Abstract

Based on our own research conducted on a purpose-built plantation, the production capacity of reed canary grass (Phalaris arundinacea L.) was assessed depending on the age of the plantation and the date of the biomass harvest. The aim of this study was to assess the influence of the harvest date and plantation age on the yield, chemical composition, and calorific value of reed canary grass intended for energy purposes. The biomass on the plantation was cut twice during the growing season (summer/winter). The obtained biomass was analyzed for its ash content and selected elements, i.e., nitrogen, phosphorus, potassium, calcium, magnesium, sodium, sulfur, and chlorine. The total moisture, calorific value in working condition, and combustion heat were also assessed. The two-cut harvest system allowed us to obtain 3.85 t∙ha−1 of biomass from reed canary grass in the first year of cultivation. The highest biomass yields were obtained in the third and sixth years of cultivation and amounted to 8.50 and 8.75 t∙ha−1, respectively. Regardless of the age of the plantation, the biomass yield harvested in the summer period was always higher than the yield obtained from the winter harvest. The contents of some elements in the biomass also depended on the age of the plantation and the harvest date. The biomass of reed canary grass obtained from the summer harvest of the annual plantation was characterized by a high content of nitrogen (1.97% d.m.), potassium (2.35% d.m.), and phosphorus (0.31% d.m.) compared to the content of these elements in the biomass obtained from the three- and six-year plantations. In the case of sodium, the highest content (0.072% d.m.) was found in the biomass obtained from the summer harvest of the three-year plantation, and the lowest was obtained from the winter harvest of the six-year plantation (0.037% d.m.). The average sulfur content was the highest in the biomass obtained from the annual plantation, regardless of the harvest date (0.20% d.m.—summer harvest and 0.21% d.m.—winter harvest). On the other hand, the lowest amount of sulfur was contained in the biomass obtained from the winter harvest of the six-year plantation (0.12% d.m.). Only the magnesium content (from 0.09% d.m. to 0.14% d.m.) in the biomass remained at a similar level, regardless of the age of the plantation or the harvest date. The calcium content was the highest in the biomass obtained from the winter harvest of the annual plantation (0.35% d.m.), and the lowest was obtained from the six-year-old plantation, also from the winter harvest. In addition, the moisture and ash content of the obtained biomass depended on the age of the plantation and the harvest date. The highest moisture content (12.50%) was characteristic of the biomass harvested in the summer period from the one-year plantation. On the other hand, the lowest moisture content was found for the biomass harvested in the winter period from the six-year plantation. The highest ash content was obtained from biomass harvested in the summer period from the one-year plantation (75 g∙kg−1 d.m.) and the three-year plantation (69 g∙kg−1 d.m.). The lowest ash content was obtained from the winter harvest from the six-year plantation (45 g∙kg−1 d.m.). The highest calorific value of 16.0–16.2 MJ∙kg−1 d.m. was obtained for biomass harvested in the sixth year of the study (irrespective of the harvest date). The value of the combustion heat was also dependent on the age of the plantation and the date of the biomass harvest. The highest value for the combustion heat of 17.5 MJ∙kg−1 d.m. was obtained for biomass harvested in the winter period from the six-year plantation

1. Introduction

One of the main goals of the EU’s policy to mitigate climate change and increase energy security in Europe is to gradually move away from fossil fuels towards renewable energy sources [1,2,3,4].

The European Union assumed that, by 2030, at least 32% of the energy produced in Europe will come from renewable sources [2]. Unfortunately, the events of the last 2 years (the war in Ukraine) and a significant reduction in the share of Russian fossil fuels in the EU’s energy structure have led to a revision of the previous assumptions. Currently, the new EU goal is to achieve 42.5% of its energy from renewable sources by 2030 [5]. In the EU, the most important renewable energy sources are solid biofuels, which account for 41% of the total renewable energy globally [5]. Also, in Poland, most energy production from renewable sources comes from solid biofuels, which account for as much as 69.3% of the overall renewable energy balance [6,7]. In Poland, the most important renewable energy source in the production of renewable energy is biomass obtained from various plants, mainly non-agricultural ones. Moreover, wind, water, and solar energy also play an important role in the overall energy balance [8,9,10,11].

However, biomass is considered the least capital-intensive and most promising source of renewable energy, being the so-called “neutral fuel”, precisely due to its low greenhouse gas emissions [12,13]. So-called non-agricultural plant species can be used to produce biomass. These are species that accumulate an appropriate amount of lignocellulose as a starting product for the production of energy carriers that are solid (e.g., wood chips, pellets, briquettes), gaseous, or liquid (e.g., biogas or bioethanol) [14,15]. The high ecological plasticity of such species creates the possibility of using them to produce biomass for energy purposes in various habitats [10,11,16,17,18,19,20,21,22].

The most commonly used species for this purpose are: Salix sp., Populus sp., Robinia pseudoacacia, Sida hermaphrodita, Miscanthus x giganteus, Spartina pectinata, and Panicum virgatum. In addition to the mentioned species, other species are also used, e.g., grass species, which include reed canary grass (Phalaris arundinacea). Due to its physicochemical properties and high efficiency, as well as the relatively low financial outlays for establishing a reed canary grass plantation, this species can be successfully used for biomass production [23,24,25,26].

Reed canary grass (P. arundinacea) occurs commonly in the wild in the temperate climate zones of North America, Asia, and Europe [27]. It is a hydro- and nitro-philous species, and is very well tolerant of even long-term surface flooding and periodic droughts. In Poland, it is found in its natural state, especially on fertile floodplains, and was also a common component of meadow sward. Due to its production of large amounts of biomass, it is used for energy production, e.g., for direct combustion and the production of biofuels and biogas [28,29,30,31,32,33,34].

This research on the possibilities of obtaining biomass from reed canary grass may contribute to obtaining the necessary information on yields depending on the age of the plantation and the harvest date, as well as the possibilities of using biomass for energy purposes.

The aim of this study was to assess the effects of the harvest date and plantation age on the yield, chemical composition, and calorific value of reed canary grass (P. arundinacea) intended for energy purposes.

2. Materials and Methods

2.1. Experiment Design

The 0.5 ha field experiment was established in 2010 on the production field belonging to the company “KULAS” Agricultural and Nursery Farm based in Pisarzowice (50°52′22.3″ N 17°27′57.4″ E). The research covered the years 2010–2016 during which the biomass yield and its chemical composition were assessed depending on the age of the plantation and the harvest date.

The reed canary grass seeds were imported from the US state of Wisconsin. The sowing of reed canary grass seeds in the amount of 16.0 kg∙ha−1 was carried out on 2 April 2010 on the production field using a grain seeder (Amazone, Hasbergen-Gaste, Germany) with a row spacing of 18 cm and a depth of 2 cm. The forecrop was corn, which was harvested in the second half of October 2009. Then, after the corn harvest, post-harvest cultivation and winter ploughing were carried out, and in 2010, in the second half of March (2 weeks before sowing reed canary grass), the soil was improved with a cultivator.

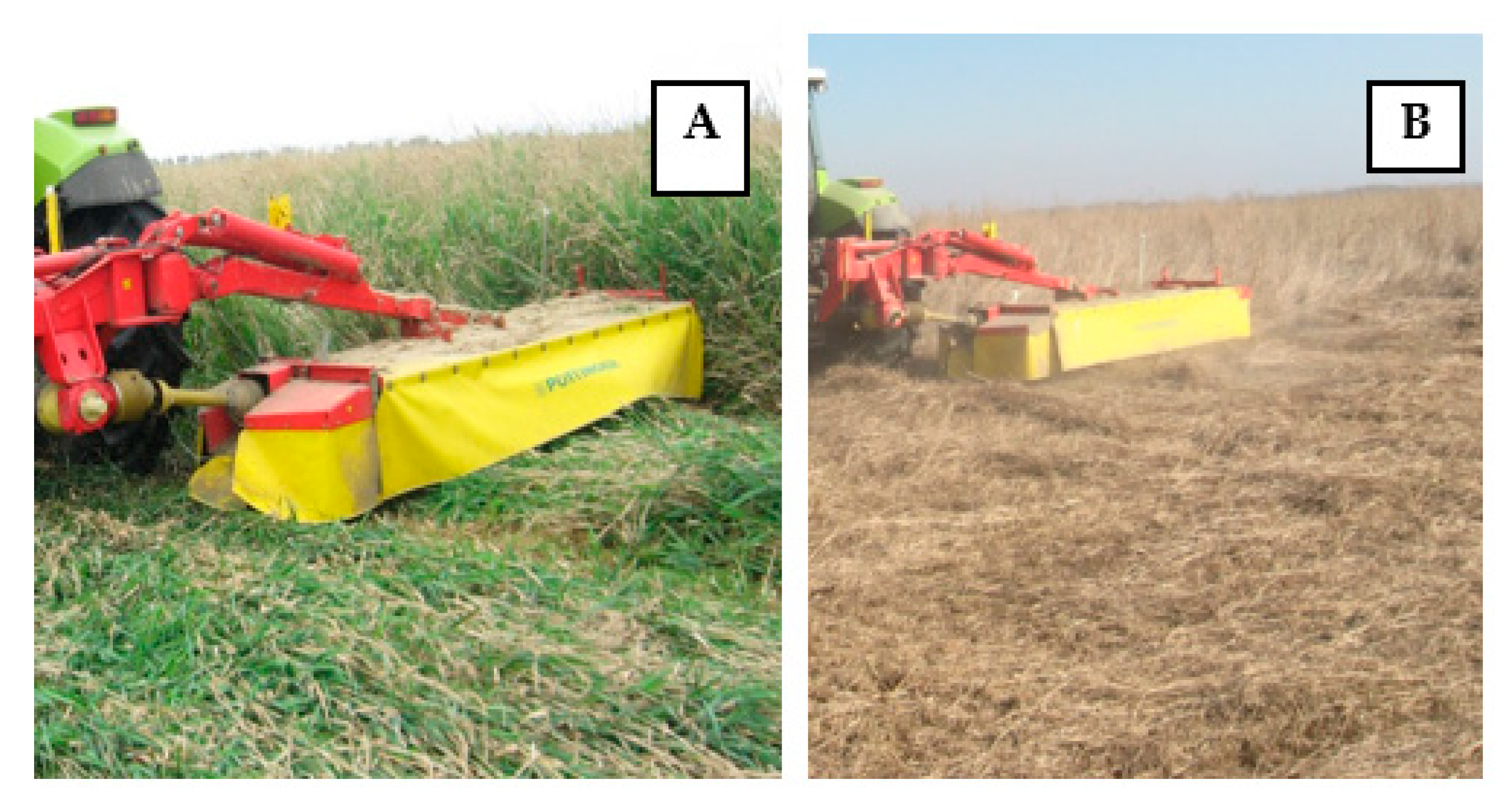

The emergence of reed canary grass plants appeared 7 days from the moment of sowing. A major problem turned out to be monocotyledonous and dicotyledonous weeds germinating together with the reed canary grass. Therefore, in order to limit weed infestation of the newly established plantation, two treatments were performed: herbicide and mechanical. For the chemical treatment, a herbicide, Chwastox Extra 300 SL (Qemetica Agricultural Solutions Poland S.A., Nowa Sarzyna, Poland) in a dose of 3.0 L∙ha−1 (a.i. MCPA) was used, which was intended to control dicotyledonous weeds. The herbicide treatment was performed in the 3–5 leaf phase (BBCH 13–15) of the reed canary grass (Figure 1). Then, in the beginning of the tillering phase (BBCH 21) of the reed canary grass, when it had reached a height of about 20 cm, a mechanical procedure was performed, consisting in cutting it with a disc mower to a height of 10 cm. This procedure was aimed at limiting the occurrence of monocotyledonous weeds and stimulating the reed canary grass plants to grow more vigorously.

Figure 1.

Reed canary grass in the first year of cultivation (A), and during flowering (B).

2.2. Study Site and Soil Properties

The experiment was conducted in the southwestern part of Poland (50°52′22.3″ N 17°27′57.4″ E) in a temperate transitional climate, on a field belonging to the “KULAS” Agricultural and Nursery Farm in Pisarzowice near Brzeg.

The experiment was conducted on a brown river of alluvial soil [35]. The characteristics of the habitat are presented in Table 1. Soil pH (pHKCl) was determined by the potentiometric method according to Polish standards [36]. Available phosphorus and potassium in the soils was determined according to the Egner Riehm method using applicable Polish standards or industry procedures. The phosphorus level was measured using the spectrophotometric method according to Polish standards [37], while potassium was determined by atomic emission spectrometry according to Polish standards [38]. Magnesium content was determined using the atomic spectrometry technique based on Polish standards [39]. The particle size distribution was determined by the laser method and the organic matter content was determined with the Tiurin method.

Table 1.

Soil characteristics of reed canary grass (P. arundinacea) plantations.

2.3. Climatic Conditions

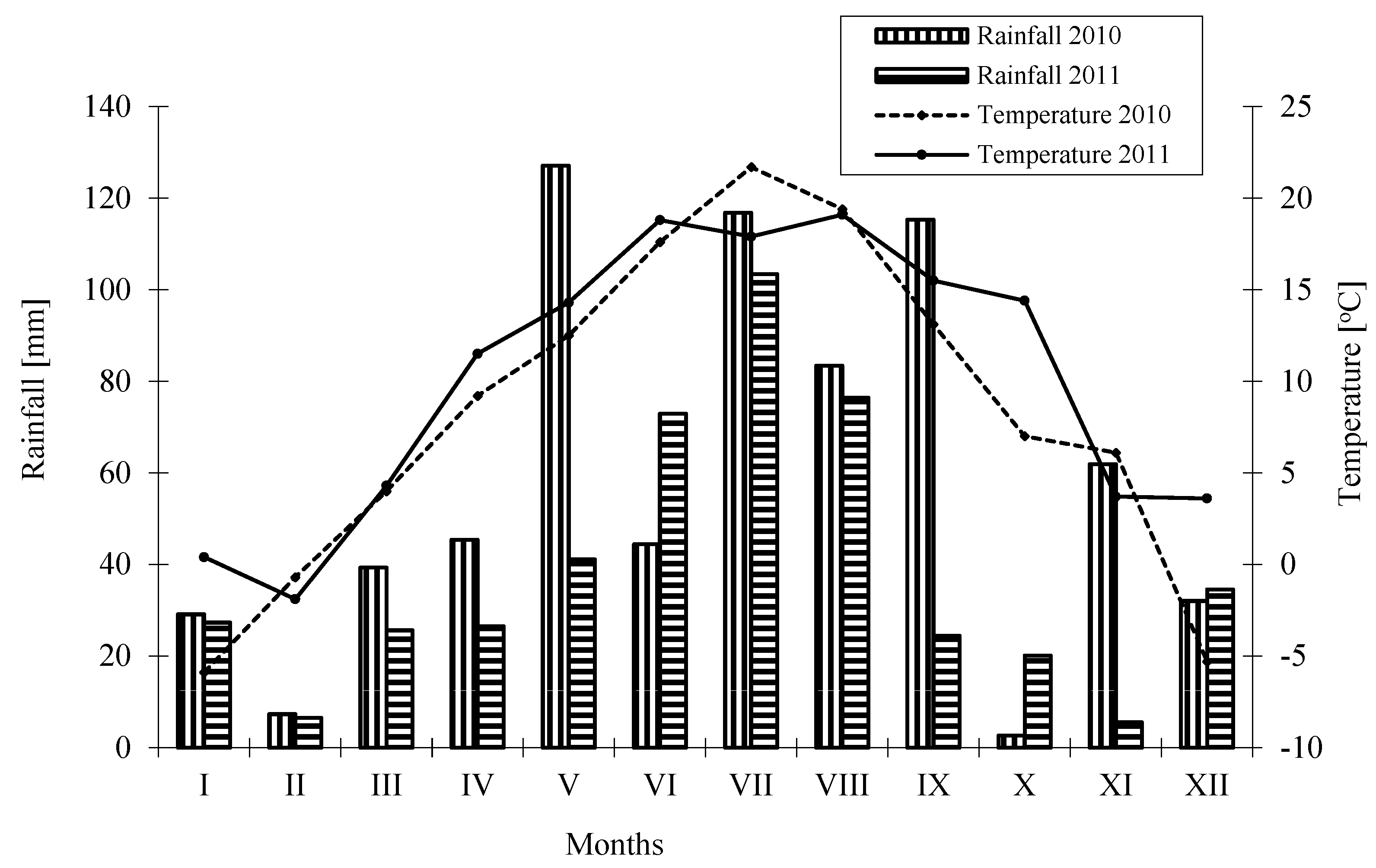

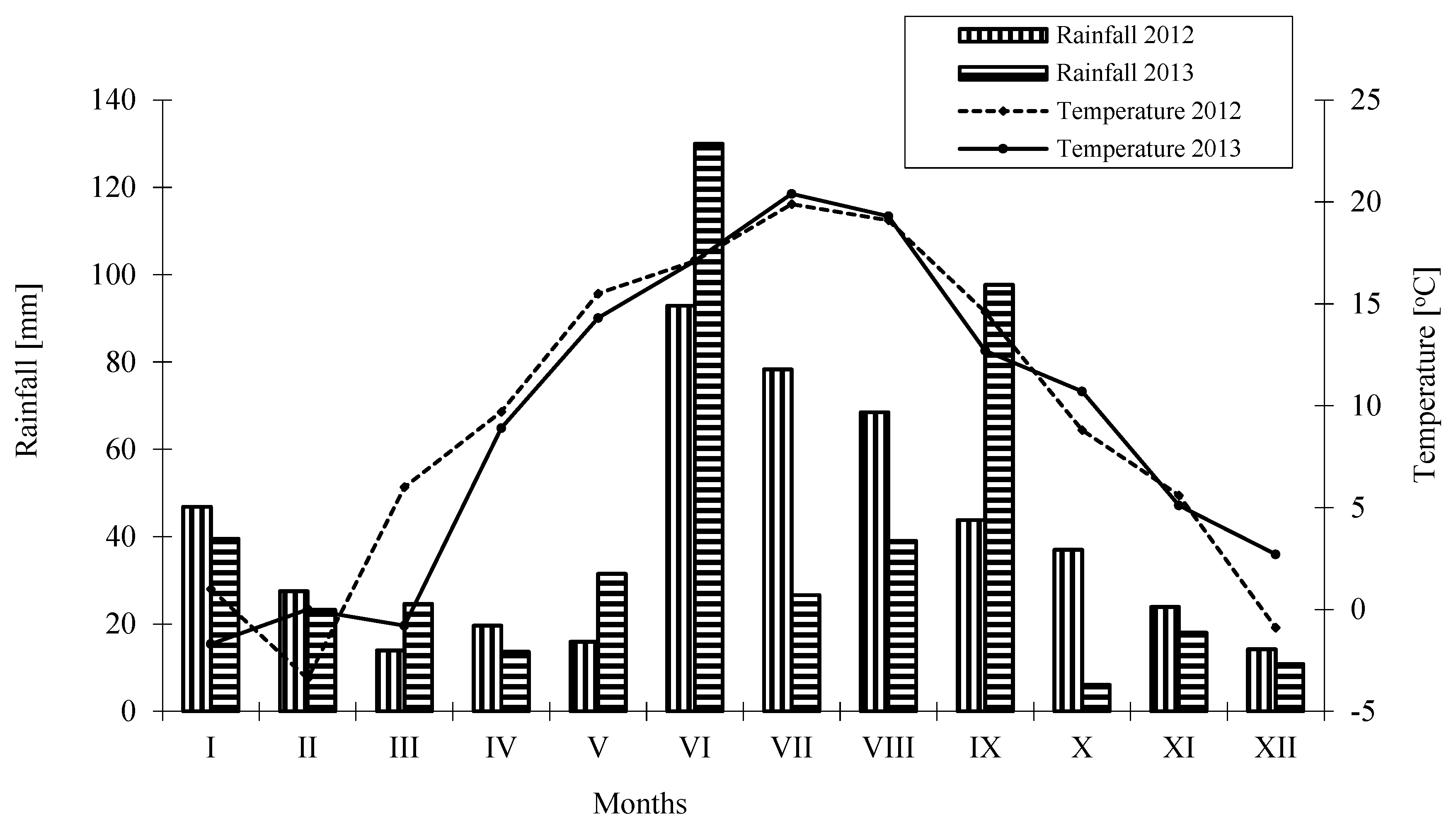

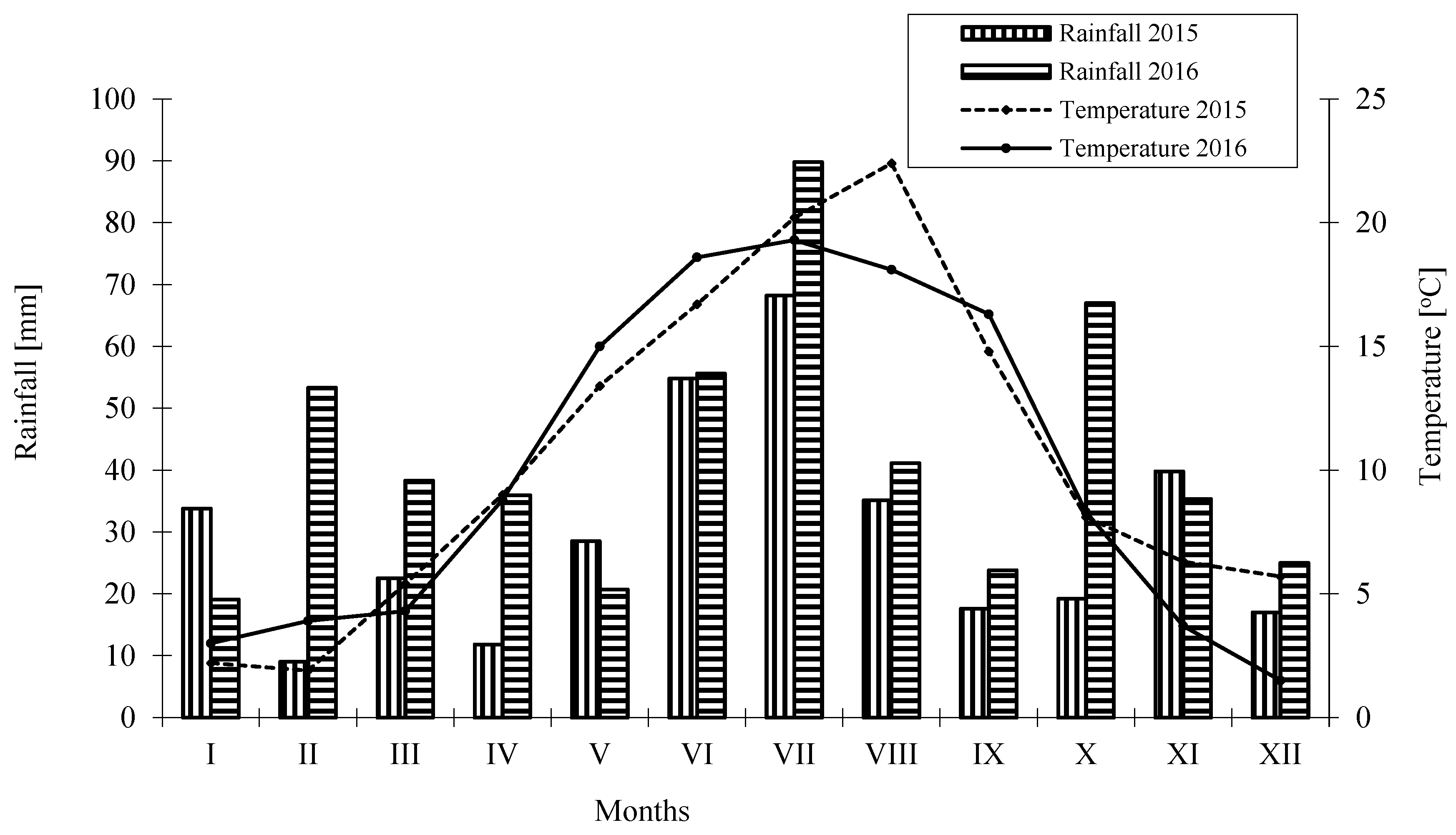

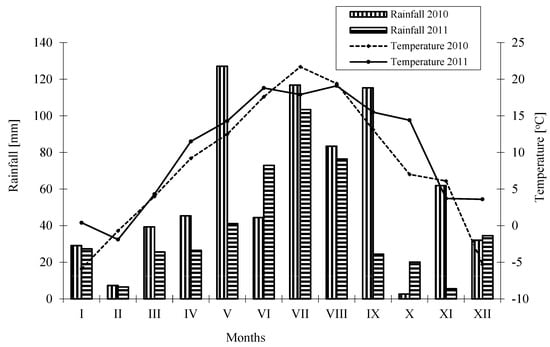

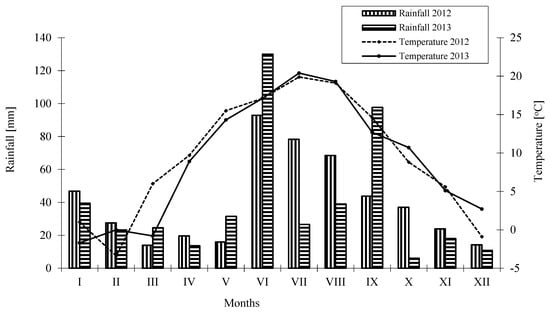

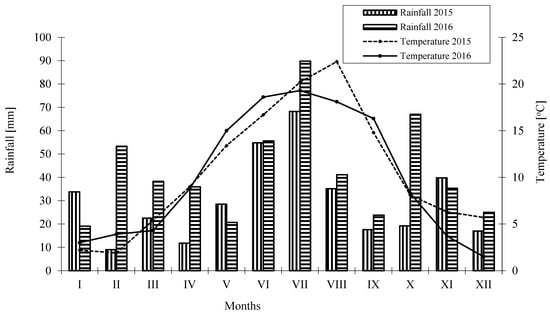

Meteorological data from 2010/2011, 2012/2013, and 2015/2016 (Figure 2, Figure 3 and Figure 4) indicate differences in precipitation and air temperatures. The warmest season was 2015/2016, in which the average air temperature was 10.3 °C. In this season, positive air temperatures were recorded in December, January, and February. The warmest months in the 2015/2016 season were July and August, with an average temperature between 19.3 °C and 22.4 °C. The coldest season was 2010/2011, with an average annual temperature of 9.1 °C. In this season, negative air temperatures were recorded for the winter months, i.e., December, January, and February. The coldest year was 2010, when the average air temperature in January was −5.9 °C; in December of the same year the average air temperature was −5.3 °C. The wettest season was 2010/2011, with the highest average total rainfall of 584.4 mm (in 2010 it was 704.6 mm and in 2011 it was 464.2 mm). The heaviest rainfall occurred in 2010 in the months of May (127.1 mm), July (116.8 mm), and September (115.3 mm). The 2012/2013 and 2015/2016 seasons were characterized by very similar total rainfalls of 471.4 mm (2012/2013) and 431.1 mm (2015/2016), respectively. The driest year was 2015, with the lowest annual rainfall of 357.3 mm.

Figure 2.

Hydro-thermal conditions prevailing in the 2010/2011 growing season.

Figure 3.

Hydro-thermal conditions prevailing in the 2012/2013 growing season.

Figure 4.

Hydro-thermal conditions prevailing in the 2015/2016 growing season.

2.4. Harvest and Biomass Analysis

The first summer harvest of biomass was carried out in 2010, 4–6 weeks after the reed canary grass plants finished flowering (first half of August). The second harvest (winter) was carried out in 2011 (first half of March). In the following years, the summer harvest was also carried out in the first half of August, and the winter harvest in the first half of March.

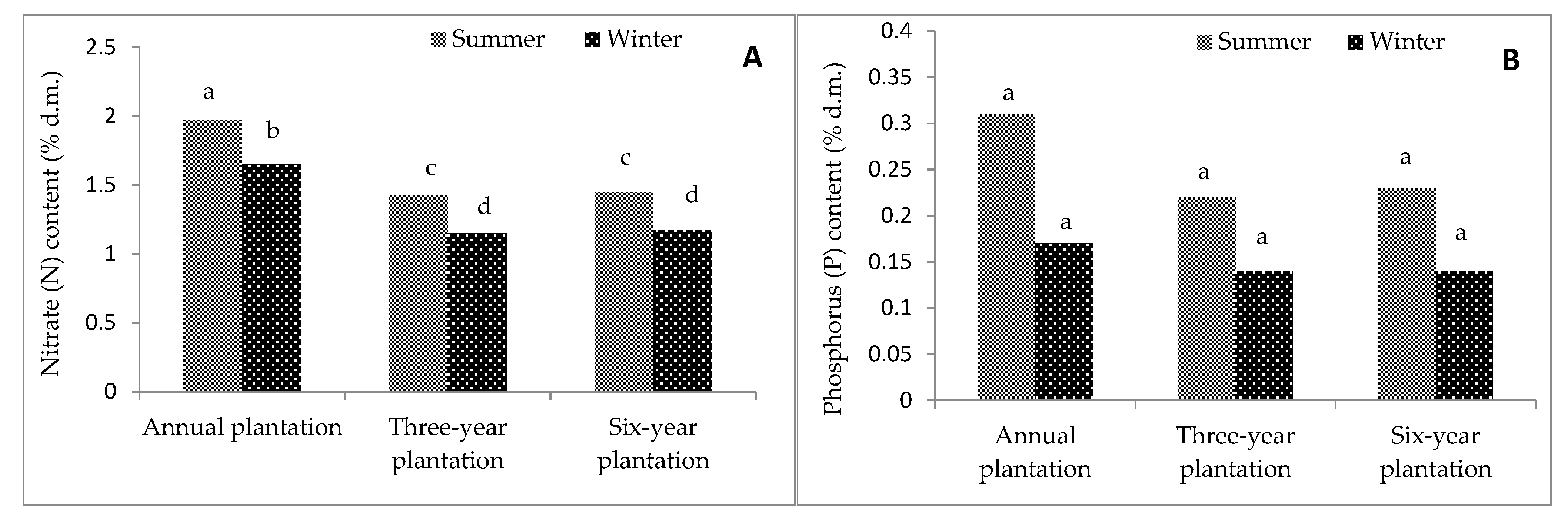

The summer harvest of reed canary grass biomass was carried out using a Kuhn disc mower (KUHN, Saverne, France) (Figure 5A). Then, the cut canary grass was laid to dry on the swath for about 10–14 days to obtain moisture in the range of 15–17%. On the other hand, the winter harvest of reed canary grass was carried out in one stage using a cutting machine and a Claas square baler (CLASS, Harsewinkel, Germany). The winter harvest was carried out in one stage, because the canary grass cut at that time contained only about 10% moisture (Figure 5B). The entire experiment was conducted up until 2016. This article uses the research results obtained from the 2010/2011 season (one-year plantation), the 2012/2013 season (three-year plantation), and the 2015/2016 season (six-year plantation).

Figure 5.

Summer (A) and winter (B) harvest of reed canary grass.

In each growing season, biomass samples were collected from randomly selected points on the field surface (0.5 ha). Nine sampling points were provided, from which primary samples of 5 kg each were obtained, from which 3 samples of 1 kg each were then collected for further laboratory tests at the District Chemical-Agricultural Station in Wrocław to determine the contents of the following elements: nitrogen (N), phosphorus (P), potassium (K), calcium (Ca), magnesium (Mg), sodium (Na), sulfur (S), and chlorine (Cl).

The analysis of the biomass obtained from reed canary grass, concerning the percentage of ash content in the working state [40] and total moisture [41], as well as the calorific value in the working state and the heat of combustion [42], were performed in the coal laboratory of BOT Elektrownia Opole S.A.

2.5. Statistical Analysis

The results concerning the yield, macro- and micro-element content, and energy value were statistically processed using the classic analysis of variance at a significance level of p = 0.05. To determine significant differences in the results for the subsequent years of the study, the Tukey test was used at a significance level of p = 0.05. The analyses were carried out using the ARM (Agriculture Research Management) program version 2024.1.

3. Results and Discussion

The basic elements that should be met when selecting a plant for biomass production are a high yield of biomass, an appropriate calorific value of the biomass, and the appropriate selection of species for the given habitat conditions [19,22,33,43,44,45,46,47,48]. Moreover, according to some authors, the criteria for assessing plants as a raw material for energy production also depend on the form of energy that the grower intends to obtain (e.g., heat, electricity) and the biomass conversion technology that will be used (e.g., direct combustion, gasification or pyrolysis) [4,12,21,49,50,51,52,53].

In our own research conducted from 2010 to 2016, the production possibilities of reed canary grass for energy purposes were assessed depending on the mowing date and the age of the plantation. This article uses the results obtained for the seasons of 2010/2011 (annual plantation), 2012/2013 (three-year plantation), and 2015/2016 (six-year plantation) (Table 2). In each research season, a two-cut system was used for reed canary grass biomass harvesting (summer/winter). In the 2010/2011 season (annual plantation), during the summer harvest, the biomass yield was 2.40 t∙ha−1, and during the winter harvest, the yield was 1.45 t∙ha−1. The total biomass yield of reed canary grass for the 2010/2011 season (annual plantation) was 3.85 t∙ha−1. In the 2012/2013 season (three-year plantation), the biomass yield was, respectively: 6.65 t∙ha−1 for the summer harvest and 1.85 t∙ha−1 for the winter harvest. The total biomass yield for the 2012/2013 season (three-year plantation) was 8.50 t∙ha−1. However, in the 2015/2016 season (six-year plantation), the biomass yield obtained was, respectively: 6.10 t∙ha−1 for the summer harvest and 2.65 t∙ha−1 for the winter harvest. The total biomass yield for the 2015/2016 season (six-year plantation) was the highest and amounted to 8.75 t∙ha−1.

Table 2.

Yields of reed canary grass (P. arundinacea) depending on the harvest time and plantation age.

The obtained observations show that the highest biomass yields were obtained from the summer harvest from the three-year plantation, and the difference was statistically significant compared to the yields obtained from the annual and six-year plantation. On the other hand, the winter harvest was characterized by a significantly lower biomass yield compared to the summer harvest (regardless of the age of the plantation). On the other hand, after summing up the biomass yields from the two cuts for each research season separately, it was found that the biomass yield from the annual plantation (season 2010/2011) was the lowest compared to the yields obtained from the three-year plantation (season 2012/2013) and the six-year plantation (season 2015/2016), which was statistically confirmed. On the other hand, the total biomass yields obtained from the three-year and six-year plantations were at a similar level and did not differ statistically. Similar research results regarding the size of the yield depending on the age of the plantation were obtained by other authors in dealing with the subject of obtaining biomass from various plants intended for energy purposes [33,51,54,55].

The yield of reed canary grass is different in natural areas of canary grass meadows, floodplains, and river valleys. Natural canary grass meadows in river valleys are a remnant of former marsh ecosystems. Therefore, the biomass yield from such natural canary grass beds is largely dependent on the percentage of reed canary grass in the plant community [15]. A study conducted by Kryszak et al. [30] shows that biomass yields obtained from natural canary grass meadows ranged from 5.80 to 6.70 t∙ha−1 and were significantly lower than yields obtained from intentionally established reed canary grass plantations. Similar conclusions were reached by Święczkowska et al. (2012) [56], who obtained an average biomass yield of 6.83 t∙ha−1 from natural canary grass meadows. However, different results were obtained from the research of Grzelak [15,24]. According to this author, the size of biomass yields obtained from natural brain meadows can be even twice as high and can reach up to 13.0 t∙ha−1.

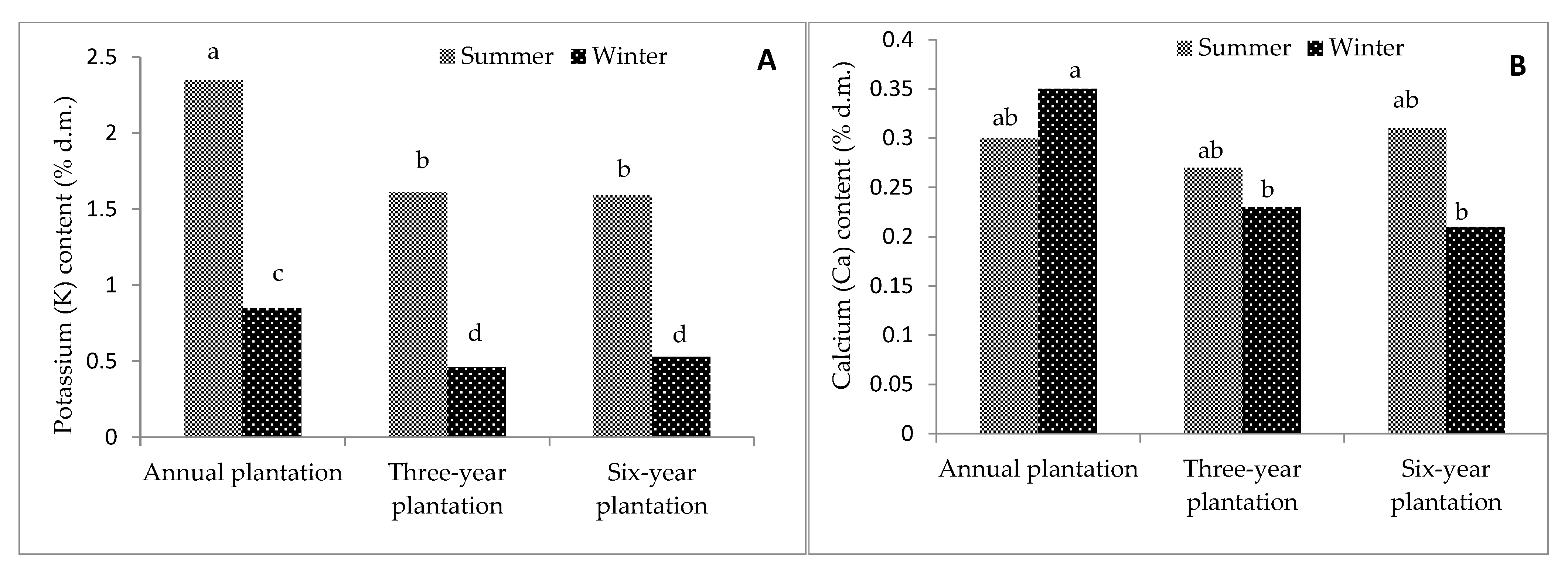

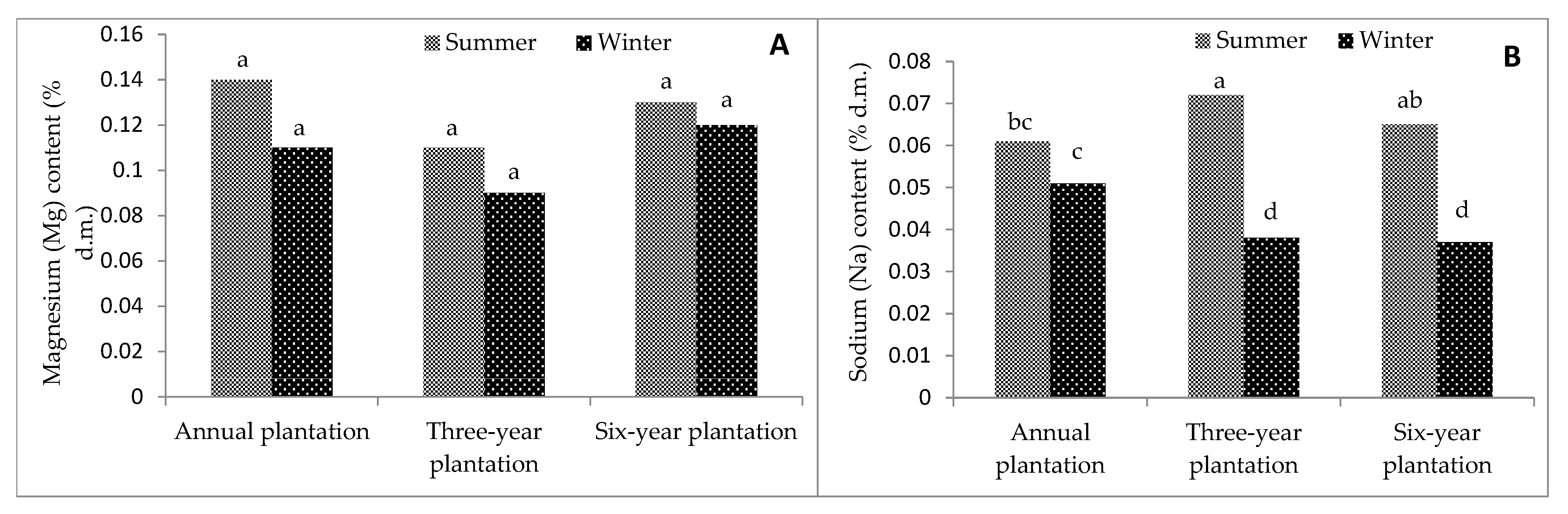

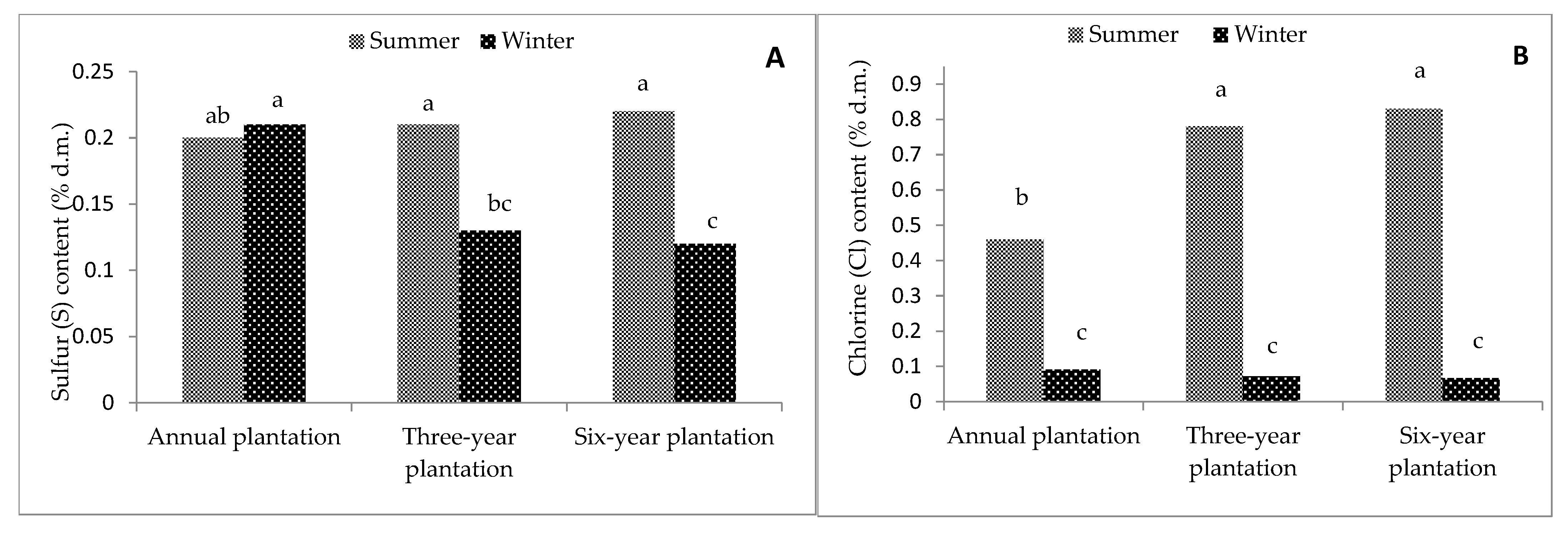

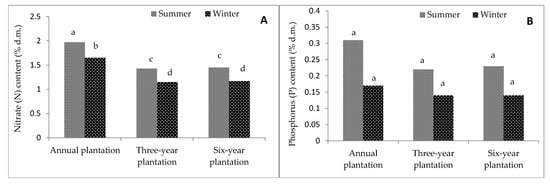

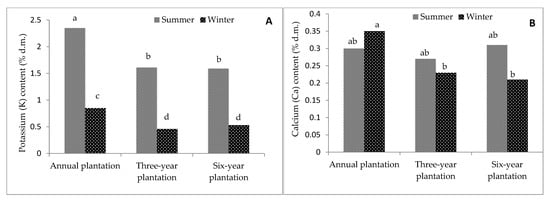

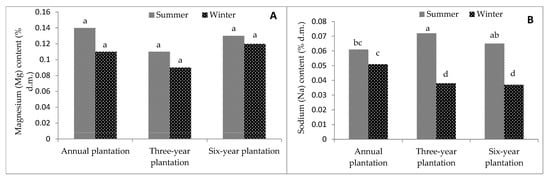

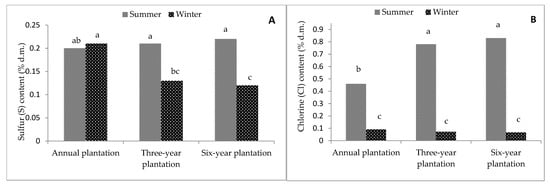

According to Golińska and Kozłowski [57], Podlaski et al. [21], Ustak et al. [53], and Zardzewiały et al. [58], each type of biomass is characterized by specific features that determine its value in the combustion process. Our own research shows that the biomass of the reed canary grass obtained from the summer harvest from the annual plantation was characterized by a high content of some elements, especially nitrogen (1.97% d.m.), potassium (2.35% d.m.), and phosphorus (0.31% d.m.), compared to the content of these elements in the biomass obtained from the three- and six-year plantations. The differences in the contents of these elements depending on the age of the plantation was statistically confirmed for nitrogen and potassium, while, for phosphorus, these differences turned out to be insignificant. Also, in the case of other elements, i.e., sodium and sulphur, the differences in the content of these elements depended on the harvest date and the age of the plantation. The highest sodium content (0.072% d.m.) was found in the biomass obtained from the summer harvest of the three-year plantation, and the lowest was from the winter harvest of the six-year plantation (0.037% d.m.). On the other hand, the average sulphur content was the highest in the biomass obtained from the annual plantation, regardless of the harvest date (0.20% d.m.—summer harvest and 0.21% d.m.—winter harvest). On the other hand, the lowest amount of sulphur was contained in the biomass obtained from the winter harvest of the six-year plantation (0.12% d.m.), which was statistically confirmed. Only the magnesium contents (from 0.09% d.m. to 0.14% d.m.) in the biomass remained at a similar level, regardless of the age of the plantation or the harvest date, which was statistically confirmed. However, different results were obtained for calcium, as its content was the highest in the biomass obtained from the winter harvest from the annual plantation (0.35% d.m.), and the lowest in that obtained from the six-year-old plantation, also from the winter harvest. However, the differences obtained in the content of this element in the biomass collected in the summer period (irrespective of the age of the plantation) were statistically insignificant (Figure 6, Figure 7, Figure 8 and Figure 9).

Figure 6.

Nitrate (N, (A)) and phosphorus (P, (B)) content in the biomass of reed canary grass (P. arundinacea) and its variability depending on the harvest date and plantation age. Means followed by same letter or symbol do not significantly differ (p = 0.05, Tukey’s HSD). Nitrate: interaction years × harvest time = 0.145, standard deviation = 0.051. Phosphorus: interaction years × harvest time = 0.666, standard deviation = 0.235.

Figure 7.

Potassium (K, (A)) and calcium (Ca, (B)) content in the biomass of reed canary grass (P. arundinacea) and its variability depending on the harvest date and plantation age. Means followed by same letter or symbol do not significantly differ (p = 0.05, Tukey’s HSD). Potassium: interaction years × harvest time = 0.232, standard deviation = 0.082. Calcium: interaction years × harvest time = 0.108, standard deviation = 0.038.

Figure 8.

Magnesium (Mg, (A)) and sodium (Na, (B)) content in the biomass of reed canary grass (P. arundinacea) and its variability depending on the harvest date and plantation age. Means followed by same letter or symbol do not significantly differ (p = 0.05, Tukey’s HSD). Magnesium: interaction years × harvest time = 0.059, standard deviation = 0.021. Sodium: interaction years × harvest time = 0.0110, standard deviation = 0.0039.

Figure 9.

Sulfur (S, (A)) and chlorine (Cl, (B)) content in the biomass of reed canary grass (P. arundinacea) and its variability depending on the harvest date and plantation age. Means followed by same letter or symbol do not significantly differ (p = 0.05, Tukey’s HSD). Sulphur: interaction years × harvest time = 0.074, standard deviation = 0.026. Chlorine: interaction years × harvest time = 0.1030, standard deviation = 0.0363.

According to the authors Burvall [28], Finell et al. [59], Heinsoo et al. [60], Kieloch et al. [19], and Melts et al. [50], the yield and content of macro- and micro-elements and the energy value of canary grass biomass depend to a large extent on the harvest date, abundance, type of habitat, and use (intentionally established plantations or natural meadow areas of canary grass).

Similar research results concerning the content of macro- and micro-elements in the biomass of reed canary grass were obtained by Golińska and Kozłowski [57], Grzelak [24], and Heinsoo et al. [60]. Also, the research conducted by Landstrom et al. [33] shows that the highest contents of nitrogen (2.32% d.m.), potassium (1.59% d.m.), and calcium (0.69% d.m.) were obtained from reed canary grass collected in the summer. On the other hand, the research conducted by Święczkowska et al. [56] shows that the average nitrogen content in the biomass of reed canary grass collected in the winter was lower and amounted to 1.17% d.m., and that the average sulfur content was higher and amounted to 0.27% d.m.

A problem during the combustion of biomass obtained from several-year-old reed canary grass plantations may be its high chlorine content, which, over time, may cause the so-called slagging and sintering of the grates. In our own studies, the chlorine content in the collected reed canary grass biomass depended on the age of the plantation and the harvest date. The highest statistically confirmed chlorine content was found in the biomass obtained from the summer harvests from the six-year-old plantation (0.83% d.m.) and the three-year plantation (0.78% d.m.). On the other hand, the lowest amount of chlorine (0.067% d.m.) was contained in the biomass harvested in the winter period from the six-year-old plantation. Our own studies show that the chlorine content was the most dependent on the age of the plantation and the harvest date of reed canary grass. The results of our own research on the chlorine content in the biomass of reed canary grass were similar to those obtained by Golińska and Kozłowski [57], Grzelak [24], and Podlaski et al. [21]. Moreover, the research conducted by Landstrom et al. [33] shows that it is possible to obtain biomass from reed canary grass with a four-fold lower chlorine content by harvesting it in the spring of the following year, at which point the average chlorine content drops from 0.795% d.m. to 0.21% d.m. The results of these authors were confirmed by our own research, which shows that, for the winter harvests, the average chlorine content in each subsequent year dropped, reaching values from 0.091% d.m. (one-year plantation) to 0.067% d.m. (six-year plantation) (Figure 9B).

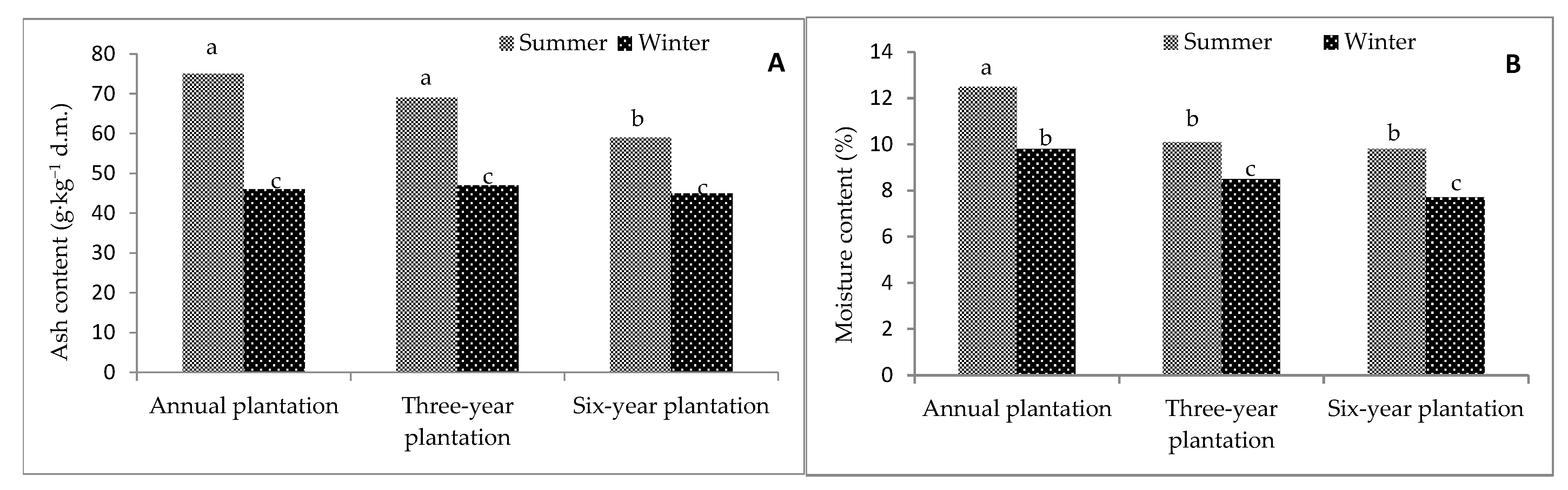

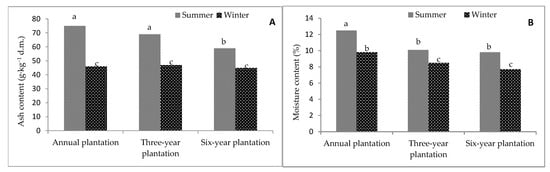

One of the most important parameters determining the calorific value of biomass it its moisture content. The air-dried mass of good quality biomass intended for direct combustion should contain 10–15% moisture. However, for the production of briquettes or pellets, the moisture content of biomass should not exceed 10% [49]. The high moisture content of the material obtained from some species is a disadvantage in the context of their energy use. According to Święczkowska et al. [56], plants whose above-ground parts dry out after the end of the growing season have a high content of dry mass without the need for additional drying, which also translates into a low moisture content of their biomass. In our own studies, the moisture content of reed canary grass biomass depended on the harvest date and the age of the plantation. The highest moisture content in the biomass was found in the summer harvest from the annual plantation (12.5%) and the lowest moisture content was obtained in the winter harvest from the six-year plantation (7.7%), which was statistically confirmed. Similar research results regarding the moisture content of reed canary grass biomass were obtained by Święczkowska et al. [56], who showed that the average moisture content of canary grass was 9.8%. However, different values for biomass moisture content were obtained by Dadrach et al. [43] and Grzelak [24], who obtained biomass from reed canary grass with moisture contents of 6.8% and 7.7%, respectively.

The final effect of any combusted biomass is solid residues called ash. Depending on its ash content, the availability of energy from biomass may vary. It has been found that the correlation between the calorific value of biomass and that of its ash content is negative. Moreover, during the combustion process in boilers, ash creates so-called slag, which worsens the heating properties of such a boiler [61].

In our own studies, the ash content in the studied biomass also depended on the harvest date and plantation age. The highest ash content was found in the biomass obtained from the summer harvest of the annual plantation (75.00 g kg−1 d.m.), and the lowest value was found in the biomass obtained from the winter harvest of the six-year plantation (45.00 g kg−1 d.m.), which was confirmed statistically. It should also be added that the ash content in the biomass of reed canary grass harvested in the winter (irrespective of the plantation age) was at a similar level (45.00–47.00 g kg−1 d.m.) to that of canary grass harvested in the summer, which was confirmed by statistical analysis (Figure 10A,B).

Figure 10.

Ash content (A) and moisture content (B) of reed canary grass (P. arundinacea) biomass depending on the harvest time and plantation age. Means followed by same letter or symbol do not significantly differ (p = 0.05, Tukey’s HSD). Ash content: interaction years × harvest time = 7.75, standard deviation = 2.73. Moisture content: interaction years × harvest time = 0.84, standard deviation = 0.30.

These values were similar to the results obtained by Landstrom et al. [33]. These authors report that, in their studies, the ash content in dry matter obtained from reed canary grass from a summer harvest was 8.51% and that from a spring harvest was 6.6%. Lower values for ash, which were 5.1% (summer harvest) and 2.3% (spring harvest), respectively, were obtained by Heinsoo et al. [60]. However, the studies conducted by Strašil et al. [51] indicate that the ash content in dry matter obtained from reed canary grass may be higher and reach the value of 9.31%.

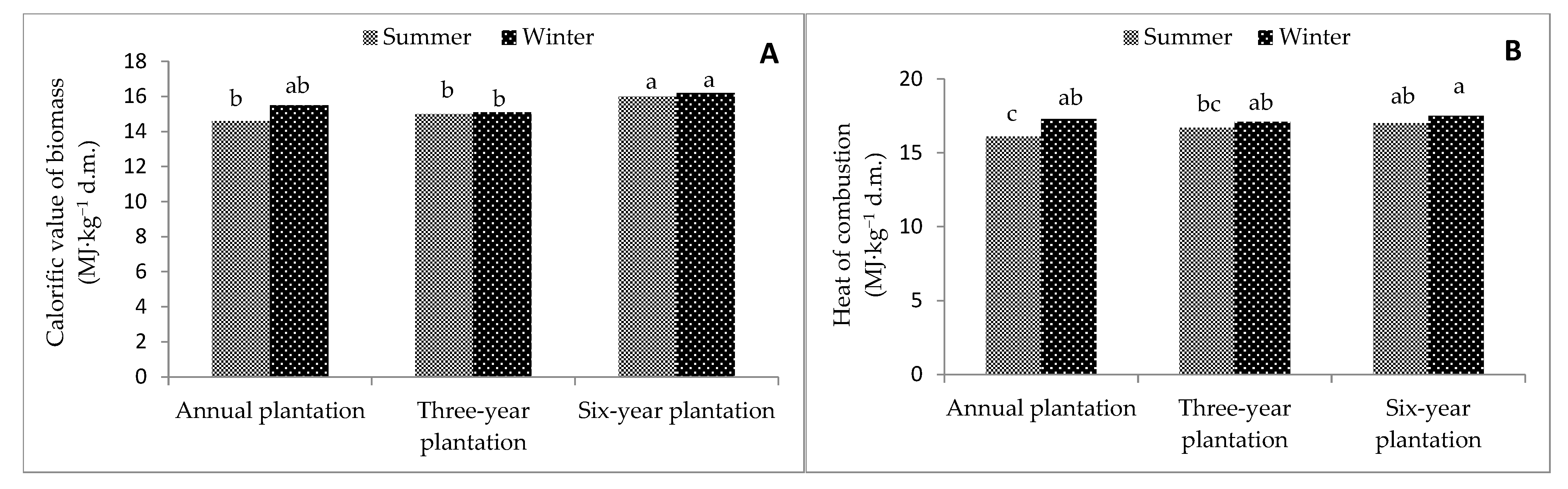

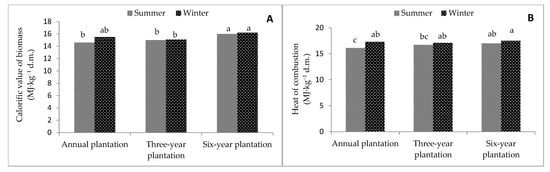

The most important thermal and physical parameters of biomass intended for energy purposes are its calorific value and combustion heat. In our own studies, it was found that the calorific value and combustion heat depended on the harvest date and the age of the plantation. Both of these parameters were the highest for biomass obtained from the winter harvest from the six-year plantation, which was statistically confirmed; they were 16.2 MJ kg−1 d.m. (calorific value) and 17.5 MJ kg−1 d.m. (combustion heat), respectively. On the other hand, the lowest statistically confirmed values obtained for these two parameters were found for biomass obtained from the summer harvest of the annual plantation (calorific value—14.6 MJ kg−1 d.m. and combustion heat—16.1 MJ kg−1 d.m.) (Figure 11A,B).

Figure 11.

Calorific value (A) and heat of combustion (B) of reed canary grass (P. arundinacea) biomass depending on the harvest time and plantation age. Means followed by same letter or symbol do not significantly differ (p = 0.05, Tukey’s HSD). Calorific value: interaction years × harvest time = 0.82; standard deviation = 0.29. Heat of combustion: interaction years × harvest time = 0.74; standard deviation = 0.26.

These values are comparable to those obtained by Heinsoo et al. [60] and Strašil [55], but lower than the values obtained by Dadrach et al. [43], Grzelak [24], Kitczak et al. [27], Muylle et al. [62], and Święczkowska et al. [56].

Also, in comparison to other plants used for energy, the calorific value of biomass from reed canary grass was significantly lower. An example is the results of Lord’s research [26], where the calorific value of miscanthus biomass was on average 19.1 MJ∙kg−1 d.m. and that for willow biomass was on average 20.3 MJ∙kg−1 d.m.

4. Conclusions

The biomass yield obtained from a purposefully established reed canary grass plantation depended on the harvest date and the age of the plantation. The highest total biomass yield of 8.75 t∙ha−1 was obtained from a six-year-old plantation. The lowest total biomass yield of 3.85 t∙ha−1 was obtained from a one-year plantation. The harvest date (summer/winter) also influenced the biomass yield. The yield obtained in the summer period was always higher (average for summer seasons was 5.05 t∙ha−1) than the yield obtained from the winter harvest (average for winter seasons was 1.98 t∙ha−1). The contents of some elements in the biomass also depended on the age of the plantation and the harvest date. An example is nitrogen (1.97% d.m.) and potassium (2.35% d.m.), the largest amounts of which were found in biomass collected in the summer from the one-year plantation. On the other hand, the highest chlorine content was found in biomass obtained from the summer harvest from the six-year plantation (0.83% d.m.).

The moisture and ash content of the obtained biomass also depended on the age of the plantation and the harvest date. The highest moisture content (12.5%) was characteristic of biomass collected in the summer from the one-year plantation. On the other hand, the lowest moisture content was found for biomass collected in the winter from the six-year plantation. The most ash was obtained from biomass collected in the summer from the annual plantation (75 g∙kg−1 d.m.) and the lowest amount was obtained from the winter harvest from the six-year plantation (45 g∙kg−1 d.m.). The highest calorific value of 16.2 MJ∙kg−1 d.m. and a combustion heat of 17.5 MJ∙kg−1 d.m. were characteristic of the biomass obtained from the winter harvest from the six-year plantation.

The total biomass yield obtained from the three-year plantation (8.50 t∙ha−1) and six-year plantation (8.75 t∙ha−1), as well as the average ash content (58–52 g∙kg−1 d.m.), average moisture (9.3–8.75%), average calorific value (15.5–16.1 t∙ha−1), and average combustion heat (16.9–17.25 t∙ha−1) of reed canary grass biomass confirm its suitability as an energy resource. A problem during the combustion of biomass obtained from several-year-old plantations may be its high chlorine content (0.426–0.449%), which, over time, may cause the so-called slagging and sintering of grates. One of the solutions to counteract this unfavorable phenomenon is following the proper regulations recommended by the boiler manufacturer, which usually consist of the appropriate configuration of the deflector and the fuel feeding time. In the case of solid fuel with high chlorine and sulfur contents, the technical break in feeding further portions of fuel should be 5 s.

In order to supplement the research in the following years, it is planned to establish a three-year rigorous experiment, the aim of which will be to demonstrate the effect of differentiated fertilization on different development stages of selected canary grass varieties in terms of their yield, the quality of their biomass for energy purposes, and the economic and energy efficiency of their production.

Author Contributions

Conceptualization, T.R.S.; methodology, T.R.S. and J.G.; validation, T.R.S. and M.Z.; formal analysis, T.R.S. and J.B. investigation, T.R.S.; resources T.R.S.; writing—original draft preparation, T.R.S. and J.G.; writing—review and editing, T.R.S., M.Z. and J.B. visualization, T.R.S.; supervision, J.G., M.Z. and T.R.S.; funding acquisition, J.G. and M.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors of the article would like to thank the company “KULAS” Agricultural-Nursery Farm for the opportunity to establish the experiment on the farm. In addition, the authors would also like to thank Bartłomiej Karamon for providing reed canary seeds and valuable comments on its cultivation and harvesting.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Annual European Union Greenhouse Gas Inventory 1990–2021 and Inventory Report 2023. p. 752. Available online: https://www.eea.europa.eu/publications/annual-european-union-greenhouse-gas-2 (accessed on 25 August 2024).

- Directive 2018/2001/EU of the European Parliament and of the Council of Dec 11 2018 on the Promotion of the Use of Energy from Renewable Sources (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/HTML/?uri=CELEX:32018L2001 (accessed on 25 August 2024).

- EC. Communication (2014) 0015 from the Commission to the European Parliament, The Council, The European Economic and Social Committee and the Committee of the Regions. A Policy Framework for Climate and Energy in the Period from 2020 to 2030, COM/2014/015 Final. Available online: https://www.eea.europa.eu/policy-documents/com-2014-15-final (accessed on 25 August 2024).

- Wiśniewski, T.P. Investigating Divergent Energy Policy Fundamentals: Warfare Assessment of Past Dependence on Russian Energy Raw Materials in Europe. Energies 2023, 16, 2019. [Google Scholar] [CrossRef]

- Share of Energy Consumption from Renewable Sources in Europe (8th EAP). Available online: https://www.eea.europa.eu/ims/share-of-energy-consumption-from (accessed on 26 August 2024).

- Malec, M. Energy use of biomass—Polish contribution to renewable energy sources. Anal. IPE 2023, 2, 1–8. (In Polish) [Google Scholar]

- Statistics Poland. Energy from Renewable Sources in 2021; Statistics Poland: Warsaw, Poland, 2022; 96p. [Google Scholar]

- Lewandowski, W.M. Pro-Ecological Renewable Sources; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2012; 432p. (In Polish) [Google Scholar]

- Maciaszczyk, M.; Czechowska-Kosacka, A.; Rzepka, A.; Lipecki, T.; Łazuka, E.; Wlaź, P. Consumer Awareness of Renewable Energy Sources: The Case of Poland. Energies 2022, 15, 8395. [Google Scholar] [CrossRef]

- Marks-Bielska, R.; Bielski, S.; Pik, K.; Kurowska, K. The Importance of Renewable Energy Sources in Poland’s Energy Mix. Energies 2020, 13, 4624. [Google Scholar] [CrossRef]

- Pietrzak, M.B.; Igliński, B.; Kujawski, W.; Iwański, P. Energy Transition in Poland—Assessment of the Renewable Energy Sector. Energies 2021, 14, 2046. [Google Scholar] [CrossRef]

- Oleszek, M.; Król, A.; Tys, J.; Matyka, M.; Kulik, M. Comparison of biogas production from wild and cultivated varieties of reed canary grass. Bioresour. Technol. 2014, 156, 303–306. [Google Scholar] [CrossRef]

- Beluhan, S.; Mihajlovski, K.; Šantek, B.; Ivančić Šantek, M. The Production of Bioethanol from Lignocellulosic Biomass: Pretreatment Methods, Fermentation, and Downstream Processing. Energies 2023, 16, 7003. [Google Scholar] [CrossRef]

- Pandur, Z.; Bačić, M.; Šušnjar, M.; Landekić, M.; Šporčić, M.; Ištok, I. Energy Gain and Carbon Footprint in the Production of Bioelectricity and Wood Pellets in Croatia. Sustainability 2024, 16, 3881. [Google Scholar] [CrossRef]

- Waliszewska, B.; Waliszewska, H.; Grzelak, M.; Majchrzak, L.; Gaweł, E.; Murawski, M.; Sieradzka, A.; Vaskina, I.; Spek-Dźwigała, A. Evaluation of changes in the chemical composition of grasses as a result of the methane fermentation process and biogas production efficiency. Energies 2024, 17, 4100. [Google Scholar] [CrossRef]

- Bełdycka-Bórawska, A.; Bórawski, P.; Borychowski, M.; Wyszomierski, R.; Bórawski, M.B.; Rokicki, T.; Ochnio, L.; Jankowski, K.; Mickiewicz, B.; Dunn, J.W. Development of Solid Biomass Production in Poland, Especially Pellet, in the Context of the World’s and the European Union’s Climate and Energy Policies. Energies 2021, 14, 3587. [Google Scholar] [CrossRef]

- Borkowska, H.; Wardzińska, K. Some effects of Sida hermaphrodita R. cultivation on sewage sludge. Pol. J. Environ. Stud. 2003, 12, 119–122. [Google Scholar]

- Jeżowski, S. The Energy plant–general characteristics, physiological conditions and significance in ecobiofuel production. Post. Nauk Rol. 2001, 48, 19–27. (In Polish) [Google Scholar]

- Kieloch, R.; Gołębowska, H.; Sienkiewicz-Cholewa, U. Impact of habitat conditions on the biological traits of the reed canary grass (Phalaris arundinacea L.). Acta Agrobot. 2015, 68, 205–210. [Google Scholar] [CrossRef][Green Version]

- Majtkowski, W. Biodiversity of energetic crops as a basis for sustainable development. Probl. Inż. Rol. 2006, 2, 25–36. (In Polish) [Google Scholar]

- Podlaski, S.; Chołuj, D.; Wiśniewski, G. Production of biomass from energy crops. Post. Nauk Rol. 2010, 62, 163–174. (In Polish) [Google Scholar]

- Szczukowski, S.; Tworkowski, J.; Stolarski, M.; Przyborowski, J. Biomass yield of willow coppice grown on arable land in annual cutting cycle. Fragm. Agron. 2004, 21, 5–18. (In Polish) [Google Scholar]

- Annuk, A.; Allik, A.; Annuk, K. Reed canary grass cultivation’s energy efficiency and fuel quality. Agron. Res. 2017, 15, 1474–1483. [Google Scholar] [CrossRef]

- Grzelak, M. Yields of reed grass and chemical composition and energetic value of reed canary grass. Fragm. Agron. 2009, 26, 38–45. (In Polish) [Google Scholar]

- Karamon, B.; Sekutowski, T.R. Yields, chemical composition and energetic value of reed canary grass (Phalaris arundinacea L.) designed for energetic purposes. Zesz. Nauk. UP Wroc. Rol. C 2012, 584, 63–72. (In Polish) [Google Scholar]

- Lord, R.A. Reed canarygrass (Phalaris arundinacea) outperforms Miscanthus or willow on marginal soils, brownfield and non-agricultural sites for local, sustainable energy crop production. Biomass Bioenergy 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Kitczak, T.; Jarnuszewski, G.; Malinowski, R. Cultivation of Reed Canary Grass (Phalaris arundinacea L.) on Light Soils in Transitional Temperate Climate to Produce Biomass and Seeds. Agriculture 2023, 13, 2129. [Google Scholar] [CrossRef]

- Burvall, J. Influence of harvest time and soil type on fuel quality in reed canary-grass (Phalaris arundinacea L.). Biomass Bioenergy 1997, 12, 149–154. [Google Scholar] [CrossRef]

- Christian, D.G.; Yates, N.E.; Riche, A.B. The effect of harvest date on the yield and mineral content of Phalaris arundinacea L. (reed canary grass) genotypes screened for their potential as energy crops in southern England. J. Sci. Food Agric. 2006, 86, 1181–1188. [Google Scholar] [CrossRef]

- Kryszak, A.; Kryszak, J.; Klarzyńska, A. Canary grass meadows (Phalaridetum arundinaceae) in the Barycz River valley. Woda—Sr.—Obsz. Wiej. 2007, 7, 209–218. (In Polish) [Google Scholar]

- Krzyżaniak, M.; Stolarski, M.J. Perennial Grasses for Energy. In Encyclopedia of Sustainable Technologies; Abraham, M.A., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 131–140. [Google Scholar]

- Księżak, J.; Faber, A. Evaluation of possibility gain of biomass with red canarygrass on Energy. Łąk. Pol. 2007, 10, 141–148. (In Polish) [Google Scholar]

- Landstrom, S.; Lomakka, L.; Andersson, S. Harvest in spring improves yield and quality of reed canary grass as a bioenergy crop. Biomass Bioenergy 1996, 11, 333–341. [Google Scholar] [CrossRef]

- Wróbel, C.; Coulman, B.E.; Smith, D.L. The potential use of reed canarygrass (Phalaris arundinacea L.) as a biofuel crop. Acta Agric. Scand. Sect. B—Soil Plant Sci. 2009, 59, 1–18. [Google Scholar] [CrossRef]

- Polskie Towarzystwo Gleboznawcze. Particle size distribution and textural classes of soils and mineral materials-classification of Polish Society of Soil Sciences 2008. Rocz. Gleboz. 2009, 60, 5–16. (In Polish) [Google Scholar]

- PN-ISO 10390/1997; Soil Quality. Determination of pH. Polish Committee for Standardization: Warszawa, Poland, 1997. (In Polish)

- PN-R-04020/1994/Az1/2004; Agrochemical Soil Analysis. Determination of Assimilated Magnesium Contents. Polish Committee for Standardization: Warszawa, Poland, 2004. (In Polish)

- PN-R-04022/1996+Az1/2002; Agrochemical Soil Analysis. Determination of Assimilated Potassium Contents. Polish Committee for Standardization: Warszawa, Poland, 2002. (In Polish)

- PN-R-04023/1996; Agrochemical Soil Analysis. Determination of Assimilated Phosphorus Contents. Polish Committee for Standardization: Warszawa, Poland, 1996. (In Polish)

- PN-80/G-04512; Solid Mineral Fuels. Determination of Ash Content. Polish Committee for Standardization: Warszawa, Poland, 1980. (In Polish)

- PN-80/G-04511; Solid Mineral Fuels–Coke. Determination of Moisture in the General Analysis Test Sample. Polish Committee for Standardization: Warszawa, Poland, 1980. (In Polish)

- PN-81/G-04513; Solid Mineral Fuels. Determination of Gross Calorific Value by the Bomb Calorimetric Method, and Calculation of Net Calorific Value. Polish Committee for Standardization: Warszawa, Poland, 1980. (In Polish)

- Dadrach, A.; Gąbka, D.; Szlachta, J.; Wolski, K. Energy value of several grass species cultivated on light soil. Łąk. Pol. 2007, 10, 29–35. (In Polish) [Google Scholar]

- Ghica, A.; Dragomir, C.; Samfira, I. Phalaris arundinacea a further energetic species. Res. J. Agric. Sci. 2012, 44, 46–51. [Google Scholar]

- Gradziuk, P.; Grzybek, A.; Kowalczyk, K.; Kościk, B. Biofuels; Wieś Jutra: Warszawa, Poland, 2003; 160p. (In Polish) [Google Scholar]

- Jeżowski, S. Energy supplying plants-productivity and some social, economic and environmental aspects of their utilization for biofuel. Post. Nauk Rol. 2003, 50, 61–73. (In Polish) [Google Scholar]

- Ibitoye, S.E.; Mahamood, R.M.; Jen, T.; Loha, L.; Akinlabi, E.T. An overview of biomass solid fuels: Biomass sources, processing methods, and morphological and microstructural properties. J. Bioresour. Bioprod. 2023, 8, 333–360. [Google Scholar] [CrossRef]

- Kuś, J.; Matyka, M. Productivity of selected crops planted for energy purposes depending on soil quality. Frag. Agron 2009, 26, 103–110. (In Polish) [Google Scholar]

- Kandel, P.T.; Sutaryo, S.; Møller, H.B.; Jørgensen, U.; Lærke, P.E. Chemical composition and methane yield of reed canary grass as influenced by harvesting time and harvest frequency. Bioresour. Technol. 2013, 130, 659–666. [Google Scholar] [CrossRef] [PubMed]

- Melts, I.; Ivask, M.; Geetha, M.; Takeuchi, K.; Heinsoo, K. Combining bioenergy and nature conservation: An example in wetlands. Renew. Sustain. Energy Rev. 2019, 111, 293–302. [Google Scholar] [CrossRef]

- Strašil, Z.; Váňa, V.; Káš, M. The reed canary grass (Phalaris arundinacea L.) cultivated for energy utilization. Res. Agric. Eng. 2005, 51, 7–12. [Google Scholar] [CrossRef]

- Tilvikienė, V.; Venslauskas, K.; Navickas, K.; Župerka, V.; Dabkevičius, Z.; Kadžiulienė, Ž. The biomass and biogas productivity of perennial grasses. Zemdirb. Agric. 2012, 99, 17–22. [Google Scholar]

- Usťak, S.; Šinko, J.; Muňoz, J. Reed canary grass (Phalaris arundinacea L.) as a promising energy crop. J. Cent. Eur. Agric. 2019, 20, 1143–1168. [Google Scholar] [CrossRef]

- Jasinskas, A.; Zaltauskas, A.; Kryzeviciene, A. The investigation of growing and using of tall perennial grasses as energy crops. Biomass Bioenergy 2008, 32, 981–987. [Google Scholar] [CrossRef]

- Strašil, Z. Evaluation of reed canary grass (Phalaris arundinacea L.) grown for energy use. Res. Agric. Eng. 2012, 58, 119–130. [Google Scholar] [CrossRef]

- Święczkowska, J.; Hołdyński, C.; Korniak, T.; Wąsowicz, K.; Kaczorowska, K. Reed canarygrass Phalaris arundinacea L. as a biofuel crop. Zesz. Nauk. UP Wroc. Rol. C 2012, 584, 129–136. (In Polish) [Google Scholar]

- Golińska, B.; Kozłowski, S. Variation in the occurrence of organic and mineral compounds in Phalaris arundinacea Zmienność w występowaniu składników organicznych i mineralnych w Phalaris arundinacea. Ann. UMCS Lub. Pol. Sect. E 2006, 61, 353–360. (In Polish) [Google Scholar] [CrossRef]

- Zardzewiały, M.; Bajcar, M.; Puchalski, C.; Gorzelany, J. The Possibility of Using Waste Biomass from Selected Plants Cultivated for Industrial Purposes to Produce a Renewable and Sustainable Source of Energy. Appl. Sci. 2023, 13, 3195. [Google Scholar] [CrossRef]

- Finell, M.; Arshadi, M.; Gref, R. Carbohydrate composition in delayed harvested reed canary grass. Biomass Bioenergy 2011, 35, 1097–1102. [Google Scholar] [CrossRef]

- Heinsoo, K.; Hein, K.; Melts, I.; Holm, B.; Ivask, M. Reed canary grass yield and fuel quality in Estonian farmers’ fields. Biomass Bioenergy 2011, 35, 617–625. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R., Jr. Combustion properties of biomass. Fuel Proc. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Muylle, H.; van Hulle, V.; de Vliegher, A.; Baert, J.; van Bockstaele, E.; Roldán-Ruiz, I. Yield and energy balance of annual and perennial lignocellulosic crops for bio-refinery use: A 4-year field experiment in Belgium. Eur. J. Agron. 2015, 63, 62–70. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).