Abstract

Lignin, the most abundant renewable aromatic biopolymer on Earth, is rapidly emerging as a powerful enabler of next-generation sustainable technologies. This review shifts the focus to the latest industrial breakthroughs that exploit lignin’s multifunctional properties across energy, agriculture, healthcare, and environmental sectors. Lignin-derived carbon materials are offering scalable, low-cost alternatives to critical raw materials in batteries and supercapacitors. In agriculture, lignin-based biostimulants and controlled-release fertilizers support resilient, low-impact food systems. Cosmetic and pharmaceutical industries are leveraging lignin’s antioxidant, UV-protective, and antimicrobial properties to create bio-based, clean-label products. In water purification, lignin-based adsorbents are enabling efficient and biodegradable solutions for persistent pollutants. These technological leaps are not merely incremental, they represent a paradigm shift toward a materials economy powered by renewable carbon. Backed by global sustainability roadmaps like the European Green Deal and China’s 14th Five-Year Plan, lignin is moving from industrial residue to strategic asset, driven by unprecedented investment and cross-sector collaboration. Breakthroughs in lignin upgrading, smart formulation, and application-driven design are dismantling long-standing barriers to scale, performance, and standardization. As showcased in this review, lignin is no longer just a promising biopolymer, it is a catalytic force accelerating the global transition toward circularity, climate resilience, and green industrial transformation. The future of sustainable innovation is lignin-enabled.

1. Introduction

Modern economies worldwide are undergoing a profound transformation as nations recognize the urgent need to shift from fossil-based resources to renewable and sustainable alternatives. This transition is driven by the dual challenges of climate change and resource depletion, which demand innovative solutions to reduce greenhouse gas emissions, protect the environment, and promote circular economic models. The bioeconomy, which integrates biological resources and processes to produce energy, materials, and chemicals, is central to this transition, offering a pathway to reduce dependence on finite petroleum sources and achieve sustainable development goals [1]. With the global bioeconomy projected to reach a value of USD 15 trillion by 2030, its role in mitigating climate change and reducing fossil fuel reliance cannot be overstated. However, the current management of agricultural and industrial waste remains a significant challenge. Annually, 998 million tons of agricultural waste are generated, with over 80% being incinerated or sent to landfills, contributing to 10% of global methane emissions [2,3].

As the global population is expected to exceed 10 billion by 2050, the need for sustainable agricultural practices and waste management systems becomes increasingly critical. Reducing fossil fuel dependency, minimizing emissions, and converting waste into reusable resources are essential steps toward achieving these goals. In this context, lignocellulosic biomass, derived from agricultural and forestry waste, represents a vast and underutilized resource. With an annual global production of 181.5 billion tons, only 8.2 billion tons are currently utilized [4], highlighting the untapped potential of this renewable feedstock [5].

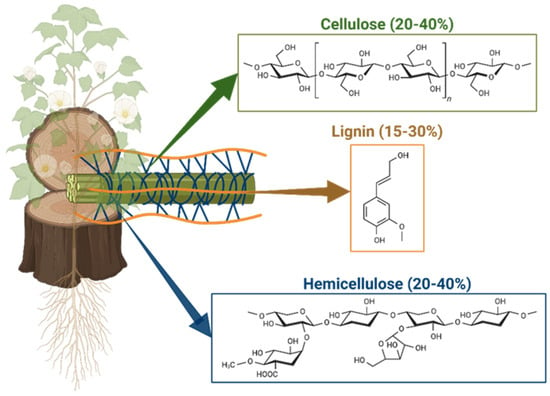

Lignocellulosic biomass, composed of cellulose, hemicellulose, and lignin, is a cornerstone of the bioeconomy (Figure 1).

Figure 1.

Composition of lignocellulosic biomass, showing the typical distribution of cellulose (20–40%), lignin (15–30%), and hemicellulose (20–40%) in plant cell walls. These components form the structural basis of biomass and are key to its utilization in bio-based applications.

While cellulose and hemicellulose are widely used in paper production and biofuel generation, lignin, the second most abundant natural polymer on Earth, has historically been undervalued. Traditionally treated as a low-value byproduct in the pulp and paper industry, lignin is often incinerated for energy recovery or discarded as waste [6]. However, recent advancements in research and technology have shifted this perspective, recognizing lignin as a versatile and renewable resource with immense potential for high-value applications.

Refs. [7,8] note its aromatic structure, functional groups, and biodegradability that make it an ideal candidate for producing biofuels, bioplastics, high-value chemicals, and advanced materials [9]. Lignin valorization is a key component of the circular bioeconomy, offering opportunities to reduce environmental impact, minimize resource utilization, and create sustainable alternatives to fossil-based products [10]. Globally, agricultural residues including wheat straw, rice husks, corn stover, and sugarcane bagasse are generated in staggering quantities, reaching an estimated 1 billion tons annually [11]. These residues contain lignin in proportions ranging from 15% to 30% [12], yet a substantial fraction of this valuable resource remains unexploited, often being burned or discarded, contributing to environmental pollution and resource inefficiency [13]. Despite its potential, the widespread adoption of lignin-based technologies faces several challenges. The structural variability and chemical resilience of lignin make its conversion into valuable products technically complex. Additionally, current industrial applications are limited by the lack of cost-effective and scalable extraction and processing technologies. However, advancements in biotechnology, catalysis, and process engineering are opening new pathways for lignin valorization, enabling the development of innovative products and applications [14].

This review provides a timely and forward-thinking synthesis of the emerging role of lignin as a cornerstone of the sustainable bioeconomy. Traditionally regarded as an industrial byproduct, lignin is now being redefined as a strategic feedstock for advanced applications across sectors including bioplastics, carbon materials, biofuels, agriculture, water purification, pharmaceuticals, and cosmetics. What sets this review apart is its focus on cutting-edge developments and industrially relevant breakthroughs, particularly those driven by startups and interdisciplinary consortia that are reshaping how lignin is extracted, processed, and integrated into value chains. The discussion emphasizes not only the versatility of lignin-derived products, but also the transformative shift from waste management to resource innovation, demonstrating how lignin valorization contributes directly to decarbonization, circularity, and green growth. Novel technologies, cross-sector collaborations, and supportive policy frameworks such as bioeconomy action plans and green innovation funding are presented as key enablers of this transition. By consolidating these trends and showcasing pioneering examples, this review highlights lignin’s growing strategic relevance and underscores its unique potential to drive systemic change toward a resilient, low-carbon future.

2. Structural Complexity and Composition of Native Lignin

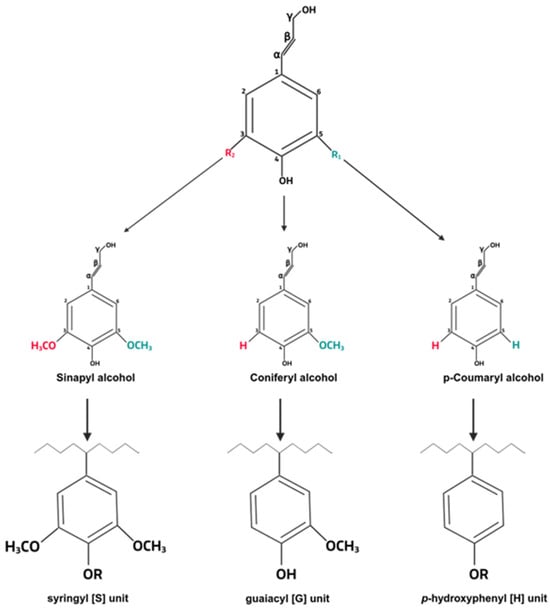

Lignin, a vital structural component of vascular plant cell walls, provides rigidity, hydrophobicity, and microbial resistance through its complex biopolymer structure [15]. It is formed via the oxidative polymerization of three monolignol precursors: p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol, which give rise to the three primary lignin units p-hydroxyphenyl (H), guaiacyl (G), and syringyl (S) [16]. Lignin, found in lignocellulosic biomass, commonly referred to as native lignin, is a highly complex polymer composed of interlinked units derived from methoxylated hydroxycinnamyl alcohols, collectively known as monolignols. The three principal monolignols are p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol, each incorporated into native lignin in species-dependent proportions. The relative abundance of these monolignols varies across plant types. In softwoods, lignin is predominantly composed of coniferyl alcohol units (≈95%), with minor contributions from p-coumaryl (≈4%) and sinapyl alcohol units (≈1%). In contrast, hardwood lignin typically exhibits a more balanced composition of coniferyl and sinapyl alcohol units, with only trace amounts of p-coumaryl alcohol (Figure 2). The distribution of these units varies significantly across plant species, tissue types, and cell wall layers, with softwoods predominantly containing G units, hardwoods a mix of G and S units, and grasses all three units in varying proportions [17]. This structural diversity is further amplified by the presence of various interunit linkages, with β-O-4 ether bonds comprising 50–60% of the total bonds, alongside carbon–carbon bonds such as β-5 (phenylcoumaran), β-β (resinol), and 5-5 (biphenyl) [18]. The random coupling of these linkages results in a highly complex, three-dimensional structure that distinguishes lignin from other biopolymers like cellulose and hemicellulose [19]. The structural complexity of lignin, characterized by its diverse functional groups hydroxyl, methoxyl, carbonyl, and carboxyl, poses both opportunities and challenges for its industrial utilization [20]. While this complexity is essential for lignin’s biological functions, it creates significant barriers for its conversion into high-value products such as biofuels, aromatic chemicals, and biopolymers [21]. The recalcitrance of lignin, driven by its irregular network and steric hindrance, complicates depolymerization processes, particularly the cleavage of β-O-4 ether bonds and more stable carbon–carbon linkages [22]. Additionally, the heterogeneity of lignin, which varies not only between species but also within individual molecules, further complicates its processing. For example, softwood lignin, rich in G units and carbon–carbon linkages, is more resistant to degradation than hardwood lignin, which contains higher proportions of S units and β-O-4 linkages [23]. Lignin’s renewable nature and unique properties make it a promising feedstock for carbon fibers, adhesives, and composite materials. However, its molecular weight, functional group composition, and solubility significantly influence the performance of lignin-derived materials, necessitating precise extraction and processing methods [24].

Figure 2.

The three main precursors of lignin (monolignols) and their corresponding structures in lignin polymers.

2.1. Lignin in Agricultural and Industrial Waste

The valorization of lignin from agricultural waste not only addresses the challenges of waste management but also provides a renewable alternative to fossil-based materials, aligning with the principles of the circular bioeconomy. Among the most prominent agricultural residues, sugarcane bagasse stands out due to its high lignin content (20–25%) and widespread availability, particularly in countries with extensive sugarcane cultivation such as Brazil and India [25]. Sugarcane bagasse, a fibrous byproduct of sugar production, is generated in large quantities and represents a readily available feedstock for lignin extraction and utilization [26]. Similarly, oilseed residues, including sunflower stalks and rapeseed straw, contribute significantly to the global lignin supply, with an annual production of approximately 182 million tons. These residues contain lignin concentrations of 20–25%, making them highly suitable for biorefinery processes aimed at producing biofuels, biochemicals, and bioplastics [27]. In addition to crop residues, the processing of nuts such as peanuts, almonds, and walnuts generates approximately 10 million tons of biomass waste annually, primarily in the form of shells. These agricultural byproducts are characterized by exceptionally high lignin content, typically ranging from 25% to 35%, which makes them ideal candidates for conversion into advanced materials such as carbon fibers, biochar, and activated carbon [28]. The high lignin content in nut shells not only enhances their thermal stability and mechanical properties but also provides a sustainable feedstock for the production of bio-based adhesives and composites [29]. The valorization of lignin from agricultural waste offers numerous environmental and economic benefits. By converting lignin-rich residues into high-value products, this approach reduces the environmental impact of agricultural waste disposal, such as open-field burning, which contributes to air pollution and greenhouse gas emissions. Furthermore, lignin valorization supports the development of a circular bioeconomy by transforming waste into valuable resources, thereby reducing reliance on finite fossil fuels and promoting sustainable industrial practices. However, the efficient extraction and utilization of lignin from agricultural waste face several challenges. These include the development of cost-effective and scalable extraction methods, the optimization of lignin properties for specific applications, and the establishment of robust supply chains and markets for lignin-derived products. Advances in extraction technologies, such as organosolv processes, enzymatic hydrolysis, and microwave-assisted extraction, are critical to overcoming these challenges and unlocking the full potential of lignin as a sustainable raw material [30]. Lignin in agricultural waste represents a vast and underutilized resource with significant potential for sustainable applications. By valorizing lignin from residues such as sugarcane bagasse, oilseed stalks, and nut shells, we can address global challenges related to waste management, resource efficiency, and climate change. Lignin derived from industrial waste streams represents a significant and underutilized resource with a high potential for economic and environmental sustainability. Industrial sectors such as pulp and paper production, bioethanol manufacturing, wood processing, and textile industries generate vast quantities of lignin-containing residues, allowing for an important increase in lignin-based companies worldwide [31]. Through emerging lignin extraction and refinement technologies, these waste streams can be transformed into high-value bio-based products, contributing to the circular bioeconomy and reducing dependence on fossil-derived materials [32]. The development of innovative lignin valorization strategies will not only contribute to the circular bioeconomy but also pave the way for a more sustainable and resilient future, where agricultural waste is transformed into valuable products that benefit both society and the environment.

2.2. Lignin in Pharmaceuticals and Cosmetics

Lignin is increasingly being recognized as a sustainable alternative to synthetic chemicals in the pharmaceutical and cosmetics industries. Its unique properties, including antioxidant, antimicrobial, and UV-protective capabilities, make it an ideal candidate for a wide range of applications, from skincare and sunscreens to drug delivery systems [33]. As consumer demand for natural, eco-friendly, and high-performance products grows, lignin is emerging as a key driver of innovation in these sectors, offering a sustainable solution that aligns with global trends toward green chemistry and circular bioeconomy principles. In the cosmetics industry, lignin is being utilized to replace synthetic stabilizers, thickeners, and UV filters, while also enhancing product performance and stability [34]. Borregaard (Sarpsborg, Norway) (https://www.borregaard.com/) (accessed on 10 June 2025), a global leader in lignin valorization, has developed Exilva®, a natural stabilizer and thickener derived from lignin that is used in skincare products to improve the texture and shelf life. Additionally, Borregaard’s EuroVanillin® Supreme, a high-quality lignin-based vanillin, serves as both an antioxidant and a fragrance additive in cosmetics, offering a sustainable alternative to synthetic vanillin (https://www.borregaard.com/markets/food/plant-based-vanillin accessed on 10 May 2025). Another notable innovation comes from LignoPure (Hamburg, Germany) (https://www.lignopure.com/lignin/ accessed on 10 May 2025), which has introduced LignoBase, a lignin-derived ingredient featured in Personal Care Magazine’s “Little Book of Skin Care Ingredients.” LignoBase enhances the stability and performance of cosmetic formulations, demonstrating lignin’s versatility as a multifunctional ingredient in personal care products (https://www.lignopure.com/lignin/ accessed on 10 May 2025). Lignin is also making waves in the sunscreen market, where its UV-protective properties are being harnessed to improve the efficacy and sustainability of sun care products. Lignovations (https://lignovations.com/ accessed on 10 May 2025), for example, has developed LignoGuard (https://lignovations.com/lignoguard-spf-booster/ accessed on 10 May 2025), an SPF enhancer derived from lignin that not only boosts UV protection but also reduces the amount of synthetic UV filters required in sunscreen formulations. This innovation addresses growing concerns about the environmental impact of conventional sunscreens, particularly their contribution to coral reef degradation, while providing a high-performance, bio-based alternative. Lignolix (https://www.lignolix.com/ accessed on 10 May 2025), a pioneer company in this field, is creating lignin adhesives with bio-based ingredients for sustainable adhesion, cosmetics containing naturally multifunctional additives, and flavors and fragrances characterized by natural phenolic compounds to replace petrochemical feedstocks. Scientific research further supports lignin’s potential in pharmaceuticals, with studies highlighting its role in developing nanoparticles for drug delivery protocols [35]. These lignin-based nanoparticles offer enhanced bioavailability, stability, and targeted delivery, making them suitable for treating a wide range of diseases, including cancer and infectious diseases [36]. The economic potential of lignin in the pharmaceutical and cosmetics industries is significant, particularly given its abundance as a byproduct of the pulp and paper industry [37]. Techno-economic analyses (TEA) indicate that lignin’s low cost and large-scale availability make it a highly attractive raw material for high-value applications [38]. For instance, the pulp and paper industry generates millions of tons of lignin annually, providing a stable and cost-effective supply chain for lignin-derived products [39]. This abundance, combined with lignin’s unique properties, positions it as a key enabler of sustainable innovation in these industries. Lignin is revolutionizing the pharmaceutical and cosmetics industries by providing a sustainable, high-performance alternative to synthetic chemicals. Innovations such as Borregaard’s Exilva® and EuroVanillin® Supreme, LignoPure’s LignoBase, Lignovations’ LignoGuard, and Lignolix’s demonstrate the versatility and potential of lignin to address key challenges in these sectors. By reducing reliance on fossil-derived resources, lowering the environmental impact, and enhancing product performance, lignin-based solutions are paving the way for a more sustainable future in pharmaceuticals and cosmetics.

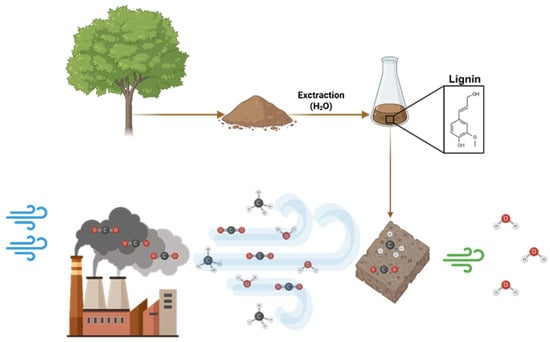

2.3. Lignin-Based Filters and Adsorbents for Water Purification and Environmental Remediation

Lignin-based materials are emerging as superior, sustainable, and cost-effective solutions for water purification and environmental remediation, leveraging the renewable and biodegradable properties of lignin to address pressing global challenges related to water contamination and resource efficiency. The unique chemical structure of lignin, characterized by its multivariate functional groups, enables it to effectively adsorb and remove a wide range of pollutants, including heavy metals, organic impurities, and dyes, making it an ideal candidate for filtration and adsorption applications [40]. Unlike traditional synthetic filtration systems, which often rely on non-renewable resources and energy-intensive production processes, lignin-based filters and adsorbents offer a sustainable alternative that aligns with the principles of the circular bioeconomy. Leading the industry in the development and commercialization of lignin-based filter media are companies like Gessner Filtration (Weidach, Germany) (https://www.gessner-filtration.com/ accessed on 10 May 2025) and Ahlstrom (https://www.ahlstrom.com/ accessed on 10 May 2025). Gessner Filtration has pioneered the production of lignin-based filter media that demonstrate exceptional adsorption capabilities, effectively removing contaminants from water and providing a renewable alternative to conventional synthetic filtration systems. These filters are not only highly efficient but also biodegradable, reducing the environmental impact of waste generated from filtration processes (https://www.gessner-filtration.com/solutions/sustainable-filter-solutions/eco-friendly-lignin-filter-media/ accessed on 10 May 2025). Similarly, Ahlstrom has introduced Ahlstrom Eco™, a lignin-based automotive filter media that showcases the scalability and versatility of lignin in water treatment applications. Ahlstrom Eco™ (Helsinki, Finland) exemplifies how lignin can be integrated into large-scale industrial processes to achieve sustainable and cost-effective solutions for water purification (https://www.ahlstrom.com/products/technologies/ahlstrom-eco/ accessed on 10 May 2025). Scientific research further supports the effectiveness of lignin as a filtration and adsorption material. Studies have shown that lignin-modified adsorbents can achieve adsorption capacities exceeding 200 mg/g for certain pollutants, such as heavy metals and dyes, making them highly competitive with traditional activated carbon [41]. This high adsorption capacity is attributed to lignin’s complex structure, which provides numerous binding sites for pollutants, as well as its ability to be chemically modified to enhance its performance. Additionally, lignin has been successfully used in cooling circuits of water treatment plants, where it acts as an anti-scaling agent and prevents the formation of sludge and biofilms, thereby improving the efficiency and longevity of water treatment systems [42]. The environmental benefits of lignin-based filters and adsorbents are further underscored by life cycle assessments (LCA), which reveal that these materials can reduce carbon emissions by 20% to 40% compared to traditional activated carbon [43]. This reduction is achieved through the use of renewable feedstock, lower energy consumption during production, and the biodegradability of lignin-based materials, which minimize waste and environmental pollution. The versatility of lignin extends beyond water purification to include applications in air filtration, soil remediation, and industrial wastewater treatment [44]. For example, lignin-based adsorbents can be used to capture volatile organic compounds (VOCs) and particulate matter from air streams, providing a sustainable solution for improving air quality (Figure 3) [45]. In soil remediation, lignin can be used to immobilize heavy metals and organic pollutants, preventing their leaching into groundwater and reducing their bioavailability [46]. These diverse applications highlight the potential of lignin to address a wide range of environmental challenges while promoting resource efficiency and sustainability. Lignin-based filters and adsorbents represent a transformative opportunity for the water treatment and environmental remediation sectors, offering a low-cost, renewable, and sustainable alternative to traditional materials. Innovations, scientific research, and life cycle assessments demonstrate the potential of lignin to reduce carbon emissions, lower production costs, and improve the efficiency of filtration and adsorption processes.

Figure 3.

Lignin-based filters. The atoms of Carbon, oxygen, and hydrogen, are reported in black, red, and white, respectively.

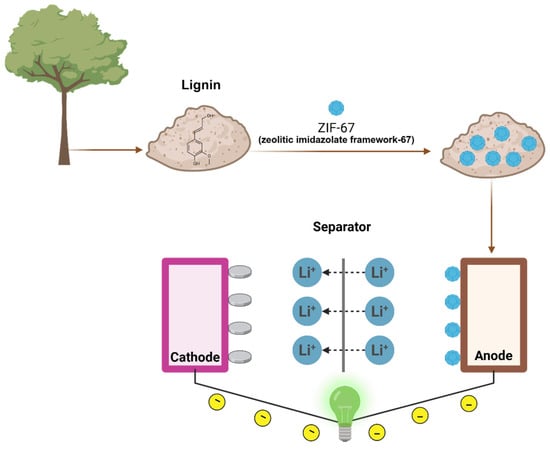

2.4. Lignin in Energy Storage

Lignin is emerging as a game-changing raw material in the energy storage sector, offering a sustainable alternative to traditional graphite and other carbon-based materials used in batteries and supercapacitors [47]. Researchers and companies are increasingly exploring lignin’s potential to produce high-performance carbon materials that can replace conventional graphite components in lithium-ion batteries, sodium-ion batteries, and supercapacitors, thereby addressing the growing demand for sustainable energy storage solutions (Figure 4) [48]. This shift toward lignin-based materials is driven by the need to reduce reliance on fossil-derived resources, lower carbon emissions, and enhance the sustainability of high-tech manufacturing processes. One of the most notable advancements in this field is Stora Enso’s (Stockholm, Sweden) (https://www.storaenso.com/en accessed on 10 May 2025) development of Lignode® (https://www.storaenso.com/en/products/lignin/lignode accessed on 10 May 2025), a lignin-based carbon material designed to serve as an anode in both lithium-ion and sodium-ion batteries. Lignode® offers a renewable and cost-effective alternative to traditional graphite anodes, which are typically derived from non-renewable sources and involve energy-intensive production processes. Stora Enso’s life cycle assessments reveal that lignin-based battery materials can achieve significant reductions in carbon emissions. This innovation positions lignin as a key enabler of sustainable energy storage technologies, supporting global efforts to transition to renewable energy systems and reduce the environmental impact of battery production. Ligna Energy (Norrköping, Sweden) (https://www.lignaenergy.com/ accessed on 10 May 2025), a Swedish startup, is developing supercapacitors using lignin as a primary material (https://www.lignaenergy.com/supercapacitors/ accessed on 10 May 2025). Supercapacitors, which are used for rapid energy storage and release, benefit from lignin’s high carbon content and structural properties, making it an ideal feedstock for producing porous carbon electrodes with a high surface area and conductivity. Similarly, FP Innovations (Vancouver, BC) (https://web.fpinnovations.ca/ accessed on 10 May 2025), a Canadian research organization, is working on the development of lignin-based carbon fibers for use as electrode materials in batteries. These fibers offer a lightweight, high-strength alternative to traditional materials, with the added benefits of being derived from a renewable resource, a reduced sulphur odor, a reduction in CO2 use by 20 to 40%, heat from the oxidation step is recovered and reused at the mill, and the lignin is purer (less than 0.5% ash content compared to 3% ash) (https://web.fpinnovations.ca/lignin-building-block-of-a-low-carbon-economy/ accessed on 10 May 2025). The advantages of lignin as a raw material for energy storage extend beyond its renewability and low carbon footprint. Lignin requires less processing energy compared to synthetic alternatives, reducing the overall energy intensity of battery production. Additionally, lignin’s abundance as a byproduct of the pulp and paper industry ensures a stable and cost-effective supply chain, further enhancing its appeal as a sustainable feedstock. These characteristics make lignin an attractive option for disrupting traditional graphite markets and advancing the development of green energy storage technologies. Optimizing lignin extraction and purification processes ensures consistent quality, improving the electrochemical performance of lignin-derived carbon materials, and reducing production costs to achieve market competitiveness. Ongoing research and innovation are focused on addressing these challenges through the development of advanced processing technologies, novel lignin modification techniques, and integrated biorefinery models that maximize the utilization of all biomass components. Lignin is poised to play a transformative role in the energy storage sector by providing a sustainable alternative to traditional graphite and other carbon-based materials. Innovations such as Stora Enso’s Lignode®, Ligna Energy’s supercapacitors, and FP Innovations’ lignin-based carbon fibers demonstrate the potential of lignin to disrupt graphite markets and advance high-tech manufacturing practices. By reducing carbon emissions, lowering energy consumption, and promoting the use of renewable resources, lignin-based energy storage materials align with global sustainability goals and support the transition to a low-carbon economy.

Figure 4.

Example of lignin-based carbon material used as an anode in lithium-ion batteries.

2.5. Agriculture: Lignin-Derived Fertilizers and Soil Amendments

The agricultural sector is increasingly turning to lignin-derived fertilizers and soil amendments as sustainable and cost-effective solutions to improve soil health, enhance crop productivity, and address environmental challenges (Figure 5) [49]. Lignin, a byproduct of the paper and pulp industry, is a renewable and abundant resource that offers unique properties for agricultural applications. When processed into soil amendments, lignin improves soil structure, enhances water retention, and stimulates microbial activity, creating a more fertile and resilient growing environment [50]. Additionally, lignin-based products minimize nutrient losses through leaching and volatilization, ensuring that essential nutrients such as nitrogen, phosphorus, and potassium are more efficiently utilized by plants [51]. These benefits make lignin an attractive alternative to synthetic fertilizers, which are often associated with environmental issues such as soil degradation, water pollution, and greenhouse gas emissions. Leading the charge in the development and commercialization of lignin-based agricultural products are companies like Borregaard (Sarpsborg, Norway) (https://www.borregaard.com/ accessed on 10 May 2025) and MetGen (Kaarina, Finland) (https://www.metgen.com accessed on 10 May 2025), which have pioneered innovative solutions to harness the potential of lignin for sustainable farming. Borregaard, a global leader in lignin valorization, offers products designed to improve plant nutrition, crop protection, biocontrol, seed coating, and other products to enhance soil health and reduce the environmental impact of agriculture. Similarly, MetGen’s METNIN™ technology platform focuses on converting lignin into high-value agricultural inputs that promote sustainable crop production while addressing key environmental challenges (https://www.metgen.com/lignin-products/ accessed on 10 May 2025). These companies have demonstrated that lignin-based products can achieve significant reductions in greenhouse gas emissions, making them a critical component of efforts to decarbonize agriculture and align with global sustainability goals. The application of lignin-derived fertilizers and soil amendments supports the principles of the circular economy by transforming an industrial byproduct into a valuable resource for agriculture. By reducing reliance on synthetic fertilizers, lignin-based products help lower the carbon footprint of farming operations, decrease dependency on fossil fuels, and promote the efficient use of resources. Furthermore, lignin’s ability to improve soil structure and water retention is particularly beneficial in regions facing soil degradation and water scarcity, as it enhances the resilience of agricultural systems to climate change and extreme weather events [52]. The stimulation of microbial activity by lignin also contributes to the long-term health of soils, fostering a more biodiverse and productive ecosystem. Along with their environmental benefits, lignin-derived agricultural products offer economic advantages for farmers. By improving nutrient efficiency and reducing the need for frequent fertilizer applications, these products can lower input costs and increase crop yields, resulting in higher profitability. The scalability and cost-effectiveness of lignin-based solutions make them accessible to farmers of all sizes, from smallholder operations to large-scale commercial farms. Moreover, the integration of lignin into agricultural practices aligns with consumer demand for sustainably produced food, providing farmers with a competitive edge in the market. Fertilizers and soil amendments from lignin represent a transformative opportunity for the agricultural sector to enhance soil health, improve crop productivity, and reduce the environmental impact. By leveraging lignin’s unique properties, companies like Borregaard and MetGen are leading the way in developing sustainable alternatives to synthetic fertilizers that support the transition to a circular bioeconomy. The significant reductions in greenhouse gas emissions achieved by lignin-based products underscore their potential to contribute to global sustainability goals and address pressing environmental challenges.

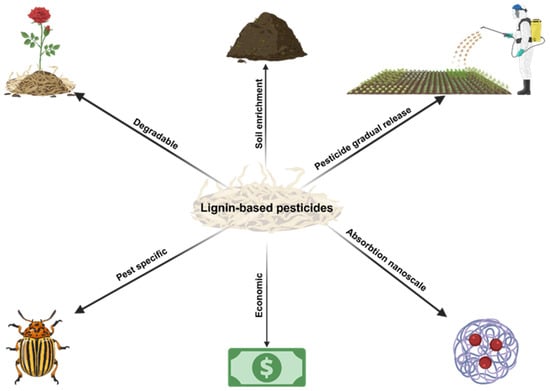

Figure 5.

Advantages and uses of lignin-based products in agriculture.

2.6. Lignin in the Textile Industry

The textile industry is a significant contributor to industrial lignin waste, particularly through the processing of natural fibers such as cotton, flax, hemp, and jute [53]. These lignocellulosic plant materials contain substantial amounts of lignin, often removed and discarded during fiber extraction, retting, and chemical processing [54]. Annually, the global production of lignin-rich textile waste is estimated at approximately 130 million tons, positioning the textile sector as one of the largest untapped sources of industrial lignin [55]. Historically, this lignin-rich waste has been underutilized, commonly disposed of in landfills or incinerated, practices that contribute to environmental degradation and resource inefficiency [56]. However, growing interest in circular economy strategies and sustainable materials has spurred efforts to recover and valorize this resource. Recent developments in alkaline and organosolv pretreatment methods have enabled the selective extraction of lignin from textile residues, with recovery rates ranging from 40% to 60%, depending on the feedstock and process parameters [57]. One promising application is in the development of biodegradable textile coatings. Lignin-based coatings can improve the UV resistance, mechanical strength, and water repellency of natural fiber fabrics, making them suitable for outdoor apparel, technical textiles, and geotextiles [58]. Companies like Lignovations (https://lignovations.com/ accessed on 10 May 2025) (Austria) are developing lignin-based functional additives and dispersions for textiles, targeting bio-based coatings with antimicrobial and antioxidative performances. Additionally, lignin-derived eco-friendly dyes are gaining attention as sustainable alternatives to synthetic dyes, which are often toxic and non-biodegradable. Lignin-based dyes not only provide a renewable pigment source but also offer inherent antimicrobial and UV-protective properties, enhancing the functional and aesthetic value of textiles. Pilot studies have demonstrated that lignin-derived chromophores can produce color hues ranging from yellow-brown to deep purple, depending on their chemical structure and processing [59]. Textile-derived lignin also shows promise in pyrolysis-based applications, particularly for the production of biochar, a porous, carbon-rich material [60]. Through thermal decomposition in the absence of oxygen, lignin-rich residues can be converted into biochar with high adsorption capacities [60]. This biochar has demonstrated the effective removal of dyes, heavy metals, and organic contaminants from textile wastewater, contributing to closed-loop water treatment systems within the industry [60]. Several pilot projects in India and China have begun implementing lignin-derived biochar in decentralized effluent treatment units, highlighting its practical viability. Beyond coatings and water treatment, lignin from textile waste can serve as a natural binder or reinforcing agent in biocomposites, enhancing the strength and thermal stability of materials used in automotive interiors, building panels, and sustainable packaging [61]. Lignin-based adhesives, which are formaldehyde-free and non-toxic, are increasingly used as sustainable alternatives in wood laminates and fiberboard products for the textile and furniture sectors [62]. Despite its potential, several barriers remain: the lack of standardized and cost-effective extraction methods, variability in lignin composition depending on fiber type and processing, and the need to establish reliable supply chains for consistent lignin quality. Promising advances in enzymatic delignification, deep eutectic solvents (DES), and low-energy pyrolysis technologies are addressing these gaps, while collaborative efforts among academia, startups, and industry are fostering commercial readiness. Lignin from textile industry waste represents a vast, renewable, and underexploited resource that can support the development of sustainable materials and circular business models. By integrating lignin-based products such as biodegradable coatings, eco-friendly dyes, biochar, and biocomposites, the textile industry can reduce its environmental impact, valorize waste streams, and contribute to the replacement of fossil-derived chemicals. These developments position lignin as a key enabler in the transition toward a low-carbon, resource-efficient textile economy.

2.7. Lignin as a Carbon Fiber Precursor

Lignin, a renewable and abundant biopolymer derived from plant biomass, represents a valuable feedstock for the development of sustainable chemicals and materials [63]. Among the most promising valorization pathways are the depolymerization of lignin into aromatic monomers and its use as a precursor for low-cost carbon fiber production (Figure 6) [64]. These routes support the transition toward a circular bioeconomy by converting lignin-rich waste streams into high-value products with reduced environmental impact. One key valorization strategy is the depolymerization of lignin to yield valuable aromatic compounds such as vanillin, syringol, and phenolic derivatives. These monomers, typically derived from petrochemical sources like benzene, serve as essential building blocks in the production of flavors, fragrances, adhesives, resins, and biofuels [65]. Depolymerization offers a renewable alternative, with typical aromatic yields ranging from 15% to 25% depending on feedstock and process conditions [66]. Technologies such as Rapid Thermal Processing (RTP™), developed by Lignol Energy and now commercialized by Ensyn Corp (Ottawa, Canada) (https://www.ensyn.com/ accessed on 10 May 2025) utilize high-temperature pyrolysis to convert lignin-rich biomass into Renewable Neutral Fuel (RNF™), a versatile bio-oil feedstock for fuels and chemicals. Further applications of lignin-derived aromatics include the synthesis of renewable polymers, surfactants, and specialty chemicals. Despite these advancements, several challenges remain. Improving the selectivity and yield of desired aromatic monomers, minimizing energy consumption, and developing efficient separation and purification methods are critical for process optimization. Innovations in catalytic technologies, including heterogeneous catalysts, ionic liquids, and enzymatic systems, are actively addressing these limitations, enhancing the efficiency and sustainability of lignin depolymerization. Integrating these processes into existing biorefineries is essential for economic viability and maximizing resource utilization. The economic and environmental benefits of lignin depolymerization are driving increased investment and innovation, with both startups and established companies pursuing commercialization strategies. In parallel, lignin is also gaining momentum as a sustainable precursor for carbon fiber production, traditionally dominated by polyacrylonitrile (PAN) [67]. A significant breakthrough in this field is the melt–spinning process, which involves heating lignin to a molten state and extruding it to form fibers that are later stabilized and carbonized into high-performance carbon fibers. This method reduces energy consumption by up to 70% compared to PAN-based processes and is compatible with the existing manufacturing infrastructure facilitating industrial adoption [68]. In addition to cost and energy benefits, lignin-based carbon fibers contribute to lower lifecycle emissions and support sustainability goals by replacing fossil-derived materials with renewable alternatives. These materials are particularly promising for lightweight applications in aerospace, automotive, wind energy, and sporting goods, and align well with the growing demand for sustainable materials in emerging sectors such as electric vehicles and renewable energy. Overall, the dual valorization of lignin into aromatic monomers and carbon fibers highlights its versatility as a renewable feedstock and reinforces its role in advancing both green chemistry and sustainable materials development. The convergence of innovations in depolymerization and fiber processing technologies is accelerating commercial interest and investment in lignin-based products, paving the way for broader implementation across industrial sectors.

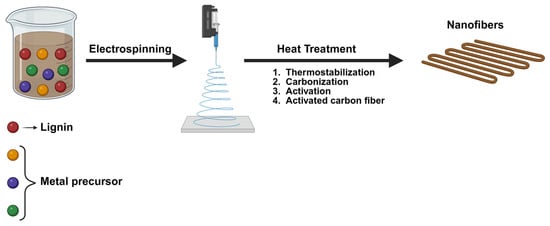

Figure 6.

Lignin electrospinning schematic diagram.

2.8. Applications of Lignin: Industrial Startups and Bio-Based Materials Innovations

The global plastics industry, which currently accounts for approximately 4% of global oil consumption, is undergoing a transformative shift toward sustainability by increasingly adopting lignin-based bioplastics as a renewable alternative to petroleum-derived plastics (Figure 7) [69]. Lignin is emerging as a key feedstock for the development of bio-based materials that not only reduce reliance on fossil fuels but also offer enhanced functional properties [70]. One of the most promising applications of lignin is its incorporation into biopolymers such as polylactic acid (PLA) and Polyurethane (PU), a widely used biodegradable plastic [71,72]. Studies have shown that the addition of lignin to PLA can improve tensile strength by up to 20% and reduce water permeability by 35%, making it a viable and competitive alternative to conventional plastics in terms of both performance and environmental impact [73]. These improvements are particularly significant for applications in packaging, agriculture, and consumer goods, where mechanical strength and barrier properties are critical. TEA and LCA studies have provided valuable insights into the economic and environmental viability of lignin-based bioplastics which can achieve cost parity with conventional plastics at production scales [74]. This cost competitiveness is further supported by advancements in processing technologies, such as solvent recovery systems, which are helping to mitigate challenges associated with lignin’s inherent hydrophobicity. However, innovative solutions, including chemical modification and the development of efficient solvent recovery processes, are reducing these costs and improving the economic feasibility of lignin-based materials [75]. The growing interest in lignin-based bioplastics is also reflected in the activities of industrial startups, which are playing a pivotal role in driving innovation and commercialization. These startups are leveraging lignin’s unique properties to develop a wide range of products, from biodegradable packaging films and agricultural mulches to high-performance composites for automotive and construction applications. Bioplastics based on lignin represent a transformative opportunity for the plastics industry to transition toward a more sustainable and circular bioeconomy. By replacing petroleum-derived plastics with renewable alternatives, lignin-based materials can significantly reduce greenhouse gas emissions, decrease reliance on fossil fuels, and contribute to the development of a low-carbon industrial landscape.

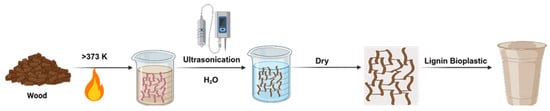

Figure 7.

Applications of lignin in bio-based materials.

2.9. Policy Guidelines for Asia and Europe: Lignin in the Global Bioeconomy

Europe and Asia are at the forefront of global efforts to advance lignin valorization, leveraging innovative policy frameworks, substantial funding, and cross-border collaborations to drive the sustainable bioeconomy transition. These regions have established themselves as leaders in lignin research and commercialization, with ambitious climate goals and strategic initiatives that prioritize the conversion of lignin into high-value products such as biofuels, bioplastics, carbon fibers, and construction materials. By integrating lignin valorization into their broader sustainability agendas, Europe and Asia are not only reducing greenhouse gas (GHG) emissions but also fostering economic growth and technological innovation. In Europe, the European Green Deal and the Circular Economy Action Plan provide a robust policy foundation for advancing lignin valorization. The European Green Deal, launched in 2019, sets ambitious targets to reduce GHG emissions by 55% by 2030 and achieve climate neutrality by 2050 (Bruxelles, Belgium) (https://commission.europa.eu accessed on 10 May 2025). Lignin valorization plays a critical role in meeting these targets, as it offers a renewable alternative to fossil-based materials and chemicals while promoting resource efficiency and waste reduction. The Circular Economy Action Plan further supports this transition by encouraging the development of bio-based products and the utilization of industrial byproducts like lignin. To accelerate innovation, the European Union has allocated significant funding through programs such as Horizon Europe, which has supported initiatives with over EUR 10 billion in investments (http://europa.eu accessed on 10 May 2025). These projects focus on converting lignin into biofuels, bioplastics, and high-value chemicals, achieving groundbreaking outcomes such as 100% biodegradable lignin-based adhesives and a 30–40% reduction in carbon emissions compared to fossil-based alternatives. These initiatives highlight Europe’s commitment to fostering innovation and creating a competitive bioeconomy that aligns with its climate and sustainability goals. In Asia, governments are also prioritizing lignin valorization as part of their national bioeconomy strategies. China’s 14th Five-Year Plan includes a dedicated bioeconomy strategy that emphasizes the development of lignin-based products. The National Key R&D Program has allocated CNY 2 billion (approximately USD 280 million) for research on lignin-based construction materials and packaging products. This investment has already led to the commercialization of lignin-based concrete additives, which enhance material durability and reduce CO2 emissions by 20% (Asian Development Bank, 2021). Similarly, Japan’s Biomass Industrial Strategy and Green Innovation Fund are driving the conversion of lignin into biofuels and biochemicals. Projects funded under these programs have demonstrated a 15% increase in energy efficiency compared to conventional fossil fuels, showcasing lignin’s potential as a sustainable energy source (World Economic Forum, 2022). South Korea is another key player in lignin valorization, with its Green New Deal bioeconomy roadmap supporting projects like LignoKR. This initiative has developed lignin-based composites that reduce production costs by 25% while maintaining high performance in pharmaceutical and industrial applications (Korean Ministry of Environment, 2021). In South Asia, countries like India and Bangladesh are beginning to explore lignin valorization as part of their sustainability agendas. India’s National Policy on Biofuels (2018) and the Sustainable Alternative Towards Affordable Transportation (SATAT) initiative encourage the use of biomass, including lignin, for bioenergy and biochemical production. The Indian Institute of Petroleum (IIP) is conducting research to achieve a 10–15% conversion efficiency of lignin into high-value products such as phenolic resins and vanillin, marking an important step toward commercialization (Asia Pacific Energy Portal, n.d.; Ministry of Petroleum and Natural Gas, India, n.d.). Central Asian nations like Kazakhstan and Uzbekistan are also recognizing the potential of lignin valorization. Kazakhstan’s Green Economy Transition Concept includes pilot projects to transform forestry and agricultural waste into biofuels and biocomposites, while Uzbekistan’s Strategy for Transition to a Green Economy identifies lignin-rich biomass as a key resource for sustainable development. Research institutions such as the Institute of Bioorganic Chemistry in Uzbekistan are actively studying lignin conversion into industrial materials, laying the groundwork for future commercialization (PAGE, 2020; Butaboev et al., 2023). The future of lignin valorization in Asia and Europe depends on continued governmental support, standardized regulations, and enhanced public–private partnerships. Increased research funding and cross-border collaborations will be essential to overcome technical and economic barriers, scale up production, and create robust markets for lignin-based products. By fostering innovation and aligning policies with global sustainability goals, these regions can unlock the full potential of lignin as a cornerstone of the bioeconomy. Europe and Asia are leading the global charge in lignin valorization, driven by ambitious policies, substantial investments, and a commitment to sustainability. Initiatives like the European Green Deal, China’s 14th Five-Year Plan, and South Korea’s Green New Deal are transforming lignin from an underutilized byproduct into a valuable resource for biofuels, bioplastics, carbon fibers, and more. As these efforts continue to gain momentum, lignin valorization will play an increasingly important role in reducing carbon footprints, advancing circular economy principles, and achieving global sustainability goals. By fostering collaboration and innovation, these regions are paving the way for a more sustainable and resource-efficient future.

2.10. Addressing Scalability Challenges in Lignin Valorization: Strategies and Future Directions

Despite the increasing body of research highlighting lignin’s potential in a wide range of industrial applications, its large-scale valorization still faces substantial technical and economic barriers. Among the most significant obstacles are the intrinsic heterogeneity of lignin, the lack of standardized processing protocols, and the cost-prohibitive nature of current purification methods. These challenges limit the reproducibility, performance, and market readiness of lignin-derived products, posing a serious constraint to the widespread adoption of lignin in commercial settings. Lignin heterogeneity stemming from variations in botanical origin, extraction methods, and processing conditions represents a critical issue in ensuring product consistency. Softwood lignins, for example, are rich in guaiacyl units and tend to form more recalcitrant structures, whereas hardwood lignins contain higher proportions of syringyl units, which are more amenable to depolymerization. Such variability influences key physicochemical parameters including molecular weight distribution, functional group content, solubility, and reactivity, ultimately affecting the performance of lignin-based materials. To mitigate this, researchers are exploring advanced fractionation techniques such as solvent-based selective precipitation, membrane filtration, and chromatographic separation, which aim to produce more uniform lignin fractions with well-defined properties tailored for specific end-use applications. In parallel, the development of efficient and cost-effective purification technologies is essential to enable the transition from lab-scale to industrial-scale production. Traditional lignin isolation processes, particularly those used in kraft or sulfite pulping, often result in technical lignins contaminated with residual carbohydrates, sulfur compounds, and ash, reducing their applicability in high-value sectors such as pharmaceuticals, energy storage, and bioplastics. Promising solutions include the use of green solvents such as gamma-valerolactone (GVL) and deep eutectic solvents (DES), which enable selective lignin extraction under mild conditions and offer excellent solvent recyclability. Additionally, integrated biorefinery approaches that combine lignin valorization with the co-production of cellulose, hemicellulose, and platform chemicals can significantly improve the economic feasibility of lignin utilization by maximizing resource efficiency and revenue streams. Overcoming the scalability bottleneck also requires addressing process intensification and modularity. Technologies such as continuous flow reactors, microwave-assisted processing, and enzymatic depolymerization systems are being investigated to enhance reaction rates, reduce energy input, and allow for better control over reaction pathways. In the context of energy storage materials, for instance, the scalable synthesis of lignin-derived carbon anodes must ensure not only material consistency but also compatibility with existing battery manufacturing infrastructure. Similarly, in agriculture, the formulation of lignin-based controlled-release fertilizers must consider cost-effective large-batch production while maintaining bioactivity and environmental stability. Furthermore, techno-economic assessments (TEA) and life cycle analyses (LCA) play a vital role in evaluating the real-world impact of lignin valorization technologies. Efficient lignin extraction remains a key challenge for the industrial implementation of biorefinery concepts, owing to lignin’s inherent recalcitrance and the complexity of biomass fractionation. Harsh operating conditions are often required to achieve effective separation, but these can result in substantial lignin degradation, thereby reducing yield and compromising downstream valorization. Furthermore, most existing kinetic models are primarily focused on cellulose fractionation and fail to adequately capture the multiscale chemical transformations associated with lignin, such as simultaneous delignification and de/repolymerization. This modeling gap becomes particularly limiting in scale-up scenarios, where predictive tools are essential for process optimization and control. In this context, multiscale modeling approaches are emerging as critical tools to guide the design and intensification of lignin extraction processes. Recent work has demonstrated the integration of ordinary differential equations (ODEs) with kinetic Monte Carlo (kMC) algorithms to simulate the coupled reaction kinetics across multiple temporal and spatial scales. Such models can predict key process variables, including residual lignin content in biomass chips and the molecular weight distribution of extracted lignin, with validation against experimental data. To facilitate real-time application, a reduced-order model (ROM) has also been developed for soft sensor design and incorporated into a model predictive control (MPC) framework to dynamically optimize operational strategies. These modeling tools not only enhance mechanistic understanding but also provide a robust platform to support process scale-up by improving selectivity, efficiency, and economic feasibility [76].

These tools can guide decision-making by identifying economic thresholds, environmental trade-offs, and optimal deployment scenarios. For example, recent LCA studies have demonstrated that the use of lignin in carbon fiber production can reduce CO2 emissions by up to 40% compared to conventional polyacrylonitrile-based fibers, provided that energy-efficient processing and high-purity lignin inputs are employed. To unlock the full potential of lignin in a sustainable bioeconomy, it is imperative that future research efforts prioritize the development of modular, scalable, and cost-effective processing frameworks. Public–private partnerships, industry–academia consortia, and supportive policy measures such as subsidies for green materials, incentives for waste valorization, and harmonized quality standards for lignin products are equally essential to facilitate market penetration and investor confidence. By explicitly addressing the scalability dimension, lignin valorization can move from being a promising laboratory concept to a commercially viable pillar of the circular economy.

3. Conclusions

Lignin, an abundant and renewable biopolymer derived from plant biomass, is emerging as a cornerstone of the global transition toward a sustainable and circular bioeconomy. Through its valorization, lignin is unlocking unprecedented opportunities to replace fossil-based materials and chemicals across a wide range of industries, including energy storage, construction, agriculture, pharmaceuticals, cosmetics, and water treatment. This review has highlighted the multifaceted potential of lignin as a sustainable raw material, demonstrating its ability to address critical environmental challenges, such as reducing greenhouse gas emissions, minimizing waste, and promoting resource efficiency, while simultaneously driving economic growth and technological innovation. In the energy sector, lignin-based carbon fibers and battery materials are disrupting traditional markets by offering cost-effective, high-performance alternatives to graphite and synthetic polymers. Innovations have demonstrated significant reductions in production costs and carbon footprints, paving the way for the widespread adoption of lignin-derived materials in lightweight industries like aerospace and automotive. Similarly, lignin’s role in supercapacitors and biofuels is enhancing energy storage and conversion efficiency, contributing to the decarbonization of energy systems and supporting the global shift toward renewable energy. In agriculture, lignin-derived fertilizers and soil amendments are improving soil health, enhancing crop productivity, and reducing reliance on synthetic fertilizers. These innovations align with the principles of the circular economy by transforming lignin-rich waste streams into valuable resources for sustainable farming. The pharmaceutical and cosmetics industries are also benefiting from lignin’s unique properties, such as its antioxidant, antimicrobial, and UV-protective capabilities. These applications underscore lignin’s potential to drive sustainable innovation in high-value markets, reducing reliance on fossil-derived chemicals and meeting consumer demand for eco-friendly products. In water treatment and environmental remediation, lignin-based filters and adsorbents are proving to be cost-effective and renewable solutions for removing pollutants such as heavy metals, dyes, and organic impurities. These advancements highlight lignin’s versatility as a sustainable material for addressing global water quality challenges. Policy initiatives in Europe and Asia are playing a pivotal role in accelerating lignin valorization. The European Green Deal, Circular Economy Action Plan, and Horizon Europe funding programs are driving innovation and commercialization, while Asia’s 14th Five-Year Plan, Japan’s Biomass Industrial Strategy, and South Korea’s Green New Deal are fostering the development of lignin-based products in construction, packaging, and biofuels. These regional efforts, supported by substantial investments and cross-border collaborations, are creating a favorable ecosystem for lignin valorization and positioning lignin as a key enabler of global sustainability goals. Despite these advancements, challenges remain in scaling up lignin valorization, including the need for cost-effective and scalable production methods, standardized lignin grades, and robust supply chains. Continued research and innovation, supported by public–private partnerships and policy frameworks, will be essential to overcome these barriers and unlock the full potential of lignin. Lignin is poised to play a transformative role in the sustainable bioeconomy, offering renewable alternatives to fossil-based materials and chemicals across diverse industries. By reducing carbon emissions, minimizing waste, and promoting resource efficiency, lignin valorization is contributing to the achievement of global sustainability goals, such as climate neutrality and circular economy principles. As technological advancements and market demand continue to drive innovation, lignin’s applications are expected to expand, solidifying its position as a key resource for a more sustainable and resilient future. The integration of lignin into industrial processes and products represents not only an environmental imperative but also an economic opportunity, paving the way for a bio-based revolution that aligns with the needs of both people and the planet.

Author Contributions

Conceptualization, A.T.; software, A.T.; writing—original draft preparation, A.T.; writing—review and editing, A.T.; visualization, A.T., L.M., A.V., M.G. and A.S.; supervision, A.T. and A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

We acknowledge financial support under the National Recovery and Resilience Plan (PNRR), Mission 4, Component 2, Investment 1.1, by the Italian Ministry of University and Research (MUR), funded by the European Union NextGenerationEU Project Title “The emergence of proto-arithmetic abilities with empty and non-empty sets” CUP B53D23030330001Prot. P2022TKY7B_003. The authors thank the following: PRIN: PROGETTI DI RICERCA DI RILEVANTE INTERESSE NAZIONALE Bando 2022 Prot. 2022LW54KC; PRIN: PROGETTI DI RICERCA DI RILEVANTE INTERESSE NAZIONALE Bando 2022 PNRR Prot. P2022RYR5W; F-Cur funds to M.G.; UE FSE REACT-EU, PON Ricerca e Innovazione 2014–2020; Progetto ERICA ARTES 4.0, E87G23000100001 Agenzia Coesione Territoriale; and Progetto “Bioeconomia circolare di Posidonia oceanica spiaggiata” Prot. NS0000021. Progetto OMNIALGAE Ministero dell’Ambiente e della Tutela del Territorio e del Mare (MATTM). J.D.D. was supported in part by the Italian Ministry of University and Research and the European Union (“Unione Europea Next Generation EU, Missione 4 Componente 2 Inv. 1.5 CUP_B63C22001400007) in the frame of the PNRR PE-13 (“Piano Nazionale di Ripresa e Resilienza, Partenariato Esteso 13, Malattie infettive emergenti”) INF-ACT project (One Health Basic and Translational Research Actions addressing Unmet Needs on Emerging Infectious Diseases).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Eversberg, D.; Holz, J.; Pungas, L. The Bioeconomy and Its Untenable Growth Promises: Reality Checks from Research. Sustain. Sci. 2023, 18, 569–582. [Google Scholar] [CrossRef]

- Karić, N.; Maia, A.S.; Teodorović, A.; Atanasova, N.; Langergraber, G.; Crini, G.; Ribeiro, A.R.L.; Đolić, M. Bio-Waste Valorisation: Agricultural Wastes as Biosorbents for Removal of (in)Organic Pollutants in Wastewater Treatment. Chem. Eng. J. Adv. 2022, 9, 100239. [Google Scholar] [CrossRef]

- Škrbić, S.; Ašonja, A.; Prodanović, R.; Ristić, V.; Stevanović, G.; Vulić, M.; Janković, Z.; Radosavac, A.; Igić, S. Analysis of Plant-Production-Obtained Biomass in Function of Sustainable Energy. Sustainability 2020, 12, 5486. [Google Scholar] [CrossRef]

- Ojo, A.O. An Overview of Lignocellulose and Its Biotechnological Importance in High-Value Product Production. Fermentation 2023, 9, 990. [Google Scholar] [CrossRef]

- Singh, N.; Singhania, R.R.; Nigam, P.S.; Dong, C.D.; Patel, A.K.; Puri, M. Global Status of Lignocellulosic Biorefinery: Challenges and Perspectives. Bioresour. Technol. 2022, 344, 126415. [Google Scholar] [CrossRef] [PubMed]

- Ullah, I.; Chen, Z.; Xie, Y.; Khan, S.S.; Singh, S.; Yu, C.; Cheng, G. Recent Advances in Biological Activities of Lignin and Emerging Biomedical Applications: A Short Review. Int. J. Biol. Macromol. 2022, 208, 819–832. [Google Scholar] [CrossRef] [PubMed]

- Mikkonen, K.S. Strategies for Structuring Diverse Emulsion Systems by Using Wood Lignocellulose-Derived Stabilizers. Green Chem. 2020, 22, 1019–1037. [Google Scholar] [CrossRef]

- Kumar, A.; Biswas, B.; Kaur, R.; Krishna, B.B.; Park, Y.K.; Bhaskar, T. Hydrotalcite Supported Cobalt and Tungsten Catalysts for Valorization of Lignin into Valuable Phenolics. J. Ind. Eng. Chem. 2024, 131, 514–530. [Google Scholar] [CrossRef]

- Patel, R.; Dhar, P.; Babaei-Ghazvini, A.; Nikkhah Dafchahi, M.; Acharya, B. Transforming Lignin into Renewable Fuels, Chemicals, and Materials: A Review. Bioresour. Technol. Rep. 2023, 22, 101463. [Google Scholar] [CrossRef]

- Shorey, R.; Salaghi, A.; Fatehi, P.; Mekonnen, T.H. Valorization of Lignin for Advanced Material Applications: A Review. RSC Sustain. 2024, 2, 804–831. [Google Scholar] [CrossRef]

- Babu, S.; Singh Rathore, S.; Singh, R.; Kumar, S.; Singh, V.K.; Yadav, S.K.; Yadav, V.; Raj, R.; Yadav, D.; Shekhawat, K.; et al. Exploring Agricultural Waste Biomass for Energy, Food and Feed Production and Pollution Mitigation: A Review. Bioresour. Technol. 2022, 360, 127566. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, A.M.; Santos, A.I.; Veiga, F.; Figueiras, A. Lignin Nanoparticle–Based Nanocomposite Hydrogels for Biomedical Applications. In Functional Nanocomposite Hydrogels: Synthesis, Characterization, and Biomedical Applications; Elsevier: Amsterdam, The Netherlands, 2023; pp. 69–90. [Google Scholar] [CrossRef]

- Wang, H.; Pu, Y.; Ragauskas, A.; Yang, B. From Lignin to Valuable Products–Strategies, Challenges, and Prospects. Bioresour. Technol. 2019, 271, 449–461. [Google Scholar] [CrossRef] [PubMed]

- Rath, S.; Pradhan, D.; Du, H.; Mohapatra, S.; Thatoi, H. Transforming Lignin into Value-Added Products: Perspectives on Lignin Chemistry, Lignin-Based Biocomposites, and Pathways for Augmenting Ligninolytic Enzyme Production. Adv. Compos. Hybrid. Mater. 2024, 7, 449–461. [Google Scholar] [CrossRef]

- Ma, Q.H. Lignin Biosynthesis and Its Diversified Roles in Disease Resistance. Genes 2024, 15, 295. [Google Scholar] [CrossRef] [PubMed]

- Del Río, J.C.; Rencoret, J.; Gutiérrez, A.; Elder, T.; Kim, H.; Ralph, J. Lignin Monomers from beyond the Canonical Monolignol Biosynthetic Pathway: Another Brick in the Wall. ACS Sustain. Chem. Eng. 2020, 8, 4997–5012. [Google Scholar] [CrossRef]

- Suota, M.J.; da Silva, T.A.; Zawadzki, S.F.; Sassaki, G.L.; Hansel, F.A.; Paleologou, M.; Ramos, L.P. Chemical and Structural Characterization of Hardwood and Softwood LignoForceTM Lignins. Ind. Crops Prod. 2021, 173, 114138. [Google Scholar] [CrossRef]

- Chambon, C.L.; Fitriyanti, V.; Verdía, P.; Yang, S.M.; Hérou, S.; Titirici, M.M.; Brandt-Talbot, A.; Fennell, P.S.; Hallett, J.P. Fractionation by Sequential Antisolvent Precipitation of Grass, Softwood, and Hardwood Lignins Isolated Using Low-Cost Ionic Liquids and Water. ACS Sustain. Chem. Eng. 2020, 8, 3751–3761. [Google Scholar] [CrossRef]

- Tarasov, D.; Leitch, M.; Fatehi, P. Lignin-Carbohydrate Complexes: Properties, Applications, Analyses, and Methods of Extraction: A Review. Biotechnol. Biofuels 2018, 11, 269. [Google Scholar] [CrossRef] [PubMed]

- Gan, M.J.; Niu, Y.Q.; Qu, X.J.; Zhou, C.H. Lignin to Value-Added Chemicals and Advanced Materials: Extraction, Degradation, and Functionalization. Green Chem. 2022, 24, 7705–7750. [Google Scholar] [CrossRef]

- Yue, P.; Hu, Y.; Yang, Z.; Peng, F.; Yang, L. Renewable and Functional Composite Film from Epoxidized Eucommia Ulmoides Gum and Industrial Lignin. Ind. Crops Prod. 2023, 194, 116381. [Google Scholar] [CrossRef]

- Sun, Z.; Fridrich, B.; De Santi, A.; Elangovan, S.; Barta, K. Bright Side of Lignin Depolymerization: Toward New Platform Chemicals. Chem. Rev. 2018, 118, 614–678. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Zhang, B.; Qi, Z.; Li, C.; Ji, J.; Dai, T.; Wang, A.; Zhang, T. Valorization of Lignin to Simple Phenolic Compounds over Tungsten Carbide: Impact of Lignin Structure. ChemSusChem 2017, 10, 523–532. [Google Scholar] [CrossRef] [PubMed]

- Lobato-Peralta, D.R.; Duque-Brito, E.; Villafán-Vidales, H.I.; Longoria, A.; Sebastian, P.J.; Cuentas-Gallegos, A.K.; Arancibia-Bulnes, C.A.; Okoye, P.U. A Review on Trends in Lignin Extraction and Valorization of Lignocellulosic Biomass for Energy Applications. J. Clean. Prod. 2021, 293, 126123. [Google Scholar] [CrossRef]

- Yadav, P.; Anu; Kumar Tiwari, S.; Kumar, V.; Singh, D.; Kumar, S.; Manisha; Malik, V.; Singh, B. Sugarcane Bagasse: An Important Lignocellulosic Substrate for Production of Enzymes and Biofuels. Biomass Convers. Biorefin. 2024, 14, 6111–6142. [Google Scholar] [CrossRef]

- Carvalho, J.A.; de Souza Miranda, M.; Pego, M.F.F.; Francisquini, E.; Resende, D.R.; Bianchi, M.L. Sugarcane Bagasse Lignin Obtained by Different Extraction Methods. Cellul. Chem. Technol. 2021, 55, 55–62. [Google Scholar] [CrossRef]

- Ziebell, A.L.; Barb, J.G.; Sandhu, S.; Moyers, B.T.; Sykes, R.W.; Doeppke, C.; Gracom, K.L.; Carlile, M.; Marek, L.F.; Davis, M.F.; et al. Sunflower as a Biofuels Crop: An Analysis Oflignocellulosic Chemical Properties. Biomass Bioenergy 2013, 59, 208–217. [Google Scholar] [CrossRef]

- Souto, F.; Calado, V.; Pereira, N. Lignin-Based Carbon Fiber: A Current Overview. Mater. Res. Express 2018, 5, 072001. [Google Scholar] [CrossRef]

- Kumari, U.; Gupta, P. Screening and Characterization of Waste Lignocellulosic Biomass as a Potential Substrate for Energy Recovery. Environ. Qual. Manag. 2023, 33, 369–386. [Google Scholar] [CrossRef]

- Chávez-Sifontes, M.; Domine, M.E. Lignin, Structure and Applications: Depolymerization Methods for Obtaining Aromatic Derivatives of Industrial Interest. Av. En. Cienc. E Ing. 2013, 4, 15–46. [Google Scholar]

- Vinod, A.; Pulikkalparambil, H.; Jagadeesh, P.; Rangappa, S.M.; Siengchin, S. Recent Advancements in Lignocellulose Biomass-Based Carbon Fiber: Synthesis, Properties, and Applications. Heliyon 2023, 9, e13614. [Google Scholar] [CrossRef] [PubMed]

- Kocaturk, E.; Salan, T.; Ozcelik, O.; Alma, M.H.; Candan, Z. Recent Advances in Lignin-Based Biofuel Production. Energies 2023, 16, 3382. [Google Scholar] [CrossRef]

- Sugiarto, S.; Leow, Y.; Tan, C.L.; Wang, G.; Kai, D. How Far Is Lignin from Being a Biomedical Material? Bioact. Mater. 2022, 8, 71–94. [Google Scholar] [CrossRef] [PubMed]

- Ariyanta, H.A.; Santoso, E.B.; Suryanegara, L.; Arung, E.T.; Kusuma, I.W.; Azman Mohammad Taib, M.N.; Hussin, M.H.; Yanuar, Y.; Batubara, I.; Fatriasari, W. Recent Progress on the Development of Lignin as Future Ingredient Biobased Cosmetics. Sustain. Chem. Pharm. 2023, 32, 100966. [Google Scholar] [CrossRef]

- Garg, J.; Nee Chiu, M.; Krishnan, S.; Kumar Tripathi, L.; Pandit, S.; Farasati Far, B.; Kumar Jha, N.; Kumar Kesari, K.; Tripathi, V.; Pandey, S.; et al. Applications of Lignin Nanoparticles for Cancer Drug Delivery: An Update. Mater. Lett. 2022, 311, 131573. [Google Scholar] [CrossRef]

- Stanisz, M.; Klapiszewski, Ł.; Collins, M.N.; Jesionowski, T. Recent Progress in Biomedical and Biotechnological Applications of Lignin-Based Spherical Nano- and Microstructures: A Comprehensive Review. Mater. Today Chem. 2022, 26, 101198. [Google Scholar] [CrossRef]

- Alam, M.M.; Greco, A.; Rajabimashhadi, Z.; Esposito Corcione, C. Efficient and Environmentally Friendly Techniques for Extracting Lignin from Lignocellulose Biomass and Subsequent Uses: A Review. Clean. Mater. 2024, 13, 100253. [Google Scholar] [CrossRef]

- Patel, R.; Rajaraman, T.S.; Rana, P.H.; Ambegaonkar, N.J.; Patel, S. A Review on Techno-Economic Analysis of Lignocellulosic Biorefinery Producing Biofuels and High-Value Products. Results Chem. 2025, 13, 102052. [Google Scholar] [CrossRef]

- Garlapati, V.K.; Chandel, A.K.; Kumar, S.P.J.; Sharma, S.; Sevda, S.; Ingle, A.P.; Pant, D. Circular Economy Aspects of Lignin: Towards a Lignocellulose Biorefinery. Renew. Sustain. Energy Rev. 2020, 130, 109977. [Google Scholar] [CrossRef]

- Suhas; Carrott, P.J.M.; Ribeiro Carrott, M.M.L. Lignin—From Natural Adsorbent to Activated Carbon: A Review. Bioresour. Technol. 2007, 98, 2301–2312. [Google Scholar] [CrossRef] [PubMed]

- Kumar Mishra, R.; Singh, B.; Acharya, B. A Comprehensive Review on Activated Carbon from Pyrolysis of Lignocellulosic Biomass: An Application for Energy and the Environment. Carbon. Resour. Convers. 2024, 7, 100228. [Google Scholar] [CrossRef]

- Wang, T.; Jiang, M.; Yu, X.; Niu, N.; Chen, L. Application of Lignin Adsorbent in Wastewater Treatment: A Review. Sep. Purif. Technol. 2022, 302, 122116. [Google Scholar] [CrossRef]

- Kylili, A.; Koutinas, M.; Georgali, P.Z.; Fokaides, P.A. Lignin Valorisation: Life Cycle Assessment (LCA) Considerations for Enabling Circular Bioeconomy. Int. J. Sustain. Energy 2023, 42, 1008–1027. [Google Scholar] [CrossRef]

- Mandal, D.D.; Singh, G.; Majumdar, S.; Chanda, P. Challenges in Developing Strategies for the Valorization of Lignin—A Major Pollutant of the Paper Mill Industry. Environ. Sci. Pollut. Res. 2023, 30, 11119–11140. [Google Scholar] [CrossRef] [PubMed]

- Sani, S.; Liu, X.; Stevens, L.; Wang, H.; Sun, C. Amine Functionalized Lignin-Based Mesoporous Cellular Carbons for CO2 Capture. Fuel 2023, 351, 128886. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.; Liu, S. Application of Lignin-Based by-Product Stabilized Silty Soil in Highway Subgrade: A Field Investigation. J. Clean. Prod. 2017, 142, 4243–4257. [Google Scholar] [CrossRef]

- Muddasar, M.; Culebras, M.; Collins, M.N. Lignin and Its Carbon Derivatives: Synthesis Techniques and Their Energy Storage Applications. Mater. Today Sustain. 2024, 28, 100990. [Google Scholar] [CrossRef]

- Zhang, J.; Xiang, H.; Cao, Z.; Wang, S.; Zhu, M. Research Progress of Lignin-Derived Materials in Lithium/Sodium Ion Batteries. Green. Energy Environ. 2025, 10, 322–344. [Google Scholar] [CrossRef]

- Izydorczyk, G.; Skrzypczak, D.; Mironiuk, M.; Mikula, K.; Samoraj, M.; Gil, F.; Taf, R.; Moustakas, K.; Chojnacka, K. Lignocellulosic Biomass Fertilizers: Production, Characterization, and Agri-Applications. Sci. Total Environ. 2024, 923, 171343. [Google Scholar] [CrossRef] [PubMed]

- Ariyanta, H.A.; Sari, F.P.; Sohail, A.; Restu, W.K.; Septiyanti, M.; Aryana, N.; Fatriasari, W.; Kumar, A. Current Roles of Lignin for the Agroindustry: Applications, Challenges, and Opportunities. Int. J. Biol. Macromol. 2023, 240, 124523. [Google Scholar] [CrossRef] [PubMed]

- Abbas, A.; Wang, Z.; Zhang, Y.; Peng, P.; She, D. Lignin-Based Controlled Release Fertilizers: A Review. Int. J. Biol. Macromol. 2022, 222, 1801–1817. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Ou, M. Experimental Study on Expansive Soil Improved by Lignin and Its Derivatives. Sustainability 2023, 15, 8764. [Google Scholar] [CrossRef]

- Islam, M.D.; Mohammad Ziaul Hyder, M.K.; Masudur Rhaman, M.; Mir, S.H. Application of Lignin-Based Biomaterials in Textile Wastewater. In Textile Wastewater Treatment. Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer: Singapore, 2022; pp. 75–99. [Google Scholar] [CrossRef]

- Haq, I.; Mazumder, P.; Kalamdhad, A.S. Recent Advances in Removal of Lignin from Paper Industry Wastewater and Its Industrial Applications—A Review. Bioresour. Technol. 2020, 312, 123636. [Google Scholar] [CrossRef] [PubMed]

- Mariana, M.; Alfatah, T.; Abdul Khalil, H.P.S.; Yahya, E.B.; Olaiya, N.G.; Nuryawan, A.; Mistar, E.M.; Abdullah, C.K.; Abdulmadjid, S.N.; Ismail, H. A Current Advancement on the Role of Lignin as Sustainable Reinforcement Material in Biopolymeric Blends. J. Mater. Res. Technol. 2021, 15, 2287–2316. [Google Scholar] [CrossRef]

- Tao, J.; Li, S.; Ye, F.; Zhou, Y.; Lei, L.; Zhao, G. Lignin–An Underutilized, Renewable and Valuable Material for Food Industry. Crit. Rev. Food Sci. Nutr. 2020, 60, 2011–2033. [Google Scholar] [CrossRef] [PubMed]

- Duarte, L.C.; Sampaio, B.; Carvalheiro, F. Organosolv Pretreatment of Lignocellulosic Biomass. In Handbook of Biorefinery Research and Technology; Springer: Dordrecht, The Netherlands, 2024; pp. 1–28. [Google Scholar] [CrossRef]

- Zimniewska, M.; Kozłowski, R.; Batog, J. Nanolignin Modified Linen Fabric as a Multifunctional Product. Mol. Cryst. Liq. Cryst. 2008, 484, 43–409. [Google Scholar] [CrossRef]

- Gao, S.; Chen, X.; Tian, G.; Fu, Y.; Qin, M.; Wang, Z. Preparation of Light-Colored Bio-Based Particles by Isocyanate-Modified Lignins and Its Application for Tetracycline Adsorption. Int. J. Biol. Macromol. 2023, 253, 127107. [Google Scholar] [CrossRef] [PubMed]

- Amalina, F.; Razak, A.S.A.; Krishnan, S.; Sulaiman, H.; Zularisam, A.W.; Nasrullah, M. Biochar Production Techniques Utilizing Biomass Waste-Derived Materials and Environmental Applications—A Review. J. Hazard. Mater. Adv. 2022, 7, 100134. [Google Scholar] [CrossRef]

- Linan, L.Z.; Fakhouri, F.M.; Nogueira, G.F.; Zoppe, J.; Velasco, J.I. Benefits of Incorporating Lignin into Starch-Based Films: A Brief Review. Polymers 2024, 16, 2285. [Google Scholar] [CrossRef] [PubMed]

- El Mansouri, N.E.; Pizzi, A.; Salvadó, J. Lignin-Based Wood Panel Adhesives without Formaldehyde. Holz Als Roh-Und Werkst. 2007, 65, 65–70. [Google Scholar] [CrossRef]

- Ejaz, U.; Sohail, M. Lignin: A Renewable Chemical Feedstock. In Handbook of Smart Materials, Technologies, and Devices: Applications of Industry 4.0: Volume 1–3; Springer: Cham, Switzerland, 2022; Volume 2, pp. 1529–1543. [Google Scholar] [CrossRef]

- Khan, R.J.; Lau, C.Y.; Guan, J.; Lam, C.H.; Zhao, J.; Ji, Y.; Wang, H.; Xu, J.; Lee, D.J.; Leu, S.Y. Recent Advances of Lignin Valorization Techniques toward Sustainable Aromatics and Potential Benchmarks to Fossil Refinery Products. Bioresour. Technol. 2022, 346, 126419. [Google Scholar] [CrossRef] [PubMed]

- Zhou, N.; Thilakarathna, W.P.D.W.; He, Q.S.; Rupasinghe, H.P.V. A Review: Depolymerization of Lignin to Generate High-Value Bio-Products: Opportunities, Challenges, and Prospects. Front. Energy Res. 2022, 9, 758744. [Google Scholar] [CrossRef]

- Kong, X.; Liu, C.; Fan, Y.; Li, M.; Xiao, R. Depolymerization of Technical Lignin to Valuable Platform Aromatics in Lower Alcohol without Added Catalyst and External Hydrogen. Fuel Process. Technol. 2023, 242, 107637. [Google Scholar] [CrossRef]

- Collins, M.N.; Culebras, M.; Ren, G. The Use of Lignin as a Precursor for Carbon Fiber-Reinforced Composites. In Micro and Nanolignin in Aqueous Dispersions and Polymers: Interactions, Properties, and Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 237–250. [Google Scholar] [CrossRef]

- Chernikova, E.V.; Osipova, N.I.; Plutalova, A.V.; Toms, R.V.; Gervald, A.Y.; Prokopov, N.I.; Kulichikhin, V.G. Melt-Spinnable Polyacrylonitrile—An Alternative Carbon Fiber Precursor. Polymers 2022, 14, 5222. [Google Scholar] [CrossRef] [PubMed]