1. Introduction

Wood bonding facilitates the effective application of wood in furniture, wooden structures, and the building sector [

1], where wood-based products are frequently encountered in the form of glued laminated timber (glulam), particleboard, fiberboard, plywood, oriented strand-board, and other products that are bonded with different resin types [

2].

Structural glulam is one of the oldest and a high-performance engineered wood products. It is a product consisting of two or more layers of wood, glued together, and is defined as a material created from suitably selected and prepared pieces of wood, in a straight or curved shape, with the fibers of all pieces practically parallel to the longitudinal axis [

3]. Glulam is most frequently applied in furniture, sports facilities and equipment, in load-bearing elements, such as beams, arched columns, parts of bridges, shipbuilding and aeronautical structures, among others [

4], mainly due to its versatility and sustainability. Nevertheless, issues including long-term durability, moisture susceptibility, and formaldehyde emissions restrict their effectiveness in demanding applications [

5].

Almost any wood species, both hardwoods and softwoods, can be utilized in the production of glulam, provided that the wood’s physical and chemical properties, as well as bonding ability, are acceptable. Douglas spruce, larch, southern pine, hem fir, and spruce are mainly used in the USA, while in Europe, and especially in the Scandinavian countries, there is a particular preference for fir, spruce, and pine species [

2]. The wood species, wood structure and properties, potential defects presence, the dimensions/cross section of wooden elements of glulam, their moisture content, density, adhesive type and adhesion conditions applied, as well as any potential treatment applied during the production process, are all significant factors that affect the properties of the glulam final product [

6]. Norway spruce wood, which is also used in the current work, demonstrates a natural gloss, without axial resin ducts, though often with axial parenchyma. The heartwood and sapwood do not differ; the wood is light, soft, and white to light brownish yellow, and the boundaries between early and latewood are usually pronounced [

7].

Thermosetting cold-bonding adhesives like epoxy, phenolic (phenol–resorcinol) are typically used for bonding of glulam and other wood-based products. Other natural or synthetic adhesives may also be utilized, depending on the application of glulam. Melamine–urea–formaldehyde (MUF) is initially produced in powder form and then combined with a catalyst, incorporating urea to create a colorless, liquid resin. Although it can tolerate hot pressure (120–150 °C), it can also function well at lower pressing temperatures. It is a resin characterized by excellent resistance to water, high resistance to both dry and humid environments, and the ability to cure quickly in high-frequency presses. Even though the particleboards and fiberboards with MUF exhibit low adhesive strength, this adhesive provides long-lasting glue bonds [

8]. MUF adhesive is considered appropriate for use in plywood products made of either softwood or hardwood species, for the connection of lamellas, dowels, mortise and tenon elements, and other wood-to-wood joint bonding [

9,

10].

Liu et al. [

11] reported that MUF exhibited good bonding performance at room temperature, but showed poor thermal resistance, with the structures being significantly degraded when the temperature increased above 200 °C. In contrast, phenol-resorcinol formaldehyde (PRF), exposed to elevated temperatures (150 °C), demonstrated similar bonding strength to that of solid wood. Jiang et al. [

12] investigated the delamination strength of five-layer glulam products made of four different European species (

Fraxinus excelsior,

Fagus sylvatica,

Larix decidua, and

Picea abies) and adhesives of PRF and Isocyanate Polymer Emulsion (EPI), MUF, and Polyurethane (PUR). Delamination strength tests (EN 391, method A) showed that only Norway spruce (

Picea abies) glulam provided satisfying delamination strength, independently of the adhesive type. Knorz et al. [

13], based on EN 302-2, investigated the delamination strength and shear performance of

Fraxinus excelsior L. glulam, glued with PRF, MUF—1 (100/20), MUF—2 (100/50), PUR, and EPI, with varying closed bonding times as a parameter to be studied. Significant differences were found between the delamination strength of different adhesives and bonding times, with the best performance to be recorded by PRF with the long bonding time, and it was the only resin to fulfil the delamination strength standard requirements. The penetration of the adhesive, as well as the adhesion line thickness, was found to be strongly related to bonding time.

Martins et al. [

14] examined the bonding efficiency of

Pinus pinaster glulam made of eight different resins (PRF, MUF, EPI, and 1C-PUR), focusing on different amounts of adhesive and pressures applied during bonding. The delamination (EN 14080 [

15], Method A) and shear strength test demonstrated excellent performance in all PRF cases. Although MUF, EPI, and 1C-PUR resins presented satisfying bonding, the use of a hardener was necessary, especially for 1C-PUR. The shear strength was not significantly affected by the adhesive type, though differences were observed in wood failure rates between EPI and PUR. Although some research has been implemented so far, a gap has been detected in the existing literature towards the optimization approach of the MUF system in glulam and other wood-based products manufacturing.

The structural reliability of glulam in construction can be enhanced by optimizing the performance of MUF resins, which are extensively utilized in such engineered wood products [

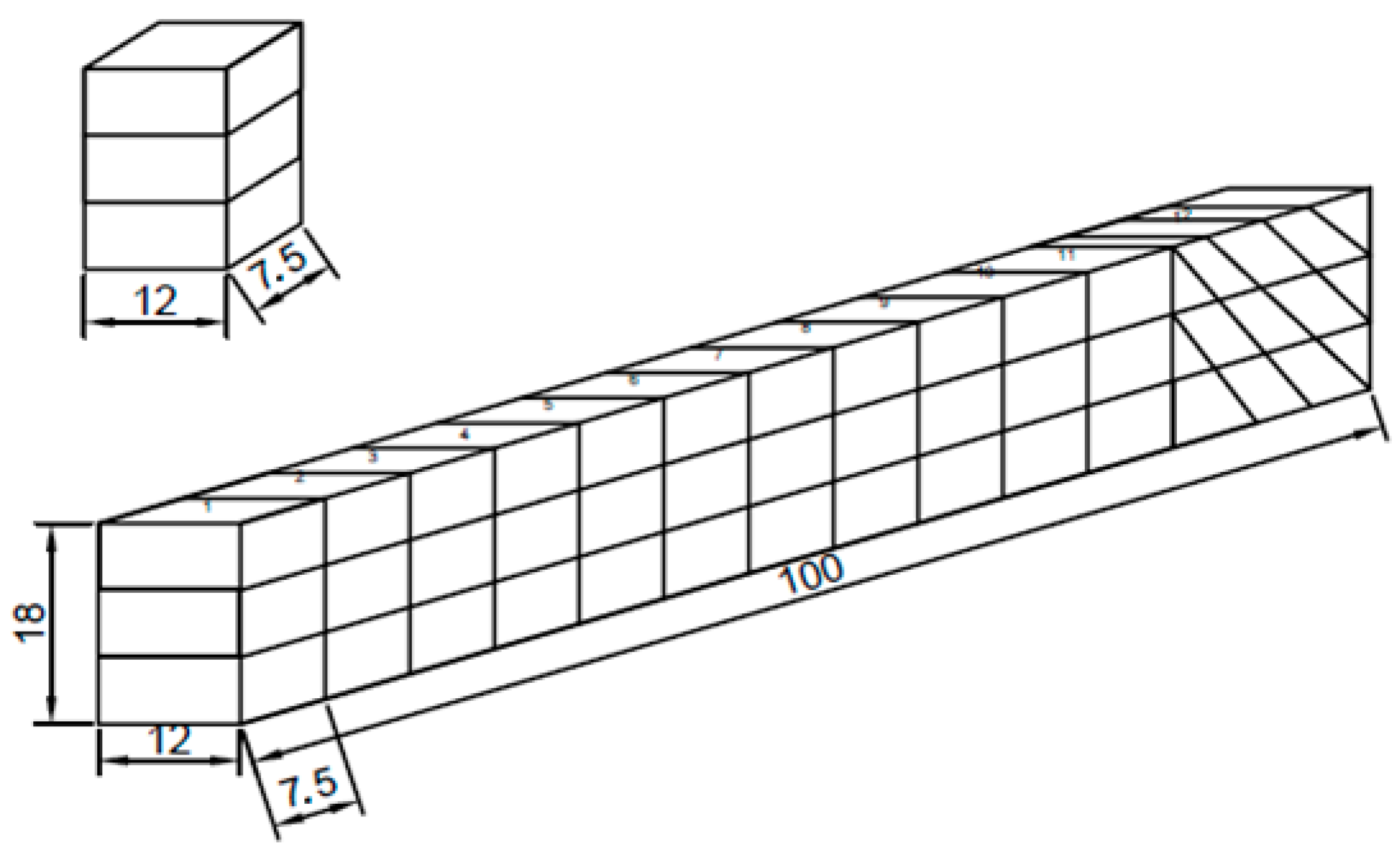

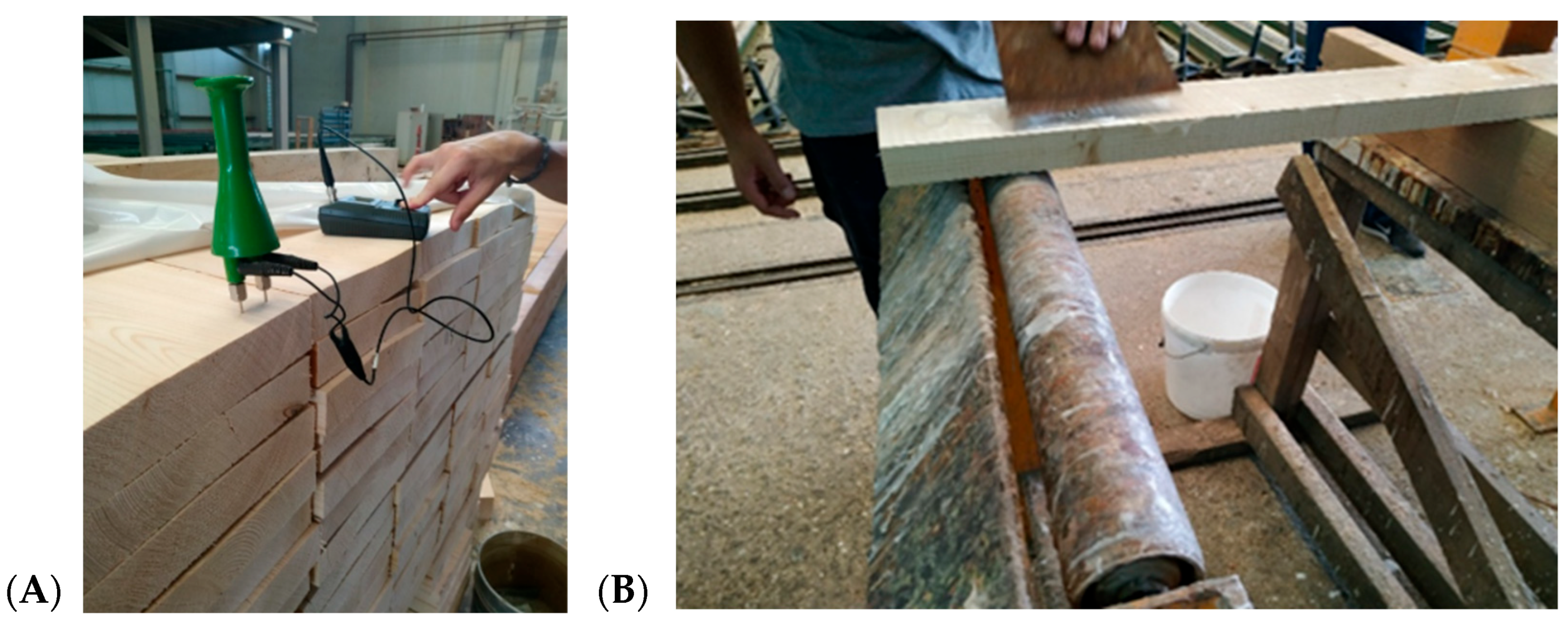

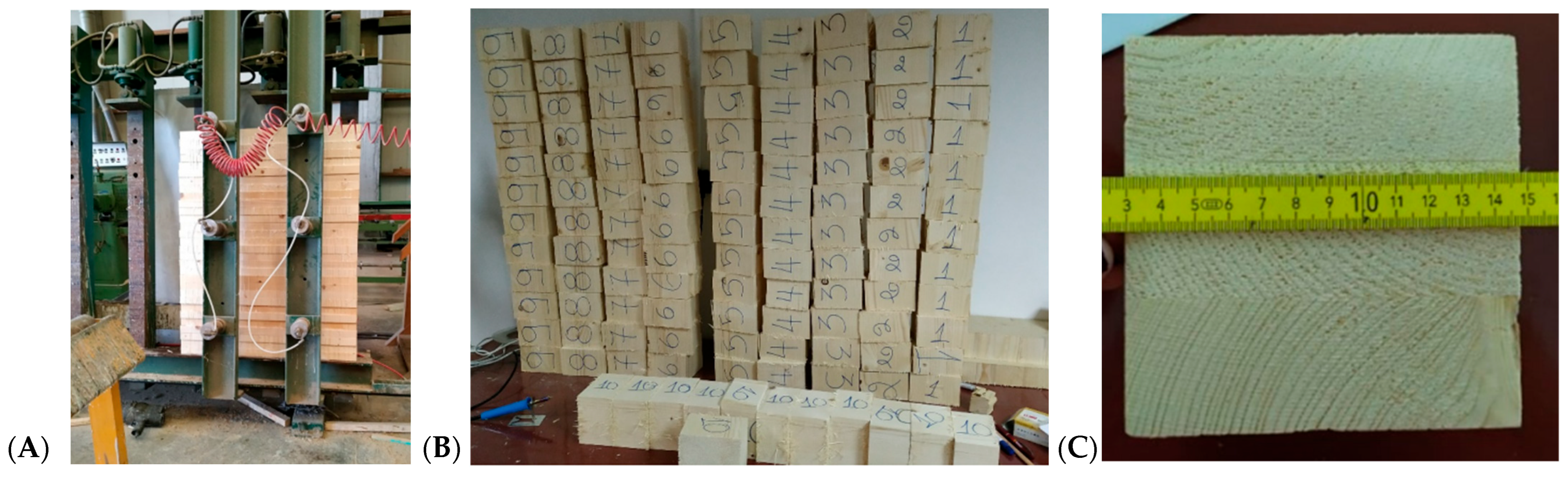

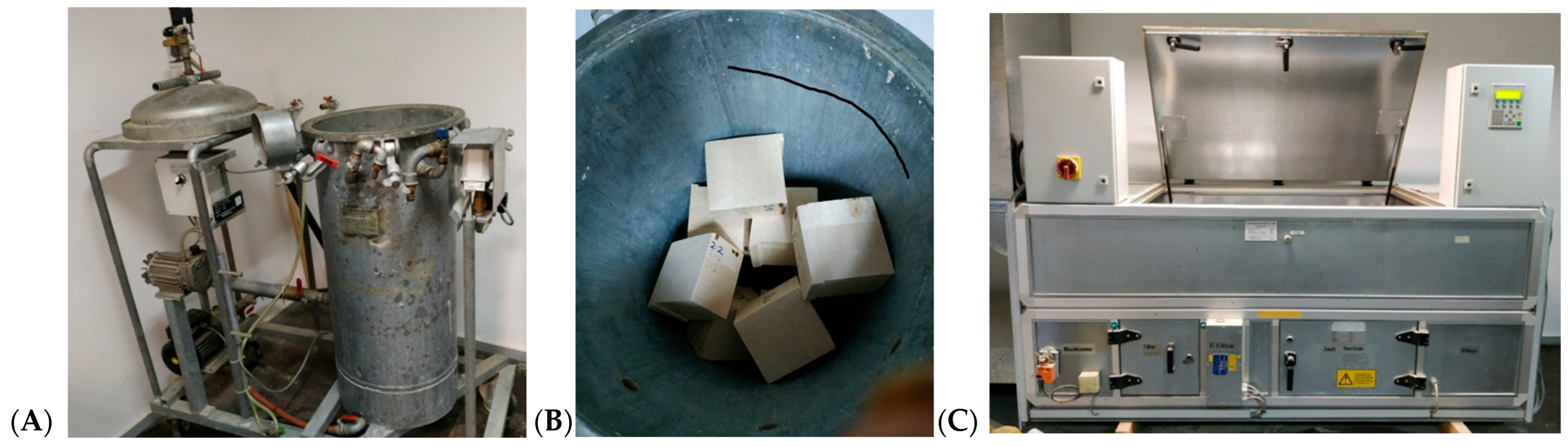

16]. Towards the attempts of optimization of MUF adhesive formulation and contribution to its current and real-world applications, the current work investigates the impact of varying chemical composition of MUF adhesive formulation on the bonding performance (in terms of delamination resistance and shear strength) of three-layer glulam samples that are manufactured using Norway spruce (

Picea abies L.) wood pieces bonded with five different MUF resin formulations. Identifying the most effective MUF formulation for structural applications and improving MUF’s resilience can prolong the lifespan of glulam, minimize waste, and encourage environmentally friendly building practices. Thoroughly assessing and comparing the mechanical characteristics, durability, and bonding quality of spruce glulam beams constructed using five versions of commercial MUF resins would also provide manufacturers vital information to assist them choose the optimum adhesives for long-lasting, high-performance glulam and other engineered wood composites production.

3. Results

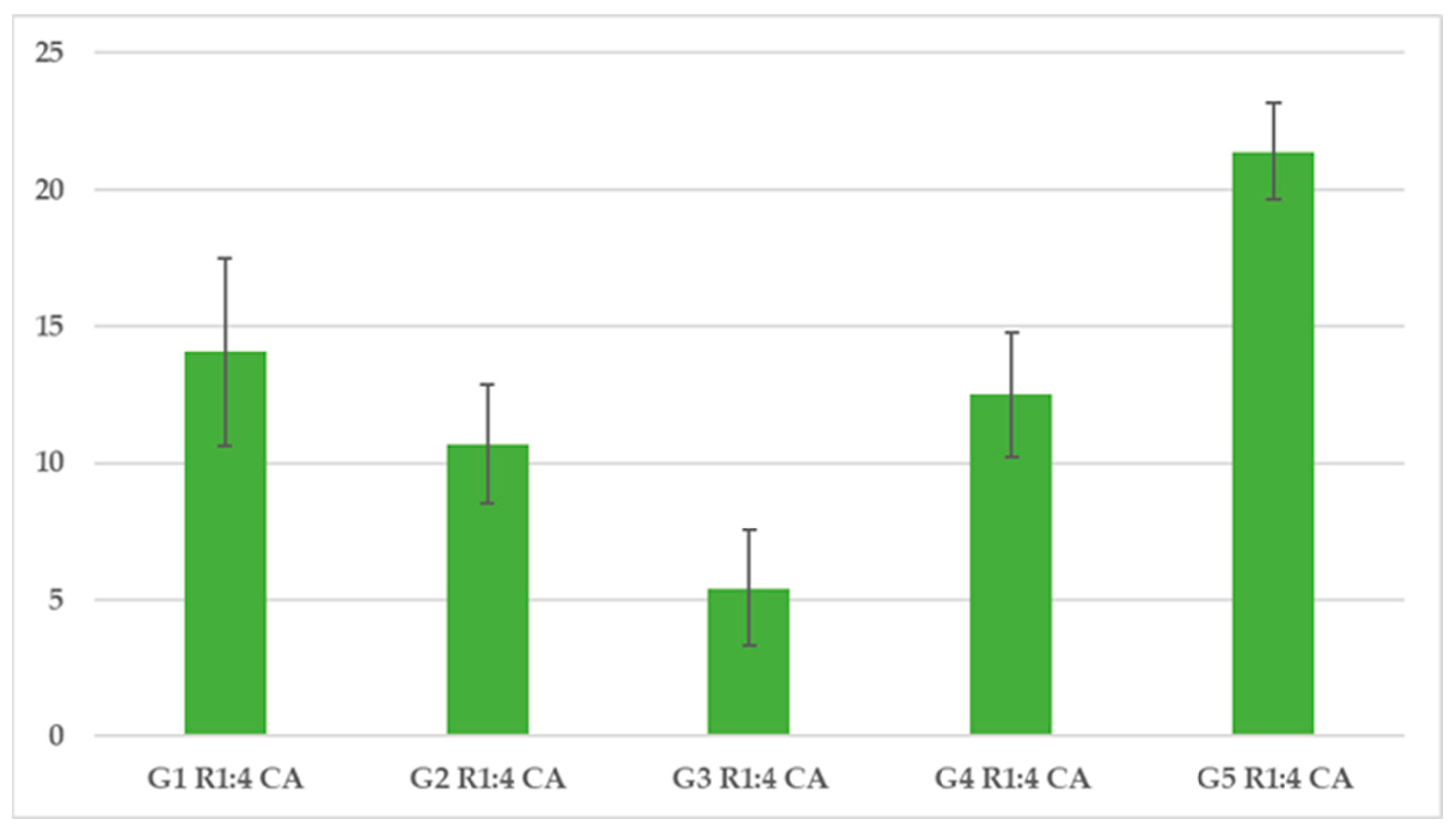

The results from the first experiment (Experiment 1) are presented in

Figure 5. It is observed that the samples individually and all of them fulfil the requirements of the respective standard of [

15] (

Figure 5). In the delamination test, in which method B was applied, Coefficient A (%) of the samples does not exceed 40%. However, the mean value of coefficient A of the samples was found to be 14.05%, which exceeds the permitted limit of 8%, as defined by the standard, and therefore, Glue 1 with a ratio of 1:4 (hardener–glue) and also having applied the correct amount of hardener–glue mixture, does not meet the requirements, therefore it should be rejected. Glues 1, 2, and 4 provided similar results of mean A% delamination coefficient values, while Glues 3 and 5 marked statistically significant differences from all the other glue categories of the current study.

The results of the first experiment show that the samples individually do not meet all the requirements of the norm [

15]. Delamination test of glue lines applying method B, that is, per sample, the A% coefficient should not exceed 40%, as sample 4 has an A (%) coefficient of 44.44%. Therefore, the average value is a value that exceeds the acceptable limit of 8%, as defined by the standard, and is equal to 10.69%, so Glue 1, with a ratio of 1:4 and with the correct (typical) amount of hardener–glue mixture, does not meet the requirements and is also rejected.

In the first experiment carried out, the results of the samples, which were glued with Glue 3, showed that the samples individually meet all the requirements of the standard. According to the delamination test of Glue Lines (method B), Coefficient A (%) should not exceed 40%. In this study, the mean value was measured to be 5.42%; therefore, it does not exceed the permitted limit of 8%, as defined by the standard. Therefore, Glue 3 with a ratio of 1:4 and with the “correct”/typical amount of hardener–glue mixture meets the requirements and is considered “accepted”.

Additionally, in Experiment 1, the results of the samples, which were glued with Glue 4, showed that the samples individually meet all the requirements of the Glulam production norm. In the delamination test (method B), the Coefficient A (%) should not exceed 40%, as mentioned previously. However, the mean value was 12.49%, exceeding the permissible limit of 8%, as defined by the standard; therefore, Glue 4 with a ratio of 1:4 and with the “correct” amount of hardener–glue mixture does not meet the requirements and can be considered rejected.

In the first experiment carried out, the results of the samples, which were glued with Glue 5, showed that the samples individually do not meet all the requirements. In the delamination test (method B), coefficient A% should not exceed 40%, as samples 1 and 5 have a coefficient A (%) equal to 51.55% and 46.67%, respectively. Therefore, it follows that the mean value also exceeds the permitted limit of 8%, as defined by the standard, and is equal to 21.40%, so a Glue 5 ratio of 1:4, with the correct amount of hardener–glue mixture, does not meet the requirements and is considered rejected.

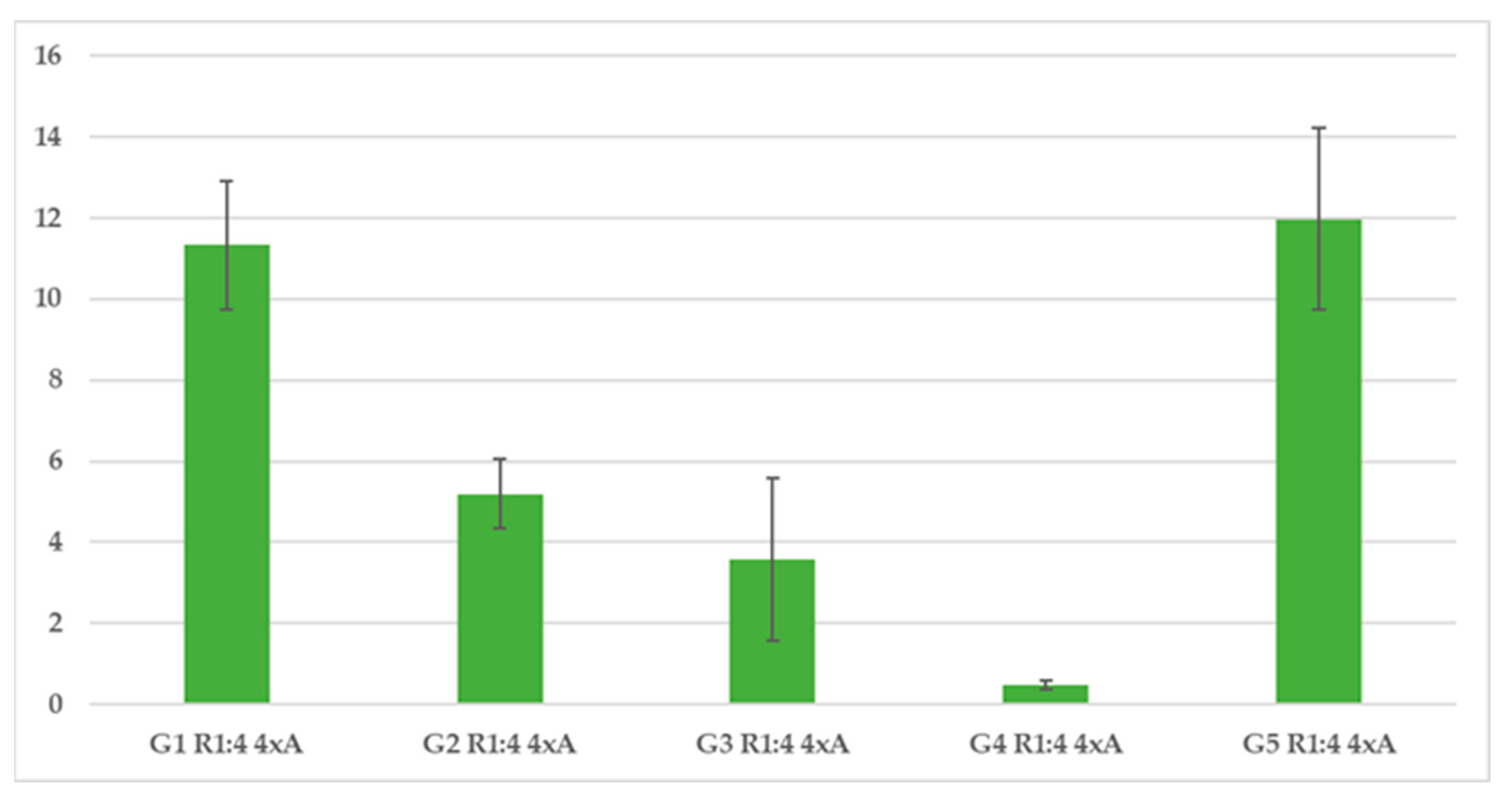

In the second experiment (Experiment 2), the results of the samples, which were glued with Glue 1, showed that the samples individually all meet the requirements (

Figure 6). In the delamination test (method B), the coefficient A% should not exceed 40%. However, the mean value was found to be 10.71%, exceeding the permissible limit of 8%, as defined by the standard; therefore, Glue 1 with a ratio of 1:5 and with the correct amount of hardener–glue mixture does not meet the requirements and is considered rejected. According to statistical analysis results, the mean value of the A% delamination coefficient of Glue 1 differed statistically significantly from all the other glue categories of the current experiment. Statistically significant differences were also detected between Glue 3 and all glue categories, except for Glue 5.

Furthermore, in Experiment 2, the results of the samples, which were glued with Glue 2, demonstrated that the samples individually meet all the requirements. The mean value of the A (%) coefficient was measured to be 5.36%, which does not exceed the permissible limit of 8%, as defined by the standard. Therefore, Glue 2 with a ratio of 1:5 and with the “correct” amount of hardener–glue mixture meets the requirements and can be accepted. In the second experiment, the results of the samples glued with Glue 3 showed that all samples, both individually and collectively, met the requirements. In the delamination test (method B), the Coefficient A% should not exceed 40%, as mentioned above. Furthermore, the mean value was 1.46%, and it did not exceed the permissible limit of 8%, as defined by the standard; therefore, Glue 3 with a ratio of 1:5 and with the “correct” amount of hardener–glue mixture meets the requirements and is considered “accepted”.

In the second experiment, the samples glued with Glue 4 showed that they individually and collectively meet the requirements. In the delamination test (method B), the Coefficient A% should not exceed 40%. Furthermore, the mean value was 3.79%, which does not exceed the permissible limit of 8%, as defined by the standard. Therefore, Glue 4 with a ratio of 1:5 and with the “correct” amount of hardener–glue mixture meets the requirements and can be considered “accepted”. The results of the samples that were glued with Glue 5 showed that the samples individually and all meet all the requirements. In the delamination test (method B), the Coefficient A% should not exceed 40%, while the mean value was measured to be 2.42%, which does not exceed the permissible limit of 8%. Therefore, Glue 5 with a ratio of 1:5 and with the “correct” amount of hardener–glue mixture meets the requirements and can be considered “acceptable”.

In the third experiment (Experiment 3), the results of the samples, which were glued with Glue 1, revealed that the samples individually meet all the requirements of the standard (

Figure 7). In the delamination test of Glue Lines (method B), the Coefficient A% should not exceed 40%, while the mean value was found to exceed the permissible limit of 8%, as defined by the standard, and is equal to 11.32%. Therefore, Glue 1 with a ratio of 1:4 and with the application of four times the amount of glue in the hardener–glue mixture does not meet the requirements and is rejected. The statistical analysis revealed that the mean value of the A% delamination coefficient of Glue 4 differed significantly from all the other glues’ respective values. Glues 1 and 5 marked similar levels of A% coefficient, while both of them differed statistically from the rest of the glue types (2, 3, and 4).

In the third experiment carried out, the results of the samples that were glued with Glue 2 showed that the samples individually meet all the requirements. In the delamination test, as mentioned previously (method B), the Coefficient A% should not exceed 40%. The mean value indeed did not exceed the permitted limit of 8%, as defined by the standard, and is equal to 5.19%. Therefore, Glue 2, with a ratio of 1:4 and with the application of four times the typical (correct) amount of glue in the hardener–glue mixture, meets the requirements and is considered acceptable. All the above results and conclusions are also depicted in the illustration of

Figure 7.

In the third experiment carried out, the results of the samples, which were glued with Glue 3, showed that the samples individually meet all the requirements. Delamination Test of Glue Lines (method B) refers to the fact that the Coefficient A% should not exceed 40%. In the current case, the mean value did not exceed the permitted limit of 8%, as defined by the standard, and is equal to 3.58%. Therefore, Glue 3 with a ratio of 1:4 and with the application of four times the amount of glue in the hardener–glue mixture, meets the requirements and can be considered as acceptable. The samples, which were glued with Glue 4, demonstrated that they individually meet all the requirements of the respective standard. The mean value here did not exceed the permitted limit of 8%, as defined by the standard, and is equal to 0.48%. Therefore, Glue 4, with a ratio of 1:4 and with the application of four times the amount of glue in the hardener–glue mixture, meets the requirements and is considered accepted.

In the third experiment carried out, the results of the samples, which were glued with Glue 5, showed that the samples individually meet all the requirements. Delamination Test of Glue Lines (method B) requires the Coefficient A% not to exceed 40%. However, the mean value here exceeded the permissible limit of 8%, as defined by the standard, and is equal to 11.97%. Therefore, Glue 5, with a ratio of 1:4 and with the application of four times the amount of glue in the hardener–glue mixture, did not meet the requirements and is rejected.

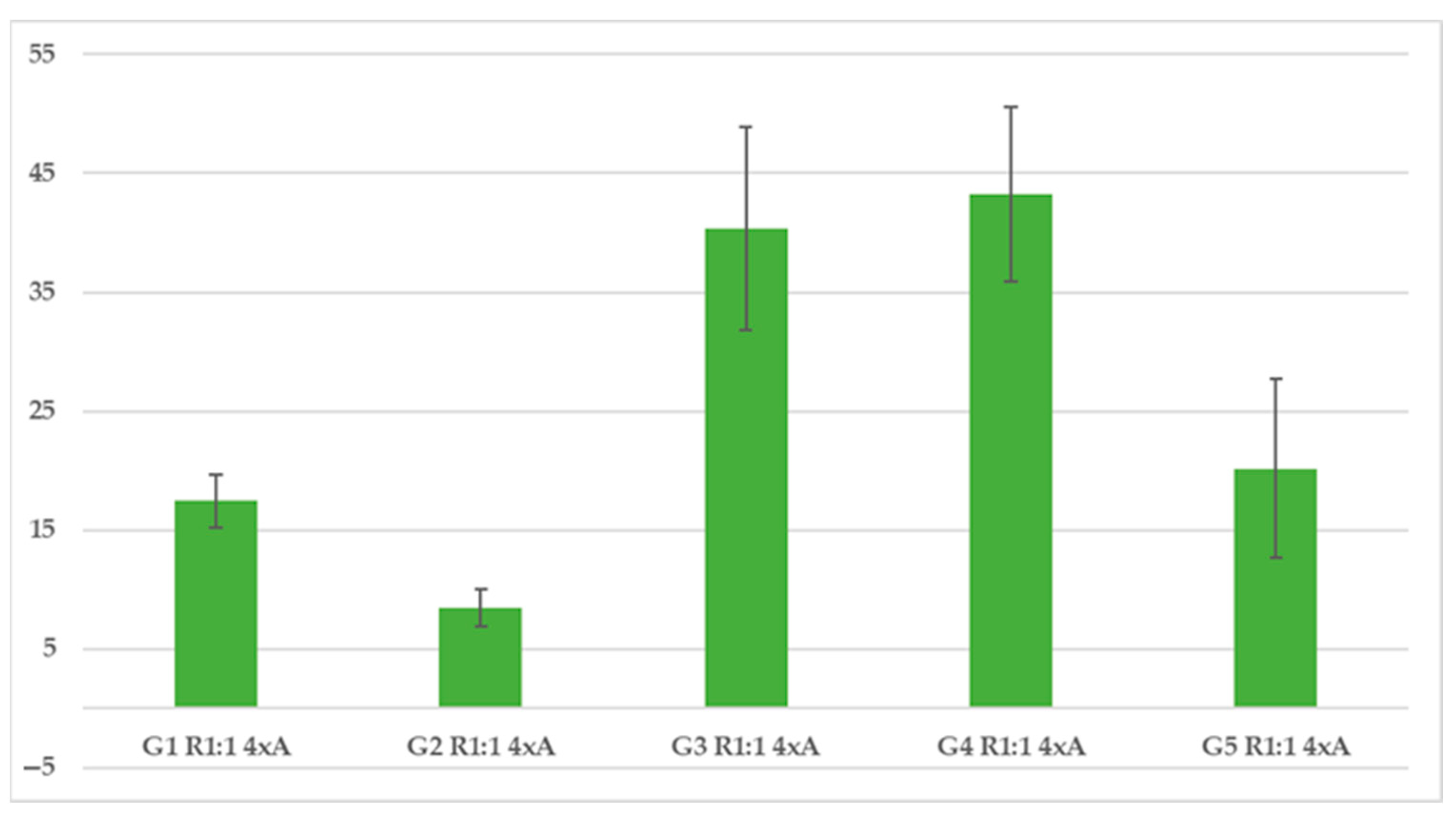

In the fourth experiment carried out (Experiment 4), the results of the samples, which were glued with Glue 1, showed that the samples individually meet all the requirements(

Figure 8). Delamination Test of Glue Lines (method B) indicates that the Coefficient A% should not exceed 40%. However, the mean value exceeds the permissible limit of 8%, as defined by the standard, and is equal to 17.42%. Therefore, Glue 1, with a ratio of 1:1 and with the application of four times the amount of glue in the hardener–glue mixture, does not meet the requirements and is rejected. According to the statistical analysis of the results, the A% delamination coefficient values of Glues 3 and 4 were found to be similar, while both of them differed significantly (from a statistical point of view) from the rest of the glue types (1, 2, and 5). Furthermore, Glue 2 marked a significantly lower (the lowest) value of delamination level than all the other glue types of the specific experiment.

In the fourth experiment carried out, the samples that were glued with Glue 2 showed that they individually meet all the requirements. The mean value exceeds the permissible limit of 8%, as defined by the standard, and is equal to 8.43%. Therefore, Glue 2, with a ratio of 1:1 and with the application of four times the amount of glue in the hardener–glue mixture, does not meet the requirements and is rejected. The results of the samples, which were glued with Glue 3, revealed that the samples individually did not meet all the requirements of the standard. Samples 1, 2, 3, 5, and 6 recorded a delamination coefficient of 69.13%, 46.19%, 46.41%, 66.74% and 53.83%, respectively. The mean value exceeds the permissible limit of 8%, as defined by the standard, and is equal to 40.37%. Therefore, Glue 3 with a 1:1 ratio and with the application of a fourfold amount of glue in the hardener–glue mixture does not meet the requirements and is rejected.

Furthermore, in the fourth experiment carried out, the results of the samples, which were glued with Glue 4, showed that the samples individually do not meet all the requirements of the norm. Delamination test of glue lines (method B) refers to the fact that the Coefficient A% should not exceed 40%. Samples of 1, 4, 5, 6, 8, 9, and 11 presented a delamination coefficient of 74.27%, 57.81%, 45.86%, 45.54%, 44.84%, 43.82% and 51.12% respectively. The mean value exceeded the permissible limit of 8%, as defined by the standard, and is equal to 43.28%. Therefore, Glue 4, with a ratio of 1 to 1 and with the application of four times the amount of glue in the hardener–glue mixture, does not meet the requirements and is rejected. The results of the samples, which were glued with Glue 5, showed that the samples individually did not meet all the requirements. The Coefficient A% should not exceed 40%, though sample 9 presented a delamination factor of 64.06%. The mean value exceeded the permissible limit of 8%, as defined by the standard, and was found to be equal to 20.16%. Therefore, Glue 5, with a ratio of 1:1 and with the application of four times the amount of glue in the hardener–glue mixture, did not meet the requirements and can be considered as rejected.

4. Discussion

The experimental findings indicate that, when put through delamination testing in accordance with EN 14080 [

15] (Method B), the five adhesive formulations’ performances varied significantly. The hardener-to-glue ratio and the quantity of adhesive used were crucial factors in determining compliance with the standard, highlighting the need for accurate formulation and application in structural glulam bonding.

Except for one experimental scenario (Experiment 4, 1:1 ratio), Glue 3 demonstrated the most consistent compliance among the tested adhesives, fulfilling the standards. In Experiments 1–3, the mean delamination coefficient A (%) remained considerably below the 8% limit, indicating dependable bonding performance in normal application circumstances.

Additionally, Glue 2 performed satisfactorily, especially at a hardener-to-glue ratio of 1:5, where its mean A% (5.36%) showed a high level of resistance to delamination. These results are consistent with earlier research highlighting how well-formulated hardeners can improve moisture resistance and decrease adhesive brittleness [

21,

22,

23].

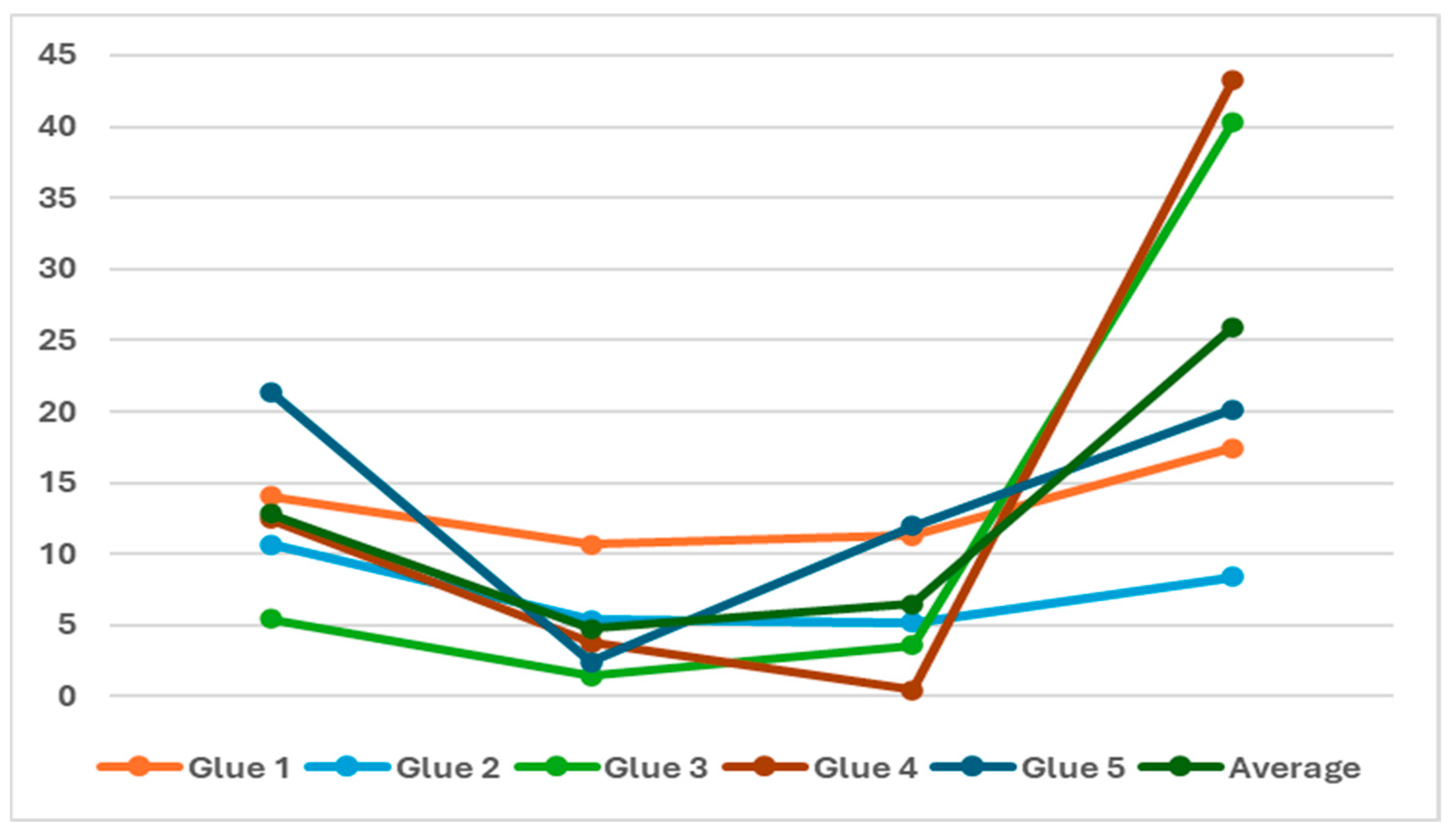

However, with mean A (%) values ranging from 10.69% to 17.42%, Glue 1 failed to meet the criterion in every setup that was evaluated (

Figure 9). This persistent underperformance indicates potential chemical formulation shortcomings such as inadequate cross-linking or inadequate moisture resistance. In similar tendencies, Glues 4 and 5 showed inconsistent performance; although they functioned well at a ratio of 1:5, their A (%) values were higher than allowed limits under excessive adhesive loading (4× application) or higher hardener concentrations (1:4). The necessity of adhesive-specific optimization in industrial settings is highlighted by this nonlinear behavior.

In comparison to the 1:4 ratio (Experiment 1), the 1:5 hardener-to-glue ratio (Experiment 2) generally increased delamination resistance. Glue 5, for example, worked satisfactorily at 1:5 (A% = 2.42%) after failing at 1:4 (A% = 21.40%), indicating that a lower hardener concentration would improve flexibility and bond durability. This conclusion is consistent with research conducted by Boursier et al. [

24], which found that using too much hardener can result in adhesive layers that are brittle and prone to breaking under pressure.

It is interesting to note that performance was not always improved by applying four times as much glue as was typically used (Experiments 3–4). When the same excess glue was applied at a 1:1 ratio, Glue 3 displayed severe delamination (A% = 40.37%); however, Glue 4 demonstrated remarkable results at this level (A% = 0.48% at a 1:4 ratio). This implies that excessive use could interfere with the kinetics of curing, especially in adhesives that are susceptible to stoichiometric imbalances. Interestingly, despite generally acceptable mean values in the current experimental work findings, certain individual samples (Glue 5, Sample 9 in Experiment 4: A% = 64.06%) showed significant delamination. Localized adhesive flaws, uneven spread, or substrate irregularities could all result in these outliers, which call for more stringent manufacturing quality control. With careful calibration of hardener ratios, Glues 2 and 3 are the most practical options for industrial applications.

The short-term delamination resistance under controlled conditions was the main emphasis of this study; long-term durability tests that include mechanical fatigue, humidity exposure, and thermal cycling would further evaluate adhesive performance, while the mechanisms underlying adhesive failure would also be more clearly evidenced by microscopic examinations of failed bond lines, which could direct formulation advancements, even though it was not possible to be provided in the current work. Future research should investigate the chemical alterations of poor-performing adhesives and assess how they respond to environmental stressors in practice.