A DEM Study on the Macro- and Micro-Mechanical Characteristics of an Irregularly Shaped Soil–Rock Mixture Based on the Analysis of the Contact Force Skeleton

Abstract

1. Introduction

2. Model Development and Numerical Computation

2.1. Establishment of Irregular Gravel Specimens in the DEM

2.2. Development of Irregular Gravel Clump Units in the DEM

2.3. Establishment of S-RM Models in the DEM

- The CT-scanned gravel microstructure model was imported into the PFC3d program. Subsequently, leveraging the parameters established in Section 2.2, the PFC particle clump template system was utilized to generate all gravel granule clumps within the microscale mold, as illustrated in Figure 4a.

- Based on the determined scales of the microscopic pattern, a test piece model comprising simple sand particles of uniform dimensions was established. Notably, the radius of the sand particles should be less than one-fifth of the gravel granule size, as shown in Figure 4b.

- Irregular clumps of gravel granules were arbitrarily generated within the specimen of simple sand particles. Sand particles overlapping with these gravel clumps were eliminated, and the S-RM model was subsequently established. To ensure close contact between gravel clumps and sand particles, and to prevent any particles from entering a floating state, the radius of all sand particles was initially scaled to 1‰ of their original size after the gravel particle clumps were clustered into the simple sand pattern. Next, sand particles in active contact with the gravel clumps were removed. The radii of the remaining sand particles were then gradually increased back to their original dimensions, with cycle operations performed after each adjustment to ensure continuous compaction and intimate contact between gravel and sand particles. Figure 4c illustrates the final three-dimensional discrete element model of the S-RM.

2.4. Contact Model and Material Parameters

2.5. Simulation Process for a Conventional Triaxial Drained Shear Test

- Conventional Consolidation: Employing the inherent servo control mechanism in conventional triaxial testing, the entire specimen undergoes initial servo-controlled consolidation to attain a fully consolidated state consistent with the required conditions.

- Flexible Consolidation: Prior to loading, a multi-particle wall servo was employed using a model with flexible membrane boundary conditions. Initially, the rigid wall was replaced by a particle membrane boundary. Alterations in boundary conditions may introduce potential disturbance to the specimens. To mitigate this, constant peripheral pressure was incrementally applied through iterative fine-tuning of the servo mechanism, thereby facilitating the specimen’s gradual transition to its initial consolidation state. For detailed information on the establishment of particle membrane boundaries, refer to Jiang et al. [60].

- Loading Stage: The particles in contact with the upper and lower loading plates at the flexible boundary interface are arranged in an adhesive contact configuration. To ensure these particles achieve the same velocity as the loading plates, synchronous velocity control is essential. To maintain the entire model in a quasi-static state [61], the inertial number I must be less than 10−3 [62]. The formula for calculating the inertial number I is presented below:

3. Results and Analyses

3.1. Macroscale Behaviors

3.1.1. Analysis of Macroscopic Mechanical Behaviors

3.1.2. Evolutionary Analysis of Shear Band Development

3.2. Microscale Behaviors

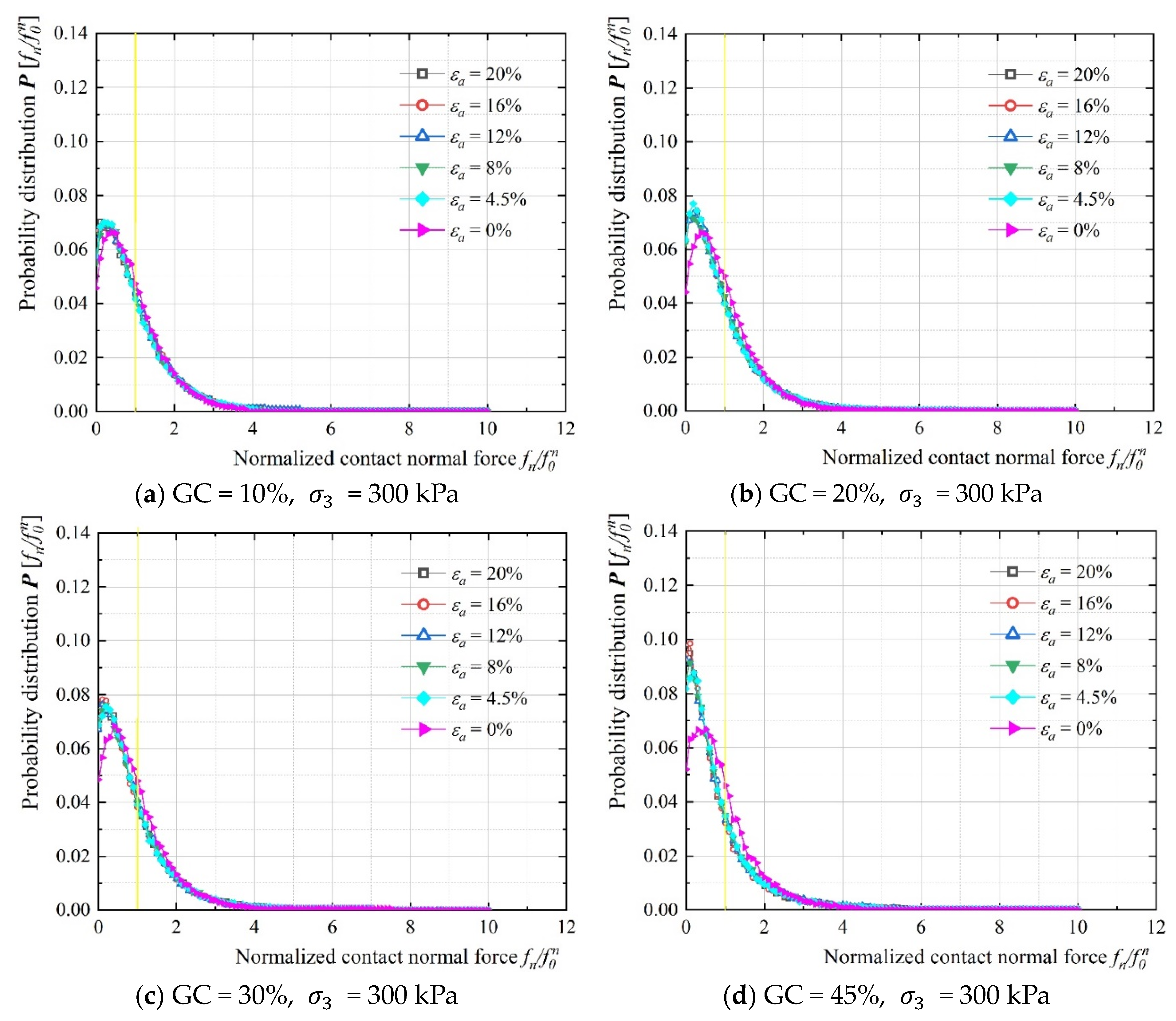

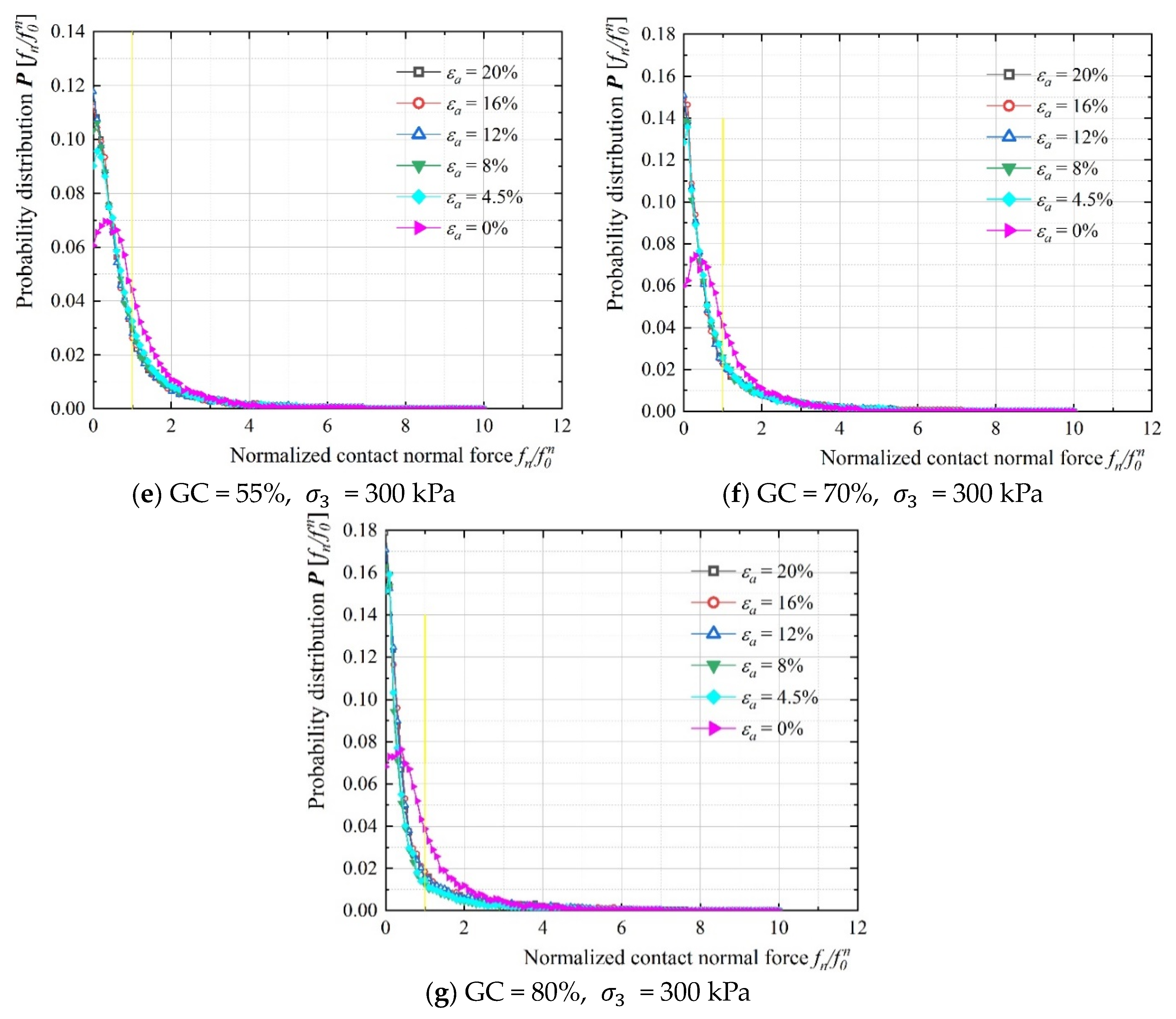

3.2.1. Probability Distributions of Contact Force

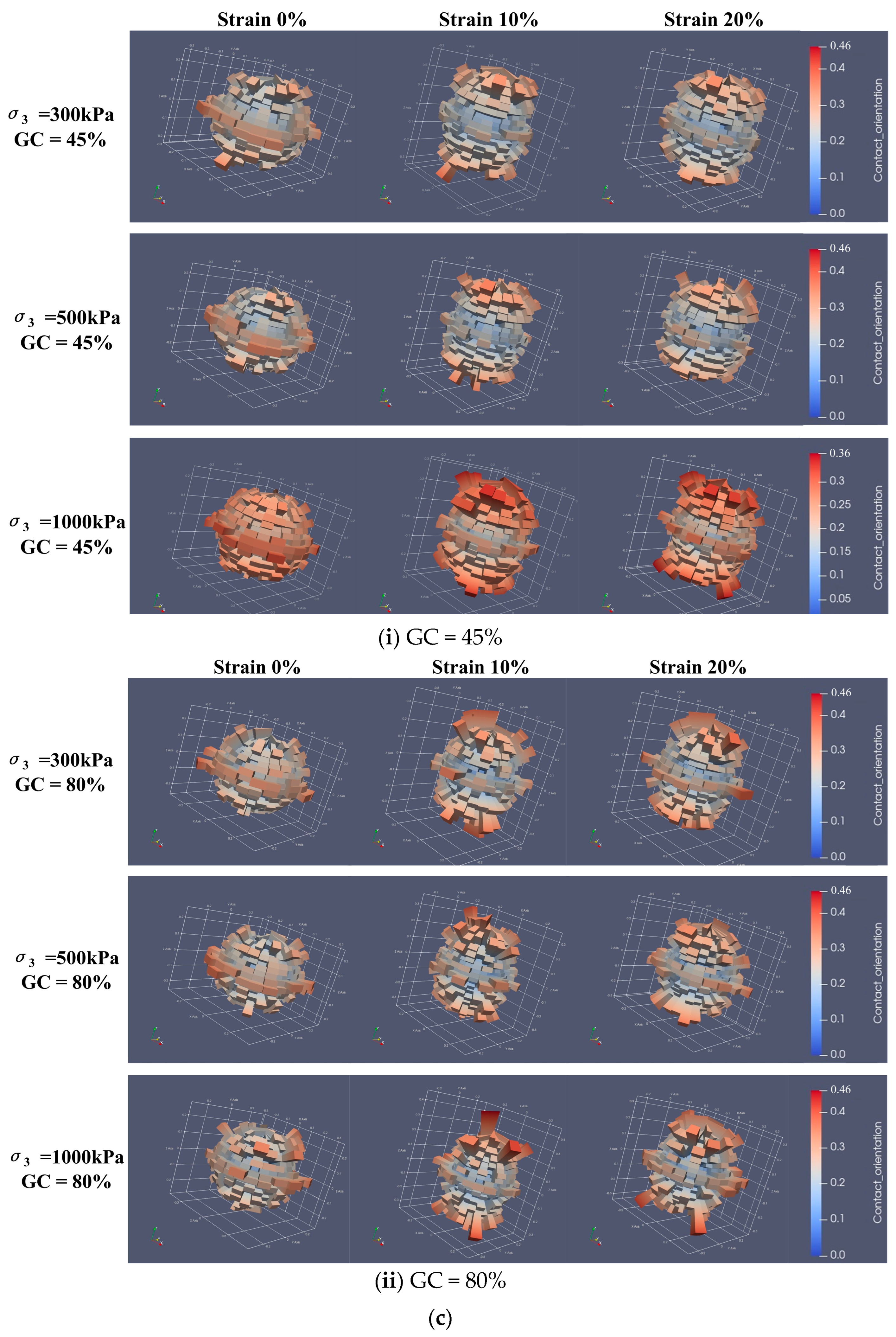

3.2.2. Three-Dimensional Polar Distributions of the Branch Vector Orientations

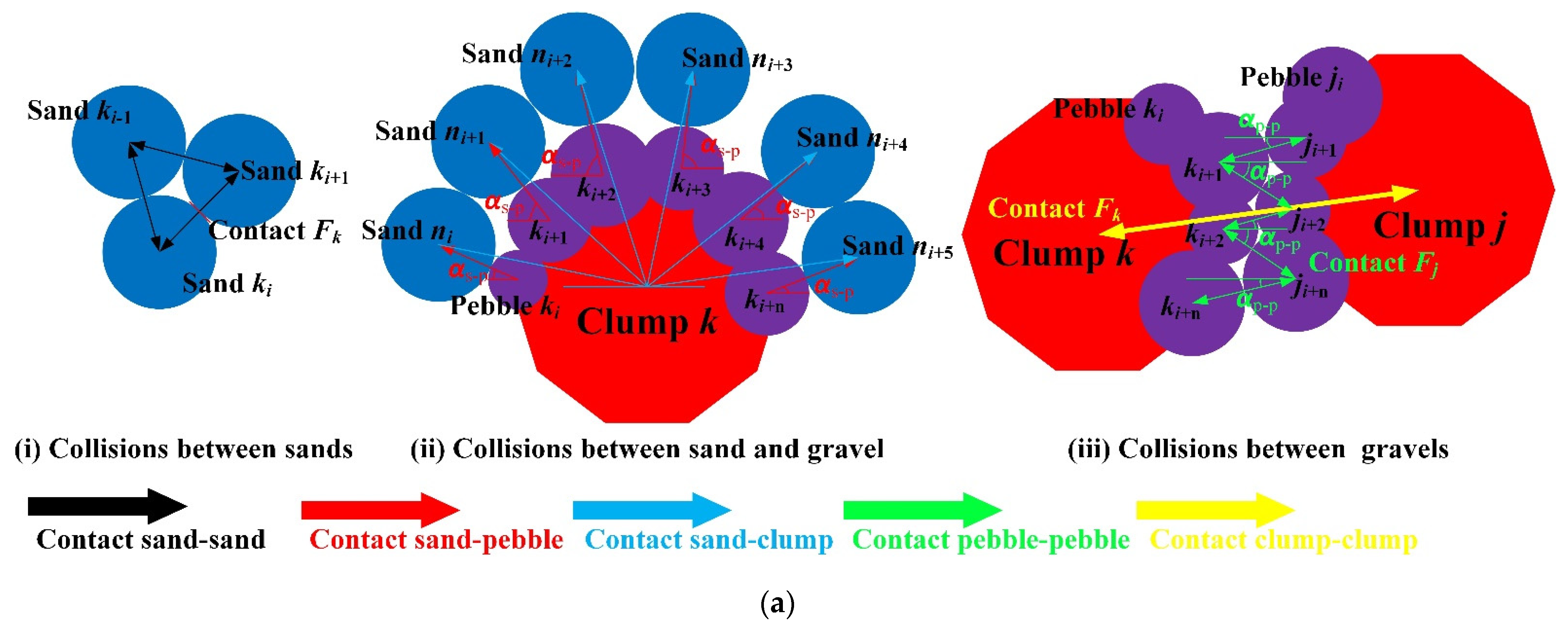

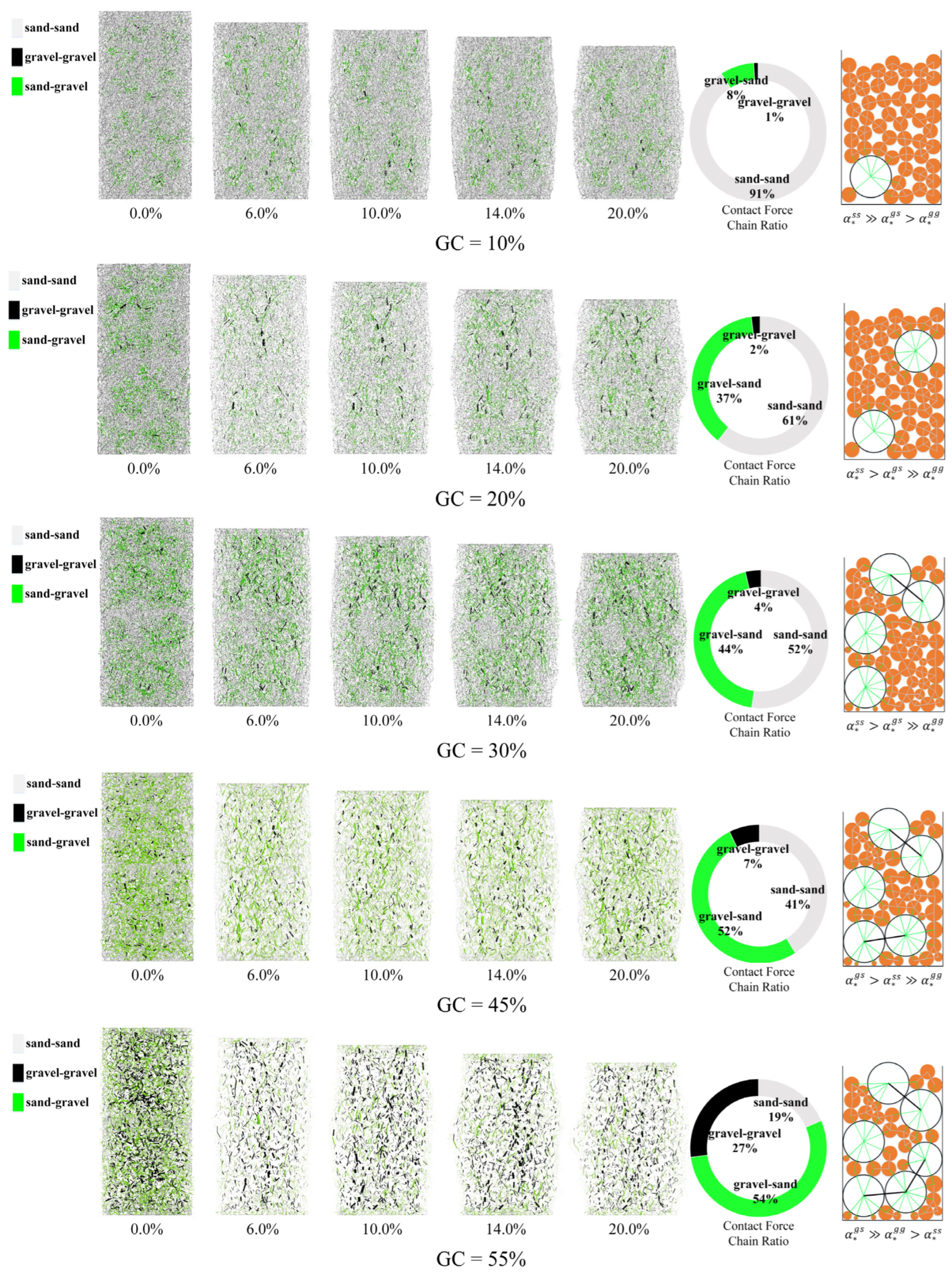

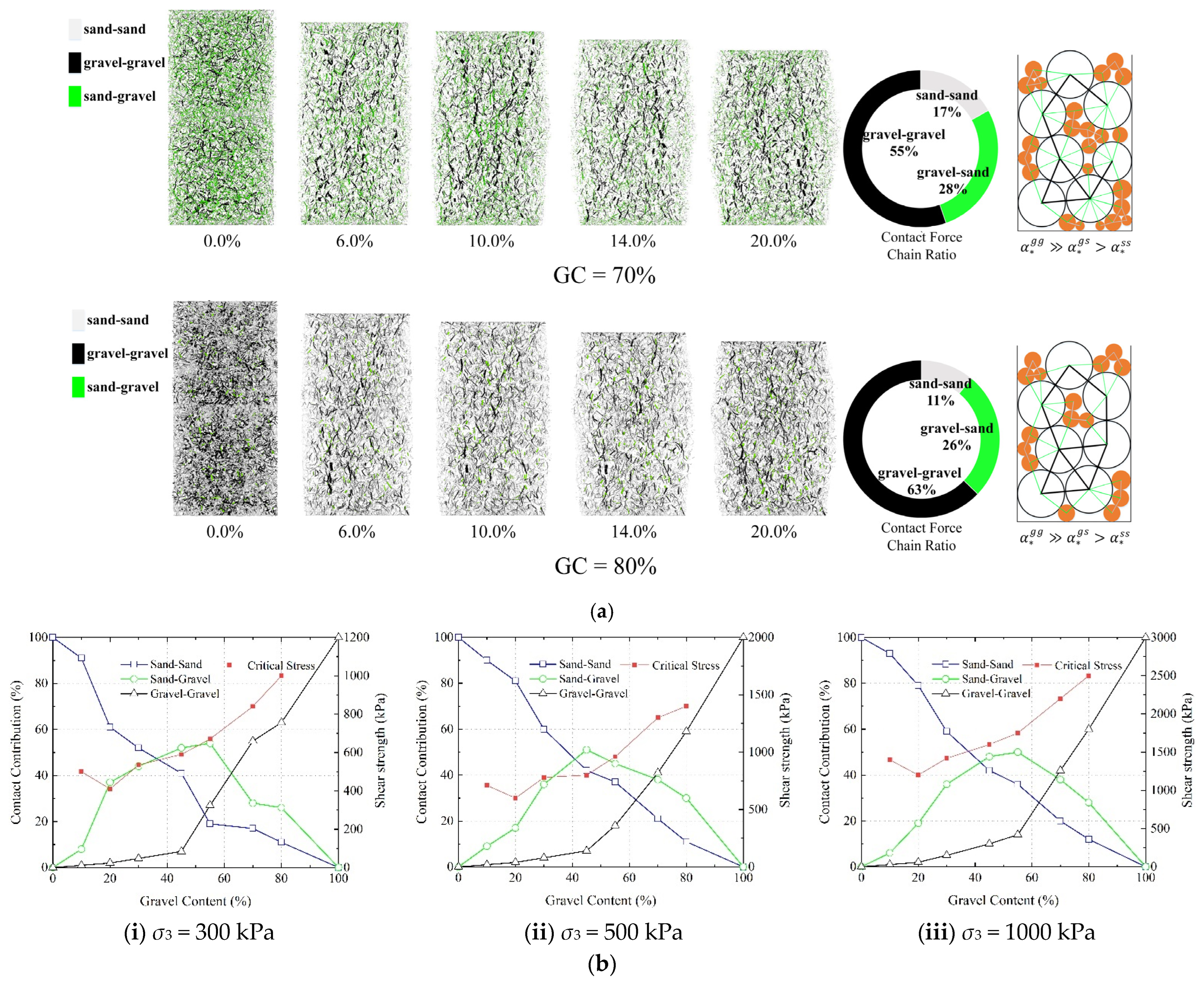

3.2.3. Contact Chain Skeleton Distributions of Contact Forces

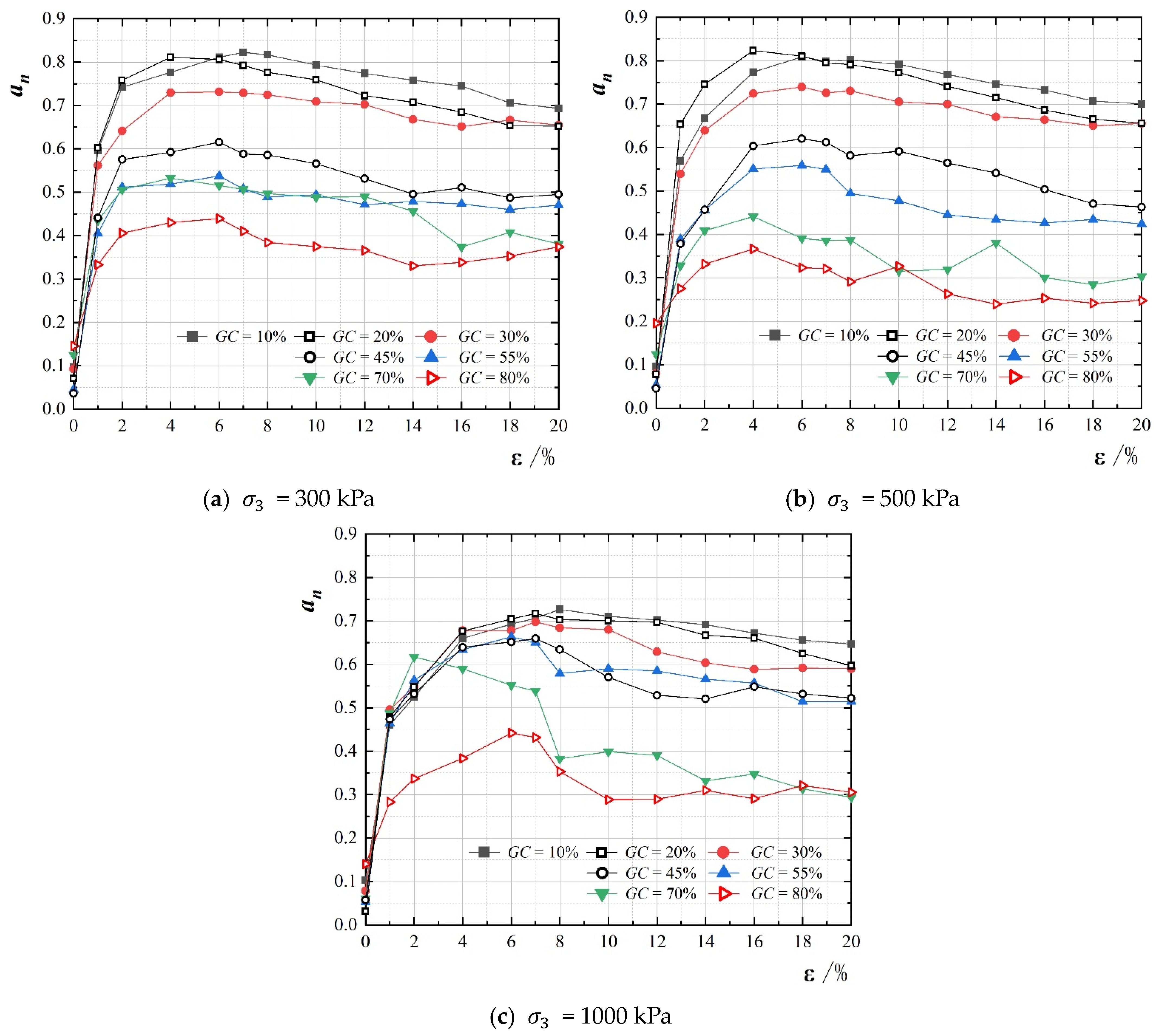

3.2.4. Analysis of Fabric Tensor in Contact Force Chain Skeletons

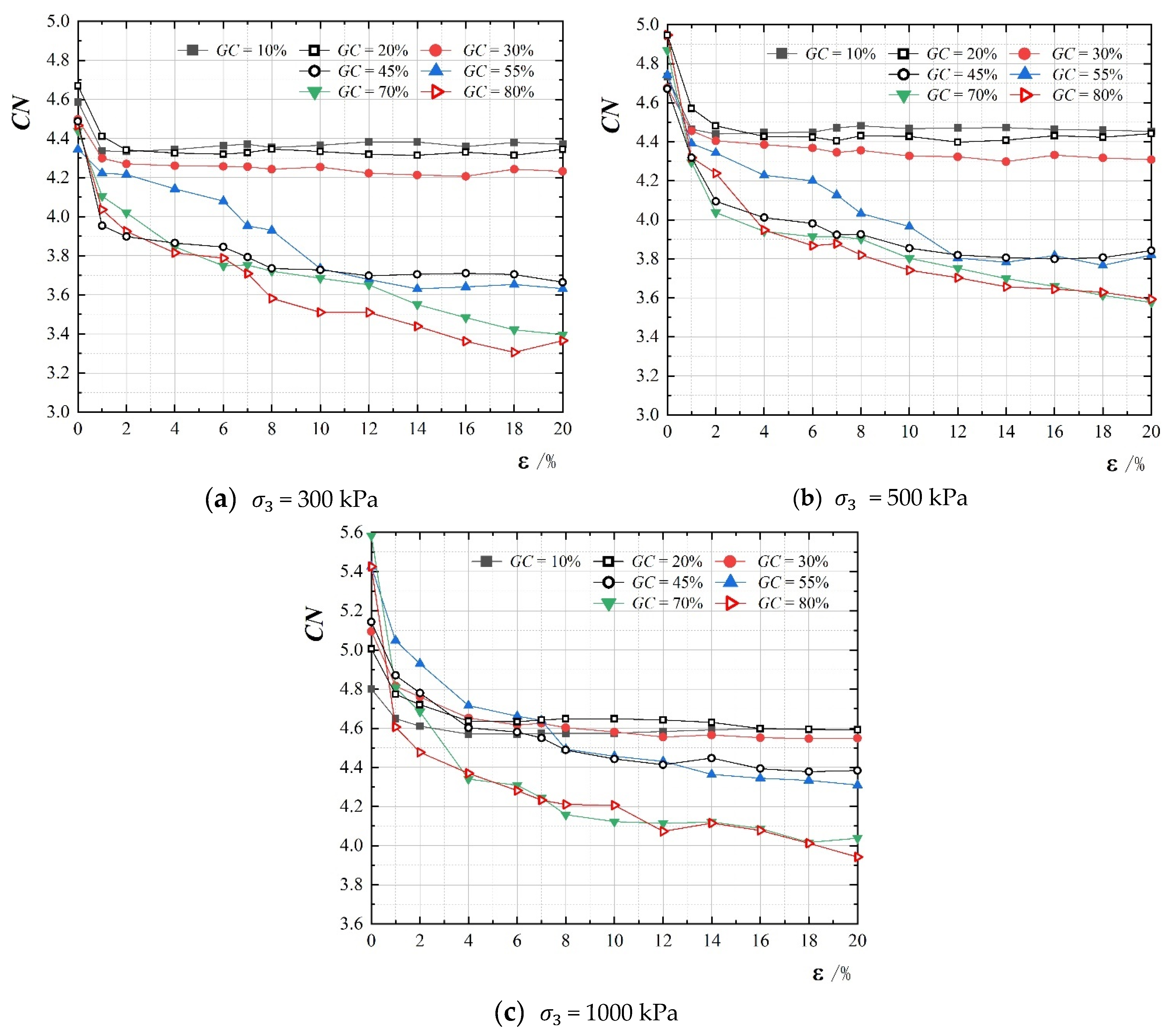

- The average coordination number, CN:

- The fabric anisotropic coefficient, :

4. Conclusions

- (1)

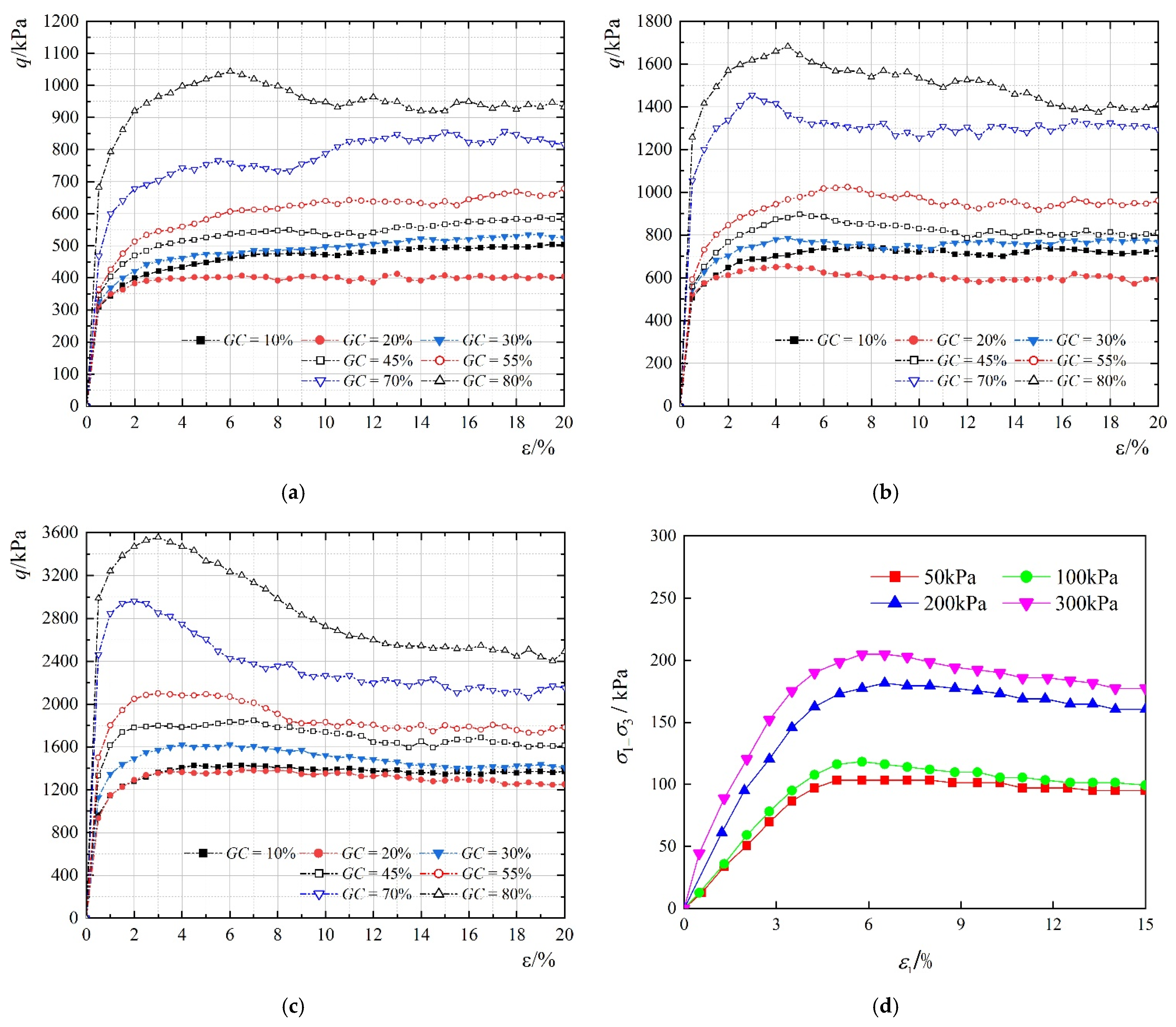

- The strength of S-RMs is intricately correlated with the gravel content and consolidation state. The relationship between the shear strength of S-RMs and gravel content is nonlinear, with a qualitative threshold identified in this study as 20% gravel content (this threshold may vary depending on parameter changes): when the gravel content reaches this threshold, the shear bearing capacity of the S-RM specimen decreases to its minimum value. Beyond this threshold, the shear strength of the specimens gradually increases; conversely, when the gravel content is below this threshold, the shear strength decreases. This indicates that insufficient addition of gravels to the sand does not significantly enhance the overall shear strength of the specimens. This conclusion not only applies to S-RMs but can also be extended to other binary granular materials. Additionally, the shear strength of S-RMs increases with increasing confining pressure, consistent with traditional understanding.

- (2)

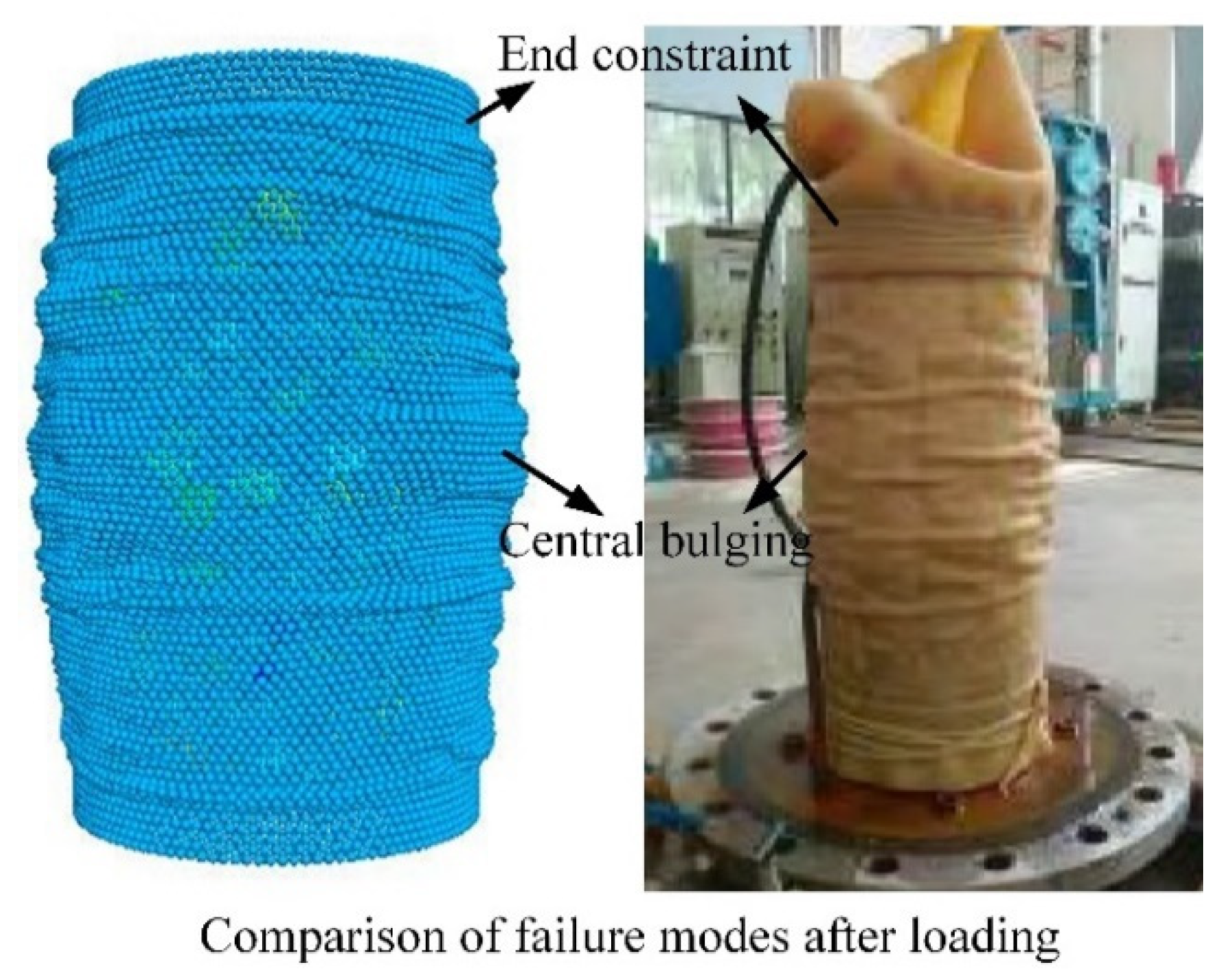

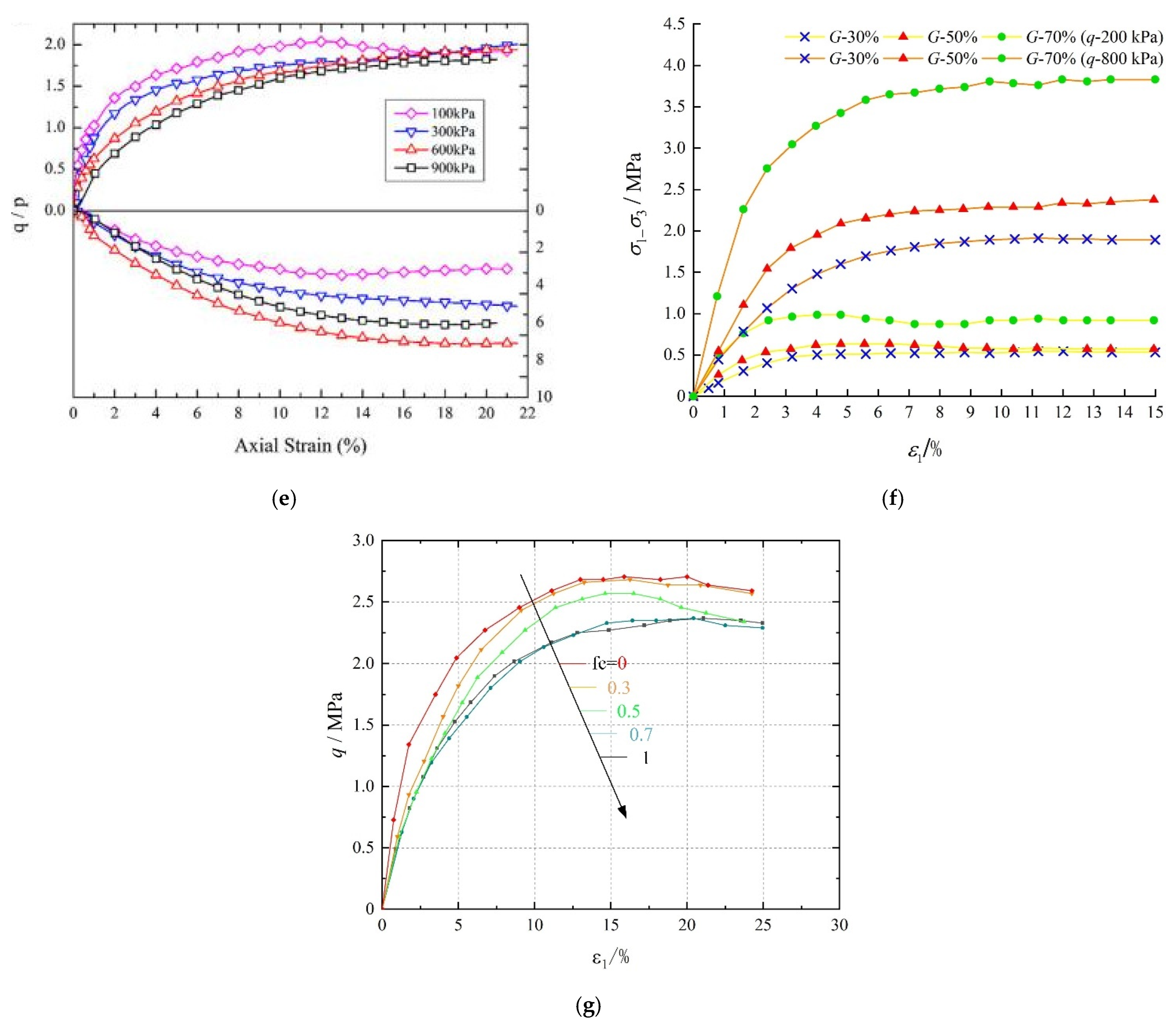

- In discrete element numerical simulation, the selection of boundary conditions for triaxial experiments is of critical importance. When a flexible boundary composed of particles is employed, the S-RM specimens exhibit lateral expansion failure, forming asymmetric ‘X’-shaped shear bands consistent with laboratory observations. Moreover, it is noteworthy that the failure pattern, size, and distribution of the shear bands are influenced not only by the gravel content but also significantly depend on the consolidation confining pressure. This observation intuitively underscores the unique characteristics of S-RMs as heterogeneous granular materials.

- (3)

- The macroscopic mechanical behavior of S-RMs has been investigated from the microscopic perspective of the contact force network. The contributions of three types of contact forces (, , and ) to the critical shear strength were quantified at the microscale, and the evolution of strong and weak contacts within the contact force chain system was analyzed. This study integrated the analysis of the microscopic contact force chain distribution to reveal the mechanisms governing the transformation of the main skeleton of the contact force chain during the transitions between ‘single-phase’ and ‘mixed-phase’ states. Furthermore, the prominence of the main skeleton of the contact force chain significantly enhanced the shear resistance capacity of the specimens, and the higher shear strength further amplified these effects. In addition, observations in S-RMs with varying gravel contents revealed that the probability distribution of contact forces and the three-dimensional polar coordinate distribution of branch vectors indicated an increasing trend in the distribution of weak force chains and contact forces in non-loading directions as gravel content increased, thereby accentuating the primary structure of the contact force chain skeleton.

- (4)

- The fabric tensor characteristics of the S-RM in the critical state are intricately linked to the force chain skeleton of the specimen’s primary structure, with minimal influence from the gravel content and consolidation state. Specimens with sand particles as the primary structure exhibit the most rapid transition to the critical state, characterized by the highest average coordination number (CN) and the most pronounced fabric anisotropic coefficient (). Conversely, when gravel–sand contacts predominantly support the contact force chain, it takes a longer time for the average coordination number to stabilize, leading to a lower stability value and a more gradual evolution of anisotropic characteristics. In contrast, specimens with gravel as the main structure exhibit a slower transition to a stable state, displaying the lowest stability value and the least degree of evolution in contact normal anisotropy. Under identical force chain conditions, the anisotropy value of the S-RMs is independent of gravel content and consolidation state but depends solely on the composition of the specimen’s skeleton.

Shortcomings of the Article

- This study did not account for the effects of particle breakage, which are crucial to the analysis of the mechanical behavior of S-RMs.

- Given the emphasis on computational efficiency, the particle model for S-RM units in this study employed ellipsoids with reduced angularity, thus failing to represent the actual angular features of gravels fully. Future research will concentrate on examining the influence of multi-angular characteristics on the mechanical behaviors of S-RMs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, S.; Zhu, F.; Wei, J.; Wang, W.; Le, H. Experimental Study on Shear Failure Mechanism and the Identification of Strength Characteristics of the Soil-Rock Mixture. Shock Vib. 2019, 2019, 7450509. [Google Scholar] [CrossRef]

- Yao, Y.; Li, J.; Ni, J.; Zhang, A. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 2022, 141, 104476. [Google Scholar] [CrossRef]

- Zhang, Z.; Sheng, Q.; Fu, X.; Zhou, Y.; Huang, J.; Du, Y. An approach to predicting the shear strength of soil-rock mixture based on rock block proportion. Bull. Eng. Geol. Environ. 2019, 79, 2423–2437. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Z. Study of Material Composition Effects on the Mechanical Properties of Soil-Rock Mixtures. Adv. Civ. Eng. 2018, 9, 3854727. [Google Scholar] [CrossRef]

- Zhao, N.; Wang, Y.; Meng, B.; Luo, N. Numerical Simulation on the Seepage Properties of Soil-Rock Mixture. Adv. Mater. Sci. Eng. 2018, 2018, 1859319. [Google Scholar] [CrossRef]

- Xu, W.; Hu, R. Conception classification and significations of soil-rock mixture. Hydrogeol. Eng. Geol. 2009, 36, 50–56+70. [Google Scholar]

- Geertsema, M.; Clague, J.J.; Schwab, J.W.; Evans, S.G. An overview of recent large catastrophic landslides in northern British Columbia. Canada Eng. Geol. 2006, 83, 120–143. [Google Scholar] [CrossRef]

- Vallejo, L.E.; Mawby, R. Porosity influence on the shear strength of granular arterial-clay mixtures. Eng. Geol. 2000, 58, 125–136. [Google Scholar] [CrossRef]

- Afifipour, M.; Moarefvand, P. Experimental study of post-peak behavior of bimrocks with high rock block proportions. J. Cent. South. Univ. 2014, 21, 761–767. [Google Scholar] [CrossRef]

- Li, B. Study on Shear Properties of the Soil-rock Mixture. E3S Web Conf. 2020, 165, 04079. [Google Scholar] [CrossRef]

- Xu, W.J.; Zhang, H.Y. Research on the effect of rock content and sample size on the strength behavior of soil-rock mixture. Bull. Eng. Geol. Environ. 2021, 80, 2715–2726. [Google Scholar] [CrossRef]

- Zhang, X.M.; Lv, Y.Z.; Zhao, Y.M.; Liao, Z. Study on Poisson ratio of soil-rock mixture in low strain. Appl. Mech. Mater. 2011, 90–93, 1921–1925. [Google Scholar] [CrossRef]

- Pincus, H.J.; Donaghe, R.T.; Torrey, V.H. A compaction test method for soil-rock mixtures in which equipment size effects are minimized. Geotech. Test. J. 1994, 17, 363–370. [Google Scholar] [CrossRef]

- Li, W.S.; Liu, J.Z. Study on bearing capacity of debris foundation in new Fengjie city. J. Yangtze River Sci. Res. Inst. 2003, 20, 61–64. [Google Scholar]

- Terzaghi, K.; Pech, R.B.; Mesri, G. Soil Mechanics in Engineering Practice; Wiley Interscience: London, UK, 1967. [Google Scholar]

- Ding, X.H.; Zhou, W.; Lu, X.; Gao, Y. Physical simulation test of soil-rock mixture from synthetic transparent soil. J. Cent. South. Univ. 2018, 25, 3085–3097. [Google Scholar] [CrossRef]

- Vallejo, L.E.; Asce, M.; Lobo-Guerrero, S.; Seminsky, L.F. The shear strength of sand-gravel mixtures: Laboratory and theoretical analysis. In Geo-Congress 2014: Geo-Characterization and Modeling for Sustainability; ASCE: Reston, VA, USA, 2014; pp. 74–83. [Google Scholar] [CrossRef]

- Coli, N.; Berry, P.; Boldini, D. In situ non-conventional shear tests for the mechanical characterization of a bimrock (Bim Test). Int. J. Rock. Mech. Min. Sci. 2011, 48, 95–102. [Google Scholar] [CrossRef]

- Jaroslav, F. Notes on the effect of grain crushing on the granular soil behavior. Eng. Geol. 2002, 63, 93–98. [Google Scholar]

- Jie, Y.; Xin, C.; Pang, Q.; Guo, X.W.; Wu, Y.L.; Zhao, J.L. Experimental Study on the Shear Strength of Cement-Sand-Gravel Material. Adv. Mater. Sci. Eng. 2018, 2018, 2531642. [Google Scholar] [CrossRef]

- Xu, W.; Yue, Z.; Hu, R. Study on the mesostructure and mesomechanical characteristics of the soil-rock mixture using digital image processing based finite element method. Int. J. Rock. Mech. Min. Sci. 2008, 45, 749–762. [Google Scholar] [CrossRef]

- Ding, X.L.; Zhang, H.M.; Huang, H.L.; Lu, B.; Zhang, Q. Research on mechanical properties of unsaturated soil-rock mixture based on numerical experiments of mesostructured. Chin. J. Rock. Mech. Eng. 2012, 31, 1553–1566. [Google Scholar]

- Gong, J.; Nie, Z.; Zhu, Y.; Liang, Z.; Wang, X. Exploring the effects of particle shape and content of fines on the shear behavior of sand-fines mixtures via the DEM. Comput. Geotech. 2019, 106, 161–176. [Google Scholar] [CrossRef]

- Zhang, P.; Dong, Y.; Galindo-Torres, S.A.; Scheuermann, A.; Li, L. Metaball based discrete element method for general shaped particles with round features. Comput. Mech. 2021, 67, 1243–1254. [Google Scholar] [CrossRef]

- Chandratilleke, G.R.; Jin, X.; Shen, Y.S. DEM study of effects of particle size and density on mixing behaviour in a ribbon mixer. Powder Technol. 2021, 392, 93–107. [Google Scholar] [CrossRef]

- Jia, X.M.; Chai, H.J.; Zheng, Y.R. Mesomechanics research of large direct shear test on soil and rock aggregate mixture with particle flow code simulation. Rock. Soil. Mech. 2010, 31, 2695–2703. (In Chinese) [Google Scholar]

- Xu, W.J.; Zhang, H.Y.; Xu, Q.; Yu, Y.Z. Numerical simulations of direct shear test with soil-rock mixture using discrete element method. Chin. J. Comput. Mech. 2014, 31, 228–234. (In Chinese) [Google Scholar] [CrossRef]

- Ding, X.L.; Li, Y.X.; Wang, X. Particle flow modeling mechanical properties of soil and rock mixtures based on digital image. Chin. J. Rock. Mech. Eng. 2010, 29, 477–484. (In Chinese) [Google Scholar]

- Zhou, J.; Zhang, L.Q.; Dai, F.C.; Ran, H. Numerical simulation of direct shear tests for rock and soil mixture in a landslide based on bonded-particle model. Chin. J. Rock. Mech. Eng. 2013, 31, 2650–2659. [Google Scholar] [CrossRef]

- Graziani, A.; Rossini, C.; Rotonda, T. Characterization and DEM modeling of shear zones at a large dam foundation. Int. J. Geomech. 2012, 12, 648–664. [Google Scholar] [CrossRef]

- Jing, X.; Xie, W.L.; Shan, S. Discrete element simulation study on micromechanical characteristics of undisturbed and remolded loess in biaxial test. Bull. Geol. Sci. Technol. 2021, 40, 184–193. [Google Scholar] [CrossRef]

- Xu, W.J.; Hu, L.M.; Gao, W. Random generation of the meso-structure of a soil-rock mixture and its application in the study of the mechanical behavior in a landslide dam. Int. J. Rock. Mech. Min. Sci. 2016, 86, 166–178. [Google Scholar] [CrossRef]

- Jin, L.; Zeng, Y.W.; Li, H.; Li, L.L. Numerical simulation of large-scale triaxial tests on soil-rock mixture based on DEM of irregularly shaped particles. Chin. J. Geotech. Eng. 2015, 37, 829–838. (In Chinese) [Google Scholar]

- Evans, T.M.; Frost, J.D. Multiscale investigation of shear bands in sand: Physical and numerical experiments. Int. J. Numerical Anal. Methods Geomech. 2010, 34, 1634–1650. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Xu, W.J.; Yu, Y.Z. Numerical analysis of soil-rock mixture’s meso-mechanics based on biaxial test. J. Cent. South. Univ. 2016, 23, 685–700. [Google Scholar] [CrossRef]

- Coetzee, C.J. Calibration of the discrete element method and the effect of particle shape. Powder Technol. 2016, 297, 57–70. [Google Scholar] [CrossRef]

- Zhu, Y.G.; Nie, Z.H.; Gong, J. Influence of the rolling-resistance-based shape of coarse particles on the shear responses of granular mixtures. Particuology 2020, 52, 67–82. [Google Scholar] [CrossRef]

- Patino-Ramirez, F.; O’Sullivan, C.; Dini, D. Percolating contacts network and force chains during interface shear in granular media. Granul. Matter 2023, 25, 31. [Google Scholar] [CrossRef]

- Wu, M.; Wang, J.; Russell, A.; Cheng, Z. Dem modelling of mini-triaxial test based on one-to-one mapping of sand particles. Géotechnique 2021, 71, 714–727. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, Q.; Jia, W.C. Investigation on stability of soil-rock mixture slope with discrete element method. Environ. Earth Sci. 2023, 82, 449.1–449.17. [Google Scholar] [CrossRef]

- Lu, Y.; Tan, Y.; Li, X.; Liu, C. Methodology for simulation of irregularly shaped gravel grains and its application to DEM modeling. J. Comput. Civ. Eng. 2017, 31, 04017023. [Google Scholar] [CrossRef]

- Fang, C.F.; Gong, J.; Nie, Z.H.; Li, B.; Li, X. DEM study on the microscale and macroscale shear behaviours of granular materials with breakable and irregularly shaped particles. Comput. Geotech. 2021, 137, 104271. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Porter, M.A.; Daniels, K.E.; Bassett, D.S. Network analysis of particles and grains. J. Complex. Netw. 2018, 6, 485–565. [Google Scholar] [CrossRef]

- Andrade, J.E.; Avila, C.F.; Hall, S.A.; Lenoir, N.; Viggiani, G. Multiscale modeling and characterization of granular matter: From grain kinematics to continuum mechanics. J. Mech. Phys. Solids 2011, 59, 237–250. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, J.; Ma, G.; Yuan, W.; Chang, X. Macroscopic and microscopic behaviors of granular materials under proportional strain path: A dem study. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 2450–2467. [Google Scholar] [CrossRef]

- Radjai, F.; Jean, M.; Moreau, J.; Roux, S. Force distributions in dense two-dimensional granular systems. Phys. Rev. Lett. 1996, 77, 274–277. [Google Scholar] [CrossRef] [PubMed]

- Ma, G.; Regueiro, R.A.; Zhou, W.; Wang, Q.; Liu, J. Role of particle crushing on particle kinematics and shear banding in granular materials. Acta Geotech. 2018, 13, 601–618. [Google Scholar] [CrossRef]

- Guo, N.; Zhao, J. The signature of shear-induced anisotropy in granular media. Comput. Geotech. 2013, 47, 1–15. [Google Scholar] [CrossRef]

- Zhai, L.; Gao, Y.; Yuan, Q.; Shi, H. Deformation characterizations of granular material in 2d dense assembly subjected to shearing. Constr. Build. Mater. 2018, 158, 1065–1072. [Google Scholar] [CrossRef]

- Elrahmani, A.; Al-Raoush, R.I.; Abugazia, H.; Seers, T. Pore-scale simulation of fine particles migration in porous media using coupled CFD-DEM. Powder Technol. 2022, 398, 117130. [Google Scholar] [CrossRef]

- Reddy, N.S.C.; He, H.; Senetakis, K. Dem multi-scale insights on the pre-failure behavior of mature structured sands: Influence of bond type, amount, breakage pattern and heterogeneity. Int. J. Numer. Anal. Methods Geomech. 2023, 14, 2587–2617. [Google Scholar] [CrossRef]

- Kozicki, J.; Tejchman, J.; Mühlhaus, H.-B. Discrete simulations of a triaxial compression test for sand by DEM. Int. J. Numer. Anal. Methods Geomech. 2015, 38, 1923–1952. [Google Scholar] [CrossRef]

- Xu, W.J.; Wang, S. Meso-mechanics of soil-rock mixture with real shape of rock blocks based on 3D numerical direct shear test. Chin. J. Rock. Mech. Eng. 2016, 35, 2152–2160. (In Chinese) [Google Scholar] [CrossRef]

- O’Sullivan, C.; Cui, L. Micromechanics of granular material response during load reversals: Combined DEM and experimental study. Powder Technol. 2009, 193, 289–302. [Google Scholar] [CrossRef]

- Lu, Y.; Li, X.; Wang, Y. Application of a flexible membrane to DEM modelling of axisymmetric triaxial compression tests on sands. Eur. J. Environ. Civil Eng. 2018, 2018, 1425157. [Google Scholar] [CrossRef]

- Qu, T.M.; Feng, Y.T.; Wang, Y.; Wang, M. Discrete element modelling of flexible membrane boundaries for triaxial tests. Comput. Geotech. 2019, 115, 103154. [Google Scholar] [CrossRef]

- Zhao, X.; Evans, T.M. Numerical analysis of critical state behaviors of granular soils under different loading conditions. Granul. Matter 2011, 13, 751–764. [Google Scholar] [CrossRef]

- Xu, R.; Liu, E.; Xing, H. Analysis on mechanical properties and evolution of mesostructure of soil–rock mixture samples from contact network perspective. Comptes Rendus Mec. 2021, 349, 83–102. [Google Scholar] [CrossRef]

- Itasca Consulting Group Inc. PFC3D-Particle Flow Code in Three-Dimension; Version 5.0; Itasca Consulting Group Inc.: Minneapolis, MN, USA, 2014. [Google Scholar]

- Jiang, C.L.; Liu, Y.J.; Zeng, L.L.; Xu, C.S.; Cao, P. Critical state uniqueness of dense granular materials using discrete element method in conjunction with flexible membrane boundary. Particuology 2024, 95, 124–144. [Google Scholar] [CrossRef]

- Radjai, F.; Roux, S. Turbulent like fluctuations in quasistatic flow of granular media. Phys. Rev. Lett. 2002, 89, 064302. [Google Scholar] [CrossRef] [PubMed]

- Lopera Perez, J.C.; Kwok, C.Y.; O’Sullivan, C.; Huang, X.; Hanley, K.J. Assessing the quasi-static conditions for shearing in granular media within the critical state soil mechanics framework. Soils Found. 2016, 56, 152–159. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Xu, W.J.; Yu, Y.Z. Triaxial tests of soil-rock mixtures with different rock block distributions. Soils Found. 2016, 56, 44–56. [Google Scholar] [CrossRef]

- Tao, Q.D.; He, Z.Y.; Jia, Y. Strength characteristics and influencing factors of soil-rock mixture based on large triaxial test. Sci. Technol. Eng. 2019, 19, 310–318. (In Chinese) [Google Scholar]

- Wang, T.; Liu, S.H.; Song, Y.J.; Kong, W.M. Strength and deformation characteristics of soil-rock mixtures using skeleton void ratio. Rock. Soil. Mech. 2020, 41, 2973–2983. (In Chinese) [Google Scholar] [CrossRef]

- Peters, J.F.; Muthuswamy, M.; Wibowo, J.; Tordesillas, A. Characterization of force chains in granular material. Phys. Rev. E 2005, 72, 041307. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.C.; Xin, H.L.; Liu, J.G.; Feng, J. Skeleton and force chain network in static granular material. Rock. Soil. Mech. 2009, 30, 83–87. [Google Scholar]

- Liu, J.; Zhou, W.; Ma, G.; Yang, S.; Chang, X. Strong contacts, connectivity and fabric anisotropy in granular materials: A 3D perspective. Powder Technol. Int. J. Sci. Technol. Wet. Dry Part. Syst. 2020, 366, 747–760. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, J. Experimental investigation of inter-particle contact evolution of sheared granular materials using X-ray micro-tomography. Soils Found. 2018, 58, 1492–1510. [Google Scholar] [CrossRef]

- Zhu, Y.G.; Nie, H.H.N.; Gong, J.; Zou, J.F.; Zhao, L.H.; Li, L. An analysis of the effects of the size ratio and fines content on the shear behaviors of binary mixtures using DEM. Comput. Geotech. 2020, 118, 103353. [Google Scholar] [CrossRef]

- Petalas, A.L.; Dafalias, Y.F.; Papadimitriou, A.G. SANISAND-F: Sand Constitutive Model with Evolving Fabric Anisotropy. Int. J. Solids Struct. 2019, 188–189, 12–31. [Google Scholar] [CrossRef]

- Kanatani, K. Distribution of directional data and fabric tensors. Int. J. Eng. Sci. 1984, 22, 149–164. [Google Scholar] [CrossRef]

- Yang, Z.X.; Xu, T.T.; Chen, Y.N. Unified modeling of the influence of consolidation conditions on monotonic soil response considering fabric evolution. J. Eng. Mech. 2018, 144, 04018073. [Google Scholar] [CrossRef]

- Li, X.S.; Dafalias, Y.F. Dissipation consistent fabric tensor definition from DEM to continuum for granular media. J. Mech. Phys. Solids 2015, 78, 141–153. [Google Scholar] [CrossRef]

| No. | Gravel Content (%) | Consolidation Pressure (kPa) | Numbers of Particles | Initial Void Ratio e0 | Consolidation-Induced Void Ratio e | |

|---|---|---|---|---|---|---|

| Gravel Clumps VG * (%) | Sand Particles VG * (%) | |||||

| 1 | 10 | 300 | 139 (10.7) | 32,275 (89.3) | 0.47 | 0.476 |

| 2 | 500 | 0.471 | ||||

| 3 | 1000 | 0.463 | ||||

| 4 | 20 | 300 | 224 (19.9) | 22,213 (80.1) | 0.48 | 0.501 |

| 5 | 500 | 0.492 | ||||

| 6 | 1000 | 0.488 | ||||

| 7 | 30 | 300 | 339 (29.7) | 19,636 (70.3) | 0.48 | 0.489 |

| 8 | 500 | 0.482 | ||||

| 9 | 1000 | 0.478 | ||||

| 10 | 45 | 300 | 537 (46.3) | 15,458 (53.7) | 0.45 | 0.458 |

| 11 | 500 | 0.458 | ||||

| 12 | 1000 | 0.443 | ||||

| 13 | 55 | 300 | 656 (55.8) | 12,397 (44.2) | 0.47 | 0.486 |

| 14 | 500 | 0.480 | ||||

| 15 | 1000 | 0.474 | ||||

| 16 | 70 | 300 | 926 (70.9) | 10,474 (29.1) | 0.49 | 0.491 |

| 17 | 500 | 0.504 | ||||

| 18 | 1000 | 0.468 | ||||

| 19 | 80 | 300 | 1083 (81.0) | 6557 (19.0) | 0.46 | 0.461 |

| 20 | 500 | 0.450 | ||||

| 21 | 1000 | 0.438 | ||||

| Reference | kn (N/m) | kt | Friction | Damping Factor |

|---|---|---|---|---|

| Fang et al. [42] | 7.5 × 107~4.6 × 108 | kt = (4/3) kn | 0.5 | 0.7 |

| Coetzee [34] | 5 × 107~1.08 × 108 | kt = kn | 0.7 | 0.8 |

| Zhu et al. [37] | 1.0 × 108 | kt = (4/3) kn | 0.5 | 0.7 |

| O’Sullivan [38] | 29 GP | - | 0.01, 0.1, 0.25 | - |

| Wu et al. [39] | 28 GP | kt = 0.25 kn | 0.3 | 0.7 |

| Yu et al. [40] | 3 × 108 | kt = 0.8 kn | 0.7 | - |

| Lu et al. [41] | 2.5 × 108 | kt = kn | 1.0 | - |

| Particle | Density (kg/m3) | Contact Stiffness (N/m) | Bond Strength (N) | Friction Coefficient | ||

|---|---|---|---|---|---|---|

| Normal | Tangent | Normal | Tangent | |||

| Gravel clump | 2650 | 1.0 × 108 | 1.0 × 108 | - | - | 0.80 |

| Sand ball | 1900 | 2.0 × 106 | 1.0 × 106 | 1.0 × 102 | 1.0 × 102 | 0.40 |

| Gravel–sand | - | 3.9 × 106 | 2.0 × 106 | - | - | 0.40 |

| Membrane particle | 1000 | 1.0 × 105 | 1.0 × 105 | 1.0 × 10300 | 1.0 × 10300 | 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, C.; Zeng, L.; Liu, Y.; Mu, Y.; Dong, W. A DEM Study on the Macro- and Micro-Mechanical Characteristics of an Irregularly Shaped Soil–Rock Mixture Based on the Analysis of the Contact Force Skeleton. Appl. Sci. 2025, 15, 7978. https://doi.org/10.3390/app15147978

Jiang C, Zeng L, Liu Y, Mu Y, Dong W. A DEM Study on the Macro- and Micro-Mechanical Characteristics of an Irregularly Shaped Soil–Rock Mixture Based on the Analysis of the Contact Force Skeleton. Applied Sciences. 2025; 15(14):7978. https://doi.org/10.3390/app15147978

Chicago/Turabian StyleJiang, Chenglong, Lingling Zeng, Yajing Liu, Yu Mu, and Wangyi Dong. 2025. "A DEM Study on the Macro- and Micro-Mechanical Characteristics of an Irregularly Shaped Soil–Rock Mixture Based on the Analysis of the Contact Force Skeleton" Applied Sciences 15, no. 14: 7978. https://doi.org/10.3390/app15147978

APA StyleJiang, C., Zeng, L., Liu, Y., Mu, Y., & Dong, W. (2025). A DEM Study on the Macro- and Micro-Mechanical Characteristics of an Irregularly Shaped Soil–Rock Mixture Based on the Analysis of the Contact Force Skeleton. Applied Sciences, 15(14), 7978. https://doi.org/10.3390/app15147978