Comparative Analysis of Studies of Geological Conditions at the Planning and Construction Stage of Dam Reservoirs: A Case Study of New Facilities in South-Western Poland

Abstract

1. Introduction

2. Materials and Methods

2.1. Boboszów Reservoir

2.2. Roztoki Bystrzyckie Reservoir

2.3. Krosnowice and Szalejów Górny Reservoirs

3. Results

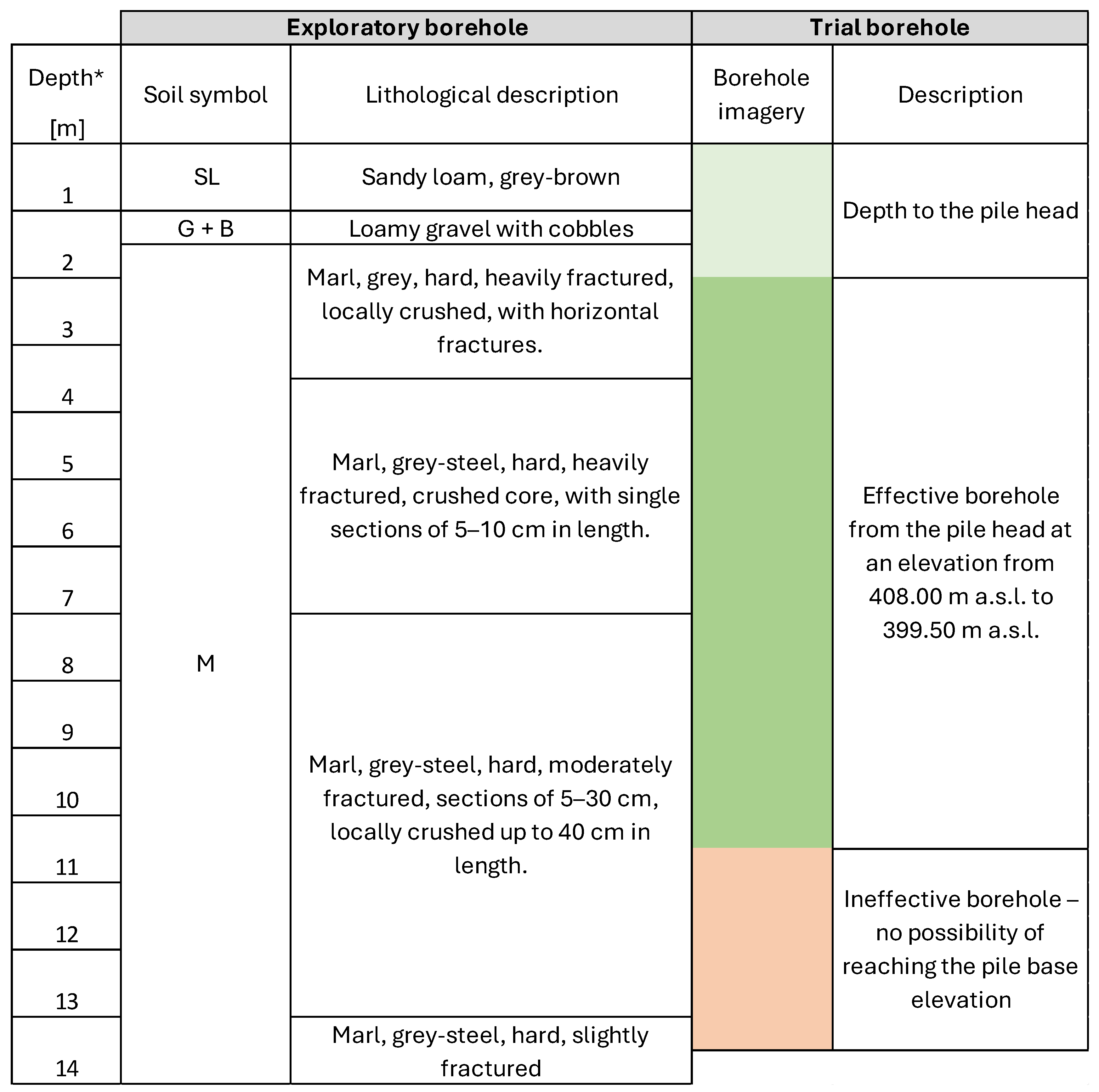

3.1. Boboszów Reservoir

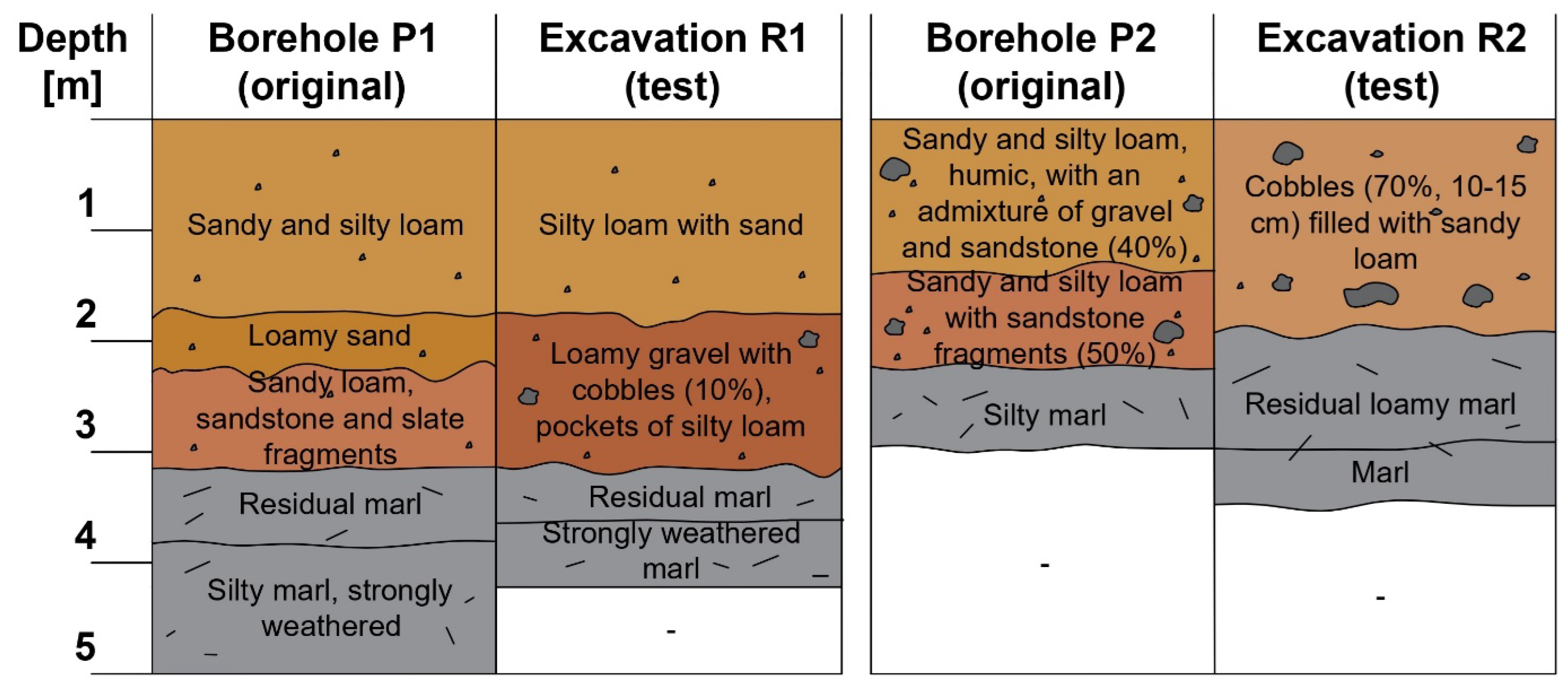

3.2. Roztoki Bystrzyckie Reservoir

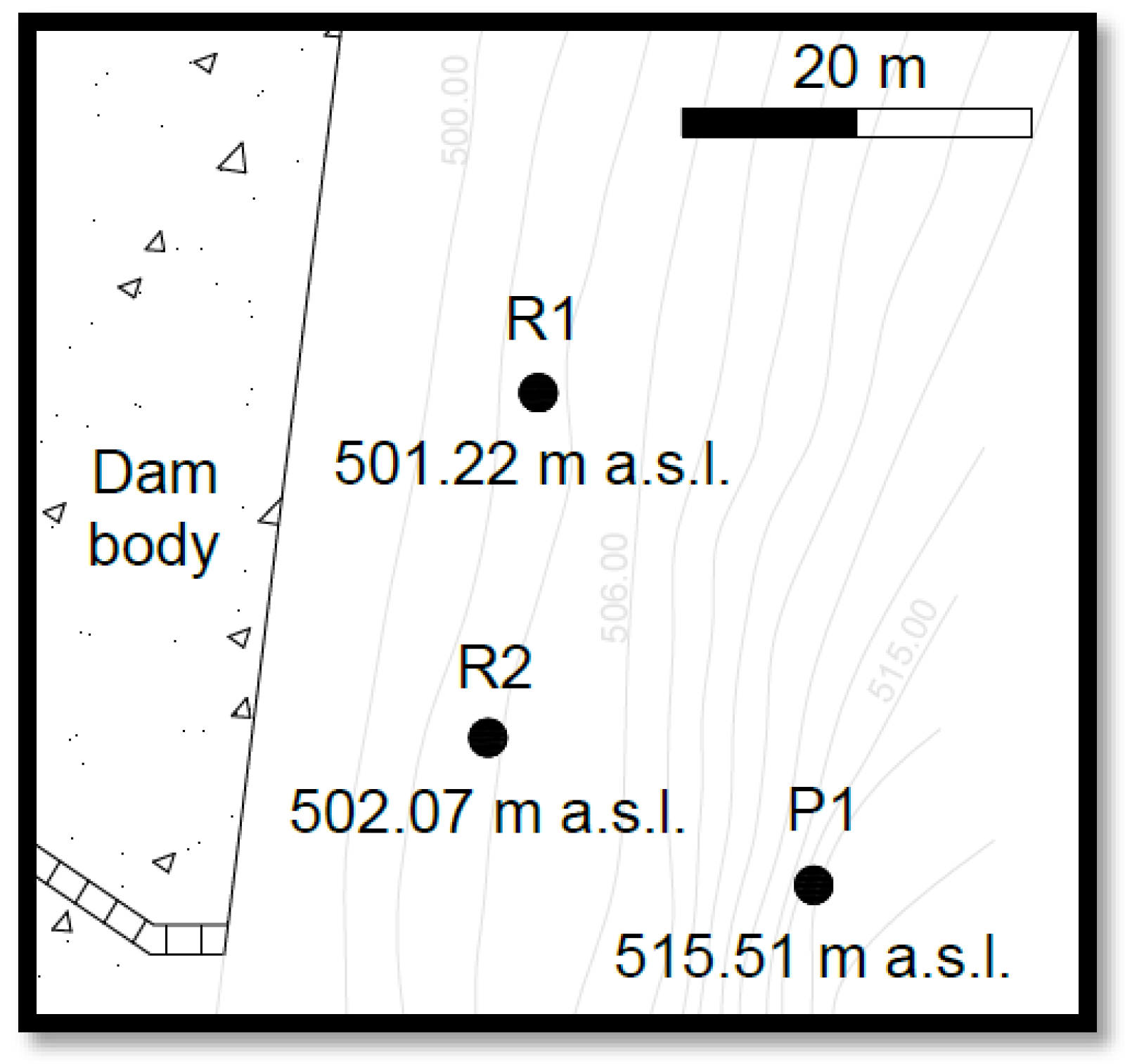

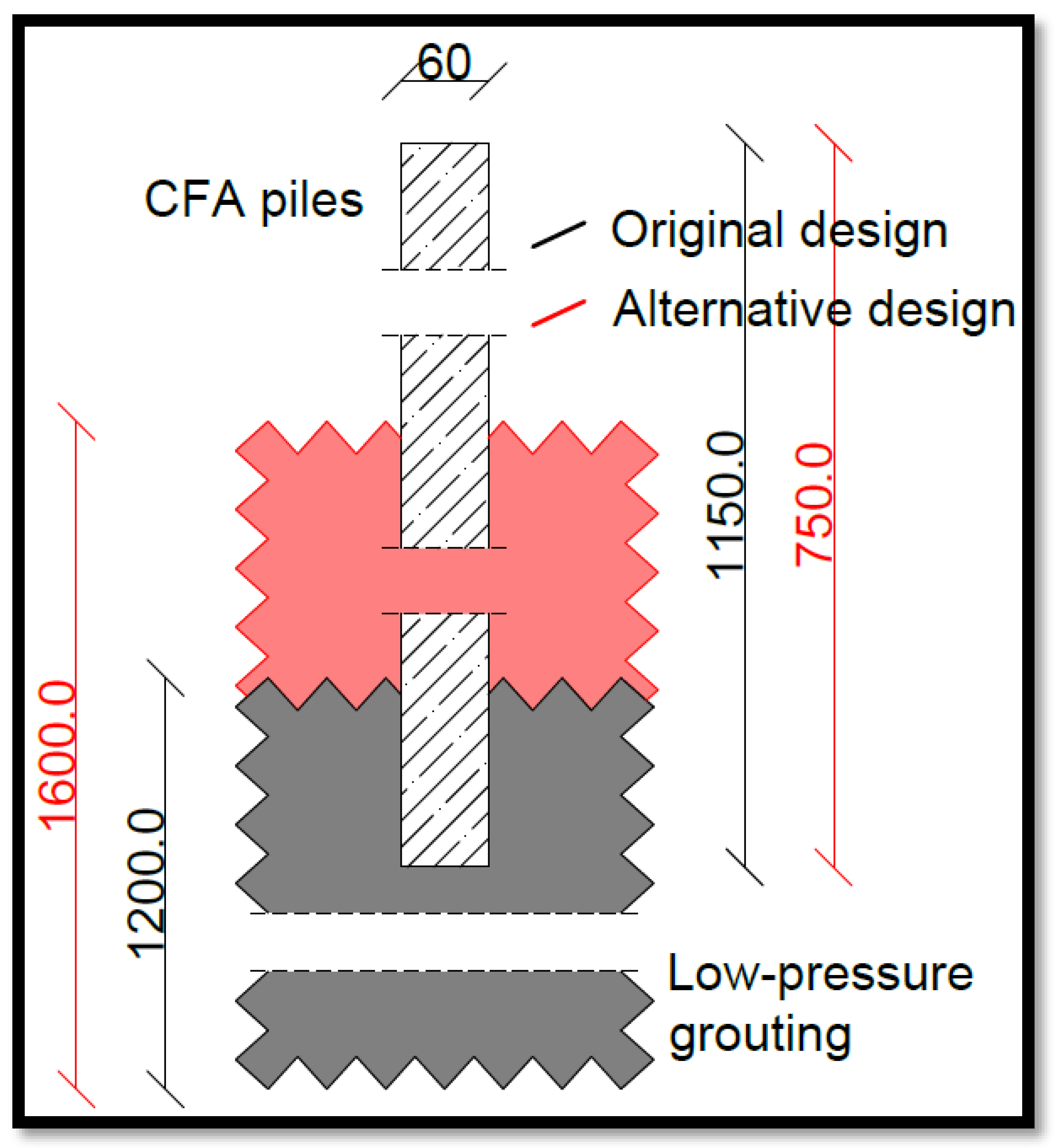

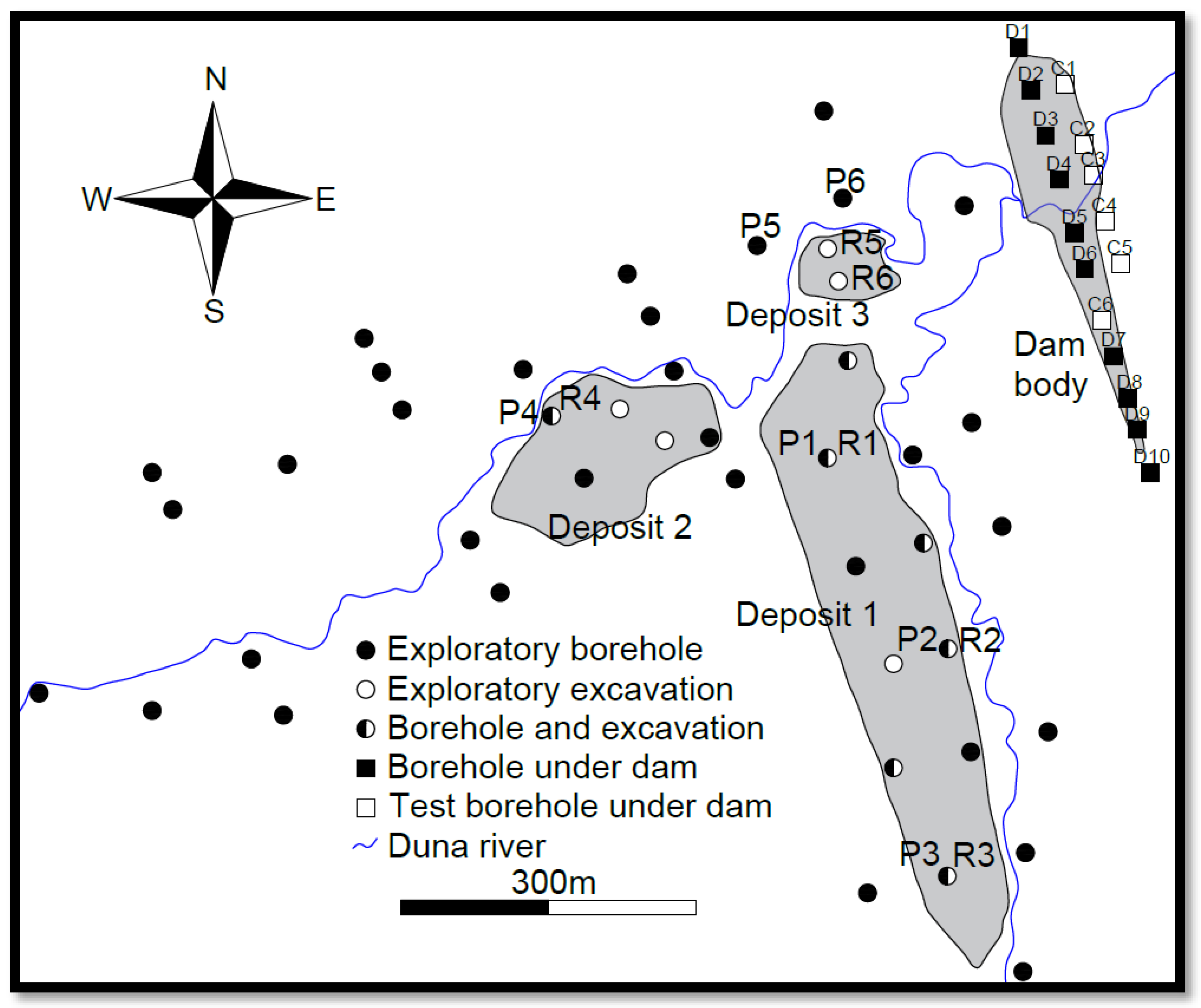

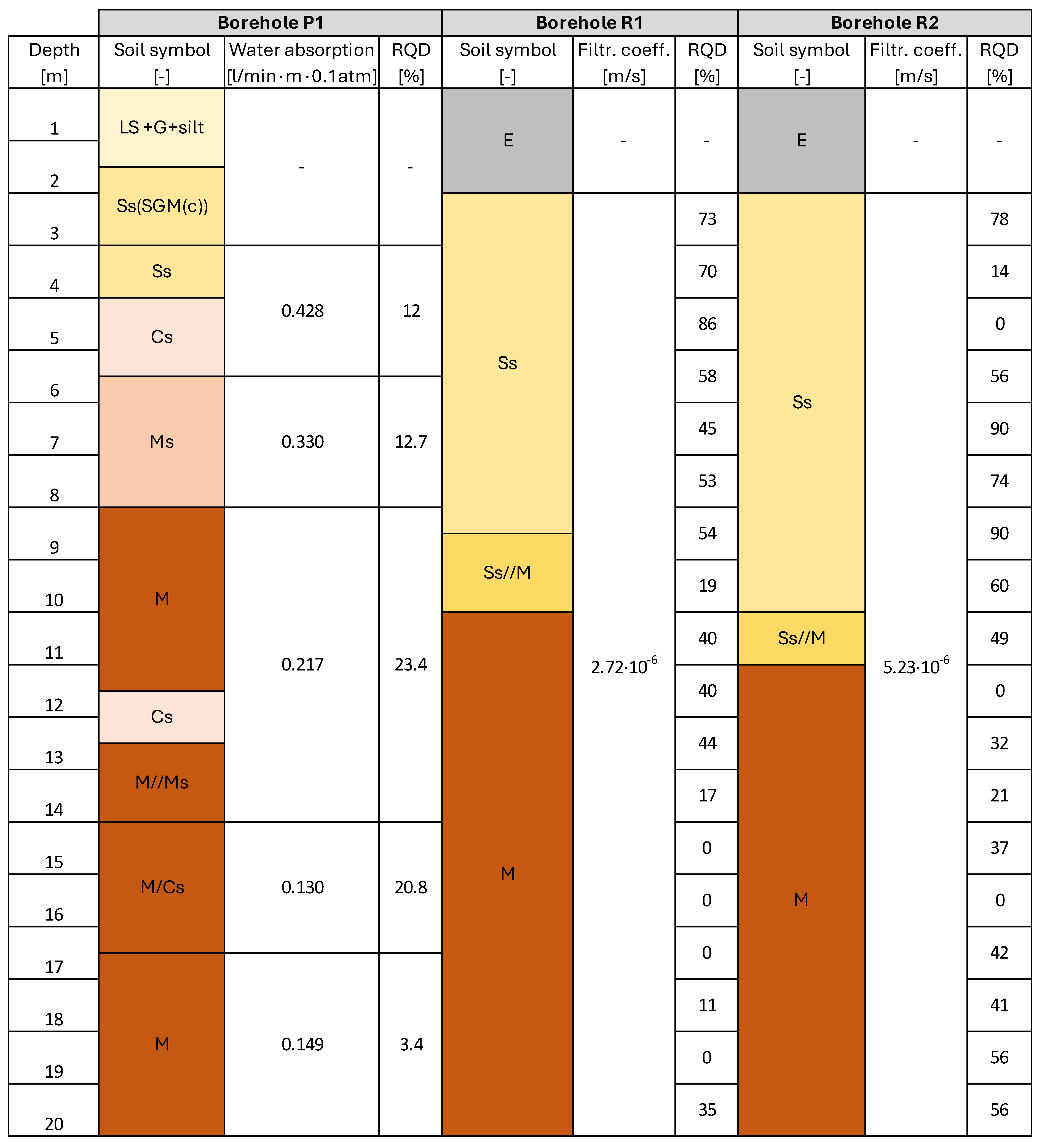

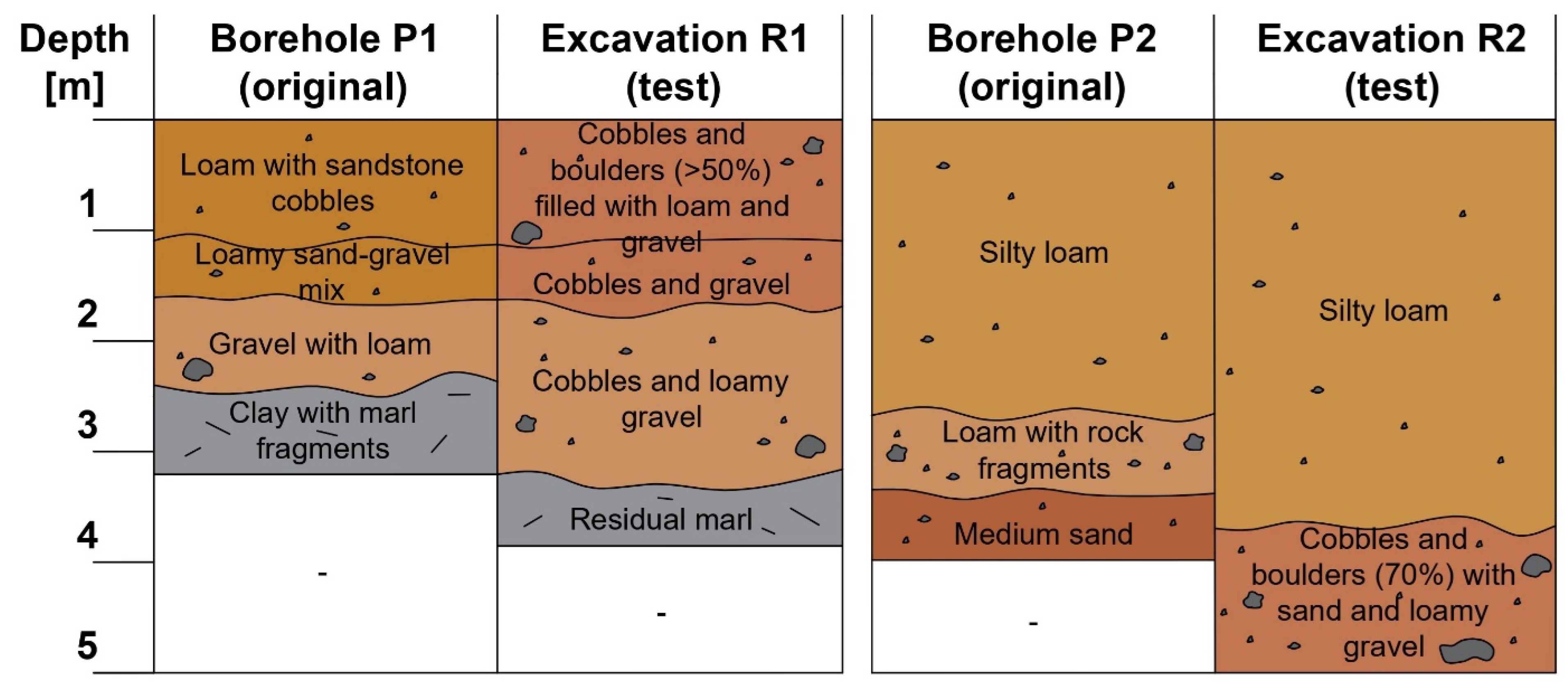

3.3. Krosnowice Reservoir

3.4. Szalejów Górny Reservoir

4. Discussion

5. Conclusions

5.1. Boboszów Reservoir

5.2. Roztoki Bystrzyckie Reservoir

5.3. Krosnowice and Szalejów Górny Reservoir

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Połomski, M.; Wiatkowski, M. The Use of Lime for Drainage of Cohesive Soils Built into Hydraulic Engineering Embankments. Water 2022, 14, 3700. [Google Scholar] [CrossRef]

- Połomski, M.; Wiatkowski, M. Impounding Reservoirs, Benefits and Risks: A Review of Environmental and Technical Aspects of Construction and Operation. Sustainability 2023, 15, 16020. [Google Scholar] [CrossRef]

- Regulation of the Minister of Transport, Construction and Maritime Economy of April 25, 2012 on Determining Geotechnical Conditions for the Foundation of Building Structures. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20120000463/O/D20120463.pdf (accessed on 1 April 2025).

- PN-B-02480:1986; Grunty Budowlane. Okreslenia Symbole Podzial i Opis Gruntow. Polish Committee for Standardization: Warsaw, Poland, 1986.

- PN-B-02481:1998; Geotechnika. Terminologia Podstawowa Symbole Literowe Jednostki Miar. Polish Committee for Standardization: Warsaw, Poland, 1998.

- PN-B-03020:1981; Building Soils—Foundation Bases—Static Calculation and Design. Polish Committee for Standardization: Warsaw, Poland, 1981.

- PN-B-04452:2002; Geotechnics—Field Tests. Polish Committee for Standardization: Warsaw, Poland, 2002.

- PN-B-04481:1998; Grunty Budowlane. Badania Próbek Gruntu. Polish Committee for Standardization: Warsaw, Poland, 1998.

- PN-EN 206-1:2003; Concrete—Part 1: Specification, Performance, Production and Confo. Polish Committee for Standardization: Warsaw, Poland, 2003.

- PN-EN ISO 14689-1:2006; Geotechnical Investigation and Testing—Identification and Classification of Rock—Part 1: Identification and Description. Polish Committee for Standardization: Warsaw, Poland, 2006.

- US Army Corps of Engineers. General Design and Construction Considerations for Earth and Rock-Fill Dams; EM 1110-2-2300; US Army Corps of Engineers: Washington, DC, USA, 2004; Available online: https://www.publications.usace.army.mil/portals/76/publications/engineermanuals/em_1110-2-2300.pdf (accessed on 1 April 2025).

- Wiłun, Z. Outline of Geotechnics; WKiŁ: Warszawa, Poland, 1987. [Google Scholar]

- Sousa, L.M.O.; Martín Freire-Lista, D.; Carter, R.; Al-Na’imi, F. Petrographic and petrophysical characterisation and structural function of the heritage stones in Fuwairit Archaeological Site (NE Qatar): Implications for heritage conservation. Materials 2023, 16, 4927. [Google Scholar] [CrossRef]

- Zhang, L.M.; Xu, Y.; Jia, J.S. Analysis of earth dam failures: A database approach. Georisk Assess. Manag. Risk Eng. Syst. Geohazards 2009, 3, 184–189. [Google Scholar] [CrossRef]

- Strzałkowski, P.; Köken, E.; Kaźmierczak, U. Estimation of cohesion for intact rock materials using regression and soft computing analyses. J. Rock Mech. Geotech. Eng. 2023, 15, 789–802. [Google Scholar] [CrossRef]

- Köken, E.; Kadakcı Koca, T. A comparative study to estimate the Mode I fracture toughness of rocks using several soft computing techniques. Bull. Eng. Geol. Environ. 2022, 81, 55. [Google Scholar] [CrossRef]

- Czyżewski, K. Earth Dams; Arkady: Warszawa, Poland, 1973. [Google Scholar]

- Strzałkowski, P.; Sousa, L.M.O.; Köken, E. Guidelines for natural stone products in connection with European standards. Materials 2023, 16, 6885. [Google Scholar] [CrossRef]

- Mieszkowski, R.; Kowalczyk, S.; Barański, M.; Szczepański, T. The use of geophysical methods to identify the roof of cohesive soils and the designation of zones of suffusion relaxation in the body of an earth dam. Zesz. Nauk. Inst. Gospod. Surowcami Miner. Energią. PAN 2014, 86, 167–180. [Google Scholar]

- Strzałkowski, P.; Bęś, P.; Szóstak, M.; Napiórkowski, M. Application of Virtual Reality (VR) Technology in Mining and Civil Engineering. Sustainability 2024, 16, 2239. [Google Scholar] [CrossRef]

- Stupnicka, E. Regional Geology of Poland; University of Warsaw Publishing House: Warszawa, Poland, 2007. [Google Scholar]

- ARCADIS. Geological and Engineering Documentation of the Designed Boboszów Reservoir on the Nysa Kłodzka River. 2012; Unpublished Technical Report. [Google Scholar]

- PROXIMA. Geological and Engineering Documentation of the Designed Roztoki Bystrzyckie Reservoir on the Goworówka River. 2014; Unpublished Technical Report. [Google Scholar]

- HYDROGEO. Geological and Engineering Documentation of the Designed Krosnowice Reservoir on the Duna Stream. 2014; Unpublished Technical Report. [Google Scholar]

- Integrated Management Services; PROXIMA; Przedsiębiorstwo Geologiczne. Geological and Engineering Documentation of the designed Krosnowice reservoir on the Duna Stream. 2012; Unpublished Technical Report. [Google Scholar]

- Uromeihy, A.; Farrokhi, R. Evaluating grout ability at the Kamal-Saleh Dam based on Lugeon tests. Bull. Eng. Geol. Environ. 2012, 71, 215–219. [Google Scholar] [CrossRef]

- Jaworksa-Szulc, B. Assessment of groundwater recharge in the Kashubian Lake District using various methods and various scales of study. Przegląd Geol. 2015, 63, 762–768. [Google Scholar]

- Wieczysty, A. Engineering Hydrogeology; PWN: Warszawa, Poland; Kraków, Poland, 1970. [Google Scholar]

- PKP Polish Railway Lines. Subsoil Testing Guidelines Land for Needs Construction and Modernization Railway Infrastructure; PKP Polish Railway Lines: Warszawa, Poland, 2016. [Google Scholar]

- Łętka, T.; Pilecki, Z. A Method for Assessing the Degree of Cracking in a Rock Medium Using a Borehole GPR; Publishing house of the Institute of Mineral Resources and Energy Management of the Polish Academy of Sciences: Kraków, Poland, 2016. [Google Scholar]

- GHEKO. Report on Control Tests Carried out on Deposits of Soil Material for the Construction of the Dam of the Krosnowice Flood Control Reservoir. 2019; Unpublished Technical Report. [Google Scholar]

- Hawrysz, M.; Stróżyk, J.; Hawrysz, P. Opinion on the abundance of soil material deposits for the formation of earth buildings in the Krosnowice Flood Control Reservoir Area. 2019; Unpublished Technical Report. [Google Scholar]

- GHEKO. Report on Control Tests Carried out on Deposits of Soil Material for the Construction of the Dam of the Szalejów Górny Flood Control Reservoir. 2019; Unpublished Technical Report. [Google Scholar]

- Hawrysz, M.; Stróżyk, J.; Hawrysz, P. Opinion on the abundance of soil material deposits for the formation of earth buildings in the Szalejów Górny Flood Control Reservoir Area. 2019; Unpublished Technical Report. [Google Scholar]

- Khurshid, M.N.; Khan, A.H.; Rehman, Z.u.; Chaudhary, T.S. The Evaluation of Rock Mass Characteristics against Seepage for Sustainable Infrastructure Development. Sustainability 2022, 14, 10109. [Google Scholar] [CrossRef]

- Ding, Q.; Wang, F.; Chen, J.; Wang, M.; Zhang, X. Research on Generalized RQD of Rock Mass Based on 3D Slope Model Established by Digital Close-Range Photogrammetry. Remote Sens. 2022, 14, 2275. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Karimiazar, J.; Sharifi Teshnizi, E.; Arjmandzadeh, R.; Bahmani, S.H. Effect of Nano-Additives on the Strength and Durability Characteristics of Marl. Minerals 2021, 11, 1119. [Google Scholar] [CrossRef]

- Kamieński, M.; Skalmowski, W. Building and Road Stones; Geological Publishing Houses: Warszawa, Poland, 1957. [Google Scholar]

- Mitelman, A. Machine Learning Analysis of Borehole Data for Geotechnical Insights. Geotechnics 2024, 4, 1175–1188. [Google Scholar] [CrossRef]

- Ji, X.; Lu, X.; Guo, C.; Pei, W.; Xu, H. Predictions of Geological Interface Using Relevant Vector Machine with Borehole Data. Sustainability 2022, 14, 10122. [Google Scholar] [CrossRef]

- Li, H.; Wan, B.; Chu, D.; Wang, R.; Ma, G.; Fu, J.; Xiao, Z. Progressive Geological Modeling and Uncertainty Analysis Using Machine Learning. ISPRS Int. J. Geo-Inf. 2023, 12, 97. [Google Scholar] [CrossRef]

- Piermattei, L.; Heckmann, T.; Betz-Nutz, S.; Altmann, M.; Rom, J.; Fleischer, F.; Stark, M.; Haas, F.; Ressl, C.; Wimmer, M.H.; et al. Evolution of an Alpine Proglacial River during Seven Decades of Deglaciation. Earth Surf. Dyn. 2023, 11, 383–403. [Google Scholar] [CrossRef]

- Jiménez Gavilán, P.; Durán Valsero, J.J.; Carrasco Cantos, F.; López Geta, J.A.; Andreo Navarro, B. Análisis de la respuesta hidrodinámica de acuíferos carbonáticos de la Cordillera Bética occidental (Sur de España). Boletín Geológico Y Min. 2004, 115, 187–198. [Google Scholar]

- Stevanović, Z.; Milanović, P. Engineering Challenges in Karst. In Karst Without Boundaries; Stevanović, Z., Krešić, N., Kukurić, N., Eds.; CRC Press/Balkema: Leiden, The Netherlands, 2015; pp. 93–102. ISBN 9781138028668. Available online: https://scispace.com/pdf/engineering-challenges-in-karst-2fod011ydu.pdf (accessed on 1 April 2025).

- Zhang, W.; Pan, X.; Liang, J.; Zeng, J.; Song, C. Study on the Hydrogeological Structure of a Karst Subterranean River and Seepage of a Karst Reservoir: A Case Study of the Yibasan Reservoir in Yunnan Province, China. Water 2024, 16, 92. [Google Scholar] [CrossRef]

- Peng, M.-Q.; Qiu, Z.-C.; Shen, S.-L.; Li, Y.-C.; Zhou, J.-J.; Xu, H. Geotechnical Site Characterizations Using a Bayesian-Optimized Multi-Output Gaussian Process. Sustainability 2024, 16, 5759. [Google Scholar] [CrossRef]

- Del Fabbro, M.; Paronuzzi, P.; Bolla, A. Geotechnical Characterisation of Flysch-Derived Colluvial Soils from a Pre-Alpine Slope Affected by Recurrent Landslides. Geosciences 2024, 14, 115. [Google Scholar] [CrossRef]

- ISO 22475-1:2011; Geotechnical Investigation and Testing—Sampling Methods and Groundwater Measurements—Part 1: Technical Principles. ISO: Geneva, Switzerland, 2011. Available online: https://www.iso.org/standard/71002.html (accessed on 1 April 2025).

- World Bank. Good Practice Note on Dam Safety—Technical Note 2: Geotechnical Risk; World Bank: Washington, DC, USA, 2021; Available online: https://documents1.worldbank.org/curated/en/241051619161798594/pdf/Geotechnical-Risk.pdf (accessed on 1 April 2025).

- Gangrade, R.; Grasmick, J.; Trainor-Guitton, W.; Mooney, M. Risk-Based Methodology to Optimize Geotechnical Site Investigations in Tunnel Projects. Tunn. Undergr. Space Technol. 2022, 127, 104589. [Google Scholar] [CrossRef]

- European Large Geotechnical Institutes Platform (ELGIP). Reduction of Geotechnical Uncertainties for Infrastructure—Vision Paper; ELGIP: Brussels, Belgium, 2015; Available online: https://elgip.org/wp-content/uploads/2020/06/20151118-Vision-paper-Transport-Infrastructure.pdf (accessed on 1 April 2025).

- Thompson, B. The Benefits of Early Geotech Risk Mitigation; HKA Insights; HKA: London, UK, 2023; Available online: https://www.hka.com/article/geotech-risks/ (accessed on 1 April 2025).

- Tao, M.; Chen, X.; Cheng, Q.; Binley, A. Evaluating the Joint Use of GPR and ERT on Mapping Shallow Subsurface Features of Karst Critical Zone in Southwest China. Vadose Zone J. 2021, 21, e20172. [Google Scholar] [CrossRef]

- Gao, R.; Kuang, T.; Meng, X.; Huo, B. Effects of Ground Fracturing with Horizontal Fracture Plane on Rock Breakage Characteristics and Mine Pressure Control. Rock Mech. Rock. Eng. 2021, 54, 3229–3243. [Google Scholar] [CrossRef]

- Shrestha, P.P.; Neupane, K.P. Identification of Geotechnical-Related Problems Impacting Cost, Schedule, and Claims on Bridge Construction Projects. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2020, 12, 04520005. [Google Scholar] [CrossRef]

- Hoek, E.; Palmieri, A. Geotechnical Risks on Large Civil Engineering Projects. In Proceedings of the Keynote address at International Association for Engineering Geologists Congress, Vancouver, BC, Canada, 21–25 September 1998; Available online: https://www.rocscience.com/assets/resources/learning/hoek/Geotechnical-Risks-on-Large-Civil-Engineering-Projects-1998.pdf (accessed on 1 April 2025).

- Flyvbjerg, B.; Bruzelius, N.; Rothengatter, W. Cost and Schedule Overruns in Large Hydropower Dams: An Assessment of Projects Completed since 2000. Int. J. Water Resour. Dev. 2019, 36, 865–887. [Google Scholar] [CrossRef]

- Temple, M.W.B.; Stukhart, G. Cost Effectiveness of Geotechnical Investigations. J. Manag. Eng. 1987, 3, 8–19. [Google Scholar] [CrossRef]

- Jaksa, M.B. Geotechnical Risk and Inadequate Site Investigations: A Case Study. Aust. Geomech. J. 2000, 35, 39–47. [Google Scholar]

- Merisalu, J.; Sundell, J.; Rosén, L. A Framework for Risk-Based Cost–Benefit Analysis for Decision Support on Hydrogeological Risks in Underground Construction. Geosciences 2021, 11, 82. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Grain size | 0–5 mm |

| Silt fraction content | 0.9% |

| Clay fraction content | 5.8–9.7% |

| Bulk density of soil skeleton | 1.98–2.15 g/cm3 |

| Filtration coefficient | approx. 9.5∙10−5 |

| Organic matter content | 0–0.4% |

| Description and Location | Bulk Density ρ [kg/m3] | Plasticity Index IL [-] | Angle of Internal Friction Φ [°] | Cohesion C [kPa] |

|---|---|---|---|---|

| Szalejów—A | 2.082 | 0.05 | 11.0 | 30.0 |

| Szalejów—B | 2.001 | 0.35 | 8.0 | 20.0 |

| Krosnowice—C | 2.032 | 0.084 | 17.0 | 18.9 |

| Symbol | Description | Symbol | Description | Symbol | Description |

|---|---|---|---|---|---|

| SL | Sandy loam | G | Gravel | RD | Rock debris |

| SIL | Silty loam | SGM | Sand and gravel mix | B | Boulders |

| SSL | Sandy and silty loam | SGM(c) | Sand and gravel mix with clay addition | Ms | Mudstone |

| LS | Loamy sand | FS | Fertile soil | Ss | Sandstone |

| SS | Silty sand | OM | Organic matter | M | Marl |

| FS | Fine sand | E | Embankment | Cs | Claystone |

| Bulk Density * | Specific Density | Compressive Strength | Deformation Modulus |

| [kg/dm3] | [kg/dm3] | [MPa] | [GPa] |

| 2.40 | 2.73 | 5.80 | 1.00 |

| Elastic Modulus | Poisson’s Ratio | Angle of Int. Friction | Cohesion |

| [GPa] | [-] | [°] | MPa |

| 4.46 | 0.09 | 30.65 | 15.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Połomski, M.; Wiatkowski, M.; Ługowska, G. Comparative Analysis of Studies of Geological Conditions at the Planning and Construction Stage of Dam Reservoirs: A Case Study of New Facilities in South-Western Poland. Appl. Sci. 2025, 15, 7811. https://doi.org/10.3390/app15147811

Połomski M, Wiatkowski M, Ługowska G. Comparative Analysis of Studies of Geological Conditions at the Planning and Construction Stage of Dam Reservoirs: A Case Study of New Facilities in South-Western Poland. Applied Sciences. 2025; 15(14):7811. https://doi.org/10.3390/app15147811

Chicago/Turabian StylePołomski, Maksymilian, Mirosław Wiatkowski, and Gabriela Ługowska. 2025. "Comparative Analysis of Studies of Geological Conditions at the Planning and Construction Stage of Dam Reservoirs: A Case Study of New Facilities in South-Western Poland" Applied Sciences 15, no. 14: 7811. https://doi.org/10.3390/app15147811

APA StylePołomski, M., Wiatkowski, M., & Ługowska, G. (2025). Comparative Analysis of Studies of Geological Conditions at the Planning and Construction Stage of Dam Reservoirs: A Case Study of New Facilities in South-Western Poland. Applied Sciences, 15(14), 7811. https://doi.org/10.3390/app15147811