Abstract

Photovoltaic (PV) energy conversion is expected to contribute to the creation of a clean energy society. For realizing such a vision, various developments such as high-efficiency, low-cost and highly reliable materials, solar cells, modules and systems are necessary. Cooperation with storage batteries is also very important for regulation and self-consumption. The creation of new applications such as building integrated PV, vehicle integrated PV, agriculture PV and floating PV is also very important for further installation of PV and reducing CO2 emission. The sustainability of material consumption, along with reducing, reusing and recycling are also key issues for widespread deployment of PV. This paper provides an overview of the current status of photovoltaics and discusses future directions for photovoltaics from the view-points of high-efficiency, low-cost, reliability, and importance of integrated photovoltaics and sustainability.

Keywords:

photovoltaics; solar cells; high-efficiency; low cost; stability; applications; sustainability 1. Introduction

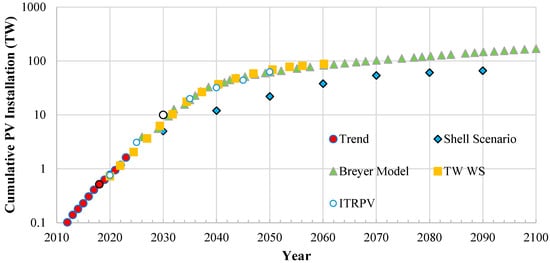

Solar photovoltaics (PV) are expected to play a massive role in the world in order to mitigate climate change. Figure 1 shows modeled cumulative installed capacity for the Shell sky scenario [1], the Breyer model [2], TW (Terawatt) Workshop analysis [3] and the ITRPV roadmap [4]. Cost efficient climate change mitigation requires installing a total of 20∼60 TWp photovoltaics until 2050 and 70∼170 TWp until 2100. Although solar PV is is expected to contribute as one of the world’s main energy sources [5,6], several developments are necessary.

Figure 1.

Modeled cumulative installed photovoltaics capacity according to the Shell sky scenario and the other analytical results.

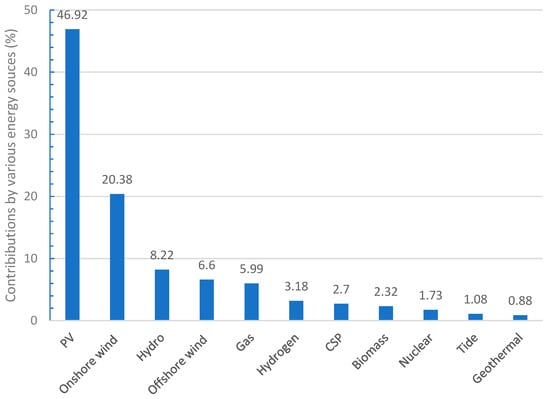

Figure 2 shows the installed capacity of various energy sources in 2050 reported by the IRENA [7]. PV is expected to contribute as the No. 1 energy source with a share of about 46.9%. Additionally, 20.4% for onshore wind, 8.2% for hydro, 6.6% for offshore wind, 6% for gas, 2.7% for CSP, 2.3% for biomass, 1.7% for nuclear, 1.1% for tide and 0.9% for geothermal are listed in the IRENA prediction [7].

Figure 2.

Installed capacity of various energy sources in 2050 reported by IRENA.

For realizing the above visions and roadmaps [1,2,3,4] or PV towards the creation of future clean energy infra-structures, we need (1) develop high-efficiency, low-cost and highly reliable PV materials, cells, modules and systems, (2) develop smart energy management including regulations, and self-consumption in cooperation with storage battery technologies, and (3) to develop new application fields such as automobile and agriculture applications towards the creation of future clean energy infrastructures.

This paper presents problems to be solved and discusses future directions for photovoltaics.

2. Key Issues for Further Developments of PV

Several works [6,8,9,10] have pointed out that an increase in the installation of PV systems increases problems.

The primary energy demand for the production and installation of PV systems is estimated [9,10] at 40 EJ/year (that is about 7% of the global primary energy consumption of 585 EJ in 2017) in the case of 5 TWp PV production in 2010. According to ref. [3], cumulative PV system installation of 75 TWp by 2050 and annual PV production of 3.7 TWp in 2050 are estimated. A decrease in the energy consumption of module production, such as the development of high-efficiency solar cells and modules, low-temperature processing of materials, solar cells, and modules, reduction in wafer thickness and material intensity, and so forth, is very important in order to realize the sustainability of PVs. As a result of the usage of such technological solutions, a decrease in primary energy demand for PV production and installation from 20 GJ/kW in 2050 to 4.1∼7.7 GJ/kW in 2100 has been estimated [10].

Cumulative green gas emission in the case of 5 TWp PV production is estimated [9,10] at 12 GtCO2-eq., which is approximately 4% of the CO2 budget 290 Gt CO2 to keep the anthropogenic global warming below 1.5 °C. Further removal of CO2 from the atmosphere is necessary to lead to a larger budget being available for PVs. Increasing the share of renewables in the energy mix is essential to reducing fossil-fuel-based energy consumption. As a result of the advancement of renewable energies, annual greenhouse gas emission has been estimated [10] to drop from 0.5 GtCO2-eq./year in 2030 to 0 in 2060.

The total module area is estimated [10] to increase from 4400 km2 in 2020 to 360,000 km2 (252,000∼466,000 km2) in 2100. The module area values for 2100 correspond roughly to the land area of the United Kingdom or Sweden, respectively. In addition to the development of high-efficiency solar cells and modules, the importance of effective applications such as agri-PV, combining agriculture land and PV, vehicle integrated PV placed on car roofs, and floating PV placed on water bodies as well as building and industries has been pointed out by the SRIA [8]. It has been presented that buildings, industries, and transportation will share 55%, 25%, and 25% as end uses in a cumulative PV capacity of 1.6 TWp (45% of electricity demand) in the United States in 2050 [11].

The European Strategic Research & Innovation Agenda (SRIA) for Photovoltaics [8] is thought to be very useful for realizing terawatt photovoltaics. Table 1 shows five challenges identified by the SRIA. In the following section, technologically important issues for the future directions of PV are discussed by referring to some papers. In particular, challenge 1: high-efficiency and low-cost, challenge 2: reliability and challenge 3: new applications, as listed in Table 1, are discussed.

Table 1.

Challenges by the European Strategic Research & Innovation Agenda (SRIA) for PV.

3. Future Direction of PV

In this section, technologically important issues for the future directions of PV are discussed by referring to some papers.

3.1. High-Efficiency

The development of high-efficiency solar cells offers a promising pathway toward achieving high power per unit cost for various applications.

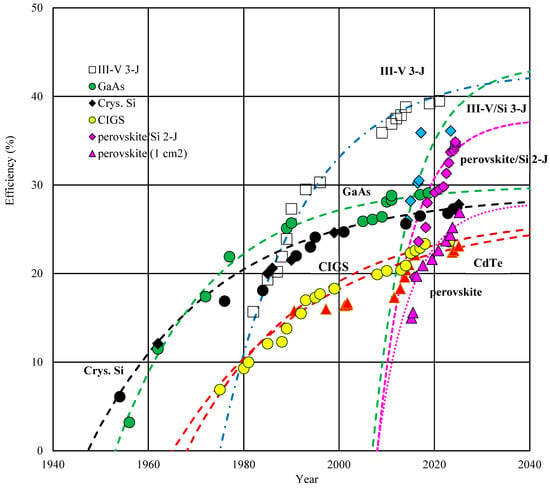

Figure 3 shows chronological efficiency improvements of various solar cells [12,13,14] and efficiency progress until 2040. As a results of the technological developments of various solar cells, efficiency improvements have been realized. Efficiencies of Si solar cells are approaching a practical feasible efficiency of 29.4% [15] and potential efficiencies of Si, GaAs, CdTe, CIGSSe, perovskite, and organic single-junction solar cells estimated by the authors [16] are 29.6%, 31.2%, 30.5%, 28.9%, 28.9%, and 30.4%, respectively. Therefore, multi-junction (tandem) solar cells [13,17,18,19,20,21] are very important.

Figure 3.

Chronological efficiency improvements of various solar cells. (adapted with permission from ref. [12]).

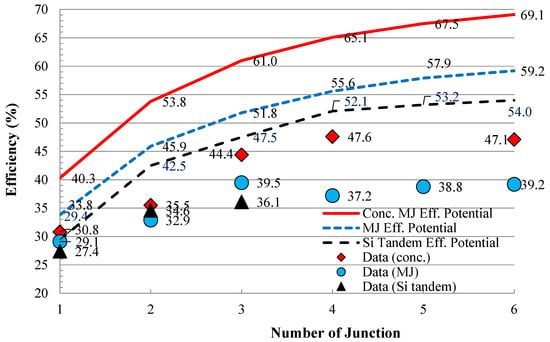

Figure 4 shows the calculated efficiencies [13] of multi-junction (MJ) and Si tandem solar cells and concentrator solar cells in comparison with their highest efficiencies achieved. two-junction and three-junction solar cells have a higher efficiency potential of about 45.9% and 51.8% with multi-junction, and 42.5% and 47.5% with Si tandem, respectively. Concentrator PV [22,23] has a higher efficiency potential of more than 60% as shown in Figure 4. In addition, concentrator PV has the possibility to solve material sustainability because high concentration is expected to reduce material consumptiom. However, efficiency improvements for MJ and Si tandem solar cells by reducing non-radiative, optical and resistance losses are necessary, because there are still efficiency gaps compared to the calculated efficiencies as shown Figure 4. Si tandem solar cells [12,24,25] such as III-V/Si and perovskite/Si tandem solar cells are seen as high-efficiency and low-cost advanced solar cells.

Figure 4.

Calculated efficiencies of multi-junction (MJ) and Si tandem solar cells in comparison with their highest efficiency achieved.

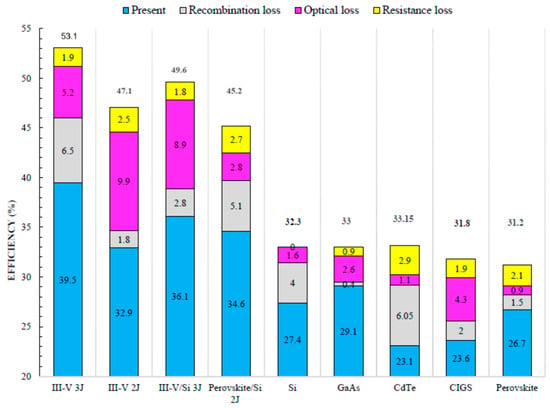

Figure 5 shows the efficiency potential of single-junction and tandem solar cells and present the best efficiencies and recombination, optical and resistance losses calculated by using the analytical procedure reported by the author’s group [16]. Although ideal efficiencies of single-junction solar cells are 31–33%, two-junction and three-junction solar cells have higher efficiency potential of about 45% and 49% with Si tandem, and 47% and 53% with multi-junction solar cells, respectively, as shown in Figure 5. A reduction in non-radiative recombination, optical and resistance losses is necessary in order to realize higher efficiencies.

Figure 5.

Calculated efficiency potential of single-junction and tandem solar cells and their current best efficiencies obtained, and recombination, optical and resistance losses.

3.2. Low-Cost

Low-cost solar cells are very important for many applications such as electric power generation systems, building integrated PV (BIPV), vehicle integrated PV (VIPV), agrivoltaics and floating PV. According to the ITRPV [4], an average Si module price at the end of 2023 is 0.118 USD/Wp.

A further cost decrease in Si modules is expected. The following important challenges are pointed out [4]: (1) Improve module area efficiency without significantly increasing the processing cost. (2) Continue cost optimization per unit along the entire value chain by increasing the Over-all Equipment Efficiency (OEE) of the installed production capacity, by implementing up-grades and new production capacities, using Si and non-Si materials more efficiently, and ensuring higher OEE of new installed capacities, (3) Introduce specialized module products for different market applications (i.e., tradeoff between cost-optimized, highest volume products and highest efficiency, higher price rooftop applications, or even fully customized niche products).

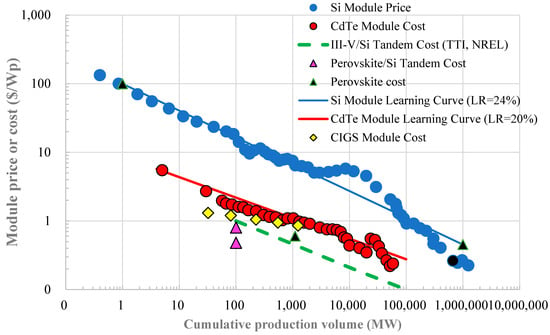

Recently, perovskite and Si tandem solar cell modules are expected as next generation solar cell modules. Figure 6 shows the trends in price reduction of Si cell modules [4], along with CdTe [26] and CIGS [27] solar cell modules and compares with cost estimation results for III-V/Si [17,28] and perovskite/Si [29] tandem solar cells. Cost analytical results for III-V/Si and perovskite/Si tandem solar cells show similar cost trends in CdTe single-junction solar cell modules. However, cost reduction of Si tandem solar cell modules by technology development and increasing market volume is necessary in order to realize cost targets of the Si tandem solar cell modules. The creation of alarge market such as solar-powered vehicle applications is very important for the cost reduction of Si tandem solar cell modules. Although perovskite/Si and III-V/Si tandem solar cell modules were expected previously as next generation high-efficiency, low-cost solar cell modules, their cost reduction due to technological developments and increase in production volume is necessary for various applications. In the field of III-V solar cell modules, high-speed epitaxial growth [30], epitaxial lift-off and the reuse of GaAs and Ge substrates [31] are key technologies for cost reduction of III-V/Si tandem solar cells [12,24,25].

Figure 6.

Cost analytical results for III-V/Si and perovskite/Si tandem solar cell modules in comparison with module price and cost trends for Si, CdTe and CIGS single-junction solar cell modules and cost analytical results for perovskite single-junction solar cell modules.

3.3. Reliability

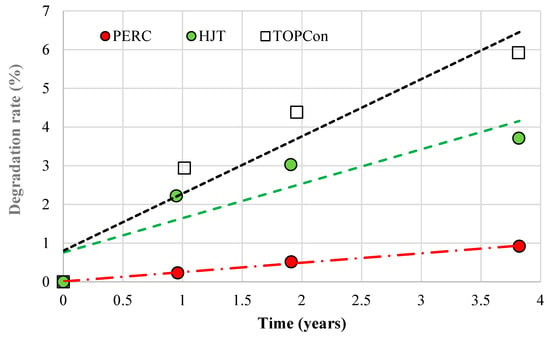

Improving device stability is also very important for practical applications of solar cell modules. Figure 7 shows typical examples of equivalent outdoor testing results of current Si PERC (Passivated Emitter Rear Contact), HJT (hetero-junction) and TOPCon (Tunnel Oxide Passivated Contact) solar cells [32]. Although current Si PERC solar cell modules show good stability with degradation rate of 0.24%/year, advanced Si solar cell modules such as HJT and TOPCon do not show good stability due to UV degradation [33].

Figure 7.

Equivalent outdoor testing results of Si PERC, hetero-junction and TOPCon solar cell modules.

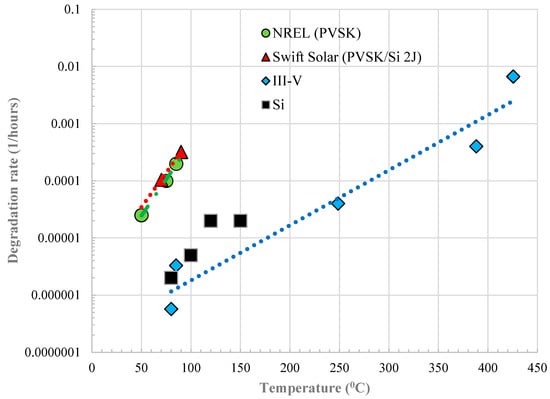

Although the perovskite and perovskite tandem solar cells are expected as next generation solar cell modules, their reliability is one of main problems that needs to be solved [34,35]. On the other hands, Si [36] and III–V compound [37,38] space solar cells have been tested under accelerating test condition over 150 °C and were demonstrated to be reliable as shown in Figure 8. Degradation rates for perovskite, perovskite/Si tandem, and Si and III–V compound solar cells are approximated by following the equations listed in Table 2 [34,35,36,37,38].

Figure 8.

Arrhenius plots for temperature dependent degradations of perovskite. Perovskite/Si, Si and III-V compound solar cells.

Table 2.

Temperature dependent thermal degradation formula for perovskite, perovskite/Si tandem, and Si and III-V three-junction solar cells.

Table 2.

Temperature dependent thermal degradation formula for perovskite, perovskite/Si tandem, and Si and III-V three-junction solar cells.

| Material | Degradation Rate (DR) Formula | Reference |

|---|---|---|

| Perovskite | DR [1/h] = 27,640 × EXP(−0.58eV/kT) (1) | [34] |

| Perovskite/Si tandem | DR [1/h] = 63,837 × EXP(−0.60eV/kT) (2) | [35] |

| Si | DR [1/h] = 3.05 × EXP(−0.44eV/kT) (3) | [36] |

| III-V three-junction | DR = 10,935 × EXP(−0.86eV/kT) (4) | [37,38] |

Where h is the hour, k is the Boltzmann constant and T is the absolute temperature.

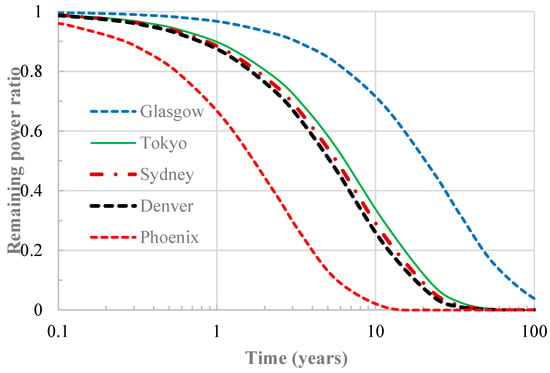

Figure 9 shows the remaining power ratio of perovskite solar cell modules operating in Glasgow, Tokyo, Sydney, Denver and Phoenix, estimated by considering only temperature dependent thermal degradation. The temperature rise in solar cell modules to be operated in Glasgow, Tokyo, Sydney, Denver and Phoenix as a function of solar irradiance, wind speed and ambient temperature was estimated by analytical procedure of the author’s group [39]. The temperature dependent thermal degradation of perovskite solar cells was calculated by the temperature rise in perovskite solar cells under weather conditions [40] using Equation (1) and the following equation.

Figure 9.

Estimated power ratio of perovskite solar cell modules operating in Glasgow, Tokyo, Sydney, Denver and Phoenix.

The temperature rise in solar cell modules in major cities in the world was estimated by using our previous paper [26]. The total temperature rise ∆TT in solar cell modules by considering effects of ambient temperature T0 is given by

where Tm is the module temperature [°C], T0 is the ambient temperature [°C], G is the solar irradiation incident on the module surface [W/m2], and v is the wind speed [m/s]. a, b, c, and d are the empirically determined coefficients. In this study, empirically determined coefficients a, b, c, and d are −2.7, −0.17, −9, and −0.16, respectively.

∆TT = Tm − T0 = 0.1844 *T0 [°C] + c*e(d*v) + G*e(a+b*v) = 0.1844 *T0 – 9 *e(−0.16 v) + G*e(−2.7−0.17 v)

At present, the reliability of perovskite solar cell modules is one of the main problems and their lifetime (at 80% remaining power ratio) is about 1 year under operation in Phoenix, Arizona. Therefore, improving the reliability of perovskite single-junction and perovskite tandem solar cell modules is essential for practical applications.

3.4. Integrated Photovoltaic Applications

From a global photovoltaic perspective, there is no lack of available area for the installation of solar photovoltaic systems. However, in some densely populated countries and regions, the needed land can compete with other land use options and related policies. Integrating photovoltaics (Integrated PV) with various already existing land use options as well as vehicles and ships opens access to PV potentials that are so far unused [40] and will help to overcome real as well as perceived area limitations. This section will give an overview about the different technology options and where available, the potential volume of applications in the world and EU by showing some references [40,41,42,43,44,45].

Table 3 shows PV installation potential for various integrated photovoltaics in addition to the power sector summarized by using some reports [40,41,42,43,44,45]. We have to reduce CO2 emission from 36 Gt (13 Gt for the power sector, 7.3 Gt for the transport sector, 3.4 Gt for the building sector and 12.1 Gt for the other sectors) to zero by 2050 [40]. From the viewpoints of reducing CO2 emission, PV installation of 13 TWp for the power sector, 6.8 TWp for the transport sector, 3.2 TWp for the building sector and 11.4 TWp for the other sectors are necessary [40,41]. Therefore, the integrated PV is expected to contribute to further reduction in CO2 emission and provide additional benefit such as multi-benefits and land use. In the case of rooftops, the solution for densely populated urban areas, rooftop cooling, lower energy building and increasing property values have multiple benefits. However, there are some problems to be solved. In the case of roads, initial installation cost, reliability, visibility issues, benefits compared to the other vehicles, theft and vandalism are challenging issues. The creation of a new large PV market of more than 110 TWp is globally expected.

Table 3.

PV installation potential of various integrated photovoltaics in addition to power sector.

Table 3.

PV installation potential of various integrated photovoltaics in addition to power sector.

| Integrated PV | Today’s Necessity [40] | EU Potential [41] | Global Potential [42,43,44,45] |

|---|---|---|---|

| Agrivoltaics | 944 GWp 1.7 TWp in Germany | ||

| Floating PV | 157 GWp | 23.3 TWp | |

| Roads and railroads (Transport) | 6.8 TWp | 401 GWp | 19.1 TWp |

| Rooftops | 3.2 TWp | 560 GWp | 44 TWp |

| Power sector | 13 TWpp | 21.9 TWp | |

| Others | 11.4 TWp | ||

| Total | 34.4 TWp | 2.06 TWp | >110 TWp |

3.5. Importance of Sustainability

Although the annual PV production volume has been predicted to be about 3 TWp since 2035 [3], there are limitations in the solar cell module production capacity that are dependent on the annual supply of materials for solar cells and modules. From the viewpoints of material sustainability, the annual production of various solar cells is discussed in this section.

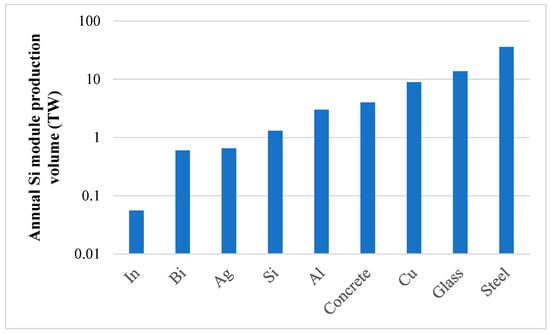

Figure 10 shows the production capacity limitation [46,47,48,49,50,51] for Si PV by considering individual material annual production volume and consumption. Although Si solar cell module shipment volume was about 500 GWp in 2023, maximum manufacturing capacities for Si solar cells are estimated to be 650 GWp, 430 GWp and 330 GWp for PERC and TOPCon solar cells, respectively, in the cases of 20% Ag consumptions of global supply [46]. In the case of In consumption, limiting the production capacity of the Si SHJ solar cells is 56 GWp [46] by considering usage of 20% In consumption of the global supply [46]. Although Si module productions are forecasted to be shifted from the PERC solar cells to the TOPCon and SHJ solar cells, considering material sustainability is very important for the further development of PV. Future trends in alternative approaches such as Cu and ZnO materials instead of Ag and ITO (Indium Tin Oxide) are necessary in order to realize multi-TWp scale manufacturing for the other solar cells. Recycling Ag and In is also very important for mainlining material sustainability for PV use.

Figure 10.

Production capacity imitations for Si PV estimated by considering individual material annual production volume and consumption.

Materials like steel, glass, Cu, concrete and Al are non-critical materials. However, the high consumption levels of those materials and substantially increased demand from primary production will raise serious concerns for CO2 emissions, and will result in negative environmental and social impacts from mineral production.

Table 4 shows the current material usage, target usage for 3 TW production scale, and material demand of various materials for Si PV and technology solutions [9,10,46,47,48,49]. Ag, Ga, Ge, In, Se and Te are rare materials. Maximum manufacturing capacities of various solar cells were estimated by assuming that the PV industry can sustainably use 20% of the global material supply, and efficiencies and layer thicknesses with 25% and 100 μm for Si, 20% and 2 μm for CdTe, 20% and 2 μm for CIGSe, 25% and 2 μm for GaAs, and 35% and 2 μm for III-V three-junction (3-J) solar cells.

Table 4.

Summary of current material usage, target usage for 3 TW production scale, and material demand of various materials for Si PV and technology solutions [9,10,46,47,48,49].

Table 4.

Summary of current material usage, target usage for 3 TW production scale, and material demand of various materials for Si PV and technology solutions [9,10,46,47,48,49].

| Annual Production | Current (400 GW Production) | 2030 (1.4 TW Production) | 2050 (3 TW Production) | Technology Solutions | |

|---|---|---|---|---|---|

| In | 2.1 kt | 22.4 kt (16 mg/W) | 22.5 kt (7.5 mg/W) | * Alternative TCO (AZO, etc.) * High-efficiency modules * Recycling of modules | |

| Bi | 21 kt | 18.2 kt (13 mg/W) | 4.2 kt (1.4 mg/W) | * Reduction in number of number of wires * Low-temperature solder alloys * High-efficiency modules * Recycling of modules | |

| Ag | 29 kt | 4 kt (2022) | 11.9 kt (8.5 mg/W) | 6 kt (2 mg/w) | * Further reduction in Ag * Usage of Cu * High-efficiency modules * Recycling of modules |

| Si | 8.5 Mt | 414 kt (2021) | 2.8 Mt (2 g/W) | 4.5 Mt (1.5 g/W) | * Thinning Si * Reduction in Kerf loss High-efficiency modules * Recycling of modules |

| Cu | 24.6 Mt | 504 kt (2021) | 3.9 Mt (2.8 g/W) | 5.4 Mt (1.8 g/W) | * Recycling of modules |

| Al | 130 Mt | 1.6 Mt (2021) | 12.6 Mt (9 g/W) | 18 Mt (6 g/W) | * Recycling of modules |

| Glass | 252 Mt | 7.56 Mt (2021) | 20.5 Mt (single glass) 41 Mt (double glass) | 73.2 MT (single glass) 146 Mt (double glass) | * Thinner glass +Glass foil * Polymer foil * High-efficiency modules * Recycling of modules |

| Steel | 1800 Mt | 10.1 Mt (2021) | 18.2 Mt (13 g/W) | 39 Mt (13 g/W) | * Recycling of modules * Green steel (decarbonization of electricity, etc.) |

| Concrete | 2040 Mt | 8.46 Mt (2021) | 70 Mt (50 g/W) | 150 Mt (50 g/W) | * Green steel (decarbonization of electricity, etc.) |

* Altenative TCO (Transparent Conductive Oxide) (AlZnO etc.).

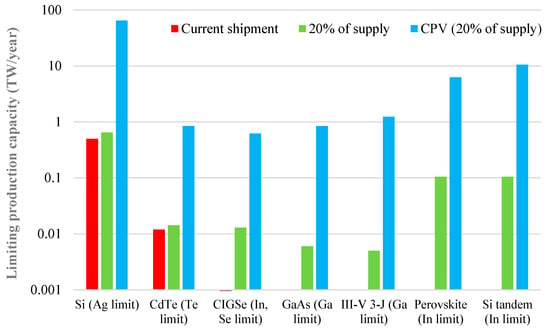

Figure 11 shows the current shipment volume and limiting production capacities for various solar cells. The maximum manufacturing capacities of the other solar cells are estimated to be 14.2 GWp (20% Te consumption of global supply) for CdTe, 13 GWp (20% In consumption of global supply) for CIGS, 6.5 GWp (20% Ga consumption of global supply) for GaAs, 5 GWp (20% Ga consumption of global supply) for III–V 3-J (20% Ga consumption of global supply) and 105 GWp for Si tandem (20% In consumption of global supply) for perovskite solar cells as shown in Figure 10, which are significantly lower compared to the maximum manufacturing capacities of Si solar cells. Alternative approaches are necessary in order to realize multi-TW scale manufacturing for the other solar cells. Even in the Si solar cell modules, limits of annual production volume are estimated to be about 2 TWp by considering the limits of Si as shown in Figure 10. Therefore, the development of thin wafer Si solar cells, and recycling and reusing Si solar cell modules are very important.

Figure 11.

Current shipment volume and limiting production capacities estimated for various solar cells.

Concentrator PV is expected to be one of key technologies to solve the material limitations of various solar cells [22,23] as shown in Figure 11, because reduction in material consumption is possible by multiplying the concentration factor 50-times for CdTe, CIGS [50,51] and perovskite, 100-times for Si [50,52] and Si tandem, 200-times for GaAs [50,53] and 300-times for III-V 3-J [50,54] solar cells under concentration operation.

4. Summary

Photovoltaic (PV) energy conversion is expected to contribute to the creation of a clean energy society. For realizing such a vision, various developments such as high performance, low-cost, and highly reliable materials, solar cells, modules and systems are necessary. Cooperation with storage batteries is also very important for regulation and self-consumption. The creation of new applications such as building integrated PV, vehicle integrated PV, agriculture PV and floating PV is also very important for the further installation of PV and reducing CO2 emission. The sustainability of material consumption, and reusing and recycling are also key issues for the widespread deployment of PV.

The current status of photovoltaics was shown in this paper. Because the efficiencies of single-junction solar cells are approaching the Shockley-Queisser limit (32∼33%) multi-junction and Si tandem solar cells are very attractive due to high-efficiency potential of more than 45%. Cost reduction and improvement of reliability based on technological development and the creation of a new market are very important. Concentrator PV is thought to contribute to higher efficiency of more than 55% and to solve material sustainability.

This paper also presented future directions for photovoltaics. After showing the current PV technology developments, key issues such as high-efficiency, low-cost, reliability, importance of integrated photovoltaics and material sustainability of PV were discussed for the future of PV.

Funding

This study was partially supported by the New Energy and Industrial Technology Development Organization (NEDO). Grant/Award Number: 20000938-0.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The author expresses thanks to the NEDO and to H. Yamada, A. Suzuki and H. Nomoto, NEDO for supporting studies and to N. Kojima, Prod. Y. Ohshita and K-H. Lee, Toyota Tech. Inst., B. Hallam, M. Green, N. Ekins-Daukes and Y. Zhang, UNSW, A. Bett, F. Dimroth and P. Schygulla, FhG-ISE, N. Haegel and J.F. Geiz, NREL, A. Luque, UPM, P. Verlinden, Yangtze Inst, Solar Tech., K. Araki, Y. Otha and K. Nishioka, University. Miyazaki for their fruitful discussion.

Conflicts of Interest

The author declares no conflicts of interest or state.

References

- Shell. Sky Scenario. Available online: http://www.shell.com (accessed on 11 August 2025).

- Breyer, C.; Bogdanov, D.; Gulagi, A.; Aghahosseini, A.; Barbosa, L.S.; Koskinen, O.; Barasa, M.; Caldera, U.; Afanasyeva, S.; Child, M.; et al. On the role of solar photovoltaics in global energy transition scenarios. Prog. Photovolt. 2017, 25, 727–745. [Google Scholar] [CrossRef]

- Haegel, N.M.; Verlinden, P.; Victoria, M.; Altermatt, P.; Atwater, H.; Barnes, T.; Breyer, C.; Case, C.; De Wolf, S.; Deline, C.; et al. Photovoltaics at multi-terawatt scale: Waiting is not an option. Science 2023, 380, 39–42. [Google Scholar] [CrossRef]

- VDMA. International Technology Roadmap for Photovoltaics (ITRPV), 15th ed.; VDMA: Frankfurt am Main, Germany, 2024. [Google Scholar]

- Victoria, M.; Haegel, N.; Peters, I.M.; Sinton, R.; Jäger-Waldau, A.; del Cañizo, C.; Breyer, C.; Stocks, M.; Blakers, A.; Kaizuka, I.; et al. Solar photovoltaics is ready to power a sustainable future. Joule 2021, 5, 1041–1056. [Google Scholar] [CrossRef]

- Choudhary, P.; Srivastava, R.K. Sustainability perspectives- a review for solar photovoltaic trends and growth opportunities. J. Clean. Prod. 2019, 227, 589–612. [Google Scholar] [CrossRef]

- IRENA. Future of Solar Photovoltaics; IRENA: Abu Dhabi, United Arab Emirates, 2019; ISBN 978-92-9260-156-0. [Google Scholar]

- Topic, M.; Drozdowski, R.; Sinke, W. European Strategic Research & Innovation Agenda (SRIA) for Photovoltaics –fit for 55% and climate neutrality. In Proceedings of the 38th European Photovoltaic Conference and Exhibition, Online, 6–10 September 2021. [Google Scholar]

- Gervais, E.; Herceg, S.; Nold, S.; Weiß, K.A. Sustainability strategies for PV: Framework, status and needs. EPJ Photovolt. 2021, 12, 5. [Google Scholar] [CrossRef]

- Goldschmidt, J.C.; Wagner, L.; Pietzcker, R.; Friedrich, L. Technological learning for resource efficient terawatt scale photovoltaics. Energy Environ. Sci. 2021, 14, 5147–5160. [Google Scholar] [CrossRef]

- Jones-Albertus, B. Technologies for a Solar-Powered Future. In Proceedings of the 49th IEEE Photovoltaic Specialists Conference, Philadelphia, PA, USA, 5–10 June 2022. [Google Scholar]

- Yamaguchi, M.; Lee, K.-H.; Araki, K.; Kojima, N. A review of recent progress in heterogeneous silicon tandem solar cells. J. Phys. D: Appl. Phys. 2018, 51, 133002. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Dimroth, F.; Geisz, J.F.; Ekins-Daukes, N.J. Multi-junction solar cells paving the way for super high-efficiency. J. Appl. Phys. 2021, 129, 240901. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hao, X.; Jiang, J.Y. Solar Cell Efficiency Tables (Version 65). Prog. Photovolt. 2025, 33, 3–15. [Google Scholar] [CrossRef]

- Richter, A.; Hermle, M.; Glunz, S.W. Reassessment of the Limiting Efficiency for Crystalline Silicon Solar Cells. IEEE J. Photovolt. 2013, 3, 1184–1191. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Ohshita, Y.; Shibata, H.; Tampo, H.; Nagai, T. Overview and Perspective for High-Efficiency Single-Junction Solar Cells. Sol. RRL 2023, 7, 2300308. [Google Scholar] [CrossRef]

- Amano, C.; Sugiura, H.; Yamamoto, A.; Yamaguchi, M. 20.2% efficiency Al0.4Ga0.6As/GaAs tandem solar cells grown by molecular beam epitaxy. Appl. Phys. Lett. 1987, 51, 1998–2000. [Google Scholar] [CrossRef]

- Olson, J.M.; Kurtz, S.R.; Kibbler, A.E.; Faine, P. A 27.3% efficient Ga0.5In0.5P/GaAs tandem solar cell. Appl. Phys. Lett. 1990, 56, 623–625. [Google Scholar] [CrossRef]

- Takamoto, T.; Ikeda, E.; Kurita, H.; Ohmori, M. Over 30% efficient InGaP/GaAs tandem solar cells. Appl. Phys. Lett. 1997, 70, 118419. [Google Scholar] [CrossRef]

- Bett, A.W.; Dimroth, F.; Lange, G.; Meusel, M.; Beckert, R.; Hein, M.; Riesen, S.V.; Schubert, U. 0% monolithic tandem concentrator solar cells for concentrations exceeding 1000 suns. In Proceedings of the 28th IEEE Photovoltaic Specialists Conference, New York, NY, USA, 15–20 September 2000; p. 15. [Google Scholar] [CrossRef]

- King, R.R.; Law, D.C.; Edmondson, K.M.; Fetzer, C.M.; Kinsey, G.S.; Yoon, H.; Sherif, R.A.; Karam, N.H. 40% efficient metamorphic GaInP∕GaInAs∕Ge multijunction solar cells. Appl. Phys. Lett. 2007, 90, 183516. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Luque, A. High efficiency and high concentration in photovoltaics. IEEE Trans. Electron Devices. 1999, ED-46, 2139. [Google Scholar] [CrossRef]

- Swanson, R.M. The Promise of Concentrators. Prog. Photovolt. 2000, 8, 93. [Google Scholar] [CrossRef]

- Essig, S.; Allebe, C.; Remo, T.; Geisz, J.F.; Steiner, M.A.; Horowitz, K.; Barraud, L.; Ward, J.S.; Schnabel, M.; Descoeudres, A.; et al. Raising the one-sun conversion efficiency of III–V/Si solar cells to 32.8% for two junctions and 35.9% for three junctions. Nat. Energy 2017, 2, 17144. [Google Scholar] [CrossRef]

- Schygulla, P.; Müller, R.; Lackner, D.; Höhn, O.; Hauser, H.; Bläsi, B.; Predan, F.; Benick, J.; Hermle, M.; Glunz, S.W.; et al. Two-Terminal III–V//Si Triple-Junction Solar Cell with Power Conversion Efficiency of 35.9% at AM1.5g. Prog. Photovolt. 2022, 30, 869–879. [Google Scholar] [CrossRef]

- Benda, V.; Cerna, L. A Note on Limits and Trends in PV Cells and Modules. Appl. Sci. 2022, 12, 3363. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, D.; Altermatt, P.P.; Zhang, S.; Wang, L.; Zhang, X.; Xu, J.; Feng, Z.; Shen, H.; Verlinden, P.J. The Silver Learning Curve for Photovoltaics and Projected Silver Demand for Net-Zero Emissions by 2050. Prog. Photovolt. 2023, 31, 1194–1204. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Nakamura, K.; Ozaki, R.; Kojima, N.; Ohshita, Y.; Masuda, T.; Okumura, K.; Satou, A.; Nakado, T.; Yamada, K.; et al. Analysis for the Potential of High-Efficiency and Low-Cost Vehicle-Integrated Photovoltaics. Sol. RRL 2022, 7, 2200556. [Google Scholar] [CrossRef]

- Sofia, S.E.; Wang, H.; Bruno, A.; Cruz-Campa, J.L.; Buonassisi, T.; Peters, I.M. Roadmap for cost-effective, commercially-viable perovskite silicon tandems for the current and future PV market. Sustain. Energy Fuels 2020, 4, 852–862. [Google Scholar] [CrossRef]

- Oshima, R.; Makita, K.; Ubukata, A.; Sugaya, T. Improvement of Heterointerface Properties of GaAs Solar Cells Grown with InGaP Layers by Hydride Vapor-Phase Epitaxy. IEEE J. Photovolt. 2019, 9, 154. [Google Scholar] [CrossRef]

- Horowitz, K.A.W.; Remo, T.; Smith, B.; Ptak, A. A Techno-Economic Analysis and Cost Reduction Roadmap for III-V Solar Cells; National Renewable Energy Laboratory: Golden, CO, USA, 2018. [Google Scholar]

- Thome, F.T.; Meßmer, P.; Mock, S.; Schrabel, E.; Schindler, F.; Kwopil, W.; Schubert, M.C. Enhanced Power Generation from PV Array Under Partial Shading Conditions by Shade Dispersion Using Su Do Ku Configuration. Sol. RRL 2024, 8, 2400628. [Google Scholar] [CrossRef]

- Sinha, A.; Qian, J.; Moffitt, S.L.; Hurst, K.; Terwilliger, K.; Miller, D.C.; Schelhas, L.T.; Hacke, P. UV-induced degradation of high-efficiency silicon PV modules with different cell architectures. Prog. Photovolt. 2023, 31, 36–51. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhu, K. Rapid advances enabling high-performance inverted perovskite solar cells. Nat. Rev. Mater. 2024, 9, 399. [Google Scholar] [CrossRef]

- Jean, J. Tandems and more at TW4. In Proceedings of the 4th Terawatt Workshop, Asilomar, CA, USA, 6–8 June 2024. [Google Scholar]

- Praventtoni, M.; Rajpud, A.S. On the metastability of silicon heterojunction solar photovoltaic modules. MRS Bull. 2023, 48, 80. [Google Scholar] [CrossRef]

- Matsuda, S.; Otoda, M.; Mitsui, K.; Kato, M.; Hokuo, S.; Yoshida, S. Recent Progress of Amorphous Silicon Solar Cell Technology. In Proceedings of the 17th IEEE Photovoltaic Specialists Conference, New York, NY, USA, 1–4 May 1984; p. 97. [Google Scholar]

- Yamaguchi, M.; Takamoto, T.; Araki, K.; Kojima, N. Recent results for concentrator photovoltaics in Japan. Jpn. J. Appl. Phys. 2016, 55, 04EA05. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Ota, Y.; Masuda, T.; Thiel, C.; Tsakalidis, A.; Jaeger-Waldau, A.; Araki, K.; Nishioka, K.; Takamoto, T.; Nakado, T.; et al. Analysis for Effects of Temperature Rise of PV Modules upon Driving Distance of Vehicle Integrated Photovoltaic Electric Vehicles. Energy Power Eng. 2024, 16, 131–150. [Google Scholar] [CrossRef]

- Chatzipanagi, A.; Kakoulaki, G.; Szabó, S.; Jager-Waldau, A. Overview and Perspective of Integrated Photovoltaics with a Focus on the European Union. Appl. Sci. Appl. Sci. 2024, 14, 10628. [Google Scholar] [CrossRef]

- Verlinden, P. Going to Multi-Terawatt Annual Production with Which Cell Technology. In Proceedings of the 34th International Photovoltaic Science and Engineering Conference (PVSEC-34), Shenzhen, China, 6–10 November 2023. [Google Scholar]

- Breyer, C.; Khalili, S.; Bogdanov, D. Solar photovoltaic capacity demand for a sustainable transport sector to fulfil the Paris Agreement by 2050. Prog. Photovol. 2019, 27, 978. [Google Scholar] [CrossRef]

- Breyer, C.; Bogdanov, D.; Aghahosseini, A.; Gulagi, A.; Child, M.; Oyewo, A.S.; Farfan, J.; Sadovskaia, K.; Vainikka, P. Solar photovoltaics demand for the global energy transition in the power sector. Prog. Photovol. 2018, 26, 505. [Google Scholar] [CrossRef]

- Molnar, G.; Ürge-Vorsatz, D.; Chatterjee, S.J. Residential energy use and its determinants: Evidence from a large-scale survey in Hungary. Clean. Prod. 2022, 375, 134133. [Google Scholar]

- Reindl, T. 100% Renewable Energy Scenario—What Are the Options to Deploy All the Solar Panels? In Proceedings of the 8th World Solar Energy Conversion (WCPEC-8), Milan, Italy, 26–30 September 2022. [Google Scholar]

- Zhang, Y.; Kim, M.; Wang, L.; Verlinden, P.; Hallam, B. Design considerations for multi-terawatt scale manufacturing of existing and future photovoltaic technologies: Challenges and opportunities related to silver, indium and bismuth consumption. Energy Environ. Sci. 2021, 14, 5587–5610. [Google Scholar] [CrossRef]

- Hallam, B.; Kim, M.; Underwood, R.; Drury, S.; Wang, L.; Dias, P. A Polysilicon Learning Curve and the Material Requirements for Broad Electrification with Photovoltaics by 2050. Sol. RRL 2022, 6, 2200458. [Google Scholar] [CrossRef]

- Lennon, A.; Lunardi, M.; Hallam, B.; Dias, P.R. The aluminium demand risk of terawatt photovoltaics for net zero emissions by 2050. Nat. Sustain. 2022, 5, 357–363. [Google Scholar] [CrossRef]

- Underwood, R.; Kim, M.; Drury, S.; Zhang, Y.; Wang, L.; Chan, C.; Hallam, B. Abundant Material Consumption Based on a Learning Curve for Photovoltaic toward Net-Zero Emissions by 2050. Sol. RRL 2023, 7, 2200705. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Araki, K. Concentrated Solar Cells. In Encyclopedia of Sustainability Science and Technology; Meyers, R.A., Ed.; Springer Nature: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Ward, J.S.; Egaas, B.; Noufi, R.; Contreras, M.; Ramanathan, K.; Osterwald, C.; Emery, K. Cu(In,Ga)Se2 solar cells measured under low flux optical concentration. In Proceedings of the 40th IEEE Photovoltaic Specialists Conference, New York, NY, USA, 08–13 June 2014; p. 2934. [Google Scholar] [CrossRef]

- Slade, A.; Garboushain, V. Investigation of high efficiency silicon solar cells. In Proceedings of the Technical Digest of the 15th International Photovoltaic Science and Engineering Conference, Shanghai, China, 10–15 October 2005; p. 701. Available online: https://www.researchgate.net/publication/267779112 (accessed on 11 August 2025).

- Schilling, C.L.; Hohn, O.; Micha, D.N.; Heckelmann, S.; Klinger, V.; Oliva, E.; Glunz, S.W.; Dimroth, F. An eye-tracking study of cueing effects in multimedia learning. IEEE J. Photovolt. 2018, 8, 348–354. [Google Scholar] [CrossRef]

- Sasaki, K.; Agui, T.; Nakaido, K.; Takahashi, N.; Onitsuka, R.; Takamoto, T. Development of Advanced Silicon Solar Cells and Their Module Integration. AIP Conf. Proc. 2013, l556, 22. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).