Abstract

The elevated needs for high-performance energy storage, dictated by electrification, renewable sources integration, and the global increase in interconnected devices, have placed batteries to the forefront of technological research. Additive manufacturing is increasingly recognized as a compelling approach to advance battery research and application by enabling tailored control over design, pore geometry, materials, and integration. This perspective work examines the opportunities and challenges associated with utilizing additive manufacturing as an enabling battery manufacturing technology. Recent advances in the additive fabrication of electrodes, electrolytes, separators, and integrated devices are examined, exhibiting the potential to acheive electrochemical performance, design adaptability, and sustainability. At the same time, key challenges—including materials formulation, reproducibility, economic feasibility, and regulatory uncertainty—are discussed as limiting factors that must be addressed for achieving the expected results. Rather than being viewed as a replacement for conventional gigafactory-scale production, additive manufacturing is positioned as a complementary fabrication technique that can deliver value in niche, distributed, and application-specific contexts. This work concludes by outlining research and policy priorities that could accelerate the maturation of 3D-printed batteries, stressing the importance of hybrid manufacturing, multifunctional printable materials, circular economy integration, and carefully phased timelines for deployment. Moreover, by enabling customized form factors, improved device–user interfaces, and seamless integration into smart, automated environments, additive manufacturing has the potential to significantly enhance user experience across emerging battery applications. In this context, this perspective provides a grounded assessment of how additive fabrication methods may contribute to next-generation battery technologies that not only improve electrochemical performance but also enhance user interaction, reliability, and seamless integration within automated and control-driven systems.

1. Introduction

The transition toward electrification across multiple sectors has placed batteries at the center of global technological and societal change. Lithium-ion batteries are vastly used in portable electronics and electric vehicles [,], while emerging solid-state and alternative chemistry aims to meet demands for higher energy density, safety, and sustainability []. Beyond transportation, large-scale stationary batteries are indispensable for balancing the intermittency of renewable energy sources such as wind and solar, enabling more resilient and decentralized energy grids []. The capacity to store and deliver energy on demand underpins the feasibility of sustainable energy transitions and supports critical infrastructures ranging from urban mobility to smart grids []. Consequently, advances in battery technology are not merely technical milestones but essential enablers of global decarbonization strategies, the electrification of industry, and the establishment of energy independence in both developed and emerging economies.

At the same time, the proliferation of interconnected devices in the Internet of Things (IoT) has generated a parallel demand for compact, reliable, and long-lasting energy storage systems. Wearable electronics [], medical implants [,], autonomous sensors [], and distributed monitoring platforms [] all rely on batteries that can be adapted to unconventional geometries, miniaturized without sacrificing performance, and seamlessly integrated into functional devices. This expanding spectrum of applications highlights the dual role of batteries: as large-scale storage units for renewable energy integration [], and as microscale power supplies enabling ubiquitous computing and data-driven infrastructures []. The diversity of these requirements stresses the need for innovative manufacturing strategies that can move beyond traditional planar designs, support architectural complexity, and provide both flexibility and performance at multiple scales of deployment.

Unlike classic review articles that aim to comprehensively catalogue research efforts, this contribution positions itself as a perspective intended to critically evaluate the role of additive manufacturing in the field of batteries. The scope of this paper is deliberately selective rather than exhaustive: priority is given to identifying the most impactful advances, the fundamental limitations that currently hinder translation from laboratory studies to real-world applications, and the directions where research and industrial investment could yield the highest returns. The authors’ standpoint is intentionally emphasized throughout the discussion, with the goal of articulating both opportunities and caveats in a manner that stimulates debate across the additive manufacturing and energy storage communities. By doing so, this work seeks to provide clarity on what is achievable in the near term, what remains aspirational, and where interdisciplinary collaboration is most urgently needed.

This perspective is particularly critical given the accelerating demand for advanced energy storage solutions and the parallel growth of additive manufacturing technologies. Without a rigorous and opinionated assessment, the field risks fragmenting into proof-of-concept demonstrations that, while scientifically interesting, may have limited industrial relevance. Thus, the intention here is not only to highlight promising aspects—such as architected electrodes [], multifunctional device integration [], and sustainability-driven fabrication []—but also to delineate the systemic challenges that must be addressed before additive manufacturing can become a meaningful contributor to battery technology at scale. By explicitly contrasting potential with limitation, this work aims to provide a grounded roadmap for the field’s progression.

Compared with recent reviews on additive manufacturing for batteries, which primarily focus on material developments, printing techniques, or specific device classes, this perspective offers a distinct forward-looking viewpoint by emphasizing the convergence of high-throughput manufacturing with emerging 3D/4D printing paradigms. While ear-lier works have catalogued printing methods, material chemistries, and performance demonstrations, our contribution lies in critically examining scalability, hybridization with established gigafactory processes, and design-driven functionalities that can unlock next-generation battery architectures. This perspective highlights not only the current technological landscape but also identifies transformative pathways—such as hybrid manufacturing, architected electrodes, and multifunctional material design—that can bridge the gap between laboratory-scale demonstrations and manufacturable, application-ready energy storage systems.

Beyond the material and manufacturing-centric benefits, the integration of additive manufacturing into battery design also carries significant implications for user experience, which closely aligns with the human-centric manufacturing perception. By enabling customized geometries, improved device ergonomics, and seamless embedding of batteries into wearables, IoT nodes, medical devices, and consumer electronics, additive manufacturing supports more intuitive, reliable, and user-adapted energy solutions. This perspective, therefore, also considers how design-driven functionalities facilitated by 3D/4D printing can enhance interaction, usability, and the overall value perceived by end-users across diverse application domains.

In the sections that follow, recent advances in the use of 3D printing for battery components and devices will be discussed, followed by a discussion of the opportunities that additive manufacturing uniquely offers. Subsequent sections will then turn to the key challenges and barriers that persist, and finally to a structured set of future directions that could guide research and application in the coming years. Taken together, these elements are intended to provide not only a snapshot of the state of the art, but also a reasoned perspective on how additive manufacturing may shape the next generation of batteries.

2. Advances in 3D Printing for Energy Storage

Additive manufacturing has emerged as an enabling approach in the development of advanced energy storage systems, offering the possibility to fabricate battery components with structural and functional features that are difficult to achieve using conventional techniques []. Traditional electrode-manufacturing processes—such as slurry casting [], calendaring [], and stacking []—are optimized for large-scale production but impose strict limitations on geometry and spatial design. In contrast, 3D printing provides precise control over material placement and architecture, allowing the creation of electrodes [], electrolytes [], and separators with tailored porosity [], thickness [], and geometry []. This level of structural control supports both the optimization of electrochemical performance and the exploration of new battery configurations []. The following subsections outline key advances, beginning with the fabrication of electrodes, which remain the most widely studied and technologically significant application of additive manufacturing in the battery field.

2.1. Printing of Electrodes

The application of 3D printing in electrode fabrication has focused on exploiting architectural complexity to enhance electrochemical performance. Interdigitated elec-trodes, in which anode and cathode structures are printed in interlocking geometries, exemplify how additive manufacturing can minimize ion diffusion distances while maximizing active surface area []. These designs improve charge–discharge kinetics and enable high power densities, which are difficult to achieve with conventional planar electrodes []. Similarly, extrusion-based printing of porous carbon or graphene-based scaffolds has demonstrated the potential to create three-dimensional frameworks with tunable pore sizes [], enhancing electrolyte accessibility and facilitating ion transport throughout the electrode. Such structural tailoring not only improves rate capability but also allows for the strategic placement of conductive pathways, thereby mitigating limitations in electron mobility within thick electrodes [].

Beyond interdigitated and porous geometries, the capacity to generate hierarchical electrode structures has emerged as a significant advantage of additive manufacturing []. By combining macropores that facilitate bulk ion transport with mesopores and micropores that increase the electrochemically active surface area, 3D-printed electrodes can achieve a balance between energy density and power density []. Advanced techniques such as direct ink writing [,] and aerosol jet printing have been employed to deposit inks containing active materials, conductive additives, and binders in precise spatial arrangements, producing electrodes with controlled gradients in composition and structure [,,]. These hierarchical designs can be tailored to the requirements of specific applications, from high-power microbatteries [] to high-energy devices for electric mobility []. Importantly, such approaches also open pathways for incorporating novel chemistries—such as sulfur cathodes or lithium metal anodes—into stable architectures, providing opportunities to overcome challenges associated with volume expansion, dendrite formation, and mechanical degradation during cycling.

2.2. Printing of Electrolytes and Separators

While electrodes have attracted the majority of research attention, the development of printable electrolytes and separators is equally important for advancing additive manufacturing in battery systems. Electrolytes serve as the medium for ion transport between electrodes, and their structural and chemical properties largely determine safety, stability, and performance []. Conventional liquid electrolytes, though widely used, are difficult to integrate into additive manufacturing processes due to handling and containment challenges []. As a result, efforts have increasingly focused on solid [] and gel [] electrolytes that can be formulated into printable inks or pastes []. For example, polymer-based electrolytes such as polyethylene oxide (PEO) [] or poly(vinylidene fluoride) (PVDF) [] composites have been extruded into solid membranes with tailored thickness and ionic conductivity. Similarly, ceramic-based electrolytes containing lithium garnets [] or sulfides [] have been processed through extrusion or stereolithography [], offering improved electrochemical stability and compatibility with high-energy-density chemistries.

Separators, which prevent electrical short-circuiting while maintaining ionic conductivity, have also been explored within additive manufacturing frameworks [,]. Unlike conventional separators that are typically fabricated as thin polymer films with limited structural variation, 3D printing enables the design of separators with controlled porosity, variable thickness, and even patterned architectures that can improve electrolyte wetting and reduce resistance [,]. Techniques such as inkjet printing [] and direct ink writing [] have demonstrated the fabrication of separators with aligned pores and interconnected channels, which enhance ionic transport efficiency while retaining mechanical stability. Furthermore, by integrating electrolyte and separator functions into a single printed structure, additive manufacturing can simplify battery assembly and reduce interfacial resistance—issues that remain critical for the adoption of solid-state batteries []. These developments suggest that the ability to print electrolytes and separators is not only relevant for performance optimization but also for enabling safer and more compact battery configurations [].

2.3. Microbatteries, Flexible and Wearable Systems

One of the most transformative applications of 3D printing in energy storage lies in the fabrication of microbatteries and energy devices tailored for flexible and wearable electronics []. Traditional microfabrication techniques often struggle to balance miniaturization with high energy and power densities. Additive manufacturing, by contrast, enables the direct patterning of intricate architectures at small scales, allowing precise control of active material distribution, thickness, and interfacial contact []. For instance, interdigitated electrode structures produced through inkjet or extrusion-based printing have been demonstrated to significantly enhance surface area and reduce ion transport paths, thereby improving charge–discharge performance in microbatteries []. Moreover, the capacity to integrate microbatteries directly onto unconventional substrates—such as textiles [], polymers [], or even biomedical implants []—illustrates the versatility of additive manufacturing in this emerging field.

Beyond miniaturization, the unique demands of flexible and wearable systems have prompted the development of mechanically resilient and stretchable energy storage devices. Here, 3D printing offers new perspectives for engineering batteries that maintain electrochemical stability under bending, twisting, or stretching [,]. Conductive elastomer composites [], printable hydrogels [], and flexible solid electrolytes [] have been investigated to achieve this mechanical–electrochemical compatibility. In particular, direct ink writing has proven effective for depositing serpentine, mesh-like, or wavy electrode geometries that accommodate mechanical deformation without loss of electrical contact []. Such advances are especially relevant for applications in smart textiles, biomedical monitoring, and consumer electronics, where conventional rigid batteries are inadequate. Taken together, additive manufacturing provides the means to downscale battery systems for microelectronics while achieving the desired structural adaptability for novel flexible and wearable technologies.

2.4. Examples of Device Integration

Additive manufacturing enables the integration of batteries directly into functional devices, moving beyond the traditional approach of adding a discrete energy storage unit []. This capability is particularly significant for applications that demand compactness, customized form factors, or multifunctional structures []. For instance, 3D-printed batteries have been embedded into unmanned aerial vehicles (drones), where conformal energy storage reduces weight and optimizes spatial utilization, ultimately enhancing flight duration and payload capacity [,]. Similarly, in wearable electronics, batteries can be printed onto flexible substrates or incorporated within structural components such as straps, textiles, or casings, minimizing device thickness and improving ergonomics. Such integration allows for more seamless interaction between the energy storage system and the device, reducing the need for additional packaging, wiring, or modular assembly [,].

In addition to drones and wearables, additive manufacturing has facilitated the creation of batteries integrated with sensors and IoT devices, enabling distributed and autonomous monitoring systems []. For example, printed microbatteries can power environmental sensors embedded in infrastructure [], or flexible energy storage units can sustain biomedical sensors within implants or skin-mounted devices []. Integration at the design stage also allows for optimization of thermal management and mechanical stability, addressing critical issues associated with high-energy-density systems []. By embedding energy storage directly within the functional architecture of devices, additive manufacturing not only enhances performance and reliability but also provides a platform for innovative designs that were previously unachievable using conventional battery assembly methods []. To provide a concise overview of the advances in additive manufacturing for battery systems discussed in this chapter, Table 1 summarizes the key components, printing approaches, structural characteristics, and representative applications. This summary highlights the connections between fabrication techniques, resulting architectures, and the functional benefits that each approach enables. By organizing the information in this manner, the table offers a clear reference for understanding how electrodes, electrolytes, separators, microbatteries, and integrated devices are being developed through 3D printing and how these innovations contribute to improved electrochemical performance, mechanical adaptability, and device integration.

Table 1.

Summary of additive manufacturing advances in battery components and systems.

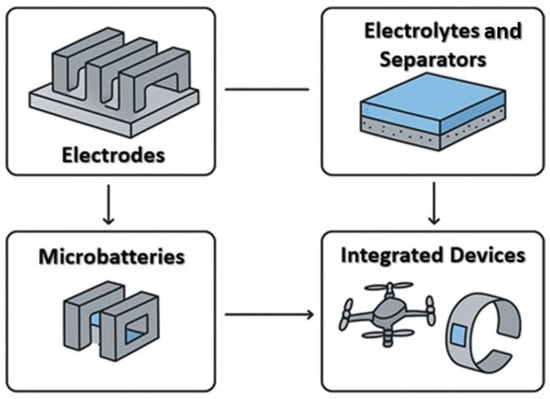

Figure 1 depicts the aforementioned hierarchical relationship between electrodes, electrolytes/separators, microbatteries, and integrated devices.

Figure 1.

Hierarchical relationship between electrodes, electrolytes/separators, microbatteries, and integrated devices.

3. Opportunities and Added Value

The application of additive manufacturing to battery systems extends beyond replicating conventional components through alternative fabrication methods; it creates opportunities to fundamentally improve performance, functionality, and sustainability. By exploiting the design freedom of 3D printing, batteries can be engineered with architectures that maximize electrochemical efficiency, integrate seamlessly into host devices, and utilize materials more effectively. These opportunities position additive manufacturing not merely as a substitute for established manufacturing approaches, but as an enabling technology capable of addressing critical limitations in energy storage, from power density and form factor adaptability to resource efficiency and environmental impact. The following subsections explore these dimensions in greater depth, outlining how 3D printing can deliver measurable added value across performance, integration, and sustainability.

3.1. Enhanced Electrochemical Performance via 3D Architectures

One of the most compelling advantages of additive manufacturing in energy storage lies in its ability to control electrode and cell architectures at multiple scales. Conventional battery manufacturing is constrained by two-dimensional fabrication methods that limit the degree of geometric customization, often resulting in trade-offs between areal capacity, ionic conductivity, and mechanical integrity []. In contrast, 3D printing enables the fabrication of electrodes with spatially optimized structures, such as interconnected macrochannels for ion transport, mesoporous domains for electrolyte accessibility, and nanoscale features for enhanced active surface area []. This hierarchical design flexibility allows the fine-tuning of both ionic and electronic pathways, thereby reducing polarization losses and improving overall energy and power densities.

Furthermore, additive manufacturing provides a platform for integrating multifunctional features within a single electrode or cell. Beyond simply increasing surface area, printed architectures can be designed to accommodate volumetric expansion of high-capacity materials, such as silicon anodes, or to incorporate built-in stress-relief patterns that extend cycle life []. Architectures can also be engineered to minimize tortuosity, thereby shortening diffusion paths for lithium ions and enabling higher charge–discharge rates without compromising stability []. Such control over internal geometries, which is not achievable with conventional slurry casting or calendaring methods, positions 3D printing as a key enabler for next-generation high-performance chemistries, including lithium–sulfur and metal–air systems.

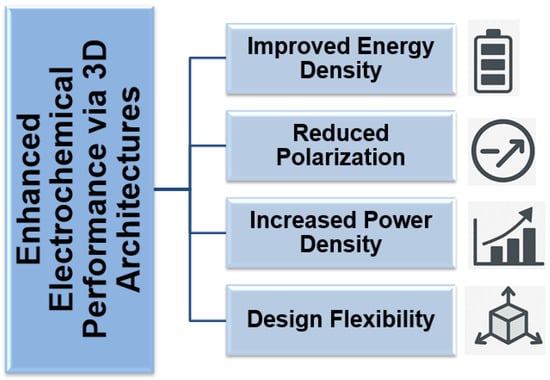

Importantly, the design-driven improvements facilitated by 3D printing are not limited to laboratory-scale prototypes but hold potential for scalable manufacturing []. The ability to digitally control architectures ensures reproducibility across multiple batches and allows for the adaptation of designs to different material systems with minimal modification of the printing process []. This digital versatility is critical for accelerating the translation of novel electrode concepts into practical devices. As such, the performance gains enabled by 3D architectures are not only scientifically significant but also strategically aligned with industrial requirements for high-throughput and application-specific energy storage solutions []. The conceptual illustration in Figure 2 summarizes how 3D-printed architectures can enhance electrochemical performance by enabling structural designs that optimize transport properties and stability.

Figure 2.

Schematic representation of the impact of 3D-printed electrode architectures on battery performance. Key benefits include improved energy density, increased power density, reduced polarization losses, and enhanced design flexibility.

3.2. Design-Driven Integration into Devices and Structures

A defining advantage of additive manufacturing in the battery field is its ability to integrate energy storage directly into the geometry and function of the host device. Unlike conventional batteries, which are fabricated as stand-alone modules and subsequently packaged into devices, 3D printing permits co-design of the battery and the device structure from the outset []. This design-driven approach makes it possible to fabricate batteries in non-standard shapes, embed them into structural elements, or conform them to curved and irregular surfaces without sacrificing performance []. Such integration reduces system-level dead volume, decreases weight associated with external packaging, and enables energy storage to become a structural component rather than an auxiliary subsystem.

The potential of this strategy is particularly evident in emerging applications where space constraints and multifunctionality are critical. In aerospace and automotive contexts, for example, conformal batteries integrated into load-bearing components can simultaneously provide energy and mechanical support, reducing the reliance on separate housings and thereby improving energy-to-weight ratios [,]. Similarly, in biomedical and wearable electronics, batteries printed directly onto flexible substrates or embedded within casings can conform to the user’s body, enhancing ergonomics and comfort while maintaining reliable power delivery [,]. Additive manufacturing also supports modularity, allowing for the rapid prototyping of application-specific devices with integrated energy storage that can be readily adapted to diverse requirements, from drones to medical implants [].

Beyond mechanical and spatial advantages, design-driven integration also has significant implications for system-level performance. By embedding batteries within device architectures, interconnect lengths can be minimized, reducing resistive losses and improving efficiency. Integration also enables co-optimization of thermal management strategies, as battery placement can be adjusted to align with cooling pathways or to distribute heat more evenly across the device []. Furthermore, digital design tools inherent to additive manufacturing workflows allow for precise tailoring of battery capacity, shape, and performance metrics to match device-specific load profiles []. In this way, additive manufacturing assists towards making a leap from standardized battery modules toward bespoke, application-driven power solutions.

3.3. Potential for Sustainable Manufacturing and Material Efficiency

Sustainability has become a central consideration in the development of next-generation battery technologies, and additive manufacturing offers several pathways to reduce environmental impact while improving material efficiency. Traditional electrode-fabrication methods often involve large-scale slurry processing [], solvent evaporation [], and mechanical treatment [], all of which generate significant waste and require energy-intensive steps. By contrast, 3D printing is inherently additive, depositing only the material required for the final structure and thereby minimizing scrap. This precision degree not only enhances the utilization of expensive or scarce materials, such as lithium, cobalt, or nickel, but also reduces the reliance on toxic solvents and extensive post-processing []. As a result, additive manufacturing aligns well with broader sustainability goals in both materials science and energy storage.

In addition to reducing waste, additive manufacturing provides opportunities to incorporate alternative, more sustainable materials into battery architectures. For instance, bio-derived polymers, water-based binders, and recyclable conductive additives can be processed into printable inks that replace more hazardous or resource-intensive materials []. Furthermore, the compatibility of 3D printing with localized and on-demand production reduces the need for global supply chains and large-scale centralized facilities, lowering the overall carbon footprint associated with transportation and logistics [,]. This potential for distributed, small-scale production is especially relevant for remote regions, where localized battery manufacturing could support renewable energy storage without dependence on imported components [].

The long-term sustainability benefits of 3D printing extend beyond material efficiency to encompass device lifecycle and recyclability. Architected electrodes and modular printed batteries can be designed for easier disassembly, facilitating material recovery and circular economy strategies []. For example, separating active materials from structural components becomes more straightforward when geometries are digitally designed and precisely fabricated. Additionally, the ability to customize battery capacity and geometry to specific applications reduces the risk of over-engineering and material overuse, ensuring that resources are deployed proportionally to device requirements []. Taken together, these features position additive manufacturing as an enabling technology of more sustainable, resource-efficient, and environmentally responsible energy storage solutions.

The sustainability potential of additive manufacturing for batteries can also be contextualized within the framework of the United Nations Sustainable Development Goals (SDGs) []. By reducing material waste and promoting the use of safer, bio-derived, or recyclable inputs, 3D-printed batteries directly support SDG 12: Responsible Consumption and Production []. Their role in enabling distributed energy storage for renewable power systems contributes to SDG 7: Affordable and Clean Energy [], while the reduction of carbon-intensive processes and logistics aligns with SDG 13: Climate Action []. Furthermore, the ability to design recyclable and modular devices enhances progress toward SDG 9: Industry, Innovation, and Infrastructure, fostering innovation in sustainable manufacturing practices []. As such, the integration of additive manufacturing into battery production not only addresses technical and economic challenges but also supports global efforts toward a more sustainable and equitable energy future. Figure 3 depicts the aforementioned corresponding SDGs. These synergies highlight the broader societal and environmental impact of advancing additive manufacturing in energy storage.

Figure 3.

Alignment of 3D-printed battery technologies with key United Nations Sustainable Development Goals (SDGs) []. Relevant targets include SDG 7 (Affordable and Clean Energy), SDG 9 (Industry, Innovation and Infrastructure), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action).

4. Challenges and Limitations

While additive manufacturing offers compelling opportunities for advancing battery technologies, significant barriers remain that hinder its translation from experimental demonstrations to practical, large-scale deployment. These challenges span across material formulation, process reliability, scalability, and regulatory frameworks. Unlike conventional battery production, which benefits from decades of industrial optimization, 3D printing for energy storage is still in an early developmental phase, where many technical and economic hurdles must be addressed. Understanding these limitations is critical not only for realistic assessments of current capabilities but also for identifying the research and innovation priorities that can unlock the full potential of additive manufacturing in the battery sector.

4.1. Materials and Ink Formulation Issues (Conductivity, Stability, Rheology)

A fundamental challenge in 3D printing of batteries lies in the formulation of functional inks and pastes that simultaneously meet electrochemical, mechanical, and rheological requirements. Conductive and electrochemically active materials, such as carbon additives, transition metal oxides, or silicon-based compounds, often need to be dispersed in a carrier medium that supports extrusion or jetting while maintaining uniform distribution of particles []. Achieving this balance is non-trivial: inks that are optimized for flowability may lack sufficient conductivity, while formulations with high active material loading may exhibit poor printability due to aggregation or clogging []. The need to reconcile these competing demands remains a bottleneck in the development of printable energy storage materials.

Stability is another critical concern, particularly when inks are designed for long processing times or stored prior to printing. Sedimentation, phase separation, or solvent evaporation can compromise homogeneity, leading to inconsistencies in printed structures and ultimately affecting device performance []. Moreover, many electrochemically promising materials are chemically reactive or hygroscopic, which complicates their incorporation into printable formulations. For example, lithium-containing compounds can be highly sensitive to moisture and oxygen, necessitating specialized ink chemistries or controlled processing environments []. Such stability issues not only increase the complexity of formulation but also raise practical barriers for scaling and industrial adoption.

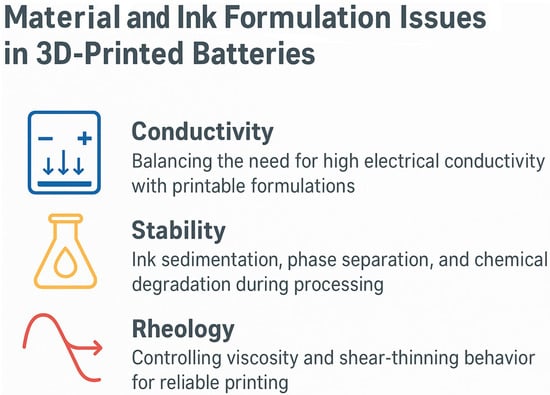

Rheological behavior further complicates the picture, as 3D printing techniques demand precise control over viscosity, shear-thinning properties, and curing mechanisms. Inks must flow easily under applied stress during printing, yet retain sufficient structural integrity to prevent collapse or spreading once deposited []. Achieving this delicate balance often requires the use of polymeric binders, surfactants, or cross-linking agents, which can introduce inactive components that reduce the overall energy density of the printed battery []. Additionally, post-processing steps such as drying, sintering, or UV curing can alter the microstructure of the printed material in ways that negatively affect electrochemical performance []. These interdependent challenges in conductivity, stability, and rheology underscore the need for systematic materials development, guided by both electrochemistry and printing science, to enable robust and reproducible additive manufacturing of batteries. Figure 4 depicts the material and ink formulation issues often faced in 3D-printed batteries.

Figure 4.

Material and ink formulated issues often faced in 3D-printed batteries.

4.2. Reproducibility, Reliability, and Long-Term Performance

A critical factor in the development of 3D-printed batteries is the reproducibility of the manufacturing process. While additive manufacturing offers elevated design freedom, its high degree of process complexity—spanning material preparation, deposition control, and post-processing—can result in significant batch-to-batch and even device-to-device variability. Small deviations in printing parameters such as extrusion rate, curing conditions, or layer alignment can lead to non-uniform electrode structures and inconsistent electrochemical properties []. This variability raises concerns not only for laboratory-scale demonstrations but also for the scalability of 3D-printed energy storage technologies toward industrial applications, where reproducibility is essential to achieve the stringent performance standards required in sectors such as electric mobility and grid storage.

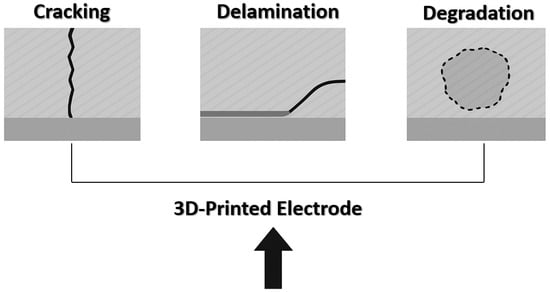

Reliability remains another major challenge, especially under the demanding operating conditions where batteries are deployed. The 3D-printed electrodes and electrolytes, often fabricated with novel inks and unconventional geometries, may suffer from mechanical instabilities such as cracking, delamination, or pore collapse during cycling []. These structural degradations can impair ionic conductivity and active material utilization, leading to rapid capacity fading. Moreover, the use of polymer-based or hybrid printable inks introduces additional uncertainties related to chemical stability, moisture uptake, or thermal degradation over long-term use. Addressing these concerns necessitates a deeper understanding of the interplay between 3D-printed architectures and their mechanical and electrochemical behavior during repeated charge–discharge cycles.

Beyond initial performance, the long-term durability of 3D-printed batteries remains largely underexplored compared to conventionally manufactured devices. Aging phenomena such as electrolyte decomposition, dendrite formation, and interfacial instability may be exacerbated by the non-equilibrium structures often produced by printing methods []. Furthermore, the lack of standardized protocols for testing printed batteries hampers the ability to compare results across laboratories and slows the identification of reliable design–performance correlations. Long-term cycling studies, accelerated aging tests, and systematic benchmarking are therefore indispensable to assess the practical feasibility of additive manufacturing in energy storage []. Without such reliability data, 3D-printed batteries are unlikely to gain traction in safety-critical applications such as electric vehicles, aerospace systems, or medical devices. To better illustrate the reliability challenges, Figure 5 summarizes the main degradation pathways and their impact on the long-term performance of 3D-printed batteries.

Figure 5.

Key reproducibility and reliability challenges in 3D-printed batteries, highlighting variability in electrode architecture, structural degradation during cycling (e.g., cracking, delamination), and long-term chemical/thermal instabilities that compromise electrochemical performance.

4.3. Scale-Up and Economic Feasibility

While 3D printing offers vast opportunities for customized and high-performance battery components, the translation of these technologies from laboratory demonstrations to industrial-scale production remains uncertain. A central challenge is throughput: additive manufacturing techniques are inherently slower than the roll-to-roll or slurry casting methods used in current gigafactories []. Even with recent advances in multi-nozzle systems and high-speed extrusion, the printing rates achievable are orders of magnitude below those required to meet the demand of mass markets such as electric vehicles or grid-scale storage []. This discrepancy creates a significant bottleneck when considering additive manufacturing as a direct substitute for conventional production, highlighting the need for either hybrid approaches or the development of niche markets where customization and functionality outweigh production volume.

Economic feasibility also poses a critical concern. The cost of printable inks, the precision equipment required, and the relatively high energy input of certain 3D printing methods can exceed that of well-established battery-fabrication processes. While prototyping or small-batch production may justify such costs due to the design flexibility and rapid iteration enabled by additive manufacturing, achieving cost parity at industrial scales remains challenging []. Life-cycle assessments have further suggested that the environmental and economic benefits of 3D-printed batteries are highly dependent on material efficiency, recyclability of feedstocks, and optimization of printing parameters to minimize waste [,]. Without breakthroughs in these areas, 3D printing risks being confined to research and specialty applications rather than becoming a transformative force in mainstream battery manufacturing.

Despite these limitations, additive manufacturing could still play a disruptive role when contrasted with the economies of scale embodied in gigafactory production []. Rather than directly competing with high-volume facilities, 3D printing may complement them by enabling distributed, on-demand production of specialized batteries tailored to specific devices or environments. This distributed model aligns with the growing interest in decentralized energy-storage systems and could reduce logistical costs and supply chain vulnerabilities []. Moreover, additive manufacturing can be leveraged for rapid prototyping and pilot-scale runs that accelerate innovation cycles and facilitate the transfer of novel chemistries from laboratory research into early commercialization []. Thus, while large-scale economic feasibility remains a formidable barrier, strategic integration of 3D printing into the broader battery ecosystem could yield tangible value without requiring direct replacement of gigafactory-based methods.

To place the challenges of scale-up and economic feasibility into perspective, it is useful to contrast the operational characteristics of conventional gigafactory production with those of 3D printing for batteries. While the former is optimized for volume, speed, and cost reduction, the latter prioritizes customization, material efficiency, and distributed manufacturing. Table 2 provides a structured comparison that highlights the complementary strengths and limitations of each approach.

Table 2.

Comparison of gigafactory-based battery production and 3D printing approaches in terms of scalability and economic considerations.

4.4. Regulatory and Standardization Gaps

The maturation of 3D-printed batteries into commercially viable technologies is closely tied to the development of appropriate regulatory and standardization frameworks. Unlike conventional battery production, which benefits from decades of industrial experience and well-defined testing protocols, additive manufacturing introduces novel materials, geometries, and processes that often fall outside the scope of existing regulations. Current safety and performance standards, such as those defined by the International Electrotechnical Commission (IEC) [] or Underwriters Laboratories (UL) [], are tailored to traditional electrodes, electrolytes, and cell formats, leaving uncertainty about their applicability to non-standard printed architectures. This gap complicates certification, limits market entry, and creates hesitation among potential adopters, particularly in safety-critical sectors like automotive, aerospace, and medical devices.

Another challenge lies in the lack of standardized methods for evaluating the performance and reliability of 3D-printed batteries. Differences in feedstock composition, printer resolution, and processing conditions can produce wide variations in cell characteristics, yet no harmonized protocols exist for benchmarking such devices across laboratories or industries []. This absence of comparability hinders progress by making it difficult to establish performance baselines, identify best practices, or ensure reproducibility at scale. Furthermore, the absence of agreed-upon metrics for durability, environmental impact, and recyclability of printed batteries complicates their integration into regulatory frameworks addressing sustainability and circular economy goals [].

Finally, intellectual property and liability considerations add further complexity. With the rise of digital design files for 3D-printed components, questions emerge over ownership, design authenticity, and accountability in the event of device failure []. For instance, if a printed battery based on a shared design underperforms or causes safety incidents, responsibility may be contested between the file designer, the printer manufacturer, and the end user. Regulatory clarity on these issues is essential to foster trust and encourage industrial adoption []. Eliminating these regulatory and standardization gaps will require coordinated efforts by international standards organizations, policymakers, and the scientific community, ensuring that safety, performance, and sustainability criteria evolve in tandem with technological advances in additive manufacturing for energy storage.

5. Discussion and Future Directions

The transition of 3D-printed batteries from proof-of-concept demonstrations to impactful technological solutions will depend on carefully directed research, industrial collaboration, and policy support. While substantial challenges remain, several ways can accelerate progress and maximize the value of additive manufacturing in energy storage. These ways include combining printing with established fabrication techniques, developing advanced materials tailored for printability and multifunctionality, embedding recycling principles into design and production, expanding application domains, and setting realistic time horizons for technological maturity [,]. Together, these elements define a strategic progression for the field, ensuring that innovations address both immediate needs and long-term sustainability goals.

A particularly novel way involves hybrid manufacturing that combines established battery production workflows with localized additive enhancements. For instance, high-capacity bulk electrodes produced via conventional slurry casting could be subsequently modified through 3D printing of microscale ion-transport channels or stress-relief lattices []. Such hybrid electrodes are expected to reduce ionic tortuosity by 30–50%, enabling up to ~20–35% higher rate capability and improved capacity retention over extended cycling, while maintaining the scalability of roll-to-roll coating. Similarly, commercial roll-to-roll–processed polymer separators could be locally patterned using additive micro-printing to introduce aligned pores, electrolyte-reservoir architectures, or thermal-shutdown motifs []. These hybrid separator designs have been shown to enhance ionic conductivity by 25–40% and improve thermal safety margins by delaying short-circuit onset under thermal runaway conditions. Together, these hybrid strategies retain the manufacturing speed and cost-efficiency of gigafactory processes while exploiting the geometric freedom of 3D printing to unlock performance, safety, and durability gains not achievable through either method alone.

Hybrid manufacturing approaches that combine additive manufacturing with conventional methods hold considerable promise for overcoming current limitations. For example, electrodes could be fabricated through slurry casting for bulk capacity while being enhanced by 3D-printed microstructures to optimize ionic pathways or mechanical stability [,]. Similarly, separators and electrolytes manufactured through established roll-to-roll processes might be locally modified by printing to introduce sensors, reinforcement features, or channels for improved transport []. Such hybridization offers a novel and synergistic approach: the speed and scalability of conventional production with the design freedom and functional integration of additive manufacturing. Rather than seeking to replace gigafactories outright, hybrid strategies could position 3D printing as a complementary fabrication method.

Another critical step forward lies in the development of printable materials that not only ensure electrochemical performance but also offer multifunctionality. Solid-state electrolytes that can be directly printed into tailored geometries, or polymer–ceramic composites with tunable mechanical and ionic properties, represent transformative opportunities []. Beyond functionality, printability itself must be designed into the material, with attention to rheology, curing, and compatibility with multi-material deposition. In addition, multifunctional materials—such as those capable of self-healing, thermal management, or structural load-bearing—could redefine the role of batteries in devices and infrastructure [,]. The synergy between material science and additive manufacturing will therefore serve as a cornerstone for the next generation of printed energy storage.

The integration of recycling and circular economy principles into the design of 3D-printed batteries is another element with significant long-term impact []. Unlike conventional production, where recycling is typically an end-of-life consideration, additive manufacturing provides an opportunity to embed sustainability at the design stage []. Feedstocks could be derived from recycled metals, polymers, or carbonaceous materials, and printing strategies can minimize waste through precise deposition. Furthermore, the modularity of printed devices could enable easier disassembly and material recovery, thereby improving recyclability []. Embedding circular economy concepts into the printing ecosystem could help align battery innovation with global sustainability targets, mitigating concerns about resource scarcity and environmental degradation.

Prospective applications are also expected to vastly contribute, as the ability to tailor battery architectures through 3D printing may lead to novel use cases. Structural batteries, where energy storage is embedded within load-bearing components, could revolutionize aerospace, automotive, and smart infrastructure systems []. Similarly, highly customized batteries for medical implants [], wearable electronics [], and miniaturized IoT devices [] may enable performance characteristics unattainable with conventional cells. Additive manufacturing also facilitates the direct integration of batteries into devices, reducing assembly complexity and improving energy density at the system level [,]. These novel applications illustrate the potential of 3D-printed batteries not only to improve current technologies but also to create tailored solutions of energy storage.

In addition, additives play a pivotal role in tailoring the physicochemical and electrochemical properties of 3D-printed battery components, serving as multifunctional agents in both electrode and electrolyte formulations while simultaneously addressing inherent limitations of printable inks. In electrode inks, conductive additives such as carbon black, graphene, or carbon nanotubes are routinely incorporated to enhance electronic percolation networks within viscous, polymer-laden pastes, thereby mitigating resistivity penalties induced by high binder content required for extrusion fidelity [,]. Similarly, rheology-modifying additives—silica nanoparticles, fumed silica, or cellulose derivatives—are employed to impart shear-thinning behavior and viscoelastic stability, ensuring shape retention post-deposition without compromising interlayer adhesion or porosity essential for ion accessibility []. In solid-state electrolyte inks, plasticizers (e.g., succinonitrile, polyethylene glycol) and ceramic fillers (e.g., LLZO, LATP) are integrated not only to improve ionic conductivity and mechanical compliance but also to suppress dendrite formation and enhance interfacial stability with printed electrodes []. However, several critical challenges persist: additive agglomeration often leads to inhomogeneous conductivity and premature mechanical failure under cyclic strain; mismatched thermal expansion between organic binders and inorganic fillers induces microcracking during sintering or drying; and leaching of low-molecular-weight plasticizers during prolonged operation degrades long-term ionic transport [,]. Moreover, the lack of standardized additive matrix compatibility protocols hinders reproducibility across printer platforms and material systems. Future research should prioritize the development of multifunctional additive packages—combining conductive, rheological, and self-healing moieties within a single nanoparticle framework—and in silico design tools that predict additive interactions via machine learning-driven viscosity–conductivity–stability maps [,]. Additionally, in operando characterization of additive redistribution during printing and cycling, coupled with closed-loop feedback printing systems, could enable real-time optimization of ink formulations, leading to robust, high-performance 3D-printed batteries suitable for distributed and structurally integrated energy-storage applications.

Finally, setting realistic time horizons is crucial for managing expectations, and directing investment is of paramount importance. In the short term, 3D printing is most likely to impact prototyping, niche applications, and hybrid approaches that complement existing manufacturing methods [,]. Mid-term developments are expected to focus on the maturation of printable solid-state materials, greater integration with sustainable feedstocks, and demonstration of functional devices in real-world conditions [,]. In the long term, the vision of fully integrated structural batteries [,] and large-scale deployment in smart infrastructure could become feasible, provided that technical and regulatory barriers are addressed [,,]. Establishing such a phased perspective ensures that the field advances in a manner consistent with both technological readiness and societal needs.

6. Conclusions

Additive manufacturing stands out as an emerging enabling technology for advancing battery features, allowing elevated levels of architectural precision, multifunctional integration, and material efficiency that are difficult to realize with conventional fabrication methods. The evidence discussed in this perspective indicates that 3D printing can substantially enhance electrochemical performance through engineered microstructures, support seamless integration of energy storage into complex devices, and foster alignment with sustainability goals through waste reduction and recyclability. Nevertheless, the field remains constrained by critical bottlenecks, including ink formulation challenges, variability in performance, scalability limitations, and the absence of standardized testing protocols. These issues must be systematically addressed if 3D-printed batteries are to progress beyond laboratory-scale demonstrations and achieve industrial impact.

The most immediate role for additive manufacturing lies in complementing conventional processes through hybrid strategies, supporting niche applications in wearables, medical devices, and distributed energy systems, and accelerating the prototyping of novel chemistries. In the longer term, advances in printable solid-state materials, the incorporation of circular economy principles, and the development of regulatory frameworks could enable broader deployment, including structural batteries and smart infrastructure systems. The future of 3D-printed batteries will therefore depend on interdisciplinary collaboration among material scientists, engineers, and policy-makers. Moreover, the user-centric design opportunities introduced by additive manufacturing—enabling more ergonomic, reliable, and seamlessly integrated battery solutions—underscore its potential to enhance end-user interaction and overall experience across diverse applications. Thus, by aligning technical innovation with industrial viability and sustainability imperatives, additive manufacturing has the potential to act as a meaningful contributor to the evolution of next-generation energy storage that elevates user experience in automation and control systems through improved responsiveness, modularity, and system-level adaptability.

Author Contributions

Conceptualization, A.K., N.L., M.P., E.P. and T.G.; methodology, A.K., M.P., E.P. and T.G.; validation, A.K.; formal analysis, A.K., N.L., M.P., E.P. and T.G.; investigation, A.K. and N.L.; resources, A.K.; writing—original draft preparation, A.K.; writing—review and editing, A.K., N.L., M.P., E.P. and T.G.; visualization, A.K.; supervision, M.P., E.P. and T.G.; project administration, A.K., M.P., E.P. and T.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The corresponding author wishes to dedicate this article to Florian Ion Tiberiu Petrescu, who, sadly, passed away in August 2025. An esteemed scientist, author of more than 200 scientific papers and books with more than 12,000 citations. A true homo universalis and a personal mentor.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 3D | Three-Dimensional |

| AM | Additive Manufacturing |

| DIW | Direct Ink Writing |

| EV | Electric Vehicle |

| IEC | International Electrotechnical Commission |

| IoT | Internet of Things |

| SDGs | Sustainable Development Goals |

| SLA | Stereolithography |

| UL | Underwriters Laboratories |

| UV | Ultraviolet |

References

- Liang, Y.; Zhao, C.-Z.; Yuan, H.; Chen, Y.; Zhang, W.; Huang, J.-Q.; Yu, D.; Liu, Y.; Titirici, M.-M.; Chueh, Y.-L.; et al. A Review of Rechargeable Batteries for Portable Electronic Devices. InfoMat 2019, 1, 6–32. [Google Scholar] [CrossRef]

- Rangarajan, S.S.; Sunddararaj, S.P.; Sudhakar, A.V.V.; Shiva, C.K.; Subramaniam, U.; Collins, E.R.; Senjyu, T. Lithium-Ion Batteries—The Crux of Electric Vehicles with Opportunities and Challenges. Clean Technol. 2022, 4, 908–930. [Google Scholar] [CrossRef]

- Shi, C.; Takeuchi, S.; Alexander, G.V.; Hamann, T.; O’Neill, J.; Dura, J.A.; Wachsman, E.D. High Sulfur Loading and Capacity Retention in Bilayer Garnet Sulfurized-polyacrylonitrile/Lithium-metal Batteries with Gel Polymer Electrolytes. Adv. Energy Mater. 2023, 13, 2301656. [Google Scholar] [CrossRef]

- Huang, Y.; Li, J. Key Challenges for Grid-scale Lithium-ion Battery Energy Storage. Adv. Energy Mater. 2022, 12, 2202197. [Google Scholar] [CrossRef]

- Pokhriyal, A.; Rueda-García, D.; Gómez-Romero, P. To Flow or Not to Flow. A Perspective on Large-Scale Stationary Electrochemical Energy Storage. Sustain. Energy Fuels 2023, 7, 5473–5482. [Google Scholar] [CrossRef]

- Rong, G.; Zheng, Y.; Sawan, M. Energy Solutions for Wearable Sensors: A Review. Sensors 2021, 21, 3806. [Google Scholar] [CrossRef]

- Shuvo, M.M.H.; Titirsha, T.; Amin, N.; Islam, S.K. Energy Harvesting in Implantable and Wearable Medical Devices for Enduring Precision Healthcare. Energies 2022, 15, 7495. [Google Scholar] [CrossRef]

- Bourdena, A.; Mavromoustakis, C.; Markakis, E.K.; Mastorakis, G.; Pallis, E. Intelligent Technologies for Healthcare Business Applications; Springer Nature: Cham, Switzerland, 2024; ISBN 9783031585272. [Google Scholar]

- Dotoli, M.; Rocca, R.; Giuliano, M.; Nicol, G.; Parussa, F.; Baricco, M.; Ferrari, A.M.; Nervi, C.; Sgroi, M.F. A Review of Mechanical and Chemical Sensors for Automotive Li-Ion Battery Systems. Sensors 2022, 22, 1763. [Google Scholar] [CrossRef]

- Tran, M.-K.; Panchal, S.; Khang, T.D.; Panchal, K.; Fraser, R.; Fowler, M. Concept Review of a Cloud-Based Smart Battery Management System for Lithium-Ion Batteries: Feasibility, Logistics, and Functionality. Batteries 2022, 8, 19. [Google Scholar] [CrossRef]

- Hassan, Q.; Pawela, B.; Hasan, A.; Jaszczur, M. Optimization of Large-Scale Battery Storage Capacity in Conjunction with Photovoltaic Systems for Maximum Self-Sustainability. Energies 2022, 15, 3845. [Google Scholar] [CrossRef]

- Dong, Z.; Tao, Y.; Lai, S.; Wang, T.; Zhang, Z. Powering Future Advancements and Applications of Battery Energy Storage Systems across Different Scales. Energy Storage Appl. 2025, 2, 1. [Google Scholar] [CrossRef]

- Chu, T.; Park, S.; Fu, K. (kelvin) 3D Printing-enabled Advanced Electrode Architecture Design. Carbon Energy 2021, 3, 424–439. [Google Scholar] [CrossRef]

- Mottaghi, M.; Pearce, J.M. A Review of 3D Printing Batteries. Batteries 2024, 10, 110. [Google Scholar] [CrossRef]

- Andries, V.; Zaharia, S.-M. Generative Design, Simulation, and 3D Printing of the Quadcopter Drone Frame. Appl. Sci. 2025, 15, 9647. [Google Scholar] [CrossRef]

- Xiao, J.; Anwer, N.; Huang, H.; Bonnard, R.; Eynard, B.; Huang, C.; Pei, E. Information Exchange and Knowledge Discovery for Additive Manufacturing Digital Thread: A Comprehensive Literature Review. Int. J. Comput. Integr. Manuf. 2025, 38, 1052–1077. [Google Scholar] [CrossRef]

- Singh, V.; Kuthe, S.; Skorodumova, N.V. Electrode Fabrication Techniques for Li Ion Based Energy Storage System: A Review. Batteries 2023, 9, 184. [Google Scholar] [CrossRef]

- Scheffler, S.; Jagau, R.; Müller, N.; Diener, A.; Kwade, A. Calendering of Silicon-Containing Electrodes and Their Influence on the Mechanical and Electrochemical Properties. Batteries 2022, 8, 46. [Google Scholar] [CrossRef]

- Bai, S.; Frigerio, N.; Matta, A. Current Status and Future Perspective in Electric Vehicle Battery Stacking: A Review. Energy Technol. 2025, 13, 2500042. [Google Scholar] [CrossRef]

- Pavlovskii, A.A.; Pushnitsa, K.; Kosenko, A.; Novikov, P.; Popovich, A.A. 3D-Printed Lithium-Ion Battery Electrodes: A Brief Review of Three Key Fabrication Techniques. Materials 2024, 17, 5904. [Google Scholar] [CrossRef]

- Czerwiński, A.; Słojewska, M.; Jurczak, J.; Dębowski, M.; Zygadło-Monikowska, E. FFF/FDM 3D-Printed Solid Polymer Electrolytes Based on Acrylonitrile Copolymers for Lithium-Ion Batteries. Molecules 2024, 29, 4526. [Google Scholar] [CrossRef]

- Shi, H.; Cao, J.; Sun, Z.; Ghazi, Z.A.; Zhu, X.; Han, S.; Ren, D.; Lu, G.; Lan, H.; Li, F. 3D Printing Enables Customizable Batteries. Batter. Supercaps 2023, 6, e202300161. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, H.; Chen, H.; Gao, H.; Yu, J.; Mo, F.; Wang, N. Recent Progress on the Research of 3D Printing in Aqueous Zinc-Ion Batteries. Polymers 2025, 17, 2136. [Google Scholar] [CrossRef]

- Qian, J.; Chen, Q.; Hong, M.; Xie, W.; Jing, S.; Bao, Y.; Chen, G.; Pang, Z.; Hu, L.; Li, T. Toward Stretchable Batteries: 3D-Printed Deformable Electrodes and Separator Enabled by Nanocellulose. Mater. Today 2022, 54, 18–26. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, Y.; Hao, J.; Wallace, G.G.; Beirne, S.; Chen, J. 3D-printed Wearable Electrochemical Energy Devices. Adv. Funct. Mater. 2022, 32, 2103092. [Google Scholar] [CrossRef]

- Habboush, S.; Rojas, S.; Rodríguez, N.; Rivadeneyra, A. The Role of Interdigitated Electrodes in Printed and Flexible Electronics. Sensors 2024, 24, 2717. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, S.; Wang, Y.; Zhang, G.; Arif, N.; Li, P.; Zeng, Y.-J. Three-Dimensional Printing, an Emerging Advanced Technique in Electrochemical Energy Storage and Conversion. Batteries 2023, 9, 546. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Ganetsos, T. From Stents to Smart Implants Employing Biomimetic Materials: The Impact of 4D Printing on Modern Healthcare. Biomimetics 2025, 10, 125. [Google Scholar] [CrossRef]

- Moser, S.; Kenel, C.; Wehner, L.A.; Spolenak, R.; Dunand, D.C. 3D Ink-Printed, Sintered Porous Silicon Scaffolds for Battery Applications. J. Power Sources 2021, 507, 230298. [Google Scholar] [CrossRef]

- Li, M.; Zhou, S.; Cheng, L.; Ren, W.; Chen, L.; Yu, S.; Wei, J. Vertical-Channel Hierarchically Porous 3D Printed Electrodes with Ultrahigh Mass Loading and Areal Energy Density for Li-Ion Batteries. Energy Storage Mater. 2024, 72, 103754. [Google Scholar] [CrossRef]

- Chen, X.; Lawrence, J.M.; Wey, L.T.; Schertel, L.; Jing, Q.; Vignolini, S.; Howe, C.J.; Kar-Narayan, S.; Zhang, J.Z. 3D-Printed Hierarchical Pillar Array Electrodes for High-Performance Semi-Artificial Photosynthesis. Nat. Mater. 2022, 21, 811–818. [Google Scholar] [CrossRef]

- Polychronopoulos, N.D.; Brouzgou, A. Direct Ink Writing for Electrochemical Device Fabrication: A Review of 3D-Printed Electrodes and Ink Rheology. Catalysts 2024, 14, 110. [Google Scholar] [CrossRef]

- Huang, H.; Liao, L.; Lin, Z.; Pan, D.; Nuo, Q.; Wu, T.-T.; Jiang, Y.; Bai, H. Direct Ink Writing of Pickering Emulsions Generates Ultralight Conducting Polymer Foams with Hierarchical Structure and Multifunctionality. Small 2023, 19, e2301493. [Google Scholar] [CrossRef]

- Fapanni, T.; Sardini, E.; Serpelloni, M.; Tonello, S. 3D Electrochemical Sensor and Microstructuration Using Aerosol Jet Printing. Sensors 2021, 21, 7820. [Google Scholar] [CrossRef]

- Jeong, H.; Lee, J.H.; Kim, S.; Han, S.; Moon, H.; Song, J.-Y.; Park, A.-Y. Optimization of Process Parameters in Micro-Scale Pneumatic Aerosol Jet Printing for High-Yield Precise Electrodes. Sci. Rep. 2023, 13, 21297. [Google Scholar] [CrossRef] [PubMed]

- Perilli, S.; Di Pietro, M.; Mantini, E.; Regazzetti, M.; Kiper, P.; Galliani, F.; Panella, M.; Mantini, D. Development of a Wearable Electromyographic Sensor with Aerosol Jet Printing Technology. Bioengineering 2024, 11, 1283. [Google Scholar] [CrossRef]

- Chen, X.; Gong, M.; Li, J.; Yang, W.; Xu, X. Engineering Hierarchical Porous Electrodes Integrated with Conformal Ultrathin Nanosheets for Achieving Rapid Kinetics in High-Power Microbatteries. Batteries 2025, 11, 81. [Google Scholar] [CrossRef]

- Han, D.-Y.; Son, H.B.; Han, S.H.; Song, C.K.; Jung, J.; Lee, S.; Choi, S.S.; Song, W.-J.; Park, S. Hierarchical 3D Electrode Design with High Mass Loading Enabling High-Energy-Density Flexible Lithium-Ion Batteries. Small 2023, 19, e2305416. [Google Scholar] [CrossRef]

- Pigłowska, M.; Kurc, B.; Galiński, M.; Fuć, P.; Kamińska, M.; Szymlet, N.; Daszkiewicz, P. Challenges for Safe Electrolytes Applied in Lithium-Ion Cells-A Review. Materials 2021, 14, 6783. [Google Scholar] [CrossRef]

- Mu, X.; Ding, H.; Wu, Y.; Hu, H.; Yu, B. Nonflammable Liquid Electrolytes for Safe Lithium Batteries. Small Struct. 2023, 4, 2300179. [Google Scholar] [CrossRef]

- Machín, A.; Morant, C.; Márquez, F. Advancements and Challenges in Solid-State Battery Technology: An in-Depth Review of Solid Electrolytes and Anode Innovations. Batteries 2024, 10, 29. [Google Scholar] [CrossRef]

- Aruchamy, K.; Ramasundaram, S.; Divya, S.; Chandran, M.; Yun, K.; Oh, T.H. Gel Polymer Electrolytes: Advancing Solid-State Batteries for High-Performance Applications. Gels 2023, 9, 585. [Google Scholar] [CrossRef]

- Tu, Z.; Chen, K.; Liu, S.; Wu, X. 3D Printing of Solid Electrolyte and the Application in All-Solid-State Batteries. Small Methods 2025, 9, e2401912. [Google Scholar] [CrossRef]

- Junoh, H.; Awang, N.; Zakria, H.S.; Zainuddin, N.A.S.; Nordin, N.A.H.M.; Suhaimin, N.S.; Enoki, T.; Uno, T.; Kubo, M. Advancements in Polyethylene Oxide (PEO)-Active Filler Composite Polymer Electrolytes for Lithium-Ion Batteries: A Comprehensive Review and Prospects. Materials 2024, 17, 4344. [Google Scholar] [CrossRef] [PubMed]

- Castillo, J.; Robles-Fernandez, A.; Cid, R.; González-Marcos, J.A.; Armand, M.; Carriazo, D.; Zhang, H.; Santiago, A. Dehydrofluorination Process of Poly(Vinylidene Difluoride) PVdF-Based Gel Polymer Electrolytes and Its Effect on Lithium-Sulfur Batteries. Gels 2023, 9, 336. [Google Scholar] [CrossRef] [PubMed]

- Waidha, A.I.; Vanita, V.; Clemens, O. PEO Infiltration of Porous Garnet-Type Lithium-Conducting Solid Electrolyte Thin Films. Ceramics 2021, 4, 421–436. [Google Scholar] [CrossRef]

- Man, B.; Zeng, Y.; Liu, Q.; Chen, Y.; Li, X.; Luo, W.; Zhang, Z.; He, C.; Jie, M.; Liu, S. A Comprehensive Review of Sulfide Solid-State Electrolytes: Properties, Synthesis, Applications, and Challenges. Crystals 2025, 15, 492. [Google Scholar] [CrossRef]

- Fan, K.; Yu, M.; Lei, J.; Mu, S. Advanced Preparation Methods for Ceramic Membrane Materials in Electrochemical Applications. Crystals 2024, 14, 623. [Google Scholar] [CrossRef]

- Marković, M.-P.; Žižek, K.; Soldo, K.; Sunko, V.; Zrno, J.; Vrsaljko, D. 3D Printed Microfluidic Separators for Solid/Liquid Suspensions. Appl. Sci. 2024, 14, 7856. [Google Scholar] [CrossRef]

- Enchinton, A.; Martinez, A.C.; Gonzalez, K.R.; Fernandez, C.A.; Balivada, S.; Merrill, L.C.; Cardenas, J.A.; Panier, S.; Maurel, A. 3D Printing of Highly Porous Polypropylene Separators for Lithium-ion Batteries Using Fused Deposition Modeling and Thermally Induced Phase Separation. Adv. Mater. Technol. 2025, e00912. [Google Scholar] [CrossRef]

- Choi, C.S.; Whang, G.J.; McNeil, P.E.; Dunn, B.S. Photopatternable Porous Separators for Micro-Electrochemical Energy Storage Systems. Adv. Mater. 2022, 34, e2108792. [Google Scholar] [CrossRef]

- Kang, C.-Y.; Su, Y.-S. Smart Manufacturing Processes of Low-Tortuous Structures for High-Rate Electrochemical Energy Storage Devices. Micromachines 2022, 13, 1534. [Google Scholar] [CrossRef] [PubMed]

- Mirbagheri, S.; Gibertini, E.; Magagnin, L. Inkjet-Printed Silver Lithiophilic Sites on Copper Current Collectors: Tuning the Interfacial Electrochemistry for Anode-Free Lithium Batteries. Batteries 2024, 10, 369. [Google Scholar] [CrossRef]

- Pinto, R.S.; Serra, J.P.; Barbosa, J.C.; Gonçalves, R.; Silva, M.M.; Lanceros-Méndez, S.; Costa, C.M. Direct-ink-writing of Electroactive Polymers for Sensing and Energy Storage Applications. Macromol. Mater. Eng. 2021, 306, 2100372. [Google Scholar] [CrossRef]

- Ji, D.; Zheng, H.; Zhang, H.; Liu, W.; Ding, J. Coaxial 3D-Printing Constructing All-in-One Fibrous Lithium-, Sodium-, and Zinc-Ion Batteries. Chem. Eng. J. 2022, 433, 133815. [Google Scholar] [CrossRef]

- Fassler, A.L.; Kohlmeyer, R.R.; Rajput, S.; Horrocks, G.A.; Deneault, J.R.; Durstock, M.F. Study on the Feasibility of Combined 3D Printing for Integrated and Conformal Batteries. J. Power Sources 2024, 600, 234241. [Google Scholar] [CrossRef]

- Deng, L.; Lin, Q.; Li, Z.; Cao, J.; Sun, K.; Wei, T. Cathodes for Zinc-Ion Micro-Batteries: Challenges, Strategies, and Perspectives. Batteries 2025, 11, 57. [Google Scholar] [CrossRef]

- Li, Z.; Li, Y.; Chen, M.; Li, W.; Wei, X. Photocuring in Lithium-Ion Battery Fabrication: Advances towards Integrated Manufacturing. Batteries 2025, 11, 282. [Google Scholar] [CrossRef]

- Shaju, A.; Ummer, R.P.; Thomas, S.; Kandasubramanian, B. Novel Approaches in 3D Printing Techniques for the Development of High-Performance Micro-Batteries. J. Electron. Mater. 2024, 54, 1531–1552. [Google Scholar] [CrossRef]

- Ribeiro, A.I.; Alves, C.; Fernandes, M.; Abreu, J.; Pedroso de Lima, F.; Padrão, J.; Zille, A. Gel Electrolytes in the Development of Textile-Based Power Sources. Gels 2025, 11, 392. [Google Scholar] [CrossRef]

- Ma, J.; Quhe, R.; Zhang, W.; Yan, Y.; Tang, H.; Qu, Z.; Cheng, Y.; Schmidt, O.G.; Zhu, M. Zn Microbatteries Explore Ways for Integrations in Intelligent Systems. Small 2023, 19, e2300230. [Google Scholar] [CrossRef]

- Zainal Abidin, A.R.; Zambry, N.S.; Ibrahim, F.; Nor Rashid, N.; Jamaluddin, N.F.; Wan Kamarul Zaman, W.S. Current Advances in Biocompatibility Assessment for MEMS in Biomedical Applications. Microfluid. Nanofluidics 2025, 29, 32. [Google Scholar] [CrossRef]

- Hu, X.; Zhu, Y.; Fu, Y.-F.; Fan, Y.; Chen, Y.; Kim, D.; Lu, X.; Yu, B.; Chen, Y.I. 3D-Printed Topological-Structured Electrodes with Exceptional Mechanical Properties for High-Performance Flexible Li-Ion Batteries. Energy Storage Mater. 2024, 70, 103560. [Google Scholar] [CrossRef]

- Han, Y.; Cui, Y.; Liu, X.; Wang, Y. A Review of Manufacturing Methods for Flexible Devices and Energy Storage Devices. Biosensors 2023, 13, 896. [Google Scholar] [CrossRef]

- Zheng, Y.; Huang, X.; Chen, J.; Wu, K.; Wang, J.; Zhang, X. A Review of Conductive Carbon Materials for 3D Printing: Materials, Technologies, Properties, and Applications. Materials 2021, 14, 3911. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wang, Q. Novel Structural Janus Hydrogels for Battery Applications: Structure Design, Properties, and Prospects. Colloids Interfaces 2025, 9, 48. [Google Scholar] [CrossRef]

- Orisekeh, D.; Roh, B.-M.; Xiao, X. Solid-to-Solid Manufacturing Processes for High-Performance Li-Ion Solid-State Batteries. Polymers 2025, 17, 1788. [Google Scholar] [CrossRef]

- Hwang, E.; Hong, J.; Yoon, J.; Hong, S. Direct Writing of Functional Layer by Selective Laser Sintering of Nanoparticles for Emerging Applications: A Review. Materials 2022, 15, 6006. [Google Scholar] [CrossRef]

- Gupta, V.; Alam, F.; Verma, P.; Kannan, A.M.; Kumar, S. Additive Manufacturing Enabled, Microarchitected, Hierarchically Porous Polylactic-Acid/Lithium Iron Phosphate/Carbon Nanotube Nanocomposite Electrodes for High Performance Li-Ion Batteries. J. Power Sources 2021, 494, 229625. [Google Scholar] [CrossRef]

- Lyu, Z.; Lim, G.J.H.; Koh, J.J.; Li, Y.; Ma, Y.; Ding, J.; Wang, J.; Hu, Z.; Wang, J.; Chen, W.; et al. Design and Manufacture of 3D-Printed Batteries. Joule 2021, 5, 89–114. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Wang, Z.; Chen, J.; Yang, L.; Xia, J.; Zhang, Y.; Zhang, J.; Zhu, W.; Zhang, H.; et al. Additive Manufacturing in Construction Using Unmanned Aerial Vehicle: Design, Implementation, and Material Properties. J. Build. Eng. 2024, 98, 111363. [Google Scholar] [CrossRef]

- Kantaros, A.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. Composite Filament Materials for 3D-Printed Drone Parts: Advancements in Mechanical Strength, Weight Optimization and Embedded Electronics. Materials 2025, 18, 2465. [Google Scholar] [CrossRef]

- Szcześniak, P.; Grobelna, I.; Novak, M.; Nyman, U. Overview of Control Algorithm Verification Methods in Power Electronics Systems. Energies 2021, 14, 4360. [Google Scholar] [CrossRef]

- Yang, H.; Fang, H.; Wang, W.; Zhang, D.; Zhu, J.; Chen, K.; Sun, Y.; Wang, P.; Zhou, Q.; Qi, C.; et al. 3D Printing of Flexible Batteries for Wearable Electronics. J. Power Sources 2024, 602, 234350. [Google Scholar] [CrossRef]

- NajafiKhoshnoo, S.; Kim, T.; Tavares-Negrete, J.A.; Pei, X.; Das, P.; Lee, S.W.; Rajendran, J.; Esfandyarpour, R. A 3D Nanomaterials-printed Wearable, Battery-free, Biocompatible, Flexible, and Wireless pH Sensor System for Real-time Health Monitoring. Adv. Mater. Technol. 2023, 8, 2201655. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Z.; Li, M.; Li, Z.; Hu, X.; Xu, Q.; Wang, Y.; Liu, H.; Wang, Y. 3D Printed Flexible Zinc Ion Micro-batteries with High Areal Capacity toward Practical Application. Adv. Funct. Mater. 2024, 34, 2310966. [Google Scholar] [CrossRef]

- Li, P.; Liao, M.; Li, J.; Ye, L.; Cheng, X.; Wang, B.; Peng, H. Rechargeable Micro-batteries for Wearable and Implantable Applications. Small Struct. 2022, 3, 2200058. [Google Scholar] [CrossRef]

- Huo, S.; Sheng, L.; Su, B.; Xue, W.; Wang, L.; Xu, H.; He, X. 3D Printing Manufacturing of Lithium Batteries: Prospects and Challenges toward Practical Applications. Adv. Mater. 2024, 36, e2310396. [Google Scholar] [CrossRef]

- Mu, Y.B.; Chu, Y.Q.; Pan, L.; Wu, B.K.; Zou, L.F.; He, J.F.; Han, M.S.; Zhao, T.S.; Zeng, L. 3D Printing Critical Materials for Rechargeable Batteries: From Materials, Design and Optimization Strategies to Applications. Int. J. Extreme Manuf. 2023, 5, 042008. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, R.; Wang, J.; Wang, Y. Current and Future Lithium-Ion Battery Manufacturing. iScience 2021, 24, 102332. [Google Scholar] [CrossRef]

- Davis, J.T.; Jayathilake, B.S.; Chandrasekaran, S.; Wong, J.J.; Deotte, J.R.; Baker, S.E.; Beck, V.A.; Duoss, E.B.; Worsley, M.A.; Lin, T.Y. 3D Printed Optimized Electrodes for Electrochemical Flow Reactors. Sci. Rep. 2024, 14, 22662. [Google Scholar] [CrossRef]

- Ben-Barak, I.; Schneier, D.; Kamir, Y.; Goor, M.; Golodnitsky, D.; Peled, E. Drop-on-Demand 3D-Printed Silicon-Based Anodes for Lithium-Ion Batteries. J. Solid State Electrochem. 2022, 26, 183–193. [Google Scholar] [CrossRef]

- Xue, X.; Lin, D.; Li, Y. Low Tortuosity 3D-printed Structures Enhance Reaction Kinetics in Electrochemical Energy Storage and Electrocatalysis. Small Struct. 2022, 3, 2200159. [Google Scholar] [CrossRef]

- Örüm Aydin, A.; Zajonz, F.; Günther, T.; Dermenci, K.B.; Berecibar, M.; Urrutia, L. Lithium-Ion Battery Manufacturing: Industrial View on Processing Challenges, Possible Solutions and Recent Advances. Batteries 2023, 9, 555. [Google Scholar] [CrossRef]

- Kim, C.; Ahn, B.Y.; Cho, S.-H.; Jung, J.-W.; Kim, I.-D. 3D Printing for Energy Storage Devices: Advances, Challenges, and Future Directions. Adv. Mater. 2025, 37, e05943. [Google Scholar] [CrossRef] [PubMed]

- Aghmadi, A.; Mohammed, O.A. Energy Storage Systems: Technologies and High-Power Applications. Batteries 2024, 10, 141. [Google Scholar] [CrossRef]

- Liu, F.; Lu, J.; Hao, Y.; Chang, Y.; Yu, K.; Liu, S.; Chu, Z. Structure Design and Characterization of 3D Printing System of Thermal Battery Electrode Ink Film. Micromachines 2023, 14, 1147. [Google Scholar] [CrossRef]

- Duan, K.; Orabi, M.; Warchock, A.; Al-Akraa, Z.; Ajami, Z.; Chun, T.-H.; Lo, J.F. Monolithically 3D-Printed Microfluidics with Embedded µTesla Pump. Micromachines 2023, 14, 237. [Google Scholar] [CrossRef]

- Liu, C.; Li, C.; Li, J.; Huang, K.; Liu, Z.; Chen, Z.; Zhang, L. Conformal 3D Printing towards Shape-Conformal Batteries: A Topical Review. Virtual Phys. Prototyp. 2025, 20, e2461752. [Google Scholar] [CrossRef]

- Paek, S.W.; Balasubramanian, S.; Stupples, D. Composites Additive Manufacturing for Space Applications: A Review. Materials 2022, 15, 4709. [Google Scholar] [CrossRef]

- Ali, F.; Koc, M. 3D Printed Polymer Piezoelectric Materials: Transforming Healthcare through Biomedical Applications. Polymers 2023, 15, 4470. [Google Scholar] [CrossRef]

- Zhu, Y.; Qin, J.; Shi, G.; Sun, C.; Ingram, M.; Qian, S.; Lu, J.; Zhang, S.; Zhong, Y.L. A Focus Review on 3D Printing of Wearable Energy Storage Devices. Carbon Energy 2022, 4, 1242–1261. [Google Scholar] [CrossRef]

- Jiang, Z.; Chen, G. Research Progress and Prospect of Printed Batteries. In Innovative Technologies for Printing and Packaging; Lecture Notes in Electrical Engineering; Springer Nature: Singapore, 2023; pp. 561–569. ISBN 9789811990236. [Google Scholar]

- Gao, X.; Zheng, M.; Yang, X.; Sun, R.; Zhang, J.; Sun, X. Emerging Application of 3D-Printing Techniques in Lithium Batteries: From Liquid to Solid. Mater. Today 2022, 59, 161–181. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Q.; Gao, X.; Wang, C.; Li, W.; Holness, F.B.; Zheng, M.; Li, R.; Price, A.D.; Sun, X.; et al. Toward High Areal Energy and Power Density Electrode for Li-Ion Batteries via Optimized 3D Printing Approach. ACS Appl. Mater. Interfaces 2018, 10, 39794–39801. [Google Scholar] [CrossRef]

- Li, J.; Fleetwood, J.; Hawley, W.B.; Kays, W. From Materials to Cell: State-of-the-Art and Prospective Technologies for Lithium-Ion Battery Electrode Processing. Chem. Rev. 2022, 122, 903–956. [Google Scholar] [CrossRef]

- Verdier, N.; Foran, G.; Lepage, D.; Prébé, A.; Aymé-Perrot, D.; Dollé, M. Challenges in Solvent-Free Methods for Manufacturing Electrodes and Electrolytes for Lithium-Based Batteries. Polymers 2021, 13, 323. [Google Scholar] [CrossRef]

- Artigas-Arnaudas, J.; Sánchez-Romate, X.F.; Sánchez, M.; Ureña, A. Effect of Electrode Surface Treatment on Carbon Fiber Based Structural Supercapacitors: Electrochemical Analysis, Mechanical Performance and Proof-of-Concept. J. Energy Storage 2023, 59, 106599. [Google Scholar] [CrossRef]

- Pei, M.; Shi, H.; Yao, F.; Liang, S.; Xu, Z.; Pei, X.; Wang, S.; Hu, Y. 3D Printing of Advanced Lithium Batteries: A Designing Strategy of Electrode/Electrolyte Architectures. J. Mater. Chem. A Mater. Energy Sustain. 2021, 9, 25237–25257. [Google Scholar] [CrossRef]

- Shen, F.; Tang, C.; Sun, X.; Song, Y.; Cai, J. Recent Advances in 3D Printing Technologies for Lithium-Sulfur Batteries. Small 2025, 21, e2412182. [Google Scholar] [CrossRef]

- Łapińska, A.; Panas, A.J.; Przekop, R.; Sztorch, B.; Pakuła, D.; Głowacka, J.; Gołofit, T.; Dużyńska, A.; Płatek, P.; Cieplak, K.; et al. Comparison of Thermal and Fire Properties of PLA-Based Composites Based on FDM Printed Graphite/Molybdenum Disulfide and Siloxene. Int. J. Heat Mass Transf. 2025, 250, 127276. [Google Scholar] [CrossRef]

- Kantaros, A. Intellectual Property Challenges in the Age of 3D Printing: Navigating the Digital Copycat Dilemma. Appl. Sci. 2024, 14, 11448. [Google Scholar] [CrossRef]