Activated Carbon from Coconut Shells as a Modifier of Urea–Formaldehyde Resin in Particleboard Production

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reh, R.; Kristak, L.; Kral, P.; Pipiska, T.; Jopek, M. Perspectives on Using Alder, Larch, and Birch Wood Species to Maintain the Increasing Particleboard Production Flow. Polymers 2024, 16, 1532. [Google Scholar] [CrossRef]

- Hua, L.S.; Chen, L.W.; Geng, B.J.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W. Particleboard from Agricultural Biomass and Recycled Wood Waste: A Review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar]

- Antov, P.; Savov, V.; Krišťák, Ľ.; Réh, R.; Mantanis, G.I. Eco-Friendly, High-Density Fiberboards Bonded with Urea-Formaldehyde and Ammonium Lignosulfonate. Polymers 2021, 13, 220. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliačik, J.; Noshchenko, G.; Kačík, F.; Bekhta, N. Characteristics of Beech Bark and Its Effect on Properties of UF Adhesive and on Bonding Strength and Formaldehyde Emission of Plywood Panels. Eur. J. Wood Wood Prod. 2021, 79, 423–433. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Walkiewicz, J.; Woźniak, M.; Dziurka, D.; Mirski, R. The Effect of Urea-Formaldehyde Adhesive Modification with Propylamine on the Properties of Manufactured Plywood. J. Adhes. 2023, 99, 1427–1440. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H.; Kazemi-Najafi, S.; Eshkiki, R.B.; Pizzi, A. Improving Urea Formaldehyde Resin Properties by Glyoxalated Soda Bagasse Lignin. Eur. J. Wood Prod. 2015, 73, 77–85. [Google Scholar] [CrossRef]

- Selakjani, P.P.; Dorieh, A.; Pizzi, A.; Shahavi, M.H.; Hasankhah, A.; Shekarsaraee, S.; Ashouri, M.; Movahed, S.G.; Abatari, M.N. Reducing Free Formaldehyde Emission, Improvement of Thickness Swelling and Increasing Storage Stability of Novel Medium Density Fiberboard by Urea-Formaldehyde Adhesive Modified by Phenol Derivatives. Int. J. Adhes. Adhes. 2021, 111, 102962. [Google Scholar] [CrossRef]

- Dorieh, A.; Selakjani, P.P.; Shahavi, M.H.; Pizzi, A.; Movahed, S.G.; Pour, M.F.; Aghaei, R. Recent Developments in the Performance of Micro/Nanoparticle-Modified Urea-Formaldehyde Resins Used as Wood-Based Composite Binders: A Review. Int. J. Adhes. Adhes. 2022, 114, 103106. [Google Scholar] [CrossRef]

- Kumar, R.N.; Pizzi, A. Environmental Aspects of Adhesives–Emission of Formaldehyde. In Adhesives for Wood and Lignocellulosic Materials; Wiley-Scrivener Publishing: Hoboken, NJ, USA, 2019; pp. 293–312. [Google Scholar]

- Demir, A. Determination of the Effect of Valonia Tannin When Used as a Filler on the Formaldehyde Emission and Adhesion Properties of Plywood with Artificial Neural Network Analysis. Int. J. Adhes. Adhes. 2023, 123, 103346. [Google Scholar] [CrossRef]

- Mazaheri, M.; Moghimi, H.; Taheri, R.A. Urea Impregnated Multiwalled Carbon Nanotubes; a Formaldehyde Scavenger for Urea Formaldehyde Adhesives and Medium Density Fiberboards Bonded with Them. J. Appl. Polym. Sci. 2022, 139, 51445. [Google Scholar]

- Kumar, A.; Gupta, A.; Sharma, K.V. Thermal and Mechanical Properties of Urea-Formaldehyde (UF) Resin Combined with Multiwalled Carbon Nanotubes (MWCNT) as Nanofiller and Fiberboards Prepared by UF-MWCNT. Holzforschung 2015, 69, 199–205. [Google Scholar] [CrossRef]

- Łukawski, D.; Hochmańska-Kaniewska, P.; Bałęczny, W.; Martin, A.; Janiszewska-Latterini, D.; Lekawa-Raus, A. Phenol-Formaldehyde Resin Enriched with Graphene Nanoplatelets as an Electroconductive Adhesive for Wood Composites. Int. J. Adhes. Adhes. 2024, 132, 103678. [Google Scholar] [CrossRef]

- Saito, K.; Hirabayashi, Y.; Yamanaka, S. Reduction of Formaldehyde Emission from Urea-Formaldehyde Resin with a Small Quantity of Graphene Oxide. RSC Adv. 2021, 11, 32830–32836. [Google Scholar] [CrossRef] [PubMed]

- Jazayeri, R.; Najafi, S.K.; Younesi, H. Modified Graphene as Potential Additive for Urea Formaldehyde (UF) Resin in Medium Density Fiberboard (MDF) Manufacturing. Int. J. Adhes. Adhes. 2023, 126, 103448. [Google Scholar] [CrossRef]

- Baker, F.S.; Miller, C.E.; Repik, A.J.; Tolles, E.D. Activated Carbon. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2000; ISBN 978-0-471-23896-6. [Google Scholar]

- Danish, M.; Ahmad, T. A Review on Utilization of Wood Biomass as a Sustainable Precursor for Activated Carbon Production and Application. Renew. Sustain. Energy Rev. 2018, 87, 1–21. [Google Scholar] [CrossRef]

- Kang, Y.-J.; Jo, H.-K.; Jang, M.-H.; Ma, X.; Jeon, Y.; Oh, K.; Park, J.-I. A Brief Review of Formaldehyde Removal through Activated Carbon Adsorption. Appl. Sci. 2022, 12, 5025. [Google Scholar] [CrossRef]

- Aussawasathien, D.; Jariyakun, K.; Pomrawan, T.; Hrimchum, K.; Yeetsorn, R.; Prissanaroon-Ouajai, W. Preparation and Properties of Low Density Polyethylene-Activated Carbon Composite Foams. AIP Conf. Proc. 2017, 1914, 60003. [Google Scholar] [CrossRef]

- Nisar, M.; Thue, P.S.; Maghous, M.B.; Geshev, J.; Lima, E.C.; Einloft, S. Metal Activated Carbon as an Efficient Filler for High-density Polyethylene Nanocomposites. Polym. Compos. 2020, 41, 3184–3193. [Google Scholar] [CrossRef]

- Salleh, Z.; Islam, M.M.; Yusop, M.Y.M.; Idrus, M.M.M. Mechanical Properties of Activated Carbon (AC) Coconut Shell Reinforced Polypropylene Composites Encapsulated with Epoxy Resin. APCBEE Procedia 2014, 9, 92–96. [Google Scholar] [CrossRef]

- Gong, J.; Tian, N.; Liu, J.; Yao, K.; Jiang, Z.; Chen, X.; Wen, X.; Mijowska, E.; Tao, T. Synergistic Effect of Activated Carbon and Ni2O3 in Promoting the Thermal Stability and Flame Retardancy of Polypropylene. Polym. Degrad. Stab. 2014, 99, 18–26. [Google Scholar] [CrossRef]

- Chandra, T.O.; Sentanu, D.A.; Gornes, W.; Sentanuhady, J.; Setiawan, A.; Santos, G.N.; Muflikhun, M.A. Tensile Properties of Epoxy Resin Filled with Activated Carbon Derived from Coconut Shell. Mater. Today Proc. 2022, 66, 2967–2971. [Google Scholar] [CrossRef]

- Wu, J.; Chung, D.D.L. Calorimetric Study of the Effect of Carbon Fillers on the Curing of Epoxy. Carbon 2004, 42, 3039–3042. [Google Scholar] [CrossRef]

- Angin, N.; Ertas, M.; Caylak, S.; Fidan, M.S. Thermal and Electrical Behaviors of Activated Carbon-Filled PLA/PP Hybrid Biocomposites. Sustain. Mater. Technol. 2023, 37, e00655. [Google Scholar] [CrossRef]

- Hu, Z.; Srinivasan, M.P. Preparation of High-Surface-Area Activated Carbons from Coconut Shell. Microporous Mesoporous Mater. 1999, 27, 11–18. [Google Scholar] [CrossRef]

- Iqbaldin, M.M.; Khudzir, I.; Azlan, M.M.; Zaidi, A.; Surani, B.; Zubri, Z. Properties of coconut shell activated carbon. J. Trop. For. Sci. 2013, 25, 497–503. [Google Scholar]

- Salleh, Z.; Yusop, M.Y.M.; Rosdi, M.S. Mechanical Properties of Activated Carbon (AC) Coir Fibers Reinforced with Epoxy Resin. J. Mech. Eng. Sci. 2013, 5, 631–638. [Google Scholar] [CrossRef]

- Ergun, M.E.; Özlüsoylu, İ.; İstek, A.; Can, A. Analysis and Impact of Activated Carbon Incorporation into Urea-Formaldehyde Adhesive on the Properties of Particleboard. Coatings 2023, 13, 1476. [Google Scholar] [CrossRef]

- Zamani, R.; Kazemi Najafi, S.; Younesi, H. Utilization of Activated Carbon as an Additive for Urea-Formaldehyde Resin in Medium Density Fiberboard (MDF) Manufacturing. J. Adhes. Sci. Technol. 2022, 36, 2285–2296. [Google Scholar] [CrossRef]

- Yeganeh, M.M.; Kaghazchi, T.; Soleimani, M. Effect of Raw Materials on Properties of Activated Carbons. Chem. Eng. Technol. 2006, 29, 1247–1251. [Google Scholar] [CrossRef]

- Neolaka, Y.A.B.; Riwu, A.A.P.; Aigbe, U.O.; Ukhurebor, K.E.; Onyancha, R.B.; Darmokoesoemo, H.; Kusuma, H.S. Potential of Activated Carbon from Various Sources as a Low-Cost Adsorbent to Remove Heavy Metals and Synthetic Dyes. Results Chem. 2023, 5, 100711. [Google Scholar] [CrossRef]

- Dukarska, D.; Kawalerczyk, J.; Kmieciak, J. Modified Pine Needles as a Formaldehyde Scavenger for Urea-Formaldehyde Resin in Plywood Production. Eur. J. Wood Wood Prod. 2023, 82, 147–158. [Google Scholar] [CrossRef]

- PN-C-89352-3; Kleje-Kleje do Drewna-Metody Badan—Oznaczanie Czasu Zelowania. Polish Committee for Standardization: Warsaw, Poland, 1996.

- EN 323; Wood-Based Panels-Determination of Density. European Committee for Standardization: Brussels, Belgium, 2001.

- EN 319; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 310; Wood-Based Panels-Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1999.

- EN 317; Particleboards and Fibreboards–Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1998.

- EN 120; Wood-Based Panels-Determination of Formaldehyde Release-Extraction Method (Called Perforator Method). CEN, European Committee for Standardization: Brusseles, Belgium, 2011.

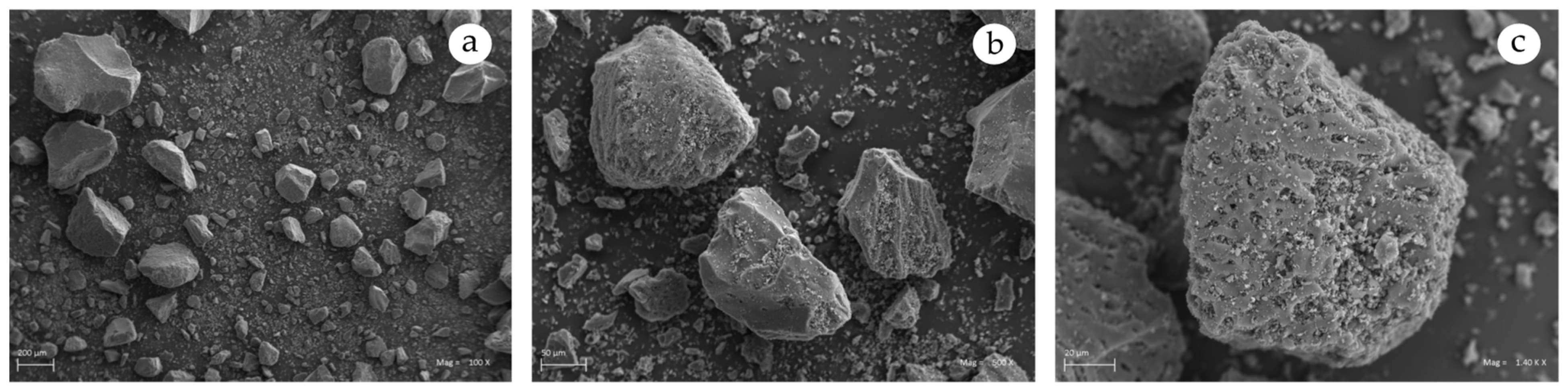

- Opoku, B.K.; Isaac, A.; Micheal, A.A.; Bentum, J.K.; Muyoma, W.P. Characterization of Chemically Activated Carbons Produced from Coconut and Palm Kernel Shells Using SEM and FTIR Analyses. Am. J. Appl. Chem. 2021, 9, 90–96. [Google Scholar] [CrossRef]

- Sujiono, E.H.; Zabrian, D.; Zharvan, V.; Humairah, N.A. Fabrication and Characterization of Coconut Shell Activated Carbon Using Variation Chemical Activation for Wastewater Treatment Application. Results Chem. 2022, 4, 100291. [Google Scholar] [CrossRef]

- Wang, Z.; Nie, E.; Li, J.; Yang, M.; Zhao, Y.; Luo, X.; Zheng, Z. Equilibrium and Kinetics of Adsorption of Phosphate onto Iron-Doped Activated Carbon. Environ. Sci. Pollut. Res. 2012, 19, 2908–2917. [Google Scholar] [CrossRef] [PubMed]

- Unugul, T.; Nigiz, F.U. Preparation and Characterization an Active Carbon Adsorbent from Waste Mandarin Peel and Determination of Adsorption Behavior on Removal of Synthetic Dye Solutions. Water Air Soil Pollut 2020, 231, 538. [Google Scholar] [CrossRef]

- Allwar, A. Characteristics of Pore Structures and Surface Chemistry of Activated Carbons by Physisorption, Ftir And Boehm Methods. IOSR J. Appl. Chem. 2012, 2, 09–15. [Google Scholar] [CrossRef]

- Saka, C. BET, TG–DTG, FT-IR, SEM, Iodine Number Analysis and Preparation of Activated Carbon from Acorn Shell by Chemical Activation with ZnCl2. J. Anal. Appl. Pyrolysis 2012, 95, 21–24. [Google Scholar] [CrossRef]

- Lu, C.; Pan, L.; Zhu, B. Study the Static Adsorption/Desorption of Formaldehyde on Activated Carbons. In Proceedings of the 2015 International Forum on Energy, Environment Science and Materials, Shenzhen, China, 25–26 September 2015; Atlantis Press: Amsterdam, The Netherlands, 2015; pp. 943–947. [Google Scholar]

- Aljundi, I.H.; Al-Dawery, S.K. Equilibrium and Thermodynamic Study of Cobalt Adsorption on Activated Carbon Derived from Date Seeds. Desalin. Water Treat. 2014, 52, 4830–4836. [Google Scholar] [CrossRef]

- Tsai, C.-H.; Tsai, W.-T. Optimization of Physical Activation Process by CO2 for Activated Carbon Preparation from Honduras Mahogany Pod Husk. Materials 2023, 16, 6558. [Google Scholar] [CrossRef]

- Gadhave, R.V.; Mahanwar, P.A.; Gadekar, P.T. Factor Affecting Gel Time/Process-Ability of Urea Formaldehyde Resin Based Wood Adhesives. Open J. Polym. Chem. 2017, 7, 33–42. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Antov, P.; Dziurka, D.; Mirski, R.; Lee, S.H. The Effect of Pressing Parameters and Hardener Content on the Properties of Plywood Bonded with Propylamine-UF Adhesive. Wood Mater. Sci. Eng. 2024, 19, 710–717. [Google Scholar] [CrossRef]

- Yim, Y.-J.; Kim, B.-J. Preparation and Characterization of Activated Carbon/Polymer Composites: A Review. Polymers 2023, 15, 3472. [Google Scholar] [CrossRef] [PubMed]

- Alston, S.; Arnold, C.; Swan, M.; Stone, C. A Source-sink Model for Water Diffusion in an Activated Carbon Fiber/Phenolic Composite. Polym. Compos. 2021, 42, 3550–3561. [Google Scholar] [CrossRef]

- Yang, L.; Quan, H.; Ji, J.; Zhang, H.; Sun, F. Research on the Preparation of Wood Adhesive Active Fillers from Tannin-/Bentonite-Modified Corn Cob. Forests 2024, 15, 604. [Google Scholar] [CrossRef]

- Maraghi, M.M.R.; Tabei, A.; Madanipoor, M. Effect of Board Density, Resin Percentage and Pressing Temprature on Particleboard Properties Made from Mixing of Poplar Wood Slab, Citrus Branches and Twigs of Beech. Wood Res. 2018, 63, 669–682. [Google Scholar]

- Kowaluk, G.; Szymanowski, K.; Kozlowski, P.; Kukula, W.; Sala, C.; Robles, E.; Czarniak, P. Functional Assessment of Particleboards Made of Apple and Plum Orchard Pruning. Waste Biomass Valorization 2020, 11, 2877–2886. [Google Scholar] [CrossRef]

- Lewis, J.; Alshami, A.; Talukder, M.; Owoade, A.; Baker, K.; Onaizi, S. Agglomeration Tendency and Activated Carbon Concentration Effects on Activated Carbon-Polysulfone Mixed Matrix Membrane Performance: A Design of Experiment Formulation Study. J. Appl. Polym. Sci. 2022, 139, e52875. [Google Scholar] [CrossRef]

- Zare, Y. Study of Nanoparticles Aggregation/Agglomeration in Polymer Particulate Nanocomposites by Mechanical Properties. Compos. Part A Appl. Sci. Manuf. 2016, 84, 158–164. [Google Scholar] [CrossRef]

- Samal, S. Effect of Shape and Size of Filler Particle on the Aggregation and Sedimentation Behavior of the Polymer Composite. Powder Technol. 2020, 366, 43–51. [Google Scholar] [CrossRef]

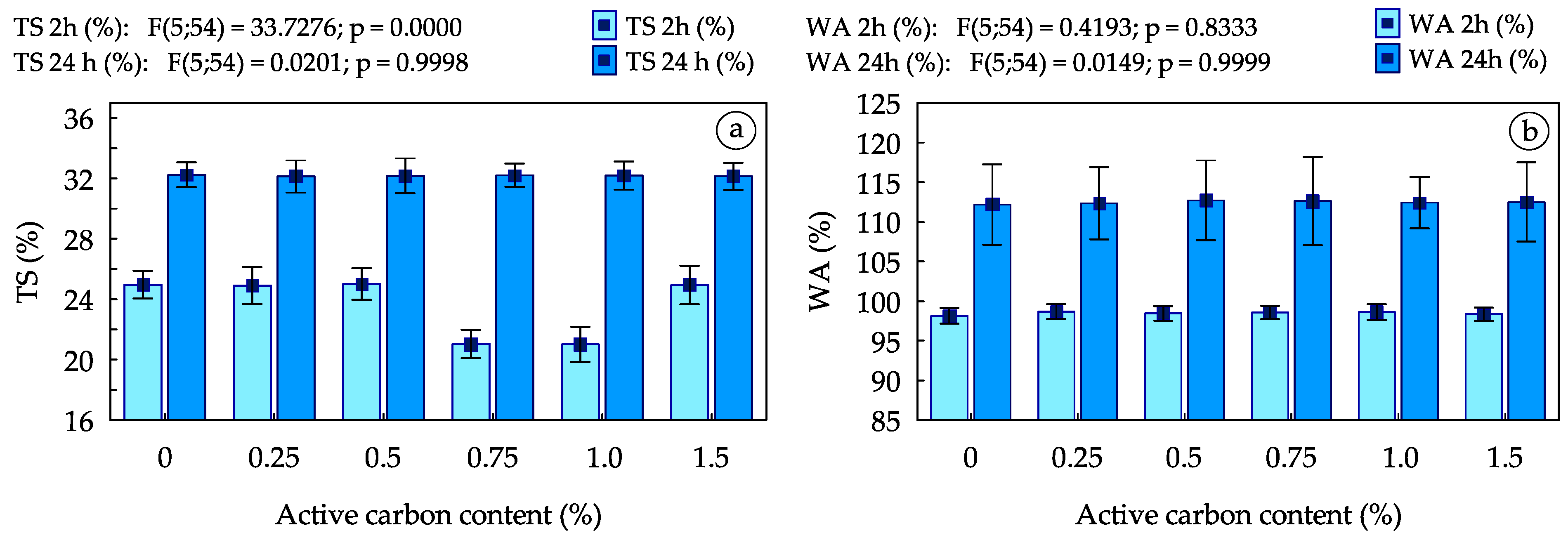

- Medved, S.; Antonović, A.; Jambreković, V. Impact of Resin Content on Swelling Pressure of Three Layer Perticleboard Bonded with Urea-Formaldehyde Adhesive. Drv. Ind. 2011, 62, 37–42. [Google Scholar] [CrossRef]

- Beech, J.C. The Thickness Swelling of Wood Particleboard. Holzforschung 1975, 29, 11–18. [Google Scholar] [CrossRef]

- Mirski, R.; Derkowski, A.; Kawalerczyk, J.; Dziurka, D.; Walkiewicz, J. The Possibility of Using Pine Bark Particles in the Chipboard Manufacturing Process. Materials 2022, 15, 5731. [Google Scholar] [CrossRef]

- Dutkiewicz, J. Hydrolytic Degradation of Cured Urea–Formaldehyde Resin. J. Appl. Polym. Sci. 1983, 28, 3313–3320. [Google Scholar] [CrossRef]

- Nuryawan, A.; Rahmawaty; Tambun, K.D.S.; Risnasari, I.; Masruchin, N. Hydrolysis of Particleboard Bonded with Urea-Formaldehyde Resin for Recycling. Heliyon 2020, 6, e03936. [Google Scholar] [CrossRef]

- Darmawan, S.; Sofyan, K.; Pari, G.; Sugiyanto, K. Effect of activated charcoal addition on formaldehyde emission of medium density fiberboard. Indones. J. For. Res. 2010, 7, 100–111. [Google Scholar] [CrossRef]

- Kristak, L.; Antov, P.; Bekhta, P.; Lubis, M.A.R.; Iswanto, A.H.; Reh, R.; Sedliacik, J.; Savov, V.; Taghiyari, H.R.; Papadopoulos, A.N. Recent Progress in Ultra-Low Formaldehyde Emitting Adhesive Systems and Formaldehyde Scavengers in Wood-Based Panels: A Review. Wood Mater. Sci. Eng. 2022, 18, 763–782. [Google Scholar] [CrossRef]

| Weight (%) | ||||

|---|---|---|---|---|

| C | O | Na | Mg | K |

| 97.6 | 2.0 | 0.1 | 0.1 | 0.2 |

| Activated Carbon Content (%) | Gel Time (s) | Viscosity (mPa·s) | pH |

|---|---|---|---|

| 0.00 | 92 ± 4 b | 282.7 ± 3.5 a | 6.21 ± 0.04 a |

| 0.25 | 95 ± 4 b | 285.0 ± 2.6 a | 6.20 ± 0.01 a |

| 0.50 | 94 ± 7 b | 302.3 ± 3.5 b | 6.21 ± 0.03 a |

| 0.75 | 99 ± 5 b | 305.0 ± 2.6 bc | 6.20 ± 0.03 a |

| 1.00 | 94 ± 5 b | 314.0 ± 6.2 c | 6.20 ± 0.02 a |

| 1.50 | 79 ± 2 a | 314.3 ± 4.0 c | 6.21 ± 0.03 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kawalerczyk, J.; Dukarska, D.; Antov, P.; Stuper-Szablewska, K.; Dziurka, D.; Mirski, R. Activated Carbon from Coconut Shells as a Modifier of Urea–Formaldehyde Resin in Particleboard Production. Appl. Sci. 2024, 14, 5627. https://doi.org/10.3390/app14135627

Kawalerczyk J, Dukarska D, Antov P, Stuper-Szablewska K, Dziurka D, Mirski R. Activated Carbon from Coconut Shells as a Modifier of Urea–Formaldehyde Resin in Particleboard Production. Applied Sciences. 2024; 14(13):5627. https://doi.org/10.3390/app14135627

Chicago/Turabian StyleKawalerczyk, Jakub, Dorota Dukarska, Petar Antov, Kinga Stuper-Szablewska, Dorota Dziurka, and Radosław Mirski. 2024. "Activated Carbon from Coconut Shells as a Modifier of Urea–Formaldehyde Resin in Particleboard Production" Applied Sciences 14, no. 13: 5627. https://doi.org/10.3390/app14135627

APA StyleKawalerczyk, J., Dukarska, D., Antov, P., Stuper-Szablewska, K., Dziurka, D., & Mirski, R. (2024). Activated Carbon from Coconut Shells as a Modifier of Urea–Formaldehyde Resin in Particleboard Production. Applied Sciences, 14(13), 5627. https://doi.org/10.3390/app14135627