Tuneable Lenses Driven by Dielectric Elastomers: Principles, Structures, Applications, and Challenges

Abstract

1. Introduction

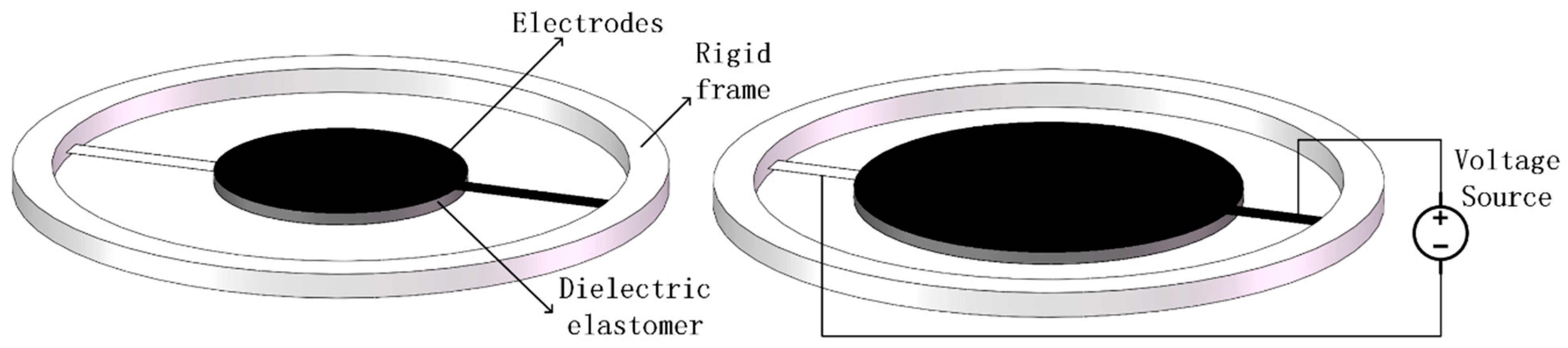

2. Principle of DETL

2.1. Principle of DE

2.2. Tuning Principle

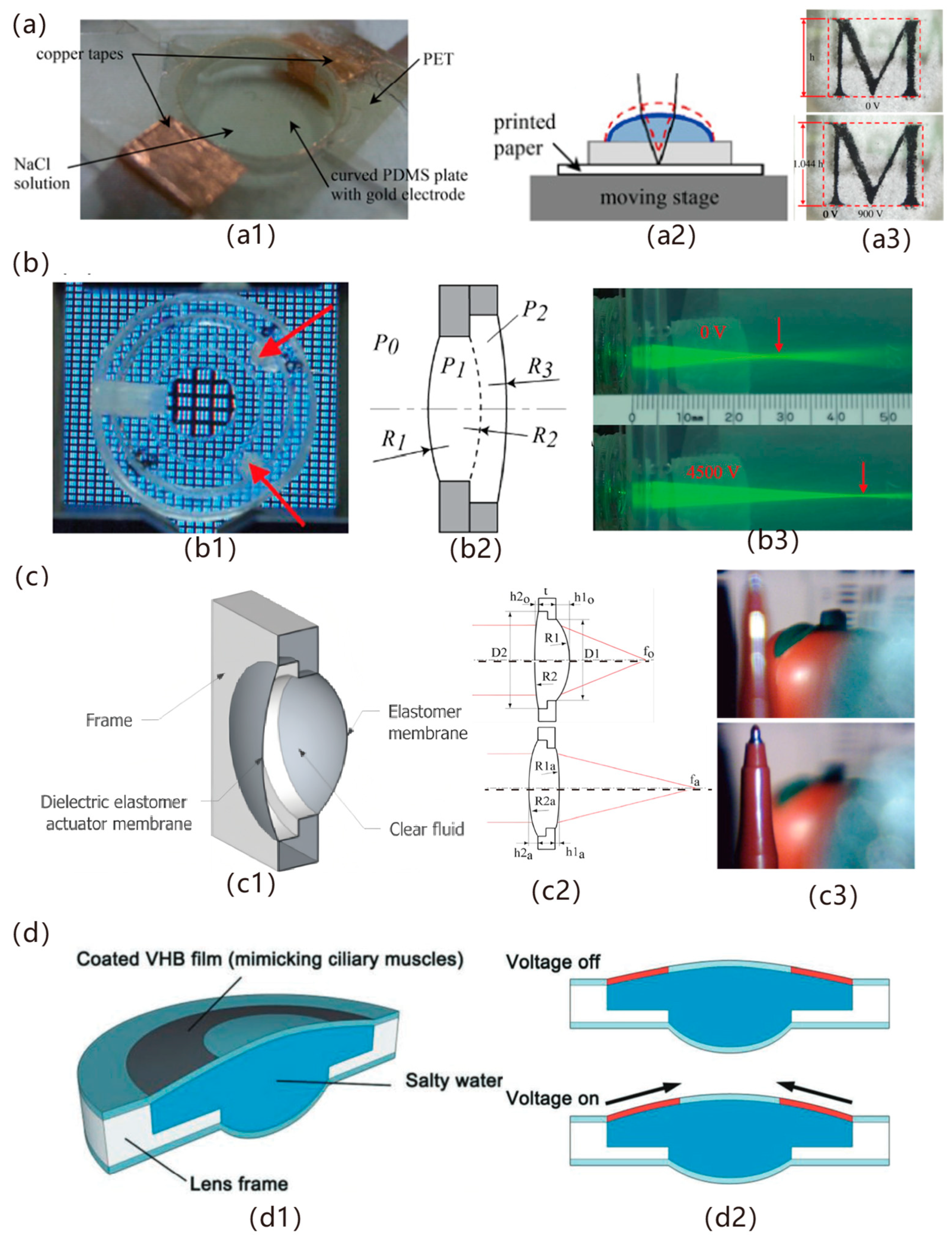

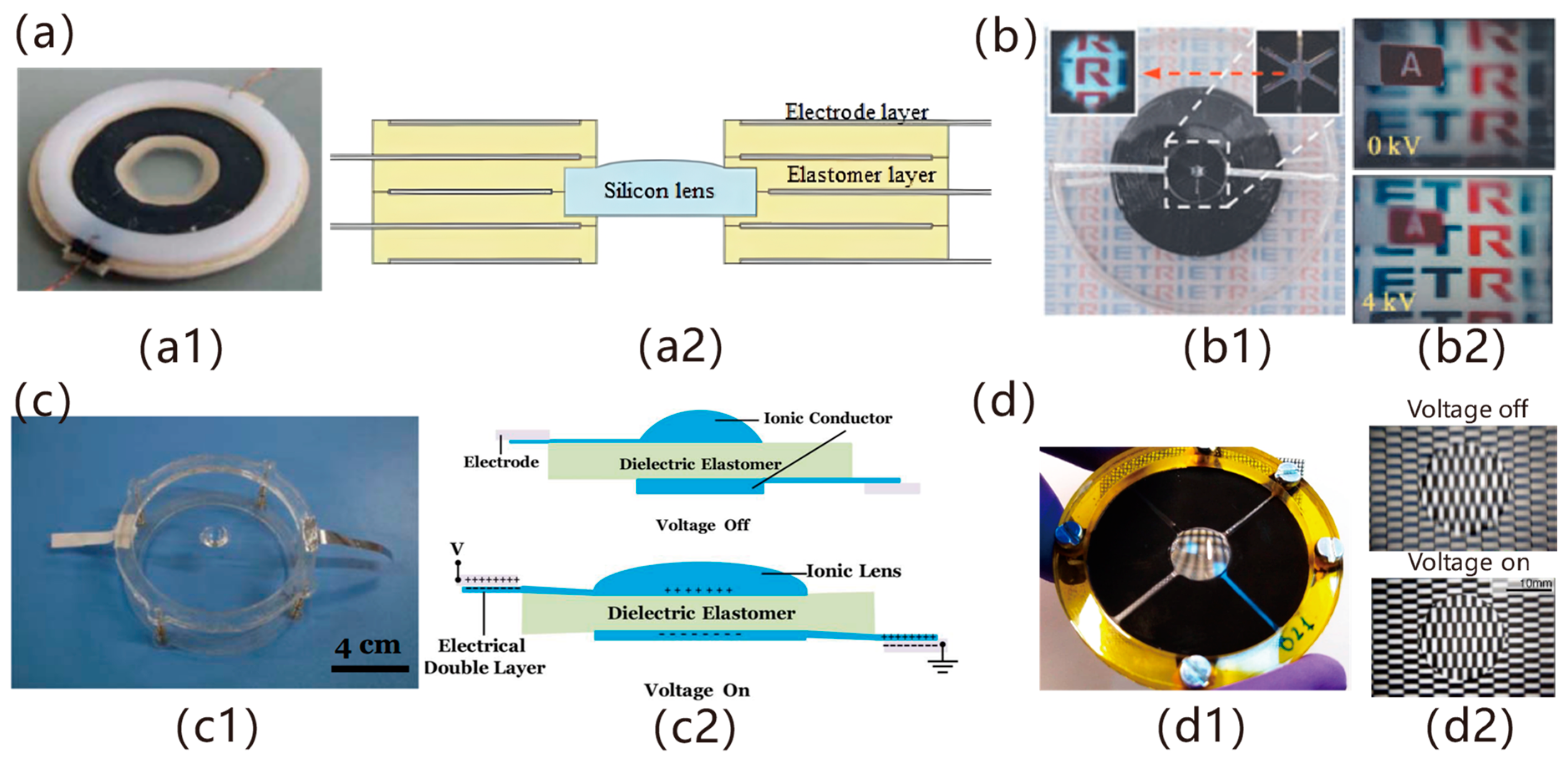

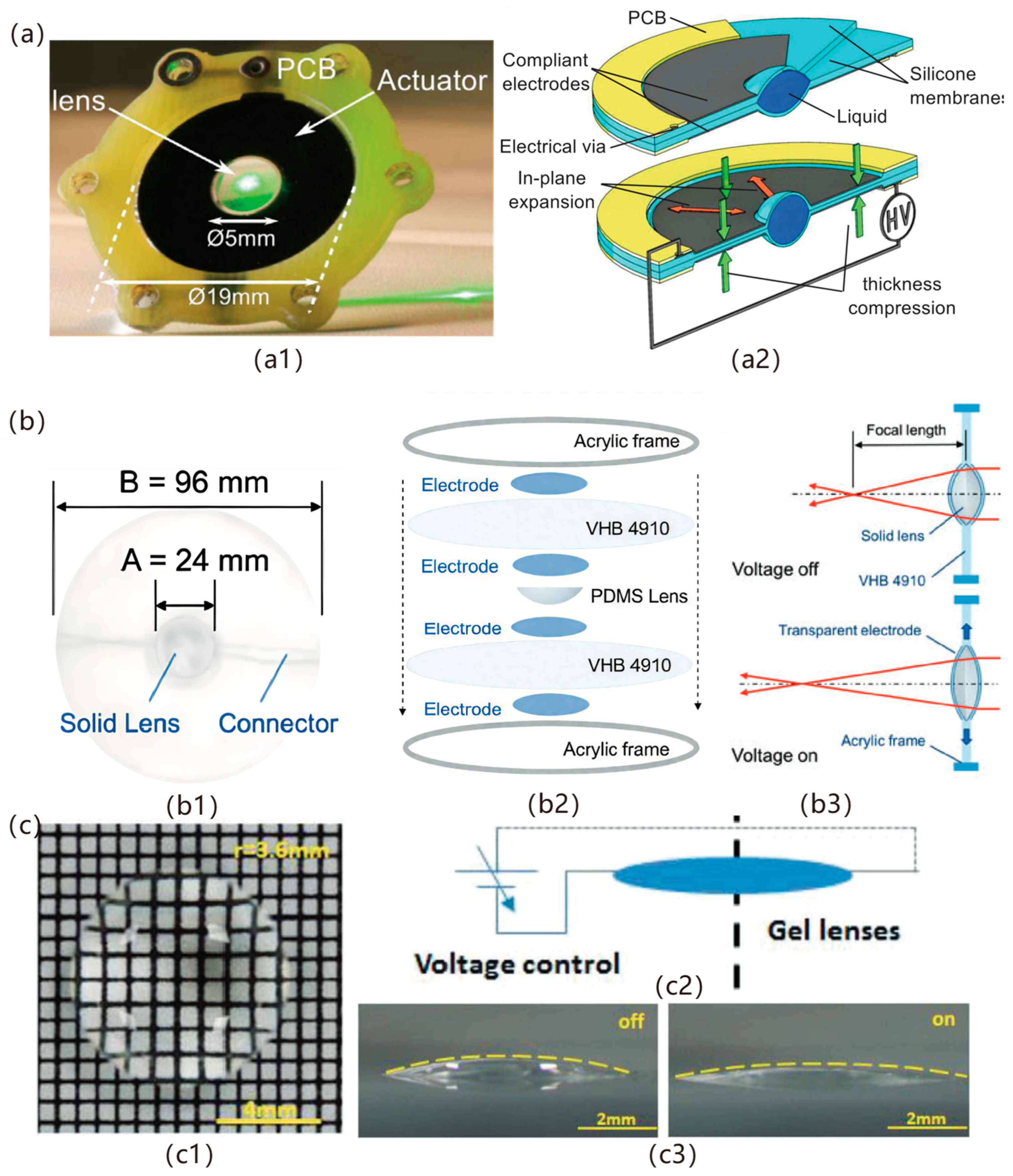

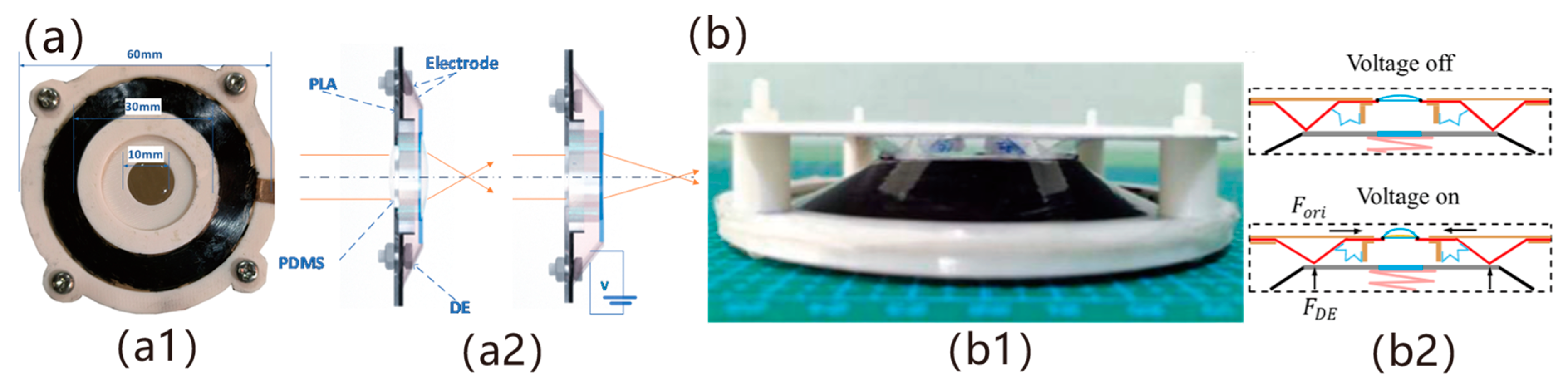

2.2.1. Deformation-Based

- 1.

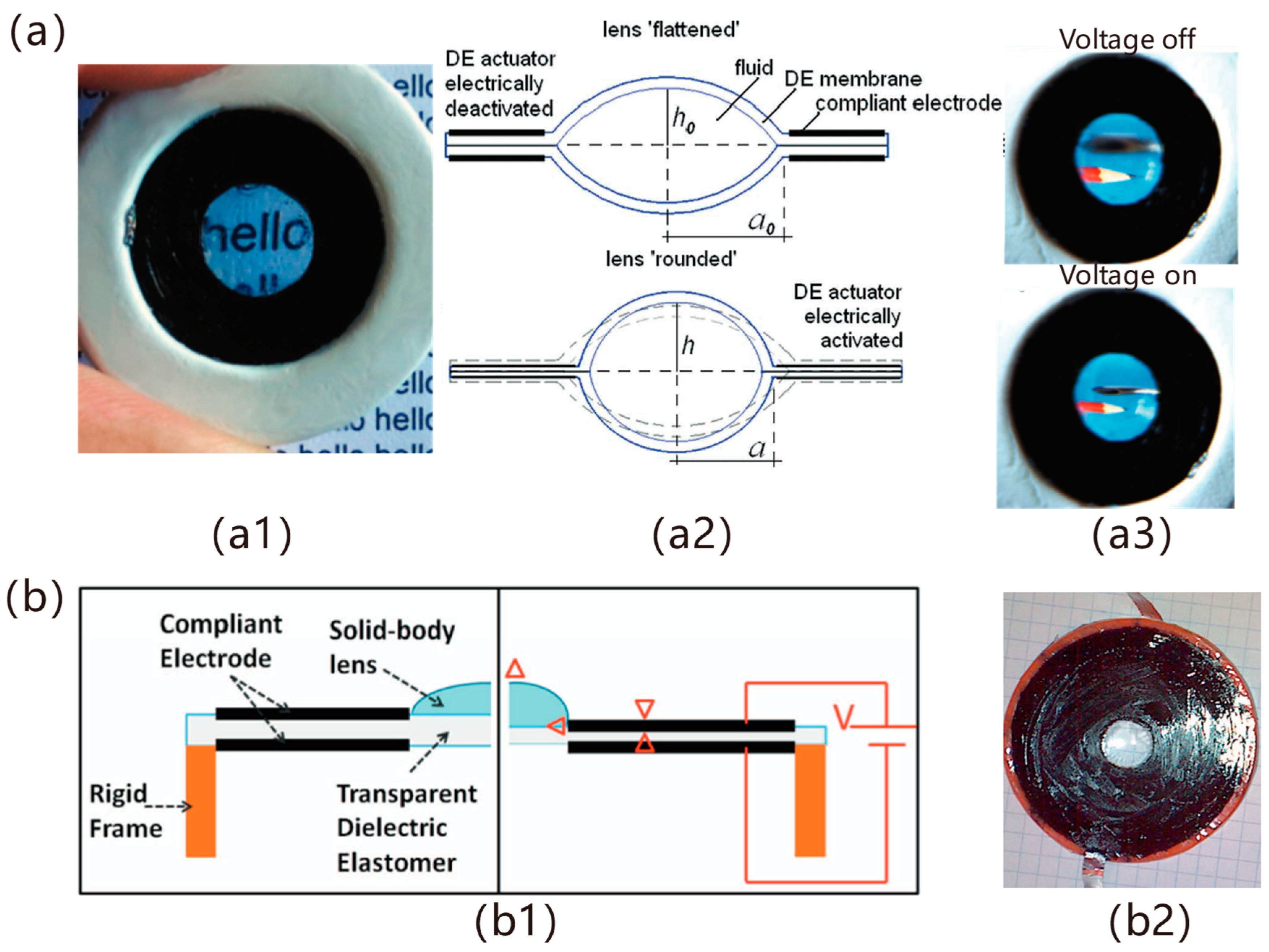

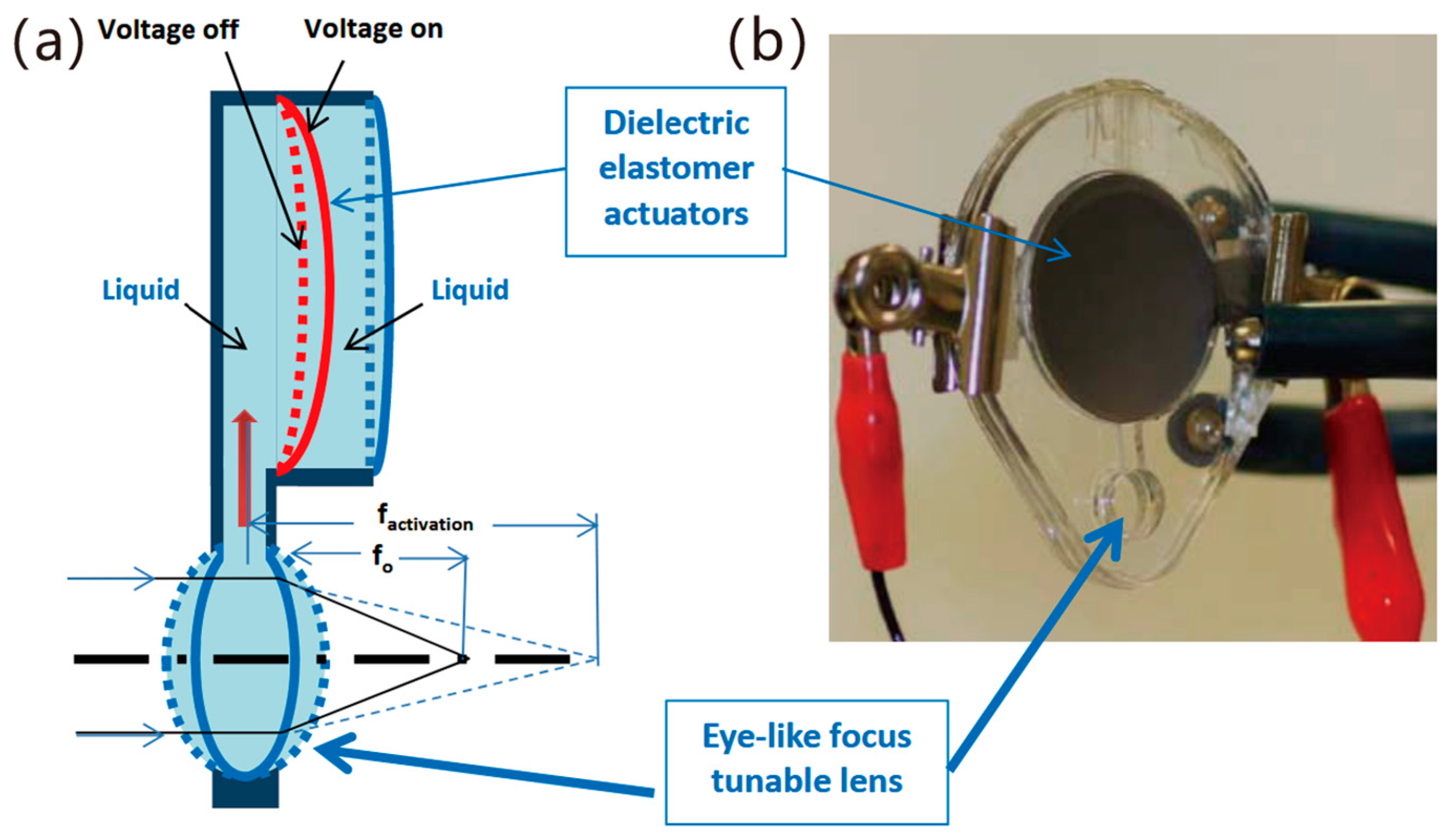

- Direct drive

- 2.

- Indirect drive

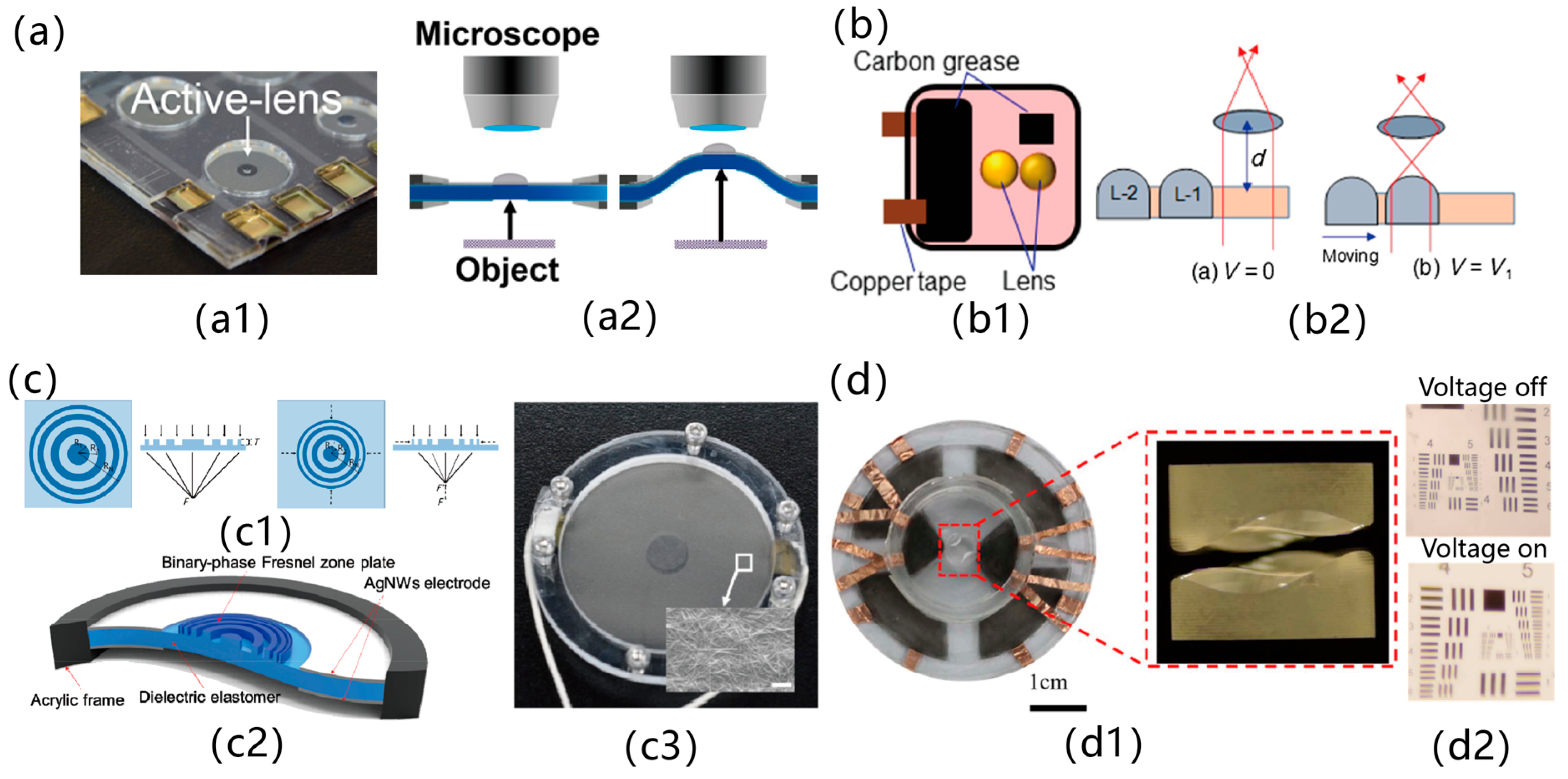

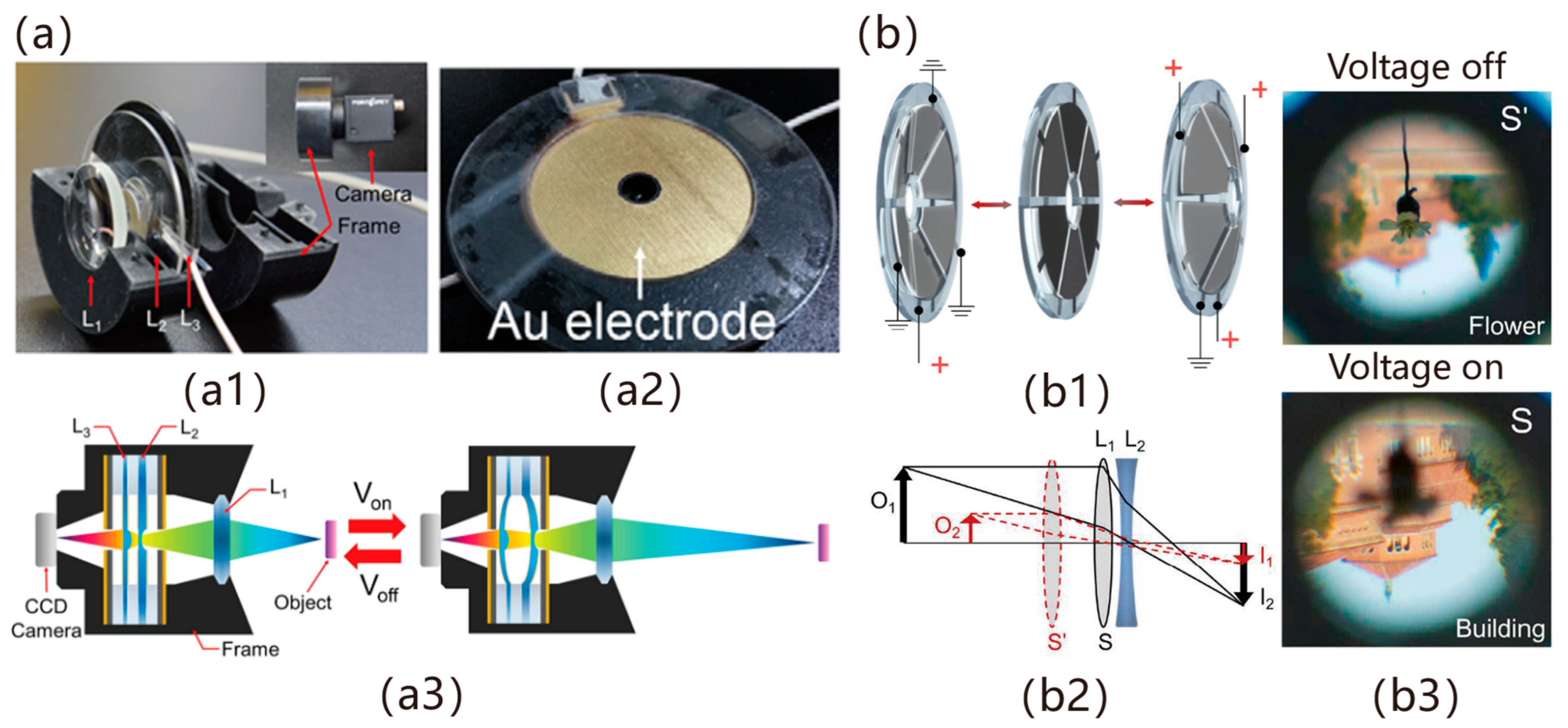

2.2.2. Displacement-Based

- 1.

- Axial displacement

- 2.

- Lateral displacement

3. Lens Construction

3.1. Monolithic Lens

- 1.

- Planar DEA

- 2.

- Spherical DEA

- 3.

- Tapered DEA

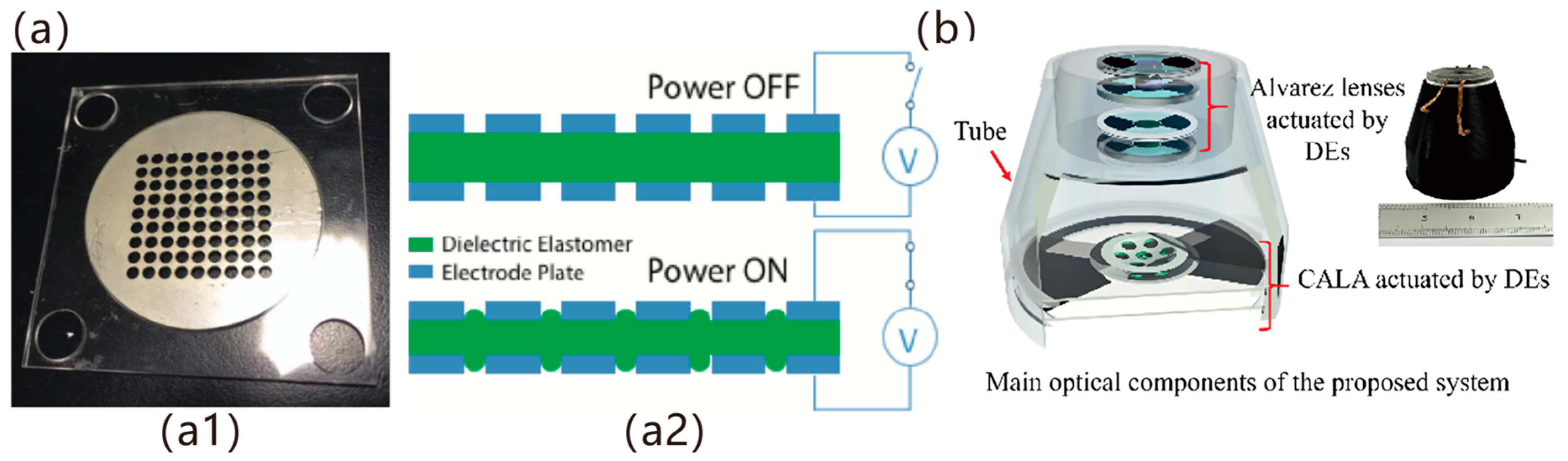

3.2. Composite Lenses

3.3. Lenes Array

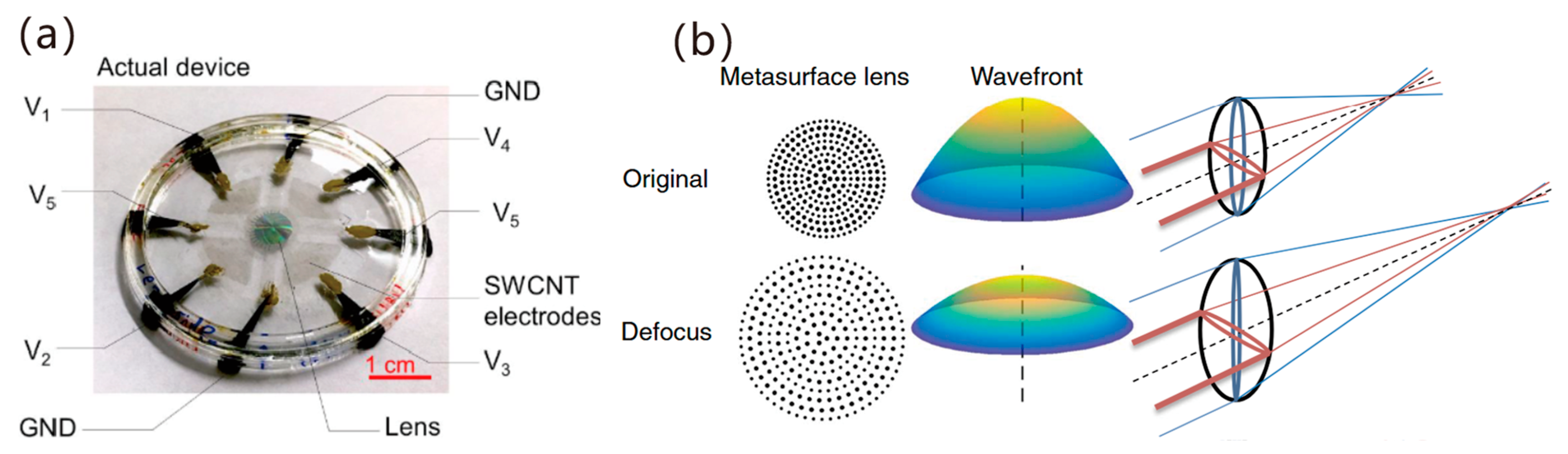

3.4. Metalenses

4. Performance Comparison

5. Applications and Challenges

5.1. Applications

5.1.1. Auto-Zoom Imaging

5.1.2. Microscopic Imaging

5.1.3. AR Display

5.1.4. Infrared Imaging

5.2. Challenges

5.2.1. Material Performance Challenges

- 1.

- Driver performance

- 2.

- Material stability

- 3.

- Material durability

- 4.

- High drive voltage

5.2.2. Modelling and Control Challenges

- 1.

- Dielectric elastomer modelling complexity

- 2.

- Control system challenges

5.2.3. Preparation Process Challenges

5.2.4. Optical Performance Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.; Liu, L.; Li, Z.; Jiao, Y.; Zhang, L.; Cui, Y. A Magnetically-Actuated Ultrasound Capsule Endoscope (MUSCE) for Endoluminal Imaging in Tubular Environments. IEEE Robot. Autom. Lett. 2025, 10, 2590–2597. [Google Scholar] [CrossRef]

- Ge, J.; Qin, Y.; Liu, X.; Tang, X. Design of Variable Spot and Zoom Optical System for Laser Cutting. Acta Opt. Sin. 2019, 39, 222001. [Google Scholar] [CrossRef]

- Fu, Q.; Ma, N.; Liu, X.; Zhang, Y.; Zhan, J.; Zhang, S.; Duan, J.; Li, Y. Analysis of Multispectral Polarization Imaging Image Information Based on Micro-Polarizer Array. PLoS ONE 2024, 19, e0296397. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-H.; Chen, M.-S.; Lin, H.-C. An Electrically Tunable Optical Zoom System Using Two Composite Liquid Crystal Lenses with a Large Zoom Ratio. Opt. Express 2011, 19, 4714. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Shi, G. General Situations of Mechanical Compensation Zoom Lens in Its Three Development Phases and Its Developing Direction. J. Appl. Opt. 1992, 1, 15–19. [Google Scholar]

- Smith, W.J. Optical Engineering: The Design of Optical Systems, 4th ed.; McGraw-Hill: New York, NY, USA, 2008; ISBN 978-0-07-147687-4. [Google Scholar]

- Liu, C.; Zheng, Y.; Yuan, R.; Jiang, Z.; Xu, J.; Zhao, Y.; Wang, X.; Li, X.; Xing, Y.; Wang, Q. Tunable Liquid Lenses: Emerging Technologies and Future Perspectives. Laser Photonics Rev. 2023, 17, 2300274. [Google Scholar] [CrossRef]

- Xu, S.; Li, Y.; Liu, Y.; Sun, J.; Ren, H.; Wu, S.-T. Fast-Response Liquid Crystal Microlens. Micromachines 2014, 5, 300–324. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Wang, Y.-J.; Reshetnyak, V. Liquid Crystal Lenses with Tunable Focal Length. Liq. Cryst. Rev. 2017, 5, 111–143. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, H.-R.; Li, X.-W.; Zhao, Y.-R.; Li, Z.-S.; Hou, Y.-H.; Liu, C.; Wang, Q.-H. Fast-Zoom and High-Resolution Sparse Compound-Eye Camera Based on Dual-End Collaborative Optimization. Opto-Electron. Adv. 2025, 8, 240285. [Google Scholar] [CrossRef]

- Hasan, N.; Kim, H.; Mastrangelo, C.H. Large Aperture Tunable-Focus Liquid Lens Using Shape Memory Alloy Spring. Opt. Express 2016, 24, 13334. [Google Scholar] [CrossRef]

- Youn, J.-H.; Hyeon, K.; Ma, J.H.; Kyung, K.-U. A Piecewise Controllable Tunable Lens with Large Aperture for Eyewear Application. Smart Mater. Struct. 2019, 28, 124001. [Google Scholar] [CrossRef]

- Wapler, M.C.; Sturmer, M.; Wallrabe, U. A Compact, Large-Aperture Tunable Lens with Adaptive Spherical Correction. In Proceedings of the 2014 International Symposium on Optomechatronic Technologies, Seattle, WA, USA, 5–7 November 2014; IEEE: New York, NY, USA, 2014; pp. 130–133. [Google Scholar]

- Wang, L.; Ishikawa, M. Dynamic Response of Elastomer-Based Liquid-Filled Variable Focus Lens. Sensors 2019, 19, 4624. [Google Scholar] [CrossRef] [PubMed]

- Nicolas, S.; Allain, M.; Bridoux, C.; Fanget, S.; Lesecq, S.; Zarudniev, M.; Bolis, S.; Pouydebasque, A.; Jacquet, F. Fabrication and Characterization of a New Varifocal Liquid Lens with Embedded PZT Actuators for High Optical Performances. In Proceedings of the 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; IEEE: New York, NY, USA, 2015; pp. 65–68. [Google Scholar]

- Wakle, S.; Lin, T.-H.; Huang, S.; Basu, S.; Lau, G.-K. How Fast Can a Robotic Drummer Beat Using Dielectric Elastomer Actuators? IEEE Robot. Autom. Lett. 2024, 9, 2638–2645. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, X.; Liu, R.; Ding, Y.; Guo, D. Polyvinyl Chloride-Based Dielectric Elastomer with High Permittivity and Low Viscoelasticity for Actuation and Sensing. Nat. Commun. 2023, 14, 1483. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Ghilardi, M.; Busfield, J.J.C.; Carpi, F. Electrically Tunable Lenses: A Review. Front. Robot. AI 2021, 8, 678046. [Google Scholar] [CrossRef]

- Yang, L.; Wang, H.; Zhang, D.; Yang, Y.; Leng, D. Large Deformation, High Energy Density Dielectric Elastomer Actuators: Principles, Factors, Optimization, Applications, and Prospects. Chem. Eng. J. 2024, 489, 151402. [Google Scholar] [CrossRef]

- Pelrine, R.E.; Kornbluh, R.D.; Joseph, J.P. Electrostriction of Polymer Dielectrics with Compliant Electrodes as a Means of Actuation. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.D.; Eckerle, J.; Jeuck, P.; Oh, S.; Pei, Q.; Stanford, S. Dielectric Elastomers: Generator Mode Fundamentals and Applications. In Smart Structures and Materials 2001: Electroactive Polymer Actuators and Devices, Proceedings of the SPIE’s 8th Annual International Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 4–8 March 2001; Bar-Cohen, Y., Ed.; SPIE: San Diego, CA, USA, 2001; p. 148. [Google Scholar]

- Lu, T.; Ma, C.; Wang, T. Mechanics of Dielectric Elastomer Structures: A Review. Extrem. Mech. Lett. 2020, 38, 100752. [Google Scholar] [CrossRef]

- Liang, X.; Cai, S. New Electromechanical Instability Modes in Dielectric Elastomer Balloons. Int. J. Solids Struct. 2018, 132–133, 96–104. [Google Scholar] [CrossRef]

- Yang, L.; Hao, M.; Yang, K.; Lan, D.; Zhang, X.; Tian, X.; Wang, Z. A Review of Methods and Applications for Improving Electric Driving Performance of Dielectric Elastomer. IEEE Trans. Dielectr. Electr. Insul. 2025, 32, 117–126. [Google Scholar] [CrossRef]

- Tang, C.; Du, B.; Jiang, S.; Wang, Z.; Liu, X.-J.; Zhao, H. A Review on High-frequency Dielectric Elastomer Actuators: Materials, Dynamics, and Applications. Adv. Intell. Syst. 2024, 6, 2300047. [Google Scholar] [CrossRef]

- Huang, W.; Chen, K.; Ma, P.; Kang, G. A Visco-Hyperelastic Constitutive Model for Temperature-Dependent Cyclic Deformation of Dielectric Elastomer. Acta Mech. Solida Sin. 2024, 37, 736–749. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, Y.; Xiao, Q.; Gao, Z.; Wang, X. Optimizing Energy Storage Density of the Multi–Layer Composite of Poly(Vinylidene Fluoride) and Nano–Ni Plated CaCu3Ti4O12 with an Ultralow Filling Content. Compos. Sci. Technol. 2024, 245, 110353. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, K.; Liu, J.; Zhu, L.; Xie, R.; Lv, S. Significant Improvements in the Electromechanical Performance of Dielectric Elastomers by Introducing Ternary Dipolar Groups. React. Funct. Polym. 2022, 172, 105177. [Google Scholar] [CrossRef]

- Hecht, E. Optics, 4th ed.; Addison-Wesley: Boston, MA, USA, 2002; ISBN 978-0-8053-8566-3. [Google Scholar]

- Carpi, F.; Frediani, G.; Turco, S.; De Rossi, D. Bioinspired Tunable Lens with Muscle-like Electroactive Elastomers. Adv. Funct. Mater. 2011, 21, 4152–4158. [Google Scholar] [CrossRef]

- Pieroni, M.; Lagomarsini, C.; De Rossi, D.; Carpi, F. Electrically Tunable Soft Solid Lens Inspired by Reptile and Bird Accommodation. Bioinspiration Biomim. 2016, 11, 65003. [Google Scholar] [CrossRef]

- Son, S.; Pugal, D.; Hwang, T.; Choi, H.R.; Koo, J.C.; Lee, Y.; Kim, K.; Nam, J.-D. Electromechanically Driven Variable-Focus Lens Based on Transparent Dielectric Elastomer. Appl. Opt. 2012, 51, 2987. [Google Scholar] [CrossRef]

- Keong, G.-K.; La, T.-G.; Shiau, L.-L.; Tan, A.W.Y. Challenges of Using Dielectric Elastomer Actuators to Tune Liquid Lens. In Electroactive Polymer Actuators and Devices (EAPAD) 2014, Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 9–13 March 2014; Bar-Cohen, Y., Ed.; SPIE: San Diego, CA, USA, 2014; p. 90561J. [Google Scholar]

- Zhang, H.; Zhang, Z. Modeling of Lens Based on Dielectric Elastomers Coupling with Hydrogel Electrodes. In Mechatronics and Machine Vision in Practice 4; Springer International Publishing: Cham, Switzerland, 2021; pp. 263–268. ISBN 978-3-030-43702-2. [Google Scholar]

- Wei, K.; Domicone, N.W.; Zhao, Y. Electroactive Liquid Lens Driven by an Annular Membrane. Opt. Lett. 2014, 39, 1318. [Google Scholar] [CrossRef]

- Cheng, Y.; Cao, J.; Wang, Y.; Ning, Y.; Hao, Q. Design and Analysis of Liquid Lens Driven by Dielectric Elastomer. Acta Opt. Sin. 2021, 41, 164–173. [Google Scholar] [CrossRef]

- Shi, H.; Wang, H. Modelling of a Soft Tunable Lens Actuated by an Annular Dielectric Elastomer Actuator with Homogeneous and Inhomogeneous Prestretches. J. Phys. D Appl. Phys. 2021, 54, 245402. [Google Scholar] [CrossRef]

- Kim, H.; Park, J.; Chuc, N.H.; Choi, H.R.; Nam, J.D.; Lee, Y.; Jung, H.S.; Koo, J.C. Development of Dielectric Elastomer Driven Micro-Optical Zoom Lens System. In Electroactive Polymer Actuators and Devices (EAPAD) 2007, Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 18–22 March 2007; Bar-Cohen, Y., Ed.; SPIE: San Diego, CA, USA, 2007; p. 65241V. [Google Scholar]

- Yun, S.; Park, S.; Park, B.; Nam, S.; Park, S.K.; Kyung, K.-U. A Thin Film Active-Lens with Translational Control for Dynamically Programmable Optical Zoom. Appl. Phys. Lett. 2015, 107, 81907. [Google Scholar] [CrossRef]

- Jin, B.; Ren, H. Position-Movable Lens Driven by Dielectric Elastomer Actuator. Opt. Eng. 2016, 55, 075101. [Google Scholar] [CrossRef]

- Rastani, K.; Marrakchi, A.; Habiby, S.F.; Hubbard, W.M.; Gilchrist, H.; Nahory, R.E. Binary Phase Fresnel Lenses for Generation of Two-Dimensional Beam Arrays. Appl. Opt. 1991, 30, 1347. [Google Scholar] [CrossRef]

- Park, S.; Park, B.; Nam, S.; Yun, S.; Park, S.K.; Mun, S.; Lim, J.M.; Ryu, Y.; Song, S.H.; Kyung, K.-U. Electrically Tunable Binary Phase Fresnel Lens Based on a Dielectric Elastomer Actuator. Opt. Express 2017, 25, 23801. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, L. Two-Element Variable-Power Spherical Lens. U.S. Patent No. 3,305,294, 21 February 1967. [Google Scholar]

- Cheng, Y.; Chen, C.; Li, Z.; Yan, Z.; Cao, J.; Hao, Q. Experimental Study on the Focal Length of Alvarez Lens Actuated by Dielectric Elastomer with Different Pre-Stretched Ratios and Diameters. In Optical Design and Testing XII, Proceedings of the SPIE/Cos Photonics Asia, Beijing, China, 5–12 December 2022; Wu, R., Wang, Y., Kidger, T.E., Eds.; SPIE: San Diego, CA, USA, 2022; p. 22. [Google Scholar]

- Hao, Q.; Chen, C.; Cao, J.; Li, Z.; Cheng, Y. Ultra-Wide Varifocal Imaging with Selectable Region of Interest Capacity Using Alvarez Lenses Actuated by a Dielectric Elastomer. Photon. Res. 2022, 10, 1543. [Google Scholar] [CrossRef]

- Kim, B.-C.; Lee, Y.; Nam, J.-D.; Moon, H.; Choi, H.R.; Koo, J.C. Smart Material Actuators for Micro Optical Zoom Lens Driving Systems. IEEE Trans. Magn. 2011, 47, 1999–2004. [Google Scholar] [CrossRef]

- Nam, S.; Yun, S.; Yoon, J.W.; Park, S.; Park, S.K.; Mun, S.; Park, B.; Kyung, K.-U. A Robust Soft Lens for Tunable Camera Application Using Dielectric Elastomer Actuators. Soft Rob. 2018, 5, 777–782. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Sun, W.; Lu, J.; Yang, J.; Chen, Y.; Zhou, J.; Suo, Z. All-Solid Ionic Eye. J. Appl. Mech. 2021, 88, 31016. [Google Scholar] [CrossRef]

- Ghilardi, M.; Boys, H.; Török, P.; Busfield, J.J.C.; Carpi, F. Smart Lenses with Electrically Tuneable Astigmatism. Sci. Rep. 2019, 9, 16127. [Google Scholar] [CrossRef]

- Maffli, L.; Rosset, S.; Ghilardi, M.; Carpi, F.; Shea, H. Ultrafast All-polymer Electrically Tunable Silicone Lenses. Adv. Funct. Mater. 2015, 25, 1656–1665. [Google Scholar] [CrossRef]

- Wang, Y.; Li, P.; Gupta, U.; Ouyang, J.; Zhu, J. Tunable Soft Lens of Large Focal Length Change. Soft Robot. 2022, 9, 705–712. [Google Scholar] [CrossRef] [PubMed]

- Lu, T.; Cai, S.; Wang, H.; Suo, Z. Computational Model of Deformable Lenses Actuated by Dielectric Elastomers. J. Appl. Phys. 2013, 114, 104104. [Google Scholar] [CrossRef]

- Wang, Q.; Cao, Y.J.; Wang, Y.N.; Liu, J.C.; Xie, Y.-X. A Computational Model of Bio-Inspired Tunable Lenses. Mech. Based Des. Struct. Mach. 2018, 46, 800–808. [Google Scholar] [CrossRef]

- Liu, S.; Qiu, Y.; Yu, W. Self-contained Focus-tunable Lenses Based on Transparent and Conductive Gels. Macromol. Mater. Eng. 2020, 305, 2000393. [Google Scholar] [CrossRef]

- Jin, B.; Lee, J.-H.; Zhou, Z.; Zhang, G.; Lee, G.-B.; Ren, H.; Nah, C. Adaptive Liquid Lens Driven by Elastomer Actuator. Opt. Eng. 2016, 55, 17107. [Google Scholar] [CrossRef]

- Huang, H.; Zhao, Y. Smartphone Based Focus-free Macroscopy Using An Adaptive Droplet Lens. In Proceedings of the 2018 Solid-State, Actuators, and Microsystems Workshop Technical Digest, Hilton Head, SC, USA, 3–7 June 2018; Transducer Research Foundation: San Diego, CA, USA, 2018; pp. 334–337. [Google Scholar]

- Cheng, Y.; Li, Z.; Chen, C.; Ning, Y.; Cao, J.; Liu, L.; Hao, Q. Varifocal Liquid Lens Driven by Dielectric Elastomer with Different Pre-Stretched Ratios. In Optical Design and Testing XII, Proceedings of the SPIE/Cos Photonics Asia, Beijing, China, 5–12 December 2022; Wu, R., Wang, Y., Kidger, T.E., Eds.; SPIE: San Diego, CA, USA, 2022; p. 48. [Google Scholar]

- Hao, Q.; Li, Z.; Chen, C.; Cao, J.; Cheng, Y. Adaptive Liquid Lens Actuated by Dielectric Elastomer with Transparent Conductive Droplet. In Optical Design and Testing XI, Proceedings of the SPIE/Cos Photonics Asia, Nantong, China, 10–20 October 2021; Wu, R., Matoba, O., Wang, Y., Kidger, T.E., Eds.; SPIE: San Diego, CA, USA, 2021; p. 33. [Google Scholar]

- Liang, D.; Lin, Z.; Huang, C.; Shih, W. Tunable Lens Driven by Dielectric Elastomer Actuator with Ionic Electrodes. Micro Nano Lett. 2014, 9, 869–873. [Google Scholar] [CrossRef]

- Shian, S.; Diebold, R.M.; Clarke, D.R. High-speed, compact, adaptive lenses using in-line transparent dielectric elastomer actuator membranes. In Electroactive Polymer Actuators and Devices (EAPAD) 2013, Proceedings of the SPIE Smart Structures And Materials + Nondestructive Evaluation And Health Monitoring, San Diego, CA, USA, 10–14 March 2013; Bar-Cohen, Y., Ed.; SPIE: San Diego, CA, USA, 2013; p. 86872D. [Google Scholar]

- Cheng, Y.; Chen, C.; Cao, J.; Bao, C.; Yang, A.; Hao, Q. Tunable Lens Using Dielectric Elastomer Sandwiched by Transparent Conductive Liquid. Opt. Lett. 2021, 46, 4430. [Google Scholar] [CrossRef]

- Hao, Q.; Chen, C.; Li, Z.; Cao, J.; Cheng, Y. Optofluidic Varifocal Lens Actuated by Dielectric Elastomer Sandwiched by Two Conductive Liquids with Different Refractive Indexes. In Advanced Optical Imaging Technologies IV, Proceedings of the SPIE/Cos Photonics Asia, Nantong, China, 10–20 October 2021; SPIE: San Diego, CA, USA, 2021; Volume 11896, pp. 8–15. [Google Scholar]

- Zhang, C.; He, H.; Li, Y.; Sun, Y.; Dong, Z. Modeling and Design of Dielectric Elastomer Actuated Tunable Lens with Dual Chambers. AIP Adv. 2022, 12, 075119. [Google Scholar] [CrossRef]

- Shian, S.; Diebold, R.M.; Clarke, D.R. Tunable Lenses Using Transparent Dielectric Elastomer Actuators. Opt. Express 2013, 21, 8669. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.; Liu, Y.; Xie, Y.-X. Explicit Computational Model of Dielectric Elastomeric Lenses: Erratum. Opt. Express 2019, 27, 37834. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Liu, L.; Xu, S.; Liu, Y.; Leng, J.; Cai, S. A Biomimetic Soft Lens Controlled by Electrooculographic Signal. Adv. Funct. Mater. 2019, 29, 1903762. [Google Scholar] [CrossRef]

- Li, J.; Lv, X.; Liu, L.; Liu, Y.; Leng, J. Computational Model and Design of the Soft Tunable Lens Actuated by Dielectric Elastomer. J. Appl. Mech. 2020, 87, 071005. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, M.; Gan, Z.; Lv, J.; Liu, Z.; Yang, M.; Hong, H. Design and Performance Study of Dielectric Elastomer-Driven Conical Tunable Soft Lens. In Tenth Symposium on Novel Optoelectronic Detection Technology and Applications, Proceedings of the Tenth Symposium On Novel Optoelectronic Detection Technology And Applications (NDTA 2024), Taiyuan, China, 1–3 November 2024; Ping, C., Ed.; SPIE: San Diego, CA, USA, 2024; pp. 478–485. [Google Scholar]

- Yin, X.; Zhou, P.; Wen, S.; Zhang, J. Origami Improved Dielectric Elastomer Actuation for Tunable Lens. IEEE Trans. Instrum. Meas. 2022, 71, 1–9. [Google Scholar] [CrossRef]

- Yun, S.; Park, S.; Nam, S.; Park, B.; Park, S.K.; Mun, S.; Lim, J.M.; Kyung, K.-U. An Electro-Active Polymer Based Lens Module for Dynamically Varying Focal System. Appl. Phys. Lett. 2016, 109, 141908. [Google Scholar] [CrossRef]

- Pu, J.; Meng, Y.; Xie, Z.; Peng, Z.; Wu, J.; Shi, Y.; Plamthottam, R.; Yang, W.; Pei, Q. A Unimorph Nanocomposite Dielectric Elastomer for Large Out-of-Plane Actuation. Sci. Adv. 2022, 8, eabm6200. [Google Scholar] [CrossRef]

- Niklaus, M.; Shea, H. Electrically Tunable PDMS Lenses Using Integrated Mm-Scale Dielectric Elastomer Actuators. In Proceedings of the 12th International Conference on New Actuators, Bremen, Germany, 14–16 June 2010. [Google Scholar]

- Wang, L.; Hayakawa, T.; Ishikawa, M. Dielectric-Elastomer-Based Fabrication Method for Varifocal Microlens Array. Opt. Express 2017, 25, 31708. [Google Scholar] [CrossRef]

- Chen, C.; Hao, Q.; Liu, L.; Cao, J.; Qiao, Z.; Cheng, Y. Continuous Optical Zoom Compound Eye Imaging Using Alvarez Lenses Actuated by Dielectric Elastomers. Biomimetics 2024, 9, 374. [Google Scholar] [CrossRef]

- Wang, H.-W.; Chang, I.-L.; Chen, L.-W. Beam Manipulating by Graded Photonic Crystal Slab Made of Dielectric Elastomer Actuators. Opt. Commun. 2012, 285, 5524–5530. [Google Scholar] [CrossRef]

- Pan, M.; Fu, Y.; Zheng, M.; Chen, H.; Zang, Y.; Duan, H.; Li, Q.; Qiu, M.; Hu, Y. Dielectric Metalens for Miniaturized Imaging Systems: Progress and Challenges. Light Sci. Appl. 2022, 11, 195. [Google Scholar] [CrossRef]

- She, A.; Zhang, S.; Shian, S.; Clarke, D.R.; Capasso, F. Adaptive Metalenses with Simultaneous Electrical Control of Focal Length, Astigmatism, and Shift. Sci. Adv. 2018, 4, eaap9957. [Google Scholar] [CrossRef]

- Hwang, T.; Kwon, H.-Y.; Oh, J.-S.; Hong, J.-P.; Hong, S.-C.; Lee, Y.; Ryeol Choi, H.; Jin Kim, K.; Hossain Bhuiya, M.; Nam, J.-D. Transparent Actuator Made with Few Layer Graphene Electrode and Dielectric Elastomer, for Variable Focus Lens. Appl. Phys. Lett. 2013, 103, 023106. [Google Scholar] [CrossRef]

- Jin, B.; Lee, J.-H.; Zhou, Z.; Lee, G.-B.; Ren, H.; Nah, C. Liquid Lens Driven by Elastomer Actuator. In Zoom Lenses, Proceedings of the SPIE Optical Engineering + Applications, San Diego, CA, USA, 9–13 August 2015; Betensky, E., Yamanashi, T., Eds.; SPIE: San Diego, CA, USA, 2015; p. 95800O. [Google Scholar]

- Park, B.J.; Park, S.; Choi, M.; Park, S.K.; Yun, S.; Shin, E.; Yoon, J.W. Monolithic Focus-Tunable Lens Technology Enabled by Disk-Type Dielectric-Elastomer Actuators. Sci. Rep. 2020, 10, 16937. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Wang, Y.; Wang, X.; Ning, F.; Wen, S.; Zhou, Y.; Chen, S.; Betts, A.; Jerrams, S.; Zhou, F.-L. Electrohydrodynamic Printing of a Dielectric Elastomer Actuator and Its Application in Tunable Lenses. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106461. [Google Scholar] [CrossRef]

- Chen, C.; Hao, Q.; Cao, J.; Xu, Y.; Cheng, Y. Two-Dimensional Varifocal Scanning Imaging Based on Alvarez and Decentred Lenses Actuated by Dielectric Elastomer. Opt. Laser Technol. 2023, 167, 109805. [Google Scholar] [CrossRef]

- Chen, C.; Hao, Q.; Liu, L.; Cao, J.; Zhang, Y.; Cheng, Y. 10× Continuous Optical Zoom Imaging Using Alvarez Lenses Actuated by Dielectric Elastomers. Opt. Express 2024, 32, 1246. [Google Scholar] [CrossRef]

- Liu, L.; Hao, Q.; Li, Z.; Xiong, J.; Zhang, Y.; Cheng, Y. Design and Demonstration of DEA-Based Tunable Planar Liquid Crystal Alvarez Lenses. Opt. Laser Technol. 2025, 182, 112068. [Google Scholar] [CrossRef]

- Rasti, P.; Kiefer, R.; Anbarjafari, G. Autofocus Liquid Lens by Using Sharpness Measurement. In Proceedings of the 2015 23nd Signal Processing and Communications Applications Conference (SIU), Malatya, Turkey, 16–19 May 2015; IEEE: New York, NY, USA, 2015; pp. 608–611. [Google Scholar]

- Rasti, P.; Kesküla, A.; Haus, H.; Schlaak, H.F.; Anbarjafari, G.; Aabloo, A.; Kiefer, R. A Passive Autofocus System by Using Standard Deviation of the Image on a Liquid Lens. In Electroactive Polymer Actuators and Devices (EAPAD) 2015, Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 8–12 March 2015; Bar-Cohen, Y., Ed.; SPIE: San Diego, CA, USA, 2015; p. 94301Q. [Google Scholar]

- Chang, Y.K.; Lim, J.; Burkland, J. How Can AR-Enhanced Books Support Early Readers? Exploring Literacy Development through AR Design Principles. Int. J. Child-Comput. Interact. 2024, 42, 100701. [Google Scholar] [CrossRef]

- Na, H.C.; Kim, Y.S. Study on an Ar-Based Circuit Practice. Appl. Comput. Sci. 2024, 20, 17–27. [Google Scholar] [CrossRef]

- Lv, C.; Liu, B.; Wu, D.; Lv, J.; Li, J.; Bao, J. AR-Assisted Assembly Method Based on Instance Segmentation. Int. J. Comput. Integr. Manuf. 2025, 38, 271–287. [Google Scholar] [CrossRef]

- Kulkarni, N.N.; Raisi, K.; Valente, N.A.; Benoit, J.; Yu, T.; Sabato, A. Deep Learning Augmented Infrared Thermography for Unmanned Aerial Vehicles Structural Health Monitoring of Roadways. Autom. Constr. 2023, 148, 104784. [Google Scholar] [CrossRef]

- Cheng, Y.; OuYang, Q.; Yao, C.; Liu, L.; Li, Z.; Hao, Q. Dielectric-Elastomer-Driven Long-Wave Infrared Alvarez Lenses for Continuous Zooming Imaging. Infrared Phys. Technol. 2024, 143, 105614. [Google Scholar] [CrossRef]

- Zhang, Q.; Yu, W.; Zhao, J.; Meng, C.; Guo, S. A Review of the Applications and Challenges of Dielectric Elastomer Actuators in Soft Robotics. Machines 2025, 13, 101. [Google Scholar] [CrossRef]

- Banet, P.; Zeggai, N.; Chavanne, J.; Nguyen, G.T.M.; Chikh, L.; Plesse, C.; Almanza, M.; Martinez, T.; Civet, Y.; Perriard, Y.; et al. Evaluation of Dielectric Elastomers to Develop Materials Suitable for Actuation. Soft Matter 2021, 17, 10786–10805. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Tang, C.; Liu, X.-J.; Zhao, H. Long-life-cycle and Damage-recovery Artificial Muscles via Controllable and Observable Self-clearing Process. Adv. Eng. Mater. 2022, 24, 2101017. [Google Scholar] [CrossRef]

- Jiang, S.; Peng, J.; Wang, L.; Ma, H.; Shi, Y. Recent Progress in the Development of Dielectric Elastomer Materials and Their Multilayer Actuators. J. Zhejiang Univ.-Sci. A 2024, 25, 183–205. [Google Scholar] [CrossRef]

- Ma, W.; Wang, H.; Sun, W.; Tang, C.; Cao, C.; Gao, X.; Liu, L.; Li, B.; Chen, G. Use of a multilayered dielectric elastomer actuator as a high-performance artificial muscle. Design, fabrication, and applications. SCI. SIN. Phys. Mech. Astron. 2024. (In Chinese) [Google Scholar] [CrossRef]

- Kim, S.; Hsiao, Y.-H.; Lee, Y.; Zhu, W.; Ren, Z.; Niroui, F.; Chen, Y. Laser-Assisted Failure Recovery for Dielectric Elastomer Actuators in Aerial Robots. Sci. Rob. 2023, 8, eadf4278. [Google Scholar] [CrossRef]

- Beco Albuquerque, F.; Shea, H.R. Effect of Electrode Composition and Patterning Method on the Lifetime of Silicone-Based Dielectric Elastomer Actuators (DEA) under Different Environmental Conditions. In Electroactive Polymer Actuators and Devices (EAPAD) XXIII, Proceedings of the SPIE Smart Structures + Nondestructive Evaluation, San Diego, CA, USA, 22–27 March 2021; Madden, J.D., Anderson, I.A., Shea, H.R., Eds.; SPIE: San Diego, CA, USA, 2021; pp. 155–166. [Google Scholar]

- Guo, Y.; Qin, Q.; Han, Z.; Plamthottam, R.; Possinger, M.; Pei, Q. Dielectric Elastomer Artificial Muscle Materials Advancement and Soft Robotic Applications. Smartmat 2023, 4, e1203. [Google Scholar] [CrossRef]

- Hill, M.; Rizzello, G.; Seelecke, S. Development and Validation of a Fatigue Testing Setup for Dielectric Elastomer Membrane Actuators. Smart Mater. Struct. 2019, 28, 55029. [Google Scholar] [CrossRef]

- Zhou, S.; Yu, C.; Chen, M.; Shi, C.; Gu, R.; Qu, D. Self-healing and Shape-shifting Polymers Controlled by Dynamic Bonds. Smart Mol. 2023, 1, e20220009. [Google Scholar] [CrossRef]

- Yuan, W.; Brochu, P.; Ha, S.M.; Pei, Q. Dielectric Oil Coated Single-Walled Carbon Nanotube Electrodes for Stable, Large-Strain Actuation with Dielectric Elastomers. Sens. Actuators A Phys. 2009, 155, 278–284. [Google Scholar] [CrossRef]

- Stoyanov, H.; Brochu, P.; Niu, X.; Lai, C.; Yun, S.; Pei, Q. Long Lifetime, Fault-Tolerant Freestanding Actuators Based on a Silicone Dielectric Elastomer and Self-Clearing Carbon Nanotube Compliant Electrodes. RSC Adv. 2013, 3, 2272. [Google Scholar] [CrossRef]

- Annapooranan, R.; Wang, Y.; Cai, S. Harnessing Soft Elasticity of Liquid Crystal Elastomers to Achieve Low Voltage Driven Actuation. Adv. Mater. Technol. 2023, 8, 2201969. [Google Scholar] [CrossRef]

- Lv, J.; Hong, H.; Gan, Z.; Zhang, M.; Liu, Z.; Hu, Z. Dielectric Elastomer-Driven Liquid Prism Enabling Two-Dimensional Beam Control. Opt. Express 2024, 32, 21517. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, H.; Chen, X.; Li, Z.; Su, C.-Y. Modeling and Adaptive Output Feedback Control of Butterfly-like Hysteretic Nonlinear Systems with Creep and Their Applications. IEEE Trans. Ind. Electron. 2023, 70, 5182–5191. [Google Scholar] [CrossRef]

- Lv, J.; Hong, H.; Zhang, M.; Gan, Z.; Liu, Z.; Hu, Z.; Yang, M. Bio-Inspired Optofluidic Focus-Tunable Imaging System with Large Two-Dimensional Field-of-View Tuning Capability. Measurement 2025, 253, 117332. [Google Scholar] [CrossRef]

- Medina, H.; Farmer, C.; Liu, I. Dielectric Elastomer-Based Actuators: A Modeling and Control Review for Non-Experts. Actuators 2024, 13, 151. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, P.; Wu, J.; Su, C.-Y. Modelling and Compound Control of Intelligently Dielectric Elastomer Actuator. Control Eng. Pract. 2022, 126, 105261. [Google Scholar] [CrossRef]

- Papaspiridis, F.G.; Antoniadis, I.A. Dielectric Elastomer Actuators as Elements of Active Vibration Control Systems. Adv. Sci. Technol. 2009, 61, 103–111. [Google Scholar]

- Wang, Y.; Zhang, X.; Li, Z.; Chen, X.; Su, C.-Y. Adaptive Implicit Inverse Control for a Class of Butterfly-Like Hysteretic Nonlinear Systems and Its Application to Dielectric Elastomer Actuators. IEEE Trans. Ind. Electron. 2023, 70, 731–740. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Huang, P.; Su, C.-Y.; Wang, Y. Inverse Dynamics Modelling and Tracking Control of Conical Dielectric Elastomer Actuator Based on GRU Neural Network. Eng. Appl. Artif. Intell. 2023, 118, 105668. [Google Scholar] [CrossRef]

- Yu, W.; Chen, W.; Yuan, W.; Li, G.; Meng, C.; Guo, S. Ultrathin and Highly-Stable Rubber Electrodes Based on Island-Bridge Multi-Filler Conductive Network for Multilayer-Stacked Dielectric Elastomer Artificial Muscles. Chem. Eng. J. 2024, 493, 152714. [Google Scholar] [CrossRef]

- Liebetraut, P.; Petsch, S.; Zappe, H. A Versatile Fabrication Process for Reaction Injection Molded Elastomeric Micro-Lenses. In Proceedings of the 2012 International Conference on Optical MEMS and Nanophotonics, Banff, AB, Canada, 6–9 August 2012; IEEE: New York, NY, USA, 2012; pp. 176–177. [Google Scholar]

- Zhang, H.; Zhu, J.; Wen, H.; Xia, Z.; Zhang, Z. Biomimetic Human Eyes in Adaptive Lenses with Conductive Gels. J. Mech. Behav. Biomed. Mater. 2023, 139, 105689. [Google Scholar] [CrossRef] [PubMed]

- Hao, Q.; Liu, L.; Cao, J.; Liu, M.; Ou, Y.; Cheng, Y. Thin Wide Range Varifocal Diffractive Alvarez Lenses Actuated by Dielectric Elastomers. Opt. Lasers Eng. 2024, 182, 108453. [Google Scholar] [CrossRef]

| Tuning Principle | Subtype | Lens Construction | Type of DEA |

|---|---|---|---|

| Deformation-based | Direct Drive | Monolithic Lens | Planar DEA, Spherical DEA and Conical DEA |

| Lens Array | Planar DEA | ||

| Indirect Drive | Monolithic Lens | Spherical DEA | |

| Lens Array | Spherical DEA | ||

| Displacement-based | Axial Displacement | Composite Lens | Planar DEA and Bending-Mode DEA |

| Lateral Displacement | Lens Array | Planar DEA | |

| Metalens | Planar DEA |

| Year | Tuning Principle | Construction | Dielectric Field Strength | Focusing Ability | Response Time | DE Material | Ref. |

|---|---|---|---|---|---|---|---|

| 2011 | Deformation-based | Monolithic | 150 V/μm | - | - | Nitrile rubber | [46] |

| 2011 | Deformation-based | Monolithic | 58 V/μm | 16.72–22.73 mm | 60 ms | Acrylic (VHB 4905) | [30] |

| 2012 | Deformation-based | Monolithic | 25 V/μm | 12.5–15.5 cm | - | Silicone (R-2652) | [32] |

| 2013 | Deformation-based | Monolithic | 40 V/μm | - | - | Silicone | [78] |

| 2013 | Deformation-based | Monolithic | 45 V/μm | 16 cm–770 cm | <1 s | Acrylic (VHB 4905, VHB 4910) | [64] |

| 2014 | Deformation-based | Monolithic | 13.3 V/μm | 25.4–105.2 mm | <450 ms (drive) <700 ms (recover) | Silicone (TC-5005 A/B) | [35] |

| 2014 | Deformation-based | Monolithic | 36 V/μm | 13.1–16.1 mm | - | Silicone (Sylgard 184) | [59] |

| 2015 | Deformation-based | Monolithic | - | Aperture 1.85 mm: 3–5.6 mm Aperture 0.376 mm: 400–620μm | 540 ms (drive) 240 ms (recover) | Silicone (Daeil Material Compound, Trigonox 101-45S-ps) | [79] |

| 2016 | Displacement-based | Composite | 17.5 V/μm | 1.8–7.8 mm | <1 ms | Silicone (Elastosil P7670) | [70] |

| 2017 | Deformation-based | Array | 5 V/μm | 950 mm-∞ | - | Acrylic (VHB 4910) | [73] |

| 2017 | Displacement-based | Monolithic | 200 V/μm | 15.4–20 cm | 23 ms (drive) 93 ms (recover) | Silicone (Elastosil P7670) | [42] |

| 2018 | Displacement-based | Metalenses | - | 50–103.5 mm | - | Acrylic (VHB 4905) | [77] |

| 2019 | Deformation-based | Monolithic | 44.1 V/μm | Zoom ratio: 180% | - | Acrylic (VHB 4910) | [65] |

| 2020 | Deformation-based | Monolithic | 25 V/μm | 4.32–8.35 mm | 7.1 ms | Silicone (PDMS-MVS, PDMS-MOS) | [80] |

| 2021 | Deformation-based | Monolithic | 41 V/μm | 26.1–33.6 mm | - | Silicone (LSR 4305, 3 wt% CuPc) | [81] |

| 2022 | Displacement-based | Composite | 24 V/μm | 20–850 mm | 330 ms (drive) 100 ms (recover) | Unimorph nanocomposite dielectric elastomer | [71] |

| 2023 | Displacement-based | Composite | 71.4 V/μm | 5.2–19.5 mm | 124 ms (drive) 203 ms (recover) | Acrylic (VHB 4905) | [82] |

| 2024 | Displacement-based | Composite | 33.6 V/μm | 6.3~12.0 mm | 150 ms (drive) 210 ms (recover) | Acrylic (VHB 4905) | [83] |

| 2025 | Displacement-based | Composite | 33.6 V/μm | −118~−1476 mm, 118~1476 mm | 185 ms (drive) 296 ms (recover) | Acrylic (VHB 4905) | [84] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Zhang, M.; Gan, Z.; Lv, J.; Lin, Z.; Hong, H. Tuneable Lenses Driven by Dielectric Elastomers: Principles, Structures, Applications, and Challenges. Appl. Sci. 2025, 15, 6926. https://doi.org/10.3390/app15126926

Hu Z, Zhang M, Gan Z, Lv J, Lin Z, Hong H. Tuneable Lenses Driven by Dielectric Elastomers: Principles, Structures, Applications, and Challenges. Applied Sciences. 2025; 15(12):6926. https://doi.org/10.3390/app15126926

Chicago/Turabian StyleHu, Zhuoqun, Meng Zhang, Zihao Gan, Jianming Lv, Zhuoyu Lin, and Huajie Hong. 2025. "Tuneable Lenses Driven by Dielectric Elastomers: Principles, Structures, Applications, and Challenges" Applied Sciences 15, no. 12: 6926. https://doi.org/10.3390/app15126926

APA StyleHu, Z., Zhang, M., Gan, Z., Lv, J., Lin, Z., & Hong, H. (2025). Tuneable Lenses Driven by Dielectric Elastomers: Principles, Structures, Applications, and Challenges. Applied Sciences, 15(12), 6926. https://doi.org/10.3390/app15126926