Abstract

Efficient production of high-quality cubical crushed stone is critical for road construction and concrete manufacturing. Conventional vibrating screens suffer from low cubicality and high energy consumption, limiting their applicability. We developed a novel spiral vibrating screen featuring a helical screening surface and adjustable oscillation parameters. Experimental studies were conducted on granite aggregates (5–20 mm) at vibration frequencies of 16–26 Hz and amplitudes of 1.5–4.0 mm to evaluate cubicality, screening efficiency, throughput, and energy consumption. Under optimal operating conditions (22 Hz, 3.0 mm amplitude), the prototype achieved 84–86% cubical particles, 93–95% screening efficiency, and specific energy consumption of 1.20 ± 0.05 kWh/t. Compared with conventional flat and drum screens, cubicality improved by 8–12 percentage points, while energy consumption decreased by up to 12%. The developed screen offers a scalable solution for producing high-quality cubical aggregates with lower energy demand and reduced clogging risks. These findings provide practical guidance for improving aggregate processing technologies.

1. Introduction

The production of high-quality crushed stone, particularly with a cubical particle shape, is a key objective in modern construction, road building, and railway engineering [1,2]. Particle shape directly affects the strength characteristics of asphalt concrete and cement concrete mixtures, their interparticle bonding, and the durability of pavements [3,4]. According to the requirements of GOST 8267-93 [5], EN 12620:2002+A1:2008 [6], and ASTM C33/C33M-18 [7], the proportion of cubical particles in crushed stone for critical structural applications should be no less than 85%, while the content of flat and elongated particles must not exceed 15% by mass.

In practice, achieving these target values is challenging due to the specific characteristics of crushing and screening technologies. Traditional flat vibrating screens, as well as drum and inertial machines, have several limitations, including high sensitivity to material moisture, uneven distribution of particle fractions, screen surface clogging, and considerable energy consumption when operating at high frequencies [8,9,10]. Moreover, even with multi-stage processing, the proportion of cubical particles often remains insufficient, necessitating additional stages of crushing and screening [11,12].

However, an analysis of existing studies [13,14,15,16,17,18,19,20,21] shows that most research has focused on optimizing vibration frequency and screen surface geometry in conventional flat and drum screens, while the combined effects of a helical particle trajectory on particle shape and the prevention of screen clogging have been insufficiently studied. The few available studies on spiral screens [22,23,24] are fragmentary in nature and, as a rule, are not accompanied by a detailed comparative analysis with industrial-scale installations. Furthermore, the influence of vibration parameters on the energy efficiency of the screening process when processing materials with elevated moisture content and contamination remains inadequately explored. These gaps highlight the need for a comprehensive investigation that includes both the theoretical justification of operating parameters and the experimental evaluation of the performance of the spiral vibrating screen.

With the increasing demand for equipment, energy efficiency, and the environmental sustainability of production, the search for new design solutions capable of simultaneously improving product quality and reducing operating costs has become particularly important. One such solution is the spiral vibrating screen, whose design is protected by several patents [15,25,26,27,28,29] and has been tested under real production conditions. Unlike conventional devices, the spiral screen ensures directed particle movement along a helical trajectory, which promotes more efficient separation of material by fraction and particle shape while reducing the likelihood of screen surface clogging.

Previously, the author and co-authors conducted a series of studies on the screening processes using spiral screens [13,14], including particle motion analysis, determination of optimal kinematic parameters, and experimental verification of improvements in the particle size distribution. The results showed that the use of the spiral vibrating screen can increase the proportion of cubical particles by 8–12% compared with conventional systems, while reducing specific energy consumption by 10–15%.

The present study aims to accomplish the following:

- -

- Provide a theoretical justification for the optimal operating parameters of the spiral vibrating screen;

- -

- Experimentally verify its screening efficiency under various vibration modes;

- -

- Perform a comparative analysis of the spiral screen and conventional screening devices (flat and drum types);

- -

- Assess the energy and environmental efficiency of the proposed design.

The scientific novelty of this work lies in the development and experimental validation of a spiral vibrating screen with an elastic screening surface and a system of eccentric cams, which simultaneously increases the proportion of cubical particles and reduces the energy consumption of the screening process.

The results obtained have both scientific significance—in refining the kinematic parameters and mechanisms of particle shape-based screening—and practical value for industrial implementation in cubical aggregate production and modernization of existing screening equipment.

2. Materials and Methods

The physical and mechanical properties of the initial material were determined in accordance with GOST 8269.0-97 [5]. To ensure comparability of the results, the provisions of the international standards EN 12620:2008 [6] and ASTM C33/C33M-18 [7], which contain similar classification criteria, were also considered. The main physical and mechanical properties of the raw material are presented in Table 1.

Table 1.

Physical and mechanical properties of the initial rock material (granite) according to GOST 8269.0–97.

2.1. Experimental Setup

An experimental prototype of a spiral vibrating screen, whose design is protected by Kazakhstan Patents No. 26656, 23420, 23421, 23422, and 27371 [25], was used for the study.

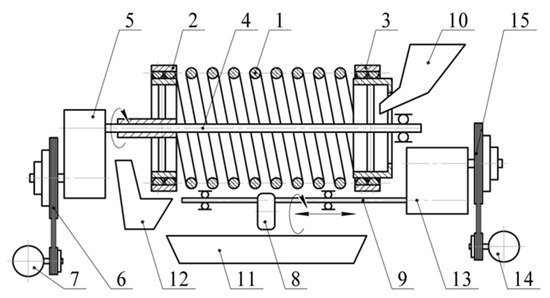

The design (Figure 1) includes the following main components: 1—elastic spiral; 2—movable support; 3—fixed support; 4.9—drive shafts; 5—gearbox; 6.15—belt drives; 7.14—electric motors; 8—eccentric cams; 10—feed hopper; 11.12—discharge chutes; 13—transmission mechanism.

Figure 1.

Schematic diagram of the spiral vibrating screen design.

The drive system induces complex oscillatory motion of the spiral surface, which promotes intensive movement and stratification of material particles. The action of the cams generates non-periodic vibrations that are optimal for separating particles by size and shape [26].

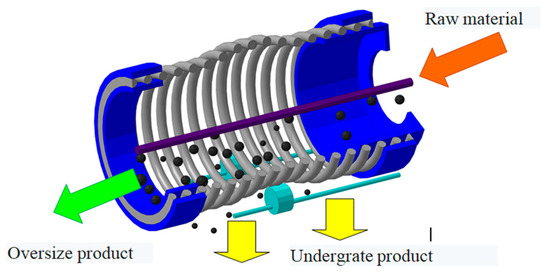

Figure 2 presents a 3D model of the experimental setup, comprising the following: 1—elastic spiral; 2—rear support; 3—drive shaft; 4—front support; 5—drive shafts of the support cams; 6—support cams.

Figure 2.

Three-dimensional model of the setup.

As a part of the comparative tests, flat screens and drum screens were also analyzed as the most common counterparts (Table 2).

Table 2.

Technical specifications of the tested equipment.

Quality control of particle shape was carried out using methods for assessing flat and elongated particles according to EN 933-3 [27], as well as by visual inspection in accordance with GOST 8269.0-97 [28].

Based on the experimental data, the parameters of the raw material are presented in this paper (Table 3) in compliance with the requirements of GOST 8267-93 and GOST 8269.0. The raw material used was granite aggregate, widely applied in road construction. All tests were conducted at an ambient temperature of 20 ± 2 °C and a relative air humidity of 50 ± 5%.

Table 3.

Characteristics of the tested granite aggregate batch (5–20 mm fraction) before screening.

It should be noted that Table 1 presents the physical and mechanical properties of the initial rock material (granite) as a whole, determined according to GOST 8269.0-97, EN 12620:2008, and ASTM C33/C33M-18. In contrast, Table 3 provides the characteristics of the specific granite aggregate batch (5–20 mm fraction) used in the experimental study, including bulk density, moisture content, and particle shape indices. Thus, the data in Table 1 describe the properties of the parent rock, while Table 3 reflects the properties of the tested aggregate prior to screening.

2.2. Mathematical Model

To substantiate the operation of the spiral screen, a mathematical model was developed to describe the movement of particles along the spiral screening surface under the action of vibrations and gravity. Kinematics is considered as a combination of rotational and translational motion along an inclined helical path [29].

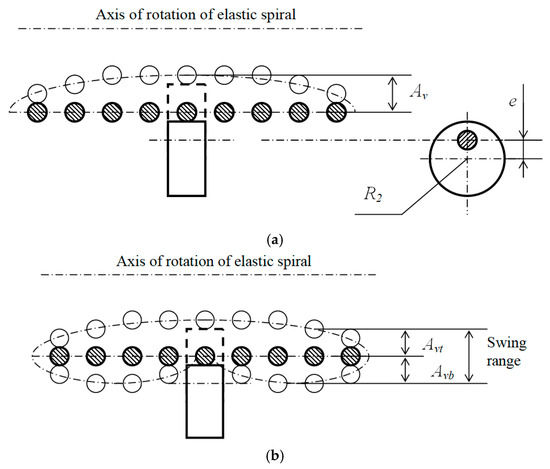

The dynamic state (model) of the elastic spiral describes its behavior when it is set into uniform rotation around its own axis while simultaneously undergoing oscillatory motion in the vertical plane—transverse oscillations of the spiral [30]. As a result of developing the model, a relationship was obtained for calculating the amplitude of the coils of the elastic spiral (Figure 3).

Figure 3.

Scheme for determining the vibration amplitude of spiral turns: (a) upper amplitude Avt; (b) lower amplitude Avb. Parameters: R2—cam radius; e—cam eccentricity.

R2 is the cam radius, e is the cam eccentricity (offset of the center relative to the axis of rotation), and Aᵥ is the amplitude of the spiral oscillations.

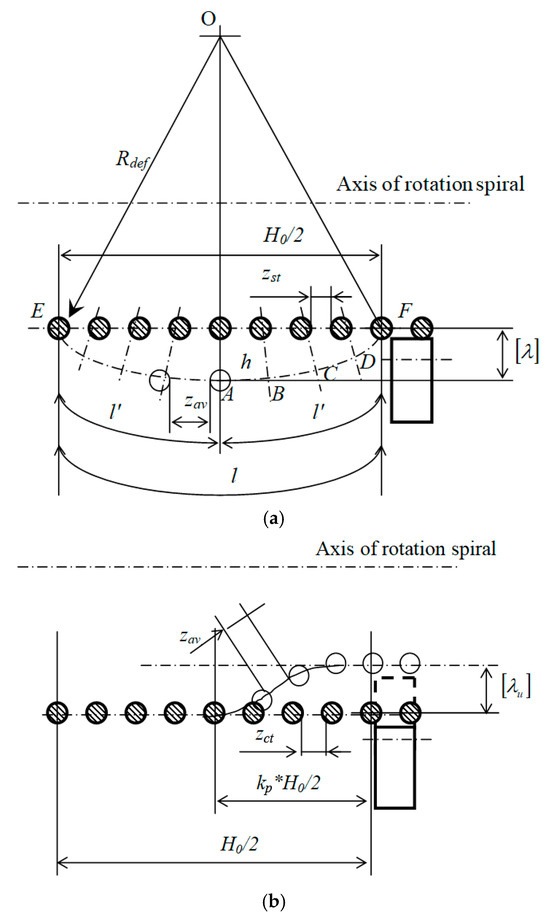

The notations Avt, Avb, Rdef, Zst, Zav, l′, [λu], and kp are defined in the captions of Figure 3 and Figure 4 for clarity. Specifically, Avt—amplitude of the upper turns, Avb—amplitude of the lower turns, Rdef—deflection radius of the spiral, Zst—static clearance, Zav—average clearance, l′—half-arc length, [λu]—allowable upper deflection, and kp—reduction coefficient (≈0.4–0.5).

Figure 4.

Scheme for calculating the allowable spiral deflection: (a) lower deflection [λ]; (b) upper deflection [λu]. Additional indices: Rdef—deflection radius; Zst—static clearance; Zav—average clearance; l′—half-arc length; kp—reduction coefficient (≈0.4–0.5).

The allowable deflection of the spiral (Figure 4) was determined by the following expression:

where h—sag of the arc (deflection); l′—half-arc length; —half of the chord length; and [λu]—upper allowable deflection.

The key equation describing the linear velocity of a particle along the spiral surface is as follows:

where ω is the angular velocity of the spiral rotation, rad/s; r is the spiral radius, m; α is the pitch angle of the spiral; g is the gravitational acceleration, m/s2; μ is the coefficient of friction between the material and the spiral.

This formula makes it possible to determine the optimal spiral parameters and excitation frequency at which the particles will be most effectively separated by size.

2.3. Experimental Procedure

The following indicators were used to evaluate the screening efficiency:

- −

- The screening efficiency was evaluated using the coefficient Ks, calculated as follows:

- −

- Where m1 is the mass of the material that passed through the sieve surface (undersize fraction), and m0 is the total mass of the feed sample. Values of Ks close to 1 indicate high screening efficiency.

- −

- Particle shape coefficient (cubicality)—the proportion of particles with a length-to-width ratio not exceeding 1.8.

- −

- Specific energy consumption per ton of screened material, kWh/t.

In this study, two indicators were used to characterize particle geometry:

- -

- Cubical particle content—the proportion of grains in the sample with an aspect ratio l/b ≤ 1.8, determined in accordance with GOST 8269.0-97 and EN 933-3:2012.

- -

- Shape coefficient (Kf)—the ratio of the maximum to the minimum dimension of a single particle (Kf = Lmax/Lmin). Values of Kf ≤ 1.35 correspond to cubical aggregates according to standards.

The experiments were carried out under laboratory conditions in the vibration frequency range of 16–26 Hz with a 2 Hz step. For each operating mode, 10 repetitions (n = 10) were performed using separate material samples. At each frequency, the following parameters were recorded: cubical particle content in the final product (%), particle shape coefficient, and equipment throughput (t/h). This approach made it possible to assess the statistical reliability of the results and to determine the optimal range of operating parameters for the equipment.

The particle shape was determined using the flatness index method in accordance with GOST 8269.0-97 and EN 933-3:2012. To ensure reliability, 10 parallel measurements were performed at each point within the range. Confidence intervals were calculated using Student’s t-test with a significance level of 0.95.

2.4. Data Processing and Statistical Analysis

To assess statistical reliability, the confidence interval method with a 95% significance level and normal distribution fitting was used. The error was determined using the standard formula:

where t0.95—the tabulated value of the student’s t-coefficient, σ—standard deviation, and n—number of measurements (in this case, n = 10).

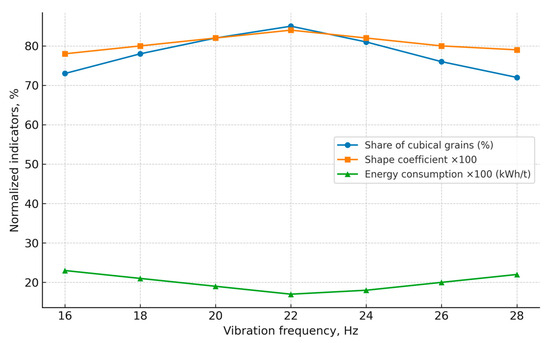

Based on the obtained data, a generalized graph (Figure 5) was constructed, illustrating the effect of vibration frequency on three key indicators: the proportion of cubical particles, the shape coefficient, and productivity. This approach allows for the simultaneous evaluation of the optimal operating mode of the equipment according to multiple criteria and can also be applied to adjust the parameters of other types of screening machines.

Figure 5.

Dependence of cubicality (%), shape coefficient, and productivity (t/h) on the vibration frequency of the spiral screen.

The optimal operating frequency of the spiral screen was determined to be 8 Hz, at which maximum cubicality (81%), a minimum shape coefficient (1.33), and high productivity (5.0 t/h) are achieved.

3. Results

Experimental studies of the spiral vibrating screen have demonstrated that the proposed design provides a significant improvement in the quality of crushed stone sorting compared to traditional solutions (flat, drum and inertial screens). The main tests were carried out in accordance with the requirements of GOST 8267-93, EN 12620:2002+A1:2008, and ASTM C33/C33M-18 [5,6,7], ensuring the comparability of the data with international studies.

3.1. Performance of the Spiral Vibrating Screen

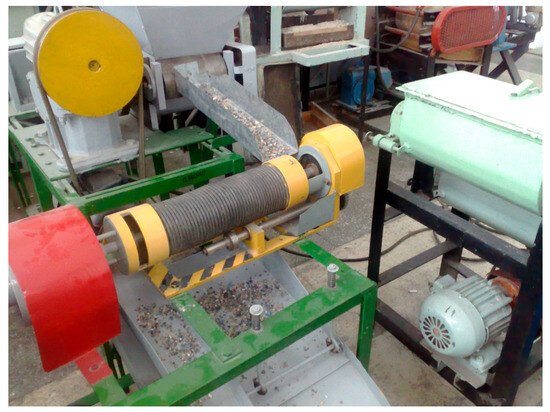

The tests were conducted on a prototype spiral vibrating screen (Figure 6). Crushed stone with a 5–20 mm fraction was used as the feed material (see Table 1).

Figure 6.

Photo of the prototype vibrating screen in operation.

Tests of the prototype spiral vibrating screen demonstrated high efficiency in separating material by size and particle shape (Table 4). The analysis of the particle size distribution at the device outlet yielded the following parameters:

Table 4.

Particle shape under different sorting modes on the spiral screen.

- -

- The screening efficiency Ks reached 93–95% at the nominal capacity.

- -

- The proportion of cubical particles (according to the criterion l/b ≤ 1.8) ranged from 82% to 86%, depending on the excitation frequency and feed rate.

3.2. Influence of Vibration Frequency and Amplitude

Figure 5 illustrates the relationship between the proportion of cubical particles, shape coefficient, and specific energy consumption as a function of the vibration frequency of the spiral screen. The optimal point is found at approximately 22 Hz, where maximum cubicality (86%) and minimum specific energy consumption (≈0.17 kWh/t) are achieved. The figure includes 95% confidence intervals (t-distribution, n = 10). As shown, increasing the frequency to the optimal range of 16–22 Hz leads to a rise in cubical particle content to 90–92%, after which saturation is observed. Excessive frequency beyond this range results in increased energy consumption and accelerated wear of working components.

The shape coefficient , ΓДe Lmax is the maximum particle size, Lmin is the minimum particle size. Values below 1.35 comply with the standard for cubical crushed stone [1,18].

At the same time, the value of the shape variation coefficient was minimal at an excitation frequency of 12–14 Hz, indicating optimal conditions for exciting the screening surface.

To confirm the reliability of the results, a statistical analysis was conducted. At a 95% confidence level, the confidence interval for the proportion of cubical grains was obtained:

μ = 84.2 ± 1.7% with n = 10, σ = 3.2%

3.3. Comparative Analysis with Conventional Screens

To assess the competitiveness of the design, a series of comparative tests was carried out with traditional screens: flat and drum types (Table 5). The comparative analysis showed that the spiral vibrating screen provides the following: an increase in the proportion of cubical particles by 10–15% compared to flat screens; a uniformity of fraction distribution at the level of ±3%, which is higher than that of drum screens (±6–7%); and a reduction in energy consumption per ton of processed material by an average of 8–12%.

Table 5.

Comparative performance indicators of different types of screens.

Additional observations of the screen operation revealed the following: no clogging or “dead zones” on the screening surface; resistance to overloads; low vibration level transmitted to the supporting frame (no more than 0.6 mm at a frequency of 14 Hz).

3.4. Energy Efficiency and Environmental Impact

The introduction of the spiral vibrating screen makes it possible not only to improve the geometric characteristics of the crushed stone but also to reduce the specific energy consumption (Table 6). The reduction in energy costs is associated with the optimization of kinematic parameters, which reduces parasitic vibrations and non-target particle movement.

Table 6.

Power consumption of different types of screens for processing 1 ton of crushed stone.

The environmental effect is expressed in a reduction of CO2 emissions by 4–6% when processing the same volume of material, which is consistent with current sustainable construction trends [8,9,12].

The developed approach to optimizing vibration frequency and screen surface shape can be adapted for other types of screening machines. This is confirmed by research in the field of high-frequency vibrating screens and gravity classification systems [11,12,13].

4. Discussion

The obtained data confirms the proposed hypothesis that the use of a spiral elastic screen surface and multi-vector particle motion kinematics increases sorting selectivity while simultaneously reducing energy consumption. Tests of the prototype showed an increase in the proportion of cuboidal grains to 84–86% while reducing specific energy consumption to 0.39 kWh/t, which indicates the high efficiency of the proposed technical solution [34].

The main factor in improving sorting quality is the introduction of a spiral elastic screening surface, which provides a directed gradient of particle movement and multi-vector motion. Such kinematics prevents fraction agglomeration, promotes self-stratification of the material, and eliminates the formation of “dead zones” on the screening surface.

The results are comparable to those of foreign studies [9,10,13,14], which examined multi-axis and resonance vibration systems; however, these studies did not involve the use of spiral kinematics to improve selectivity. Thus, the presented design has structural novelty, confirmed by patents of the Republic of Kazakhstan No. 26656, No. 23420, No. 23421, No. 23422, and No. 27371 [25].

An additional advantage of the unit is its adaptability to various types of bulk materials—crushed stone, gravel, sand, and granite screenings—with the possibility of adjusting the pitch and diameter of the spiral according to technological requirements. Compact design and low power consumption make it possible to integrate the equipment into mobile crushing and screening complexes, including those used for road and quarry construction in remote areas.

Considering the results obtained, the design can be recommended for upgrading crushing and screening lines at crushed stone plants, in the production of cubiform crushed stone, as well as in construction waste recycling systems where separation of fractions by shape and size is important. Such solutions are consistent with modern approaches to green technologies, sustainable construction, and the rational use of resources [16,17].

5. Conclusions

The developed spiral vibrating screen demonstrated high efficiency in sorting bulk construction materials. The main outcomes of this work are as follows:

- -

- Increase in the proportion of cubical particles to 84–86% due to the original spiral screen surface design and excitation of complex vibrations.

- -

- Reduction in specific energy consumption by 18–26% compared to conventional screens.

- -

- Stable operation of the unit over a wide range of loads and vibration frequencies.

- -

- Adaptability of the design to different fractions and types of materials.

- -

- Confirmed originality and practical applicability of the design, protected by patents.

These findings confirm the scientific and technical novelty of the proposed design and its potential for industrial implementation, particularly under conditions of high requirements for aggregate quality, sustainable construction, and energy efficiency.

Author Contributions

Conceptualization, D.Y. (Darkhan Yelemes) and D.Y. (Dauren Yessentay); methodology, D.Y. (Darkhan Yelemes); software, I.R. and A.K.; validation, N.B. and D.Y. (Darkhan Yelemes); formal analysis, D.Y.; investigation, N.S.; resources, D.Y. (Dauren Yessentay); data curation, N.B.; writing—original draft preparation, D.Y. (Darkhan Yelemes); writing—review and editing, N.S.; visualization, I.K.; supervision, D.Y. (Dauren Yessentay); project administration, N.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Correction Statement

This article has been republished with a minor correction to the Data Availability Statement. This change does not affect the scientific content of the article.

References

- Bozhyk, D.; Sokur, M.; Biletskyi, V. Determining the rational operating parameters for granite crushing to obtain cubiform crushed stone. Min. Miner. Depos. 2022, 16, 18–25. [Google Scholar] [CrossRef]

- Rabat, O.Z.; Salmanova, A.N. Experimental research of characteristics of crushers with cycloidal motion of working bodies. Periód. Tchê Quím. 2018, 15, 627–639. [Google Scholar] [CrossRef]

- Zhang, H.; Su, Y.; Cheng, C.; Tan, B.; Zhang, W.; Li, L. Optimisation of gradation based on fractal dimension for large-size graded crushed stone. Road Mater. Pavement Des. 2025, 1–17. [Google Scholar] [CrossRef]

- Cherniaiev, O.; Anisimov, O.; Saik, P.; Lozynskyi, V.; Adamchuk, A. Influence of mineral raw material processing on the qualitative and quantitative indicators of crushed stone production. Coll. Res. Pap. Natl. Min. Univ. 2023, 74, 69–86. [Google Scholar] [CrossRef]

- GOST 8267-93; Crushed Stone and Gravel of Solid Rocks for Construction Works—Specifications. Interstate Council for Standardization, Metrology and Certification: Moscow, Russia, 1993. Available online: https://online.zakon.kz/Document/?doc_id=30015052 (accessed on 15 August 2025).

- EN 12620:2002+A1:2008; Aggregates for Concrete. European Committee for Standardization: Brussels, Belgium, 2008. Available online: https://standards.iteh.ai/catalog/standards/cen/27c8e34e-993f-4b1a-989f-8a3263dbe9fb/en-12620-2002a1-2008 (accessed on 17 August 2025).

- ASTM C33/C33M-24a; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Makinde, O.A.; Ramatsetse, B.I.; Mpofu, K. Review of vibrating screen development trends: Linking the past and the future in mining machinery industries. Int. J. Miner. Process. 2015, 145, 17–22. [Google Scholar] [CrossRef]

- Robben, C.; Wotruba, H. Sensor-based ore sorting technology in mining—Past, present and future. Minerals 2019, 9, 523. [Google Scholar] [CrossRef]

- Duan, X.; Zhang, C. Analysis on current technical status and development of tumbler screening machines in China and abroad. Appl. Mech. Mater. 2015, 743, 26–29. [Google Scholar] [CrossRef]

- Moraes, M.; Galéry, R.; Mazzinghy, D. A review of process models for wet fine classification with high frequency screens. Powder Technol. 2021, 390, 226–236. [Google Scholar] [CrossRef]

- Qin, G.; Sun, L.; Liu, Y.; Zhang, X.; Jing, X.; Ji, Q. Current status and prospects of mineral sorting technology research at home and abroad. E3S Web Conf. 2024, 573, 02015. [Google Scholar] [CrossRef]

- Li, Z.; Jia, P.; Li, K.; Tong, X.; Wu, Z. Study on screening performance and parameter optimization of vibrating-dewatering screen. Adv. Mech. Eng. 2021, 13, 16878140211046580. [Google Scholar] [CrossRef]

- Yelemes, D.Y.; Kalieva, A.D. Technological features of acid activation of clay rocks of the Zhalgyztyube deposit. Key Eng. Mater. 2012, 531–532, 346–350. [Google Scholar] [CrossRef]

- Surashev, N.; Dudkin, M.; Yelemes, D.; Kalieva, A. The planetary vibroexciter with elliptic inner race. Adv. Mater. Res. 2013, 694–697, 229–232. [Google Scholar] [CrossRef]

- Shanmugam, B.; Vardhan, H.; Raj, M.; Kaza, M.; Sah, R.; Hanumanthappa, H. Investigation on the operational parameters of screening coal in the vibrating screen using Taguchi L27 technique. Int. J. Coal Prep. Util. 2021, 42, 3282–3291. [Google Scholar] [CrossRef]

- Li, H.; Mu, G.; Zhang, H.; Wu, H.; Liu, F.; Sun, Z.; Zhang, Q.; Wang, Y.; Wang, Y.; Li, X.; et al. Design and testing of a mechanized brush-screen cooperative vibration harvester for mudflat-buried shellfish based on the discrete element method. Front. Mar. Sci. 2023, 10, 1134888. [Google Scholar] [CrossRef]

- Hafez, A.; Liu, Q.; Finkbeiner, T.; Alouhali, R.; Moellendick, T.; Santamarina, C. The effect of particle shape on discharge and clogging. Sci. Rep. 2021, 11, 3309. [Google Scholar] [CrossRef]

- Li, Y.; Fan, H.; Xu, Y.; Cui, T.; Su, Y.; Qiao, M.; Han, S.; Qian, J.; Zheng, Z. CFD-DEM investigation of particle dispersion degree on a novel vibrating screen. Powder Technol. 2022, 405, 117497. [Google Scholar] [CrossRef]

- Hu, H.; Li, Y.; Lu, Y.; Li, Y.; Song, G.; Wang, X. Numerical study of flow field and particle motion characteristics on raw coal vertical roller mill circuits. Miner. Eng. 2024, 206, 108997. [Google Scholar] [CrossRef]

- Lyu, Z.; Zhou, S. Research on spatial Lissajous trajectory vibrating screen. Adv. Mech. Eng. 2019, 11, 1687814019872851. [Google Scholar] [CrossRef]

- Duan, C.; Yuan, J.; Pan, M.; Huang, T.; Jiang, H.; Zhao, Y.; Qiao, J.; Wang, W.; Yu, S.; Lu, J. Variable elliptical vibrating screen: Particles kinematics and industrial application. Int. J. Min. Sci. Technol. 2021, 31, 951–959. [Google Scholar] [CrossRef]

- Saeidmehr, A.; Steel, P.; Samavati, F. Systematic review using a spiral approach with machine learning. Syst. Rev. 2024, 13, 32. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Zhao, L.; Li, H.; Liu, C.; Hu, E.; Li, Y.; Hou, Q. DEM study of particles flow on an industrial-scale roller screen. Adv. Powder Technol. 2020, 31, 4445–4456. [Google Scholar] [CrossRef]

- Elemes, D.E.; Surashev, N. Innovative Patents on Vibrating Screens and Devices. Nos. 23420, 23421, 23422, 26656, 27371 (IPC B07B 1/22), 2010–2013. Available online: https://kz.patents.su/metka/grohot (accessed on 15 August 2025).

- Arifuzzaman, S.; Dong, K.; Yu, A. Process model of vibrating screen based on DEM and physics-informed machine learning. Powder Technol. 2022, 409, 117869. [Google Scholar] [CrossRef]

- EN 933-3:2012; Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape: Flakiness Index. European Committee for Standardization: Brussels, Belgium, 2012. Available online: https://standards.iteh.ai/catalog/standards/cen/0ccc19d3-9861-4d02-b943-5f166e7cf6d6/en-933-3-2012 (accessed on 15 August 2025).

- GOST 8269.0–97; Mountainous Rock Road Metal and Gravel, Industrial Waste Products for Construction Works—Methods of Physical and Mechanical Tests. Interstate Council for Standardization, Metrology and Certification: Moscow, Russia, 1998. Available online: https://www.russiangost.com/p-19969-gost-82690-97.aspx (accessed on 15 August 2025).

- Shkut, A. Research on the dynamics of transitional regimes in an inertial screen with two motor vibrators. Coll. Res. Pap. Natl. Min. Univ. 2023, 75, 203–210. [Google Scholar] [CrossRef]

- Pylypaka, S.; Volina, T.; Hropost, V.; Babka, V.; Hryshchenko, I. Determination of the form of a spiral spring in a free state. ScienceRise 2023, 12, 46–51. [Google Scholar] [CrossRef]

- Practical Maintenance. Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens. 2018. Available online: https://practicalmaintenance.net/wp-content/uploads/Construction-Working-and-Maintenance-of-Vibrators-and-Vibrating-Screens.pdf (accessed on 15 August 2025).

- Ecoverse. Trommel Screen Drums: Everything You Need to Know. 2023. Available online: https://www.ecoverse.net/blog/trommel-screen-drums-everything-you-need-to-know/ (accessed on 15 August 2025).

- Edge Innovate. Trommel Screens—The Ultimate Guide. 2023. Available online: https://edgeinnovate.com/trommel-screens-the-ultimate-guide/ (accessed on 15 August 2025).

- Yamada, M.; Seko, W.; Yanai, T.; Ninomiya, K.; Seki, M. Slanted, asymmetric microfluidic lattices as size-selective sieves for continuous particle/cell sorting. Lab. Chip 2017, 17, 304–314. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).