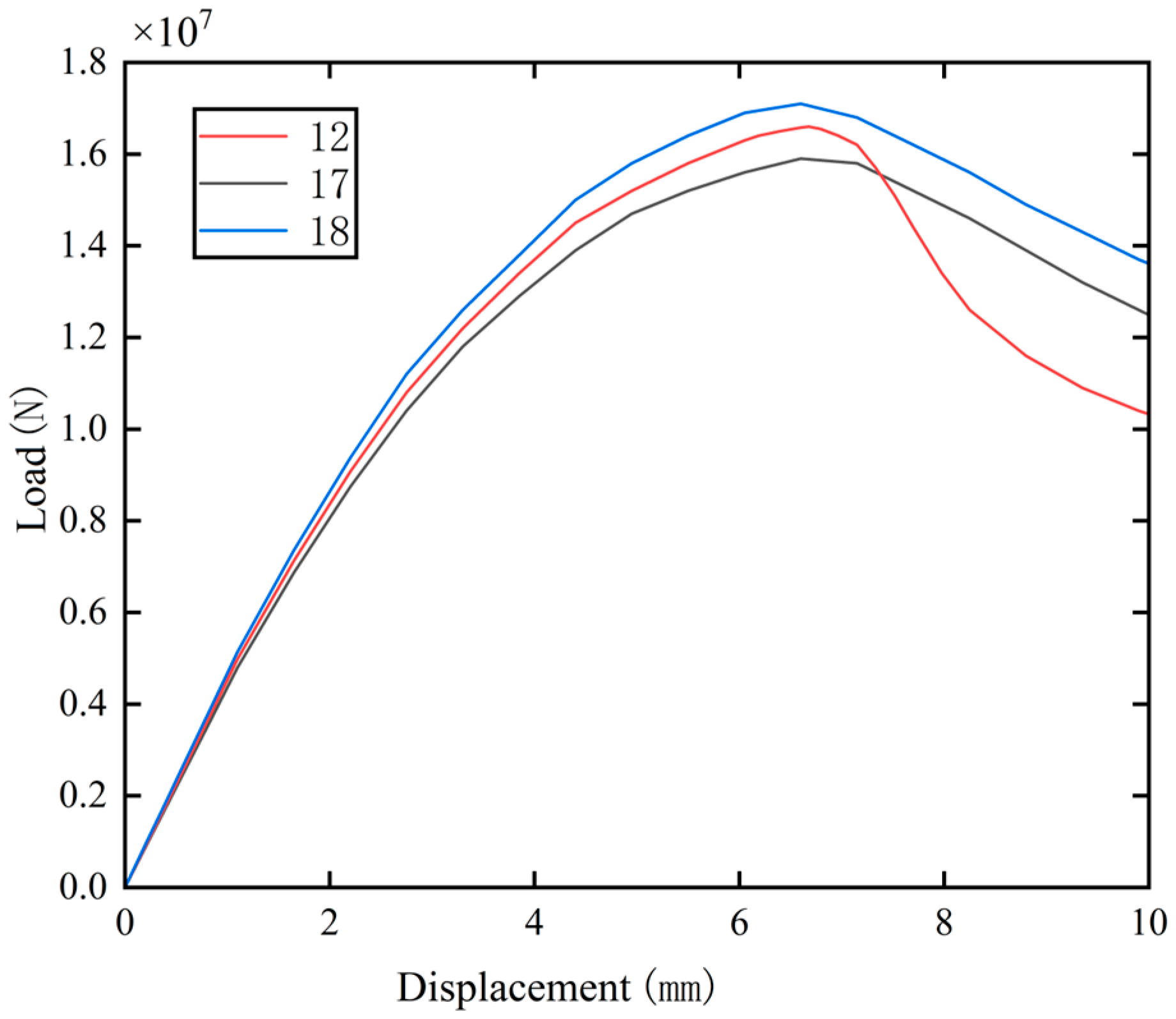

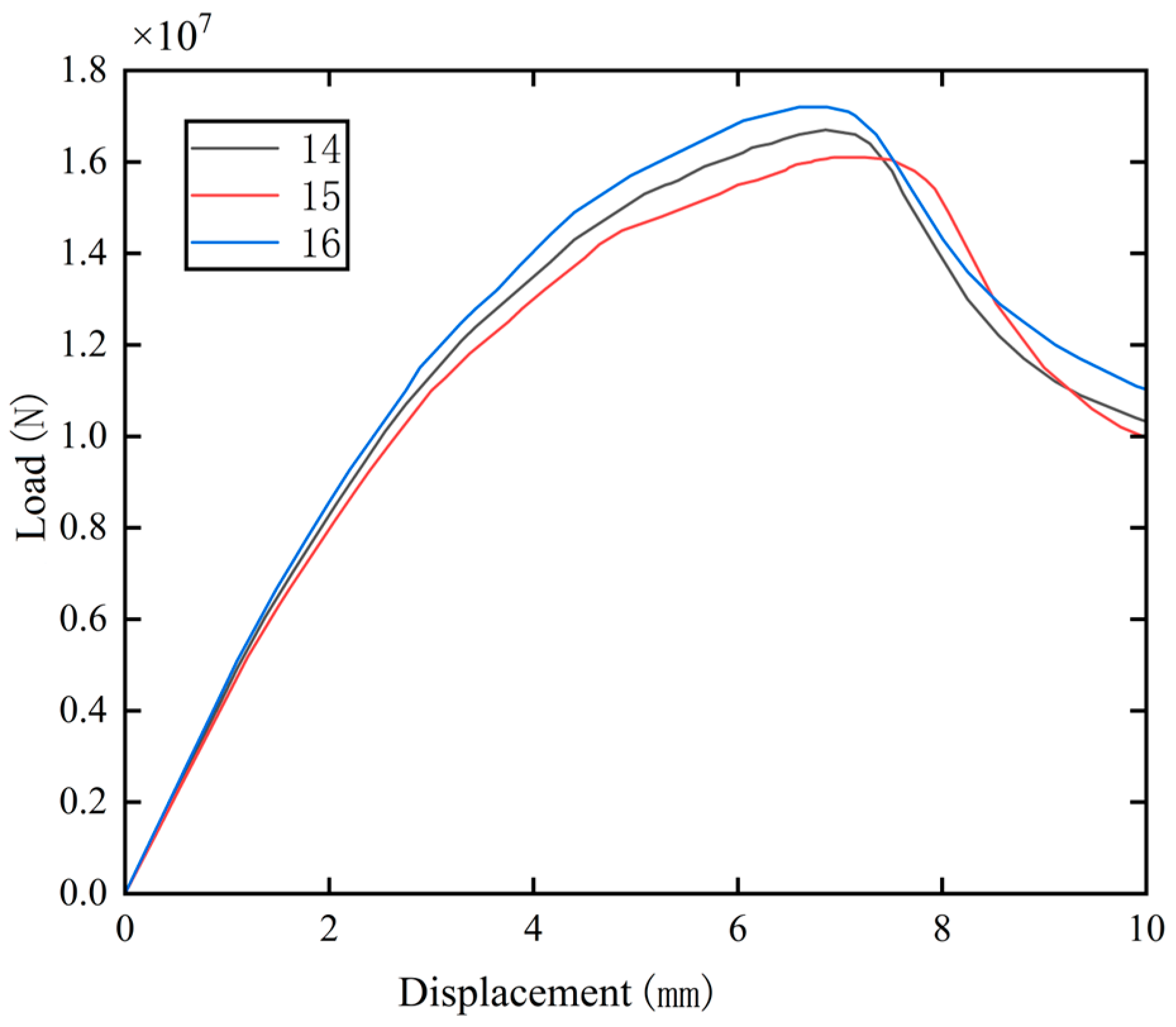

3.6. Influence of Beam Sleeve Thickness on the Mechanical Properties of Specimens Subjected to Axial Compression

4. Conclusions

- (1)

- For specimens without a steel beam sleeve, the compressive strength decreased by 11.3%, 16.7%, and 18%, respectively, when the hole diameters were 35 mm, 40 mm, and 45 mm compared to specimens without holes. Beam-end holes significantly reduced the compressive strength of beam segments without a sleeve, and the reduction in compressive strength increased with larger hole diameters.

- (2)

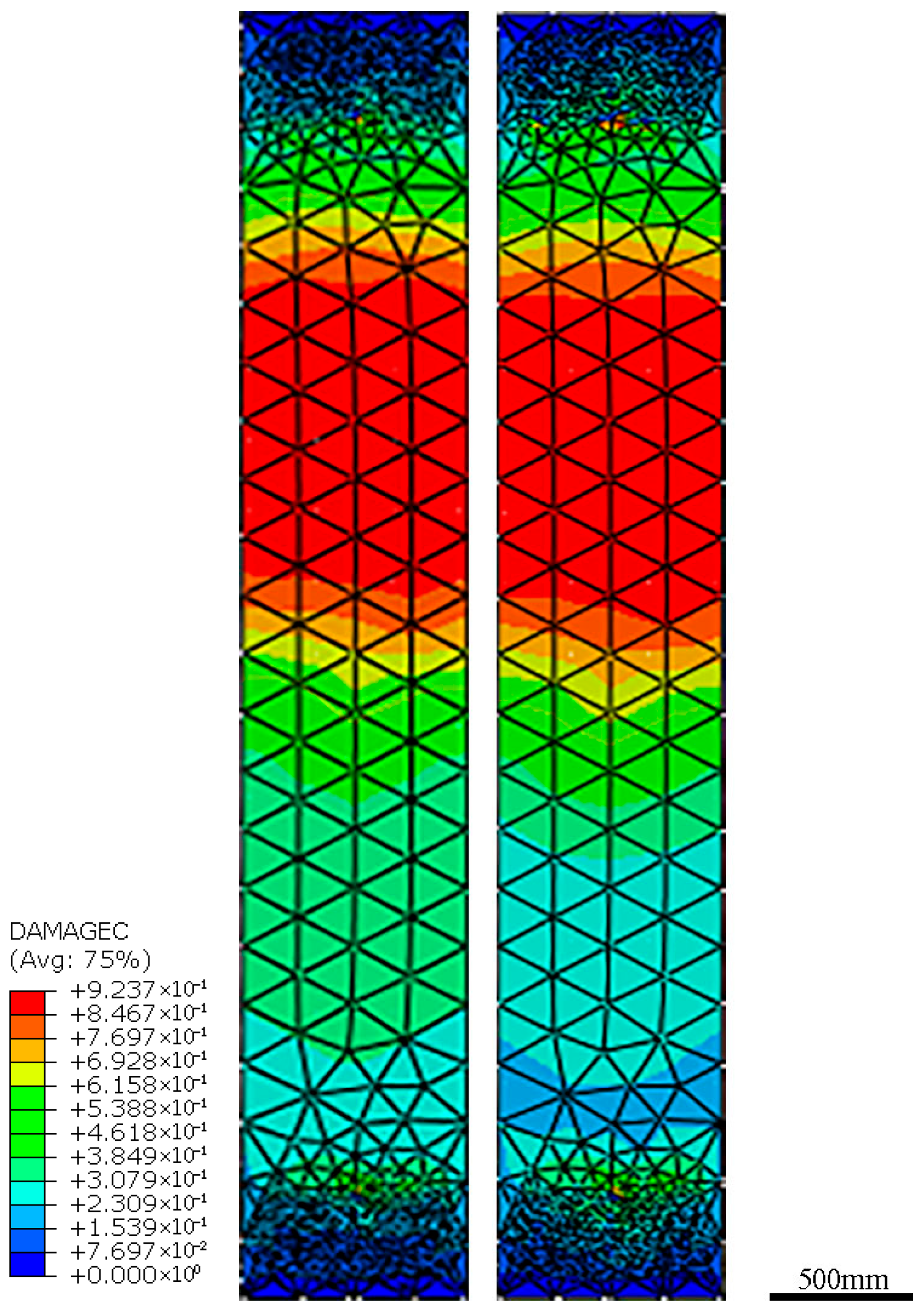

- In specimens with holes and steel beam sleeves of 5 mm, 10 mm, and 15 mm thickness, respectively, the compressive bearing capacity was higher than that of specimens without beam sleeves and holes. The beam sleeves exert a decisive influence on the compressive bearing capacity of the specimens, and the confinement effect of the beam sleeve on the beam segment compensated for the weakening effect caused by the holes. As the thickness of the beam sleeve increased, the bearing capacity of the beam segment increased significantly. Moreover, the presence of beam sleeves markedly reduced concrete damage at the specimen ends, shifting the location of maximum damage from the end hole regions to the mid-span of the beam segment. These findings confirm that the designs of holes in beam segment ends and beam sleeves can meet safety requirements.

- (3)

- The end restraint condition has little effect on the compressive bearing capacity of the beam segment, but it changes the location of the concrete compression-damage cross-section. As the end face friction coefficient decreases from 0.6 to 0.1, the maximum compression damage location of the beam section moves closer to the end face, and the damage at the hole location also increases gradually.

5. Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shan, Y.H.; Zhang, M.J.; Guo, C.X.; Li, P.; Liu, W. A Fixed End Composed of Long Bolts and Mold Bag Concrete for Prefabricated Internal Support and Its Bearing Performancein Foundation Pit Engineering. In Proceedings of the 18th Conference of the Associated Research Centers for the Urban Underground Space, Singapore, 1–4 November 2023. [Google Scholar]

- Zhou, Y.Z.; Yang, S.Y.; Wang, S.; Xu, M.X.; Zhou, H.X. Analysis and treatment for collapse accident of a foundation pit in deep and thick sullage soft-soil area. Build. Struct. 2024, 54, 128–135. [Google Scholar]

- Ye, J.J.; Peng, Q.B.; Xiao, J.Z.; Lan, W.; Wang, J. Green demolishing technology of beams or columns with embedded holes by mechanical cutting and off-site blasting. Archit. Civ. Eng. 2023, 40, 111–117. [Google Scholar]

- Ye, J.J.; Chen, F.; Xiao, J.Z.; Cheng, D.C. Green Blasting Demolition Technology of Reinforced Concrete Structures. Blasting 2019, 36, 90–97. [Google Scholar]

- Yan, N.; Hao, Z.M.; Bai, X.Y.; Zhang, L.; Sun, L.N.; Zhang, Q.J. Force and deformation characteristics of double-row miniature pile-anchor-support combination support structure for deep foundation pit. J. Cent. South Univ. 2024, 55, 2295–2309. [Google Scholar]

- Sun, W.W.; Feng, J.; Gu, L.N. Anti-Collapse Analysis of Fabricated Steel Support System Consisting of Prestressed Fish-Bellied Beams in Excavation. Chin. J. Undergr. Space Eng. 2022, 18, 989–996. [Google Scholar]

- Hu, L.Q. Theoretical Study on the Deformation Control of Retaining Piles by Steel Support of Prestressed Fish-bellied Beams. Chin. J. Undergr. Space Eng. 2021, 17, 141–149. [Google Scholar]

- Xia, G.; Liu, B.; Qi, X.C.; Li, J.H.; Zhang, T.M.; Ye, J.J.; Wu, T.L.; Xu, K.J.; Tan, B.H.; Wang, B. Easily Dismantled Hybrid Prefabricated RC-SS Foundation Pit Bracing System and Construction Method. CN119640814A, 18 March 2025. [Google Scholar]

- Zhang, T.M.; Gu, L.; Zhou, C.Y.; Wang, L.C.; Xia, G.; Ye, J.J.; Wu, T.L.; Tan, B.H.; Xu, K.J.; Gao, Y.; et al. Hybrid Prefabricated RC-SS Foundation Pit Bracing System and Demolition Method. CN119777388A, 8 April 2025. [Google Scholar]

- Ye, J.J.; Wu, T.L.; Xu, K.J.; Liu, B.; Zhang, X.H.; Gao, P.; Wei, S.S.; Zhang, J.M.; Tan, B.H.; Xu, G.H. Prefabricated Reinforced Concrete Beam Segment for Foundation Pit Bracing and Its Pre-Fabrication Method. CN119711508A, 28 March 2025. [Google Scholar]

- Tahir, M.F.; Shabbir, F.; Ahmad, A.; Ejaz, N. Experimental and Numerical Investigation of Transverse Circular Holes on Load-Carrying Capacity of RC Columns. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2021, 45, 683–696. [Google Scholar] [CrossRef]

- Campione, G.; Cucchiara, C.; Minafo, G. Effects of circular openings on the compressive behaviour of RC columns. Mater. Struct. 2015, 48, 1995–2008. [Google Scholar] [CrossRef]

- Liang, J.; Wang, Y.; Zou, W.; Wang, C.; Li, W. Axial compression performance of partially encased concrete columns with web opening. Sci. Rep. 2024, 14, 11853. [Google Scholar] [CrossRef]

- Minafo, G. Load-carrying capacity of axially-loaded RC members with circular openings. Eng. Struct. 2012, 41, 136–145. [Google Scholar] [CrossRef]

- Yang, X. Study on Mechanical Performance and Reinforced Method of Opening at the Beam End in Existing Reinforced Concrete Frame Structure; Suzhou University of Science and Technology: Suzhou, China, 2022. [Google Scholar]

- Hu, Q.; Jia, S.; Wu, H.; Wang, T. Experimental Research of Axial Compression Bearing Capacity on RC Columns Strengthened with Angle Steel and Self-Compacting Concrete. Int. J. Steel Struct. 2022, 22, 253–262. [Google Scholar] [CrossRef]

- Han, L.H.; Liu, W.; Yang, Y.F. Behavior of thin walled steel tube confined concrete stub columns subjected to axial local compression. Thin-Walled Struct. 2008, 46, 155–164. [Google Scholar] [CrossRef]

- Liu, J.; Abdullah, J.A.; Zhang, S. Hysteretic behavior and design of square tubed reinforced and steel reinforced concrete (STRC and/or STSRC) short columns. Thin-Walled Struct. 2011, 49, 874–888. [Google Scholar] [CrossRef]

- Lai, M.H.; Ho, J.C.M. Axial strengthening of thin-walled concrete-filled-steel-tube columns by circular steel jackets. Thin-Walled Struct. 2015, 97, 11–21. [Google Scholar] [CrossRef]

- Li, X.Z.; Zhang, S.M.; Tao, Y.; Zhang, B. Numerical Study on the Axial Compressive Behavior of Steel-Tube-Confined Concrete-Filled Steel Tubes. Materials 2024, 17, 155. [Google Scholar]

- Choi, E.; Utui, N.; Kim, H.S. Experimental and analytical investigations on debonding of hybrid FRPs for flexural strengthening of RC beams. Compos. Part B-Eng. 2013, 45, 248–256. [Google Scholar]

- Kim, H.S.; Shin, Y.S. Flexural behavior of reinforced concrete (RC) beams retrofitted with hybrid fiber reinforced polymers (FRPs) under sustaining loads. Compos. Struct. 2011, 93, 802–811. [Google Scholar] [CrossRef]

- Saini, A.; Prakash, S.S. Analytical study on the effectiveness of hybrid FRP strengthening on behaviour of slender reinforced concrete square columns. Structures 2021, 33, 4218–4242. [Google Scholar] [CrossRef]

- Pham, T.M.; Doan, L.V.; Hadi, M.N.S. Strengthening square reinforced concrete columns by circularisation and FRP confinement. Constr. Build. Mater. 2013, 49, 490–499. [Google Scholar] [CrossRef]

- Hu, T.Y.; Zhang, H.; Zhou, J.T. Machine learning-based model for recognizing the failure modes of FRP-strengthened RC beams in flexure. Case Stud. Constr. Mater. 2023, 18, e02076. [Google Scholar] [CrossRef]

- Abuodeh, O.R.; Abdalla, J.A.; Hawileh, R.A. Prediction of shear strength and behavior of RC beams strengthened with externally bonded FRP sheets using machine learning techniques. Compos. Struct. 2020, 234, 111698. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Hu, L.; Li, S.; Wang, K.-H. Experimental study and analysis on fatigue stiffness of RC beams strengthened with CFRP and steel plate. J. Cent. South Univ. 2016, 23, 701–707. [Google Scholar] [CrossRef]

- Lin, Y.; Wei, Y.; Gong, Z.H.; Xu, W.; Zhao, K. Flexural Behavior of an RC Beam Externally Strengthened with a Steel- and CFRP-Based Method. Appl. Sci. 2024, 14, 9281. [Google Scholar] [CrossRef]

- Liu, Y.L.; Hong, J.Q.; Deng, J.; Guo, D.; Dai, J.-G. Structural performance of RC beams strengthened with hybrid bonded CFRP. J. Build. Eng. 2024, 88, 109–178. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Pham, T.M.; Lei, X. New Method of Strengthening Reinforced Concrete Square Columns by Circularizing and Wrapping with Fiber-Reinforced Polymer or Steel Straps. J. Compos. Constr. 2013, 17, 229–238. [Google Scholar] [CrossRef]

- Yan, F.; Lin, Z.B. New strategy for anchorage reliability assessment of GFRP bars to concrete using hybrid artificial neural network with genetic algorithm. Compos. Part B-Eng. 2016, 92, 420–433. [Google Scholar] [CrossRef]

- Zhang, T.; Hou, Z.; Li, X.; Chen, Q. Research on the calculation of model parameters for concrete plastic damage model in ABAQUS. Chin. J. Comput. Mech. 2024, 41, 1130–1137. [Google Scholar]

- Zeng, Y.; Hu, M. Calculation Transformation and Calibration of ABAQUS Concrete Plastic Damage Constitutive Model. Water Resour. Power 2019, 37, 106–109. [Google Scholar]

- Zhang, T. Evaluation and Application of Typical Material Models Used in FE Modelling Under Monotonic and Cyclic Loading Conditions; Kunming University of Science And Technology: Kunming, China, 2020. [Google Scholar]

- Walraven, J. Fib Model Code for Concrete Structures 2010: Mastering challenges and encountering new ones. Struct. Concr. J. FIB 2013, 14, 3–9. [Google Scholar] [CrossRef]

- Yang, F.; Dong, X.; Zhou, S.; Huang, Y.C. ABAQUS Concrete Plastic Damage Factor Calculation Method and Application Research. Sichuan Archit. 2017, 37, 173–177. [Google Scholar]

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2011.

- Zhang, T.; Hou, Z.; Chen, Q.; Li, X.; Fang, Y.; Zhang, S.; Sun, W. A novel damage model integrated into the elastoplastic constitutive model and numerical simulations of reinforced concrete structures under cyclic loading. J. Build. Eng. 2024, 84, 108–670. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Oh, B.H. Crack band theory for fracture of concrete. Matériaux Constr. 1983, 16, 155–177. [Google Scholar] [CrossRef]

- Li, J.; Chen, J. Stochastic Dynamics of Structures; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- D’amato, M.; Braga, F.; Gigliotti, R.; Kunnath, S.; Laterza, M. A numerical general-purpose confinement model for non-linear analysis of R/C members. Comput. Struct. 2012, 102, 64–75. [Google Scholar] [CrossRef]

| Expansion Angle | Eccentricity | Ratio of Biaxial to Uniaxial Compressive Strength | Yield Surface Parameter | Viscosity Coefficient |

|---|---|---|---|---|

| 30 | 0.1 | 1.16 | 0.667 |

| (N/mm2) | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 |

|---|---|---|---|---|---|---|

| (10−6) | 65 | 81 | 95 | 107 | 118 | 128 |

| 0.31 | 0.70 | 1.25 | 1.95 | 2.81 | 3.82 |

| (N/mm2) | 20 | 25 | 30 | 35 | 40 |

|---|---|---|---|---|---|

| (10−6) | 1470 | 1560 | 1640 | 1720 | 1790 |

| 0.74 | 1.06 | 1.36 | 165 | 1.94 | |

| 3.0 | 2.6 | 2.3 | 2.1 | 2.0 |

| Treatment | Boundary Friction Coefficient | Connection Holes Diameter | Beam Sleeve Thickness |

|---|---|---|---|

| 1 | - | 0 | 0 |

| 2 | 40 | 10 | |

| 3 | 40 | 0 | |

| 4 | 40 | 5 | |

| 5 | 40 | 15 | |

| 6 | 0 | 40 | 0 |

| 7 | 0.1 | 40 | 0 |

| 8 | 0.2 | 40 | 0 |

| 9 | 0.4 | 40 | 0 |

| 10 | 0.6 | 40 | 0 |

| 11 | 35 | 0 | |

| 12 | 35 | 10 | |

| 13 | 45 | 0 | |

| 14 | 45 | 10 | |

| 15 | 45 | 5 | |

| 16 | 45 | 15 | |

| 17 | 35 | 5 | |

| 18 | 35 | 15 |

| Treatment | Mesh Size | Mesh Shape | Axial Compressive Bearing Capacity |

|---|---|---|---|

| 1 | 250 | hexahedral mesh | 15,004,800 |

| 220 | 14,824,700 | ||

| 200 | 15,000,000 | ||

| 180 | 14,878,600 | ||

| 1 | 250 | tetrahedral mesh | 15,000,400 |

| 220 | 15,017,400 | ||

| 200 | 15,012,200 | ||

| 180 | 14,824,700 | ||

| 3 | 250 | 12,712,900 | |

| 220 | 12,676,500 | ||

| 200 | 12,300,000 | ||

| 180 | 12,592,300 | ||

| 14 | 250 | 16,630,000 | |

| 220 | 16,540,000 | ||

| 200 | 16,500,000 | ||

| 180 | 16,710,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, J.; Wu, T.; Xue, P.; Zhao, W.; Xu, K.; Li, S. The Influence of Holes and Beam Sleeves on the Compressive Mechanical Properties of Reinforced Concrete Beam Segments. Appl. Sci. 2025, 15, 11956. https://doi.org/10.3390/app152211956

Ye J, Wu T, Xue P, Zhao W, Xu K, Li S. The Influence of Holes and Beam Sleeves on the Compressive Mechanical Properties of Reinforced Concrete Beam Segments. Applied Sciences. 2025; 15(22):11956. https://doi.org/10.3390/app152211956

Chicago/Turabian StyleYe, Jianjun, Tianlong Wu, Pengfei Xue, Wei Zhao, Kaijun Xu, and Song Li. 2025. "The Influence of Holes and Beam Sleeves on the Compressive Mechanical Properties of Reinforced Concrete Beam Segments" Applied Sciences 15, no. 22: 11956. https://doi.org/10.3390/app152211956

APA StyleYe, J., Wu, T., Xue, P., Zhao, W., Xu, K., & Li, S. (2025). The Influence of Holes and Beam Sleeves on the Compressive Mechanical Properties of Reinforced Concrete Beam Segments. Applied Sciences, 15(22), 11956. https://doi.org/10.3390/app152211956