Experimental Study on the Axial Compressive Behavior of Concrete-Filled Steel Tube Short Columns Confined by Carbon Fiber-Reinforced Polymer Composites

Abstract

1. Introduction

2. Methodology

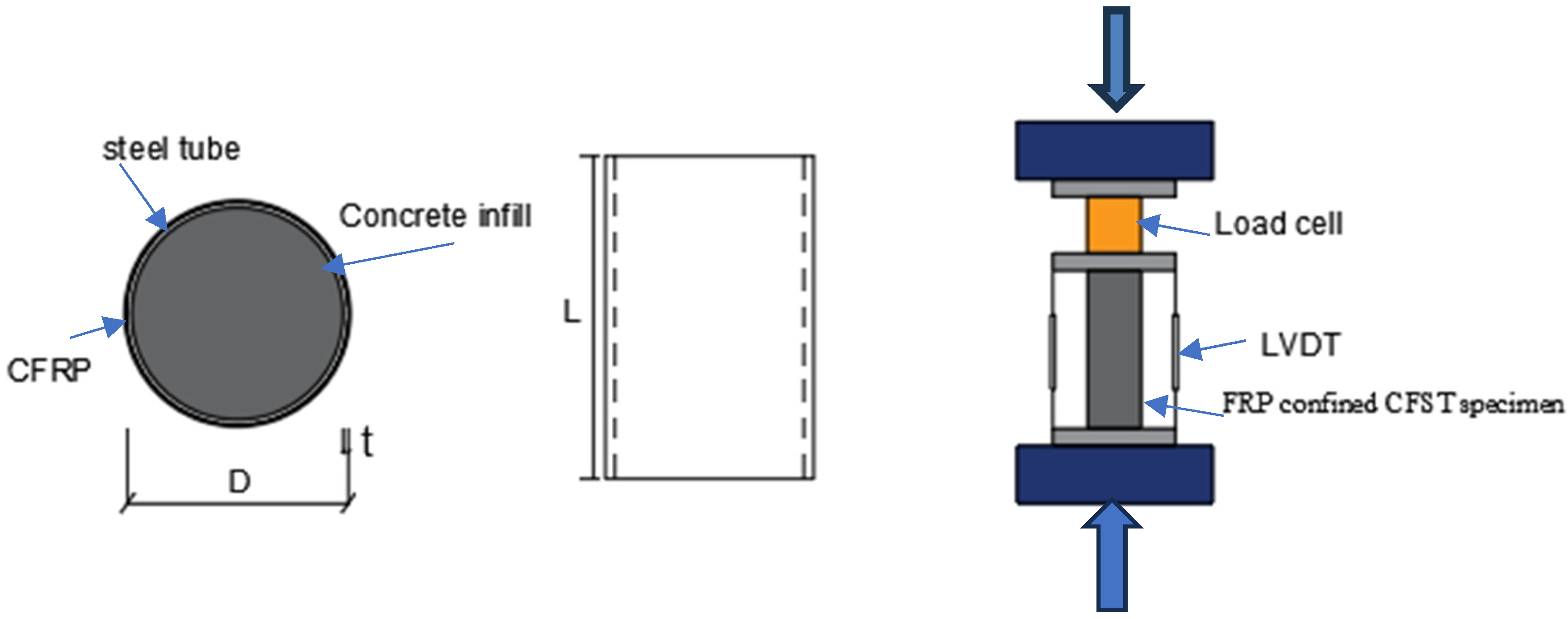

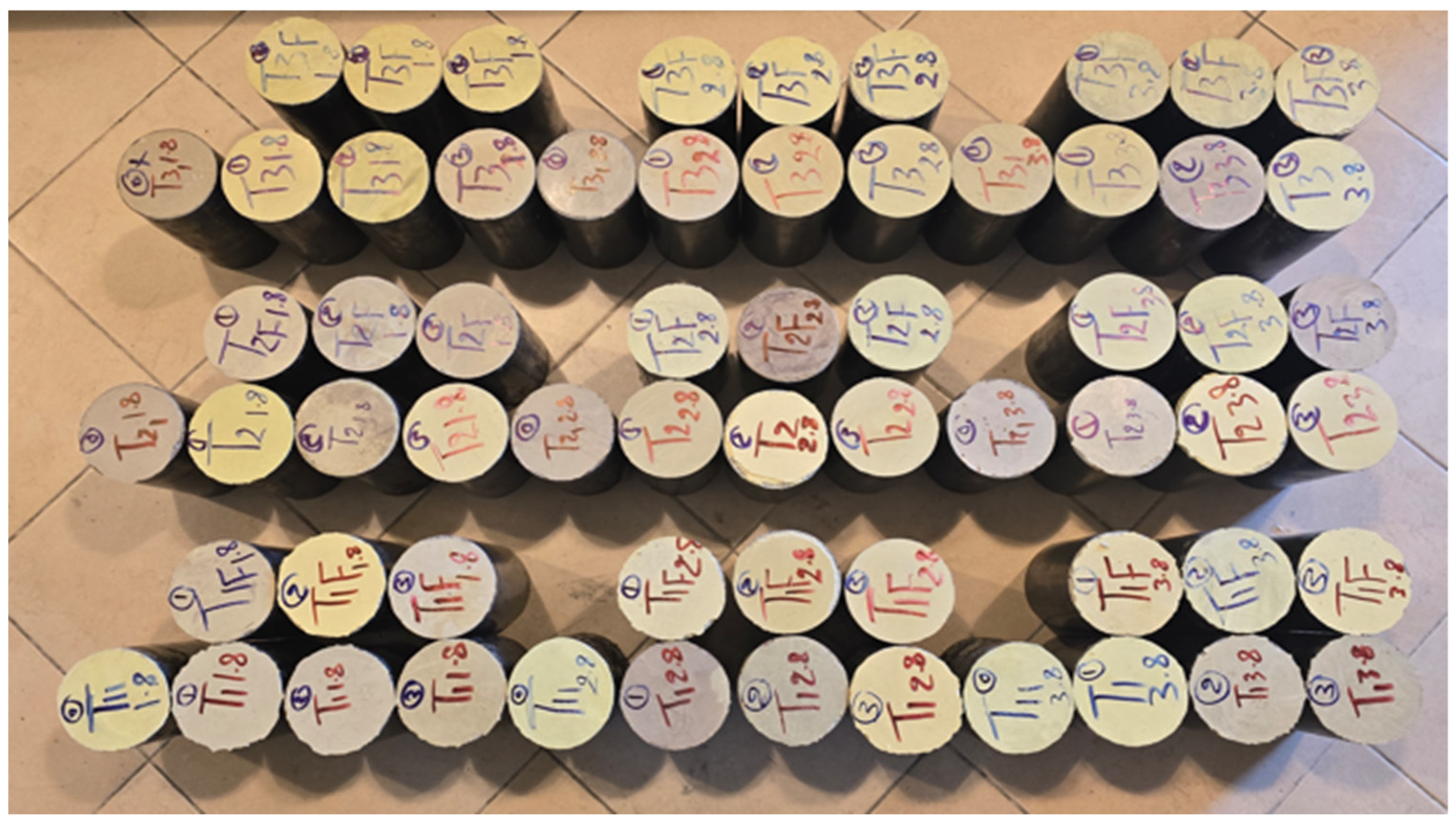

2.1. Test Specimens

2.2. Material Properties

2.3. Preparation of Specimens

2.4. Test Setup and Instrumentation

3. Results and Discussion

3.1. General Studies

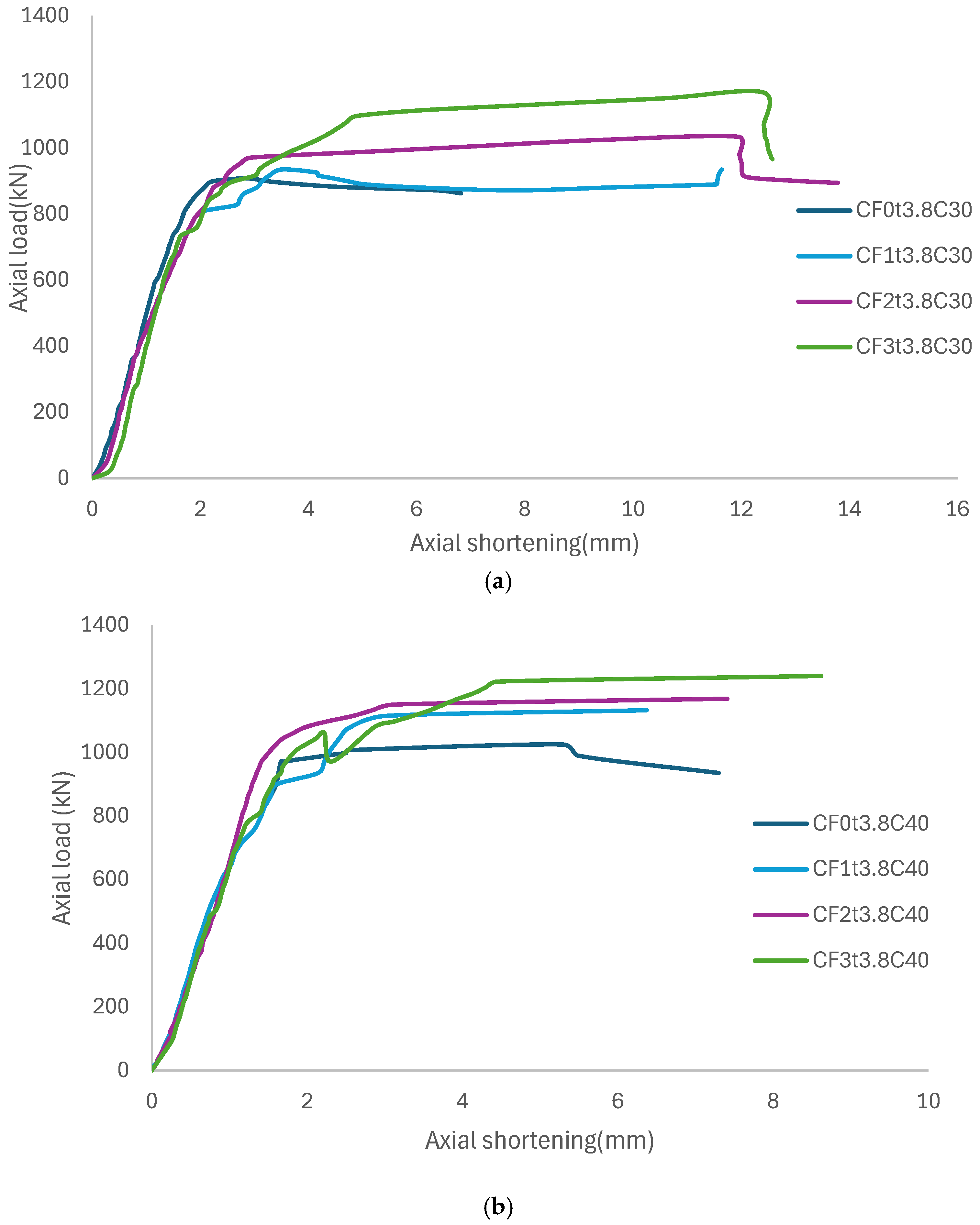

3.2. Axial Load-Axial Shortening Behavior

3.2.1. Effect of Fiber-Reinforced Polymer (FRP) Confinement

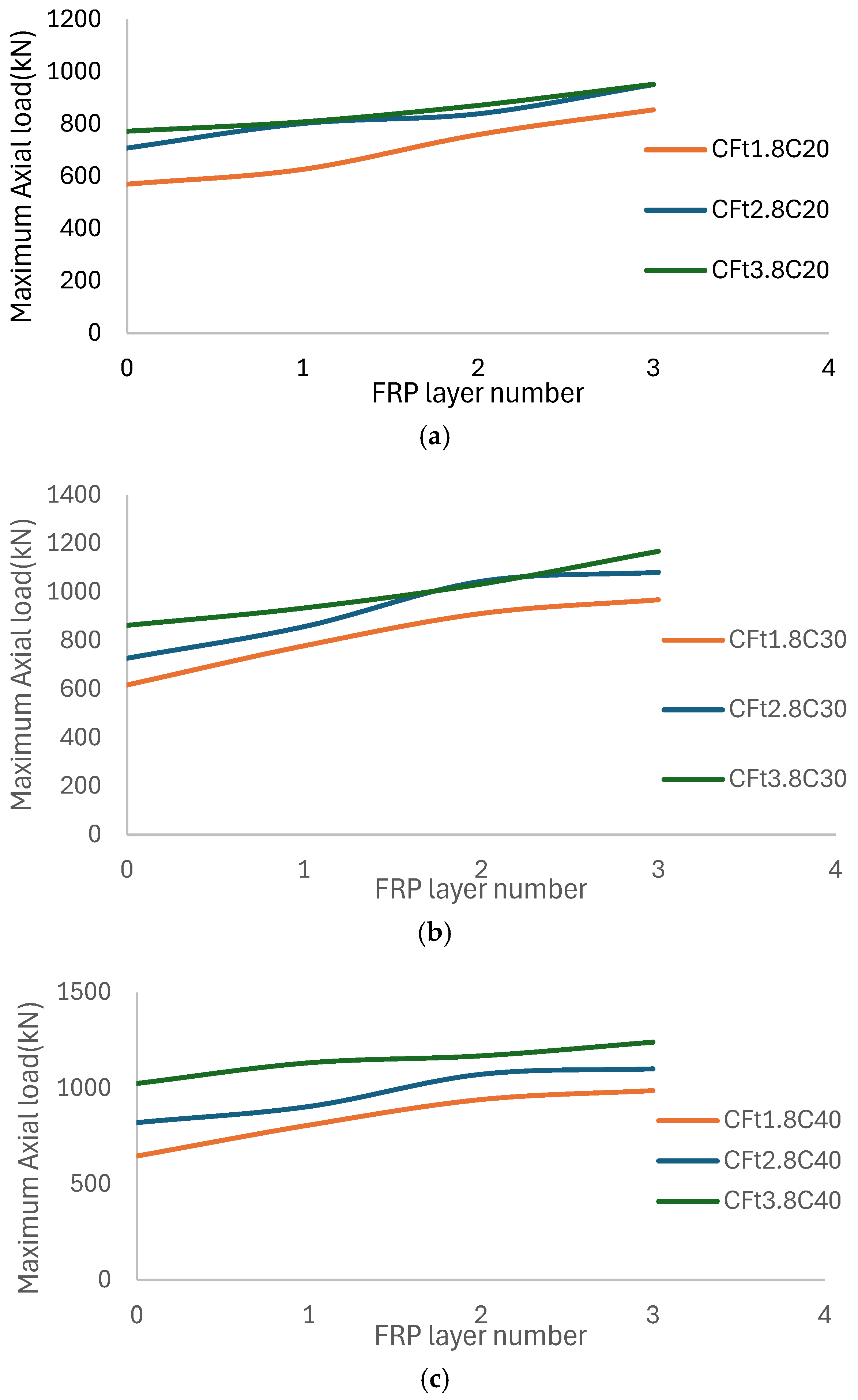

3.2.2. Effect of the Thickness of the Steel Tube

3.2.3. Effect of Concrete Strength

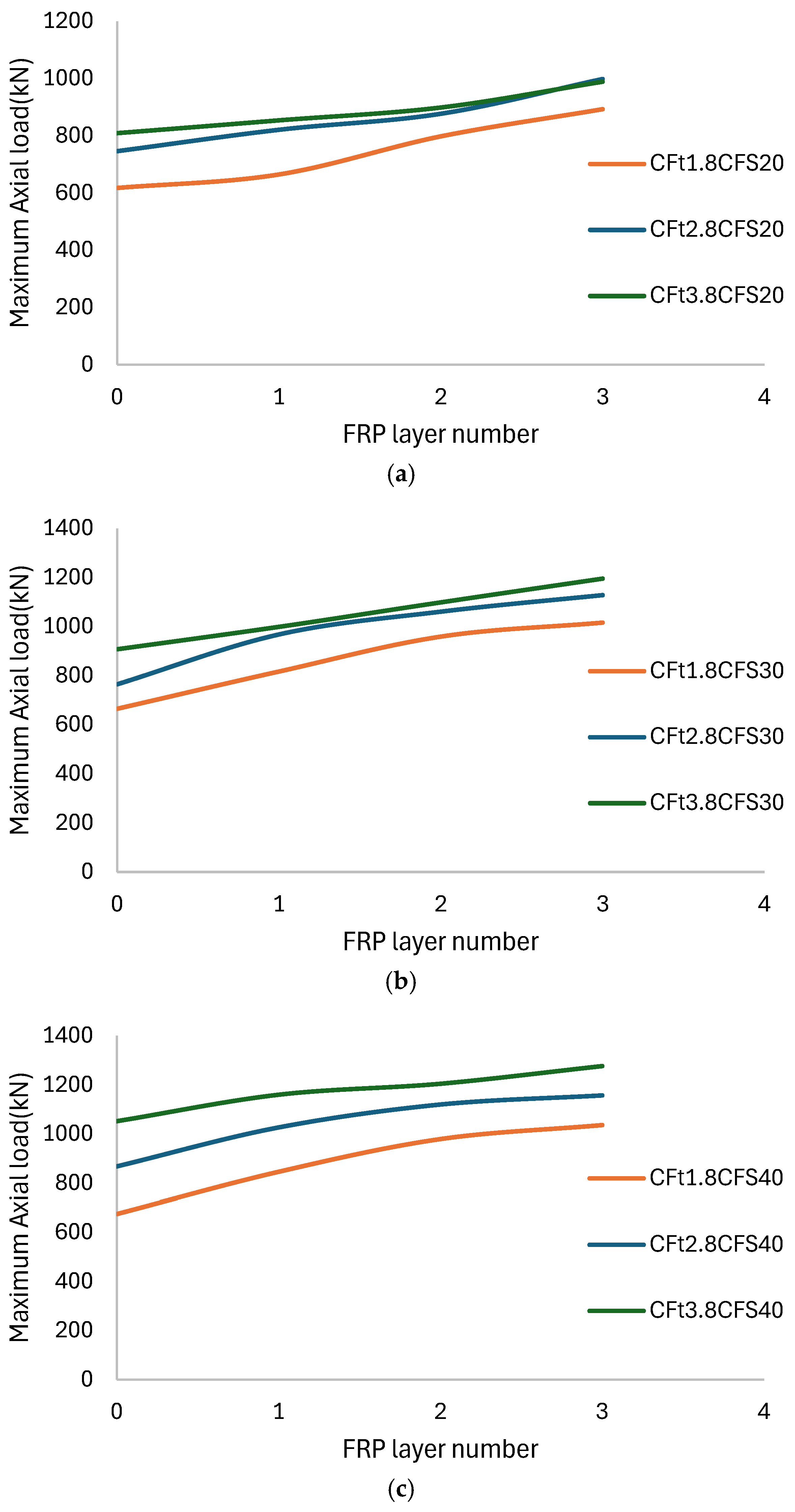

3.2.4. Effect of FRP Layer

3.3. Prediction of Load-Carrying Capacity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FRP-CFST | Fiber-Reinforced Polymer Confined Concrete-Filled Steel Tube |

| CFRP | Carbon Fiber-Reinforced Polymer |

| FRP | Fiber-Reinforced Polymer |

| CFST | Concrete-Filled Steel Tube |

References

- Fam, A.; Qie, F.; Rizkalla, S. Concrete-filled steel tubes subjected to axial compression and lateral cyclic loads. J. Struct. Eng. 2004, 130, 631–640. [Google Scholar] [CrossRef]

- O’Shea, M.D.; Bridge, R.Q. Design of circular thin-walled concrete-filled steel tubes. J. Struct. Eng. 2000, 126, 1295–1303. [Google Scholar] [CrossRef]

- Xiao, Y. Applications of FRP Composites in Concrete Columns. Adv. Struct. Eng. 2004, 7, 335–343. [Google Scholar] [CrossRef]

- Abbasnia, R.; Ahmadi, R.; Ziaadiny, H. Effect of confinement level. aspect ratio and concrete strength on the cyclic stress-strain behavior of FRP-confined concrete prisms. Composites 2012, 43 Pt B, 825–831. [Google Scholar] [CrossRef]

- Abbasnia, R.; Hosseinpour, F.; Rostamian, M.; Ziaadiny, H. Effect of corner radius on stress-strain behavior of FRP confined prisms under axial cyclic compression. Eng. Struct. 2012, 40, 529–535. [Google Scholar] [CrossRef]

- Wei, S.; Mau, S.T.; Vipulanandan, C.; Mantrala, S.K. Performance of new sandwich tube under axial loading: Experiment. J. Struct. Eng. ASCE 1995, 121, 1806–1814. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress–strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 3, 471–489. [Google Scholar] [CrossRef]

- Spoelstra, M.M.R.; Giorgio, M. FRP-confined concrete model. J. Compos. Constr. 1999, 3, 143–150. [Google Scholar] [CrossRef]

- Hu, H.-T.; Huang, C.-S.; Wu, M.-H.; Wu, Y.-M. Nonlinear analysis of axially loaded concrete-filled tube columns with confinement effect. J. Struct. Eng. 2003, 129, 1322–1329. [Google Scholar] [CrossRef]

- Abdalla, S.; Abed, F.; AlHamaydeh, M. Behavior of CFSTs and CCFSTs under quasistatic axial compression. J. Constr. Steel Res. 2013, 90, 235–244. [Google Scholar] [CrossRef]

- Tao, Z.; Han, L.H.; Zhuang, J.P. Axial loading behavior of CFRP strengthened concrete-filled steel tubular STUB columns. Adv. Struct. Eng. 2007, 10, 37–46. [Google Scholar] [CrossRef]

- Jiao, C.; Ta, J.; Niu, Y.; Meng, S.; Chen, X.-F.; He, S.; Ma, R. Analysis of the flexural properties of ultra-high-performance concrete consisting of hybrid straight steel fibers. Case Stud. Constr. Mater. 2022, 17, e01153. [Google Scholar] [CrossRef]

- Yaseri, S.; Hajiaghaei, G.; Mohammadi, F.; Mahdikhani, M.; Farokhzad, R. The role of synthesis parameters on the workability, setting and strength properties of binary binder based geopolymer paste. Constr. Build. Mater. 2017, 157, 534–545. [Google Scholar] [CrossRef]

- Habibi, A.; Ramezanianpour, A.M.; Mahdikhani, M.; Bamshad, O. RSM-based evaluation of mechanical and durability properties of recycled aggregate concrete containing GGBFS and silica fumes. Constr. Build. Mater. 2021, 270, 121431. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Understanding the role of particle packing characteristics in rheo-physical properties of cementitious suspensions: A literature review. Constr. Build. Mater. 2018, 161, 340–353. [Google Scholar] [CrossRef]

- Köksal, F.; Altun, F.; Yiğit, İ.; Şahin, Y. Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater 2008, 22, 1874–1880. [Google Scholar]

- Khodabakhshian, A.; Ghalehnovi, M.; De Brito, J.; Shamsabadi, E.A. Durability performance of structural concrete containing silica fume and marble industry waste powder. J. Clean. Prod. 2018, 170, 42–60. [Google Scholar] [CrossRef]

- Shi, C.; Wang, D.; Wu, L.; Wu, Z. The hydration and microstructure of ultra-high-strength concrete with cementesilica fumeeslag binder. Cem. Concr. Compos. 2015, 61, 44–52. [Google Scholar]

- ASTM D3039/D3039M-08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Material. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2006.

- Hamed, A.Y.; Hassanein, M.F.; Hasan, M.A. Stress-strain modelling of circular concrete-filled FRP–steel composite tube columns under axial compression load. Structures 2024, 67, 107040. [Google Scholar]

- Wang, J.; Xiao, H.; Lu, L.; Yang, J.; Lu, S.; Shayanfar, J. Axial stress-strain model for concrete in partially FRP wrapped reinforced concrete columns. Constr. Build. Mater. 2024, 416, 135028. [Google Scholar] [CrossRef]

- Lu, Y.; Li, N.; Li, S.; Liang, H. Behavior of steel fiber reinforced concrete-filled steel tube columns under axial compression. Constr. Build. Mater. 2015, 95, 74–85. [Google Scholar] [CrossRef]

- Chen, Z.; Dong, S.; Du, Y. Experimental study and numerical analysis on seismic performance of FRP confined high-strength rectangular concrete-filled steel tube columns. Thin-Walled Struct. 2021, 162, 107560. [Google Scholar] [CrossRef]

- Lu, Y.; Li, N.; Li, S. Behavior of FRP-Confined Concrete-Filled Steel Tube Columns. Polymers 2014, 6, 1333–1349. [Google Scholar] [CrossRef]

- Ma, Y.; Ma, K.; Han, X.; Yao, T. Experimental investigation of FRP-confined HSC-filled steel tube stub columns under axial compression. Eng. Struct. 2023, 280, 115670. [Google Scholar] [CrossRef]

- Tan, X.; Zhu, M.; Liu, W. Experimental Study and Numerical Analysis of the Seismic Performance of Glass-Fiber Reinforced Plastic Tube Ultra-High Performance Concrete Composite Columns. Materials 2023, 16, 6941. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, G.; Li, G. Performance of circular concrete-filled fiber-reinforced polymer steel composite tube columns under axial compression. J. Reinf. Plast. Compos. 2014, 33, 1911–1928. [Google Scholar] [CrossRef]

- Park, J.W.; Hong, Y.K.; Hong, G.S.; Kim, J.H.; Choi, S.M. Design formulas of concrete filled circular steel tubes reinforced by carbon fiber reinforced plastic sheets. The twelfth East Asia-Pacific conference on structural engineering and construction. Procedia Eng. 2011, 14, 2916–2922. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, J.N.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. ASCE 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Richart, F.E.; Brandzaeg, A.; Brown, R.L. A Study of the Failure of Concrete Under Combined Compressive Stresses; University of Illinois, Engineering Experimental Station: Champaign, IL, USA, 1928. [Google Scholar]

- Lam, L.; Teng, G. Strength models for fiber-reinforced plastic-confined concrete. J. Struct. Eng. ASCE 2002, 128, 612–623. [Google Scholar] [CrossRef]

- Xiao, Y.; Long, H.; Wang, Y.; Hu, H.; Liu, Y.; Wu, Q. Failure modes and energy absorption mechanism of CFRP thin-walled square tubes filled with gradient foam aluminum under axial compression. Mater. Today Commun. 2023, 37, 107569. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Mousa, S.; Mohamed, H.M.; Benmokrane, B. Deflection Control Methodologies for Curvilinear Concrete Members Reinforced with Glass Fiber-Reinforced Polymer Bars. ACI Struct. J. 2023, 120, 153. [Google Scholar] [CrossRef]

- Zhou, G.; Fang, N.; Liu, H.; Han, C.; Yin, L. Internal Force Analysis of CFST Lattice Columns with Flat Lacing Tubes Based. In Proceedings of the 4th International Civil Engineering and Architecture Conference: CEAC 2024, Seoul, Republic of Korea, 15–17 March 2024; Springer Nature: Singapore, 2024; Volume 534. [Google Scholar]

| Mix Proportion (kg/m3) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Gravel (kg/m3) | Sand (kg/m3) | Fine sand (kg/m3) | Cement (kg/m3) | Superplasticizer | Polypropylene Fiber (kg/m3) | Silica Fume (kg/m3) | Water (kg/m3) | w/c Ratio | Concrete Class |

| 545.88 | 227.45 | 1197.91 | 272.02 | 2.72 | 0 | 0 | 114.24 | 0.42 | C20 |

| 545.88 | 232.50 | 1142.31 | 332.67 | 3.33 | 0 | 0 | 106.45 | 0.32 | C30 |

| 551.40 | 242.61 | 1093.61 | 389.65 | 3.90 | 0 | 0 | 105.20 | 0.27 | C40 |

| 545.88 | 227.45 | 1197.91 | 272.02 | 2.72 | 3.03 | 3.03 | 114.24 | 0.42 | CF20 |

| 545.88 | 232.50 | 1142.31 | 332.67 | 3.33 | 3.03 | 3.03 | 106.45 | 0.32 | CF30 |

| 551.40 | 242.61 | 1093.61 | 389.65 | 3.90 | 3.03 | 3.03 | 105.20 | 0.27 | CF40 |

| Specimens | L (mm) | D (mm) | FRP | nf | ts (mm) | tf (mm) | fy (MPa) | fc (MPa) |

|---|---|---|---|---|---|---|---|---|

| CF0t1.8C20 | 220 | 110 | CFRP | 0 | 1.8 | 0 | 307 | 19.3 |

| CF1t1.8C20 | 220 | 110 | CFRP | 1 | 1.8 | 0.34 | 307 | 19.3 |

| CF2t1.8C20 | 220 | 110 | CFRP | 2 | 1.8 | 0.34 | 307 | 19.3 |

| CF3t1.8C20 | 220 | 110 | CFRP | 3 | 1.8 | 0.34 | 307 | 19.3 |

| CF0t2.8C20 | 218 | 109 | CFRP | 0 | 2.8 | 0 | 307 | 19.3 |

| CF1t2.8C20 | 218 | 109 | CFRP | 1 | 2.8 | 0.34 | 307 | 19.3 |

| CF2t2.8C20 | 218 | 109 | CFRP | 2 | 2.8 | 0.34 | 307 | 19.3 |

| CF3t2.8C20 | 218 | 109 | CFRP | 3 | 2.8 | 0.34 | 307 | 19.3 |

| CF0t3.8C20 | 214 | 107 | CFRP | 0 | 3.8 | 0 | 307 | 19.3 |

| CF1t3.8C20 | 214 | 107 | CFRP | 1 | 3.8 | 0.34 | 307 | 19.3 |

| CF2t3.8C20 | 214 | 107 | CFRP | 2 | 3.8 | 0.34 | 307 | 19.3 |

| CF3t3.8C20 | 214 | 107 | CFRP | 3 | 3.8 | 0.34 | 307 | 19.3 |

| CF0t1.8CFS20 | 220 | 110 | CFRP | 0 | 1.8 | 0 | 307 | 22.1 |

| CF1t1.8CFS20 | 220 | 110 | CFRP | 1 | 1.8 | 0.34 | 307 | 22.1 |

| CF2t1.8CFS20 | 220 | 110 | CFRP | 2 | 1.8 | 0.34 | 307 | 22.1 |

| CF3t1.8CFS20 | 220 | 110 | CFRP | 3 | 1.8 | 0.34 | 307 | 22.1 |

| CF0t2.8CFS20 | 218 | 109 | CFRP | 0 | 2.8 | 0 | 307 | 22.1 |

| CF1t2.8CFS20 | 218 | 109 | CFRP | 1 | 2.8 | 0.34 | 307 | 22.1 |

| CF2t2.8CFS20 | 218 | 109 | CFRP | 2 | 2.8 | 0.34 | 307 | 22.1 |

| CF3t2.8CFS20 | 218 | 109 | CFRP | 3 | 2.8 | 0.34 | 307 | 22.1 |

| CF0t3.8CFS20 | 214 | 107 | CFRP | 0 | 3.8 | 0 | 307 | 22.1 |

| CF1t3.8CFS20 | 214 | 107 | CFRP | 1 | 3.8 | 0.34 | 307 | 22.1 |

| CF2t3.8CFS20 | 214 | 107 | CFRP | 2 | 3.8 | 0.34 | 307 | 22.1 |

| CF3t3.8CFS20 | 214 | 107 | CFRP | 3 | 3.8 | 0.34 | 307 | 22.1 |

| Specimens | L (mm) | D (mm) | FRP | nf | ts (mm) | tf (mm) | fy (MPa) | fc (MPa) |

|---|---|---|---|---|---|---|---|---|

| CF0t1.8C30 | 220 | 110 | CFRP | 0 | 1.8 | 0 | 307 | 26.8 |

| CF1t1.8C30 | 220 | 110 | CFRP | 1 | 1.8 | 0.34 | 307 | 26.8 |

| CF2t1.8C30 | 220 | 110 | CFRP | 2 | 1.8 | 0.34 | 307 | 26.8 |

| CF3t1.8C30 | 220 | 110 | CFRP | 3 | 1.8 | 0.34 | 307 | 26.8 |

| CF0t2.8C30 | 218 | 109 | CFRP | 0 | 2.8 | 0 | 307 | 26.8 |

| CF1t2.8C30 | 218 | 109 | CFRP | 1 | 2.8 | 0.34 | 307 | 26.8 |

| CF2t2.8C30 | 218 | 109 | CFRP | 2 | 2.8 | 0.34 | 307 | 26.8 |

| CF3t2.8C30 | 218 | 109 | CFRP | 3 | 2.8 | 0.34 | 307 | 26.8 |

| CF0t3.8C30 | 214 | 107 | CFRP | 0 | 3.8 | 0 | 307 | 26.8 |

| CF1t3.8C30 | 214 | 107 | CFRP | 1 | 3.8 | 0.34 | 307 | 26.8 |

| CF2t3.8C30 | 214 | 107 | CFRP | 2 | 3.8 | 0.34 | 307 | 26.8 |

| CF3t3.8C30 | 214 | 107 | CFRP | 3 | 3.8 | 0.34 | 307 | 26.8 |

| CF0t1.8CFS30 | 220 | 110 | CFRP | 0 | 1.8 | 0 | 307 | 30.1 |

| CF1t1.8CFS30 | 220 | 110 | CFRP | 1 | 1.8 | 0.34 | 307 | 30.1 |

| CF2t1.8CFS30 | 220 | 110 | CFRP | 2 | 1.8 | 0.34 | 307 | 30.1 |

| CF3t1.8CFS30 | 220 | 110 | CFRP | 3 | 1.8 | 0.34 | 307 | 30.1 |

| CF0t2.8CFS30 | 218 | 109 | CFRP | 0 | 2.8 | 0 | 307 | 30.1 |

| CF1t2.8CFS30 | 218 | 109 | CFRP | 1 | 2.8 | 0.34 | 307 | 30.1 |

| CF2t2.8CFS30 | 218 | 109 | CFRP | 2 | 2.8 | 0.34 | 307 | 30.1 |

| CF3t2.8CFS30 | 218 | 109 | CFRP | 3 | 2.8 | 0.34 | 307 | 30.1 |

| CF0t3.8CFS30 | 214 | 107 | CFRP | 0 | 3.8 | 0 | 307 | 30.1 |

| CF1t3.8CFS30 | 214 | 107 | CFRP | 1 | 3.8 | 0.34 | 307 | 30.1 |

| CF2t3.8CFS30 | 214 | 107 | CFRP | 2 | 3.8 | 0.34 | 307 | 30.1 |

| CF3t3.8CFS30 | 214 | 107 | CFRP | 3 | 3.8 | 0.34 | 307 | 30.1 |

| Specimens | L (mm) | D (mm) | FRP | nf | ts (mm) | tf (mm) | fy (MPa) | fc (MPa) |

|---|---|---|---|---|---|---|---|---|

| CF0t1.8C40 | 220 | 110 | CFRP | 0 | 1.8 | 0 | 307 | 35.8 |

| CF1t1.8C40 | 220 | 110 | CFRP | 1 | 1.8 | 0.34 | 307 | 35.8 |

| CF2t1.8C40 | 220 | 110 | CFRP | 2 | 1.8 | 0.34 | 307 | 35.8 |

| CF3t1.8C40 | 220 | 110 | CFRP | 3 | 1.8 | 0.34 | 307 | 35.8 |

| CF0t2.8C40 | 218 | 109 | CFRP | 0 | 2.8 | 0 | 307 | 35.8 |

| CF1t2.8C40 | 218 | 109 | CFRP | 1 | 2.8 | 0.34 | 307 | 35.8 |

| CF2t2.8C40 | 218 | 109 | CFRP | 2 | 2.8 | 0.34 | 307 | 35.8 |

| CF3t2.8C40 | 218 | 109 | CFRP | 3 | 2.8 | 0.34 | 307 | 35.8 |

| CF0t3.8C40 | 214 | 107 | CFRP | 0 | 3.8 | 0 | 307 | 35.8 |

| CF1t3.8C40 | 214 | 107 | CFRP | 1 | 3.8 | 0.34 | 307 | 35.8 |

| CF2t3.8C40 | 214 | 107 | CFRP | 2 | 3.8 | 0.34 | 307 | 35.8 |

| CF3t3.8C40 | 214 | 107 | CFRP | 3 | 3.8 | 0.34 | 307 | 35.8 |

| CF0t1.8CFS40 | 220 | 110 | CFRP | 0 | 1.8 | 0 | 307 | 39.8 |

| CF1t1.8CFS40 | 220 | 110 | CFRP | 1 | 1.8 | 0.34 | 307 | 39.8 |

| CF2t1.8CFS40 | 220 | 110 | CFRP | 2 | 1.8 | 0.34 | 307 | 39.8 |

| CF3t1.8CFS40 | 220 | 110 | CFRP | 3 | 1.8 | 0.34 | 307 | 39.8 |

| CF0t2.8CFS40 | 218 | 109 | CFRP | 0 | 2.8 | 0 | 307 | 39.8 |

| CF1t2.8CFS40 | 218 | 109 | CFRP | 1 | 2.8 | 0.34 | 307 | 39.8 |

| CF2t2.8CFS40 | 218 | 109 | CFRP | 2 | 2.8 | 0.34 | 307 | 39.8 |

| CF3t2.8CFS40 | 218 | 109 | CFRP | 3 | 2.8 | 0.34 | 307 | 39.8 |

| CF0t3.8CFS40 | 214 | 107 | CFRP | 0 | 3.8 | 0 | 307 | 39.8 |

| CF1t3.8CFS40 | 214 | 107 | CFRP | 1 | 3.8 | 0.34 | 307 | 39.8 |

| CF2t3.8CFS40 | 214 | 107 | CFRP | 2 | 3.8 | 0.34 | 307 | 39.8 |

| CF3t3.8CFS40 | 214 | 107 | CFRP | 3 | 3.8 | 0.34 | 307 | 39.8 |

| Specimens | Nu (kN) | Specimens | Nu (kN) | Specimens | Nu (kN) |

|---|---|---|---|---|---|

| CF0t1.8C20 | 570 | CF0t1.8C30 | 617 | CF0t1.8C40 | 646 |

| CF1t1.8C20 | 627 | CF1t1.8C30 | 779 | CF1t1.8C40 | 807 |

| CF2t1.8C20 | 760 | CF2t1.8C30 | 912 | CF2t1.8C40 | 940 |

| CF3t1.8C20 | 855 | CF3t1.8C30 | 969 | CF3t1.8C40 | 988 |

| CF0t2.8C20 | 709 | CF0t2.8C30 | 728 | CF0t2.8C40 | 821 |

| CF1t2.8C20 | 802 | CF1t2.8C30 | 858 | CF1t2.8C40 | 905 |

| CF2t2.8C20 | 839 | CF2t2.8C30 | 1045 | CF2t2.8C40 | 1073 |

| CF3t2.8C20 | 951 | CF3t2.8C30 | 1082 | CF3t2.8C40 | 1101 |

| CF0t3.8C20 | 773 | CF0t3.8C30 | 863 | CF0t3.8C40 | 1025 |

| CF1t3.8C20 | 809 | CF1t3.8C30 | 935 | CF1t3.8C40 | 1132 |

| CF2t3.8C20 | 872 | CF2t3.8C30 | 1034 | CF2t3.8C40 | 1168 |

| CF3t3.8C20 | 953 | CF3t3.8C30 | 1169 | CF3t3.8C40 | 1240 |

| CF0t1.8CFS20 | 617 | CF0t1.8CFS30 | 665 | CF0t1.8CFS40 | 674 |

| CF1t1.8CFS20 | 665 | CF1t1.8CFS30 | 817 | CF1t1.8CFS40 | 845 |

| CF2t1.8CFS20 | 798 | CF2t1.8CFS30 | 959 | CF2t1.8CFS40 | 978 |

| CF3t1.8CFS20 | 893 | CF3t1.8CFS30 | 1016 | CF3t1.8CFS40 | 1035 |

| CF0t2.8CFS20 | 746 | CF0t2.8CFS30 | 765 | CF0t2.8CFS40 | 867 |

| CF1t2.8CFS20 | 821 | CF1t2.8CFS30 | 989 | CF1t2.8CFS40 | 1026 |

| CF2t2.8CFS20 | 877 | CF2t2.8CFS30 | 1091 | CF2t2.8CFS40 | 1119 |

| CF3t2.8CFS20 | 998 | CF3t2.8CFS30 | 1129 | CF3t2.8CFS40 | 1157 |

| CF0t3.8CFS20 | 809 | CF0t3.8CFS30 | 908 | CF0t3.8CFS40 | 1052 |

| CF1t3.8CFS20 | 854 | CF1t3.8CFS30 | 962 | CF1t3.8CFS40 | 1159 |

| CF2t3.8CFS20 | 899 | CF2t3.8CFS30 | 1070 | CF2t3.8CFS40 | 1204 |

| CF3t3.8CFS20 | 989 | CF3t3.8CFS30 | 1195 | CF3t3.8CFS40 | 1276 |

| Source | Proposed Model |

|---|---|

| [27] | where |

| [28] | where |

where |

| Specimens | Model by [27] | Model-1 by [28] | Model-2 by [28] |

|---|---|---|---|

| Nu,pre/Nu,exp | |||

| CF1t1.8C20 | 1.96 | 1.85 | 1.23 |

| CF2t1.8C20 | 2.66 | 2.39 | 0.96 |

| CF3t1.8C20 | 3.30 | 2.88 | 0.70 |

| CF1t2.8C20 | 1.74 | 1.66 | 1.04 |

| CF2t2.8C20 | 2.64 | 2.34 | 0.92 |

| CF3t2.8C20 | 3.20 | 2.73 | 0.66 |

| CF1t3.8C20 | 1.93 | 1.81 | 1.09 |

| CF2t3.8C20 | 2.75 | 2.38 | 0.91 |

| CF3t3.8C20 | 3.41 | 2.82 | 0.68 |

| CF1t1.8CFS20 | 1.89 | 1.78 | 1.27 |

| CF2t1.8CFS20 | 2.57 | 2.30 | 1.04 |

| CF3t1.8CFS20 | 3.19 | 2.78 | 0.81 |

| CF1t2.8CFS20 | 1.74 | 1.64 | 1.12 |

| CF2t2.8CFS20 | 2.56 | 2.26 | 1.00 |

| CF3t2.8CFS20 | 3.07 | 2.62 | 0.76 |

| CF1t3.8CFS20 | 1.86 | 1.74 | 1.12 |

| CF2t3.8CFS20 | 2.70 | 2.33 | 1.00 |

| CF3t3.8CFS20 | 3.31 | 2.73 | 0.78 |

| CF1t1.8C30 | 1.67 | 1.56 | 1.24 |

| CF2t1.8C30 | 2.30 | 2.05 | 1.09 |

| CF3t1.8C30 | 2.99 | 2.60 | 0.96 |

| CF1t2.8C30 | 1.71 | 1.61 | 1.21 |

| CF2t2.8C30 | 2.19 | 1.93 | 0.99 |

| CF3t2.8C30 | 2.88 | 2.44 | 0.88 |

| CF1t3.8C30 | 1.74 | 1.62 | 1.16 |

| CF2t3.8C30 | 2.39 | 2.05 | 1.02 |

| CF3t3.8C30 | 2.83 | 2.34 | 0.82 |

| CF1t1.8CFS30 | 1.63 | 1.52 | 1.28 |

| CF2t1.8CFS30 | 2.22 | 1.97 | 1.15 |

| CF3t1.8CFS30 | 2.88 | 2.50 | 1.04 |

| CF1t2.8CFS30 | 1.52 | 1.42 | 1.13 |

| CF2t2.8CFS30 | 2.13 | 1.87 | 1.05 |

| CF3t2.8CFS30 | 2.78 | 2.36 | 0.96 |

| CF1t3.8CFS30 | 1.73 | 1.60 | 1.21 |

| CF2t3.8CFS30 | 2.34 | 2.00 | 1.08 |

| CF3t3.8CFS30 | 2.80 | 2.30 | 0.90 |

| CF1t1.8C40 | 1.72 | 1.59 | 1.44 |

| CF2t1.8C40 | 2.32 | 2.06 | 1.34 |

| CF3t1.8C40 | 3.02 | 2.62 | 1.27 |

| CF1t2.8C40 | 1.72 | 1.59 | 1.37 |

| CF2t2.8C40 | 2.21 | 1.93 | 1.22 |

| CF3t2.8C40 | 2.90 | 2.46 | 1.16 |

| CF1t3.8C40 | 1.51 | 1.39 | 1.14 |

| CF2t3.8C40 | 2.18 | 1.87 | 1.13 |

| CF3t3.8C40 | 2.74 | 2.25 | 1.03 |

| CF1t1.8CFS40 | 1.68 | 1.55 | 1.47 |

| CF2t1.8CFS40 | 2.27 | 2.01 | 1.40 |

| CF3t1.8CFS40 | 2.92 | 2.53 | 1.34 |

| CF1t2.8CFS40 | 1.55 | 1.43 | 1.29 |

| CF2t2.8CFS40 | 2.15 | 1.88 | 1.27 |

| CF3t2.8CFS40 | 2.79 | 2.36 | 1.22 |

| CF1t3.8CFS40 | 1.51 | 1.38 | 1.18 |

| CF2t3.8CFS40 | 2.15 | 1.83 | 1.19 |

| CF3t3.8CFS40 | 2.69 | 2.21 | 1.10 |

| Parameter | Advantage | Disadvantage | Risks/Limits | Supporting Studies |

|---|---|---|---|---|

| FRP layer number | Up to 30% load capacity increase; up to 40% ductility | Marginal gains after 3 layers | FRP rupture from lateral expansion | [24,25] |

| Steel tube thickness | Enhances stiffness and load (>15%) | Increased weight and cost | Fabrication challenges | [32,33] |

| Concrete strength | Boosts ultimate load | Less ductile at very high strengths | Potential brittle failure | [33,34] |

| Fiber-enhanced concrete | Improved tensile strength and toughness | Cost and complexity of the mix | Mixing uniformity | [33] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, B.M.; Mete Güneyisi, E. Experimental Study on the Axial Compressive Behavior of Concrete-Filled Steel Tube Short Columns Confined by Carbon Fiber-Reinforced Polymer Composites. Appl. Sci. 2025, 15, 11728. https://doi.org/10.3390/app152111728

Mohammed BM, Mete Güneyisi E. Experimental Study on the Axial Compressive Behavior of Concrete-Filled Steel Tube Short Columns Confined by Carbon Fiber-Reinforced Polymer Composites. Applied Sciences. 2025; 15(21):11728. https://doi.org/10.3390/app152111728

Chicago/Turabian StyleMohammed, Bzhar Muheddin, and Esra Mete Güneyisi. 2025. "Experimental Study on the Axial Compressive Behavior of Concrete-Filled Steel Tube Short Columns Confined by Carbon Fiber-Reinforced Polymer Composites" Applied Sciences 15, no. 21: 11728. https://doi.org/10.3390/app152111728

APA StyleMohammed, B. M., & Mete Güneyisi, E. (2025). Experimental Study on the Axial Compressive Behavior of Concrete-Filled Steel Tube Short Columns Confined by Carbon Fiber-Reinforced Polymer Composites. Applied Sciences, 15(21), 11728. https://doi.org/10.3390/app152111728