Remarkable results have been made on the blasting construction of nearby tunnels. Qi and Liu [

4] studied the mechanical properties of fiber-reinforced concrete shield segments, and obtained that the bending, yield, and ultimate bending moment of the segments with fiber are significantly higher than those of ordinary segments under the same reinforcement ratio. Xu et al. [

5] simulated the pure steel fiber segment of a hard rock tunnel through FLAC3D, and conducted field tests in Qingdao Metro Line 1. The result showed that the pure steel fiber concrete segment has better crack resistance, and it is feasible to replace steel. He et al. [

6] also adopted FLAC3D in Hangzhou Metro Line 5 to analyze the blasting vibration in the excavation of small clear-distance tunnels to the support of the adjacent tunnel in an urban area. In the Aiminshan Tunnel in Dandong, Liaoning Province, Wang et al. [

7] used ANSYS to analyze the seismic impact of blasting excavation on the surface and concluded that the cavity effect caused the excavated surface to vibrate more quickly than the unexcavated surface. Zhang et al. [

8] adopted field monitoring and software simulation to study the influence of blasting from the rear tunnel on the structural optimization of the secondary lining of the advance tunnel under soft and broken surrounding rocks in the Xinmin Tunnel. Pan et al. [

9] used the numerical model to analyze the construction sequence, the time and method of secondary lining in three parallel tunnels with the middle one constructed first, as well as the impact of blasting the tunnels on both sides of the secondary lining of the middle tunnel in the parallel section of the Sunjiawan Tunnel 1 on the Yongzhou Highway and the Niupilingxia Tunnel on the Yongzhou Railway. Wang et al. [

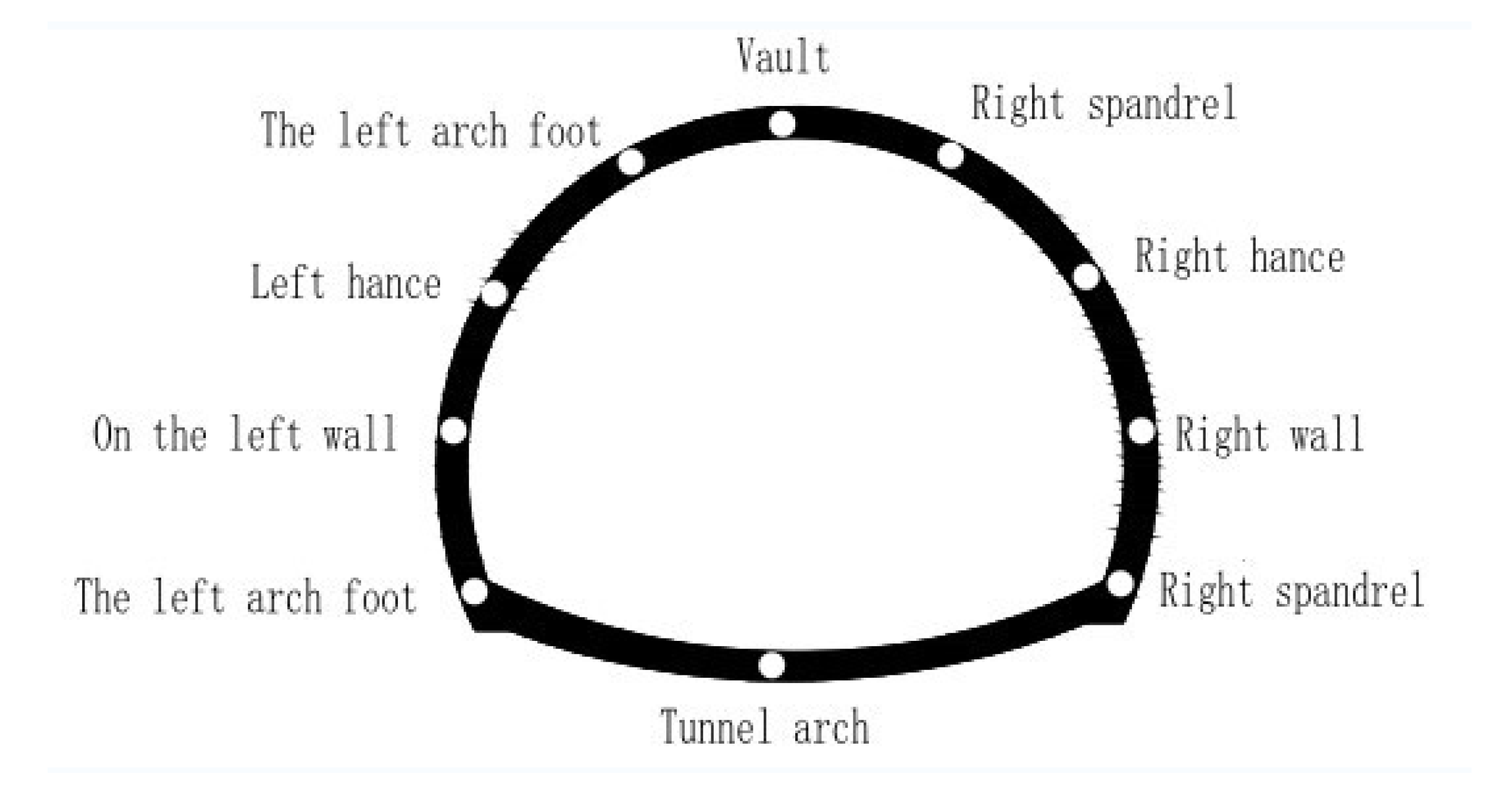

10] studied the dynamic response characteristics of the blasting from the adjacent tunnel on the lining structure at the intersection of the first tunnel in the intersection of the Wuwu high-speed railway tunnel and Xizengshan highway tunnel, and concluded that the arch shoulder and crown of the first tunnel are sensitive to blasting stress, and that close attention should be paid during construction. Wu and Ren [

11] used ABAQUS to study the stress response of the first tunnel to the blasting of the rear tunnel in the small clear-distance tunnel, and concluded that the inner arch waist and the foot are most affected and deserve further observation. Guo et al. [

12] used LS-DYNA and field tests to study the rule of tunnel failure under the blasting load of adjacent tunnels with different spacings, and obtained the form of the failure and the location of the crack. Mao [

13] observed the on-site expansion project of the Fuzhou Mawei Tunnel, and studied the attenuation characteristics of the velocity of the vibration energy under multiple cavities. Chen et al. [

14] tested on site the in situ expansion project of the Jinjishan Tunnel on the Second Ring Road in Fuzhou, Fujian Province, and concluded that in the blasting construction, the number of explosives used in the cut hole should be appropriately reduced, and increased in the wide slot hole and auxiliary hole. Ding et al. [

15] studied the influence of blasting construction on the 33-story frame structure at Exit A of the Xizhen of Qingdao Metro Line 1, and the result is a reference for the protection of high-rise buildings during urban blasting construction. By employing on-site monitoring, Wu et al. [

16] investigated the law of vibration in the unique stratum of the upper soft and lower hard, and confirmed the viability of numerical simulation for engineering blasting. Bao et al. [

17] studied the impact of blasting on surrounding rocks in the seepage area of the tunnel ahead through on-site monitoring and numerical simulation, and concluded that the arch waist has the maximum vibration velocity, the excavation of the lower bench has greater destructive force than that of the upper bench under the same spacing, and the minimum safety clearance is D (D is the tunnel span). Guan et al. [

18] first summarized the development stage of failure evolution based on the field data, then used LS-DYNA to determine the vibration response and failure mode of the temporary middle wall under different explosive amounts and blasting distances. Zhou et al. [

19] studied the impact of blasting in the adjacent tunnel on the initial support and lining of the ultra-small distance tunnel based on the Jiuwuji tunnel blasting project in Guizhou Province, and the result showed that the main frequency distribution of the initial support and lining is very wide and the vibration is diverse, within 200 Hz. Zhang et al. [

20], by monitoring particles on the lining of the tunnel, studied the influence of blasting on the tunnel, and concluded that the peak particle velocity generated is always caused by the cutting hole blasting. Wu et al. [

21] through field monitoring and simulation by FLAC3D, analyzed the influence of blasting of a new tunnel on the operating tunnel, and concluded that the vibration velocity of the arch in the blasting surface of the existing tunnel is larger, and the blasting will have an impact on a moving train. Fang et al. [

22] carried out research on the Qiandouquan Tunnel project by adopting single-layer and double-layer p blasting schemes, and found that the double-layer presplitting blasting can reduce the vibration speed better by comparison. By tracking and analyzing the field particle vibration velocity through numerical simulation in the Nanjing Metro’s ultra-small clear-distance tunnel project, Zhu et al. [

23] discovered that the vibration velocity of the side wall of the tunnel is greater than that of the arch foot. Moreover, the closer the blasting point, the greater the vibration velocity. Cui et al. [

24] studied the improvement of the energy performance of subway tunnels using steel fiber-reinforced concrete lining to enhance shallow geothermal energy. They found that the thermal conductivity of the steel fiber-reinforced concrete lining is better than that of ordinary concrete lining with advantages in heat exchange and cooling operation. Hosseini et al. [

25] studied the use of glass fiber-reinforced polymer (GFRP) to reinforce high-strength concrete lining segments, and found that the segments with GFRP have bending and shear strength, but with little effect on the lining segments after cracking.

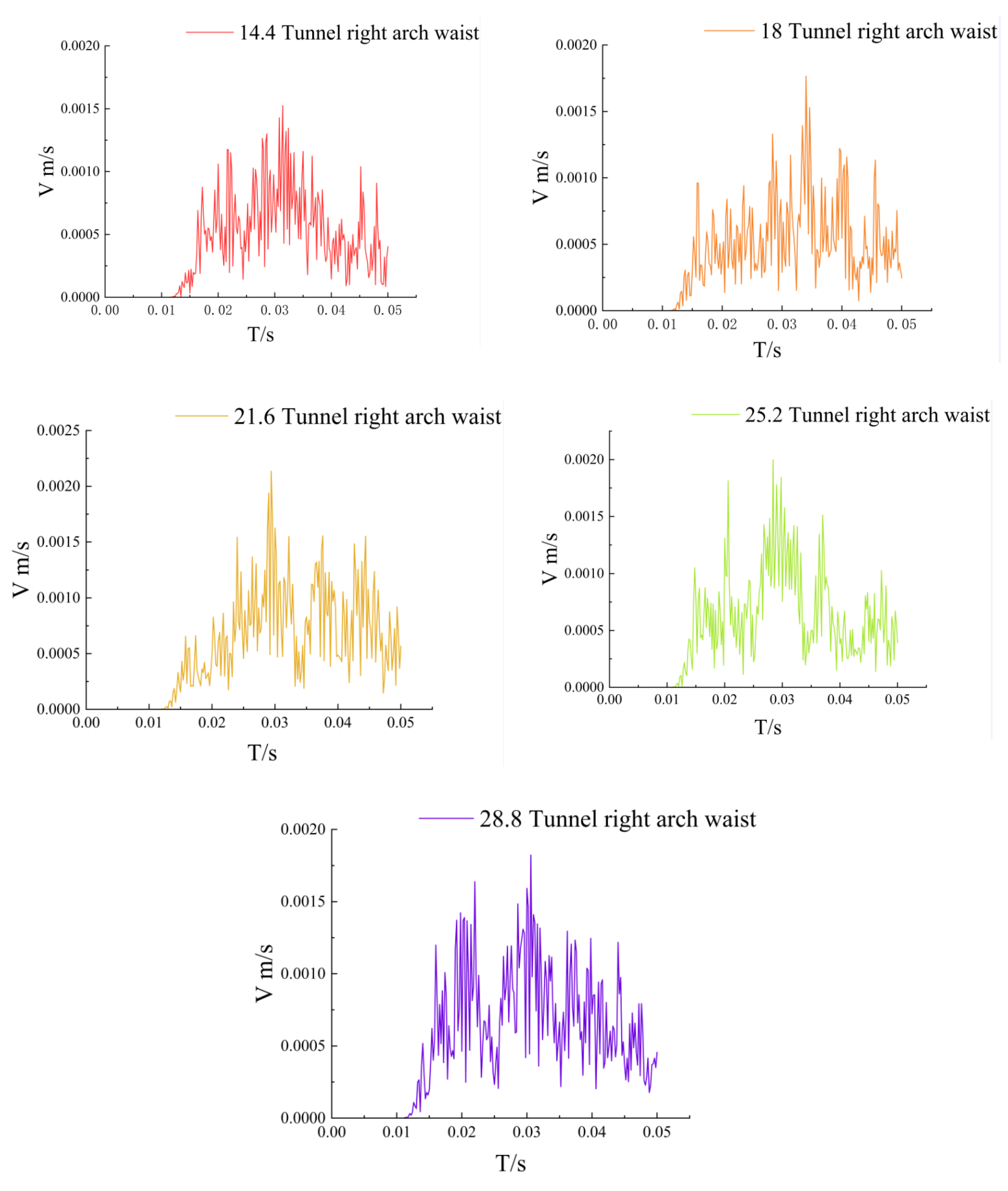

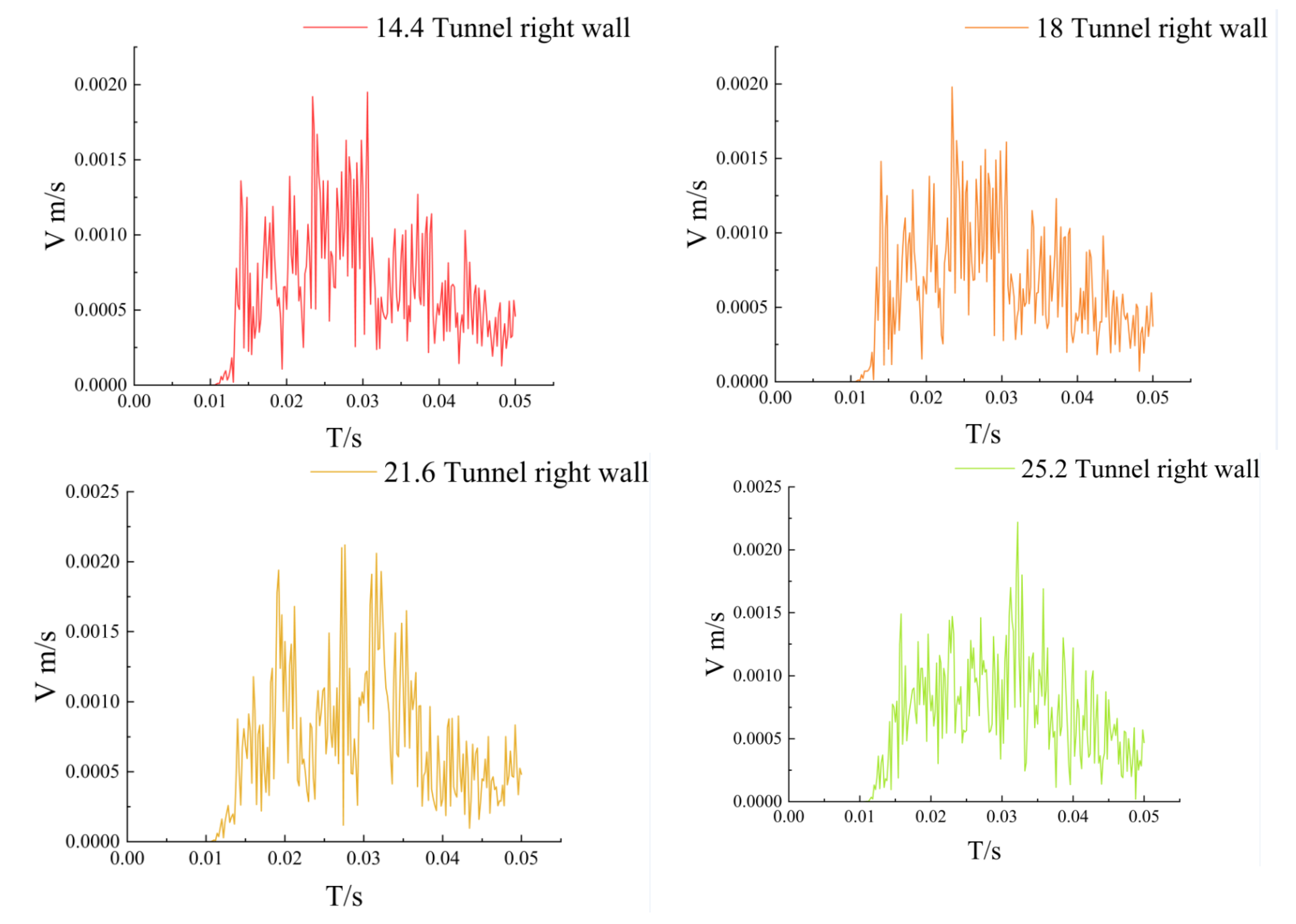

In summary, there is little research on the impact of small-spacing tunnel blasting construction on adjacent steel fiber tunnel linings. Some scholars have found that steel fiber-reinforced concrete lining has significant improvements in bending moment, yield moment, and ultimate moment compared with steel-reinforced concrete lining. The structural vibration velocity from blasting can be used as an indicator of the strength of the blasting vibration effect. The peak vibration velocity during blasting construction differs in tunnels, but the closer the blasting point, the greater the vibration velocity.

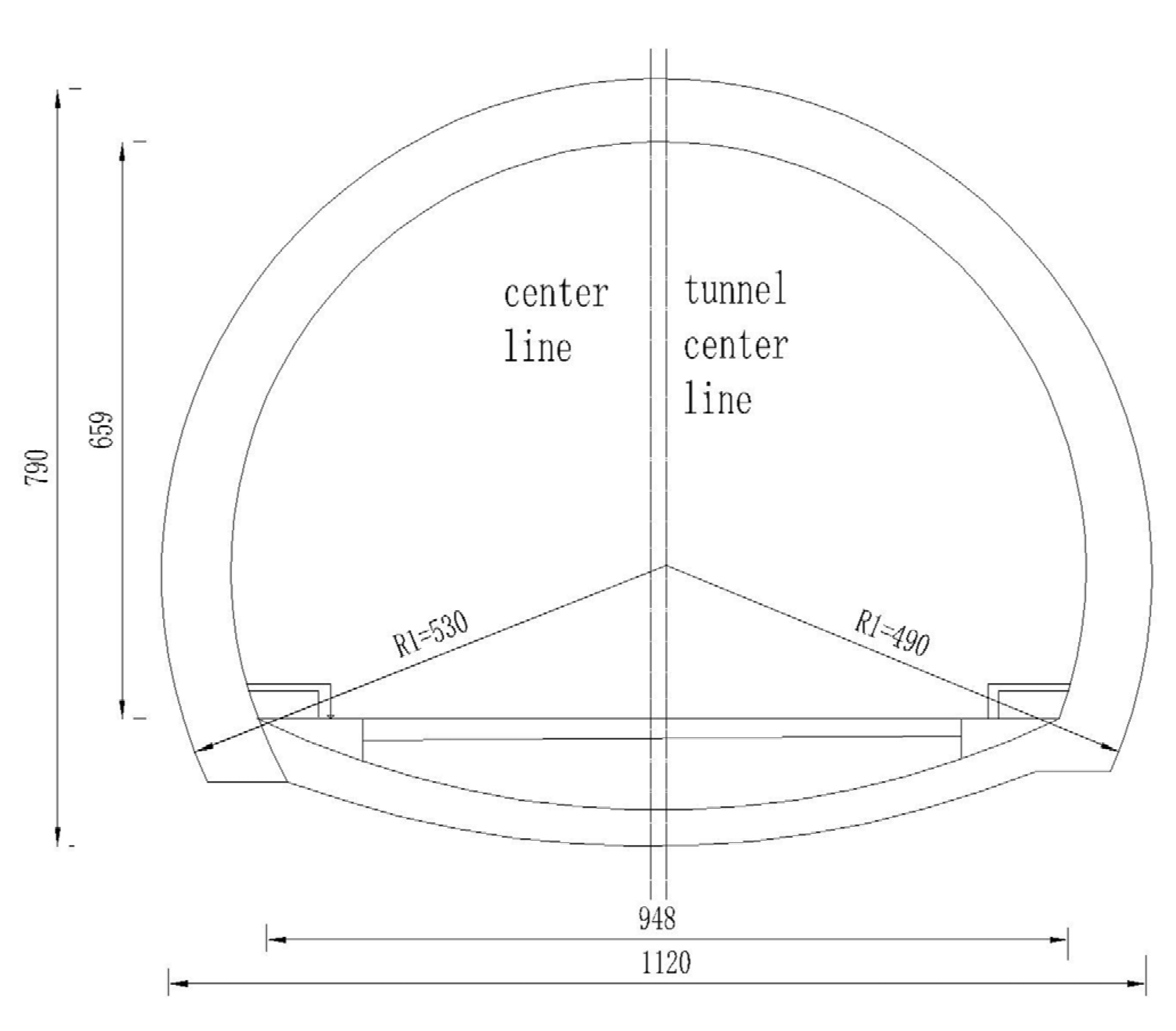

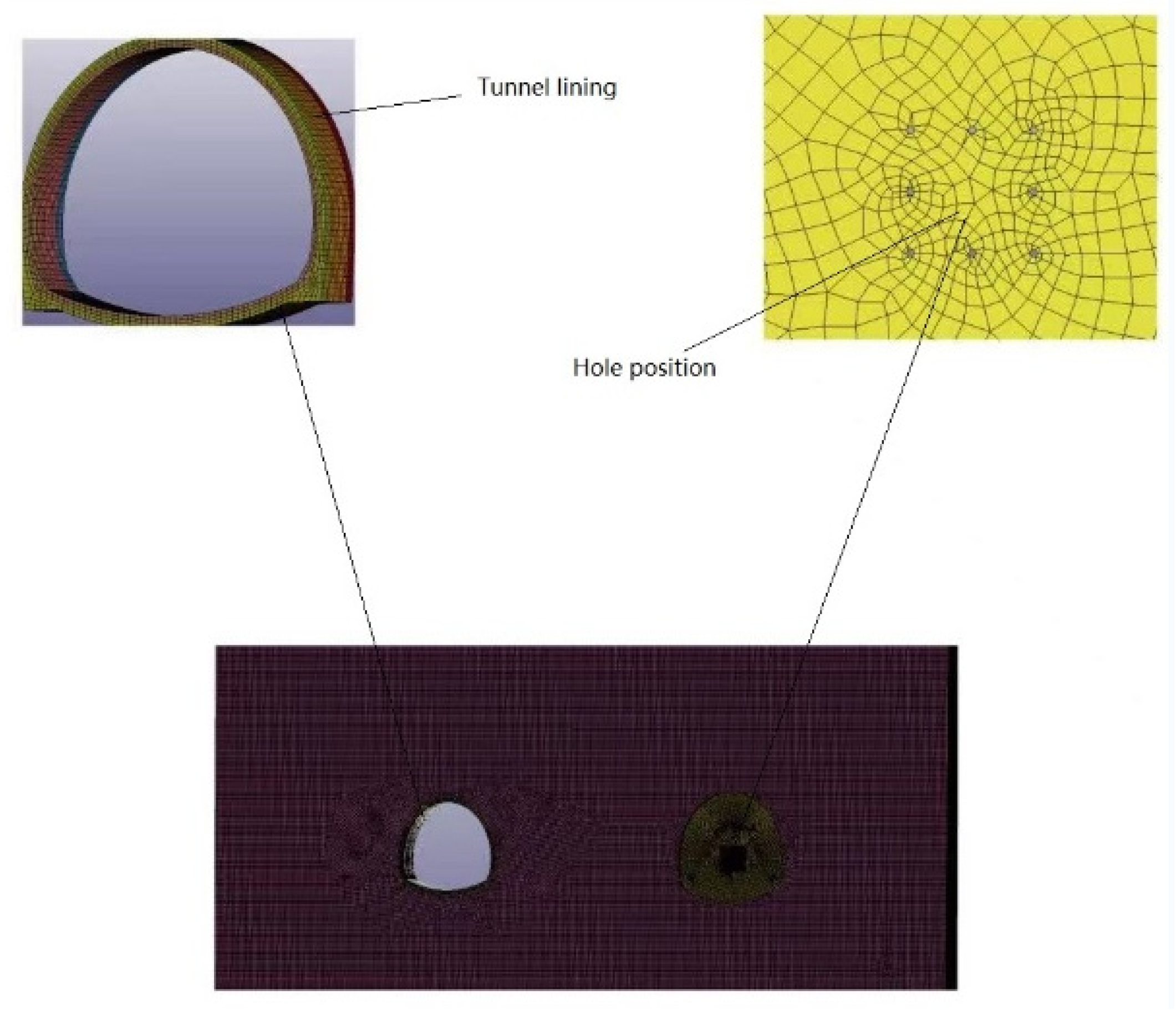

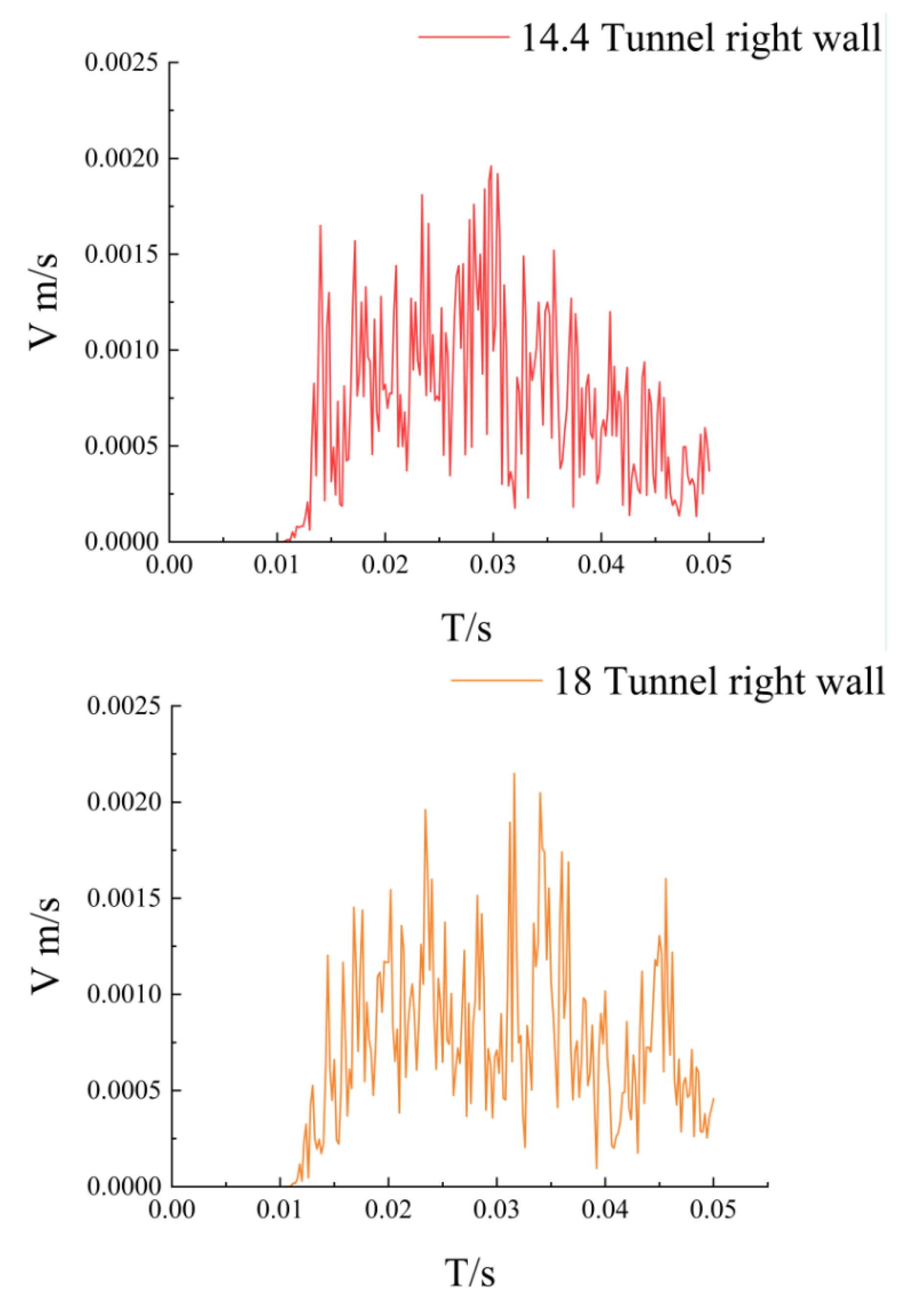

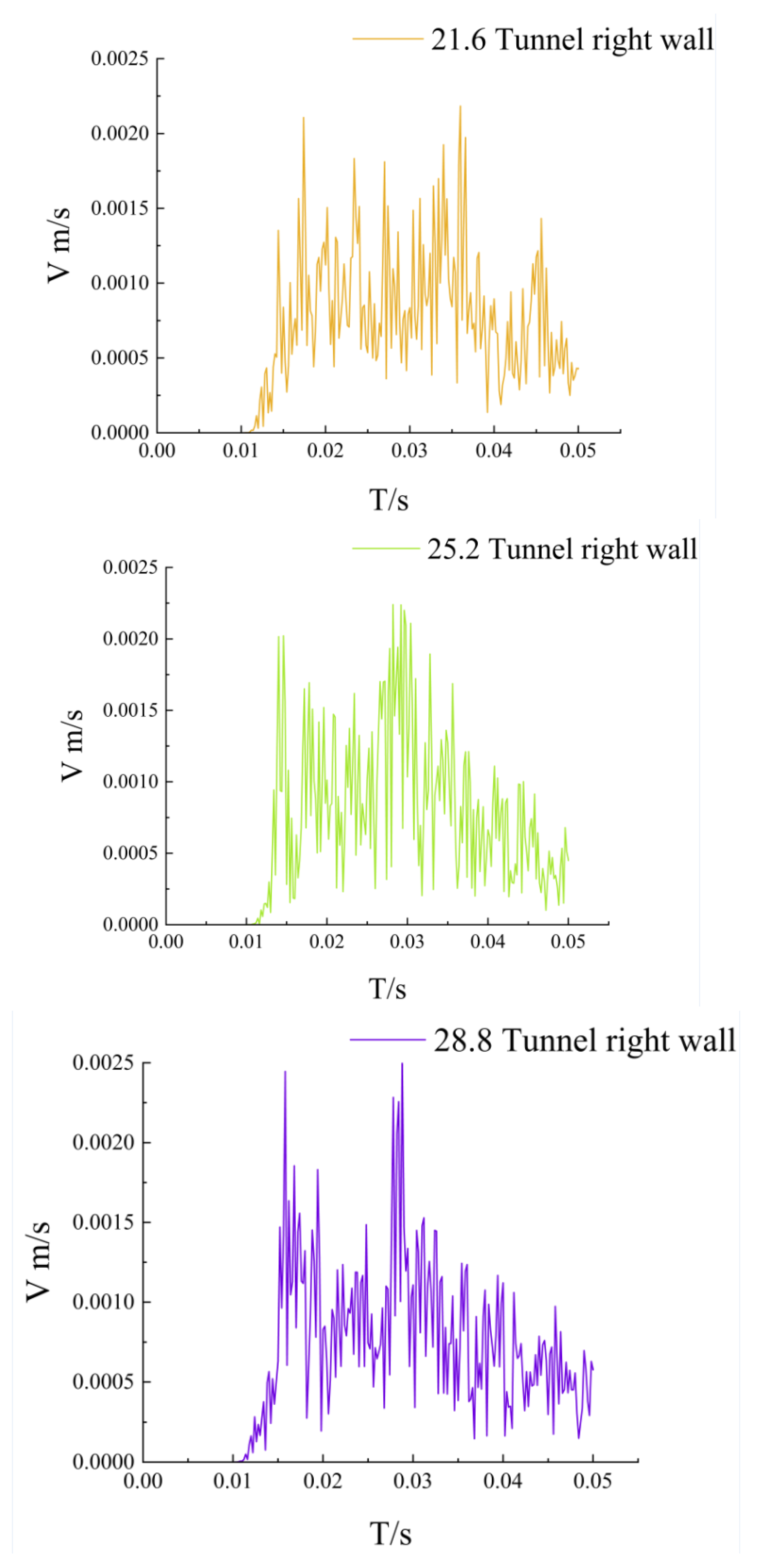

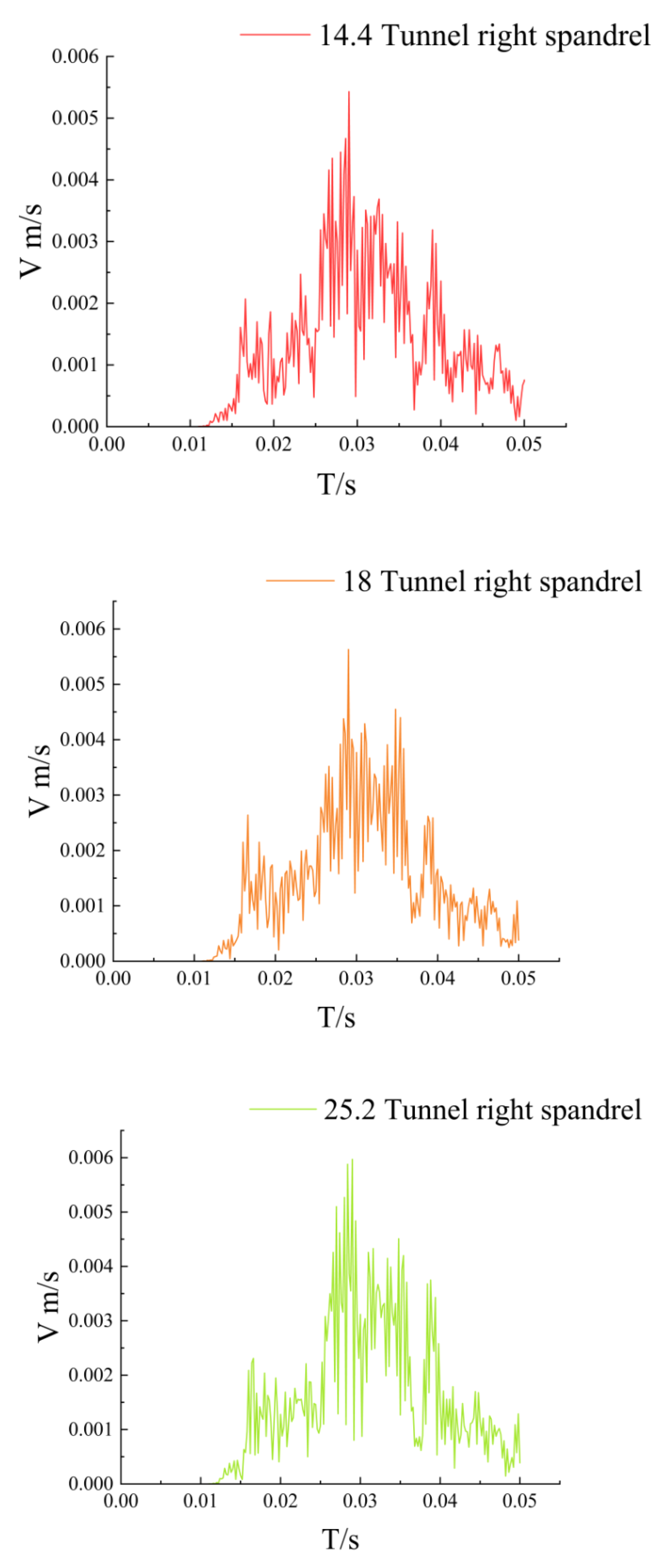

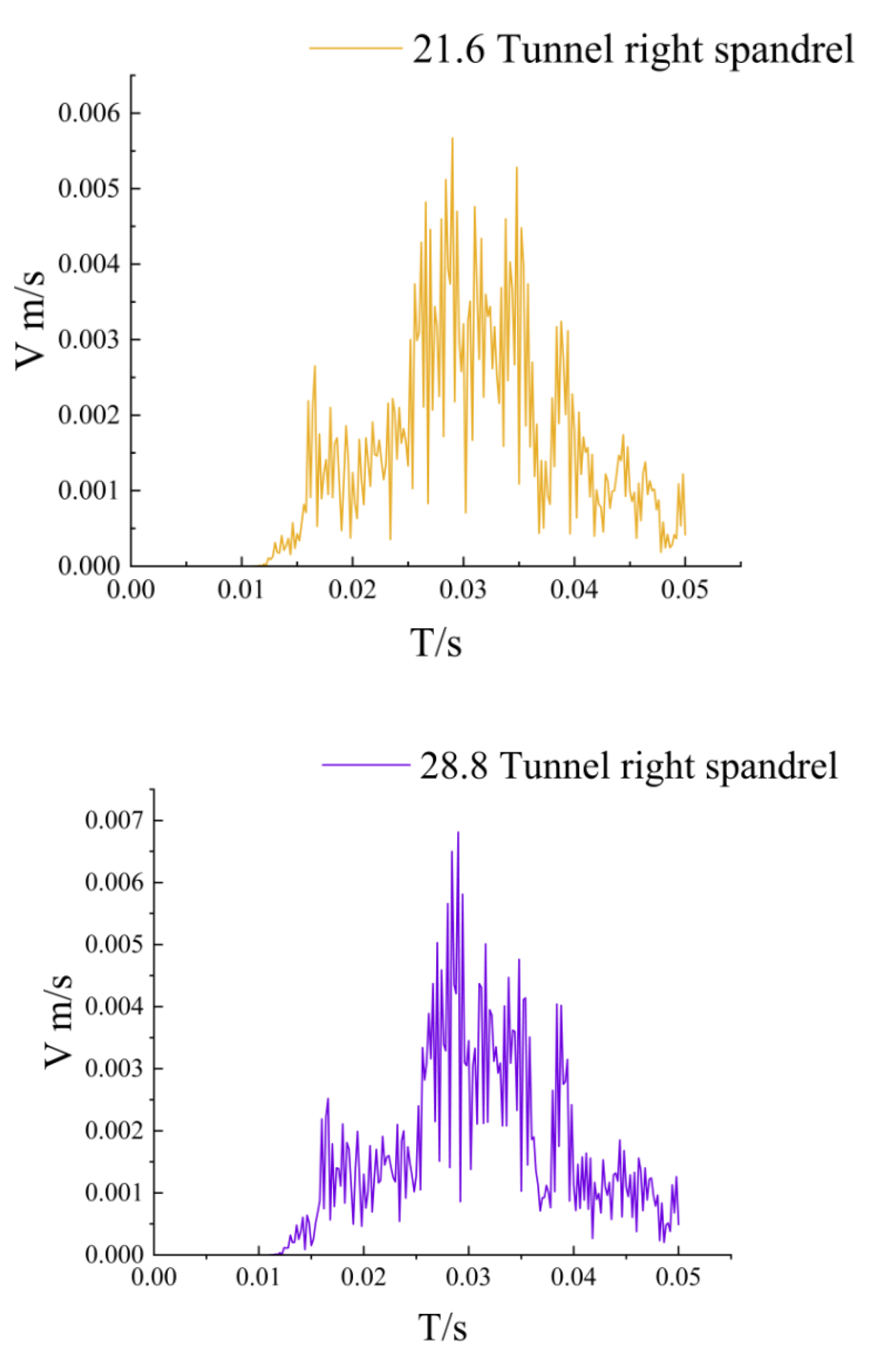

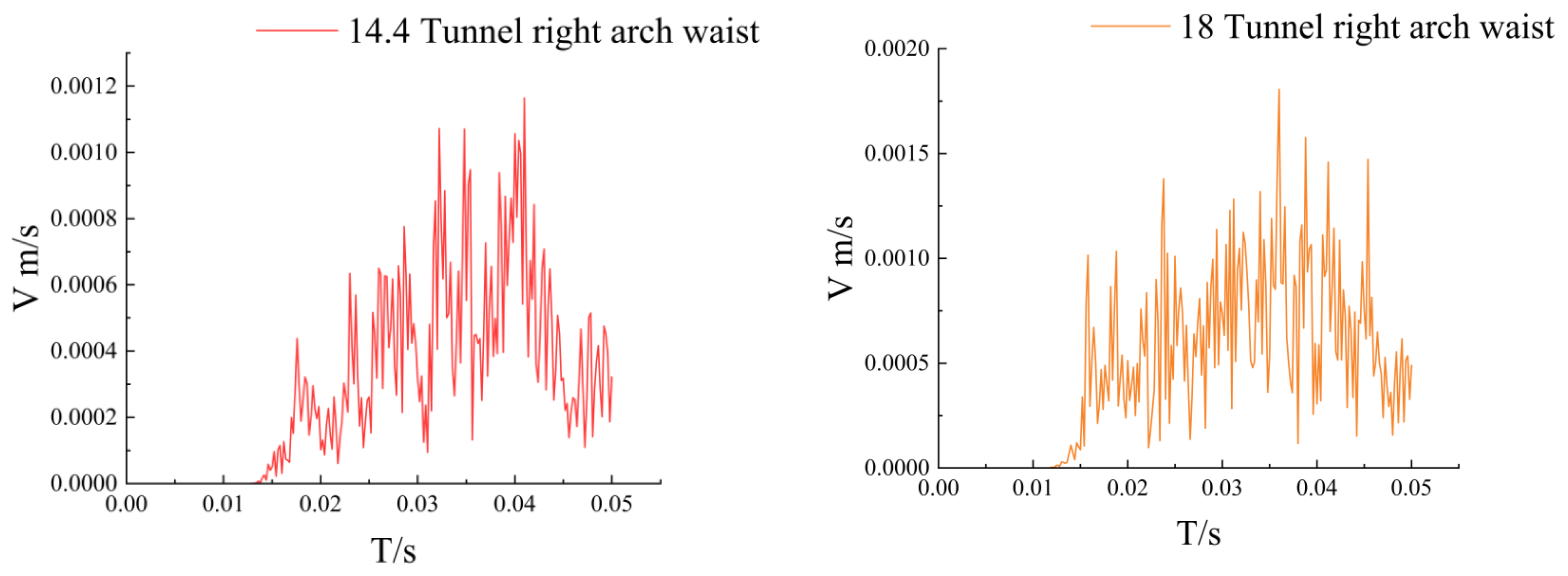

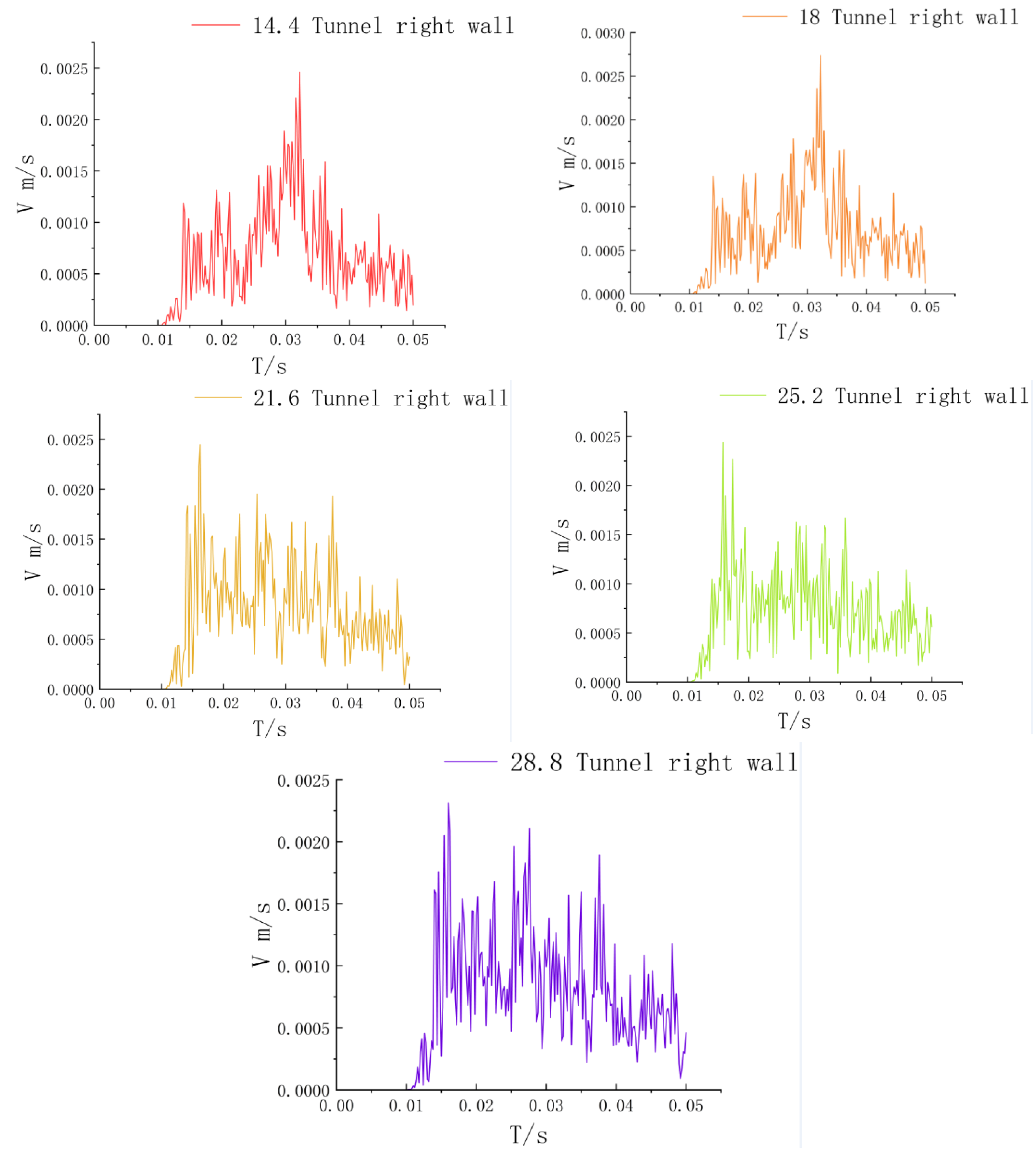

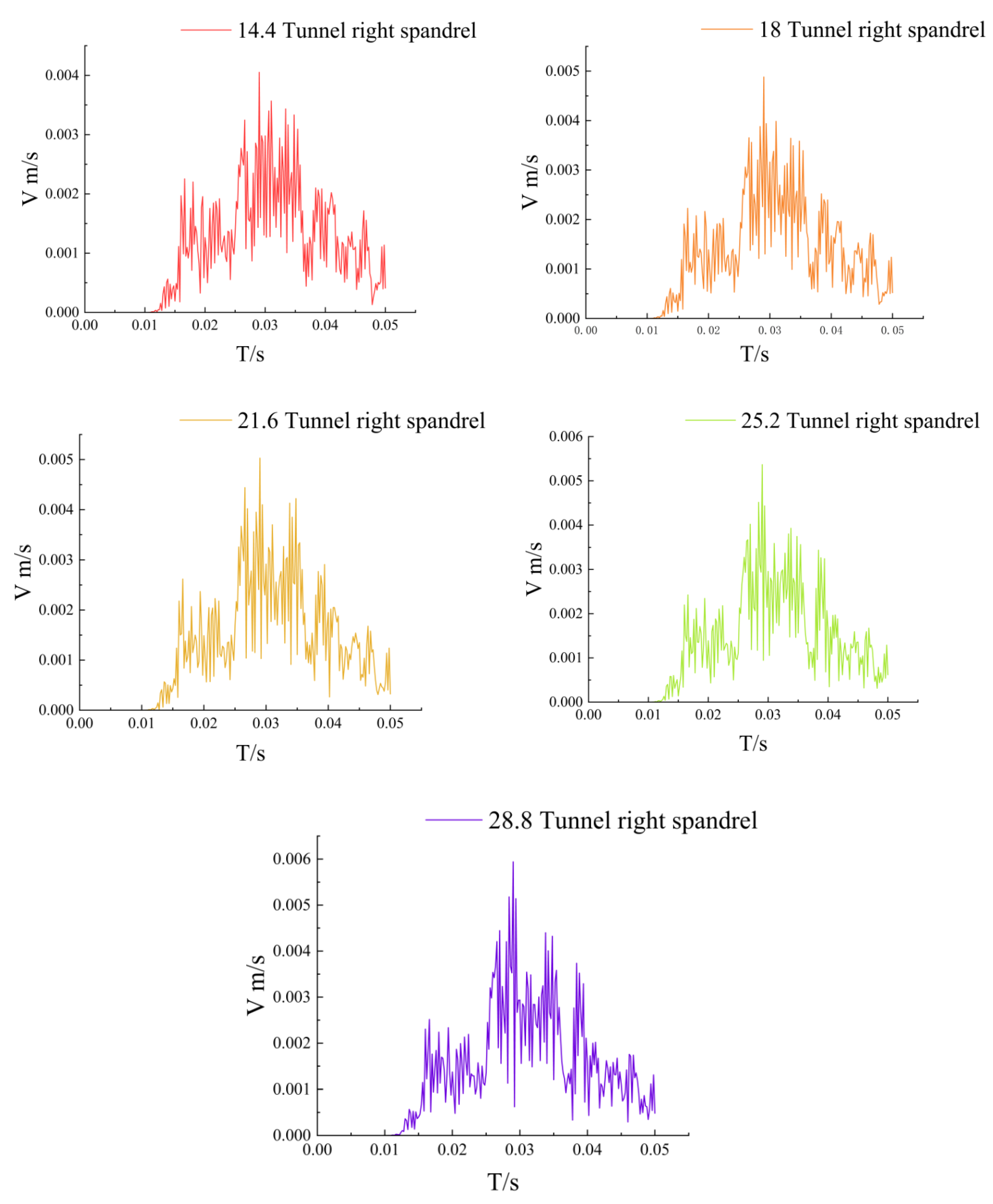

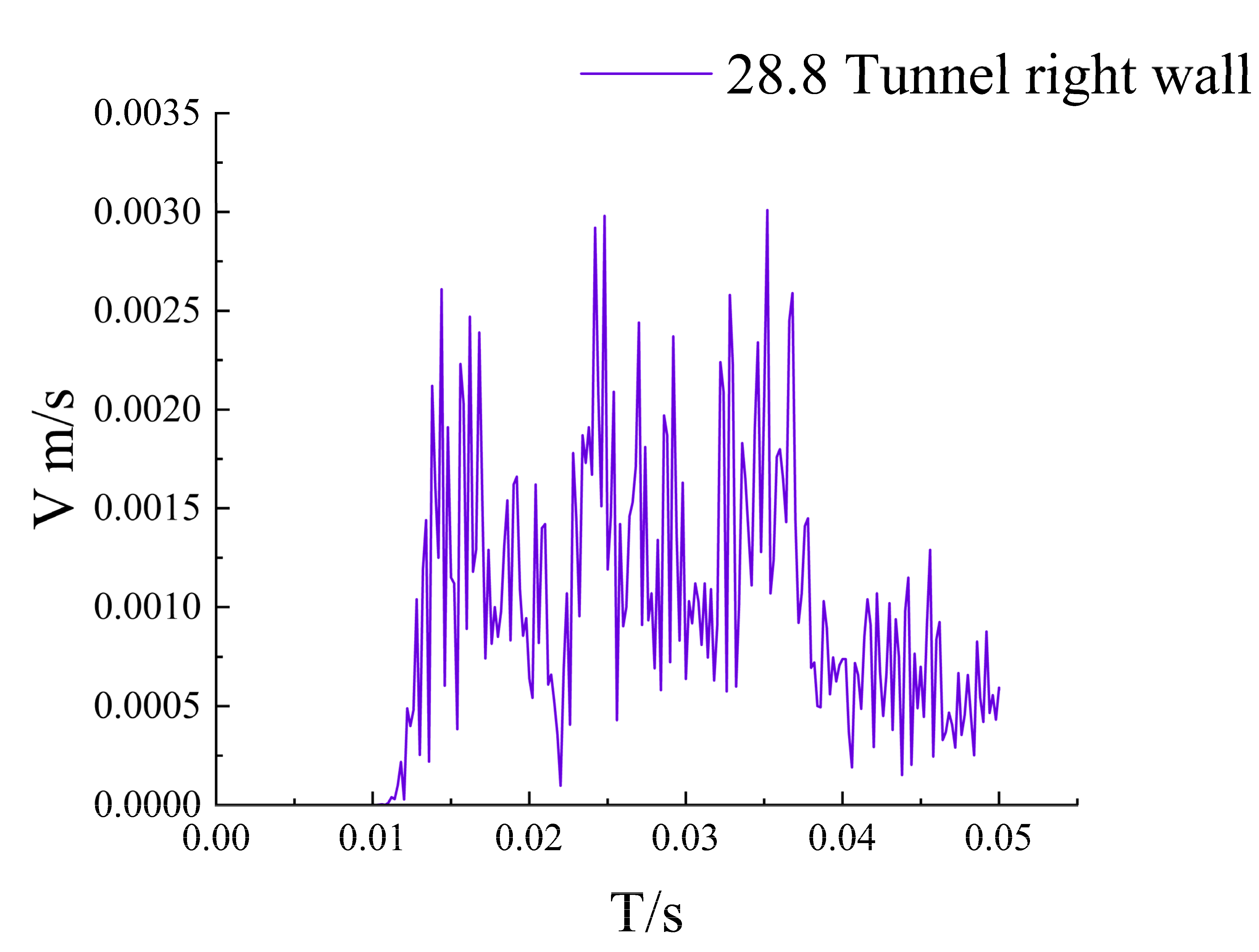

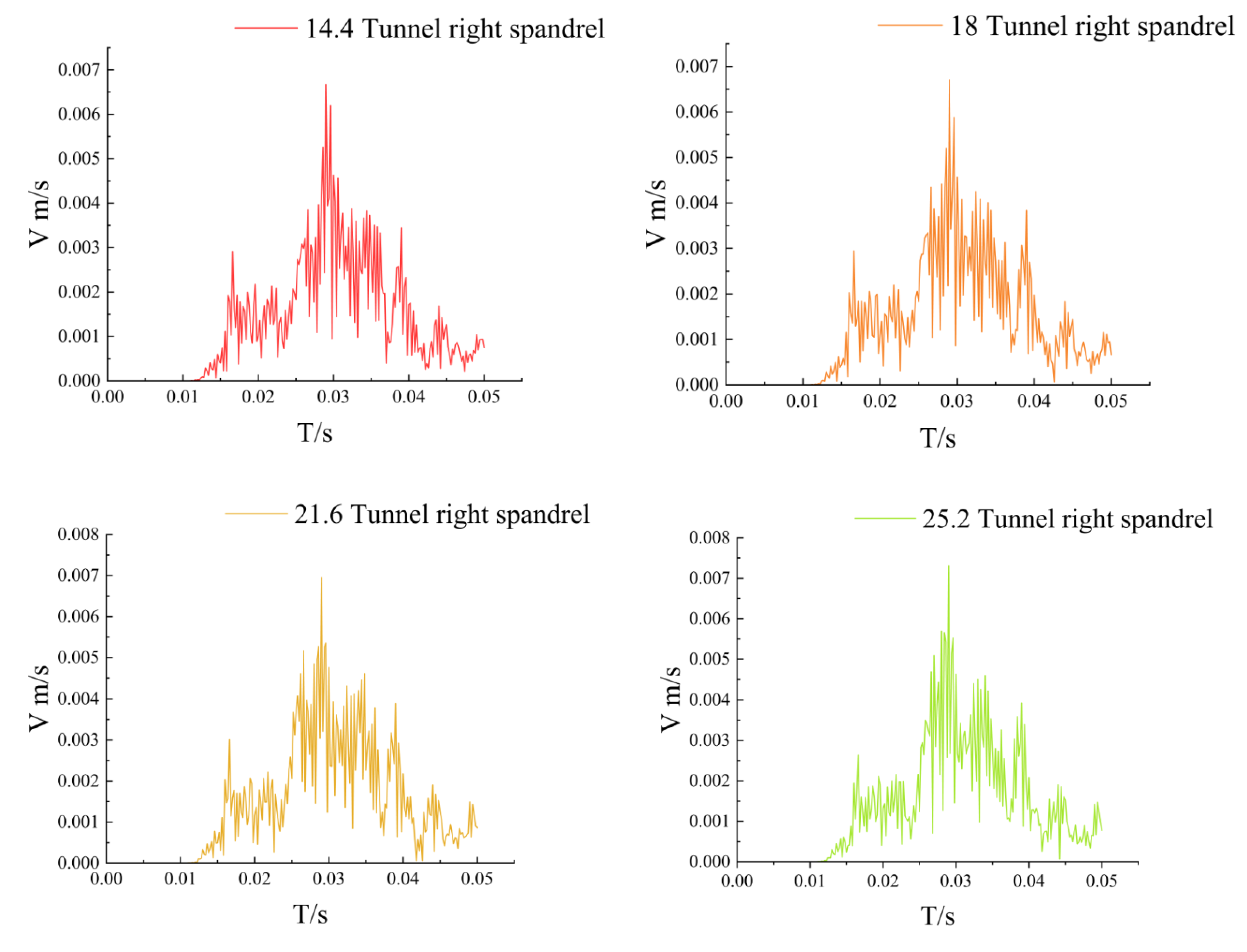

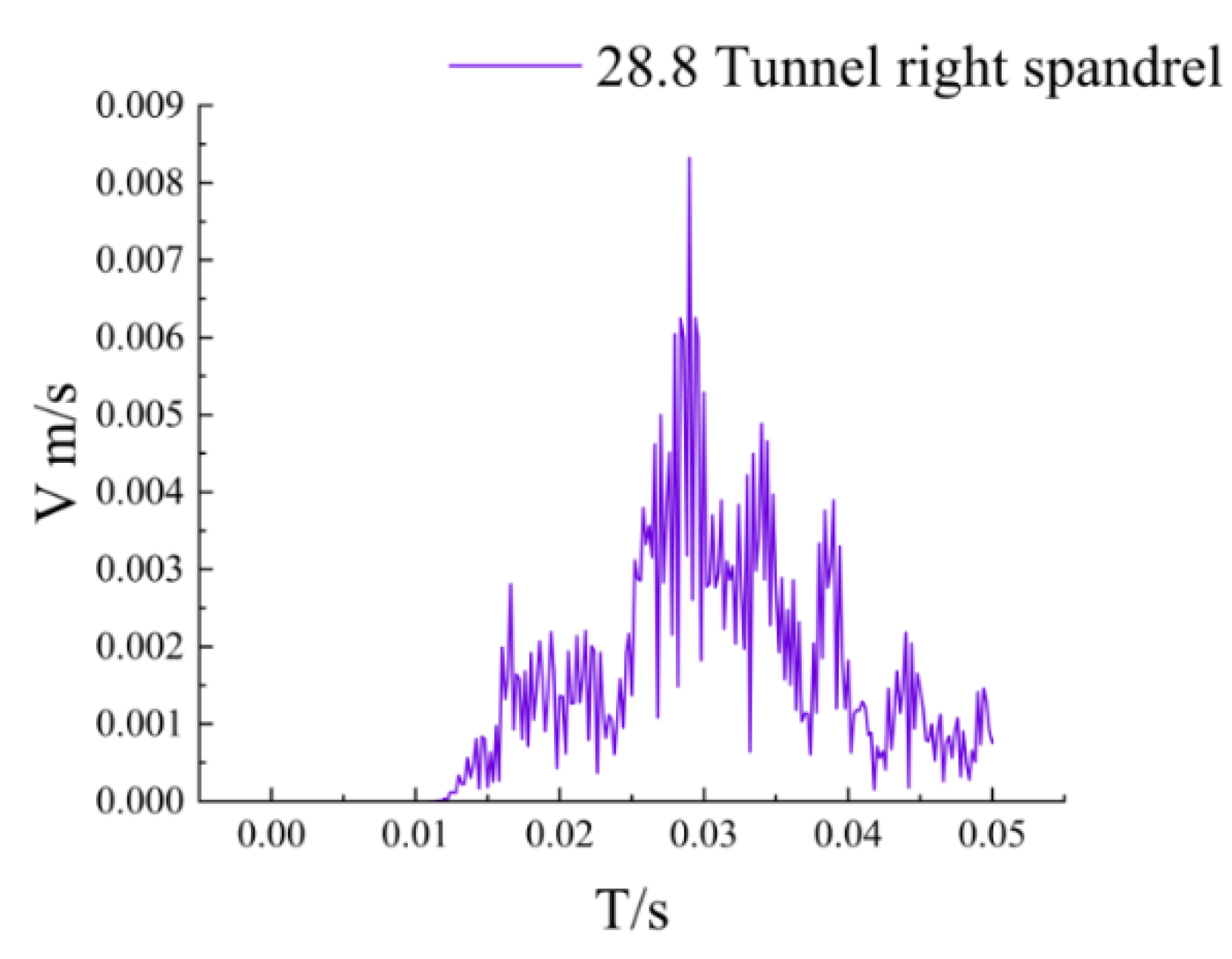

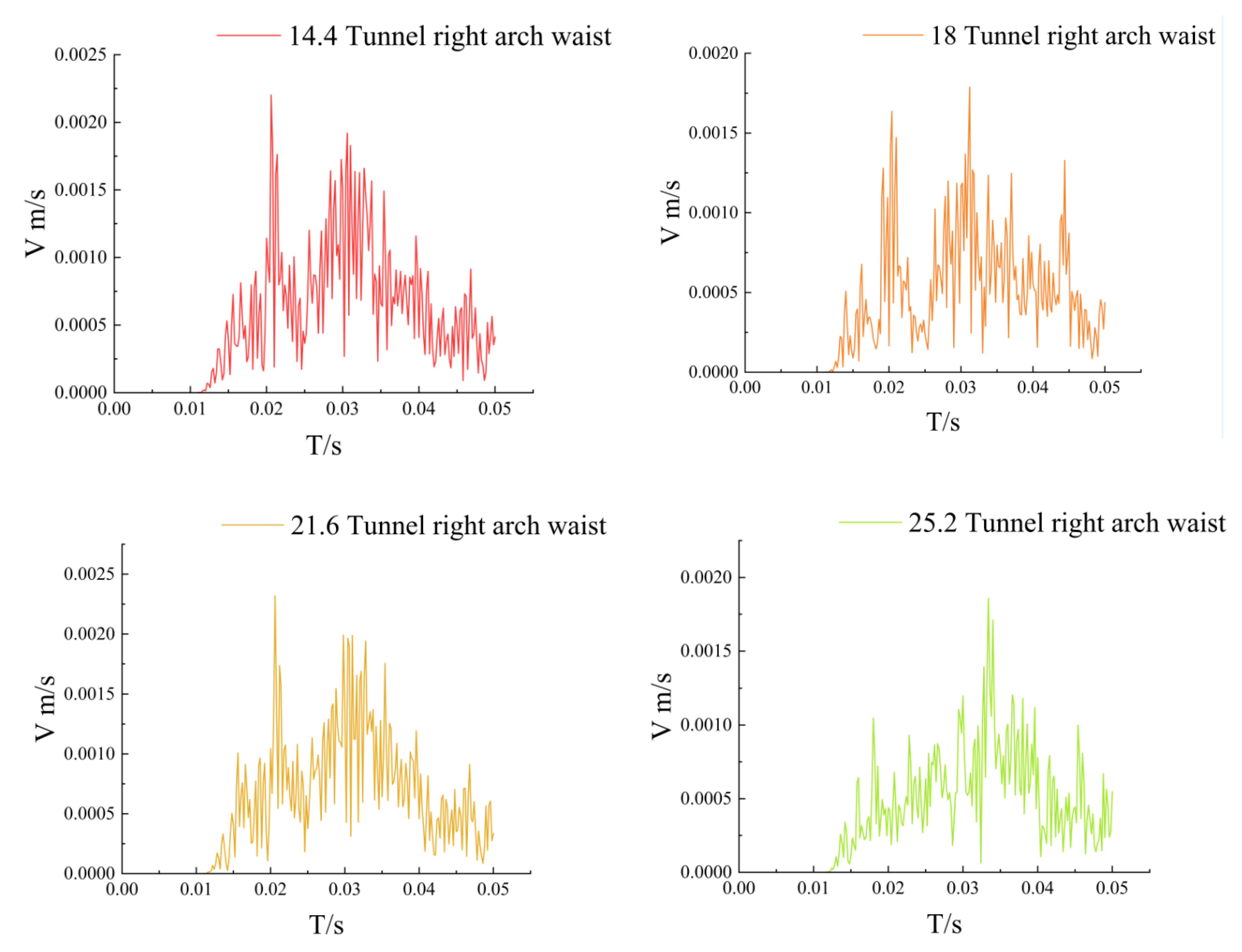

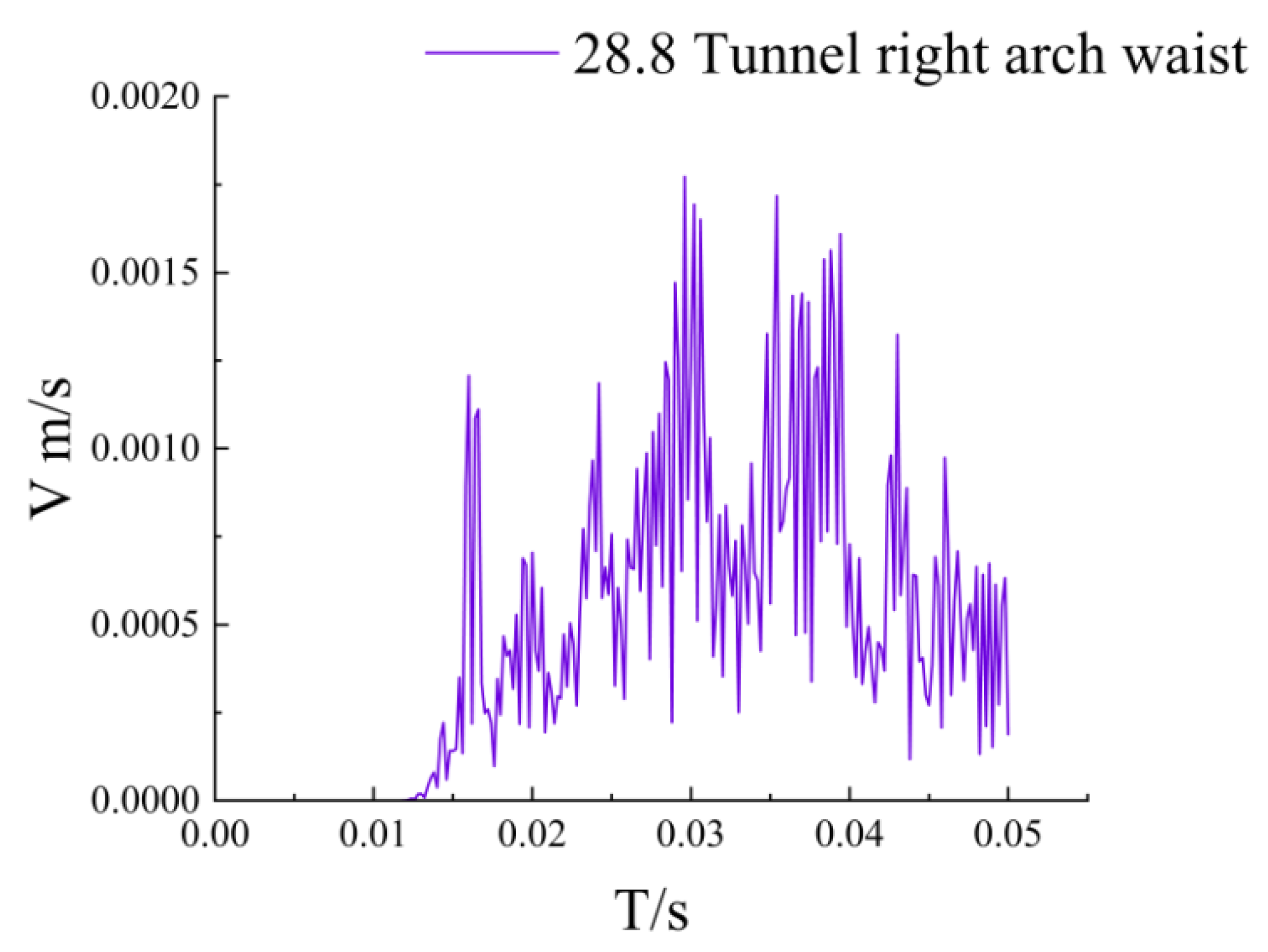

This paper uses LS-DYNA to establish three tunnel-lining models and simulates the impact of blasting construction on adjacent tunnel linings with different explosive amounts. The three types of tunnel linings are plain, ordinary reinforced, and steel fiber-reinforced concrete, and the explosive amounts are 14.4 kg, 18 kg, 21.6 kg, 25.2 kg, and 28.8 kg. The vibration response law of the adjacent tunnels in the three lining models under different explosive amounts is analyzed. Hopefully, the research results will provide a reference for future engineering design and tunnel construction.