Abstract

Valorizing natural resources through sustainable and eco-friendly processes is a cornerstone in pursuing a greener and more sustainable future. This study focuses on the green extraction of valuable compounds from rubber seed trees (Hevea brasiliensis). This underutilized resource has the potential to yield bioactive compounds of economic and ecological significance. We explore the application of environmentally friendly extraction techniques, including supercritical fluid extraction (SFE), microwave-assisted extraction (MAE) and ultrasound-assisted extraction (UAE), to harness the bioactive potential of rubber seeds. Our research encompasses a comprehensive analysis of the extracted compounds, including their characterization and quantification using state-of-the-art analytical techniques. Environmental and economic sustainability aspects are evaluated, shedding light on the green extraction processes’ ecological footprint and economic feasibility. The paper also delves into these extracted compounds’ diverse applications and utilization prospects, ranging from pharmaceuticals and nutraceuticals to cosmetic and industrial products. We discuss the commercial potential, market opportunities, and emerging trends these sustainable endeavours may shape. In conclusion, this study paves the way for a more sustainable path in harnessing valuable compounds from rubber seed trees, exemplifying the potential for green extraction techniques to play a pivotal role in the journey toward environmental stewardship and economic prosperity.

1. Introduction

In the annals of botanical taxonomy, Hevea brasiliensis stands as an unassuming yet profoundly consequential species, commonly known as rubber seed trees. These trees have earned their place in the annals of the human industry as the primary source of natural latex, serving as the lifeblood of the rubber manufacturing sector for centuries [1]. However, their significance transcends the sprawling rubber plantations that have dotted landscapes worldwide [2]. In an era where the spotlight is firmly fixed on environmental sustainability, these modest trees have emerged as potential champions of a greener, more sustainable future [3].

Beyond their role as the latex supplier for rubber production, rubber seed trees have become increasingly vital in the broader context of sustainability [4]. As the world grapples with mounting concerns over deforestation, escalating carbon emissions, and the inexorable depletion of natural resources, these hardy evergreens offer hope. They partake in the tireless battle for reforestation, rejuvenating landscapes depleted by human activity. Nevertheless, their contributions go even further. In a world where climate change looms large, rubber seed trees act as stalwart sentinels of carbon sequestration, diligently mitigating the adverse effects of a warming planet.

Moreover, the extraordinary adaptability of rubber seed trees to a myriad of ecosystems renders them indispensable to biodiversity conservation efforts [5]. Their presence enhances the resilience of ecosystems, promoting the survival of diverse flora and fauna. Rubber seed trees have emerged as emblematic exemplars of the multifaceted contributions that agroforestry can make to the tapestry of environmental sustainability [6]. However, the significance of these trees transcends their ecological benefits. Beyond their well-documented latex-producing prowess, rubber seed trees house a hidden treasure trove of bioactive compounds within their seeds, leaves, and bark. Within these unassuming plant parts lies the potential to further enhance the sustainability quotient of rubber seed trees. The objectives of this comprehensive review are threefold, converging towards a holistic exploration of rubber seed trees and their potential for sustainability.

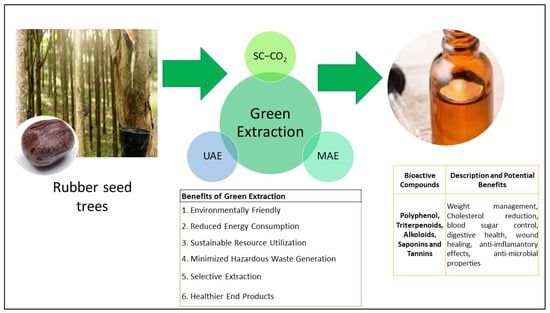

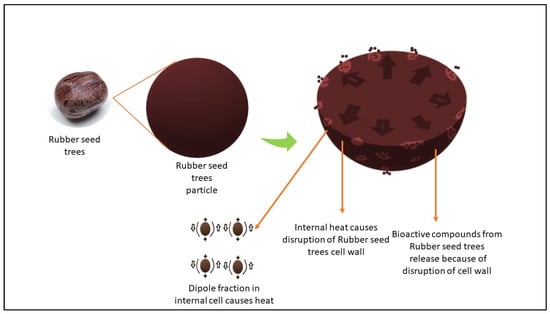

Firstly, we embark on a journey to provide a comprehensive overview of rubber seed trees’ role in sustainability, navigating through their environmental, economic, and social contributions. Through this lens, we seek to paint a vivid picture of how these trees intertwine with the sustainability narrative. Secondly, we examine the burgeoning green extraction techniques applied to rubber seed trees. Our quest is to unravel the current state of research in this domain, deciphering the potential of these green extraction methods to maximize the value derived from rubber seed trees while minimizing the often substantial environmental footprint associated with traditional extraction methods (Figure 1). Lastly, as torchbearers of scientific inquiry, we set our sights on the horizon, scanning for uncharted territories in sustainable rubber seed tree utilization. We aim to identify research gaps and plot the course for future investigations. We aspire to ignite the spark of innovation that will propel us toward a more sustainable coexistence with these invaluable trees.

Figure 1.

Schematic representation of valorization of rubber seed trees extract using a green process.

In the grand tapestry of sustainable resource utilization, the choice of extraction techniques is pivotal. In this review, we journey through green extraction methods. These techniques have ascended to prominence due to their remarkable capacity to diminish the environmental toll exacted by conventional counterparts. From the ethereal world of supercritical fluid extraction to the transformative power of microwave-assisted and ultrasound-assisted extraction, we explore the remarkable potential of these techniques when applied to the humble yet invaluable rubber seed trees.

In this multifaceted narrative, we envision a world where rubber seed trees flourish as emblematic assets of green extraction and sustainability, forging a path towards a more prosperous coexistence between humanity and the natural world. Through this comprehensive review, we embark on a profound journey of discovery, one that promises to unravel the myriad contributions of rubber seed trees to sustainability, explore the boundless potential of eco-friendly extraction techniques, and lay the groundwork for a future where these unassuming trees stand as steadfast sentinels of a greener, more sustainable world.

2. Scope and Method of the Review

This review encompasses a broad examination of rubber seed trees with a focus on their sustainability and the green extraction practices used to obtain them. We delve into the diverse extraction methods employed, such as supercritical fluid extraction, microwave-assisted extraction, and ultrasonic-assisted extraction, to provide insights into their environmental implications and efficiency. Furthermore, the review addresses the potential for upcycling rubber seed waste materials, a practice that aligns with the principles of sustainability by reducing agricultural waste and maximizing resource utilization. Additionally, we investigate the sustainability aspects of rubber seed tree, including their biodegradability and low residue concerns, emphasizing their suitability for integrated pest management approaches.

In the following sections of this manuscript, we explore the economic and ecological benefits of rubber seed trees. We also present case studies and applications to provide real-world examples of the success and challenges associated with their use.

The bibliographic research process conducted for this study was thorough and rigorous, encompassing a wide range of sources to ensure a comprehensive review of the literature. The research strategy included searching multiple reputable databases, systematically applying inclusion criteria, and scrutinizing reference lists for additional relevant studies. The research methodology involved searching three prominent databases: PubMed, Google Scholar, and ScienceDirect. These databases are known for their extensive coverage of the scientific literature, making them valuable resources for academic research. The inclusion criteria applied to these searches ensured that only studies relevant to the topic of rubber seed oil using green processes were considered.

The inclusion criteria required the presence of specific keywords from various categories. This approach helped to narrow down the search results and focus on studies directly related to the subject matter. The categories of keywords included “rubber seed tree”, “fatty acids”, “polyphenols”, “phytosterols”, “Green extraction”, “Environmental impact”, and “sustainability”. This method of categorization helped to ensure that the selected studies covered various aspects of the research topic. The decision not to impose a specific time frame limit on the search was deliberate and aimed at capturing a broad spectrum of literature. By not restricting the search to a particular period, the review encompassed studies published over several years, thus offering a more comprehensive understanding of the subject’s historical and contemporary aspects.

In total, the research process led to the review of approximately 108 journals, comprising journal articles and conference proceedings. This extensive scope of sources indicates the diligence of the research process in seeking a well-rounded view of the subject matter. Additionally, the effort to scrutinize the reference lists of reviewed articles is a commendable practice, as it helps identify further relevant studies that might have been overlooked during the initial search. Overall, this bibliographic research methodology demonstrates a rigorous and inclusive approach to sourcing and reviewing the literature on the topic of rubber seed trees using green processes. The extensive search, the categorization of keywords, and the absence of a time frame limit all contributed to a well-rounded and thorough examination of the subject.

3. Rubber Seed Trees: A Sustainable Resource

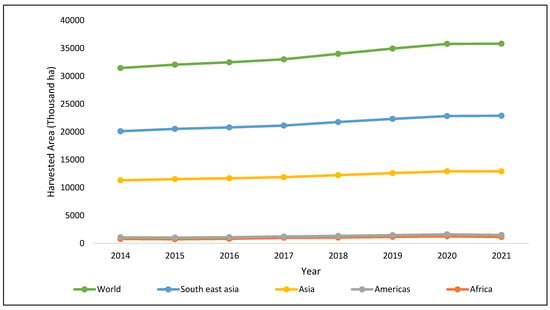

In 2023, the global harvested area of rubber seed trees surpassed a staggering 12.9 million tons, as illustrated in Figure 2. This substantial figure underscores the significant scale of rubber seed tree cultivation worldwide, revealing the species as a substantial agricultural resource. Furthermore, it is noteworthy that more than half of the world’s rubber production occurs in Asia, particularly in Southeast Asia [7], emphasizing the region’s pivotal role in global agricultural practices. However, despite the abundance of rubber seeds generated by the rubber industry, these seeds are frequently regarded as waste byproducts. This realization has sparked a crucial sustainability principle: the valorization of waste materials.

Figure 2.

Harvested area of rubber in the world from 2014 to 2021 [7].

Furthermore, rubber seeds are particularly rich in bioactive compounds [8]. They contain a variety of phytochemicals, including polyphenols, flavonoids, and tannins, which are known for their antioxidant properties [9]. These compounds can help combat oxidative stress in the human body, potentially reducing the risk of chronic diseases. By processing these seemingly discarded rubber seeds into valuable products, we not only minimize waste but also unlock additional economic and environmental value. In light of this, waste valorization becomes a commendable strategy for the global community, aligning with broader sustainability objectives by promoting efficient resource use, reducing waste generation, and potentially fostering economic opportunities from materials that were once considered mere byproducts [10].

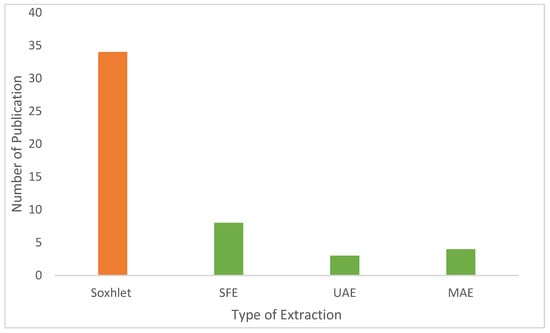

4. Significant Green Extraction for Rubber Seed Trees

The observed trend depicted in Figure 3, where research publications focusing on green extraction methods for rubber seed trees are fewer than those concentrating on conventional techniques like Soxhlet extraction, can be attributed to several key factors. Firstly, conventional extraction methods such as Soxhlet extraction have a long history of use in the scientific community, making them a default choice due to their established track record. Secondly, researchers often gravitate towards familiar and well-understood techniques, with expertise and historical precedence playing pivotal roles in method selection. Additionally, the standardized protocols and well-defined parameters of traditional methods make them easier to replicate and compare across studies, ensuring consistency in results.

Figure 3.

Numbers of publications related to extraction of rubber seed trees in Google Scholar from 2013 to 2023 with keywords “supercritical carbon dioxide extraction of rubber seed trees/microwave assisted extraction of rubber seed trees/Soxhlet extraction of rubber seed trees”.

Moreover, the availability of equipment and resources in laboratories catering to conventional techniques can pose a barrier to adopting green extraction methods, which may require additional investments. Publication bias favoring established methods in journals and a need for more awareness about the advantages of green extraction techniques can also influence researchers’ choices. Furthermore, some researchers may only embrace newer green methods with comprehensive validation and standardization. Lastly, industry practices, funding considerations, and the need for alignment with existing industrial processes can further perpetuate the dominance of conventional techniques.

In the foreseeable future, a significant shift in research trends is anticipated as awareness of environmental sustainability and the advantages of green extraction methods continue to grow. Several interconnected factors propel this transformation. Firstly, the global recognition of environmental issues, such as climate change and resource depletion, has fostered heightened sensitivity to the ecological impact of research practices. Secondly, green extraction methods inherently prioritize reduced environmental harm by employing eco-friendly solvents, reducing energy consumption, and minimizing hazardous waste generation, aligning with the prevailing sustainability ethos.

Thirdly, regulatory and ethical considerations are coming to the forefront, with stricter environmental regulations and heightened consumer expectations necessitating environmentally responsible research approaches. Furthermore, ongoing advancements in green technology are enhancing the efficiency and reliability of these methods, making them increasingly appealing. Research funding priorities also shift towards sustainability, incentivizing researchers to adopt green techniques. Additionally, the success stories of green extraction across diverse scientific fields erode skepticism and foster acceptance. Collaborative knowledge-sharing efforts within the scientific community and industry demands for sustainable practices further catalyze this change. As a result, researchers are poised to explore and adopt eco-friendly extraction methods, thereby contributing to a more sustainable and environmentally conscious trajectory for research and industry practices.

5. Green Extraction Principle Techniques

Green extraction principles encompass a set of guidelines and strategies aimed at minimizing the environmental impact of compound extraction processes while maximizing efficiency, safety, and product quality. These principles are aligned with the broader philosophy of green chemistry, emphasizing sustainability, resource efficiency, and the reduction in hazardous waste. Adhering to green extraction principles is essential for promoting ecological well-being and technological advancement in rubber seeds and bioactive compound extraction. Some fundamental green extraction principles include aspects detailed below.

5.1. Use of Renewable and Sustainable Solvents

Green extraction methods prioritize solvents that are derived from renewable sources. These are resources that can be naturally regenerated, ensuring their long-term availability. An exemplary choice in this category is CO2. Water is a ubiquitous and replenishable resource that is both environmentally benign and readily available. It plays a central role in numerous green extraction techniques, such as aqueous extraction and steam distillation. The use of CO2 aligns with sustainability goals by avoiding depletion of finite resources [11].

5.2. Minimization of Energy Consumption

The primary objective of green extraction procedures is to systematically minimize energy consumption by prioritizing the use of gentle operating conditions whenever feasible [12,13]. By implementing these eco-conscious technologies and methodologies, green extraction achieves a dual benefit: a significant reduction in the overall carbon footprint associated with the extraction process and a notable decrease in dependence on non-renewable energy sources. Essential techniques, such as microwave-assisted extraction (MAE) and ultrasound-assisted extraction (UAE), exemplify innovative approaches that optimize energy utilization throughout the extraction process, ultimately resulting in substantial energy consumption reduction [14].

5.3. Reduced Waste Generation

The core objective of green extraction techniques is to proactively reduce the generation of waste by optimizing the efficiency of the extraction process [15,16]. This sustainability-driven approach aims to minimize waste generation through various means, including the reduction in solvent volumes and shorter extraction durations. A prime example of a technique renowned for its capability to achieve substantial extraction yields while concurrently minimizing waste production is supercritical carbon dioxide (SC-CO2) extraction [17].

5.4. Preservation of Bioactive Compound Integrity

Green extraction methods are characterized by their unwavering commitment to preserving the integrity of bioactive compounds throughout the extraction process. At the heart of this approach is the conscious choice to utilize lower temperatures and to avoid harsh conditions that might lead to degradation or alteration of these valuable compounds [18]. By implementing gentler operating conditions and steering clear of extreme pH levels or exposure to strong acids or bases, green extraction methods minimize the risk of adverse chemical reactions that could compromise the structure and functionality of bioactive compounds [19]. Additionally, the selection of solvents is meticulously considered, with a preference for sustainable options like supercritical carbon dioxide or water, which selectively extract bioactive compounds without resorting to harsh organic solvents [20]. The ultimate goal is not only to safeguard the chemical structure of these compounds, but also to preserve their biological activity, ensuring that they remain efficacious for use in pharmaceuticals, nutraceuticals, and functional foods [21]. This commitment to the preservation of bioactive compounds reflects the holistic and responsible approach of green extraction, aligning with principles of sustainability and responsible resource utilization [22].

5.5. Enhanced Selectivity

Green extraction methodologies are distinguished by their emphasis on selectivity during the extraction process [23]. This strategic approach allows for the precise targeting of desired compounds while concurrently minimizing the extraction of undesirable components. By isolating the specific compounds of interest, green extraction techniques significantly enhance the purity of the extracted substances [24]. This, in turn, translates into a notable reduction in the requirement for additional purification steps. Such selectivity not only streamlines the extraction process, but also minimizes resource consumption and waste generation, aligning with principles of sustainability. It ensures that the final products are of high purity and quality, making them well-suited for applications in pharmaceuticals, nutraceuticals, and various other industries. Green extraction’s commitment to selectivity underscores its role in advancing both environmental responsibility and industrial efficiency [23].

5.6. Consideration of Health and Safety

Green extraction principles are underpinned by a steadfast commitment to safeguarding the health and safety of workers, consumers, and the environment [25]. This conscientious approach is achieved by avoiding the use of hazardous solvents and conditions that may pose risks to human health and the ecosystem. Traditional extraction processes often involve the deployment of toxic organic solvents and harsh conditions that can jeopardize the well-being of individuals involved in the extraction process [26]. In contrast, green extraction techniques prioritize the use of benign and eco-friendly solvents, such as water or supercritical carbon dioxide, which do not pose health risks to workers or consumers. By adopting milder operating conditions and choosing sustainable solvents, green extraction not only reduces the potential for accidents, but also contributes to a safer working environment and a healthier planet. This commitment to health and safety underscores the responsible and sustainable ethos that defines green extraction practices [27].

5.7. Economic Viability

While environmental sustainability remains a paramount objective, green extraction methods take a multifaceted approach that also considers economic viability [28]. These methods recognize that for widespread adoption and real-world impact, they must be not only eco-conscious but also economically feasible. As such, green extraction techniques prioritize cost-effective and efficient processes that ensure the practicality of large-scale implementation. By optimizing resource usage, minimizing waste generation, and reducing the need for costly purification steps, green extraction methods strike a balance between sustainability and economic competitiveness. This dual focus not only aligns with the broader principles of responsible resource utilization, but also positions green extraction as a pragmatic and viable solution for industries seeking to reduce their environmental footprint while maintaining economic viability [29].

Embracing green extraction principles in the context of rubber seed bioactive compound extraction not only contributes to sustainable practices, but also aligns with the increasing demand for environmentally responsible technologies across various industries. By harnessing the potential of green extraction, researchers and industries can unlock the bioactive treasures of rubber seeds while minimizing their ecological footprint.

6. Valuable Compounds in Rubber Seeds

Rubber seeds have long been revered for their pivotal role in the rubber industry as the primary source of natural rubber latex (NRL). However, beneath their reputation as rubber producers, these unassuming seeds conceal a treasure trove of valuable compounds that have garnered increasing attention from various industries. The economic and ecological potential of rubber seeds extends far beyond latex production, making them an intriguing subject of exploration. In recent years, research efforts have unveiled a diverse array of compounds within rubber seeds, ranging from proteins and oils to phytochemicals and antioxidants, each with its own unique set of applications in agriculture, food, cosmetics, pharmaceuticals, and renewable energy [30]. This review delves into the multifaceted world of valuable compounds harbored within rubber seeds, shedding light on their significance, extraction methods, and potential contributions to sustainability and industry. Beyond their conventional role, rubber seeds emerge as a promising resource in the quest for eco-friendly and economically viable solutions.

6.1. Phytochemicals

Rubber seeds harbor a rich reservoir of phytochemicals that have piqued the interest of researchers and industries alike [31]. Among these phytochemicals, prominent classes include saponins, alkaloids, and phenolic compounds, each with distinctive properties and potential applications in pharmaceuticals and nutraceuticals. Saponins are naturally occurring compounds in various plant species, including rubber seeds [32]. These compounds are characterized by their amphiphilic nature, which imparts them the ability to form foamy solutions when agitated, hence the name “saponin” derived from the Latin word “sapo”, meaning soap. Saponins are known for their potential medicinal properties, including anti-inflammatory, antioxidant, and immunomodulatory effects [33]. Some saponins have demonstrated cardioprotective and cholesterol-lowering activities, making them valuable for cardiovascular health. Additionally, saponins may have applications in drug delivery systems due to their unique physicochemical properties [34].

Alkaloids are a diverse group of nitrogen-containing compounds that exhibit various biological activities [35]. While alkaloids in rubber seeds have been reported, the specific types and their potential applications are subjects of ongoing research [31]. Alkaloids are well-known for their role as bioactive constituents in various medicinal plants. Depending on their chemical structure, they can have analgesic, antispasmodic, and even psychoactive effects [36]. Rubber seed alkaloids hold promise as potential candidates for drug development or as a source of bioactive compounds for nutraceutical applications.

Phenolic compounds are secondary metabolites widely distributed in plants, including rubber seeds [37]. These compounds encompass a broad spectrum of molecules, such as flavonoids, phenolic acids, and tannins, known for their potent antioxidant properties. Antioxidants are crucial in neutralizing harmful free radicals in the body, protecting against oxidative stress-related diseases, including cardiovascular disorders and cancer [38]. Phenolic compounds from rubber seeds are being explored for their potential nutraceutical and medicinal applications, contributing to the development of functional foods and dietary supplements.

Agbai, Olawuni, Ofoedu, Ibeabuchi, Okpala, Shorstkii and Korzeniowska [31]‘s study revealed a diverse range of anti-nutrient and phytochemical compositions obtained from rubber seed oil. The variations were observed in phytate levels (ranging from 19.62 to 6.97 mg/100 g), oxalate levels (ranging from 13.26 to 3.36 mg/100 g), tannin levels (ranging from 8.98 to 0.92 mg/100 g), saponin levels (ranging from 4.91 to 1.60 mg/100 g), HCN (hydrogen cyanide) levels (ranging from 12.41 to 1.97 mg/100 g), TI (Trypsin Inhibitor) levels (ranging from 8.43 to 0.97 TiU/mg), alkaloid levels (ranging from 4.54 to 0.97 mg/100 g), phenol levels (ranging from 2.77 to 0.50 mg GAE/g), and flavonoid levels (ranging from 60.00 to 40.00 mg QE/100 g). These findings highlight the variability in the chemical composition of rubber seed oil, providing valuable insights into its nutritional and bioactive content.

These phytochemicals in rubber seeds have sparked research into their potential pharmaceutical and nutraceutical applications [31]. Studies are ongoing to elucidate these compounds’ precise bioactive properties, mechanisms of action, and potential health benefits. The pharmaceutical industry is particularly interested in harnessing the therapeutic potential of these phytochemicals for drug development. Simultaneously, the nutraceutical sector explores how rubber seed phytochemicals can be incorporated into functional foods and dietary supplements to promote health and well-being.

In conclusion, the phytochemicals found in rubber seeds, including saponins, alkaloids, and phenolic compounds, represent a promising avenue of research with potential applications in pharmaceuticals and nutraceuticals. While much exploration remains, these compounds hold the key to unlocking rubber seeds’ health-promoting and medicinal properties, further emphasizing their significance beyond their traditional role in the rubber industry.

6.2. Tocopherols and Tocotrienols

Rubber seed oil is a noteworthy source of tocopherols, vitamin E and tocotrienols [31,39,40]. These compounds belong to the vitamin E family. They are renowned for their potent antioxidant properties, which have far-reaching implications in promoting health and their applications in the food and cosmetic industries. Tocopherols are a group of four closely related compounds: alpha-tocopherol, beta-tocopherol, gamma-tocopherol, and delta-tocopherol [41]. Among them, alpha-tocopherol is the most biologically active form and is recognized as a crucial nutrient with remarkable antioxidant abilities [42]. These compounds protect cells from oxidative damage caused by free radicals, highly reactive molecules that can harm DNA, proteins, and lipids. In rubber seed oil, tocopherols can significantly enhance its oxidative stability, prevent the oil from becoming rancid, and extend its shelf life [43].

Tocotrienols are structurally similar to tocopherols but possess a unique molecular configuration that enables them to penetrate cell membranes more effectively [44]. This property sets tocotrienols apart and enhances their bioavailability. Emerging research has highlighted the potential health benefits of tocotrienols, which include their antioxidant, anti-inflammatory, and neuroprotective properties [45]. Tocotrienols have shown promise in managing conditions like cardiovascular disease, diabetes, and cancer. In rubber seed oil, tocotrienols contribute to its overall antioxidant profile, bolstering its stability and making it an attractive choice for various applications.

Tocopherols and tocotrienols extracted from rubber seed oil can be applied in the food industry as natural antioxidants. They serve as alternatives to synthetic antioxidants like BHT (butylated hydroxytoluene) and BHA (butylated hydroxyanisole), often used to extend the shelf life of food products [46]. Tocopherols and tocotrienols are incorporated into various food products, including oils, baked goods, snacks, and nutritional supplements, to prevent oxidative rancidity, maintain product quality, and enhance food safety.

The findings of Reshad et al. [47], as indicated by the Proton Nuclear Magnetic Resonance (1H NMR) spectra, unveiled the composition of the obtained rubber seed oil (RSO). The analysis revealed that RSO comprises 13.17% linolenic acid, 39.86% linoleic acid, 27.06% oleic acid, and 19.91% saturated fatty acids. This detailed breakdown provides valuable insights into the fatty acid profile of rubber seed oil, contributing to a comprehensive understanding of its chemical composition.

The cosmetic industry also harnesses the antioxidant power of tocopherols and tocotrienols in rubber seed oil [48]. These compounds protect the skin from oxidative stress, UV radiation, and environmental pollutants. They play a vital role in promoting skin health, reducing the signs of ageing, and maintaining skin elasticity and hydration. Rubber seed oil and its derivatives formulate skincare products such as moisturizers, serums, and anti-ageing creams, offering consumers natural and effective solutions for their skincare needs.

In summary, tocopherols and tocotrienols in rubber seed oil are potent antioxidants known for their health benefits [40]. These compounds play a pivotal role in enhancing the oxidative stability of rubber seed oil, making it an ideal choice for applications in the food and cosmetic industries.

6.3. Phytosterols

Rubber seed oil is distinguished by its significant content of phytosterols, plant compounds structurally similar to cholesterol. Liu et al. [49] found that the contents of P-sitosterol are 12.13 and 11.22 mg/g in crude and refined rubber seed oil, respectively. These natural compounds have garnered attention for their potential health benefits, particularly their cholesterol-lowering effects, making them valuable components in functional food products. Phytosterols, also known as plant sterols or stanols, share a structural resemblance to cholesterol, which is a vital component of cell membranes in humans [50]. However, phytosterols differ in their origins and sources, primarily from plants. Their structural similarity to cholesterol allows them the ability to compete with cholesterol for absorption in the intestinal tract.

The primary health benefit associated with phytosterols is their cholesterol-lowering effect [51]. When consumed, phytosterols interfere with the absorption of dietary cholesterol in the gut. By competing with cholesterol for absorption, phytosterols effectively reduce the amount of cholesterol that enters the bloodstream [52]. This mechanism has been well documented in clinical studies, demonstrating that regular consumption of phytosterol-rich foods can reduce low-density lipoprotein (LDL) cholesterol, often called “bad” cholesterol. This effect is particularly significant for individuals with elevated cholesterol levels and those at risk of heart disease.

Phytosterols have found a prominent place in the formulation of functional food products to promote heart health [53]. Functional foods offer specific health benefits beyond their essential nutritional value. Phytosterol-enriched foods, such as spreads, margarine, yoghurt, and cereal bars, have been developed to provide a convenient and effective means of incorporating these cholesterol-lowering compounds into one’s diet. These products are often marketed as heart-healthy options for individuals looking to manage their cholesterol levels naturally.

Phytosterol-enriched foods have also received regulatory approval in various countries, including the United States and the European Union, as practical dietary tools for managing cholesterol [54]. Health organizations like the American Heart Association endorse consuming phytosterol-rich foods as part of a heart-healthy diet. Phytosterols can also work synergistically with other heart-healthy nutrients, such as soluble fiber and omega-3 fatty acids, further enhancing their cholesterol-lowering potential [55]. Functional foods that combine these ingredients offer a comprehensive approach to cardiovascular health.

In conclusion, phytosterols found in rubber seed oil might represent a valuable natural resource with notable health benefits, particularly in managing cholesterol levels. Their incorporation into functional food products provides consumers with accessible and effective means of promoting heart health. The cholesterol-lowering effects of phytosterols underscore their potential contribution to reducing the risk of cardiovascular disease, making them a key player in functional foods and nutritional interventions for heart health.

6.4. Squalene

Squalene is a remarkable natural hydrocarbon found in various sources, including rubber seed oil. The study by Bessa et al. [56] revealed a significant finding that when the extraction conditions by supercritical carbon dioxide are set at 20 MPa and 60 °C, squalene constitutes a remarkable 78% of the oil composition. Its unique chemical structure and properties make it a versatile compound with applications spanning different industries, from cosmetics to pharmaceuticals. Squalene has earned recognition in the cosmetics industry for its exceptional moisturizing properties [57]. It is highly compatible with human skin due to its structural similarity to the skin’s natural lipids, specifically sebum. This compatibility makes squalene an effective emollient and skin conditioner. When applied topically, squalene helps hydrate and nourish the skin, sealing in moisture and preventing water loss. This not only enhances skin hydration, but also improves its softness and elasticity. These properties make squalene a valuable ingredient in various skincare products, including moisturizers, serums, creams, and lotions [58]. Squalene’s ability to penetrate the skin’s barrier allows it the ability to deliver other beneficial compounds, such as vitamins and antioxidants, deeper into the skin, maximizing its effectiveness. This makes it an essential component in many anti-ageing and repairing skincare formulations.

Squalene also has a crucial role in vaccine development as an adjuvant studied by Garçon et al. [59]. Adjuvants are added to vaccines to enhance the body’s immune response to the target antigen (e.g., a virus or bacteria). Squalene’s immunological properties make it an ideal candidate for vaccine adjuvants [60]. When introduced into a vaccine formulation, squalene stimulates a more potent and more effective immune response. It achieves this by increasing the persistence of the antigen at the injection site, recruiting immune cells, and promoting the production of antibodies. Squalene-based adjuvants have been utilized in influenza vaccines and have shown promise in enhancing the body’s defense against viral infections described by Nicholls et al. [61]. They are particularly beneficial in vaccines for vulnerable populations, such as the elderly, where a robust immune response is critical. Importantly, squalene-based adjuvants have demonstrated a high level of safety and efficacy in vaccine formulations, contributing to developing protective and well-tolerated vaccines.

In conclusion, squalene, a natural hydrocarbon in rubber seed oil, exhibits diverse and valuable applications. In the cosmetics industry, it is a potent moisturizing agent and skin conditioner, enhancing skin hydration and promoting health and appearance. In the realm of vaccines, squalene is an adjuvant, bolstering the immune response to antigens and contributing to the development of effective and safe vaccines. This versatility underscores the importance of squalene as a natural resource with many applications, from skincare to public health.

6.5. Glyceride Components of Rubber Seed

The glyceride components of rubber seeds refer to the various forms of glycerol esters found in the seed oil. Glycerides are the main constituents of plant oils and fats, and they play a crucial role in determining the properties and applications of the oil [62]. In the context of rubber seed oil, glyceride components include different triglycerides which are formed by the esterification of glycerol with fatty acids. Rubber seed oil typically contains a diverse array of glycerides, each composed of glycerol and three fatty acid chains [63]. The specific composition of glycerides in rubber seed oil can vary based on factors such as the plant’s genetics, environmental conditions, and the extraction method used [64]. Triglycerides are the predominant glyceride form, and the types of fatty acids linked to glycerol contribute to the oil’s characteristics, such as its viscosity, stability, and potential applications [65].

The potential of rubber seed oil (RSO) as a feedstock for biodiesel production in Bangladesh was explored by Morshed, Ferdous, Khan, Mazumder, Islam and Uddin [62]. Various extraction methods, including mechanical press with and without solvent and cold percolation, were employed to extract RSO from locally collected rubber seeds. The highest oil content, reaching 49%, was achieved using a mechanical press with a periodic addition of solvent. The physico-chemical properties of the oil were extensively investigated. The impact of seed storage time on the free fatty acid (FFA) content revealed an increase from 2 wt.% in fresh seeds to 45 wt.% after 2 months of storage at room temperature. The biodiesel production process involved a three-step method, encompassing saponification of the oil, acidification of the soap, and esterification of FFA. The overall yield of FFA from RSO was determined to be approximately 86%. The final esterification step yielded fatty acid methyl ester (FAME), confirmed by the analysis of 1H NMR spectra of both RSO and biodiesel samples.

7. Green Extraction of Rubber Seed Oil

The introduction to the green extraction of rubber seed oil (RSO) signifies a pivotal step towards sustainable and environmentally conscious practices in the oil extraction process. As the global demand for alternative and eco-friendly energy sources continues to rise, the exploration of green extraction methods gains significance in harnessing the potential of rubber seeds. This section delves into the innovative approaches and methodologies employed in extracting RSO, emphasizing a commitment to ecological responsibility, reduced environmental impact, and the maximization of bioactive compounds from rubber seeds through environmentally friendly techniques. The green extraction of RSO holds promise not only for its potential applications in biodiesel production but also for contributing to a more sustainable and eco-conscious energy landscape. Description of green extraction is shown below.

7.1. Supercritical Fluid Extraction (SFE)

Supercritical Fluid Extraction (SFE) is regarded as a very promising and environmentally friendly method for the extraction of bioactive chemicals from rubber seed plants, as highlighted by Yiana et al. [66]. This novel approach utilizes the distinctive attributes of supercritical fluids, which are substances that are kept at temperatures and pressures beyond their critical points, hence displaying features that lie between those of gases and liquids. Carbon dioxide (CO2) is generally recognized as the most extensively used supercritical fluid due to its non-toxic, non-flammable, and easily accessible characteristics.

SFE utilizes the tunability of supercritical carbon dioxide (CO2) to selectively extract particular compounds, eliminating the need for hazardous solvents [10]. In the case of rubber seed trees, this strategy has a number of discernible benefits. The procedure involves subjecting carbon dioxide (CO2) to compression above its critical pressure, resulting in its transition to a “supercritical” state. This state is characterized by a combination of diffusivity similar to that of a gas and density comparable to that of a liquid [67]. Within this particular condition, CO2 permeates complex structures, such as rubber seed trees, with a high degree of effectiveness, sucessfully dissolving certain substances, such as phenolic compounds, fatty acids and lipids.

One notable advantage of SFE is its ability to function at lower temperatures, hence reducing the potential destruction of heat-sensitive bioactive compounds [68]. Moreover, the process of supercritical CO2 extraction exhibits a remarkable degree of versatility as it allows for precise control over pressure and temperature parameters [69]. This enables the extraction of targeted molecules while effectively excluding undesirable elements. After the extraction process, the supercritical CO2 rapidly undergoes phase transition to its gaseous state, resulting in the formation of a concentrated extract that is free from solvents. This extract can be readily separated from the solvent. The lack of residual solvents enhances the quality of the extracted chemicals [70].

However, the implementation of SFE does provide a series of difficulties. According to Putra et al. [71], the financial obstacle that may arise from the initial investment in equipment, namely the high-pressure systems required to sustain supercritical conditions, may be significant. Furthermore, thorough study and testing is necessary due to the complexities involved in optimizing extraction parameters for various kinds of rubber seed trees and its compounds. In spite of the obstacles faced, the sustainable and targeted characteristics of SFE position it as an environmentally friendly substitute for traditional extraction methods. This aligns harmoniously with the growing need for extraction techniques that are both environmentally responsible and efficient in obtaining bioactive compounds from rubber seed trees.

Furthermore, the intricate nature of optimizing extraction parameters for various species of rubber seed trees and their corresponding chemicals need comprehensive investigation and empirical analysis. Notwithstanding these obstacles, the sustainable and discerning characteristics of SFE establish it as an ecologically sound alternative to traditional extraction methodologies, thereby harmonizing with the increasing need for environmentally conscious and effective extraction approaches within the domain of bioactive compounds derived from rubber seed trees.

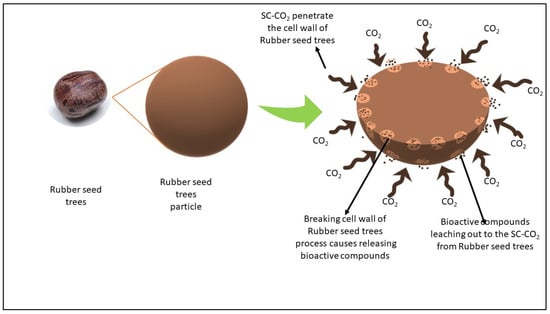

7.1.1. Principle and Mechanism

In the context of SFE for the retrieval of bioactive compounds from rubber seed trees, the precise control of different extraction parameters is of utmost significance in defining the overall yield and efficiency of the extraction procedure (Figure 4). Pressure plays a pivotal role among these factors, since elevated pressure levels are often associated with enhanced yields and its solubility [72]. Increasing the pressure applied to SC-CO2 boosts its ability to dissolve compounds, leading to more efficient dissolving of substances and subsequently enhanced recovery from the matrix of rubber seed trees (Table 1).

Figure 4.

The extraction mechanism of rubber seed plants using supercritical carbon dioxide (SC-CO2).

Temperature is an additional crucial factor that significantly impacts extraction yields, although requiring careful balance. The careful choice of the most suitable temperature is of utmost importance, as excessively elevated temperatures have the potential to cause thermal degradation of delicate compounds, which may lead to a compromise in their integrity and overall quality [73]. On the other hand, very low temperatures might potentially hinder the efficacy of extraction due to the restricted solubility of the desired compounds [74].

The impact of CO2 flow rate on overall yield has been identified as a significant factor [75]. Increasing the flow rate has the potential to boost the overall output and solubility of compounds into the solvent. A higher rate of CO2 flow enhances the effectiveness of mass transfer, accelerating the movement of extracted compounds from the matrix of rubber seed trees into the supercritical fluid phase [76]. The deliberate incorporation of co-solvents into a process offers an additional approach for enhancing the overall production output. By strategically integrating a co-solvent into SC-CO2, it is possible to significantly enhance the solubility of certain compounds [77]. This, in turn, facilitates the extraction of these compounds from the matrix of shrimp shells.

Ultimately, the manipulation of particle size presents a supplementary aspect to augmenting productivity. The use of smaller particle sizes results in an increased surface area, which facilitates a higher number of interaction sites between SC-CO2 and the matrix of rubber seed trees [78]. The increased level of interaction between components leads to a greater breakdown of compounds, hence augmenting the effectiveness and output of the extraction process [79]. The aforementioned subtle adjustments made to the extraction parameters highlight the complexities associated with SFE and its capacity for precise optimization in order to achieve the highest possible retrieval of bioactive compounds from rubber seed trees.

The period of time of the extraction process is also an important component. According to Lenucci et al. [80], lengthier extraction times often lead to increased yields due to the prolonged engagement between the supercritical fluid and the matrix. This extended interaction time facilitates higher diffusion of compounds into the solvent [81]. Nevertheless, the process of matrix pre-treatment has the potential to substantially modify this dynamic. The use of pre-treatment techniques to the matrix of rubber seed trees, such as the disruption of cell walls, has been shown to significantly enhance the overall yield [82]. The use of this procedure improves the availability of bioactive compounds, especially fatty acids from rubber seed trees, facilitating more effective interaction with the supercritical fluid and resulting in increased compound retrieval. Finally, it is crucial to carefully analyze the density of particle packing inside the matrix. The achievement of an optimized packing density plays a crucial role in facilitating the effective penetration of SC-CO2, hence enhancing the interaction between SC-CO2 and the surface area of rubber seed trees. This ultimately leads to better extraction efficiency and higher recovery of the desired compounds.

Table 1.

The impact of supercritical carbon dioxide (SC-CO2) on the recovery of yield and bioactive compounds: an analysis of parameters.

Table 1.

The impact of supercritical carbon dioxide (SC-CO2) on the recovery of yield and bioactive compounds: an analysis of parameters.

| Parameter | Effect on Yield and Recovery | Explanation | Ref |

|---|---|---|---|

| Pressure | The application of elevated pressure results in a corresponding augmentation in the quantity of yield product obtained. | The solubility of compounds is observed to be enhanced at elevated pressure conditions. | [72] |

| Temperature | The adjustment of temperature conditions facilitates the accomplishment of maximal yield recovery. | Increased temperatures possess the capacity to initiate the degradation of chemical substances. | [83] |

| CO2 Flow Rate | The possibility for enhancing the total yield exists with an increase in flow rates. | Increased flow velocity may lead to enhanced mass transfer. | [84] |

| Co-Solvent | Increasing the concentration of co-solvent has the potential to enhance the total yield in some cases. | The inclusion of a co-solvent has the capacity to augment solubility. | [71] |

| Particle Size | The use of smaller particles has the potential to enhance overall yield. | The augmentation of surface area promotes the process of extraction. | [79] |

| Extraction Time | Extended extraction durations have the potential to result in increased yield. | A longer duration of extraction facilitates enhanced diffusion of compounds. | [85] |

| Matrix Pre-Treatment | The use of matrix pre-treatment has the potential to enhance yield. | The enhancement of bioactive compound release is facilitated by the disruption of cell walls. | [86] |

7.1.2. Current Studies on Rubber Seed Trees by SC-CO2

The utilization of SC-CO2 for the extraction of bioactive compounds from rubber seed trees has been the subject of recent research. These investigations have provided significant insights into the potential and effectiveness of this extraction method. The aforementioned investigations examine a range of facets pertaining to the extraction process, including the optimization parameters, characterization of extracted substances, and the prospective uses thereof. The impact of many essential factors, including pressure, temperature, and extraction time, on the yield and selectivity of SC-CO2 extraction from rubber seed trees has been the subject of investigation by researchers. Numerous studies have been conducted with the objective of determining the ideal circumstances that may effectively enhance the extraction of certain bioactive chemicals, while simultaneously ensuring the maintenance of their overall quality. These studies provide significant insights and recommendations for attaining increased yields and preserving target molecules via comprehensive testing and analysis.

In addition, current scholarly investigations have been dedicated to the characterization of bioactive compounds obtained by the utilization of the SC-CO2 extraction method from rubber seed trees (as shown in Table 2). Sophisticated analytical techniques, including chromatography and spectroscopy, have been used to discern and measure the precise chemical constituents found inside the extracts. The characterization of the extracted compounds is of utmost importance in comprehending their composition and possible bioactivity, as this knowledge might have significant ramifications for their use in industrial and medicinal sectors. In addition to the optimization and characterization of chemicals, scholarly investigations have been conducted to study the possible uses of bioactive compounds derived from rubber seed trees using supercritical carbon dioxide extraction. These uses include a wide range of sectors, such as medicines, nutraceuticals, functional foods, cosmetics, and agriculture. The compounds under investigation are now being assessed by researchers for their potential antioxidant, anti-inflammatory, antibacterial, and other health-enhancing qualities. These studies aim to showcase the utility and adaptability of these compounds in various situations.

Table 2.

Previous study of rubber seed tree extract by SC-CO2 extraction.

In their study, Lee, Mohd-Setapar, Sharif, Ahmad, Khatoon, Ida-Idayu and MuhamadAzizi [87] explored various extraction methods to obtain seed oil. They utilized both traditional and environmentally friendly techniques. One such eco-friendly method was SC-CO2 extraction, which employed carbon dioxide in its supercritical state as a solvent. Under optimized conditions of a 30 MPa pressure and a 60 °C temperature, SC-CO2 extraction yielded the highest oil yield at approximately 33.562% grams of oil per sample. This method showcased its effectiveness in obtaining a significant amount of rubber seed oil while maintaining environmental sustainability. In contrast, the traditional Soxhlet extraction method was employed using petroleum ether as the solvent. Based on their studies, this method yielded a relatively higher percentage of oil per sample, with an oil yield of 56%. The efficiency of Soxhlet extraction in extracting rubber seed oil was evident, making it a potent technique for obtaining substantial oil yields. On the other hand, the use of a mixture of water and ethanol as a solvent in the extraction process resulted in a considerably lower oil yield, ranging from 7% to 12%. This indicated that the water and ethanol mixture was less effective compared to the other extraction methods. In summary, the study of Lee et al. presented a comparative analysis of extraction methods for rubber seed oil, showcasing the potential of SC-CO2 extraction as a green and efficient technique and the efficiency of Soxhlet extraction with petroleum ether. These findings underscored the importance of selecting appropriate extraction methods based on both their effectiveness and their environmental impact.

In their study, Yiana, Putraa, Idhama, Mohd, Idrusa, Setaparb, Azizi and Yunusa [66] conducted a comprehensive investigation into the impact of particle sizes on the supercritical carbon dioxide extraction process of rubber seed oil. Under the experimental conditions of a 30 MPa pressure and a 60 °C temperature, utilizing rubber seed particles with an average size of 500 μm yielded remarkable results. The maximum oil recovery rate achieved was 34.71%, showcasing the pivotal role played by this specific particle size in optimizing oil yield. Additionally, the study revealed a diffusivity coefficient of 5.13 × 10−12 m2/s, indicating efficient mass transfer during extraction, and an extraction rate of 0.6 mg/sec, denoting the speed at which oil was extracted. Morphological characterization using scanning electron microscopy (SEM) aligned with the particle size results, highlighting the importance of particle size control. Furthermore, gas chromatography mass spectrometry (GC-MS) analysis unveiled the presence of essential fatty acids and valuable chemical constituents within the extracted rubber seed oil, underscoring its potential beyond yield. These findings collectively emphasized the critical role of particle size in optimizing the supercritical carbon dioxide extraction process for rubber seed oil and illuminated the valuable chemical composition of the extracted oil.

The supercritical carbon dioxide extract of rubber seeds, as analyzed by Nian-Yiana, Penga, Mohd-Setapara, Idhama, Yunusa and Muhamadb [88], stands out for its high content of alpha-linolenic acid (ALA), measuring at 19.22% ± 0.21. This concentration surpasses the levels found in commonly used oils such as palm oil and soybean oil. ALA is a pivotal component of omega-3 fatty acids, which hold significant importance in human metabolism. These fatty acids not only serve structural roles in cell membranes, but also function as precursors to bioactive molecules crucial for various physiological processes. Omega-3 fatty acids, categorized as polyunsaturated fatty acids, possess notable properties that make them valuable for human health. Their easy absorption by the skin plays a key role in expediting the healing process within the body, primarily attributed to their capacity to promote angiogenesis, the formation of new blood vessels. This angiogenic effect facilitates improved blood circulation to injured areas, aiding in the delivery of essential nutrients and oxygen for tissue repair. Furthermore, studies have indicated that unsaturated fatty acids, like omega-3 fatty acids, can enhance the production of cytokines and growth factors that regulate local cellular responses to injury. These bioactive molecules play a critical role in orchestrating the body’s healing mechanisms, including inflammation control, tissue regeneration, and immune response modulation. As a result, the presence of ALA in the supercritical carbon dioxide extract of rubber seeds not only underscores its nutritional value, but also suggests its potential as a natural resource for promoting health and facilitating the body’s healing processes. In summary, the rich content of alpha-linolenic acid (ALA) in the supercritical carbon dioxide extract of rubber seeds highlights its significance as a source of omega-3 fatty acids, known for their multifaceted roles in human metabolism and health. The potential benefits of ALA, including its angiogenic properties and influence on cytokines and growth factors, make it a valuable component with promising applications in nutrition, skincare, and potentially in promoting healing and recovery in the human body.

The extraction of rubber tree seed oil was conducted using both Soxhlet and supercritical extraction methods, with varying operational conditions also conducted by Nian-Yiana, Penga, Mohd-Setapara, Idhama, Yunusa and Muhamadb [88]. Among the tested conditions, it was observed that the combination of a 50 MPa pressure and a 60 °C temperature yielded the highest oil extraction yields. The extraction time ranged from 220 min for the condition of 35 MPa at 60 °C to 360 min for 24.4 MPa at 74 °C. Notably, there were significant differences in the composition of the extracts obtained through these methods. The extracts obtained using supercritical carbon dioxide exhibited a high degree of selectivity, particularly for alpha-linolenic acid, linoleic acid, and squalene. It is worth mentioning that while the extraction of alpha-linolenic acid required pressures higher than 40 MPa, lower pressures proved effective in obtaining squalene-rich extracts. Squalene is a valuable compound with diverse applications, including the use as a moisturizing agent in cosmetics and as an adjuvant in vaccines. Statistical analysis of the extraction process revealed that pressure was the most critical variable in increasing oil yield, enhancing oil solubility, and extracting the main components effectively. Solubility models were employed to establish correlations between experimental data and predict the optimal conditions for extracting rubber tree seed oil. In summary, the study demonstrated that the choice of extraction method and operational conditions significantly impacted the composition of the extracted oil. Supercritical CO2 extraction displayed selectivity for specific components, particularly alpha-linolenic acid, linoleic acid, and squalene. The findings emphasized the importance of pressure as a key factor in optimizing oil extraction and solubility. The use of solubility models allowed for the prediction of optimal conditions for extracting oil from rubber tree seeds, contributing to the efficient utilization of this valuable resource.

Cumulatively, the present investigations emphasize the importance of using SC-CO2 extraction as a means to unleash the bioactive capabilities inherent in rubber seed trees. The current research endeavors are not only enhancing the scientific comprehension of extraction procedures, but also uncovering novel opportunities for using the wide array of chemicals found in rubber seed plants for pragmatic and environmentally friendly applications in numerous sectors. The use of supercritical carbon dioxide extraction has significant potential owing to its acknowledged safety and ecologically sustainable attributes as a solvent. This approach presents a prospective resolution for the extraction of bioactive components from undesirable or inferior seaweeds. The extracted substances possess several uses, including their utilization as additives in the culinary and medicinal industries. Furthermore, these extracts possess the potential to be used in the advancement of novel health supplements. The ecologically friendly characteristics of SC-CO2 extraction are in line with current trends in sustainable and eco-friendly extraction methods, making it a desirable choice for the extraction of valuable chemicals from natural sources such as rubber seed trees. This study presents novel opportunities for the use of extracts derived from rubber seed trees across many sectors, hence presenting potential advantages for human well-being and ecological preservation.

7.2. Microwave Assisted Extraction (MAE)

The use of MAE has garnered considerable interest due to its unique and effective approach in extracting bioactive compounds from rubber seed plants, as highlighted by Creencia et al. [89]. The method described in this study employs microwave radiation to expedite the heating process of both the solvent and the matrix, hence promoting the liberation of desired compounds into the extraction solution. The utilization of MAE presents a range of benefits, such as the reduction in extraction duration, enhancement of compound output, and safeguarding of thermally bioactive compounds. Recent research has been conducted on the use of MAE for the extraction of rubber seed trees, with a focus on investigating its efficacy in improving the extraction process. The impacts of several factors, including microwave power, extraction duration, solvent type, and solid-to-solvent ratio, have been examined by researchers in order to assess their impact on the yield and quality of extracted chemicals. Through the methodical manipulation of these factors, researchers endeavor to identify the optimal circumstances that result in the greatest extraction efficiency while preserving the bioactivity of the substances.

In addition to the process of optimization, scholarly investigations have been directed towards the characterization of bioactive chemicals acquired using MAE from rubber seed trees. Analytical techniques, such as chromatography and spectroscopy, are used for the purpose of identifying and quantifying distinct chemical components. The present research offers valuable information into the chemical makeup and possible bioactivity of the isolated chemicals, hence providing guidance for their prospective use across diverse sectors. The broad range of applications of MAE has motivated researchers to investigate its possible use in many industries. The extracts acquired by this methodology have shown promising properties as antioxidants, antimicrobials, anti-inflammatories, and have also shown promise in other applications such as biodiesel production. The significance of MAE as an environmentally friendly extraction technique for harnessing the wide range of bioactive properties inherent in rubber seed trees is highlighted by its versatile use. In general, contemporary research on the MAE technique for rubber seed trees underscores its effectiveness in efficiently extracting bioactive chemicals that hold promise for many industrial uses. As scholars persist in enhancing and broadening their understanding of this extraction methodology, it presents a hopeful pathway for the sustainable and effective extraction of compounds from rubber seed tree sources.

7.2.1. Microwave Extraction Mechanism

MAE is a specialized approach that employs microwave energy to expedite the extraction process. This is achieved by subjecting the sample matrix to regulated microwave radiation, as seen in Table 3 and Figure 5. The process of MAE encompasses the collaborative action of thermal and non-thermal factors, which together contribute to the improved extraction of bioactive constituents from various botanical sources such as rubber seed trees. The primary mechanisms involved in microwave extraction are described below.

Figure 5.

The extraction mechanism of rubber seed trees with the use of microwave-assisted extraction (MAE).

- Thermal Effects: Microwave radiation is used to achieve rapid and uniform heating of both the solvent and the sample matrix. The occurrence of localized heating leads to an increase in temperature inside the matrix, hence enhancing the solubility and diffusion of bioactive substances. Increased temperatures might potentially lead to a degradation of cell walls, hence facilitating the subsequent liberation of chemicals into the extraction solvent. The use of this thermal phenomenon demonstrates significant advantages in the extraction procedure of heat-sensitive compounds from rubber seed plants, as it efficiently mitigates the amount of their degradation [90].

- Non-Thermal Effects (Dielectric Heating): The phenomenon of microwave radiation is known to cause interactions with polar molecules present in the sample matrix, resulting in the induction of molecular rotations and the generation of frictional heating [91]. The occurrence referred to as dielectric heating leads to fast generation of heat inside the matrix itself. The enhanced extraction efficiency of non-polar molecules, such as lipids and essential oils, may be attributed to the preferential heating of polar constituents (e.g., water) present in the matrix. The non-thermal phenomenon in question plays a significant role in facilitating the extraction process by disrupting cellular structures and facilitating the liberation of bioactive compounds [92].

- Cavitation and Microbubbles: Another result linked with microwave extraction is the production of cavitation and microbubbles inside the solvent [93]. As microwave radiation warms the solvent, vaporization may occur, leading to the production and subsequent collapse of microbubbles. These bubbles generate mechanical disturbance inside the sample matrix, assisting in the extraction process by increasing the contact area between the matrix and the solvent [94].

The simultaneous operation of these processes expedites the extraction process, diminishes extraction durations, and amplifies the production of bioactive chemicals from rubber seed plants. MAE is considered a highly efficient and ecologically sustainable alternative to traditional extraction techniques due to its ability to provide regulated and fast heating, which leads to the rupture of cell structures and enhanced solubility. Nevertheless, it is essential to acknowledge that the optimization of microwave power, extraction duration, and several other factors plays a pivotal role in attaining the necessary level of extraction efficiency, all the while ensuring the preservation of the extracted compounds’ purity.

Table 3.

Previous study of rubber seed tree extract by microwave-assisted extraction (MAE).

Table 3.

Previous study of rubber seed tree extract by microwave-assisted extraction (MAE).

| Parameter | Effect on Yield and Recovery | Explanation | Ref. |

|---|---|---|---|

| Microwave Power | Higher microwave power may boost extraction yield. | Increased power results in a higher rate of heating and extraction. | [95] |

| Extraction Time | Extended extraction durations have the potential to result in increased recovery of yield. | Increased duration facilitates comprehensive compound diffusion. | [96] |

| Solvent Type | The enhancement of yield may be achieved by the optimization of solvent polarity and concentration. | The enhancement of solubility of bioactive chemicals derived from the material may be achieved by the careful selection of an appropriate solvent. | [97] |

| Sample Matrix Size | Reducing the size of particles has the potential to enhance the overall yield. | The decrease in particle size may lead to an increase in surface area, hence facilitating the release yield of compounds. | [98] |

| Solid-to-Solvent Ratio | Balanced solid–solvent ratio can produce the optimum yield recovery. | Adequate solvent ensures efficient compound release. | [99] |

| Matrix Pre-Treatment | The use of Matrix Pre-Treatment has the potential to enhance the overall yield. | The process of pre-treatment facilitates the disruption of cell walls, hence assisting in the extraction process. | [100] |

| Temperature | The optimization of temperature conditions may lead to the maximization of yield. | Elevated temperatures have the potential to induce the breakdown of compounds. | [101] |

7.2.2. Current Extraction on Rubber Seed Trees by MAE

The utilization of MAE for extracting bioactive components from rubber seed trees has garnered significant attention in recent investigations. This method has drawn interest due to its potential efficacy, reduced extraction durations, and environmentally sustainable characteristics. Researchers have explored various aspects of MAE, primarily focusing on optimizing extraction parameters to achieve the highest possible yield of bioactive compounds. These parameters include microwave power, extraction duration, solvent type, and solid-to-solvent ratio, and by fine-tuning them, researchers aim to determine the conditions that yield the optimal extraction of specific bioactive molecules while ensuring the preservation of their structural and functional integrity [102].

Another crucial area of emphasis in these studies is the examination and analysis of the isolated substances. Researchers employ a range of analytical methods, including chromatography, spectroscopy, and mass spectrometry, to identify and quantify the bioactive compounds present in the extracts. This characterization provides valuable insights into the composition, bioactivity, and potential applications of the recovered compounds, spanning various fields such as pharmaceuticals, functional foods, and cosmetics. Furthermore, scholars are exploring the potential benefits of matrix pre-treatment in the context of MAE. Pre-treatment techniques, such as mechanical disruption or enzymatic treatment, are being investigated for their ability to enhance the accessibility of bioactive chemicals within the matrix of rubber seed trees [103]. This, in turn, leads to improved extraction efficiency, aligning with the overarching goal of optimizing the extraction process to maximize yields while minimizing resource utilization. In summary, the adoption of Microwave-Assisted Extraction for rubber seed tree bioactive compounds offers a promising and sustainable approach. Researchers are diligently working on parameter optimization, compound characterization, and pre-treatment methods to enhance the efficiency and effectiveness of MAE, ultimately unlocking the full potential of these valuable bioactive compounds for various applications.

The rubber tree is primarily cultivated for its latex, which holds significant economic importance described by Creencia, Nillama and Librando [89]. However, an often-underutilized byproduct of this tree is its rubber seeds, which have not found major applications. Even the natural production of these seeds remains underutilized. In this study, researchers explore the use of microwave-assisted Soxhlet extraction as an environmentally friendly alternative to extract oil from rubber seeds. The extraction is carried out with a reaction time of 90 min and a microwave power of 300 W. The primary objective of this study is to evaluate the effects of various processing conditions, including drying time, temperature, solid–solvent ratio, and the choice of extraction solvent, on the yield of rubber seed oil. Additionally, the study examines microwave-assisted aqueous extraction (MAAE) under acidic conditions. The results indicate that n-hexane is the most effective solvent for extracting rubber seed oil, providing the highest yield when using an optimized seed-hexane ratio of 1:20 at a temperature of 72 °C. This yield is compared with the traditional Soxhlet extraction method and the acidic MAAE.

Furthermore, the chemical characteristics of the extracted rubber seed oil reveal certain key properties. The oil exhibits a relatively high percentage of free fatty acids (% FFA) ranging from 1.15% to 7.61%. Additionally, the oil’s iodine value (IV) ranges from 100 to 150, indicating that it is a semi-drying oil. This characteristic makes rubber seed oil suitable as an ingredient in surface coatings and in the formulation of products where the presence of unsaturation is essential. In summary, this study explores the potential of using microwave-assisted Soxhlet extraction to extract oil from rubber seeds, an underutilized byproduct of rubber tree cultivation. The choice of n-hexane as the solvent under optimized conditions results in highest oil yield. The chemical characteristics of the extracted oil, including its semi-drying nature, make it suitable for various industrial applications, particularly in products requiring the presence of unsaturated oils, such as surface coatings. This research highlights the potential value of rubber seed oil and offers an eco-friendly extraction method for its utilization.

In broader terms, MAE offers advantages such as rapid extraction, minimal solvent use, and maintained compound integrity. It proves to be effective in extracting various compounds, including phenolics, antioxidants, and bioactive molecules from diverse sources like rubber seed trees. MAE is an evolving technique with a substantial potential impact on various industries, including food, pharmaceuticals, and cosmetics. As researchers continue to refine parameters and optimize conditions, MAE’s utility in extracting bioactive compounds from natural materials remains promising.

7.3. Ultrasound Assisted Extraction (UAE)

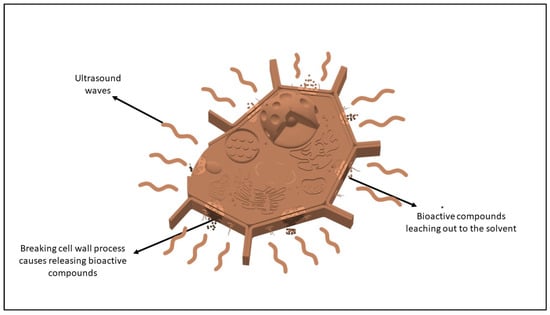

UAE is a novel methodology used for the extraction of bioactive chemicals from rubber seed trees. UAE employs ultrasonic waves to optimize the extraction process via the induction of cavitation phenomena [104]. The process encompasses the generation, expansion, and collapse of minute gas-filled cavities inside the extraction matrix, resulting in the disintegration of cellular membranes and the liberation of biologically active substances, as seen in Figure 6 [10]. UAE has several benefits, such as improved efficiency in extraction processes, decreased extraction duration, reduced solvent use, preservation of thermally delicate substances, and adherence to environmentally sustainable practices. Enhanced mass transfer leads to increased extraction yields and accelerated extraction durations. Additionally, UAE necessitates a reduced amount of solvent and functions at lower temperatures, hence maintaining the structural integrity of thermally delicate molecules. Through the use of UAE capacity, researchers have the opportunity to enhance the extraction process and comprehensively investigate the beneficial substances that are inherent in rubber seed trees.

Figure 6.

An illustration of the Ultrasound-assisted extraction technique employed for the extraction of rubber seed trees.

7.3.1. Mechanism of UAE

Ultrasonic-assisted extraction (UAE) is a methodology that utilizes high-frequency sound waves to optimize the retrieval of bioactive chemicals from solid substrates, including plant matter or biomass. The process of UAE encompasses a sequence of physical and chemical phenomena that are propelled by acoustic cavitation. Acoustic cavitation refers to the creation, enlargement, and forceful collapse of minuscule bubbles (referred to as cavities) inside the solvent. The following is an elucidation of the mechanism shown in Figure 6 and explicated thereafter.

- Formation of Microbubbles: The application of ultrasonic waves to the extraction solvent leads to the production of successive cycles of elevated pressure and reduced pressure [105]. During the phase characterized by low pressure, the solvent experiences expansion and development, leading to the enlargement of minute gas bubbles or nuclei inside it [106].

- Growth of Cavities: During the phase characterized by low pressure, the ultrasonic waves facilitate an expansion in the dimensions of the gas bubbles [107]. The occurrence of bubbles may be attributed to the existence of dissolved gases in the solvent or the liberation of gas by the sample matrix [108].

- Sudden Implosive Collapse: When the bubbles reach a certain size, they experience a vigorous collapse or implosion during the high-pressure phase of the ultrasound cycle [109]. The phenomenon of this collapse gives rise to the generation of shockwaves, localized intense heating, and the creation of liquid microjets.

- Physical Effects: The closeness of these bubbles to the solid sample leads to their collapse, which in turn generates microturbulence and micro-convection [110]. These phenomena cause disruptions inside the solid matrix, enhancing the rate of mass transfer between the solid substance and the solvent, hence increasing the release of certain chemicals.

- Chemical Effects: The occurrence of chemical reactions may be initiated by the elevated temperatures and pressures experienced during the collapse of bubbles [111]. The reported phenomena include the possible disruption of chemical bonds or the degradation of certain molecules, dependent upon the specific ultrasonic circumstances.

- Enhanced Extraction: In a broad sense, the aforementioned physical and chemical processes contribute to an increased efficiency in the extraction process [112]. The penetration of solvent into the solid matrix is increased, hence enhancing the release of bioactive compounds. This phenomenon leads to higher extraction efficiency and shorter extraction periods compared to conventional approaches.

In brief, UAE functions based on the phenomenon of acoustic cavitation, whereby the generation and collapse of small bubbles lead to both physical and chemical alterations within the extraction process. The use of UAE has been shown to significantly improve the efficiency of extracting bioactive chemicals from solid materials. As a result, UAE has gained recognition as a beneficial approach in a range of sectors, such as food, pharmaceuticals, and environmental research.

7.3.2. Current Extraction on Rubber Seed Trees by UAE