Featured Application

This study provides valuable insights for the food industry seeking sustainable ways to valorize spent osmotic solutions. By converting these by-products into functional powders through spray drying, manufacturers can reduce waste and develop natural flavorings, sweeteners, or ingredients for functional foods. The use of inulin as a drying carrier offers added nutritional benefits, such as prebiotic effects. Powders with favorable flowability and solubility can be used in instant beverages, supplements, or encapsulated products.

Abstract

Spent osmotic solutions (sucrose, buckwheat honey, acacia honey, apple juice concentrate, chokeberry juice concentrate, cherry juice concentrate, and mannitol) were tested for their valorization to produce powders by spray drying. Simultaneously, the application of inulin as an alternative carrier was verified. The drying yield varied from 6 to 92%. For acacia honey, apple juice concentrate, chokeberry juice concentrate, and cherry juice concentrate, high stickiness was observed, which resulted in low yield and the production of significantly bigger particles of regular size distribution, higher hygroscopicity and bulk density, and better flowability. Sucrose, acacia honey, and mannitol were dried with lower stickiness, and the physical properties of the powders were acceptable. However, the yield of mannitol drying was low due to very small particles, low bulk density, and low cyclone efficiency. Therefore, sucrose and buckwheat honey solutions can be successfully spray dried using inulin as a carrier to produce powders suitable for further food applications. However, for the other tested materials, alternative carriers should be considered to reduce stickiness during drying.

1. Introduction

Osmotic dehydration (OD) is a method for the partial removal of water from different solid food materials, including fruits and vegetables [,]. It is commonly applied before the main drying process, although it can also extend shelf life by reducing water activity, slowing down deteriorating physicochemical and biological processes []. The principle of OD is the immersion of plant tissue in a hypertonic solution (osmotic solution—OS) composed of sugars, salts, or other solutes, which causes counter-current mass transfer: water flows from the food material to the OS, and simultaneously, the molecules of the osmotic agent diffuse from the solution into the food []. Water removal from lower solute concentrations to higher concentrations through semi-permeable membranes results in equilibrium conditions on both sides of the membranes []. OD operates at ambient temperature; thus, it consumes less energy than drying processes and has a lower impact on the thermal degradation of sensitive bioactive compounds, including color- and flavor-related compounds [,,].

Several OSs can be used in OD as single agents or blends. An OS should be effective, convenient, nontoxic, cheap, and taste good [,]. Among the OSs applied for fruit OD, the most popular has been sucrose solution, while nowadays there is a trend to replace it with other types. This trend is caused mainly by increasing awareness of the impact of sugar/sucrose consumption on health. Applying other types of OSs can create products with a lower glycemic index and improved nutritional value. Various types of fruit juice concentrates were tested for OD. Pomegranate seeds were osmo-dehydrated using date juice by Bchir et al. []. Kowalska et al. [] used strawberry or cherry concentrates for strawberry OD and reported that this OS had a positive effect on the color of dehydrated strawberries, while a specific strong sensory profile of chokeberry juice concentrate passed to osmo-dehydrated strawberries. In addition, honey solution can potentially be applied as an OS. Durrani et al. [] prepared carrot candy using honey by the process of OD. Dhungana et al. [] presented that honey was a more suitable osmotic agent than sucrose solution for yacon dehydration. Polyols are another group of substances that can be used as OS. They are characterized by their strong dehydrating capabilities, sweet taste, and low caloric content [].

Another critical issue in the OD process is the management of the spent OS. During osmotic treatment, OS is diluted and its dewatering potential is reduced []. Moreover, some aromas, pigments, acids, and proteins are leached into the solution, leading to chemical, physical, and sensory changes []. For industrial applications, recycling the solution is necessary, and it can be achieved by concentrating, adding solute, or mixing with a more concentrated solution. It is also crucial to continuously clean it by a complex process involving coarse filtration, pasteurization, and restoring the initial concentration (i.e., by adding dry sugar). Recycling should consider microbiological safety aspects []. According to Dela Rosa and Giroux [], some authors have pointed out that the limited large-scale industrial development of OD is due to the problems of concentrated solution management. On the other hand, OD promotes OS enrichment in certain water-soluble natural components extracted from fruits, such as vitamins and minerals. For this reason, recycling it for new food formulation seems to be an attractive alternative []. In a recent study by Zimmer et al. [], tomato juice-based spent OS was valorized by spray drying to produce powders, which can be further applied as a food ingredient. However, other types of sugar-rich OSs were not examined.

Spray drying (SD) is the most convenient method for transforming liquid foods into powders. It is widely applied for milk and dairy powder production, but can be also used for production of fruit, honey, or molasses powders []. Even though such materials are more demanding because they contain low-molecular-weight sugars with low glass transition temperatures (Tg), which cause stickiness-related problems during drying, the common approach to avoid such problems is the application of drying carriers []. The carriers increase the Tg of the material, and drying can be performed with good powder recovery/yield. The most popular carrier is maltodextrin (MD), but nowadays, there is a trend to replace it with other types to create additional health-promoting properties of the final powders. MD can be replaced by some proteins, fibers, or prebiotics, including inulin []. Currently, among the group of carriers that can offer some health-promoting properties, inulin has gained more interest []. It can be found in more than 36,000 plant species and, given this fact, it is abundant in a variety of mass-produced plants such as chicory, Jerusalem artichoke, onion, garlic, barley, and asparagus. It is a polysaccharide with a linear fructan structure. Its structure is solely composed of fructose units with the only exception at the molecule’s residual spot, where a D-glucopyranosyl (terminal glucose molecule) can or cannot be found. The β-D-fructosyl residues are linked together by β-(2→1)-D-fructosyl-fructose bonds, whereas the terminal glucose molecule is linked through an α-(1→2) bond [,]. The polymerization level of inulin spans from 2 to 60 units; hence, this degree of polymerization (DP) results in the classification between ‘fructooligosaccharides’ (up to 10 units) and ‘fructopolysaccharides’ (>10 units). The variation in inulin’s degree of polymerization significantly affects its technological and therefore its industrial applications. It is effective as green wall material for phytochemical encapsulation [], and due to its technological and nutritional benefits, it can also be tested for spray drying applications. However, the efficiency of such an alternative carrier must be verified each time for a particular raw material.

The aim of this research was to valorize spent osmotic solutions (applied in another study for apple osmotic dehydration, including classic sucrose solution, honey solution, fruit juice concentrate solution, and mannitol solution) for the production of powders through spray drying operation. Additionally, inulin was tested as a value-added replacement for maltodextrin to determine its usefulness as a drying carrier. The powder recovery after drying was specified, and after spray drying, the powders were tested in terms of selected physical properties. Data analysis was supported by advanced chemometric methods.

2. Materials and Methods

2.1. Materials and Experimental Plan

The materials used in this study are presented in Table 1. First, solutions of sucrose (50% solids, w/w), two types of honey (buckwheat, acacia; 50% solids, w/w), three types of fruit juice concentrates (apple, chokeberry, sour cherry; 50% solids, w/w), and mannitol (30% solids, w/w) were applied for osmotic dehydration of apples (osmotic dehydration is not the subject of this study), and were diluted during this process due to water transfer from apples. Then, during this valorization study, they were supplemented with inulin (Orafti GR, DP > 10, Brenntag Polska Sp. z o.o., Kędzierzyn-Koźle, Poland) and distilled water to obtain 500 g of 50% (solids, w/w) feed solutions with a ratio of osmotic material solids to inulin solids of 50:50. The exception was mannitol, which was dried without the addition of inulin (based on the knowledge that it does not require a carrier during spray drying).

Table 1.

Raw materials applied for spray drying, their concentration at different stages of processing, and information regarding the addition of the carrier inulin.

2.2. Spray Drying

Spray drying was carried out using a NIRO MINOR (GEA, Søborg, Denmark) spray dryer equipped with a rotating disc for atomization (26,000 rpm), with atmospheric air as the drying gas in an open cycle mode. The feed rate was 0.3 mL/s, while the inlet air temperature/outlet air temperature (IAT/OAT) was 160/60 °C. After the drying process (500 g of feed solution was dried in duplicate) and removal of the powder from the drying chamber, the powder was weighed. The yield (Y) was calculated as the ratio (percentage) of the mass of solids in the collected powder to the mass of solids in the feed solution [].

2.3. Analytical Methods

2.3.1. Particle Morphology—SEM Analysis

The morphology of the powder particles was described based on photos taken with an XL scanning electron microscope (PHENOM, Shibuya, Japan) at a magnification of 500× and an accelerating voltage of 5 kV. Before the photos were taken, the samples were covered with a layer of gold using a Sputter Coater 108 auto (Cressington, Liverpool, UK).

2.3.2. Particle Size Measurement

Measurements were performed by laser diffraction using a 1190 device (CILAS, Orléans, France) in a liquid (ethanol) dispersion at a maximum obscuration of 10%. The particle size distribution and cumulative particle size distribution were derived graphically. The median diameter D50 was also presented, while parameters D10 and D90 of volumetric fractions (values of the dimension below which 10 and 90% of all particles occur, respectively) were used to calculate the polydispersity index (PDI) based on Formula (1) []:

PDI = (D90 − D10)/D50

2.3.3. Moisture Content and Water Activity

The moisture content (MC) of the powders was determined by the oven method. The samples were weighed on an analytical balance of about 0.5 g (with an accuracy of 0.0001 g) and then dried at the temperature of 105 °C for 4 h. The water activity (aw) of the powders was determined using a HygroLab C1 (Rotronic, Bassersdorf, Switzerland) device. The measurements were made at the temperature of 25 °C [].

2.3.4. Hygroscopicity

To evaluate hygroscopicity (H), 1 g of powder was incubated at 25 °C and 75% relative humidity (above saturated NaCl solution) for 168 h. The weight gain was noted to calculate the amount of water absorbed by 100 g of powder solids and expressed as a percentage []. The determinations were performed in triplicate.

2.3.5. Solubility

The water solubility index (WSI) was analyzed as described by Jafari et al. [], with some minor modifications. An aliquot of 2 g (m0) of the sample (of known solids content, DB) was suspended in 30 mL of distilled water at ambient temperature in a centrifuge tube. After mixing for 1 min on a vortex mixer, it was placed in a water bath (37 °C/30 min) and centrifuged (2054× g/20 min/ambient temperature). The supernatant (15 mL) was placed into a Petri dish of known weight and dried at 105 °C for 24 h. The final mass of the residue (m1) was recorded, and the WSI [%] was calculated as follows:

WSI = m1/(m0/2 × DB) × 100

2.3.6. Bulk Density and Flowability

The mass of the powder occupying the 25 mL cylinder was measured to determine the loose bulk density (DL). An automatic tapper STAV 2003 (Engelsmann AG, Rhein, Germany) was used to evaluate the tapped bulk density (DT) by determining the volume of a sample after 100 taps. The flowability was expressed as the Hausner Ratio (HR) []:

HR = DT/DL

2.4. Statistical Methods

2.4.1. Analysis of Variance (ANOVA)

All measurements were performed in triplicate, and the results were expressed as mean ± standard deviation. A one-way analysis of variance (ANOVA) and Tukey’s test (p < 0.05) were used to establish the evaluation of the significance of the differences between average values of response variables, descriptors of the drying process performance and powder properties. The data were analyzed using STATISTICA 13.3 software (Statsoft, Tulsa, OK, USA).

2.4.2. Chemometric Analysis

Pearson correlation analysis was performed to derive the correlation coefficient between the yield of drying and the physical properties of the powders at the significance level α = 0.05 [].

Principal Component Analysis (PCA) and Hierarchical Cluster Analysis (HCA, Euclidean distance, Ward’s method) were used to transform the original variables into a smaller set of linear combinations and to find the relationships between response variables [].

3. Results

3.1. Yield

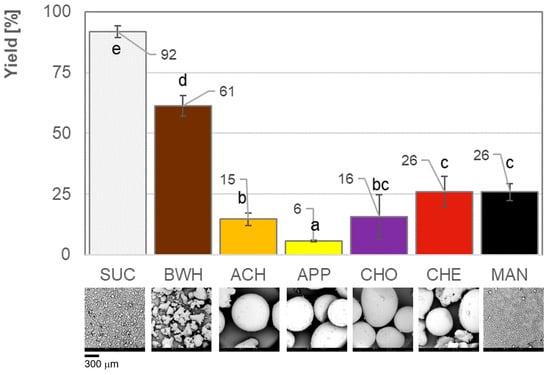

The yield (Y) of SD was dependent on the type of raw material and varied from 6 to 92% (Figure 1). According to the criteria presented by Bhandari et al. [], successful SD at the laboratory and pilot scales should have a Y above 50%; therefore, only two materials could be classified as efficient: SUC and BWH. This was strongly related to the chemical composition of the OSs and the relationship between the carbohydrate profile and Tg. It is well known that sucrose has a higher Tg (62 °C) than the low-molecular-weight sugars glucose (31 °C) and fructose (5 °C) []. Thus, SUC, characterized by a higher Tg, could be dried without stickiness, which is usually observed for fruit juices or honey. This stickiness results from the difference between the outlet air temperature (OAT) and Tg of the material when the OAT is higher than Tg + 20 °C [,]. The feed solution is not transformed into a powder form, or the formed particles adhere to each other and to the internal wall of the drying chamber [,], which results in low drying yields. Such behavior is typical for fruit juices, concentrates, and honey, and has been presented by numerous researchers [,,,,,,,]. As far as honey spray drying is concerned, in some cases, it is easier than in the case of fruit concentrates, which is also a consequence of the sugar profile. Usually, the fructose/glucose (F/G) ratio in honey varies from close to 1 (rape honey) to 1.5 (acacia honey) [], while for various fruit concentrates, this ratio can be much higher. A much higher amount of fructose than glucose, typical for apple concentrate (F/G ratio from 2 to 6) [], also creates higher stickiness owing to the lower Tg of fructose than glucose. This resulted in a low Y value of the APP variant. Similar results of lower Tg and powder recovery of apple powder than honey dried with the same carrier and under the same conditions were presented by Samborska et al. []. For honey powder spray dried with MD, nutriose powder recovery was 74–75%, while for apple concentrate it was 44–55%. Among different types of honey, the yield of SD can also be different because buckwheat honey contains higher amounts of proteins [], which have higher Tg than sugars and can prevent stickiness due to surface activity. Protein-rich surface films can decrease particle-to-particle cohesion and particle-to-surface adhesion, as previously described by Adhikari et al. [] and Mirlohi et al. [].

Figure 1.

The yield of spray drying and SEM pictures (mag. 500×) of powders obtained from different raw materials—spent osmotic solutions: sucrose (SUC), honey buckwheat (BWH), acacia honey (ACH), apple juice concentrate (APP), chokeberry juice concentrate (CHO), cherry juice concentrate (CHE), mannitol (MAN). a–e: Different letters indicate statistically significant differences between mean values (HSD Tukey, p < 0.05).

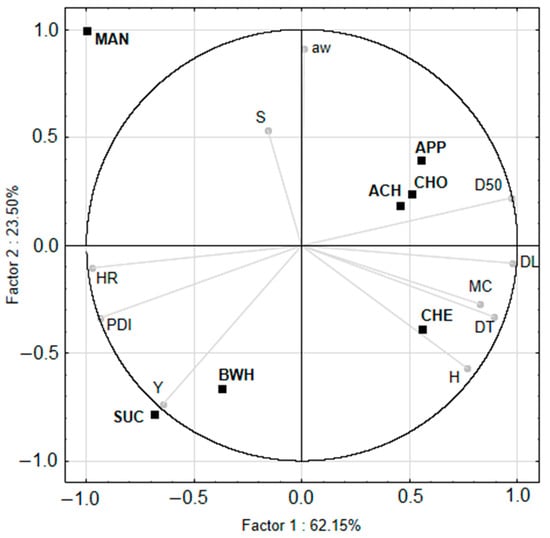

PCA illustrated as a biplot (Figure 2) was used to evaluate the relationship between Y, the physical properties of the powders, and the type of dried OS. According to this analysis, it can be stated that Y was the main variable which discriminated SUC and BWH powders—points SUC and BWH are located close to the Y vector. These two principal components explained 88.97% of the total variance. The first component (F1) explained 62.15% of the variance, whereas the second component (F2) explained 23.50%. A clear discrimination between the powders based on the type of OS was observed.

Figure 2.

PCA biplot diagram. Vectors are dependent variables: drying yield (Y) and physical properties of the powders: median particle size (D50), polydispersity index (PDI), moisture content (MC), water activity (aw), hygroscopicity (H), solubility (WSI), loose bulk density (DL), tapped bulk density (DT), and Hausner Ratio (HR). Points are experimental variants; powders obtained from different raw materials—spent osmotic solutions: sucrose (SUC), honey buckwheat (BWH), acacia honey (ACH), apple juice concentrate (APP), chokeberry juice concentrate (CHO), cherry juice concentrate (CHE), and mannitol (MAN).

When comparing Y of APP and ACH (honey) with the previous study cited above [], it can be noticed that values obtained in the current work were lower. Previously, MD and nutriose were applied as carriers, while in the current study, inulin was used. Y below 20% indicates much worse properties of inulin as a carrier. Previously, other researchers also suggested inulin as an SD additive, which is effective when applied as a wall material for the encapsulation of different extracts such as green tea extract [], anthocyanins extracted from Jussara pulp [], or as a single carrier for sugar-rich materials, such as cranberry juice [], orange juice [], and blueberry juice []. According to Araujo-Díaz et al. [], inulin presents a Tg of 105 °C, which is appropriate for spray drying microencapsulation of sugar-rich juices. However, the results are difficult to compare because in the research cited above, the yield of SD was not presented. Recently, inulin was tested by Zimmer et al. [] as a carrier for SD of spent osmotic solution—tomato concentrate used for garlic dehydration. They concluded that the properties of inulin as a carrier are worse than for MD—Y values were as low as 2.75–14.12% (depending on the level of addition and the inlet air temperature), while with MD, it was in a range from 13.52 to 28.83% (thus it was also lower than the limit of 50% of successful SD).

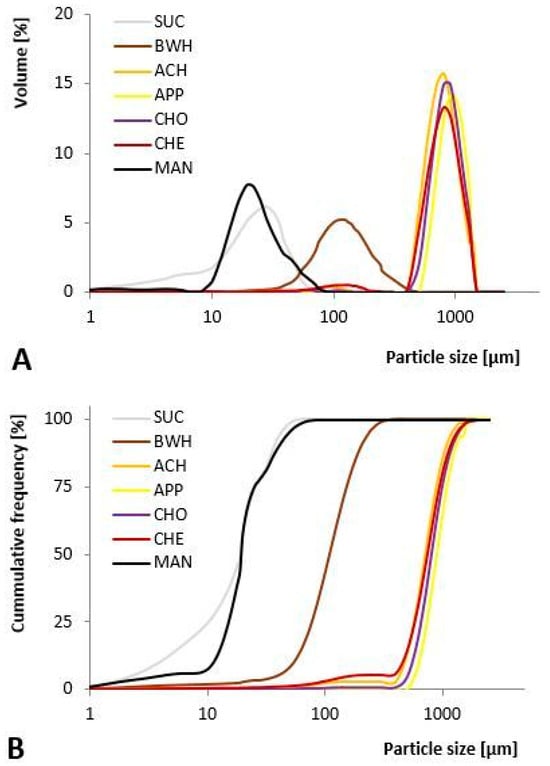

Mannitol is a compound from a different group than the rest of the OSs. It is not a sugar-rich material, but a sugar alcohol, characterized by low hygroscopicity, high water solubility, and low toxicity []. It is approved for pulmonary drug delivery and has been investigated as an alternative carrier for dry powder inhalers [,,], diluent in tablet formulations [], and was also tested as a superior anticaking agent for spray dried hydroxypropyl-beta-cyclodextrin microcapsules []. Mannitol is commercially available in spray dried form []; thus, it is not a problematic material to be spray dried, in contrast to sugar-rich materials. Even though there can be some issues during the SD of mannitol, they relate to the final form of the particles. Mannitol can exist in different polymorphic forms or mixtures of polymorphs, as well as amorphous materials. Littringer et al. [] reported that pure mannitol does not normally exist in the amorphous state after SD or freeze-drying. This was also confirmed by Hulse et al. [], who reported that after SD, there was no amorphous material within the samples. However, mannitol may crystallize in three different polymorphs during SD, with slightly different crystal habits, possibly leading to different surface topographies []. Because polymorphism, particle size, and surface roughness can affect the final suitability of mannitol as a carrier for dry powder inhalers, the SD of mannitol is still a topic of interest, but none of the available papers on mannitol SD concern the yield of SD. Therefore, it was expected in the current study that Y of MAN should be high. However, on the other hand, it is known that Y can be affected, for example, by particle size, moisture content, or bulk density, because they can also affect the cyclone efficiency. MAN had the smallest particle size (Figure 3, Table 2), the lowest moisture content, and bulk density (Table 2) among all samples; thus, this could be the reason for the decreased Y—the smallest and lightest particles were probably unable to separate in the cyclone, being easily blown out of the cyclone in the outlet air [].

Figure 3.

Particle size distribution (A) and cumulated particle size distribution (B) of powders obtained from different raw materials—spent osmotic solutions: sucrose (SUC), honey buckwheat (BWH), acacia honey (ACH), apple juice concentrate (APP), chokeberry juice concentrate (CHO), cherry juice concentrate (CHE), and mannitol (MAN).

Table 2.

Physical properties: median particle size (D50), polydispersity index (PDI), moisture content (MC), water activity (aw), hygroscopicity (H), solubility (WSI), loose bulk density (DL), tapped bulk density (DT), and Hausner Ratio (HR) of powders obtained from different raw materials—spent osmotic solutions: sucrose (SUC), honey buckwheat (BWH), acacia honey (ACH), apple juice concentrate (APP), chokeberry juice concentrate (CHO), cherry juice concentrate (CHE), and mannitol (MAN).

3.2. Particle Morphology and Particle Size

The type of OS significantly affected particle morphology (Figure 1) and particle size (Figure 3), which varied from 20 to 896 µm (D50 value). Particle morphology and size were good indicators of the stickiness observed during SD because more problematic OSs (with lower Y (APP, ACH, CHE, CHO)) had larger particles, while the samples with lower stickiness and higher drying Y (SUC, BWH) had significantly smaller particles (p < 0.05). At the same time, BWH of lower Y also had larger particles than SUC. According to Pearson correlation analysis, Y was significantly correlated with particle size (negative correlation) and PDI (positive correlation). These correlations can also be confirmed based on PCA, because in PCA, biplot vectors lower than 90° indicate positive associations, and angles near 180° indicate negative associations between variables []. The PCA biplot also clearly illustrated that particle size was an important discriminator for the APP, ACH, and CHO samples. The increase in particle size with increased stickiness and more difficult SD was previously observed by Samborska et al. [] and Jedlińska et al. [] during the spray drying of honey, Barańska et al. [] for cherry powders, or Fazaeli et al. [] for black mulberry juice powders. The increase in honey content in the feed solution caused higher stickiness and the production of particles of higher magnitudes. The particle sizes of spray dried APP, ACH, CHE, and CHO (above 700 µm) were significantly larger than those usually observed for spray dried materials. This resulted in high stickiness and low usefulness of inulin as a carrier for these raw materials. At the same time, the PDI of these four samples were significantly lower than that of other easier-to-be-dried samples.

The exception to the relationships described above between particle size and Y was the MAN sample, which had low Y and at the same time the smallest particles. As explained earlier, MAN is a completely different type of material than the other sugar-rich materials in this study. The low Y of MAN resulted not from stickiness, but from the effect of small particle size, low moisture, and bulk density, as explained before.

3.3. Moisture Content and Water Activity

MC (from 0.4 ± 0.1 to 4.8 ± 0.5%) and aw (from 0.040 ± 0.009 to 0.208 ± 0.004) results were consistent with the results commonly obtained in spray drying experiments [,,]. Significant differences (p < 0.05) were observed among the samples. The highest aw was for the MAN sample, even though the MC was the lowest in this powder. This could result from the physical form of the particles. According to Almeida et al. [], the presence of free water is characteristic of crystallized powders. Nevertheless, the value was still lower than 0.35, indicating resistance to the growth of microorganisms and the occurrence of unfavorable biochemical reactions, increasing the useful life of the products []. All powders containing raw materials rich in low-molecular-weight sugars (BWH, ACH, APP, CHO, CHE) were characterized by significantly higher MC than the other samples (SUC, MAN). This could have resulted from the water-binding effect of the sugars. Such an observation of increased MC after drying of materials more abundant in sugars was previously presented by Barańska et al. [] for sour cherry concentrate and by Bhusari et al. [] for tamarind pulp powder. In general, an MC below 5% in all the obtained powders ensures their stability and prevents microbial growth.

3.4. Hygroscopicity

The type of OS significantly affected the hygroscopicity of the obtained powders. It ranged from 0.5 ± 0.1 to 27.3 ± 0.2%. The lowest H value was observed for MAN, which was caused by its physical form. As described above, mannitol usually forms a crystalline structure that is typically not hygroscopic. Similar observations were presented by Gonnissen et al. []: spray drying of drug/excipient solutions containing erythritol and mannitol resulted in crystalline non-hygroscopic powder mixtures. In contrast, other powders of sugar-rich materials, typically forming an amorphous structure after spray drying, were characterized by high H. Hygroscopicity above 20% is typical for these kinds of powders because their amorphous glassy form is susceptible to water adsorption []. A similar level of H above 20% was observed before for guava powder [], barberry juice powder [], honey powder [], and sour cherry powder [].

3.5. Solubility

All formulations were highly soluble in water (WSI > 94%, Table 2). The differences between the samples were not statistically significant. In general, the solubility of spray dried powders is influenced by many factors such as carrier agents, raw materials, and powder properties such as particle size and moisture content []. However, no significant correlations were observed in the current work in the case of solubility (Table 3). According to Murugesan and Orsat [] and George et al. [], powders based on raw materials abundant in carbohydrates and low-molecular-weight sugars have high solubility. Carriers from the polysaccharide group, including inulin, are known to form highly soluble powders [,,]. A similarly high level of WSI was previously observed for pomegranate juice powder with maltodextrin [], while it was lower for powdered sour cherry juice []. As was presented by Taengsopha et al. [], the partial replacement of maltodextrin by inulin in spray dried yogurt powder enhanced solubility.

Table 3.

Pearson correlation matrix between the yield of drying (Y) and physical properties of the powders: moisture content (MC), water activity (aw), hygroscopicity (H), loose bulk density (DL), tapped bulk density (DT), Hausner ratio (HR), solubility (S), median particle size (D50), and polydispersity index (PDI). The colors of the cells are proportional to the corresponding correlation coefficients: significant positive correlations are displayed in red, significant negative correlations are displayed in blue, and cells with a white background indicate non-significant correlations.

3.6. Bulk Density and Flowability

DL of powders ranged from 0.45 ± 0.02 (MAN) to 0.88 ± 0.02 g/mL (ACH) (Table 2). This range is typical for spray dried powders and is similar to that reported by Fazaeli et al. [] for black mulberry juice powder, and Michalska-Ciechanowska et al. [] for cranberry juice powder. Bulk density was significantly correlated with particle size (Table 3); higher density was observed for larger particles. The typical correlation presented by many researchers is usually the opposite—smaller particles typically tend to have higher bulk densities because of the arrangement of the particles; the particles are in close form, and there are fewer spaces between them [,]. Such a correlation was presented for spray dried pitaya fruit powder [] or spray dried microcapsules containing fish oil []. However, in the current work, high DL was observed for samples characterized by high stickiness during drying. The stickiness effect, leading to problems with evaporation and the formation of particles, could also affect the low internal porosity of particles and easy bed packing, both of which result in high bulk density. In contrast, MAN powder of very low particle size and SUC had the lowest bulk density.

HR—the indicator of powder flowability—varied from 1.00 ± 0.04 (APP) to 1.34 ± 0.06 (MAN). According to the flowability criteria presented by Shah et al. [], some of the powders were in the range of excellent flowability (HR < 1.11 for samples ACH, APP, CHO, CHE), while some of them were in the range of passable flow (HR 1.26–1.34 for SUC, BWH, MAN). Contrary to the previous correlation—the correlation between HR and particle size was typical, as described in the literature—powders with smaller particles had worse flowability owing to higher cohesiveness []. Such a correlation was previously reported for pitaya fruit powder [] and sugarcane juice powder []. According to Goh et al. [], particles larger than 250 μm flow freely, whereas those less than 10 μm are considered cohesive. This was explained by the fact that larger particle sizes have a smaller number of points at which particles can combine and interact with each other, which results in lower cohesiveness of the powders and thus better flow properties []. Additional reasons for the excellent flowability of samples ACH, APP, CHO, and CHE can be the morphology of particles (smooth surfaces) and lower PDI (more uniform particle size reduces the number of interparticle interactions) [].

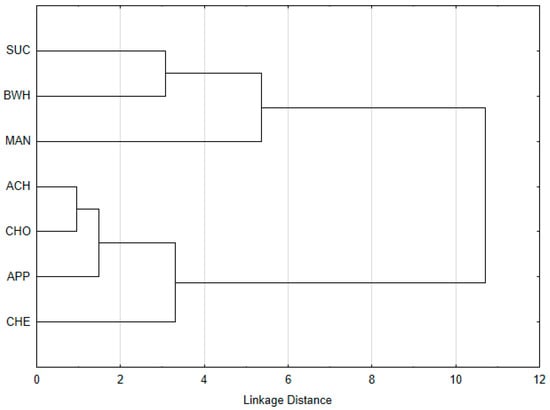

3.7. Hierarchical Cluster Analysis

HCA was used to classify the powders based on the drying yield and physical properties. The dendrogram plot (Figure 4) shows division into two main clusters at a high level of similarity. Cluster 1 contained powders produced with lower stickiness and smaller particles of worse flowability (SUC, BWH, MAN), while powders in cluster 2 (ACH, CHO, APP, CHE) were obtained during the process of low yield (high stickiness) and had much bigger particles and excellent flowability.

Figure 4.

HCA dendrogram showing the clustering of powders obtained from different raw materials—spent osmotic solutions: sucrose (SUC), honey buckwheat (BWH), acacia honey (ACH), apple juice concentrate (APP), chokeberry juice concentrate (CHO), cherry juice concentrate (CHE), and mannitol (MAN).

4. Conclusions

This study demonstrated that some of the tested spent osmotic solutions can be valorized to produce powders via spray drying, although this possibility depends on the type of solution. The application of inulin as an alternative carrier was tested. The application of inulin as a drying carrier was not very efficient in the case of acacia honey, apple juice concentrate, chokeberry juice concentrate, and cherry juice concentrate solutions—the yield of drying was low. On the contrary, for sucrose and buckwheat honey solutions, it was at an acceptable level. Mannitol solution could also be powdered successfully, even without the addition of a carrier. However, as the material has different characteristics, it requires adjustment of the powder separation method—particles of crystalline structure, very small in size, and of low bulk density are difficult to discharge by the standard cyclone. It has to be highlighted that the physical properties of the powders are highly dependent on their susceptibility to stickiness during drying. Highly sticky materials (acacia honey, apple juice concentrate, chokeberry juice concentrate, and cherry juice concentrate solutions) had significantly larger particles of more regular size distribution, higher hygroscopicity, and higher bulk density, but better flowability (lower Hausner ratio).

Thus, sucrose and buckwheat honey can be spray dried with inulin as a carrier to produce powders for further food applications, but for other tested materials, other types of carriers should be selected to avoid stickiness.

Author Contributions

Conceptualization, K.S., K.K., I.M., and M.N.; methodology, A.B.-D., K.K., A.J., and M.N.; validation, R.C. and M.N.; formal analysis, K.K.; investigation, K.S., A.B.-D., K.K., and A.J.; data curation, K.S., A.B.-D., A.J., and K.K.; writing—original draft preparation, K.S., R.C., K.K., and I.M.; writing—review and editing, K.S. and R.C.; visualization, K.S. and R.C.; supervision, K.S.; funding acquisition, M.N. All authors have read and agreed to the published version of the manuscript.

Funding

The research for this publication was carried out with the use of equipment purchased as part of the “Food and Nutrition Centre—modernization of the WULS campus to create a Food and Nutrition Research and Development Centre (CŻiŻ)”, co-financed by the European Union from the European Regional Development Fund under the Regional Operational Programme of the Mazowieckie Voivodeship for 2014–2020 (Project No. YMA.01.01.00-14-8276/17).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are openly available in RepOD at https://doi.org/10.18150/9QACDK (accessed on 22 May 2025).

Acknowledgments

The authors from Warsaw University of Life Sciences and the Polytechnic Institute of Coimbra express their gratitude to UNIGREEN European University for fostering collaboration and providing the opportunity to work together. This support and encouragement have been invaluable for the development of this research.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ACH | Acacia honey |

| ANOVA | One-way analysis of variance |

| APP | Apple |

| BWH | Buckwheat honey |

| CHE | Cherry |

| CHO | Chokeberry |

| D10 | 10th percentile of the particle size distribution |

| D50 | Median diameter |

| D90 | 90th percentile of the particle size distribution |

| DL | Loose bulk density |

| DT | Tapped bulk density |

| H | Hygroscopicity |

| HCA | Hierarchical Cluster Analysis |

| HR | Hausner Ratio |

| IAT | Inlet air temperature |

| MAN | Mannitol |

| MC | Moisture content |

| MD | Maltodextrin |

| OAT | Outlet air temperature |

| OD | Osmotic dehydration |

| OS | Osmotic solution |

| PCA | Principal Component Analysis |

| PDI | Polydispersity index |

| SD | Spray drying |

| SUC | Sucrose |

| Tg | Glass transition temperature |

| WSI | Water solubility index |

| Y | Yield |

References

- Phisut, N. Factors affecting mass transfer during osmotic dehydration of fruits. Int. Food Res. J. 2012, 19, 7–18. [Google Scholar]

- Salehi, F. Recent advances in the ultrasound-assisted osmotic dehydration of agricultural products: A review. Food Biosci. 2023, 51, 102307. [Google Scholar] [CrossRef]

- Manzoor, A.; Jan, B.; Rizvi, Q.U.E.H.; Junaid, P.M.; Pandith, J.A.; Dar, I.H.; Bhat, S.A.; Ahmad, S. Osmotic dehydration technology for preservation of fruits and vegetables. In Quality Control in Fruit and Vegetable Processing; Apple Academic Press: Palm Bay, FL, USA, 2023; pp. 167–184. [Google Scholar]

- Wiktor, A.; Chadzynska, M.; Rybak, K.; Dadan, M.; Witrowa-Rajchert, D.; Nowacka, M. The Influence of Polyols on the Process Kinetics and Bioactive Substance Content in Osmotic Dehydrated Organic Strawberries. Molecules 2022, 27, 1376. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.K.; Singh, S.V. Osmotic dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2014, 51, 1654–1673. [Google Scholar] [CrossRef] [PubMed]

- Abrahao, F.R.; Correa, J.L.G. Osmotic dehydration: More than water loss and solid gain. Crit. Rev. Food Sci. Nutr. 2023, 63, 2970–2989. [Google Scholar] [CrossRef]

- Kaur, D.; Singh, M.; Zalpouri, R.; Singh, I. Osmotic dehydration of fruits using unconventional natural sweeteners and non-thermal-assisted technologies: A review. J. Food Process. Preserv. 2022, 46, e16890. [Google Scholar] [CrossRef]

- Bchir, B.; Besbes, S.; Karoui, R.; Paquot, M.; Attia, H.; Blecker, C. Osmotic Dehydration Kinetics of Pomegranate Seeds Using Date Juice as an Immersion Solution Base. Food Bioprocess Technol. 2010, 5, 999–1009. [Google Scholar] [CrossRef]

- Kowalska, H.; Trusinska, M.; Rybak, K.; Wiktor, A.; Witrowa-Rajchert, D.; Nowacka, M. Shaping the Properties of Osmo-Dehydrated Strawberries in Fruit Juice Concentrates. Appl. Sci. 2023, 13, 2728. [Google Scholar] [CrossRef]

- Durrani, A.M.; Srivastava, P.K.; Verma, S. Development and quality evaluation of honey based carrot candy. J. Food Sci. Technol. 2011, 48, 502–505. [Google Scholar] [CrossRef]

- Dhungana, A.; Kharel, G.P.; Ojha, P. Effect of osmotic agents on dehydration of yacon (Smallanthus sonchifolia) slices. GoldenGate J. Sci. Technol. 2017, 3, 46–51. [Google Scholar]

- Aguirre-García, M.; Cortés-Zavaleta, O.; Ruiz-Espinosa, H.; Ochoa-Velasco, C.E.; Ruiz-López, I.I. The role of coupled water and solute diffusion and product shrinkage during osmotic dehydration. J. Food Eng. 2022, 331, 111121. [Google Scholar] [CrossRef]

- Li, H.; Ramaswamy, H.S. Osmotic dehydration. Stewart Postharvest Rev. 2005, 1, 1–9. [Google Scholar]

- Dalla Rosa, M.; Giroux, F. Osmotic treatments (OT) and problems related to the solution management. J. Food Eng. 2001, 49, 223–236. [Google Scholar] [CrossRef]

- Garcıa-Martınez, E.; Martínez-Monzó, J.; Camacho, M.M.; Martınez-Navarrete, N. Characterisation of reused osmotic solution as ingredient in new product formulation. Food Res. Int. 2002, 35, 307–313. [Google Scholar] [CrossRef]

- Zimmer, A.; Masztalerz, K.; Serowik, M.; Nejman, M.; Lech, K. Utilization of Post-Process Osmotic Solution Based on Tomato Juice Through Spray Drying. Agriculture 2024, 14, 1883. [Google Scholar] [CrossRef]

- Samborska, K.; Barańska, A.; Boostani, S.; Riazi, M.; Jafari, S.M. Introduction to the spray drying process. In Spray Drying for the Food Industry; Elsevier: Amsterdam, The Netherlands, 2024; pp. 3–28. [Google Scholar]

- Samborska, K.; Sarabandi, K.; Tonon, R.; Topuz, A.; Eroğlu, E.; Kaymak-Ertekin, F.; Malekjani, N.; Jafari, S.M. Recent progress in the stickiness reduction of sugar-rich foods during spray drying. Dry. Technol. 2023, 41, 2566–2585. [Google Scholar] [CrossRef]

- Samborska, K.; Boostani, S.; Geranpour, M.; Hosseini, H.; Dima, C.; Khoshnoudi-Nia, S.; Rostamabadi, H.; Falsafi, S.R.; Shaddel, R.; Akbari-Alavijeh, S.; et al. Green biopolymers from by-products as wall materials for spray drying microencapsulation of phytochemicals. Trends Food Sci. Technol. 2021, 108, 297–325. [Google Scholar] [CrossRef]

- Michalska-Ciechanowska, A.; Majerska, J.; Brzezowska, J.; Wojdyło, A.; Figiel, A. The Influence of Maltodextrin and Inulin on the Physico-Chemical Properties of Cranberry Juice Powders. ChemEngineering 2020, 4, 12. [Google Scholar] [CrossRef]

- Meyer, D.; Blaauwhoed, J.P. Inulin. In Handbook of Hydrocolloids; Woodhead Publishing: Cambridge, UK, 2009; pp. 829–848. [Google Scholar]

- Wan, X.; Guo, H.; Liang, Y.; Zhou, C.; Liu, Z.; Li, K.; Niu, F.; Zhai, X.; Wang, L. The physiological functions and pharmaceutical applications of inulin: A review. Carbohydr. Polym. 2020, 246, 116589. [Google Scholar] [CrossRef]

- Vickovic, D.; Czaja, T.P.; Gaiani, C.; Pedersen, S.J.; Ahrné, L.; Hougaard, A.B. The effect of feed formulation on surface composition of powders and wall deposition during spray drying of acidified dairy products. Powder Technol. 2023, 418, 118297. [Google Scholar] [CrossRef]

- Kurek, M.A.; Moczkowska, M.; Pieczykolan, E.; Sobieralska, M. Barley β-d-glucan–modified starch complex as potential encapsulation agent for fish oil. Int. J. Biol. Macromol. 2018, 120, 596–602. [Google Scholar] [CrossRef] [PubMed]

- Gong, Z.; Zhang, M.; Mujumdar, A.S.; Sun, J. Spray Drying and Agglomeration of Instant Bayberry Powder. Dry. Technol. 2007, 26, 116–121. [Google Scholar] [CrossRef]

- Pombo, J.C.P.; de Medeiros, H.; Pena, R.D.S. Optimization of the spray drying process for developing cupuassu powder. J. Food Sci. Technol. 2020, 57, 4501–4513. [Google Scholar] [CrossRef] [PubMed]

- Jafari, S.M.; Ghalegi Ghalenoei, M.; Dehnad, D. Influence of spray drying on water solubility index, apparent density, and anthocyanin content of pomegranate juice powder. Powder Technol. 2017, 311, 59–65. [Google Scholar] [CrossRef]

- Saw, H.Y.; Davies, C.E.; Paterson, A.H.J.; Jones, J.R. Correlation between Powder Flow Properties Measured by Shear Testing and Hausner Ratio. Procedia Eng. 2015, 102, 218–225. [Google Scholar] [CrossRef]

- Combrzynski, M.; Oniszczuk, T.; Kupryaniuk, K.; Wojtowicz, A.; Mitrus, M.; Milanowski, M.; Soja, J.; Budziak-Wieczorek, I.; Karcz, D.; Kaminski, D.; et al. Physical Properties, Spectroscopic, Microscopic, X-ray, and Chemometric Analysis of Starch Films Enriched with Selected Functional Additives. Materials 2021, 14, 2673. [Google Scholar] [CrossRef]

- Matwijczuk, A.; Oniszczuk, T.; Matwijczuk, A.; Chruściel, E.; Kocira, A.; Niemczynowicz, A.; Wójtowicz, A.; Combrzyński, M.; Wiącek, D. Use of FTIR Spectroscopy and Chemometrics with Respect to Storage Conditions of Moldavian Dragonhead Oil. Sustainability 2019, 11, 6414. [Google Scholar] [CrossRef]

- Bhandari, B.; Datta, N.; Howes, T. Problems associated with spray drying of sugar-rich foods. Dry. Technol. 1997, 15, 671–684. [Google Scholar] [CrossRef]

- Mirlohi, M.; Manickavasagan, A.; Ali, A. The effect of protein drying aids on the quantity and quality of spray dried sugar-rich powders: A systematic review. Dry. Technol. 2022, 40, 1068–1082. [Google Scholar] [CrossRef]

- Adhikari, B.; Howes, T.; Bhandari, B.R.; Truong, V. Characterization of the Surface Stickiness of Fructose–Maltodextrin Solutions During Drying. Dry. Technol. 2003, 21, 17–34. [Google Scholar] [CrossRef]

- Kudra, T. Sticky Region in Drying—Definition and Identification. Dry. Technol. 2003, 21, 1457–1469. [Google Scholar] [CrossRef]

- Araujo-Díaz, S.; Leyva-Porras, C.; Aguirre-Bañuelos, P.; Álvarez-Salas, C.; Saavedra-Leos, Z. Evaluation of the physical properties and conservation of the antioxidants content, employing inulin and maltodextrin in the spray drying of blueberry juice. Carbohydr. Polym. 2017, 167, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Samborska, K.; Wiktor, A.; Jedlińska, A.; Matwijczuk, A.; Jamróz, W.; Skwarczyńska-Maj, K.; Kiełczewski, D.; Tułodziecki, M.; Błażowski, Ł.; Witrowa-Rajchert, D. Development and characterization of physical properties of honey-rich powder. Food Bioprod. Process. 2019, 115, 78–86. [Google Scholar] [CrossRef]

- Miravet, G.; Alacid, M.; Obón, J.M.; Fernández-López, J.A. Spray-drying of pomegranate juice with prebiotic dietary fibre. Int. J. Food Sci. Technol. 2016, 51, 633–640. [Google Scholar] [CrossRef]

- Barańska, A.; Jedlińska, A.; Samborska, K. Is it Possible to Produce Carrier-Free Fruit and Vegetable Powders by Spray Drying? Pol. J. Food Nutr. Sci. 2023, 73, 214–223. [Google Scholar] [CrossRef]

- Jedlińska, A.; Samborska, K.; Wiktor, A.; Balik, M.; Derewiaka, D.; Matwijczuk, A.; Gondek, E. Spray drying of pure kiwiberry pulp in dehumidified air. Dry. Technol. 2022, 40, 1421–1435. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. A new technique for spray drying orange juice concentrate. Innov. Food Sci. Emerg. Technol. 2010, 11, 342–351. [Google Scholar] [CrossRef]

- Tomczyk, M.; Zaguła, G.; Dżugan, M. A simple method of enrichment of honey powder with phytochemicals and its potential application in isotonic drink industry. Lwt 2020, 125, 109204. [Google Scholar] [CrossRef]

- Osés, S.M.; Cantero, L.; Puertas, G.; Fernández-Muiño, M.Á.; Sancho, M.T. Antioxidant, antimicrobial and anti-inflammatory activities of ling-heather honey powder obtained by different methods with several carriers. Lwt 2022, 159, 113235. [Google Scholar] [CrossRef]

- Krauze, A. Sugar spectrum of Polish nectar and honeydew honeys. Acta Aliment. Pol. 1991, 17, 109–117. [Google Scholar]

- Markowski, J.; Baron, A.; Le Quéré, J.-M.; Płocharski, W. Composition of clear and cloudy juices from French and Polish apples in relation to processing technology. LWT Food Sci. Technol. 2015, 62, 813–820. [Google Scholar] [CrossRef]

- Samborska, K.; Barańska, A.; Szulc, K.; Jankowska, E.; Truszkowska, M.; Ostrowska-Ligęza, E.; Wołosiak, R.; Szymańska, E.; Jedlińska, A. Reformulation of spray dried apple concentrate and honey for the enhancement of drying process performance and the physicochemical properties of powders. J. Sci. Food Agric. 2020, 100, 2224–2235. [Google Scholar] [CrossRef] [PubMed]

- Milek, M.; Bocian, A.; Kleczynska, E.; Sowa, P.; Dzugan, M. The Comparison of Physicochemical Parameters, Antioxidant Activity and Proteins for the Raw Local Polish Honeys and Imported Honey Blends. Molecules 2021, 26, 2423. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, B.; Howes, T.; Bhandari, B.R.; Langrish, T.A.G. Effect of addition of proteins on the production of amorphous sucrose powder through spray drying. J. Food Eng. 2009, 94, 144–153. [Google Scholar] [CrossRef]

- Đorđević, V.; Balanč, B.; Belščak-Cvitanović, A.; Lević, S.; Trifković, K.; Kalušević, A.; Kostić, I.; Komes, D.; Bugarski, B.; Nedović, V. Trends in encapsulation technologies for delivery of food bioactive compounds. Food Eng. Rev. 2015, 7, 452–490. [Google Scholar] [CrossRef]

- Lacerda, E.C.Q.; de Araújo Calado, V.M.; Monteiro, M.; Finotelli, P.V.; Torres, A.G.; Perrone, D. Starch, inulin and maltodextrin as encapsulating agents affect the quality and stability of jussara pulp microparticles. Carbohydr. Polym. 2016, 151, 500–510. [Google Scholar] [CrossRef]

- Saavedra–Leos, M.Z.; Leyva-Porras, C.; Alvarez-Salas, C.; Longoria-Rodríguez, F.; López-Pablos, A.L.; González-García, R.; Pérez-Urizar, J.T. Obtaining orange juice–maltodextrin powders without structure collapse based on the glass transition temperature and degree of polymerization. CyTA-J. Food 2018, 16, 61–69. [Google Scholar] [CrossRef]

- Kou, X.; Zhang, X.; Cheng, Y.; Yu, M.; Meng, Q.; Ke, Q. Mannitol Is a Good Anticaking Agent for Spray-Dried Hydroxypropyl-Beta-Cyclodextrin Microcapsules. Molecules 2023, 28, 1119. [Google Scholar] [CrossRef]

- Littringer, E.M.; Mescher, A.; Eckhard, S.; Schröttner, H.; Langes, C.; Fries, M.; Griesser, U.; Walzel, P.; Urbanetz, N.A. Spray Drying of Mannitol as a Drug Carrier—The Impact of Process Parameters on Product Properties. Dry. Technol. 2012, 30, 114–124. [Google Scholar] [CrossRef]

- Littringer, E.M.; Paus, R.; Mescher, A.; Schroettner, H.; Walzel, P.; Urbanetz, N.A. The morphology of spray dried mannitol particles—The vital importance of droplet size. Powder Technol. 2013, 239, 162–174. [Google Scholar] [CrossRef]

- Littringer, E.M.; Noisternig, M.F.; Mescher, A.; Schroettner, H.; Walzel, P.; Griesser, U.J.; Urbanetz, N.A. The morphology and various densities of spray dried mannitol. Powder Technol. 2013, 246, 193–200. [Google Scholar] [CrossRef]

- Hulse, W.L.; Forbes, R.T.; Bonner, M.C.; Getrost, M. The characterization and comparison of spray-dried mannitol samples. Drug Dev. Ind. Pharm. 2009, 35, 712–718. [Google Scholar] [CrossRef] [PubMed]

- Akhbarifar, S.; Shirvani, M. Improving cyclone efficiency for small particles. Chem. Eng. Res. Des. 2019, 147, 483–492. [Google Scholar] [CrossRef]

- Asensio, C.M.; Paredes, A.J.; Martin, M.P.; Allemandi, D.A.; Nepote, V.; Grosso, N.R. Antioxidant Stability Study of Oregano Essential Oil Microcapsules Prepared by Spray-Drying. J. Food Sci. 2017, 82, 2864–2872. [Google Scholar] [CrossRef] [PubMed]

- Jedlinska, A.; Samborska, K.; Wieczorek, A.; Wiktor, A.; Ostrowska-Ligeza, E.; Jamroz, W.; Skwarczynska-Maj, K.; Kielczewski, D.; Blaowski, L.; Tulodziecki, M.; et al. The application of dehumidified air in rapeseed and honeydew honey spray drying—Process performance and powders properties considerations. J. Food Eng. 2019, 245, 80–87. [Google Scholar] [CrossRef]

- Barańska, A.; Świeca, M.; Samborska, K. Sour cherry juice concentrate powdered by high and low temperature spray drying with pea protein as a carrier—Physical properties, antioxidant activity and in vitro bioaccessibility. Dry. Technol. 2023, 41, 444–459. [Google Scholar] [CrossRef]

- Fazaeli, M.; Emam-Djomeh, Z.; Kalbasi Ashtari, A.; Omid, M. Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food Bioprod. Process. 2012, 90, 667–675. [Google Scholar] [CrossRef]

- Nishad, J.; Mir, S.A.; Walia, K. Optimization of Spray Drying Technology for Sugarcane Juice Using Natural and Synthetic Encapsulating Agents. Sugar Tech 2019, 21, 749–755. [Google Scholar] [CrossRef]

- Aragüez-Fortes, Y.; Robaina-Morales, L.M.; Pino, J.A. Optimization of the spray-drying parameters for developing guava powder. J. Food Process Eng. 2019, 42, e13230. [Google Scholar] [CrossRef]

- Almeida, R.F.; Gomes, M.H.G.; Kurozawa, L.E. Rice bran protein increases the retention of anthocyanins by acting as an encapsulating agent in the spray drying of grape juice. Food Res. Int. 2023, 172, 113237. [Google Scholar] [CrossRef]

- Karrar, E.; Mahdi, A.A.; Sheth, S.; Mohamed Ahmed, I.A.; Manzoor, M.F.; Wei, W.; Wang, X. Effect of maltodextrin combination with gum arabic and whey protein isolate on the microencapsulation of gurum seed oil using a spray-drying method. Int. J. Biol. Macromol. 2021, 171, 208–216. [Google Scholar] [CrossRef] [PubMed]

- Bhusari, S.; Muzaffar, K.; Kumar, P. Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technol. 2014, 266, 354–364. [Google Scholar] [CrossRef]

- Gonnissen, Y.; Remon, J.P.; Vervaet, C. Development of directly compressible powders via co-spray drying. Eur. J. Pharm. Biopharm. 2007, 67, 220–226. [Google Scholar] [CrossRef]

- Moghaddam, A.D.; Pero, M.; Askari, G.R. Optimizing spray drying conditions of sour cherry juice based on physicochemical properties, using response surface methodology (RSM). J. Food. Sci. Technol. 2017, 54, 174–184. [Google Scholar] [CrossRef] [PubMed]

- Nadali, N.; Pahlevanlo, A.; Sarabi-Jamab, M.; Balandari, A. Effect of maltodextrin with different dextrose equivalents on the physicochemical properties of spray-dried barberry juice (Berberis vulgaris L.). J. Food. Sci. Technol. 2022, 59, 2855–2866. [Google Scholar] [CrossRef]

- Ganaie, T.A.; Masoodi, F.A.; Rather, S.A.; Gani, A. Exploiting maltodextrin and whey protein isolate macromolecules as carriers for the development of freeze dried honey powder. Carbohydr. Polym. Technol. Appl. 2021, 2, 100040. [Google Scholar] [CrossRef]

- George, S.; Thomas, A.; Kumar, M.V.P.; Kamdod, A.S.; Rajput, A.; Abdullah, S. Impact of processing parameters on the quality attributes of spray-dried powders: A review. Eur. Food Res. Technol. 2022, 249, 241–257. [Google Scholar] [CrossRef]

- Murugesan, R.; Orsat, V. Spray Drying for the Production of Nutraceutical Ingredients—A Review. Food Bioprocess Technol. 2011, 5, 3–14. [Google Scholar] [CrossRef]

- Michalska, A.; Wojdyło, A.; Brzezowska, J.; Majerska, J.; Ciska, E. The influence of inulin on the retention of polyphenolic compounds during the drying of blackcurrant juice. Molecules 2019, 24, 4167. [Google Scholar] [CrossRef]

- Acosta-Vega, L.; Martínez-Suárez, J.F.; Sánchez-Garzón, F.S.; Hernández-Carrión, M.; Nerio, L.S. Optimization of the encapsulation process of Cupuassu (Theobroma grandiflorum) pulp by spray drying as an alternative for the valorization of Amazonian fruits. Lwt 2023, 184, 114994. [Google Scholar] [CrossRef]

- Taengsopha, P.; Junyusen, T.; Moolkaew, P.; Junyusen, P. Comparative effects of prebiotic addition on the physicochemical and microstructural properties of spray-dried yogurt powder. Eng. Appl. Sci. Res. 2023, 50, 657–663. [Google Scholar] [CrossRef]

- Elversson, J.; Millqvist-Fureby, A. Particle size and density in spray drying-effects of carbohydrate properties. J. Pharm. Sci. 2005, 94, 2049–2060. [Google Scholar] [CrossRef] [PubMed]

- Tze, N.L.; Han, C.P.; Yusof, Y.A.; Ling, C.N.; Talib, R.A.; Taip, F.S.; Aziz, M.G. Physicochemical and nutritional properties of spray-dried pitaya fruit powder as natural colorant. Food Sci. Biotechnol. 2012, 21, 675–682. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Mobli, H.; Madadlou, A.; Rafiee, S. Influence of wall material and inlet drying air temperature on the microencapsulation of fish oil by spray drying. Food Bioprocess Technol. 2013, 6, 1561–1569. [Google Scholar] [CrossRef]

- Shah, N.; Sandhu, H.; Choi, D.S.; Chokshi, H.; Malick, A.W. Amorphous solid dispersions. In Theory and Practice; Springer: Berlin, Germany, 2014. [Google Scholar]

- Guiling, X.; Xiaoping, C.; Cai, L.; Pan, X.; Changsui, Z. Experimental investigation on the flowability properties of cohesive carbonaceous powders. Part. Sci. Technol. 2016, 35, 322–329. [Google Scholar] [CrossRef]

- Goh, H.P.; Heng, P.W.S.; Liew, C.V. Comparative evaluation of powder flow parameters with reference to particle size and shape. Int. J. Pharm. 2018, 547, 133–141. [Google Scholar] [CrossRef]

- Jedlińska, A.; Barańska, A.; Witrowa-Rajchert, D.; Ostrowska-Ligęza, E.; Samborska, K. Dehumidified Air-Assisted Spray-Drying of Cloudy Beetroot Juice at Low Temperature. Appl. Sci. 2021, 11, 6578. [Google Scholar] [CrossRef]

- Fan, A.; Pallerla, S.; Carlson, G.; Ladipo, D.; Dukich, J.; Capella, R.; Leung, S. Effect of particle size distribution and flow property of powder blend on tablet weight variation. Am. Pharm. Rev. 2005, 8, 73–78. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).