Abstract

Aquafaba is the water solution left over from cooking legumes, mainly chickpeas. The liquid can also be obtained from canned beans. Aquafaba is currently very popular as an egg replacement in vegan diets. The chemical composition of aquafaba depends on the type of legume, variety, genotype and parameters during production, such as cooking time or proportions of water to seeds. Aquafaba can be used for its nutritional properties. Aquafaba is starting to be used more widely in food technology as well, due to its innovative texture-shaping properties. The foaming, emulsifying, gelling and thickening properties of aquafaba can be used in plant-based food recipes, but also in animal-based food recipes and 3D printing. So far, aquafaba has been used to make meringues, cakes, cookies, bread, crackers and vegan dairy substitutes. This raw material is used for the production of low-calorie food and for people on an egg-free diet. Perhaps the potential of this product is greater. The use of waste from legumes will be the answer from food producers to the needs of consumers, for whom environmental protection or the clean label trend are particularly important. In order to effectively use aquafaba in food technology, it is necessary to standardize its production process and conduct further research on the potential of using other legumes.

1. Introduction

As the world’s population increases, so does the need for food [1]. In order to ensure food reserves and guarantee their appropriate quality and safety, new technological solutions are being sought [2,3]. High hopes are associated with the use of plants and waste. Estimates indicate that four and a half times less land is needed to produce plant products than to produce food of animal origin [3,4]. Six liters of water are needed to produce 1 kg of wheat, while 2500–6000 L are needed for 1 kg of meat [5]. Therefore, it is justified to develop food technology based on the use of plants. Production of legumes, rich in protein, is a partial alternative to animal sources food production. The greatest quantity of vegetable protein at the lowest production cost is obtained when growing soybeans, peas and beans [6,7]. According to FAOSTAT data, in 2021 the countries of the European Community produced about 483,000 tons of chickpeas, and 10 years earlier about 537,000 tons. This shows that a consistently high production of these legumes is maintained. Presumably, this will generate larger amounts of aquafaba, which until recently was treated only as post-production waste now, in line with the zero-waste trend, it can be used in many ways [8,9].

Currently, healthy eating is the right way of human development and is becoming more popular. People are more likely to reach for functional food, but they also carefully choose products from store shelves. Low-calorie or low-fat foods are very popular [10]. It should also be noted that more and more people, for various reasons, choose a meat-free diet [11,12,13]. These reasons include economic, health, religious, ethical or environmental considerations [14]. The growing demand for new and functional food products, especially of plant origin, contributes to the expansion of the assortment of food producers [15]. Both food technologists and scientists are constantly looking for new technologies and new possibilities to shape good quality food with the desired textural and physicochemical properties [16].

Aquafaba is a raw material that responds to the previously mentioned needs; it is reasonable to conduct research devoted to it. So far, researchers have conducted research in the field of understanding the chemical composition, physicochemical properties and use of aquafaba in products, mainly as a substitute for eggs [17].

The aim of this review is to present the current state of knowledge on aquafaba and to indicate potential directions for the development of food technology, with particular emphasis on the possibility of shaping the texture in the technology of food of plant origin, mainly in baking.

2. History and Etymology

Due to changing consumer needs, scientists and technologists have long been trying to develop a plant-based egg substitute [16]. The reasons for searching for an egg substitute are an increasing number of vegans, [11] the reduction of allergens—in this case for egg white—a growing interest in healthy nutrition, [10] facilitation of the technological process at the storage and pre-treatment stages in terms of safety, environmental sustainability and lower prices [18]. Eggs are characterized by many functional properties. These include binding, emulsifying, raising, thickening, gelling, antimicrobial and moisture retention properties. In addition, what should be noted is their high protein content, about 12.5% [18]. Currently, egg replacement products are soy lecithin, chia seeds, fruit or vegetable pulp, flaxseed, silk tofu, pulses flour, corn flour, agar, cane arrowroot and black Himalayan salt [16,18]. Unfortunately, none of these products has such versatile properties as eggs do, and it is often necessary to combine some substitutes with each other to achieve a satisfactory effect [16,18].

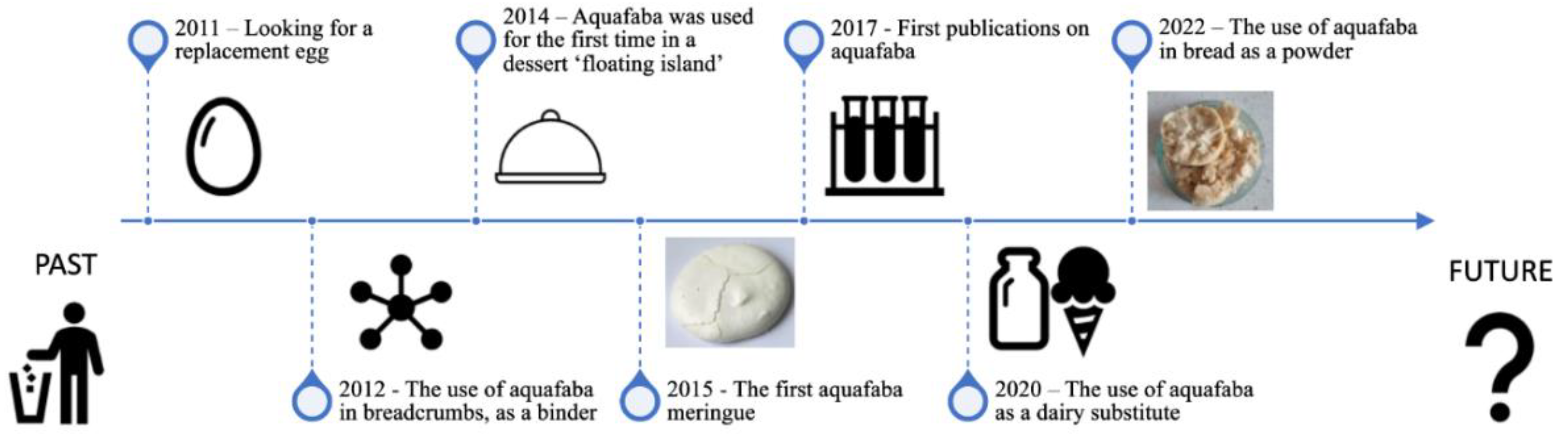

The first reports related to the use of aquafaba date back to 10 years ago (Figure 1). In March 2011, Miyoko Schinner published a post on the website artisanve-ganlife.com, in which she described how to make a meringue from linen gel. Unfortunately, the proposed recipe had a significant disadvantage: the foam fell during baking and the flax flavor was too strong. The preparation of the gel itself was also time-consuming, but this discovery turned out to be the basis for later experiments. In August 2012, another vegan meringue was created, in which saponin extract was used as an egg substitute [www.aquafaba.com]. Meringue prepared according to this recipe had a better texture and did not fall apart, but still had a significant disadvantage. Its big problem was the unpleasant taste, and saponin extract is difficult to access by the general public [www.aquafaba.com/history.html# (accessed on 3 January 2023)].

Figure 1.

A simplified history of aquafaba.

A key discovery of aquafaba’s properties was made in December 2014 by Joël Roessel, a French tenor who tested egg substitutes on the example of the ‘floating island’ dessert, which uses egg white foam [http://www.revolutionvegetale.com/en (accessed on 18 December 2022)]. He found that red bean and hearts of palm aquafaba could produce foam similar to that from egg whites, but it was not stable. It was necessary to add corn starch and guar gum. A little later, in February 2015, two Frenchmen prepared a ganache using aquafaba. At the same time, an American, Goose Wohlt, made the first vegan meringue from aquafaba. The foam from aquafaba after the addition of sugar was stable and did not require any other stabilizers [www.aquafaba.com/history.html# (accessed on 3 January 2023)].

The term ‘aquafaba’ was coined on 13 March 2015 by Goose Wohlt and was adopted by the local community in a Facebook group and then officially included in the Oxford English Dictionary, Merriam Webster and Scrabble Dictionary. ‘Aquafaba’ consists of two Latin words. ‘Aqua’ means water and ‘faba’ means beans. Aquafaba means water from boiling the seeds of edible legumes [16]. Currently, the most popular is chickpea aquafaba, due to the high consumption of chickpeas in the world [14]. Since 2015, aquafaba has been constantly gaining popularity thanks to its simplicity and accessibility. It is used by cooking enthusiasts, professional chefs and bartenders. Scientists and food technologists are trying to deepen their knowledge about it and find new applications for it to best meet the current needs of consumers [www.aquafaba.com/community.html (accessed on 3 January 2023)].

Aquafaba has become popular due to its diverse functional attributes such as gelling, foaming, emulsifying and thickening properties. It owes them to its unique chemical composition rich in oligosaccharides, soluble polysaccharides, low molecular and water-soluble protein, phenolic compounds and saponins. In addition, aquafaba is attractive to many consumers because of its ease of accessibility, plant origin, ecofriendliness and low calorie content [16].

3. Methods of Production and Storage of Aquafaba

Most aquafaba is produced during chickpea processing [17]. Ready-to-use aquafaba can be obtained from the finished product: canned chickpea seeds [16]. Self-preparation of aquafaba consists of soaking the seeds in water in order to hydrate them to extract anti-nutrients from the raw material and reduced the time of cooking the seeds. Wieczorek et al. [19] proved using the example of beans and peas that soaking in hot water for two hours causes greater losses of anti-nutrients than soaking in cold water for 10 h. In contrast, He et al. [20] showed that aquafaba from chickpeas soaked for 16 h at 4 °C has the best emulsifying properties. Not all scientists decide to soak seeds [21]. Example parameters of soaking and cooking seeds of legumes are shown in Table 1.

Table 1.

Parameters of soaking and cooking seeds of legumes.

The next step is to cook the legumes, usually in boiling water at normal atmospheric pressure. High pressure cooking is also possible [37]. Soaking and cooking seeds is not a standardized process, but standardization of the aquafaba production process should be a priority for future aquafaba research [21]. Baik and Han [22] proposed one method of preparing aquafaba, i.e., boiling chickpeas in water, in a ratio of 1:5, for 30 min at 98 °C.

Another challenge for researchers is to determine an effective storage method for aquafaba. Most often it is sterilized and stored in cans or jars. The liquid can be frozen, but there are still no extensive studies evaluating the effect of freezing on the quality of the raw material. Probably a good way to store aquafaba is to dry it at 70 °C [38].

4. Chemical Composition of Aquafaba

The composition of aquafaba is formed by the diffusion of chemical molecules from seeds into water during cooking. In the process of soaking and cooking the seeds of legumes, the shell is weakened, so that the components contained in the cotyledons transfer into the water [37]. Soaking and cooking cause hydration and denaturation of proteins, gelatinization of starch, as well as progressive solubilization, depolymerization and loss of pectin polysaccharides [39]. Temperature, water-to-seed ratio, seed size and seed variety determine the diffusion rate of the various components and thus affect the composition of the aquafaba [40].

The chemical composition of aquafaba varies (Table 2). It depends on the seed species, variety and genotype; environmental conditions during seed growth (e.g., climate, soil type, fertilization); the time and proportions of soaking the seeds; the time, proportions and method of cooking the seeds; and other factors [41]. The researchers demonstrated differences between chickpea genotypes in seed weight, cover thickness and chemical composition, justifying differences in aquafaba composition of samples prepared under the same conditions [42]. Chickpea aquafaba was also examined in terms of preparation steps to obtain aquafaba with the best possible parameters. The chemical composition of aquafaba formed because of cooking the remaining legumes is not yet precisely known. Already during the soaking of seeds, the diffusion of components from seeds into water begins. The dry matter of water for soaking chickpeas contains 0.25 g/100 g of insoluble carbohydrates, 0.19 g/100 g of water-soluble carbohydrates, 0.13 g/100 g of ash and 0.08 g/100 g of protein [22].

Table 2.

Chemical composition of aquafaba.

Shim et al. [42] performed tests on aquafaba from 10 different cans of chickpeas and showed that aquafaba is characterized by a high-water content and is a fat-free product. The total carbohydrate content in the dry matter of aquafaba is 55–74% (70% for chickpeas) [45]. Carbohydrates insoluble in chickpea aquafaba constitute approx. 47% [46]. Aquafaba does not contain starch, which is probably due to the fact that large granules are created with intertwined chains that are resistant to high temperature [46]. Proton-NMR analysis showed the presence of about 20 compounds in aquafaba, including sugar (glucose, sucrose), alcohol (isopropanol, ethanol, methanol), amino acid (alanine), organic acid (lactic acid, acetic acid, succinic acid, citrate, formate, malate) and nucleoside (inosine, adenosine) [42].

The ash content in aquafaba was for green beans 0.75 g/100 g, chickpeas 0.57 g/100 g, green lentils 0.48 g/100 g and yellow split peas 0.40 g/100 g [24]. Aquafaba has a high content of micronutrients, especially copper, potassium and manganese [26]. Heat treatment of chickpeas and aquafaba itself can cause losses of micronutrients [47].

It is assumed that the content of anti-nutrients in aquafaba is much lower than in raw seeds [47]. Other anti-nutrients (mainly carbohydrates) contained in chickpeas include phytates (5.9 mg/g), oxalates, phenolic compounds (0.72–6.10 mg/g), tannins (4.85 mg/g), saponins (0.75–0.91 mg/g) and oligosaccharides (3.87–6.98 g/100 g) [25]. Oligosaccharides include raffinose (0.62–1.45 g/100 g), stachyose (0.74–2.56 g/100 g) and verbascose (0–0.19 g/100 g) [48].

5. Functional Properties of Aquafaba in Food Technology

5.1. Foaming Properties

The foaming properties of aquafaba were discovered first. It turns out that the foaming of aquafaba is similar to egg white (1:1 ratio) [17]. The foaming properties of aquafaba result from the presence of albumin as well as polysaccharides and saponins. Thanks to its protein content, aquafaba can foam, and thanks to the carbohydrate content, it remains stable. Saponins are believed to be responsible for facilitating the formation of air bubbles because they have an amphiphilic structure. He et al. [33] showed in their research that the higher the protein content in aquafaba, the higher the foaming efficiency. It was observed that extending the foaming time of aquafaba did not adversely affect the foaming properties, as is the case with egg white foam [17]. The foaming ability of aquafaba can be used in mousses, meringues, biscuits and meat roasts. Foamed chickpea aquafaba is shown in Figure 2.

Figure 2.

Meringue mass based on aquafaba (photo by Joanna Stasiak).

Other authors report that ultrasonic treatment can be used to enhance the foaming properties of aquafaba. Ultrasonication also improved foam stability, color and texture, as well as emulsifying capacity [31,45]. The foaming properties of aquafaba have been fairly well studied; however, the results of individual scientists vary depending on the other parameters of aquafaba (Table 3). Based on the examples of the collected publications, it can be concluded that one of the best yields and stability of aquafaba foaming can be obtained using chickpea seeds, which were previously soaked in water and then boiled in a ratio of 1:4 with water for 60 min.

Table 3.

Foaming and emulsifying properties of aquafaba.

5.2. Emulsifying Properties

The emulsion that is created using aquafaba is an ‘oil-in-water’ (O/W) emulsion. Using mechanical energy (e.g., a hand blender), oil molecules disperse in the aquafaba. The emulsifier is responsible for creating a layer separating oil from water [28]. It is thanks to the emulsifier that there is no stratification of the two fractions. Proteins that have amphiphilic properties are the emulsifier in aquafaba. They expose their hydrophilic part to the water contained in the aquafaba and their hydrophobic part to the oil. Saponins are considered surfactants that reduce the interfacial tension between water and oil. Polysaccharides contribute to increasing the stability of the emulsion by increasing the viscosity of the aqueous phase [16]. Aquafaba is characterized by a low content of dry matter (5–8%) and protein (0.85–1.5% in the wet state), which is another factor increasing the stability of the emulsion. Overall, more stable emulsions, protein–oil–water, contain low protein concentrations (0.2–1%) [16]. Aquafaba’s emulsifying ability can be used in, e.g., vegan mayonnaise [45].

Foaming and emulsification depend on many different factors including diversity and seed species and aquafaba production conditions. One publication noted that the best emulsion was formed when the seeds were soaked at a refrigeration temperature for 16 h [20]. Buhl et al. [44] have shown that the best properties for forming and stabilizing emulsions occur at pH 7. In other studies, it was found that the best emulsion was obtained by using chickpeas and water in a 2:3 ratio and boiling for 60 min. [37]. Subjecting aquafaba to high pressure also positively affects its emulsifying ability [30].

5.3. Gelling and Thickening Properties

When cooking seeds, there is a complete or partial denaturation of proteins that interact with water-soluble carbohydrates and retain water molecules, forming a gel, coagulate or sediment. During cooking, there is also the Maillard reaction [16,21]. Chickpeas have been found to have the best gelling properties and that the ability to gel is inversely correlated with the content of insoluble fiber [24]. The gelling and thickening process takes place in products with a higher water content (e.g., mousse) [50]. In products with a high dry matter content that are heat-treated (e.g., meringue), it only occurs to a small extent [20]. Alsalman et al. [30] have proven that aquafaba subjected to high pressure treatment improves its structure and gelling ability.

A promising area of use for aquafaba is 3D printing of food. A major problem faced by researchers is the shaping of the rheological properties of materials (paints, pastes, filaments) used for printing [51]. The specific structural-forming properties of aquafaba may contribute to the development of this new food production technique [52].

6. The Use of Aquafaba in Baking and Confectionery

6.1. Meringue

The physicochemical properties of aquafaba have a huge and only partially discovered innovative potential in the design of food for vegans. The use of aquafaba began with vegan meringue, and now it is added to food as an egg substitute and a substance that imparts desirable sensory properties and texture. The first meringues prepared from aquafaba from beans, chickpeas, whole green lentils and yellow split peas were tested. Meringue with chickpea and yellow pea aquafaba most closely resembled egg meringue. Aquafaba meringues were generally characterized by higher water activity and lower hardness [24]. In another experiment, meringue was prepared from chickpea aquafaba. Aquafaba was characterized by low efficiency and foaming stability, which may be due to too long cooking time. In sensory evaluation, meringue from aquafaba has gained a general acceptance. No differences in taste and texture were observed [27]. In the next experiment, a French meringue from chickpea aquafaba was prepared. Ultrasound was used at 50% and 100% of the device’s power, for 10, 20 and 30 min. The results showed that viscosity increased slightly, and foaming performance increased from 259% to 548% after 30 min of ultrasound use [31].

6.2. Crackers

Aquafaba has many unrecognized technological properties and nutritional values. When added to the dough for gluten-free crackers, it significantly changed the texture parameters of the product [25]. An increase in moisture content and a decrease in brittleness of crackers during 2-day storage at room temperature were found, probably because of increased water dynamics. The results obtained by Serventi et al. [25] show one of the limitations regarding the use of aquafaba, as a natural feature of crackers is their crunchiness.

6.3. Mousse

The foaming and emulsifying properties of aquafaba obtained from chickpeas and yellow peas make it possible to use it as an egg substitute in some dishes e.g., cream mousse [26]. The presence of specific chemical compounds (e.g., proteins, fiber, saponins) results in high emulsifying activity (46–54%). The aquafaba emulsions were extremely stable even after 1 day of storage (Figure 3).

Figure 3.

Dessert with vegan chocolate mousse from aquafaba (photo by Joanna Stasiak).

Damian et al. [26] showed that surface-active saponins may modify emulsions’ stability. Aquafaba showed a greater affinity for oil than for water. Aquafaba can replace eggs in raw confectionery products. This is a particularly valuable advantage in terms of food safety (microbial hazard, allergen). The panelists positively assessed the quality of the aquafaba product. They noticed a slightly lower sweetness, which may be due to the natural presence of calcium and sodium ions in the aquafaba.

6.4. Cake

A sponge cake was made with eggs replaced with aquafaba from canned chickpeas. The vegan sponge cake was similar to the traditional one. It had larger empty spaces and a darker skin [17]. A similar study also replaced eggs with chickpea aquafaba. The study prepared a control sample from eggs and four samples with varying degrees of egg replacement with aquafaba. It was concluded that replacing 50% of eggs with aquafaba does not adversely affect the physical properties of the dough, and the foaming efficiency is at a similar level [29]. Another product made of chickpea aquafaba was the muffin. Vegan muffins had similar characteristics to egg muffins. The best attempt turned out to be a muffin with the addition of citric acid [14]. In the production of dough, aquafaba can also replace palm oil. A lower level of color parameters in the crumb was observed. In addition, the dough with aquafaba retained moisture longer, which had a positive effect on sensory characteristics. It was found that aquafaba does not significantly alter the other parameters of the dough and can be used as a substitute for palm oil [53]. In another study, a gluten-free dough was made with eggs replaced with a mixture of aquafaba dry matter from chickpeas, lentil protein and citric acid. Physical characteristics were slightly lower than in the control sample with eggs, while sensory characteristics were at a similar level, and the final product contained more fiber [36]. Using aquafaba from chickpeas, Italian cookies were made—macaroons. The macaroons were subjected to sensory analysis, and quite a few testers did not distinguish between those made from aquafaba and the controls. Especially the texture of aquafaba macaroons was similar to the control sample [54].

6.5. Bread

The quality of various types of gluten-free bread was studied including the addition of aquafaba, xanthan gum, chickpea flour, cooked chickpea paste and water after soaking chickpeas. Bread with aquafaba was characterized by a softer consistency and a more homogeneous structure than the control sample. The remaining parameters were close to the control sample [23]. In another experiment, gluten-free bread was prepared with the addition of water after soaking the seeds (beans, garbanzo chickpeas, yellow split peas, whole green lentils and yellow soybeans). The seeds were soaked for 16 h in a ratio of 1: 3.3 (seeds/water). The structure of the bread with the addition of water after soaking the whole green lentils was the most porous and best represented the texture of the control sample [55].

6.6. Vegan Dairy Substitutes

Vegan whipped cream was prepared using aquafaba from chickpeas, sugar and xanthan gum. The product may correspond to Swiss meringue. Vegan whipped cream has been found to be a very good alternative to whipped cream in the production of vegan desserts [32]. A technology to produce vegan yogurt based on oat drink using aquafaba was also developed. Aquafaba had a beneficial effect on increasing water retention capacity and reducing syneresis. It has been found that aquafaba can serve as a gelling agent in vegan fermented products; however, the production process needs to be standardized [56]. Vegan ice cream was designed using chickpea aquafaba and yellow split peas. Aquafaba was used as an emulsifier. Ice cream using chickpea aquafaba was slightly darker, but in sensory assessment the difference was not noticeable; however, the overall acceptance was at a lower level [57,58].

7. Conclusions

Until recently, aquafaba was only seen as a waste product, but this view is changing. It was similar a long time ago with milk whey, which is now a valuable food raw material. Aquafaba possesses unique functional properties in food production and is an example of science’s response to the specific needs of the food market, especially in terms of shaping the structure. The application potential of aquafaba prepared from legumes opens up new possibilities in food technology, especially in the field of modifying rheological properties. In addition to the use of aquafaba as an egg replacement, new applications can be sought to improve the structural-shaping properties and nutritional value of food. It is necessary to optimize the production process in order to standardize the physical and chemical properties of aquafaba for industrial applications. The chemical composition and properties of many legume seeds remain unknown. The production and storage of aquafaba also needs to be addressed economically and logistically. Such efforts are highly empirical and require much experimentation. All the above-mentioned properties indicate the need for further research on aquafaba and its use in new products, not only in baking and confectionery, but also in the production of pasta or even in animal-based food recipes and 3D printing.

Author Contributions

Conceptualization, J.S., D.M.S. and J.L.; investigation and writing—original draft preparation, J.S.; writing—review and editing, J.L.; supervision, funding acquisition, D.M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- De Queiroz, F.L.N.; Raposo, A.; Han, H.; Nader, M.; Ariza-Montes, A.; Zandonadi, R.P. Eating competence, food consumption and health outcomes: An overview. Int. J. Env. Res. Public. Health 2022, 19, 4484. [Google Scholar] [CrossRef] [PubMed]

- Szczepaniak, I. Evaluation of food security and food self-sufficiency of Poland against the background of European Union countries. Int. Bus. Glob. Econ. 2008, 37, 168–182. (In Polish) [Google Scholar] [CrossRef]

- Schepers, J.; Annemans, L. The potential health and economic effects of plant-based food patterns in Belgium and the United Kingdom. Nutrition 2018, 48, 24–32. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Escamilla, R. Food Security and the 2015–2030 sustainable development goals: From human to planetary health. Curr. Dev. Nutr. 2017, 1, 1007005. [Google Scholar] [CrossRef]

- Tomczyk, E. Pro-ecological social attitudes as one of today’s ways of understanding sustainable development: Contemporary nutritional trends: Vegetarianism and veganism. Zrównoważony Rozw. Deb. Nauk. 2018, 3, 111–118. (In Polish) [Google Scholar]

- Boczar, P. Plant protein—Sources, production costs and quality. Zesz. Nauk. SGGW Warszawie Probl. Rol. Swiat. 2018, 18, 122–132. (In Polish) [Google Scholar] [CrossRef]

- Sharif, H.; Williams, P.; Sharif, M.; Abbas, S.; Majeed, H.; Masamba, K.; Safdar, W.; Zhong, F. Current progress in the utilization of native and modified legume proteins as emulsifiers and encapsulants—A review. Food Hydrocoll. 2018, 76, 2–16. [Google Scholar] [CrossRef]

- Szulc, K. Assessment of the possibility of using aquafaba in the production of vegetable emulsion. Technol. Prog. Food Process. 2021, 2, 56–61. [Google Scholar]

- Erem, E.; Icyer, N.C.; Tatlisu, N.B.; Kilicli, M.; Kaderoglu, G.H.; Toker, Ö.S. A new trend among plant-based food ingredients in food processing technology: Aquafaba. Crit. Rev. Food Sci. Nutr. 2021, 11, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Seid, H.; Rosenbaum, M. Low carbohydrate and low-fat diets: What we don’t know and why we should know it. Nutrients 2019, 11, 2749. [Google Scholar] [CrossRef]

- Vainio, A.; Niva, M.; Jallinoja, P.; Latvala, T. From beef to beans: Eating motives and the replacement of animal proteins with plant proteins among Finnish consumers. Appetite 2016, 106, 92–100. [Google Scholar] [CrossRef] [PubMed]

- Cader, P.; Lesiów, T. Veganism and vegetarianism as diets in the contemporary consumer society. Eng. Sci. Technol. 2021, 1, 9–33. (In Polish) [Google Scholar] [CrossRef]

- Bakaloudi, D.R.; Halloran, A.; Rippin, H.L.; Oikonomidou, A.C.; Dardavesis, T.I.; Williams, J.; Wickramasinghe, K.; Breda, J.; Chourdakis, M. Intake and adequacy of the vegan diet. A systematic review of the evidence. Clin. Nutr. 2021, 40, 3503–3521. [Google Scholar] [CrossRef] [PubMed]

- Nguyet, T.; Ngọc, N.; Quoc, L.; Tran, G. Application of chickpeas aquafaba with pre-treatment as egg replacer in cake production. Chem. Eng. Trans. 2021, 89, 7–12. [Google Scholar] [CrossRef]

- McKeown, P.; Dunn, R.A. ‘Life-style choice’ or a philosophical belief?: The argument for veganism and vegetarianism to be a protected philosophical belief and the position in England and Wales. Liverp. Law. Rev. 2021, 42, 207–241. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, R.; Reaney, M. Aquafaba, from food waste to a value-added product. Food Wastes By-Prod. 2020, 10, 93–126. [Google Scholar] [CrossRef]

- Mustafa, R.; He, Y.; Shim, Y.; Reaney, M. Aquafaba, wastewater from chickpea canning, functions as an egg replacer in sponge cake. Int. J. Food Sci. Technol. 2018, 53, 2247–2255. [Google Scholar] [CrossRef]

- Grizio, M.; Specht, L.; The Good Food Institute. Plant-Based Egg Alternatives: Optimizing for Functional Properties and Applications. 2021. Available online: https://gfi.org/wp-content/uploads/2021/02/Plantbasedeggalternatives.pdf (accessed on 29 January 2023).

- Wieczorek, C.; Sionek, B.; Przybylski, W.; Lahuta, L. The influence of culinary processing of legume seeds on the content of soluble carbohydrates. Zesz. Probl. Postępów Nauk. Rol. 2016, 584, 139–150. (In Polish) [Google Scholar]

- He, Y.; Purdy, S.; Tse, T.; Tar’an, B.; Meda, V.; Reaney, M.; Mustafa, R. Standardization of aquafaba production and application in vegan mayonnaise analogs. Foods 2021, 10, 1978. [Google Scholar] [CrossRef]

- Echeverria-Jaramillo, E.; Kim, Y.; Nam, Y.; Zheng, Y.; Cho, J.; Hong, W.; Kang, S.; Kim, J.; Shim, Y.; Shin, W. Revalorization of the cooking water (Aquafaba) from soybean varieties generated as a by-product of food manufacturing in Korea. Foods 2021, 10, 2287. [Google Scholar] [CrossRef]

- Baik, B.; Han, I. Cooking, roasting, and fermentation of chickpeas, lentils, peas, and soybeans for fortification of leavened bread. Cereal Chem. 2012, 89, 269–275. [Google Scholar] [CrossRef]

- Bird, L.; Pilkington, C.; Saputra, A.; Serventi, L. Products of chickpea processing as texture improvers in gluten-free bread. Food Sci. Technol. Int. 2017, 23, 690–698. [Google Scholar] [CrossRef]

- Stantiall, S.; Dale, K.; Calizo, F.; Serventi, L. Application of pulses cooking water as functional ingredients: The foaming and gelling abilities. Eur. Food Res. Technol. 2018, 244, 97–104. [Google Scholar] [CrossRef]

- Serventi, L.; Wang, S.; Zhu, J.; Liu, S.; Fei, F. Cooking water of yellow soybeans as emulsifier in gluten-free crackers. Eur. Food Res. Technol. 2018, 244, 2141–2148. [Google Scholar] [CrossRef]

- Damian, J.; Huo, S.; Serventi, L. Phytochemical content and emulsifying ability of pulses cooking water. Eur. Food Res. Technol. 2018, 244, 1647–1655. [Google Scholar] [CrossRef]

- Lafarga, T.; Villaró, S.; Bobo, G.; Aguiló-Aguayo, I. Optimization of the pH and boiling conditions needed to obtain improved foaming and emulsifying properties of chickpea aquafaba using a response surface methodology. Int. J. Gastron. Food Sci. 2019, 18, 100177. [Google Scholar] [CrossRef]

- He, Y.; Shim, Y.; Mustafa, R.; Meda, V.; Reaney, M. Chickpea cultivar selection to produce aquafaba with superior emulsion properties. Foods 2019, 8, 685. [Google Scholar] [CrossRef]

- Aslan, M.; Ertaş, N. Possibility of using ‘chickpea aquafaba’ as egg replacer in traditional cake formulation. Harran Tarım Gıda Bilim. Derg. 2020, 24, 1–8. [Google Scholar] [CrossRef]

- Alsalman, F.; Tulbek, M.; Nickerson, M.; Ramaswamy, H. Evaluation and optimization of functional and antinutritional properties of aquafaba. Legume Sci. 2020, 1, 1–15. [Google Scholar] [CrossRef]

- Meurer, M.; de Souza, D.; Ferreira Marczak, L. Effects of ultrasound on technological properties of chickpea cooking water (aquafaba). J. Food Eng. 2020, 265, 109688. [Google Scholar] [CrossRef]

- Nguyet, T.; Nguyen, T.; Buu, T.; Quoc, L. Effect of processing methods on foam properties and application of lima bean (Phaseolus lunatus L.) aquafaba in eggless cupcakes. J. Food Process. Preserv. 2020, 44, e14886. [Google Scholar] [CrossRef]

- He, Y.; Shim, Y.; Shen, J.; Kim, J.; Cho, J.; Hong, W.; Meda, V.; Reaney, M. Aquafaba from Korean Soybean II: Physicochemical properties and composition characterized by NMR analysis. Foods 2021, 10, 2589. [Google Scholar] [CrossRef] [PubMed]

- Nguyet, T.; Quoc, L.; Buu, T. Evaluation of textural and microstructural properties of vegan aquafaba whipped cream from chickpeas. Chem. Eng. Trans. 2021, 83, 421–426. [Google Scholar] [CrossRef]

- Karatay, G.; Galvão, A.; Hubinger, M. Storage stability of conventional and high internal phase emulsions stabilized solely by chickpea aquafaba. Foods 2022, 11, 1588. [Google Scholar] [CrossRef]

- Silva, P.; Kalschne, D.; Salvati, D.; Bona, E.; Rodrigues, A. Aquafaba powder, lentil protein and citric acid as egg replacer in gluten-free cake: A model approach. Appl. Food Res. 2022, 2, 100188. [Google Scholar] [CrossRef]

- Alsalman, F.; Tulbek, M.; Nickerson, M.; Ramaswamy, H. Evaluation of factors affecting aquafaba rheological and thermal properties. LWT 2020, 1, 1–33. [Google Scholar] [CrossRef]

- Aslan, M.; Ertaş, N. Foam drying of aquafaba: Optimization with mixture design. J. Food Process. Preserv. 2021, 4, e15185. [Google Scholar] [CrossRef]

- Chigwedere, C.M.; Olaoye, T.F.; Kyomugasho, C.; Jamsazzadeh Kermani, Z.; Pallares Pallares, A.; Van Loey, A.M.; Grauwet, T.; Hendrickx, M.E. Mechanistic insight into softening of Canadian wonder common beans (Phaseolus vulgaris) during cooking. Food Res. Int. 2018, 106, 522–531. [Google Scholar] [CrossRef]

- Kinyanjui, P.; Njoroge, D.; Makokha, A.; Christiaens, S.; Ndaka, D.; Hendrickx, M. Hydration properties and texture fingerprints of easy-and hard-to-cook bean varieties. Food Sci. Nutr. 2015, 3, 39–47. [Google Scholar] [CrossRef]

- Wood, J.A.; Tan, H.-T.; Collins, H.M.; Yap, K.; Khor, S.F.; Lim, W.L.; Xing, X.; Bulone, V.; Burton, R.A.; Fincher, G.B.; et al. Genetic and environmental factors contribute to variation in cell wall composition in mature desi chickpea (Cicer arietinum L.) cotyledons. Plant. Cell. Env. 2018, 41, 2195–2208. [Google Scholar] [CrossRef]

- Shim, Y.; Mustafa, R.; Shen, J.; Ratanapariyanuch, K.; Reaney, M. Composition and properties of aquafaba: Water recovered from commercially canned chickpeas. J. Vis. Exp. 2018, 132, e56305. [Google Scholar] [CrossRef]

- Raikos, V.; Hayes, H.; Ni, H. Aquafaba from commercially canned chickpeas as potential egg replacer for the development of vegan mayonnaise: Recipe optimization and storage stability. Int. J. Food Sci. Technol. 2020, 55, 1935–1942. [Google Scholar] [CrossRef]

- Buhl, T.; Christensen, C.; Hammershøj, M. Aquafaba as an egg white substitute in food foams and emulsions: Protein composition and functional behavior. Food Hydrocoll. 2019, 96, 354–364. [Google Scholar] [CrossRef]

- He, Y.; Meda, V.; Reaney, M.; Mustafa, R. Aquafaba, a new plant-based rheological additive for food applications. Trends Food Sci. Technol. 2021, 111, 27–42. [Google Scholar] [CrossRef]

- Lamich, L. Aquafaba, an Egg Substitute for Food Applications. Available online: http://hdl.handle.net/2445/184718 (accessed on 6 December 2022).

- El-Adawy, T. Nutritional composition and antinutritional factors of chickpeas (Cicer arietinum L.) undergoing different cooking methods and germination. Plant. Food Hum. Nutr. 2002, 57, 83–97. [Google Scholar] [CrossRef] [PubMed]

- Rachwa-Rosiak, D.; Nebesny, E.; Budryn, G. Chickpeas—Composition, nutritional value, health benefits, application to bread and snacks: A review. Crit. Rev. Food Sci. Nutr. 2015, 55, 1137–1145. [Google Scholar] [CrossRef]

- Kiliçli, M.; Bayram, M.; Said, O. Usage of Green. Pea Aquafaba Modified with Ultrasound in Production of Whipped Cream; Research Square: Durham, NC, USA, 2022. [Google Scholar]

- Tsykhanovska, I.; Yevlash, V.; Trishch, R.; Lazarieva, T.; Alexandrov, A.; Nikulina, A. Functional and technological properties of food additive “Magnetofood” in production of shaped jelly marmalade on agar and pectin. Food Sci. Technol. 2021, 15, 143–154. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Pandya, J.K.; McClements, D.J.; Lu, J.; Kinchla, A.J. Advancements in 3D food printing: A comprehensive overview of properties and opportunities. Crit. Rev. Food Sci. Nutr. 2022, 62, 4752–4768. [Google Scholar] [CrossRef]

- Baiano, A. 3D printed foods: A comprehensive review on technologies, nutritional value, safety, consumer attitude, regulatory framework, and economic and sustainability issues. Food Rev. Int. 2020, 38, 986–1016. [Google Scholar] [CrossRef]

- Karatay, G.; Rebellato, A.; Joy Steel, C.; Dupas Hubinger, M. Chickpea aquafaba-based emulsions as a fat replacer in pound cake: Impact on cake properties and sensory analysis. Foods 2022, 1, 2484. [Google Scholar] [CrossRef]

- Horner, D.; Huneycutt, E.; Ross, B. Nutrition and dietetic practice aquafaba and flax seed gel as a substitute for egg whites in french macaron cookies. J. Nutr. Diet. Pr. 2019, 3, 1–9. [Google Scholar]

- Huang, S.; Liu, Y.; Zhang, W.; Dale, K.; Liu, S.; Zhu, J.; Serventi, L. Composition of legume soaking water and emulsifying properties in gluten-free bread. Food Sci. Technol. Int. 2018, 24, 232–241. [Google Scholar] [CrossRef] [PubMed]

- Raikos, V.; Juskaite, L.; Vas, F.; Hayes, H. Physicochemical properties, texture, and probiotic survivability of oat-based yogurt using aquafaba as a gelling agent. Food Sci. Nutr. 2020, 8, 6426–6432. [Google Scholar] [CrossRef]

- Serventi, L.; Yang, Y.; Bian, Y. Cooking water applications. In Upcycling Legume Water: From Wastewater to Food Ingredients, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 105–120. [Google Scholar] [CrossRef]

- Yazici, G.; Taspinar, T.; Ozer, M. Aquafaba: A multifunctional ingredient in food production. Biol. Life Sci. Forum 2022, 18, 24. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).