1. Introduction

Since the launch of the 14th Five-Year Plan, China’s coal industry has continued to serve as the nation’s energy security “ballast stone.” As the core component of China’s coal reserves, thick and ultra-thick coal seams are currently the primary targets for achieving high-yield and high-efficiency mining operations [

1]. Compared to traditional rock roadway development, the coal roadway system has emerged as the predominant technical approach for efficiently exploiting extra-thick coal seams due to its significant advantages in resource utilization, mining efficiency, and economic benefits. However, geological factors, notably the considerable thickness and deep burial of these coal bodies, lead to a more complex stress field distribution in extra-thick seams compared to conventional ones [

2]. Consequently, controlling roadways’ surrounding rock becomes increasingly challenging. This challenge is exacerbated by the trend of reducing coal pillar widths. Roadways are often situated within high-stress concentration zones and subjected to significant asymmetric loading effects, intensifying surrounding rock damage and thereby increasing maintenance difficulties and mining risks.

In recent years, many mining workers have conducted extensive theoretical and practical studies on fracture mechanisms in thick coal seam surrounding rock [

3,

4], overburden structures [

5,

6,

7,

8], and strata behavior (mine pressure) [

9,

10,

11,

12]. These investigations have examined roof deformation, stress characteristics, failure modes, and dynamic loading effects. Through research on the theory and technology of mining-induced stress evolution and surrounding rock control, the distribution characteristics and influencing factors of in situ stress, mining-induced stress, and support stress have been analyzed. Furthermore, corresponding surrounding rock control technologies based on mining-induced stress evolution have been proposed. Consequently, numerous scholars have explored the morphological characteristics and evolution of this plastic zone [

13,

14,

15,

16]. These studies have examined the distribution characteristics of the plastic zone under non-hydrostatic stress conditions and its correlation with deformation and failure behavior of the surrounding rock, revealing the evolutionary patterns and expansion mechanisms of the plastic zone morphology in non-uniform stress fields. By investigating the effect of working face retreat on the stress field and plastic zone morphology in the surrounding rock of extraction roadways in extra-thick coal seams, it has been demonstrated that the plastic zone morphology is influenced by the biaxial load ratio. Furthermore, substantial theoretical and practical research has systematically investigated the evolution of stress distribution in roadway surrounding rock, as well as its failure mechanisms and control, using key indicators such as deviatoric stress [

17,

18,

19], the second invariant of deviatoric stress [

20,

21], and principal stress [

22,

23].

Previous research has achieved certain results regarding the stability control of main roadways in ultra-thick coal seams and the distribution laws of surrounding rock stress. However, it has primarily focused on the influence of abutment pressure [

24,

25] on the roadway surrounding rock, lacking an in-depth revelation of the stress evolution laws in surrounding rock at different roadway stratum positions under ultra-thick coal seam conditions. Furthermore, the application value of the deviatoric stress index in analyzing surrounding rock instability has not been systematically introduced or explored. In modern coal mining practice, traditional symmetrical support designs prove inadequate for addressing the significant stress concentration and differential loading effects induced by mining disturbances within the main roadway zone. This differential loading effect is a critical trigger for severe disasters such as roof collapse, floor heaving, and rib spalling, posing a serious threat to the stability and safety of main roadways. Therefore, deeply probing into the differential loading effects, stress distribution, and evolution laws of main roadways arranged at different stratum positions within ultra-thick coal seams and clearly identifying the zones of deviatoric stress concentration have become core scientific problems to be solved in the field of mining engineering.

Grounding the work in a 20 m ultra-thick coal seam mining scenario, finite-element simulations reveal the following: (1) principal stress vector deflection mechanisms within main roadway periphery during development; (2) deviatoric stress distribution patterns and the laws governing differential loading effects in surrounding rock under different roadway stratum positions (roof, middle, floor); (3) evolution characteristics of surrounding rock stress and stratum position effects under the influence of stopping coal pillars. This study systematically reveals, for the first time, the stress bias load response of surrounding rock in roadways at different layers within extra-thick coal seams under mining-induced disturbances. It clarifies the synergistic evolution mechanism between the deflection of principal stress orientations and the asymmetric intensification effect of deviatoric stress, thereby bridging theoretical gaps in the optimization of main roadway positioning and the rational design of stopping coal pillar widths in such geological conditions. Notably, the innovative application of the deviatoric stress indicator to analyze surrounding rock instability demonstrates its engineering value in identifying critical control zones. By uncovering the laws governing biased load increase and stratum effects, the study enables precise identification of key support areas in main roadway surrounding rock. An asymmetric zonal directional synergistic anchoring control technology targeting deviatoric stress concentration and directional deflection is proposed, overcoming the limitations of traditional symmetrical support schemes. Furthermore, a control methodology termed “One Directional Penetration and Three Synergies” was established, offering novel insights for roadway stability control under analogous conditions. This research not only deepens the understanding of stress evolution in surrounding rock of main roadways in extra-thick coal seams but also provides theoretical support and a decision-making basis for main roadway layer selection, optimum stopping pillar design, and the safe and efficient execution of similar engineering projects.

3. Numerical Investigation of Stress Redistribution in 20 m-Ultra-Thick Coal Seam Roadway Periphery

3.1. Simulation Method and Model Establishment

Through finite-difference formulations, computational simulations track stress evolution and rock mass degradation in excavation peripheries, providing mechanistic insights beyond empirical observation. Under various in situ stress field conditions, stress concentration zones and plastic development areas within the roadway undergo a deflection process, resulting in an asymmetric stress distribution pattern and localized stress enhancement phenomena. Numerical simulation enables clear visualization of the evolution characteristics of deflection loads in main roadway surrounding rock masses induced by coal seam extraction. This finding holds both theoretical and practical significance for analyzing plastic deformation mechanisms of surrounding rocks and determining optimal reinforcement zones in roadways.

To investigate the deviatoric stress amplification effect in main roadways within ultra-thick coal seams, Employing FLAC

3D 7.0’s finite-difference formulation, this study establishes a 3D numerical model for quantitative characterization of principal and deviatoric stress distributions in surrounding rock masses. The Mohr-Coulomb constitutive model was adopted for the computations, with the relevant geomechanical parameters for each stratum provided in

Table 1.

Figure 2 presents the simulation domain scaled to 245 m × 10 m × 88 m (L × W × H), geometrically constrained by field-mapped geological boundaries. The 20 m thick coal seam is replicated within this framework, with a 9.75 MPa overburden load applied vertically to the model crown, calculated from seam burial depth. A coefficient of lateral pressure of 1.2 was employed to define layer stresses. Displacement boundary conditions were applied as follows: layer displacements were constrained on the front, rear, left, and right boundaries; vertical displacement was fixed at the bottom boundary; and the top surface remained a stress boundary (free surface). Numerical simulation analyses were conducted to examine three key aspects: (1) the principal stress direction and its deflection patterns at various positions relative to the advancing working face during different excavation stages; (2) deviatoric tensor distributions and confinement loss mechanisms in same-elevation transportation roadways with parametric pillar width variation; (3) the evolutionary behavior of deviatoric stress in the surrounding rock of the track roadway under a constant coal pillar width but located at different layers within the coal seam.

3.2. Principal Stress Evolution Law of Surrounding Rock in Extra-Thick Coal Seam Roadway

To investigate the stress evolution during the systematic reduction in the pillar width from 120 m to 20 m, three-dimensional stress component data for the surrounding rock at different layers were extracted using the established 3D numerical model. The principal stress directions at each monitoring point within the main roadway of the extra-thick coal seam were derived from stress component calculations. Six strategically positioned measuring points per layer, located at distances ranging from 120 m to 20 m ahead of the advancing working face, were selected to analyze the principal stress direction variation. The reorientation magnitude of the maximum principal stress trajectory relative to a prescribed layer datum quantifies maximum principal stress (σ

1) deflection. Relative to the stratigraphic axis, clockwise rotation of the σ

1 trajectory is designated positive (“+”α), while counterclockwise deflection carries negative polarity (“−”α). The principal stress variations at these measuring points relative to the working face position, when the roadway is situated at different layers within the coal seam, are presented in

Figure 3.

Figure 4,

Figure 5,

Figure 6 and

Figure 7 demonstrate progressive abutment pressure redistribution within the ultra-thick seam’s gate road surroundings during staged longwall extraction, revealing:

(1) Significant layer-dependent variation in principal stress deflection: Analysis of the roadway layers, progressing from upper to lower, reveals a pronounced increasing trend in α. Investigation of the main roadway’s downward movement indicates that α at various measuring points within the advance abutment zone ranges from 17° to 34°. The maximum difference in α between upper and lower layers occurs at the 40 m measuring point ahead of the face. Under these conditions, the mining influence on the lower layer is more pronounced.

(2) Spatial disparity in layer angle difference: The difference in α between the upper and lower layers is the most significant, reaching a maximum of 34°. This value substantially exceeds the differences observed between the upper-middle layers and the middle-lower layers. Furthermore, the variation in α difference between the middle and lower layers is more gradual compared to that between the upper and lower layers. Consequently, special attention to surrounding rock control is warranted for the lower roadway in engineering practice. The peak difference in α occurs at the 40 m measuring point, signifying this location as the area of most significant layer effect.

(3) Attenuation of deflection angle with distance: α for each track roadway layer exhibits a decreasing trend as the distance from the measuring point to the working face increases. The attenuation magnitude is greatest for the lower roadway. The trajectory of σ1 direction evolution is characterized by the following: the deflection of the goaf side → the near layer orientation → the deflection of the solid coal side. Notably, α reverses sign (from positive “+” to negative “−”) within the 60~80 m and 100~120 m measuring point ranges. Specifically: α at the upper layer becomes negative (−11°) for the first time at the 80 m point; α at the middle layer approaches the layer axis (−1°) at the 80 m point and stabilizes as a negative deflection by 100 m; α at the lower layer maintains a weak negative value (−5°) up to the 120 m point, indicating a significant reversal lag effect.

3.3. Deflection Stress Load-Increasing Law of the Surrounding Rock of the Roadway with Variable Stoping Pillar Dimensions

Coal and rock masses undergo a complex stress evolution process under varying degrees of mining influence. As a core parameter characterizing the shear deformation energy of rock masses, the variation in deviatoric stress effectively reveals the expansion mode and failure mechanism of the plastic zone. Typically, the peak deviatoric stress area indicates a state of failure or instability. Extraction activities, especially those involving extra-thick coal seams which cause significant disturbance, redirect the principal stresses and create localized stress concentrations within the host rock surrounding main roadways. Consequently, this alters the position and configuration of the deviatoric stress peak zone (DSPZ). Consequently, investigating the formation mechanism and evolution of the peak stress area is crucial for understanding mining-induced failure. To further elucidate the evolution law and development trend of surrounding rock deformation and failure, this study employs deviatoric stress as the primary indicator. Parametric analysis of principal stress deflection across protective coal pillar widths (120 m, 100 m, 80 m, 60 m, 40 m, 20 m) quantitatively elucidates the impact mechanism of pillar dimensions on roadway host rock stress redistribution. Additionally, the evolutionary behavior of the peak value of the deviatoric stress field (PVDSF) and the plastic zone within the surrounding strata of an extra-thick seam roadway under mining-induced disturbance is examined.

As depicted in

Figure 8,

Figure 9 and

Figure 10, the deviatoric stress field evolution in the track roadway surrounding rock of the extra-thick coal seam exhibits the following patterns across different protective coal pillar widths:

(1) With continuous working face advancement, PVDSF on the mining side and non-mining side of the roadway generally exhibit asymmetric loading characteristics. With diminishing protective coal pillar dimensions, the stress on both sides of the roadway increases. The unloading effect in the goaf area combined with pillar width reduction leads to stress concentration. Where pillar dimensions meet or exceed 60 m, PVDSF on both sides change minimally. When the pillar width is ≤40 m, these peak values increase sharply. The final pillar width significantly influences PVDSF of the roadway surrounding rock. Throughout the process, the peak deviatoric stress value on the mining side consistently exceeds that on the non-mining side.

(2) DSPZ of the roadway surrounding rock demonstrates a significant asymmetric eccentric load effect. Continuous working face advancement causes this peak area to exhibit pronounced spatial offset characteristics. Initially concentrated at the “roof-mining side” and “floor-non-mining side” intersections, it gradually deflects towards the transition zone between the “roof-non-mining side” and “floor-mining side”. While the pillar width is reduced to 60 m, a clear spatial deflection of DSPZ becomes apparent. With further decreases in pillar width, this peak area progressively shifts outwards.

(3) A corresponding relationship exists between the deflection of DSPZ and the principal stress deflection in the corresponding region: σ1 trajectory progressively rotates counterclockwise from the gob-side toward the solid-coal side. Concurrently, the minimum principal stress axis consistently traverses DSPZ within the host rock surrounding the main roadway. The evolution of the roadway surrounding rock plastic zone exhibits distinct anisotropic characteristics. Spatiotemporal evolution of the plastic zone correlates directly with principal stress vector rotation, manifesting progressive offset of failure boundaries.

3.4. The Law of Deviatoric Stress Load Increases in the Surrounding Rock in Different Roadway Layers

During staged coal pillar width reduction (120–20 m), the local stress fields within different layers of the track roadway were systematically analyzed to identify key control areas for the surrounding rock stability at each layer.

As shown in

Figure 11,

Figure 12 and

Figure 13, the deviatoric stress field of the surrounding rock in different layers of roadways under the longwall-induced perturbations has the following rules:

(1) PVDSF of the surrounding rock of the roadway shows a significant increase with the downward movement of the layer. At the stopping coal pillar width ≥ 80 m, PVDSF of the main roadway is stable when the roadway layer moves down, and PVDSF of the non-mining side increases slowly. With the decrease in the width of the stop coal pillar, the layer effect gradually appears. When coal pillar dimensions fall below 60 m, PVDSF shows a significant increase in the lower position. When the dimensions of the stopping coal pillar are less than 80 m, PVDSF gradually shifts in the direction of the roadway, as analyzed through the downward movement of the layer (upper layer → middle layer → lower layer). Below the critical 60 m coal pillar width, PVDSF shows a reverse movement away from the roadway.

(2) DSPZ of the surrounding rock in different layers shows an asymmetric partial loading effect. Throughout the entire process, PVDSF on the mining side of the track roadway exceeds that on the non-mining side. DSPZ of the roadway is approximately in a “crescent-shaped” distribution pattern with an opening to the side of the roadway. When the coal pillar is stopped >80 m, DSPZ is mainly located at the junction of the roof and the mining side and the junction of the floor and the non-mining side. When the stopping coal pillar is 80 m, DSPZ is deflected to the position of the roof and floor. When the stopping coal pillar is ≤60 m, DSPZ is mainly distributed in the transition zone of “mining side-floor” and the transition zone of “non-mining side-roof”.

(3) There is also a corresponding relationship between the deflection of DSPZ of the surrounding rock of the main roadway based on the layer effect and the deflection of σ1 in the corresponding area: A coupling effect exists between σ1 rotations in DSPZ of main roadway surrounding rock: the σ1 orientation progressively rotates counterclockwise (goaf-side to non-goaf-side), while the σ3 axis persistently traverses stress concentration zones. At the same time, the contour line of the plastic zone of the surrounding rock of the main roadway passes through the core area of DSPZ, and with the deflection of the σ1, the development shape and size of the plastic zone of the surrounding rock also change.

3.5. Similar Simulation Experiment Analysis

To investigate the evolution of stress within the surrounding rock of main roadways, physical similarity model experiments were conducted. A model was designed and constructed based on the geological conditions of the working face. Comparative analysis of the deviatoric stress field evolution characteristics in main roadways at different layers revealed that the lower-layer track gateway is most significantly affected by mining-induced disturbances. Consequently, the simulation analysis focused primarily on the impact state of the surrounding rock in this lower-layer gateway.

The physical similarity simulation model was designed according to the prototype’s geological conditions and similarity theory. The established similarity ratios were: geometric ratio 1:100, unit weight ratio 1:1.14, stress ratio 1:150, time ratio 1:10, and Poisson’s ratio 1:1. The model test rig accommodated model dimensions of length × width × height = 200 cm × 15 cm × 120 cm. Based on the model apparatus size and actual field geological production conditions (

Figure 14), a physical similarity model (length × width × height = 200 cm × 15 cm × 84 cm) oriented along the strike direction of the working face was constructed. Uniform stress loading was applied to the model’s upper surface using hydraulic jacks, reflecting the actual overburden conditions and similarity scales. The similarity materials comprised sand as aggregate, lime and gypsum as binders, and mica flakes as bedding material. Layer thicknesses were calculated based on similarity constants, with the material mix proportions detailed in

Table 2. The model was incrementally built using the tamping and layering method at a scale of 1:100. Mica powder was interlaid to demarcate strata boundaries. The construction procedure was as follows: (a) Install channel steel along the front and rear sides of the model frame. Build the model layer-by-layer from bottom to top according to the design dimensions, adding an appropriate amount of mica powder between layers, followed by compaction of each layer; (b) After model construction, allow it to cure naturally for 3–15 days. Subsequently, remove the channel steel and allow the model to air-dry under natural ventilation; (c) Once the model is completely dry and set, excavation can commence. The excavation sequence simulated was the following: Track Roadway → Working Face (excavated sequentially while retaining coal pillars of varying widths).

During the experiment, the deformation state of the surrounding rock around the track gateway was closely monitored to study its failure behavior under different chain pillar widths. The similarity simulation results demonstrated that when the chain pillar width exceeded 100 cm, the surrounding rock of the gateway remained stable with no significant deformation or failure observed. However, at a pillar width of 80 cm, initial signs of deformation, primarily manifested as subsidence of the immediate roof, became apparent in the gateway surrounding rock. Further reduction to a pillar width of 60 cm induced localized large deformations within the transition zones between the “mining-side (working face side)—floor” and the “non-mining-side—roof” of the gateway surrounding rock. This phenomenon aligns with the patterns obtained from numerical simulation, and the location of large deformation exhibited a high degree of correspondence with the evolving zone of peak deviatoric stress. When the chain pillar width was reduced to ≤ 40 cm, the gateway surrounding rock experienced large deformations across the entire cross-section, characterized by a sharp increase in roof-to-floor convergence and rib-to-rib closure. Consequently, considering both economic efficiency and safety requirements, a chain pillar width of 60 m (corresponding to the 60 cm model dimension at the 1:100 geometric scale) represents a preferable choice for controlling the stability of the surrounding rock.

3.6. Evolution Mode of the DSPZ of the Roadway Surrounding Rock

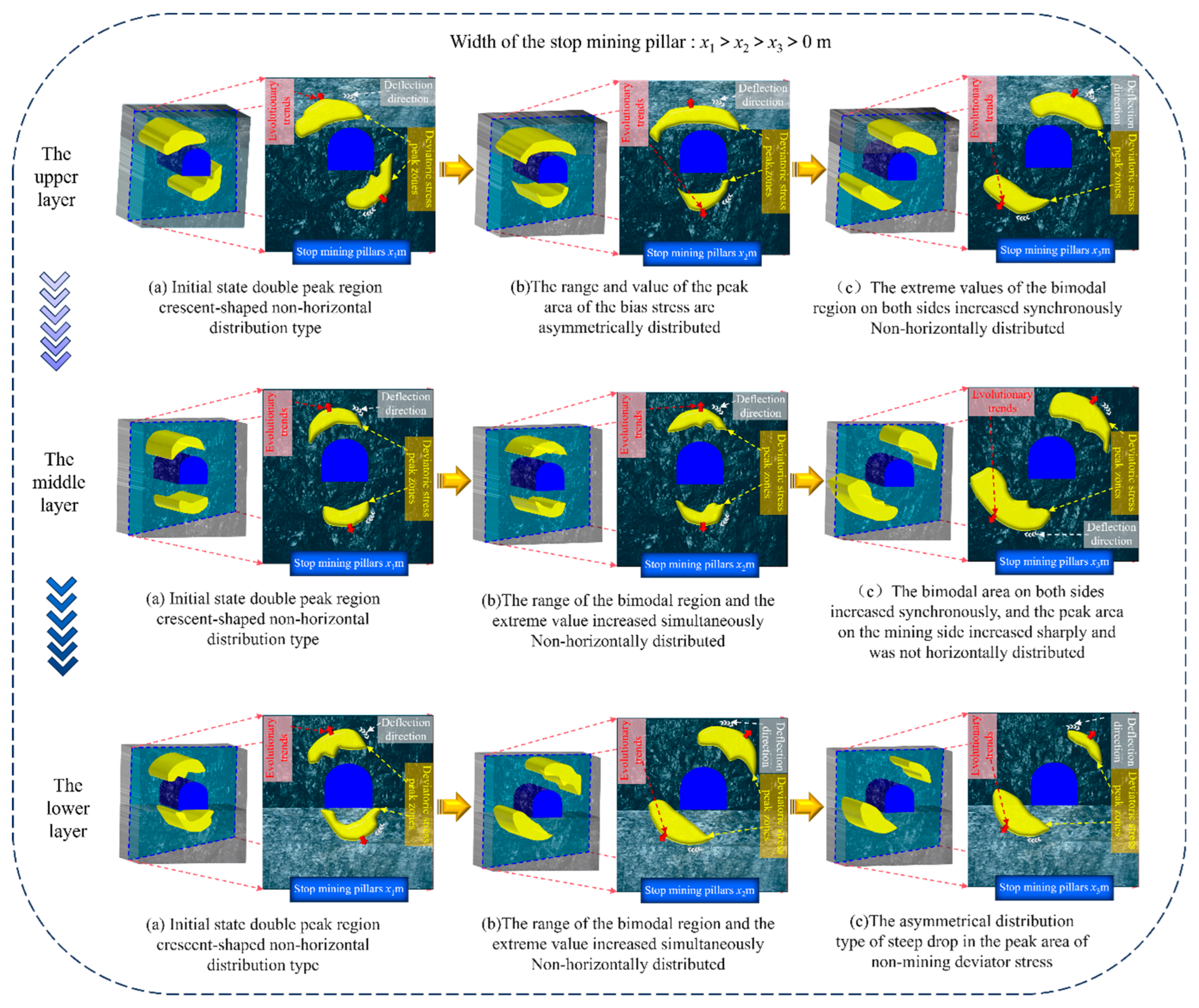

Under mining influence, the main stress field within the roadway surrounding rock undergoes varying degrees of evolution, characterized by asymmetric deflection of σ1 directions. This deflection alters the spatial morphology and evolution mode of DSPZ, which reflects the principal stress changes. Based on conditions of different stop coal pillar widths and roadway layers, the distinct evolution modes of the deviatoric stress peak area correspond to the deformation and failure behavior of the roadway surrounding rock. To achieve scientifically justified and rational control of roadway surrounding rock deformation, corresponding support schemes are determined according to the different developmental stages of DSPZ.

Due to its intrinsic complexity and the studied layer effect, the surrounding rock behavior in extra-thick coal seam roadways is more complicated than in other roadways. Consequently, guided by the evolution law of DSPZ in extra-thick coal seam roadway surrounding rock and combined with the observed σ

1 direction deflection, the evolution characteristics and modes of DSPZ within the track roadway surrounding rock (the main control area) under varying stop coal pillars and layers are obtained, as summarized in

Table 3.

It is shown in

Table 3 and

Figure 15, when the track roadway is arranged in the lower layer, the initial stress of the surrounding rock is the largest and the asymmetric partial load effect is the most significant. Therefore, the evolution model of DSPZ (the main control area of the surrounding rock) based on the width of different stopping coal pillars is proposed for the lower track roadway.

Under the influence of longwall-induced perturbations, the dynamic evolution law of DSPZ of the surrounding rock of the lower track roadway is: (a) When the stop coal pillar is x1 m, PVDSF on both sides of the track roadway is significantly different. The concentration of deviatoric stress on the lower side of the roadway is higher than that on the upper side, and DSPZ forms an asymmetric pattern. The spatial position of the two DSPZ is layer and asymmetric, and the upper DSPZ from the layer axisymmetric spatial position of the ideal lower DSPZ. At the same time, the two DSPZ show a tendency to develop in the direction of the crescent-like outer arc and deflect clockwise, forming the evolution form of “crescent-like layer asymmetry”; (b) When the stop coal pillar is x2 m, the concentration degree of deviatoric stress on both sides of the track roadway tends to be balanced, and DSPZ presents a quasi-symmetrical distribution, but the two DSPZ deviate from the ideal layer axisymmetric position, and both develop and expand along the crescent-like outer arc direction, accompanied by synchronous clockwise rotation, forming a “crescent-like non-layer symmetry” stress field distribution mode; (c) When the stop coal pillar is x3 m, DSPZ in the surrounding rock of the main roadway shows significant asymmetric characteristics-the peak stress on the non-mining side is attenuated. At the same time, the two DSPZ inherit the evolution law of the development of the outer arc direction and the clockwise rotation. However, due to the unilateral stress concentration strengthening effect, the “crescent-shaped unilateral deviatoric stress attenuation asymmetric” evolution form with asymmetric characteristics is finally formed.

According to the above analysis and research, the evolution mode of DSPZ of surrounding rock in the lower track roadway is as follows: Initial state double peak region crescent-shaped non-layer distribution type → The range of the bimodal region and the extreme value increased simultaneously Non-layer distributed → The bimodal area on both sides increased synchronously, and the peak area on the mining side increased sharply and was not layer distributed. Through the above rules, it can be concluded that DSPZ of the surrounding rock in the lower track roadway is located at the junction of the floor-mining side and the roof-non-mining side. In engineering practice, key support should be carried out in this area.

4. Surrounding Rock Control and Roadway Support

4.1. Support Scheme of Lower Track Roadway in Extra-Thick Coal Seam

During coal seam extraction, the reduction in stop coal pillar width within the track roadway induces changes in both the direction and magnitude of the principal stresses within the surrounding rock. Under mining influence, a critical zone of stress and localized stress enhancement emerges in the track roadway surrounding rock. This zone of stress deflection and localized enhancement corresponds to DSPZ and represents the precursor zone and dominant region for surrounding rock failure or progressive failure development. Accordingly, an asymmetric directional synergistic anchoring control technology was proposed to address the deviatoric stress concentration and directional deflection in the surrounding rock of the main roadway. Based on the evolution of stress direction deflection and deviatoric stress enhancement zones, the combined control technology of “anchor cable foundation support + concrete floor + asymmetric reinforcing anchor cable support” is implemented. As shown in

Figure 16, directional high-prestressed reinforcing anchor cable technology is employed to achieve synergistic anchoring with the original support scheme, ensuring the stability of the main roadway.

(1) Surrounding rock support parameters of the track roadway

The foundation support for the main track roadway utilizes “basic anchor cable + concrete floor”. Roof and rib bolts are Φ20 mm × 3100 mm left-handed non-longitudinal reinforcement spiral bolts, spaced at 800 mm × 900 mm. The downward and layer installation angles for the two bolts at the bottom of the mining side and non-mining side ribs are both 15°. The angles between the semi-circular arch roof bolts and the layer direction are 10°, 30°, and 60°, respectively. Anchor cables are Φ21.8 mm × 6500 mm, with a row spacing of 1600 mm × 2700 mm. The angle between the semi-circular arch anchor cables and the layer direction is 30°. Bolt plates measure 300 mm × 300 mm × 16 mm. The floor employs a C30 strength concrete layer with a thickness of 300 mm.

Guided by the evolution law of deviatoric stress in extra-thick coal seam roadway surrounding rock, directional high-prestress reinforcement anchorage is applied to the peak deviatoric stress area when the stop coal pillar width is 60 m. This area is located at the junction of the roof-non-mining side and the floor-mining side (see

Figure 16). Reinforcing anchor cables are added at three locations: the right side of the semi-circular arch roof, the floor at the bottom of the mining-side rib, and the floor 300 mm away from the mining-side rib. The reinforcing anchor cable specification for the right roof of the semi-circular arch is Φ21.8 mm × 6500 mm, installed at a 30° angle to the layer. The specification for the floor reinforcing anchor cables at the bottom of the mining side and 300 mm away is Φ21.8 mm × 4300 mm. The downward and layer installation angle for the reinforcing anchor cable at the bottom of the mining side is 15°. The row spacing of all reinforcing anchor cables matches that of the foundation support.

(2) Coordinated control principle of the surrounding rock in the track roadway of the extra-thick coal seam

① The roof, mining side and floor of the track roadway adopt the arrangement mode of reinforcing long bolt directional crossing the peak area of deviatoric stress (i.e., “One Directional Penetration”), and the long-span long anchor cable is arranged along the roof, mining side and floor of the roadway to ensure that the anchoring trajectory of the reinforcing anchor cable passes through DSPZ. Reinforcement cables impart high-preload anchoring and enhanced shear resistance, elevating load transfer efficiency within the Deviatoric Stress Peak Zone (DSPZ). This system integrates shallow fractured strata with competent deep rock masses, forming a composite structure that enhances global load-bearing integrity in roadway peripheries.

② The synergistic control of anchor cable foundation support system, concrete floor structure and reinforcing anchor cable group (i.e., “Three Synergies”): the initial design of track roadway provides basic support for anchor cable, forming a strength strengthening zone of surrounding rock; pouring 300 mm concrete floor can effectively inhibit the plastic deformation of surrounding rock. The roof, mining side, and floor of the main roadway are supplemented with long anchor cables to further improve the bearing capacity of the surrounding rock of the main roadway. Based on this collaborative support system, the stability of the surrounding rock of the main roadway is improved.

4.2. Field Monitoring

To comprehensively evaluate the performance of the support structure under the proposed design and accurately determine the control effectiveness of surrounding rock with targeted reinforcement, displacement monitoring stations were established following roadway enlargement. As illustrated in

Figure 17, after mining activities commenced, the convergence of the roof-to-floor and rib-to-rib in the track gateway increased rapidly. This rapid convergence subsided when the protective coal pillar width reached 90 m, defining the rapid convergence zone of the track gateway. As mining advanced and the protective coal pillar width was ultimately reduced to 60 m, the roof-to-floor and rib-to-rib convergence gradually stabilized. This phase represents the gradual stabilization zone of the track gateway convergence. Monitoring results of the track gateway displacement revealed a maximum floor heave of 52 mm, roof displacement of 31 mm, and rib displacement of 66 mm. Crucially, no failure occurred within the bolt-cable support system. The roadway achieved complete stability 50 days after mining cessation. These findings demonstrate that the proposed support design exhibits favorable applicability and effectiveness in controlling surrounding rock deformation, adequately fulfilling the ground control requirements.

5. Conclusions

(1) Under mining-induced disturbances, the stress field in the surrounding rock of main roadways within ultra-thick coal seams exhibits significant stratum position dependency. Comparative analysis identifies the lower stratum position as the primary load-bearing stratum controlling surrounding rock stability. Based on a comprehensive assessment of the surrounding rock stress response characteristics—specifically, the deflection and reduction in principle stress vectors and the asymmetric concentration and increase in peak deviatoric stress—the optimal stopping coal pillar width for these geological conditions is determined to be 60 m.

(2) The evolution trend of the principal stress vector orientation in the surrounding rock of roadways at different stratum positions is consistent. The trajectory of the maximum principal stress direction deflection exhibits a progressive evolution characterized by the following: deflection towards the goaf side → near-layer orientation → deflection towards the solid coal side. This result aligns with established mechanisms of principal stress deflection in heterogeneous stress fields, verifying the generalized pattern of stress redistribution induced by mining activities.

(3) DSPZ within the main roadway surrounding rock demonstrate distinct asymmetric loading intensification and spatial migration. These zones progressively shift in orientation: initially located at the junctions of the roof-mining side and floor-non-mining side, they migrate towards the roof-non-mining side and floor-mining side. Furthermore, as the stopping coal pillar width decreases, these high-stress zones gradually migrate outwards, elucidating the dynamic evolution of precursor zones to surrounding rock failure during the mining process.

(4) DSPZ in the surrounding rock of roadways across all stratum positions exhibit a “three-stage” evolutionary pattern. Specifically, the evolution of DSPZ in the surrounding rock of the lower roadway under partial loading mode is as follows: initial state featuring a crescent-shaped, non-layer bimodal distribution → concurrent increase in both the range and peak values of the bimodal region, maintaining a non-layer distribution → transition to an asymmetrical distribution type characterized by a steep drop in the peak deviatoric stress on the non-mining side, This result deepens the comprehension of the phased evolution of deviatoric stress and shows robust agreement with the J2 failure criterion.

(5) Based on the asymmetric evolution law of the deviatoric stress field and the expansion mechanism of the plastic zone, this paper proposes an asymmetric directional synergistic anchoring technique targeting the localized intensification and deflection of the deviatoric stress field in the surrounding rock of the main roadway. Based on the evolution of stress direction deflection and the areas of intensified deviatoric stress in the surrounding rock, a combined control technology was designed, incorporating “anchor cable foundation support + concrete floor + asymmetric reinforcing anchor cable support”. This approach forms the “One Directional Penetration and Three Synergies” control methodology for the surrounding rock stability of track roadways in ultra-thick coal seams.