Abstract

In today’s competitive conditions, firms compete in every aspect. It is essential to meet the quality requirements in all processes and to meet customer needs quickly. It should be ensured that all processes in the enterprises, all the technology used, and all the workforce employed are included in the total quality of the enterprise; necessary controls and corrections are made; and the quality is sustainable. In this study, (1) one of the critical processes of an enterprise, the process of a material arriving at the warehouse after its procurement and the process of its storage in the warehouse, is discussed. (2) The basic processes in storing raw materials or finished products have been redesigned based on quality with the help of the Blockchain (BC) method from Industry 4.0 (I-4.0) technologies. (3) A model has been developed for the BC-based Quality 4.0 (Q-4.0). This model was applied to the warehouse management processes of an enterprise and compared with the enterprise’s existing system. (4) As a result of the comparison, it has been seen that the developed Q-4.0 model is more effective and more comprehensive. (5) Due to the originality of the developed model, such a study is not encountered in the literature.

1. Introduction

With developing technologies, competition between businesses increases. Businesses can have a sustainable market share depending on their adaptation to these technologies. For sustainable market share, businesses must be able to manage their value chains carefully [1]. In order to overcome the difficulties that may arise in the meantime, companies need to manage their entire value chains in an agile and sensitive manner [2].

In addition, companies need imaginary structures that will allow for quick adaptation in many processes [3]. Meeting the needs ensures that the process chains of the companies are more effective. In addition, companies will grow more with the development of digitalization, where these processes can progress more smoothly by contributing to each other without harming each other [4,5]. In order to adapt to the changes in the processes, some time-studies should be performed, and unnecessary time losses should be reduced. Therefore, the quality of work will also increase.

The systems and processes used to create value evolve as technology advances. Developing processes and technologies are expected to adapt to I-4.0 to increase value production. The industrial revolution, which we call I-4.0, occurred when product processes in companies operated in a digital environment [6]. I-4.0 can be defined as the digitalization of all physical assets to create an infrastructure and stakeholders that form the e-value chain [7]. With I-4.0, all elements in the production process, namely equipment, management processes, and communication environments, are digitalized [8,9,10].

Having high technologies is the basic condition to ensure digitalization in every field. The most advanced level of technologies is evident in every sector. The continuity of this digitalization must be ensured. In this context, the sustainability of Industry 4.0 must be ensured. Iyer (2018) [11] investigated the developments in sustainable production processes. By making an exemplary application in India, the study examined what path developing economies should follow to transition to I-4.0. In recent years, the increasing environmental problems of consumers have led companies to offer environmentally monitored and certified products. Papetti et al. (2019) [12] state that a structure that can effectively model the complex supply chain process and measure the environmental sustainability of the elements of the process can be created by sharing data among stakeholders.

While new practices continue to ensure sustainability, activities such as ensuring/increasing the product/process/employee quality remain essential. Quality is the degree to which a service or product meets the specifications or possible needs. Quality means trying to ensure customer satisfaction [13]. Increasing the quality is possible by involving the employees in the process at all stages [14]. Participation of senior management employees and all team employees is required at all stages. Employees’ work to achieve business goals in line with a common goal increases the quality of the business in every field [15]. Although the importance of quality has remained the same, the concept of quality is developing and diversifying with industrial revolutions and changes in management philosophies.

1.1. Main Idea of the Study

The Total Quality Management philosophy is based on meeting quality requirements in all processes and involving the contribution of all employees in order to meet customer needs in a timely and accurate manner. Based on this idea, this study was carried out to monitor whether all processes in the enterprises, all the technology used, and all the workforce employed are up to the total quality of the enterprise; to make the necessary controls and corrections; and to ensure that the quality is sustainable. In addition, while all these are achieved, a new model that offers a digital environment with the help of I-4.0 technologies is proposed to treat the economy as a constraint. With the reference model called Q-4.0, the quality of the business processes can be monitored and controlled, and the sustainability of quality can be ensured.

1.2. Originality of the Study

In this study, the Q-4.0 model was implemented in a warehouse management system. General explanations and literature research about I-4.0 and Q-4.0 are included in the first and second parts of this study.

Additionally, how I-4.0 technologies are used sectorally has been researched. The reference model developed for Q-4.0 is explained in detail in the third part of this study, and its operation is explained. I-4.0 includes many technologies. For this study, other technologies, especially IoT, could have been used. However, when the literature was examined, it was seen that the most suitable technology for the developed model was BC. IoT technology can be used when working with real-time data. BC was preferred due to its strong security structure and ease of use. When using BC, the fact that it is easy to update instant data changes and that the tracking of data is secure thanks to the cryptographic structure brought BC technology to the fore.

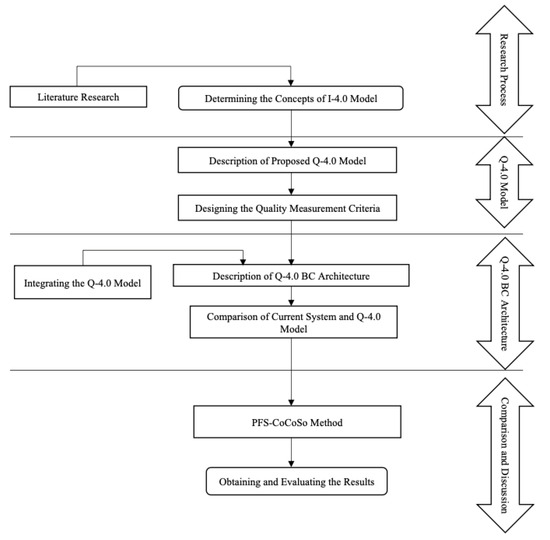

The role of I-4.0 in ensuring the quality traceability/controllability/sustainability of the technology used in all processes in the enterprises and the workforce employed is explained. The fourth Section shows the proposed Q-4.0 model and BC architectural structure. Based on this architectural structure, the application made in the warehouse management process of a business is included in the fifth chapter. The Pythagorean Fuzzy SWARA (PFS)-CoCoSo method, one of the multi-criteria decision-making methods (MCDMs), was used to demonstrate the model’s effectiveness. The general flow of the study is shown in Figure 1.

Figure 1.

Flowchart of the study.

2. Literature Research

Industry 4.0, one of the industrial revolutions, aims to increase the capacity of the processes in a business. The digitalization of the processes in the system and their automatic progress enable the formation of smart factory systems [16]. I-4.0, one of the industrial revolutions, includes many new technologies. With the help of these technologies, data transfers between processes and compatibility of devices with technology have improved [17,18].

An organization located on a specific chain where communication between technologies is at the highest level is referred to as I-4.0 [19,20]. I-4.0 technologies are implemented in many smart factories, from procurement to production, and more efficient and maximum capacity work is supported. With technological developments, the way factories work has also had to change. Smart factories have begun to be used with the use of developing technologies. The leading technologies of I-4.0 are smart activities such as smart production, smart products, and smart supply [16,21]. In smart factories, processes at any stage of production can be renewed and improved using automation [22], and work can be conducted [23] and controllable [24,25].

With the development of technology, keeping data in central systems is no longer necessary. With I-4.0, more reliable and faster communication will be provided between units because when the requested datasets increase, these data are shared only with certain people [26]. By using BC technology, data in units can be shared between departments, and updates can be made when necessary [27,28]. BC consists of a data block based on cryptography theory [29,30]. Blocks are recorded on a distributed ledger according to consensus rules agreed upon by network partners [31].

Additionally, the system allows trade between individuals without needing a trusted third party. All individuals can view the entire transaction history. A complete transaction history also ensures the validity of each virtual transaction, and all virtual transactions can be tracked from the moment they are created. It also prevents modification of existing records. Thus, the need for management decreases [32,33]. BC applications can be encountered in many areas, for example, in the tracking of materials during the supply chain process in production [34], in tracking patients by creating a digital identity in healthcare services [35] and in the intervention of patients in emergencies [36], in storing student grades and protecting personal data in the education sector [37], in ensuring data communication between suppliers and businesses [38], and in securing money transfers using bitcoin in finance [39].

The traditional meaning of quality has recently gained a more significant role. Q-4.0 can be described as the digitalization of Total Quality Management (TQM) and its impact on quality technology, processes, and individuals [40], just as it can be defined as the application of I-4.0 technologies to quality [41]. Their ability to decide how and why information should be used is crucial for quality professionals because the process must drive the use of information rather than the other way around [42]. Q-4.0 is a new concept. For this reason, Q-4.0 studies in the literature are limited. Carvalho et al. [43] conducted a study aiming to analyze the relationship between different applications of quality management and the new technologies of I-4.0, which could lead to improving quality management. Through literature review, this study has led to the development of a table that relates the relationship between quality management practices and quality-improving I-4.0 technologies as intended. Escobar et al. [44], in their study, propose a Q-4.0 initiative and a certification program for quality/production engineers, managers, and managers. The proposed work presents a method that combines six knowledge areas (statistics, quality, production, programming, learning, and optimization) and a seven-step problem-solving strategy. Singh et al. [45] used the Q-4.0 concept to digitalize the traditional Quality Management System (QMS) and demonstrated the effectiveness of the Autonomous Quality Management System (AQMS) in their application. Haleem et al. [46] explored the role of Q-4.0 and how it can be used to meet challenges and maintain healthcare quality during the pandemic.

Additionally, they have implemented essential practices of Q-4.0 in healthcare during the COVID-19 pandemic. With Q-4.0, quality can be maintained using innovative and advanced digital technologies. Christou et al. [47], in their study, created an end-to-end Q-4.0 architecture that includes machine learning and the Internet of Things. Javaid et al. [48] showed how Q-4.0 will significantly impact the production field. In their study, researchers discussed various vital aspects and enablers of Q-4.0 for manufacturing, and finally, eighteen critical applications of Q-4.0 in the field of manufacturing were identified. A summary of the studies in the literature, along with their methods, is given in Table 1.

Table 1.

Literature research methods.

Within the scope of this study, many studies in the literature have been examined. Table 1 analyzes the main studies conducted in the fields related to our study. As can be seen, I-4.0 technologies are frequently encountered in studies conducted in recent years. In our study, the BC technique from I-4.0 technologies was applied to the warehouse management system. There is no study conducted in this field using this method in the literature. Despite this, in our study, the originality of our study was increased by using different methods. The evaluation was also made with the Pythagorean Fuzzy SWARA-CoCoSo method. In addition, the study with the developed Q-4.0 architectural structure has become original among the studies conducted in the relevant field in the literature. As can be seen from Table 1, studies on Q-4.0 have generally focused on the inputs and outputs of Q-4.0. Research has been conducted on the areas in which Q-4.0 can be applied. Studies have been conducted on how Q-4.0 can be useful for different sectors. There is no Q-4.0 application in the literature as in this study.

3. Quality 4.0 Model

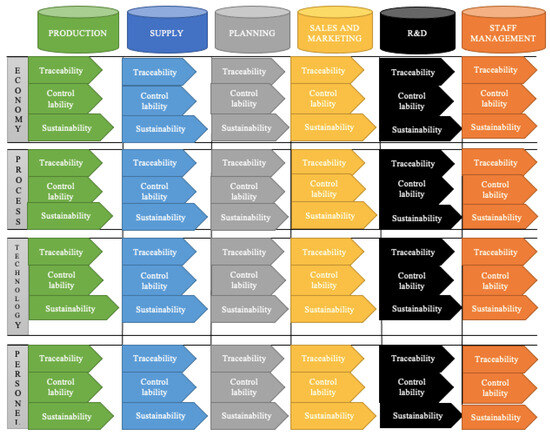

With the development of technology, it is becoming increasingly important to integrate these technologies into businesses and achieve a certain quality. In order to say to what extent a process or situation is of high quality, its quality must be measurable. Some criteria can be used to measure quality. Quality criteria are criteria used to determine the process’s quality and measure how well the process meets relevant standards. With the Q-4.0 model proposed in this study, the quality of the business will be evaluated in terms of both processes, the technology used in the processes, and the personnel operating the processes by using traceability–controllability–sustainability criteria to evaluate the level of quality met in business processes. Since cost is an essential factor when making this evaluation, it will also be considered whether all the improvement works to be carried out for the transition to Q-4.0 are economically worthwhile. The developed Q-4.0 model is shown in Figure 2.

Figure 2.

Quality 4.0 model.

In the proposed Q-4.0 model, four components must be evaluated for the business: process, technology, human resources management, and economy. Quality criteria have been determined to determine the quality of the processes, technology used, and workforce in the business (traceability, controllability, and sustainability). That is, each component will be evaluated in terms of three criteria. While ensuring traceability, controllability, and sustainability of the quality of technology in the business, it should also be monitored whether the practices and improvements made for quality are economically appropriate.

Quality Process: If the processes are controlled, repeatable, reliable, and stable, we can discuss a quality process [49]. Increasing the quality of processes will positively affect the quality of the business. However, to comment on the increase or decrease in the quality of the process, the quality must be measurable. There are studies in the literature that include the measurement [50], structuring [51], and design [52] of the process. However, studies have yet to be found in the literature that measure the quality of the process using I-4.0 technologies. The Q-4.0 model proposed in this study aims to ensure the traceability, controllability, and sustainability of the quality of the processes operated in the enterprise and, therefore, to measure the process quality.

Quality of Technology: Along with the industrial revolutions, technological development also accelerated. The use of high technology directly affects production quality. With advanced technology, demands can be responded to faster and better. Many studies in the literature include the integration of I-4.0 technologies with the technology used in production and management activities in enterprises (Internet of Things technology in product development in R&D) [53] and the use of big data in the processing of suppliers. Cloud-computing technology is used for information in purchasing [54], for keeping personnel information records in human resources [55], and for remote access to production information in production [56]. However, studies have yet to be found that use I-4.0 technologies to measure the traceability, controllability, and sustainability of the quality of the technology used in the business. The Q-4.0 model aims to ensure traceability, controllability, and sustainability of the quality of technology by using I-4.0 technologies and, therefore, to measure the quality of technology.

Quality of Personnel: For the products and services offered by businesses to be high, more is needed for the technology to be of high quality and all processes to be defined. In order to obtain more efficiency from the technology used and to run the processes more efficiently, the quality of the personnel who use the technology and run the processes must also be suitable for the technology and the process. In the literature, there are studies in which I-4.0 technologies are used to store employee information (such as using cloud-computing technology to keep the information of R&D employees [55]). The proposed Q-4.0 model aims to measure how effectively and efficiently the personnel employed in the enterprise use the technology and also to what extent it contributes to the quality of the processes in which they are involved by using I-4.0 technologies for the traceability, controllability, and sustainability of the quality of the employee.

Quality of Economy: Costs must be considered when producing quality products or services that meet customer expectations and ensure sustainable market share. Costs also increase while improving the quality of processes, employees, and technology used in the business. The economic dimension of business activities has the opposite effect on other quality components (technology, process, and employee). Economic components should also be considered when improving the quality of technology, processes, and employees. Trying to obtain more quality than the customer wants will result in a sales price that will reduce the sales rate of the product/service. This result will not comply with the general objectives of the business. A balance must be established between the process, technology, and the quality of the employees and the economy. For this reason, while trying to improve the quality of the processes, technology, and employees of the products/services produced with the Q-4.0 model, the “economy” component is considered a constraint. With I-4.0 technologies, the traceability, controllability, and sustainability of the economy component will be ensured.

The Q-4.0 Model can be applied to all business functions in the enterprise (manufacturing, procurement, planning, sales and marketing, R&D, human resources management). In the proposed Q-4.0 model, traceability, controllability, and sustainability criteria are used to evaluate the level of quality met in businesses.

Traceability of Quality: With traceability of the quality improvement process, businesses will be able to notice any coordination problems [57]. In these criteria, whether the process is run with the right method/at the right time/at the right cost is monitored, considering the quality expected from the process. In the Q-4.0 model, I-4.0 technologies are used to ensure traceability of quality. By ensuring quality traceability, problems that may arise will be responded to promptly. In any business function where the Q-4.0 model is applied, the appropriate I-4.0 technologies can be used depending on the complexity of the processes–technology or the competence of the employees. This study applied the Q-4.0 model to the warehouse management system. BC technology, one of the I-4.0 technologies, was used to ensure traceability of the processes, technology, and employee quality within the warehouse management system within the scope of the economy component. With BC technology, accessibility between authorities and relevant stakeholders is also determined, and confidentiality is ensured through information protocols. Since BC records all data, the businesses and relevant stakeholders will be able to monitor the quality of the products and ensure the traceability of products [58].

Controllability of Quality: The traceability criterion of the Q-4.0 model ensures traceability of the quality of processes, technology, and employees in the enterprise. However, it is also necessary to control the quality of processes, technology, and employees and intervene when necessary. With the criterion of controllability of quality, processes, technology, and employees will be checked in terms of quality. At the same time, they will be checked in terms of economic components. Definitions will be made to intervene if productivity decreases. In the proposed Q-4.0 model, I-4.0 technologies will be used to ensure quality controllability. As with traceability, creating an information protocol for controllability is essential. Quality controllability can be achieved with BC technology.

Sustainability of Quality: The desired quality will be achieved by ensuring the continuity of assets in a business [59]. The Q-4.0 model aims to ensure the sustainability of quality in all business functions in the enterprise. Siva et al. [60] examined studies using sustainable product development and quality management approaches. In terms of quality management support to sustainable product development, they have identified four areas: supporting sustainability through the integration of management systems, supporting the implementation of quality and environmental management systems, supporting the integration of sustainability issues, and supporting stakeholder management and customer focus. Bastas and Liyanage [61] identified critical themes for the sustainability of product quality. These include leadership, customer focus, supply chain integration, relationship management, and evidence-based decision-making. Hattinger and Stylidis [62] conducted a study to translate Q-4.0 into resilient operator 5.0 needs. Antonino et al. [63] prepared a Q-4.0 model for architecting I-4.0 systems. Quality is an important criterion when measuring the effectiveness of I-4.0 technologies [64]. Aichouni et al. [65] also presented a systematic literature review for integrating quality to I-4.0. Sader et al. [66] conducted a literature review for Q-4.0 to investigate which technologies could be implemented and how. Maganga ve Taifa [67] developed a quality management system by conceptualizing Q-4.0. Saihi et al. [68] conducted a systematic Q-4.0 literature review on what can be performed to implement quality management more effectively by utilizing I-4.0 technologies. Liu et al. [69] conducted a study on how to transition from quality management to Q-4.0. With the Q-4.0 model proposed in this study, while performing the functions in the business, it focuses on targets such as adapting to the economy, adapting to the environment, adapting to/guiding customer expectations, and improving knowledge in order to ensure environmental/social assurance, as well as ensuring the sustainability of processes, technology, and employee quality. I-4.0 technologies will be used to ensure sustainability.

With the developed Q-4.0 model, a model that can be used in six essential business functions in businesses (manufacturing, procurement, planning, sales and marketing, R&D, human resources management) is proposed. The model can be applied to all systems belonging to these functions in the enterprise. Four components (process, technology, employee, and economy) were determined to evaluate and measure quality in each function. In order to measure quality, three quality criteria were determined: traceability, controllability, and sustainability. It is recommended that I-4.0 technologies be used for these criteria.

4. Blockchain-Based Quality 4.0 Architecture

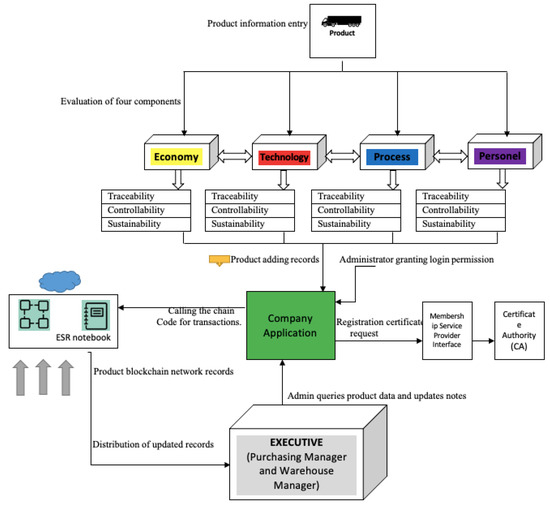

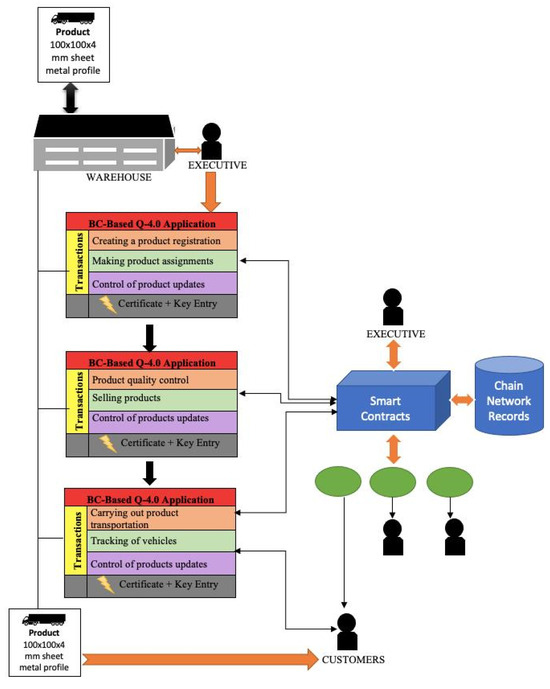

In this study, the Q-4.0 model was applied to the warehouse management system, one of the supply functions of a company that buys and sells sheet metal and profiles. An application was made for a 100 × 100 × 4 mm sheet metal profile, which is one of the product groups of the enterprise. An architecture for the Q-4.0 model has been developed using Blockchain (BC), one of the I-4.0 technologies. The architecture is shown in Figure 3.

Figure 3.

Blockchain-based Quality 4.0 architectural structure.

While the Q-4.0 model was applied to the enterprise’s warehouse management system, the sub-processes of the warehouse management system were first determined. There are four participants in the warehouse management system: product supplier, worker, warehouse manager, and purchasing manager. Afterward, a BC-based Q-4.0 architecture was created for the determined processes. With the support of BC, the participants were given the necessary authorization.

In this system, in addition to the architectural structure in the figure, CreateProductRecord, GrantAccessToProvider, GrantAccessToWarehouse, RevokeAccess, and RevokeAccessToWarehouse commands will also be included. With these commands, transactions in the blockchain algorithm will be grouped. However, various assets and smart contracts will also be defined without being limited to these. According to the architecture shown in Figure 3, system participants first request a registration certificate from the certification authority through the Membership Service Provider (MSP). They register to the system via the client application when their requests are met. The certification authority then issues the participant a new identity with their certificate and private key. All transactions are distributed through Product Blockchain Network Records. It is also recorded in the ESR (Electronic Supply Records) book. Participants have different roles in the system, and due to the BC structure, they can only access the records to which they have access rights. To register the products in the system, the warehouse manager uses the client application by calling the relevant chain code and registering the products. Once the registration process is transferred to the BC network, the updated transactions are distributed to all participants over the network. Records in the BC network are constantly updated, and updates are visible to all users. Therefore, this distribution process ensures that unauthorized users cannot change and delete every transaction. Each new transaction is added to the previous block with just a timestamp. Therefore, the network is entirely secure. Providers with high authority can query the necessary data over the network. Suppose providers with more authority (purchasing manager and warehouse manager for the application) allow providers with less authority (workers and suppliers) to view and update the records in the ESR ledger. In that case, these providers can also view and update the products’ records.

In this architectural structure, an architectural structure has been created for the use of a single warehouse and multiple users. If there is more than one warehouse in the firm, the data will be evaluated in terms of traceability, controllability, and sustainability in the developed mathematical model and will be processed in the address book in the architectural structure. Adding more users and warehouses to the system in terms of scalability will not create a problem in terms of the functioning of the architectural structure.

In cases where there are more warehouses, when real-time data are used, the variability of the data must be constantly monitored. The amount of products in each warehouse must be kept up-to-date, and users must be able to view them up-to-date when needed. Due to the flexible structure of BC, when working with real-time data, there will be no incompatibility despite the dynamic structure of the data.

5. Application

5.1. Blockchain Application

For the BC architectural structure to work, the BC algorithm must be created for each participant. The BC algorithm developed for a manager with high authority is shown in Algorithm 1. The administrator’s registration certificate is requested from the certification authority. The administrator has full access to the system, including writing, reading, updating, and removing participants. Administrators can give other participants an ID to access the BC network. If it is determined that one of the participants is making inappropriate use, the administrator can remove this participant by making a statement on the BC network. In Algorithm 2 is the BC algorithm created for the cycle of products coming from the supplier; in Algorithm 3 is the BC algorithm of a participant with less authority (worker for this application); in Algorithm 4, the BC algorithm prepared for the relevant work functions (warehouse work for this application) is shown. (The algorithms are developed for warehouse management system application, such as PHL: product registry, WHL: labor register, SHL: warehouse manager registry, NAdmin: network administrator, BN: blockchain network, WID: worker ID, PID: product ID, SID: warehouse manager ID, PK: private key, UName: user name, PREC_I: product registrations, and MPID: product movement records).

| Algorithm 1: BC algorithm in manager work |

| Input: Enrollment Certificate (EC) requested from Certification Authority (CA) Output: Access to PHL, WHL and SHL transactions for all (PHL, WHL, SHL) E BN Initialization: NAdmin should be valid node. NAdmin can Write/Read/Update/Remove nodes WID, PID, SID 1: procedure ADMIN(PID, WID, SID) 2: while (True) do 3: if (WID is valid) then 4: Add_Worker to the blockchain Network 5: Add_Worker(BN, WID) 6: Grant_access(WID, UName, PK) 7: else 8: Not_exist(WID) 9: end if 10: if (PID is valid) then 11: Add Product to the blockchain Network 12: Add_Worker(BN, PID) 13: grant_access(PID, UName, PK) 14: else 15: Not_exist(PID) 16: end if 17: if (SID is valid) then 18: Add Storage to the blockchain Network 19: Add_Storage(BN, SID) 20: grant_access(SID, UName, PK) 21: else 22: Not_exist(SID) 23: end if 24: end while 25: int N; (0 means bad behaviour, 1 means good behaviour) 26: for all (,,) do 27: if (behaviour_node(N)) then 28: Not update(WID, PID, SID) 29: else 30: Remove_update(WID, PID, SID) 31: end if 32: end for 33: end procedure |

| Algorithm 2: BC algorithm in product work |

| Input: ID and key requested from NAdmin Output: Get access to PHL transactions Initialization: PHL should be valid node. PHL can Read/Write/Grant/Revoke ESR records. 1: procedure PRODUCT(PID) 2: while (True) do 3: if (PID E BN) then 4: if (PREC_I not BN) then 5: Create_records(PID, PREC_I, BN) 6: else 7: Update_records(PID, PREC_I, BN) 8: Read_records(PID, PREC_I, WID, SID, BN) 9: end if 10: else 11: Not_exist(PID) 12: end if 13: if Visit(PID, WID, SID, BN) then 14: MPID= Moverecord(PID) 15: if then MPID E PHL(BN) 16: Grant_records(MPID, WID, SID, BN) 17: else 18: (WID, SID) <<< NOTIFY(“Movement record does not exist”) 19: end if 20: if (MPID E WID, SID Treatment_completed(PID)) then 21: Revoke_records(MPID, PREC_I, WID, SID, BN) 22: else 23: (CID, LID) <<< NOTIFY(“PID voluntary revoke MPID”) 24: Revoke_records(MPID, PREC_I, WID, SID, BN) 25: end if 26: else 27: Not Visit 28: end if 29: end while 30: end procedure |

| Algorithm 3: BC algorithm for workers’ work |

| Input: ID and key requested from NAdmin Output: Get access to WHL transactions Initialization: WHL should be valid node. WHL can Read/Write Permissioned ESR records by the workers and write movement records of the workers. 1: procedure WORKER(WID) 2: while (True) do 3: if (WID E BN) then 4: if (Granted MPID E WID) then 5: Read_records(WID, PREC_I, MPID, BN) 6: Update_records(WID, PREC_I, MPID, BN) 7: else 8: Write_records(WID, MPID, BN) 9: Read_records(WID, SID, BN) 10: end if 11: else 12: Not_exist(CID) 13: end if 14: end while 15: end procedure |

| Algorithm 4: BC algorithm in warehouse operation |

| Input: ID and key requested from NAdmin Output: Get access to SHL transactions Initialization: SHL should be valid node. SHL can Read/Write Permissioned ESR records by the workers. 1: procedure STORE(SID) 2: while (True) do 3: if (SID E BN) then 4: if (Granted MPID E SID) then 5: Read_records(SID, PREC_I, MPID, BN) 6: Write_records(SID, PREC_I, MPID, BN) 7: else 8: Read_records(SID, MPID, BN) 9: end if 10: else 11: Not_exist(SID) 12: end if 13: end while 14: end procedure |

When applying the proposed Q-4.0 model in businesses, support can be obtained from different I-4.0 technologies depending on the business function to which the model is applied. In this study, the Q-4.0 model was applied in the warehouse management system of a commercial enterprise engaged in buying and selling activities. The BC technology was preferred due to the structure of the processes in the warehouse management system.

For the warehouse management system, four participants (purchasing manager, warehouse manager, worker, and supplier representative) monitor and control the quality of all processes run from the time the product is ordered to the supplier until the business receives the product, the quality of the technology used, and the quality of the employees in the processes, and to ensure their quality is sustainable. BC algorithms are needed. Additionally, an interface was created for the participants. Thanks to this interface, all activities regarding the quality of the purchased product can be easily monitored. Participants will be able to log in to the interface using their system login information and measure the quality of activities in the warehouse management system in terms of the four quality components of the Q-4.0 model (process, technology, employee, economy) and quality criteria (traceability, controllability, and sustainability) according to their authority levels.

Participants will see the “product selection” menu after logging in from the main screen with their username and password. In this menu, participants will be able to make four different selections: product selection, warehouse selection, supplier selection, and customer selection. When the product is selected, the participant will be presented with the “main operational process” tab (supply process, product acceptance process, product placement process, and product delivery process) and the “quality component selection” tab (process, technology, employee, economy). When the quality component is selected, the participant will be able to see the quality criteria (traceability, controllability, and sustainability) of that component within their authority. When the relevant quality criterion is selected, the participant will be able to see the results of the quality measurements of that quality criterion within their authority.

The BC-based Q-4.0 model allows for many operations to be carried out efficiently and quickly. Thanks to the traceability, controllability, and sustainability criteria offered by the Q-4.0 model, any problems that may occur in quality will be noticed in a shorter time, and a solution can be provided in a shorter time. Running the Q-4.0 model based on BC will also increase the security of the warehouse management system.

The location of the products can also be tracked during transportation through this system. The locations of the vehicles on the map can be determined through this application during procurement from the supplier and delivery to the customer.

BC-based application of the proposed Q-4.0 model for the warehouse management system was made in a commercial enterprise that buys and sells sheet metal and profiles. The company has five different warehouses in Ankara. Warehouses are far from each other, and different products are stored.

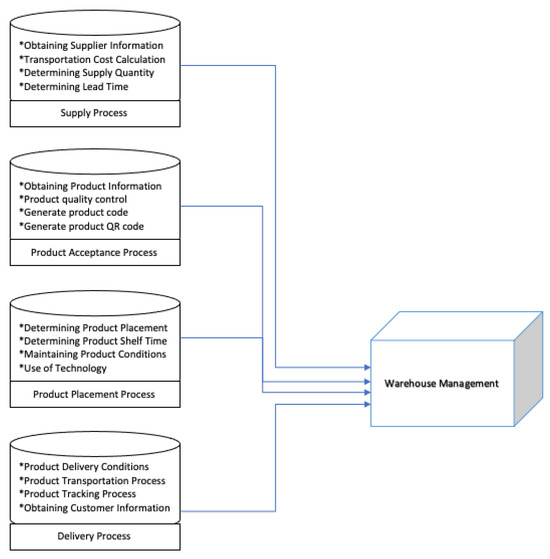

The company’s warehouse management system’s first operational process is the “ supply process.” Orders come from supplier companies at certain time intervals using company-owned vehicles. Products purchased from two different suppliers are transported to five warehouses belonging to the company. The second operational process after procuring products from supplier companies is the “product acceptance process”. When the product acceptance process is positive, the product entered into the warehouse is included in the “product placement process” operational process. Appropriate and planned placement of the warehouse is essential to ensure rapid shipment of products in line with the customer’s needs. The last operational process of the warehouse management system is the “delivery process.” Knowing in advance how much of which product is in the warehouse is very important for the timely delivery. Figure 4 shows the main operational processes of the warehouse management system.

Figure 4.

Main operational processes.

In this study, the Q-4.0 model was applied on a BC basis to ensure the traceability, controllability, and sustainability of the quality of the technology and process employees used in the four main operational processes of the warehouse management system of the enterprise within an acceptable economic framework for the enterprise. Each primary process has sub-processes and activities that need to be performed in these sub-processes. Figure 5 shows the sub-processes of the warehouse management system.

Figure 5.

Sub-processes.

The business has an existing warehouse management system where the application is made. In the current warehouse management system, product tracking can only monitor shelf status and quantity. Other systems are used to access financial, employee, and supply vehicle status information. Obtaining all this different information in an integrated manner through a single system will speed up business processes and, therefore, increase the efficiency of the business. With the BC-based Q-4.0 model, all processes of the warehouse management system, the quality of the process, the quality of the technology used, and the quality of the employee can be monitored and controlled sustainably within the economic framework determined by the business. BC algorithms will also ensure the security of the system. The application steps of the BC-based Q-4.0 model developed for the enterprise’s warehouse management system are shown in Figure 6.

Figure 6.

Blockchain-based Quality 4.0 implementation.

The proposed Q-4.0 model transfers the quality information (belonging to the product’s process, technology, and employee) of the products that the business purchases and sells to the BC network structure in a broader context. With the model, traceability, controllability, and sustainability of all information regarding quality measurement will be ensured.

5.2. Application of the Pythagorean Fuzzy SWARA(PFS)–CoCoSo Method

In this article, a PFS-CoCoSo method was also applied to evaluate the comparison of our developed method with the system used by the company where the application was made and with other stock control systems used in the sector. The reason for using this method is that it provides a more comprehensive analysis than other MCDMs in the literature. The criteria were evaluated based on expert opinions, and a selection was made among the alternatives using the CoCoSo method, considering the calculated benefit values.

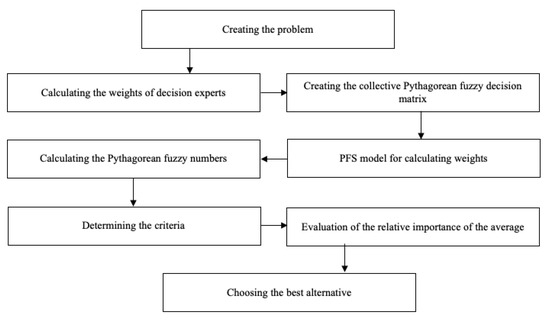

The PFS method has been widely applied to various disciplines. It can be used to estimate subjective criterion weights or the importance of attributes. SWARA is a method that works on weighting criteria, depending on priorities. There are very few studies using PFS in the literature. In this study, originality was added to the study by using the PFS-CoCoSo method. When used with PFS, the CoCoSo approach can be practical in applications with I-4.0 technologies, such as the Internet of Things. This method was preferred in this study because I-4.0 technologies were used. The application area of the CoCoSo method will be more advanced when used with PFS. A flowchart of the PFS-CoCoSo method is given in Figure 7.

Figure 7.

Flowchart of the PFS-CoCoSo method.

There are four alternatives in total, three of which are the most widely used in our country and the method we developed. Alternative methods are shown in Table 2.

Table 2.

PFS-CoCoSo method alternatives.

Here, the S1 alternative is the developed BC-based Q-4.0 model. The S2 alternative refers to the warehouse-tracking system used by the company where the application is made. In the system used by the business, the entry and exit of the products are tracked through the warehouse management software they use.

With this software, information such as the purchase price, sales price, quantity of units purchased, and purchase date of the materials purchased by the business from suppliers can also be tracked. The S3 alternative refers to the software many businesses operate in our country use.

With the S3 alternative, information such as actual warehouse quantity of products, actual warehouse quantity, product codes, stock type, buying–selling prices, and supply dates can be tracked. The S4 alternative is a software preferred by many businesses in our country, especially those that store metal and tube sheets.

With the S4 alternative, transactions such as buying and selling prices, product quantities in the warehouse, tracking with QR coding, and monitoring transfers between warehouses can be followed.

The 41 criteria were preferred as criteria in this study. While creating these criteria, the processes of a warehouse management system and the criteria and components in our model were used. The criteria are shown in Table 3.

Table 3.

PFS-CoCoSo method criteria.

Among these criteria, B1 is how to contribute to the quality of supplier information by using any I-4.0 in obtaining supplier information; criterion B2 examines the impact of the cost of obtaining supplier information at appropriate levels on the economic quality of the business; criterion B3 determines the effect of the experience and competence of the personnel involved in obtaining supplier information on the quality of information acquisition; criterion B4 examines the impact of technology use on transportation quality during the transportation of raw materials, semi-finished products, and finished products purchased from suppliers; criterion B5 determines whether the competence of the personnel working during the transportation of raw materials, semi-finished products and finished products purchased from suppliers affects the carrying capacity; criterion B6 examines the impact of technology use on order quality when determining the quantity of orders to be ordered from suppliers; criterion B7 includes the contribution of the cost of determining the order quantity to be ordered from suppliers to the economic quality of the enterprise; criterion B8 examines the impact of the personnel working on order quality in determining the quantity of orders to be ordered from suppliers; criterion B9 determines the impact of technology use on the quality of time in determining lead time; criterion B10 examines the impact of the cost of determining the lead time at appropriate levels on the quality of business economics; criterion B11 determines the effect of the competence of the personnel working in determining the supply time on the quality of the time; criterion B12 determines the impact of the use of technology in obtaining information about the products provided on the quality of information acquisition; criterion B13 determines the effect of the cost of obtaining information about the products supplied at appropriate levels on the economic quality of the enterprise; criterion B14 determines the effect of the competence of the personnel working in obtaining information about the products supplied on the quality of information acquisition; criterion B15 includes quality control of the use of technology in product quality control; criterion B16 examines the impact of the cost of product quality control at appropriate levels on the economic quality of the enterprise; criterion B17 determines the effect of the competence of the personnel performing product quality control on quality control; criterion B18 includes the use of technology in creating product QR codes; criterion B19 determines the impact of the cost of creating a product QR code at appropriate levels on the economic quality of the business; B20 criterion determines the competence of the personnel working in creating the product QR code; B21 criterion includes the use of technology when determining the placement of products in the business warehouse; B22 criterion determines the impact of the cost of determining the placement of products in the business warehouse at appropriate levels on the economic quality of the business; B23 criterion determines the competence of the personnel who place the products in the business warehouse; B24 criterion includes the use of technology in determining the shelf time of products in the warehouse; B25 criterion determines the impact of the cost of determining the shelf time of products in the warehouse at appropriate levels on the quality of business economy; B26 criterion determines the competence of the personnel working in determining the shelf time of the products in the warehouse; criterion B27 includes the use of technology while maintaining product conditions; criterion B28 examines the impact of the cost of maintaining product conditions at appropriate levels on the economic quality of the enterprise; criterion B29 determines the competence of personnel in maintaining product conditions; B30 criterion includes the use of technology when determining product delivery conditions; B31 criterion, the effect of appropriate cost levels in determining product delivery conditions on the economic quality of the enterprise; B32 criterion determines the competence of the personnel working in determining product delivery conditions; criterion B33 examines the impact of technology use in the product transportation process on the quality of the transportation process; criterion B34 determines the impact of the cost of the product transportation process at appropriate levels on the economic quality of the enterprise; B35 criterion determines the effect of the competence of the personnel working in the product transportation process on the quality of the transportation process; criterion B36 examines the impact of technology use in the product-tracking process on the quality of product tracking; criterion B37 determines the impact of the cost of the product-tracking process at appropriate levels on the economic quality of the business; criterion B38 determines the impact of the competence of the personnel working in the product-tracking process on the quality of the tracking process; criterion B39 examines the impact of technology use in obtaining customer information on the quality of information acquisition; criterion B40 examines the impact of the cost of obtaining customer information at appropriate levels on the economic quality of the business; criterion B41 also measures the impact of the competence of the personnel working in obtaining customer information on the quality of information acquisition.

The three decision experts (DEs) who evaluated this method were selected from various businesses according to their work and profession. The number of years that the DEs had worked in their fields of expertise was also considered. Data obtained from the business were used for evaluations.

The three DEs selected for the method were evaluated through an online survey using the linguistic variables given in Table 4 below. The weights given by DEs are shown as Pythagorean Fuzzy Numbers (PFN). Then, the PFS method was applied to calculate the criterion weight, considering the weights specified by the DEs. The CoCoSo method was used to rank the alternatives according to weighted criteria. Below, the PFS-CoCoSo method is explained in detail.

Table 4.

Linguistic values of options and degrees of decision experts.

The decision-making process is scientifically and logically choosing the best option. When decision experts make such decisions, it is necessary to evaluate the alternatives by considering essential criteria from various aspects for the decisions to be considered multi-criteria. In this study, decision experts used linguistic variables to apply Pythagorean fuzzy sets against uncertainties. Below are the steps of the PFS-CoCoSo method.

Step 1: Creating an MCDM problem:

S = {S1,S2,…,Sm} set of alternatives, B = {B1,B2,…,Bn} set of criteria, P = (), and each i,j denotes the decision experts. The set of decision experts {E1, E2, …, Eι} is shown.

Step 2: Calculating the weights of decision experts:

In the MCDM, evaluating the weights decision experts allocate is very important. k. In order to evaluate the weight of the decision expert, (bk, nk) shows the rating of experts given by a decision expert. In this case, the weight value is calculated as follows:

Step 3: Creating the collective Pythagorean fuzzy decision matrix:

Linguistic values are used to form the collective Pythagorean fuzzy decision matrix. These linguistic values are given in the table below.

Step 4: PFS model for calculating weights:

The following tables are used to estimate weights. As we mentioned, the first step in making a decision is to create the decision matrix.

Step 5: Exact degrees are estimated. Point degrees of Pythagorean fuzzy numbers are calculated with Equation (2).

Step 6: Criteria are selected. Criteria are prioritized from most important to least important according to the decision experts’ preferences.

Step 7: The relative importance of the average value is evaluated. The importance is estimated from the criterion listed in the second position, and the relative importance is calculated by comparing the Bj criterion with the Bj−1 criterion.

Step 8: The relative coefficient Kj can be calculated as follows:

Step 9: Weights are calculated. The recalculated weight is defined as ρj.

Step 10: Normalized weights are calculated. Criterion weights are normalized as follows:

Step 11: Normalized Pythagorean fuzzy decision-making is evaluated.

Step 12: Evaluation of the weighted sum model, weighted product model:

It is calculated with the weighted sum model Ci(1) and the weighted product model Ci(2) as follows:

Step 13: Balancing the scores of the alternatives:

This step involves evaluation scores to evaluate the balanced consensus score of the alternatives, which is derived as follows:

Here, γ is the decision strategy coefficient.

Step 14: The general situation is evaluated.

The consensus index Qi is evaluated to indicate the importance of the alternative as follows:

The priorities of the alternatives are calculated by increasing the degrees of the consensus index Q.

In applying the PFS-CoCoSo method, Table 4 and Table 5 show the weights given by decision experts as linguistic values. The information in Table 6 was created using the values in Table 7 and using Equation (1). The weights of three decision experts on the alternatives for different criteria are shown in Table 8. The weight of each criterion created by decision experts using PFS is given in Table 9. Each decision expert was asked to select the importance of each criterion. Using Equations (4)–(6), decision experts ranked all available features from first to last. Based on PFS, the criterion with the highest importance was given first place, while the criterion with the most minor importance was given last place. Overall rankings obtained by decision experts were estimated. The weights of all criteria are shown as wj in Table 10. Using Equations (10)–(13), the results of the PFS-CoCoSo model were estimated and shown in Table 11. According to the results obtained according to the consensus index Qi value, the order was S1 > S2 > S3 > S4. In line with these results, it was seen that the best option was the Q-4.0 model (S1) we developed. The software used by the company where the application was made (S2) ranked second.

Table 5.

Linguistic values of options and degrees of performance.

Table 6.

Decision experts’ weights for evaluating options.

Table 7.

Linguistic values determined by decision experts for the criteria.

Table 8.

Pythagorean fuzzy values of criteria and alternatives determined by decision experts.

Table 9.

Linguistic values of the criteria given by decision experts.

Table 10.

Determining the importance criteria using the PFS method.

Table 11.

General ranking of alternatives.

6. Discussion

When the current warehouse management system of the business and the quality criteria (traceability, controllability, and sustainability) of the proposed BC-based Q-4.0 model are compared according to the quality components (process, technology, employee, and economy), the proposed BC-based Q-4.0 model will be much more beneficial for the business. It was observed that it met the criteria more. The comparison of the two systems according to the process quality component is in Table 12; the comparison according to the technology quality component is in Table 13; the comparison according to the employee quality component is in Table 14; the comparison according to the economy quality component is shown in Table 15.

Table 12.

Benchmarking for process criteria.

Table 13.

Benchmarking for technology criteria.

Table 14.

Benchmarking for personnel criteria.

Table 15.

Benchmarking for economic criteria.

According to the process quality component comparison between the current system and the proposed system given in Table 12, the main difference is in the warehouse’s monitoring and control of waiting times. While monitoring and control are carried out manually in the current system, these times can be viewed and controlled from the network structure with the BC algorithms of the Q-4.0 model. If there is a problem and it is necessary to intervene in subsequent processes, it can intervene quickly.

According to the technology quality component comparison between the current and proposed systems in Table 13, the two systems are similar regarding product entry, exit, and product inquiry. However, while the movements of the products after leaving the warehouse cannot be tracked in the current system, they can be tracked with the recommended Q-4.0 model. In addition, while efficiency calculations cannot be made in the current system, real-time efficiency calculations can be made in the proposed Q-4.0 model, as the current capacity and occupancy rate can be seen instantly.

Table 14 compares the employee quality component between the current and proposed systems. Work has yet to be conducted on the employee quality component in the current system. The employee list prepared for product purchase, sale, and shipment is recorded in a document separate from the warehouse management system. The list has yet to be transferred to the existing warehouse management system. Information about all employees is available in the BC base of the proposed Q-4.0 model. Employee movements and changes can be viewed and reported in real-time.

The main difference, according to the economy quality component comparison between the current system and the proposed system shown in Table 15, is that in the current system, there is only economic data about the product, while in the proposed Q-4.0 model, there is also information about other components related to the product. While cost calculations cannot be made for products in the current warehouse management system, real-time cost calculations can be made in the Q-4.0 model.

In the company’s existing warehouse management system, anyone in the warehouse management system can view and make changes to the purchase. In the proposed BC-based Q-4.0 model, product purchase information can only be viewed by authorized users, thanks to the cryptographic structure provided by BC. There are limited permissions for changes to the system, and changes can only be made by authorized users. With the BC base, the security of the warehouse management system will increase.

7. Conclusions

This study describes the Q-4.0 model, which was developed to ensure the traceability, controllability, and sustainability of all processes in a business; the technology used in the processes; and the quality of the employees in the processes within an acceptable economic framework for the business. The model can be used in all business functions (manufacturing, procurement, planning, sales and marketing, R&D, and human resources management) by utilizing I-4.0 technologies. By using augmented-reality technology from I-4.0 technologies in the production department, a suitable production plan can be prepared for a company with the developed model. By using cloud technology in the supply department, the traceability of all suppliers can be ensured. A suitable plan can be created for a company by using IoT for planning. By using augmented reality for sales and marketing, the most suitable potential customers in the sector can be determined. A secure data control can be provided for R&D by using BC technology. By integrating cloud technology into the developed model for human resources management, the most effective management of employees can be provided. The business application of the proposed Q-4.0 model was made with the support of BC technology for the warehouse management system.

The products in the warehouse are tracked in the warehouse management system currently used by the company that buys and sells sheet metal and profiles. More is needed to measure the quality of processes–technology–employees. With the Q-4.0 model developed based on BC, the quality of all sub-processes in the warehouse management system, the quality of the technology used in the processes, and the quality of the employees in the processes can be monitored and controlled according to the economic constraints of the business. What needs to be carried out to ensure the sustainability of quality will be known.

With BC, a cryptographic structure is created in the system, and all system components are connected, ensuring a secure information flow. Thanks to the chain structure, product information can be viewed instantly. Thanks to the certification in the system, data/information security has increased significantly compared to the current system. No unauthorized person can view or make changes to the system.

With the use of the PFS-CoCoSo method, the effectiveness of the developed Q-4.0 model has been seen. Along with the model, a comparison of three different leading methods in the industry was made. As a result, the most comprehensive and suitable option was the Q-4.0 model developed.

Author Contributions

Conceptualization, methodology, software, validation, formal analysis, investigation, resources, data curation, writing—original draft preparation, writing—review and editing, visualization, supervision, project administration, and funding acquisition were all carried out by T.K. and E.B. together. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, G.; Hou, Y.; Wu, A. Fourth industrial revolution: Technological drivers, impacts and coping methods. Chin. Geogr. Sci. 2017, 27, 626–637. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Gligor, D.M.; Holcomb, M.C. Antecedents and consequences of supply chain agility: Establishing the link to firm performance. J. Bus. Logist. 2012, 33, 295–308. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. A critical investigation of industry 4.0 in manufacturing: Theoretical operationalization framework. Prod. Plan. Control 2018, 29, 633–644. [Google Scholar] [CrossRef]

- Cottyn, J.; Landeghem, H.V.; Stockman, K.; Derammelaere, S. A method to align a manufacturing execution system with lean objectives. Int. J. Prod. Res. 2011, 49, 4397–4413. [Google Scholar] [CrossRef]

- Weking, J.; Stöcker, M.; Kowalkiewicz, M.; Böhm, M.; Krcmar, H. Archetypes for industry 4.0 business model innovations. In Proceedings of the Twenty-Fourth Americans Conference on Information Systems, New Orleans, LA, USA, 16–18 August 2018. [Google Scholar]

- Bibby, L.; Dehe, B. Defining and assessing industry 4.0 maturity levels–case of the defence sector. Prod. Plan. Control 2018, 29, 1030–1043. [Google Scholar] [CrossRef]

- Alcacer, V.; Cruz-Machado, V. Scanning the industry 4.0: A literature review on Technologies for manufacturing systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Ku, C.; Chien, C.; Ma, K. Digital transformation to empower smart production for industry 3.5 and an empirical study for textile dyeing. Comput. Ind. Eng. 2020, 142, 106297. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Iyer, A. Moving from industry 2.0 to industry 4.0: A case study from India on leapfrogging in smart manufacturing. Procedia Manuf. 2018, 21, 663–670. [Google Scholar] [CrossRef]

- Papetti, A.; Marconi, M.; Rossi, M.; Germani, M. Web-based platform for eco-sustainable supply chain management. Sustain. Prod. Consum. 2019, 17, 215–228. [Google Scholar] [CrossRef]

- Budianto, A. Customer loyalty: Quality of service. J. Manag. Rev. 2019, 3, 299–305. [Google Scholar] [CrossRef]

- Kauffman, R.; Dougles, Z. Quality Management Plus: The Continuous Improvement of Education; Corwin Press, Inc.: Thousand Oaks, CA, USA, 1993. [Google Scholar]

- Othman, I.; Ghani, S.N.M.; Choon, S.W. The total quality management (TQM) journey of Malaysian building contractors. Ain Shams Eng. J. 2020, 11, 697–704. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Ozsoylu, A.F. Endustri 4.0. J. Cukurova Univ. Fac. Econ. Adm. Sci. 2017, 21, 41–64. [Google Scholar]

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in management studies: A systematic literature review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Fox, B.; Subic, A. An industry 4.0 approach to the 3D printing of composite materials. Engineering 2019, 5, 621–623. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital twins and cyber-physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Brettel, M.; Friederichsen, N.; Keller, M.; Rosenberg, M. How virtualization, decentralization and network building change the manufacturing landscape: An industry 4.0 perspective. Int. J. Sci. Eng. Technol. 2014, 8, 37–44. [Google Scholar]

- Wang, Q.; Zhu, X.; Ni, Y.; Gu, L.; Zhu, H. Blockchain for the IoT and industrial IoT: A review. Internet Things 2020, 10, 100081. [Google Scholar] [CrossRef]

- Radziwon, A.; Bilberg, A.; Bogers, M.; Madsen, E.S. The smart factory: Exploring adaptive and flexible manufacturing solutions. Procedia Eng. 2014, 69, 1184–1190. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big databased feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Kshetri, N. Blockchain’s roles in strengthening cybersecurity and protecting privacy. Telecommun. Policy 2017, 41, 1027–1038. [Google Scholar] [CrossRef]

- Rao, A.R.; Clarke, D. Perspective on emerging directions in using IoT devices in blockchain applications. Internet Things 2020, 10, 100079. [Google Scholar] [CrossRef]

- Gupta, R.A.; Chow, M.Y. Networked control system: Overview and research trends. IEEE Trans. Ind. Electron. 2010, 57, 2527–2535. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System 2017. Available online: http://www.bitcoin.org (accessed on 10 June 2021).

- Agrawal, T.K.; Kumar, V.; Pal, R.; Wang, L.; Chen, Y. Blockchain-based framework for supply chain traceability: A case example of textile and clothing industry. Comput. Ind. Eng. 2021, 154, 107130. [Google Scholar] [CrossRef]

- Swan, M. Blockchain: Blueprint for a new Economy. O’reilly Media Inc.: Newton, MA, USA, 2015. [Google Scholar]

- Beck, R.; Czepluch, J.S.; Lollike, N.; Malone, S. Blockchain-the Gateway to Trust-Free Cryptographic Transactions; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–14. [Google Scholar]

- Risius, M.; Spohrer, K. A blockchain research framework. Bus. Inf. Syst. Eng. 2017, 59, 385–409. [Google Scholar] [CrossRef]

- Ducas, E.; Wilner, A. The security and financial implications of blockchain technologies: Regulating emerging technologies in Canada. Int. J. 2017, 72, 538–562. [Google Scholar] [CrossRef]

- Kuo, T.T.; Kim, H.E.; Ohno-Machado, L. Blockchain distributed ledger Technologies for biomedical and healthcare applications. J. Am. Med. Inform. Assoc. 2017, 24, 1211–1220. [Google Scholar] [CrossRef]

- Tandon, A.; Dhir, A.; Islam, A.K.M.N.; Mantymaki, M. Blockchain in healthcare: A systematic literature review, synthesizing framework and future research agenda. Comput. Ind. 2020, 122, 103290. [Google Scholar] [CrossRef]

- Chen, G.; Xu, B.; Lu, M.; Chen, N. Exploring blockchain technology and its potential applications for education. Smart Learn. Environ. 2018, 5, 1. [Google Scholar] [CrossRef]

- Thoben, K.; Wiesner, S.; Wuest, T. Industry 4.0 and smart manufacturing—A review of research issues and application examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- Pisa, M.; Juden, M. Blockchain and economic development: Hype vs. reality. Cent. For. Glob. Dev. 2017, 107, 5–7. [Google Scholar]

- Jacob, D. (n.d.). Quality 4.0 Impact and Strategy Handbook. 2017. Available online: https://www.sas.com/content/dam/SAS/en_us/doc/whitepaper2/quality-4-0-impact-strategy-109087.pdf (accessed on 31 May 2021).

- Bowers, K.; Pickerel, T.V. Vox Pouli 4.0: Big data tools zoom in on the voice of the customer. Qual. Progress. 2019, 52, 32–39. [Google Scholar]

- ASQ. Industry and Quality 4.0: Bringing them Together. Quality Magazine. 2018. Available online: https://www.qualitymag.com/articles/95011-industry-and-quality-40-bringing-them-together (accessed on 31 July 2021).

- Carvalho, A.V.; Enrique, D.V.; Chouchene, A.; Charrua-Santos, F. Quality 4.0: An overview. Procedia Comput. Sci. 2021, 181, 341–346. [Google Scholar] [CrossRef]

- Escobar, C.A.; Chakraborty, D.; MCgovern, M.; Macias, D.; Morales-Menendez, R. Quality 4.0-Green, black and master black belt curricula. Procedia Manuf. 2021, 53, 748–759. [Google Scholar] [CrossRef]

- Singh, J.; Ahuja, I.P.S.; Singh, H.; Singh, A. Development and implementation of autonomous quality management system (AQMS) in an automotive manufacturing using quality 4.0 concept—A case study. Comput. Ind. Eng. 2022, 168, 108121. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Singh, R.P.; Suman, R. Quality 4.0 technologies to enhance traditional Chinese medicine for overcoming healthcare challenges during COVID-19. Digit. Chin. Med. 2021, 4, 71–80. [Google Scholar] [CrossRef]

- Christou, I.T.; Kefalakis, N.; Soldatos, J.K.; Despotopoulou, A.-M. End-to-end industrial IoT platform for Quality 4.0 applications. Comput. Ind. 2022, 137, 103591. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Significance of Quality 4.0 towards comprehensive enhancement in manufacturing sector. Sens. Int. 2021, 2, 100109. [Google Scholar] [CrossRef]

- Vörös, J.; Rappai, G. Process quality adjusted lot sizing and marketing interface in JIT environment. Appl. Math. Model. 2016, 40, 6708–6724. [Google Scholar] [CrossRef]

- Benesova, A.; Hirman, M.; Steiner, F.; Tupa, J. Determination of changes in process management within Industry 4.0. Procedia Manuf. 2019, 38, 1691–1696. [Google Scholar] [CrossRef]

- Kabugo, J.C.; Jamsa-Jounela, S.L.; Schiemann, R.; Binder, C. Industry 4.0. based process data analytics platform: A waste-to-energy plant case study. Int. J. Electr. Power Energy Syst. 2020, 115, 105508. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunities at the product, process, and system levels. Resour. Conversat. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Landherr, M.; Schneider, U.; Bauernhansl, T. The application center Industry 4.0–industry-driven manufacturing, research and development. Procedia CIRP 2016, 57, 26–31. [Google Scholar] [CrossRef]

- Yu, F.; Schweisfurth, T. Industry 4.0 technology implementation in SMEs—A survey in the Danish-German border region. Int. J. Innov. Stud. 2020, 4, 76–84. [Google Scholar] [CrossRef]

- Neumann, W.P.; Winkelhaus, S.; Groose, E.H.; Glock, C.H. Industry 4.0 and the human factor—A systems framework and analysis methodology for successful development. Int. J. Prod. Econ. 2021, 233, 107992. [Google Scholar] [CrossRef]

- Grassi, A.; Guizzi, G.; Santillo, L.C.; Vespoli, S. A semi-heterarchical production control architecture for industry 4.0—Based manufacturing systems. Manuf. Lett. 2020, 24, 43–46. [Google Scholar] [CrossRef]

- Ramesh, B. Process knowledge management with traceability. IEEE Softw. 2002, 19, 50–52. [Google Scholar] [CrossRef]

- Baran, E.; KorkusuzPolat, T. Classification of industry 4.0 for total quality management: A review. Sustainability 2022, 14, 3329. [Google Scholar] [CrossRef]

- Daoutidis, P.; Zachar, M.; Jogwar, S.S. Sustainability and process control: A survey and perspective. Chem. Eng. Mater. Sci. 2016, 44, 184–206. [Google Scholar] [CrossRef]

- Siva, V.; Gremyr, I.; Bergquist, B.; Garvare, R.; Zobel, T. The support of quality management to sustainable development: A literature review. J. Clean. Prod. 2016, 138, 148–157. [Google Scholar] [CrossRef]

- Bastas, A.; Liyanage, K. Sustainable supply chain management: A systematic review. J. Clean. Prod. 2018, 181, 726–744. [Google Scholar] [CrossRef]

- Hattinger, M.; Stylidis, K. Transforming quality 4.0 towards resilient operator 5.0 needs. Procedia CIRP 2023, 120, 1600–1605. [Google Scholar] [CrossRef]

- Antonino, P.O.; Capilla, R.; Pelliccione, P.; Schnicke, F. A quality 4.0 model for architecting industry 4.0 systems. Adv. Eng. Inform. 2022, 54, 101801. [Google Scholar] [CrossRef]

- Memika, T.; KorkusuzPolat, T. Internet of things supported airport boarding system and evaluation with fuzzy. Intell. Autom. Soft Comput. 2023, 35, 026955. [Google Scholar] [CrossRef]

- Aichouni, A.B.E.; Silva, C.; Ferreira, L.M.D. A systematic literature review of the integration of total quality management and industry 4.0: Enhancing sustainability performance through dynamic capabilities. Sustainability 2024, 16, 9108. [Google Scholar] [CrossRef]

- Sader, S.; Husti, I.; Daroczi, M. A review of quality 4.0: Definitions, features, technologies, applications and challenges. Total Qual. Manag. Bus. Excell. 2022, 33, 1164–1182. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W.R. Quality 4.0 conceptualisation: An emerging quality management concept for manufacturing industries. TQM J. 2023, 35, 389–413. [Google Scholar] [CrossRef]

- Saihi, A.; Awad, M.; Ben-Daya, M. Quality 4.0: Leveraging industry 4.0 technologies to improve quality management practices—A systematic review. Int. J. Qual. Reliab. Manag. 2023, 40, 628–650. [Google Scholar] [CrossRef]

- Liu, H.C.; Gu, X.; Yang, M. From total quality management to quality 4.0: A systematic literature review and future research agenda. Front. Eng. Manag. 2023, 10, 191–205. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).