Abstract

The ground surface of green parks in arid and semi-arid areas may not be comfortable at specific times during the day and night due to the sun and the rate at which the subsoil gains or loses heat. Knowledge of the subsurface soil’s thermal properties can provide designers with convenient and comfortable settings. Design focus is generally directed toward stability, density, and hydraulic conductivity. An assessment of the thermal properties of clay–sand mixtures of 10%, 20%, and 30% clay content is conducted. The proposed clay–sand layers are subjected to three different thermal gradients of 30, 20, and 10 degrees of magnitude. The profile of temperature changes was monitored using 5TE sensors and data loggers. The mixtures were also subjected to cooling at room temperature. The results indicate that the clay type and the clay content govern the response of subsurface clay–sand liners to temperature gain and loss. Two field sections with clay–sand layers of 15% and 20% clay were examined for temperature changes over an extended period. In winter, green areas rich in clays were found to keep heat for several hours and provide relatively warm evenings. In summer, the mixture retains a cool temperature for some time during the day.

1. Introduction

The addition of clay to the sand material used in the top layers of green parks is usually needed to improve the subsurface material with regard to strength, hydraulic conductivity, chemistry, and nutrients. The elements of thermal conductivity and temperature are rarely investigated. The degree of temperature makes a difference when park visitors use the facility. When little or more clay content is used, different temperature profiles and changes are expected. It is known that subsurface soils gain heat slowly and lose it slowly. Green areas used as parks can be conditioned to create more comfortable weather, if the design is optimized.

The thermal properties of clay–sand mixtures used in green park post-applications have received little attention. However, in order to maximize the effectiveness and convenience of green park infrastructures, it is essential to understand the thermal behavior of these combinations. The characterization of the thermal conductivity and thermal diffusivity of clay–sand mixtures is one research gap in this field. These characteristics affect the materials’ capacity for thermal storage and thermal insulation, as well as the pace at which heat is transferred inside them. Investigating the differences in these characteristics with varying moisture levels and clay-to-sand ratios would yield insightful information for improving the thermal performance of green park subsoils.

Further research is needed to determine the thermal stability of clay–sand mixtures under cyclic heating and cooling circumstances, which are other significant factors. Analyzing the effects of numerous temperature cycles on the mixes’ mechanical qualities and structural soundness is part of this process. The results of this study can be used to highlight probable heat-related changes that need to be taken into account to develop effective mitigation plans.

Overall, the thermal properties of clay–sand mixtures used in green park post-applications constitute a developing field of study that still includes a number of knowledge gaps. Researchers can aid in the creation of more dependable and effective green park infrastructure through examining these gaps.

Solid particles determine how heat moves and other thermal characteristics. Both air and water can be found inside these pores, and both have an impact on heat storage and transfer. The temperature profile of the soil below grade level is generally influenced by the type of material, moisture content, and degree of compaction of the soil, as stated by Dafalla [1]. Temperature variations and the conditions of the strata’s moisture content are closely related. The moisture content of clayey soil is significantly impacted by temperature variations. Considerable fluctuations in soil moisture levels can arise from temperature shifts between day and night, according to a study by Johnson et al. [2]. While colder nighttime temperatures encourage water intake, high daytime temperatures can enhance evaporation, leading to soil desiccation. These cycles of moisture fluctuation can have an impact on soil permeability and soil structure in general.

Côté and Konrad [3] investigated how various characteristics affect thermal conductivity. These included mineral composition, grain size distribution, particle shape, and porosity. Based on the aforementioned parameters, a model was created to forecast thermal conductivity. Nidal and Reederb [4] pointed out that thermal conductivity can increase with an increase in soil density and water content. Thermal conductivity decreases with the addition of salts. When the same salt type and same concentrations are considered, sand’s thermal conductivity is higher than that of clay.

Heat capacity is generally defined as the ability of a material to store heat energy. This is similar to specific heat. The higher the specific heat, the more heat a material gains or loses. Air and water phases show different thermal conductivities and can affect the overall flow of heat. Heat conduction is influenced by soil composition, structure, and density, and by the geometry of pores. Farouki [5] and Tien et al. [6] considered three major parameters contributing to changes in the thermal conductivity of bentonite–sand mixtures. These are the proportion of bentonite/sand, the dry density (which can be a function of the void ratio), and the water content. Prediction models for subsoil temperature suggested in the literature require many parameters to be employed in order to establish a range of expected temperatures. Models based on computational approaches depend on energy balance calculation and heat transport in the soil to solve the heat equation. Other empirical models involve numerous parameters and measurements, which may not be readily available.

Boukella et al. [7] stated that the thermal conductivity and thermal diffusivity increased significantly for clays compacted on the dry side of the compaction curve at high temperatures. Prediction models can be formulated based on the thermal characteristics of soils and ambient temperature [8]. More advanced, thermo-enhanced viscoplastic models can also be utilized [9,10].

The thermal characteristics of soil materials, including thermal conductivity, thermal diffusivity, and specific heat capacity, have a significant impact on how much heat is gained and lost from them. Through laboratory trials, Xie et al.’s [11] research looked into the thermal characteristics of clay and sand mixtures. They discovered that when the clay concentration rose, so did the combination of clay and sand’s heat conductivity. With more clay present, the specific heat capacity likewise rose, albeit more slowly. These results contribute to our understanding of clay–sand combination heat transfer behavior.

In order to examine the heat gain properties of compacted clay–sand mixes at various temperatures, Kim and Cho [12] conducted laboratory studies. Due to clay’s higher thermal conductivity and lesser porosity, they discovered that as the clay content increases, the heat gain in the soil mixture increases. Sand particles changed the heat transmission channels, which also changed how much heat was gained. When studying the heat loss characteristics of compacted clay–sand mixtures, it is expected that as the clay content increases, the heat loss rate will decrease due to the reduction in pore size and the increased moisture content within the mixture.

When conducting laboratory experiments on compacted clay–sand mixtures subjected to different temperature conditions, the heat gain can increase significantly as the temperature increases from 30 °C to 50 °C. Similarly, the clay–sand mixtures at different temperatures will show a decrease in heat loss as the temperature drops from 50 to 30 degrees Celsius.

Knowledge of temporal fluctuations in soil temperature is also necessary for vegetation cover or plants. Many plant processes rely on the ambient and surrounding environment [13]. Bergman et al. [14] utilized Newton’s law of cooling, which relates the heat transfer coefficient λ to soil temperature Tsoil,t as follows:

Tsoil,t = Tenv,t − ∆ T exp (−λ)

Based on the fundamental rules of thermodynamics, several empirical models were developed to forecast soil thermal conductivity measurements [6,15,16]. Due to the complexity of the fabric and the nonhomogeneous character of soils, such models need to use a lot of parameters in order to make accurate predictions. In order to arrive at a reliable estimation, predictions were primarily made based on summing up the proportions of composite materials.

Moreover, the use of clay-based liners may be complicated by desiccation fissures, which lower thermal conductivity and hydraulic efficiency. Under such circumstances, geosynthetics may be employed to improve mechanical crack resistance [17,18]. Aldaeef and Rayhani [19] reported that there were noticeable improvements in the hydraulic performance of liners during various thermal wet–dry cycles, particularly for low-plastic clays. Although high-plasticity clays have a high ability to resist the effects of heat change, the medium-plasticity clays may also provide a comparable benefit [20].

This work is composed of laboratory and field measurements for predicting soil temperature changes at different clay contents when subjected to variable-temperature environments. Three different liner mixtures of sand with 10%, 20%, and 30% clay were prepared, and the temperature gain/loss profiles were established at ambient temperatures of 30 °C, 40 °C, and 50 °C. In addition, the field profiles of liners with 15% and 30% of the same clay content were constructed, and the necessary instruments were provided to indicate the real gain/loss profile of the field temperature. The laboratory test results are compared to field measurements obtained for grass-vegetated layers.

2. Materials and Methods

2.1. General

Sand material is abundant in the Arabian Peninsula and is commonly used in the construction industry as a filler material or a component of cement mortar. In wastewater containment and barriers, it is used as a liner when enhanced with a clay proportion to reduce hydraulic conductivity. In this study, the sand used to compose layers for use in liners and cover layers for green parks was generally poorly graded sand. The grain size distribution indicated a coefficient of uniformity of 1.737 and a coefficient of curvature of 1.078. The measured specific gravity was found to be 2.66.

The clay used in this study came from Al-Qatif, a town in Saudi Arabia’s eastern province. The standard categorization tests were run on this clay. The physical characteristics of Al-Qatif clay are shown in Table 1. Al-Qatif clay is a highly plastic soil [21] that is categorized as CH under the unified soil classification system (or ASTM D 2487 [22]) and is recognized for its high expansion and shrinkage parameters. The clay’s maximum standard Proctor dry density was determined to be 11.5–12 kN/m3 at an optimum moisture content of 30–32%. The Al-Qatif clay’s consistency limits revealed a liquid limit of 130 to 150 and a plasticity index of 60 to 70. Over the past 20 years, this particular sort of clay has been the subject of numerous investigations. This clay can be used in cover layers and clay–sand liners for a variety of environmental applications [23,24].

Clay–sand mixtures were prepared using clay contents of 10%, 20%, and 30%. The compaction properties of these mixtures were measured. The maximum dry density of clay–sand mixtures with clay contents of 10%, 20%, and 30% in terms of dry weight of sand was reported to be in the range of 17.5–18 kN/m3 at an optimum moisture content of 13–15%. The same material was used for a field section.

Table 1.

Physical properties of Al-Qatif clay.

Table 1.

Physical properties of Al-Qatif clay.

| Property | Range |

|---|---|

| Material passing sieve number 200 (%) | >90 |

| Liquid Limit (%) | 130–150 |

| Plastic Limit (%) | 60–70 |

| Plasticity Index (%) | 70–80 |

| Maximum Dry Density (kN/m3) | 11.5–12.0 |

| Optimum Moisture Content (%) | 32–40 |

| Swell Percent, ASTM D4546 [10], (%) | 16–18 |

| Swelling pressure (ASTM D4546) at a density of 12.0 kN/m3 (kN/m3) | 500–800 |

2.2. Laboratory Thermal Tests

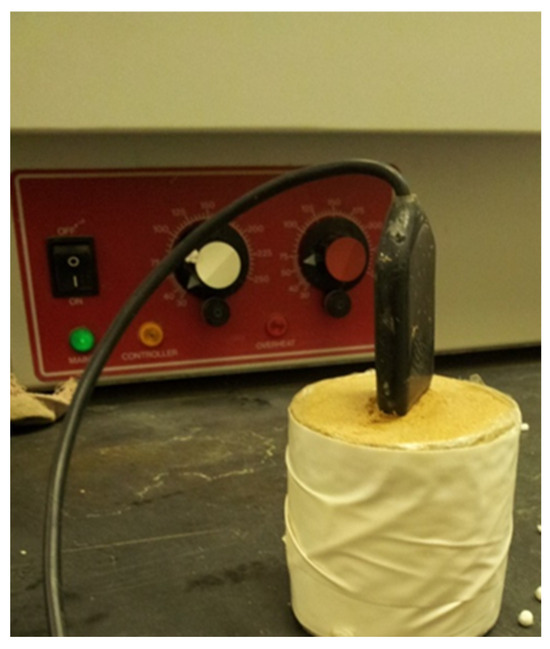

Samples of the clay–sand mixture were heated in the laboratory as part of the designed testing program. A steady temperature was maintained in the oven. Samples of clay–sand mixtures were cast in cylindrical molds of 75 mm in diameter and 50 mm in height. The primary goal is to examine the rate of heat uptake and loss for clay–sand combinations with 10%, 20%, and 30% clay concentrations. According to the results of a typical Proctor test, all soils were prepared at their optimum moisture content and maximum dry density. Using 5TE Decagon sensors (Figure 1) coupled to an Em50 data logger (Figure 2), changes in temperature, electrical conductivity, and volumetric water content were all monitored.

The sensors were programmed to record data at intervals of 10 min. The cylindrical sample was covered with 5 cm thick polystyrene to prevent heat loss, allowing heat gain and heat loss to happen in either the top or bottom direction (as indicated in Figure 3). The oven was designed to maintain a temperature of 30, 40, and 50 °C, replicating or approaching the temperature in Saudi Arabia during the summer. The soil samples were allowed to warm up in the oven for a full day (24 h). After gaining heat, the samples were allowed to cool down to room temperature. The progress of heat gains and heat losses was monitored and measured using sensors and data loggers.

Figure 1.

5TE Decagon Sensor.

Figure 2.

Em50 data logger used for 5TE sensors.

Figure 3.

Setup of soil sample connected to transducer.

2.3. Field Section Tests

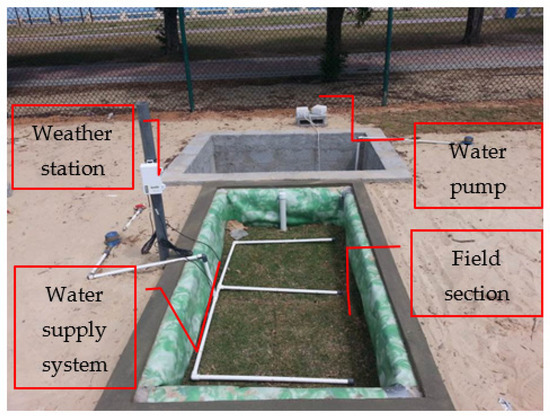

In order to evaluate a clay–sand liner under real-world weather circumstances with varying temperatures and moisture, experimental field sections were built on the site. As seen in Figure 4, a weather station was erected to track the temperature, wind, rainfall, and other variables.

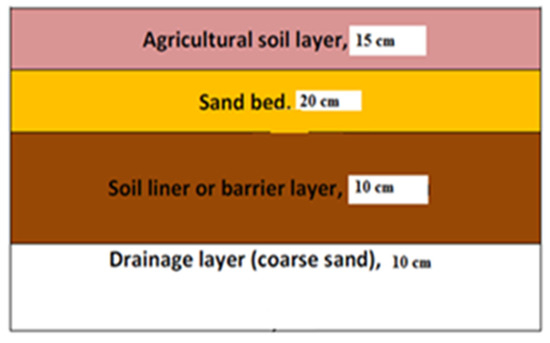

The field sections (i.e., Figure 5) were constructed on-site using varying clay contents. For this study, only two sections were addressed: the 15% clay content and 20% clay content layers. The layers consisted of clay–sand mixtures 10 cm in thickness, with a 20 cm top layer of silty sand material. The sketch of these layers is presented in Figure 6. The top layer was predominantly sand, with silt content in the order of 5 to 10%. 5TE sensors were inserted to the mid-depth of both layers, and one more sensor was installed to record the ambient temperature. The sections were originally designed to assess the hydraulic conductivity of the layers for use as water retention barriers. For this study, we traced the temperature changes within the clay–sand layers compared to the ambient temperature. An agricultural top layer was used to support green grass.

Figure 5.

Typical field section.

Figure 6.

Typical layers used for the field section. (Reproduced with permission from Springer Nature, 2023.)

Figure 4.

A weather station constructed on-site and a typical field section.

3. Results

The main objective and scope of this study are to observe the rate at which heat buildup or gain is achieved in clay–sand layers exposed to a high temperature gradient. The temperature gradients created are as follows:

- A 30 degree gradient (for material at a room temperature of 20 degrees, put into an oven at 50 degrees).

- A 20 degree gradient (for material at a room temperature of 20 degrees, put into an oven at 40 degrees).

- A 10 degree gradient (for material at a room temperature of 20 degrees, put into an oven at 30 degrees).

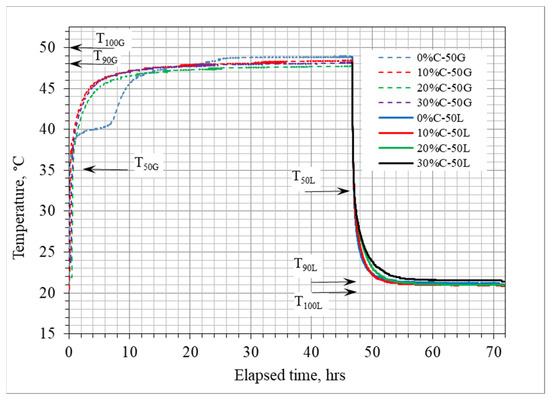

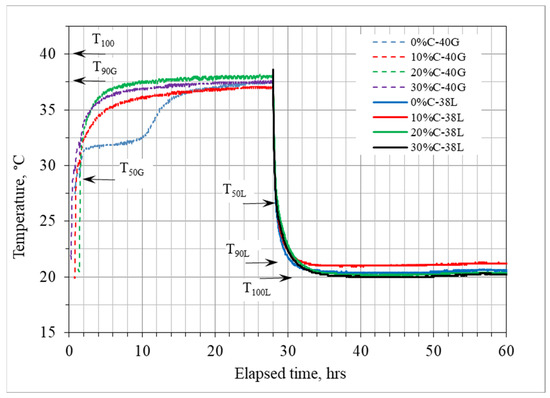

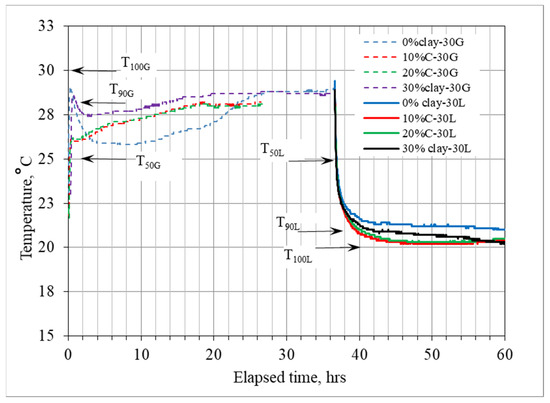

The temperature profiles of the compacted clay mixtures while in the oven for a period of 24 h are recorded by the 5TE sensors, just like temperatures when taken out of the oven and allowed to cool down to room temperature. Figure 7, Figure 8 and Figure 9 present the results for the three gradients of temperature, covering three different clay contents. The symbols are given in the form % clay content–temperature, followed by gain (G) or loss (L). For example, 10%C-50G stands for ten percent clay resulting in a gain of 50 °C in temperature.

This study suggests introducing new reference measurement levels. The first reference point is the T50 gain, defined as the time required to achieve 50% of the applied temperature gradient. This is normally referred to as a linear increase in temperature, occurring over an initial period of time.

T90 gain is defined as the time required to achieve 90% of the applied temperature gradient. This is normally referred to as a non-linear transition zone in temperature, occurring before a final steady rate of heat gain is reached. Beyond this level, the rate of gain is slow and it is expected to take a long time to reach the maximum temperature, T100 gain.

The temperature loss phase is treated similarly, and the terms T50 loss, T90 loss, and T100 loss are introduced. The profile of the loss is also observed to start with a linear zone, a non-linear transitional zone, and finally a slow linear rate. Table 2, Table 3 and Table 4 present the time required to reach the suggested levels.

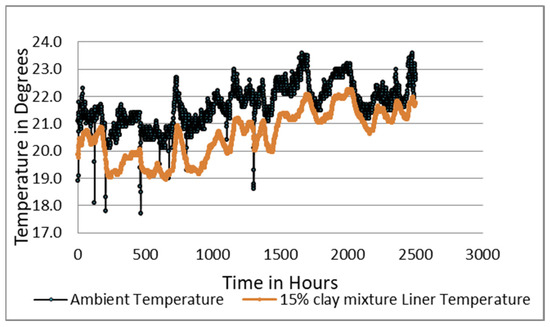

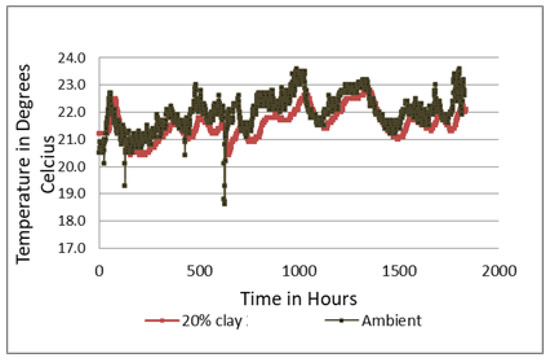

The field sections are monitored over a long period of time, and the temperatures measured within the mid-layers consisting of 15% clay content and 20% clay content are presented in graphical form.

Figure 7.

Heat gain and heat loss for laboratory, compacted clay–sand mixtures subjected to 50 °C.

Figure 8.

Heat gain and heat loss for laboratory, compacted clay–sand mixtures subjected to 40 °C.

Figure 9.

Heat gain and heat loss for laboratory, compacted clay–sand mixtures subjected to 30 °C.

Table 2.

Exposure to 50 °C temperature and time in hours to reach 50% and 90% levels.

Table 2.

Exposure to 50 °C temperature and time in hours to reach 50% and 90% levels.

| Clay Percent | 0% | 10% | 20% | 30% |

|---|---|---|---|---|

| T50G | 0.2 | 0.3 | 0.6 | 0.7 |

| T90G | >45 | 9.5 | 24.0 | 10.0 |

| T50L | 0.3 | 0.3 | 0.4 | 0.4 |

| T90L | 6.0 | 7.2 | 7.3 | 13.3 |

Table 3.

Exposure to 40 °C temperature and time in hours to reach 50% and 90% levels.

Table 3.

Exposure to 40 °C temperature and time in hours to reach 50% and 90% levels.

| Clay Percent | 0% | 10% | 20% | 30% |

|---|---|---|---|---|

| T50G | 1.4 | 1.2 | 1.6 | 0.9 |

| T90G | 28.0 | 28.1 | 20.3 | 28.0 |

| T50L | 0.2 | 0.2 | 0.3 | 0.2 |

| T90L | 1.8 | 2.4 | 2.7 | 2.4 |

Table 4.

Exposure to 30 °C temperature and time in hours to reach 50% and 90% levels.

Table 4.

Exposure to 30 °C temperature and time in hours to reach 50% and 90% levels.

| Clay Percent | 0% | 10% | 20% | 30% |

|---|---|---|---|---|

| T50G | 0.03 | 0.13 | 0.20 | 0.37 |

| T90G | 0.2 | >24 | >24 | 0.5 |

| T50L | 0.2 | 0.3 | 0.3 | 0.1 |

| T90L | 22.5 | 2.8 | 3.3 | 4.5 |

4. Discussion

Heat waves produced by the sun and daily temperature changes dissipate rapidly and generally influence the upper 1.5 to 2 m levels below ground. Temperature variation at deep levels or, for example, below the vadose level, is negligible. This is mainly attributed to the type, moisture, voids, and porous nature of the soil [25].

Soil–moisture interaction is a very complex phenomenon, but with the recent introduction of digital sensors capable of recording moisture and electrical conductivity, it has become more convenient and has helped researchers, geotechnical engineers, and landscape industries to conduct more useful studies. It has also been useful in predicting soil behavior and monitoring temperature and moisture at any time under different weather conditions. When soil becomes dry, or when there is not enough water for plants, automatic irrigation pumps can be started. When included in clay–sand liners, these sensors can provide information that is useful to environmental engineers. The trends and temperature profile variations in clay–sand mixtures used as cover liners for landscaping or landfills are the main subjects of this study.

Three components make up unsaturated soils: solids, air, and water. According to Shmulik [26], an aqueous solution is the only conducting phase for apparent electrical conductivity. This made it possible to employ this to assess volumetric water contents (θ). The soil density, porosity, particle shape and orientation, cation content, and temperature are just a few of the variables that might affect how the electrical conductivity is determined. The electrical resistance of the soil can also decrease as the temperature rises.

The profiles presented in Figure 7, Figure 8 and Figure 9 indicate three levels of heat gain and heat loss. The time required to reach 50% of the exposure temperature (T50 gain) is estimated as half an hour to one hour for all exposures, and this seems to be independent of the soil composition and clay content; however, the time to reach 90% exposure temperature (T90 gain) is variable. The rate of heat gain is low in pure sand compared to sand enhanced with clay additives. The variation in the time necessary to achieve a 90% level gain for a high temperature gradient (50 °C) is small when comparing the 10%, 20%, and 30% clay admixtures. The results of elevating the temperatures to low and medium gradients (40 °C and 30 °C) are not consistent. This can be attributed to other factors influencing the gain of heat, namely, air and fluid within the system. It is important to note that these results cannot be compared because the field and lab settings have different clay contents. Therefore, if a comparison is to be made, these variations must be taken into account.

Lower clay content gains heat faster than the than higher clay content. Therefore, it can be useful to adopt a higher clay content in order to make the morning cool last longer before the hot weather of midday in summer prevails.

As the temperature gradient in nature is not applied abruptly, as in the laboratory experiments, the difference between the ambient and gained temperatures is small. Examining the field section data over extended periods, the temperature difference is in the order of 1 degree for the 20% clay content and 1.5 to 2 degrees for the 15% clay content, as indicated in Figure 10 and Figure 11.

The loss of heat is also found to have three typical zones of temperature changes, in which a fast change occurs after exposure to cooling at first, a transition zone is observed, and finally a slow rate of cooling is reached, where approximately 90% of the ambient or surrounding temperature is achieved.

Knowledge of these thermal characteristics will help designers select the appropriate fill required for designing green areas in parks and landscape zones. However, these characteristics need to be weighed against the hydraulic conductivity and irrigation requirements of the project.

The development of numerical models and simulations to forecast the thermal behavior of clay–sand mixtures under various environmental circumstances should also be a primary goal of future research in this area. These models can offer a practical and affordable way to assess the thermal insulation, energy efficiency, and long-term sustainability of green parks.

The examination of the thermal expansion and contraction behavior of clay–sand mixtures during temperature fluctuations is another area of research that should be undertaken. This is crucial in places with extreme temperature swings, because differential thermal expansion can cause cracks and other types of damage to green parks. The design of more robust and resilient green park facilities will benefit from an understanding of the connection between the thermal characteristics of clay–sand mixtures and their susceptibility to heat-induced deformation. Pure clay has a thermal conductivity of up to 0.1 W/mK, while pure sand has a range of 0.25 to 0.35 W/mK. However, when clay and sand are combined, the mixture’s heat conductivity may be altered. Due to the clay’s lower thermal conductivity, combinations with a higher clay component typically have lower thermal conductivity. The clay–sand mixtures’ compaction and moisture content also play roles. Thermal conductivity is found to be higher in highly compacted and highly moist mixtures. The heat capacity of soils in general is in the order of 0.800 Joules/g·K.

Figure 10.

Ambient temperature versus 15% clay mixture liner temperature. (Reproduced with permission from Springer Nature, 2023).

Figure 11.

Ambient temperature versus 20% clay mixture liner temperature. (Reproduced with permission from Springer Nature, 2023).

5. Conclusions

The type of clay and the clay content affect how subsurface clay–sand liners react to temperature changes. A first linear segment, a transition zone, and a sluggish rate of change after 90% of the original temperature was gained or lost were discovered to be the three patterns that the changes in the temperature gain and loss profile follows. New parameters were defined to characterize the gains and losses in temperature. These are T50 gain/loss and T90 gain/loss. Factors that influence temperature variation include the type of clay, clay content, porosity, moisture content, and placement conditions. The field sections tested over an extended period indicated that clay-rich layers retain a narrow difference from the ambient temperature. A temperature difference in the order of 1 degree was observed for the 20% clay content layer, and 1.5 to 2 degrees for the 15% clay content layer.

Designers can use these attributes as required to provide extended hours of comfortable time. In winter, green areas rich in clay will keep heat for several hours and provide relatively warm evenings. In summer, the mixture will retain a cool temperature for some time during the day.

Clay–sand mixtures with a higher clay content exhibit higher heat-gain characteristics due to increased thermal conductivity, while their heat loss rate is relatively low. Understanding these thermal properties is vital for designing foundations, embankments, and other geotechnical applications where temperature differentials play roles.

Author Contributions

Conceptualization, M.D.; Data curation, A.A.-M.; Funding acquisition, M.D.; Investigation, A.A.-M.; Methodology, A.A.-M. and M.D.; Writing—original draft, M.D.; Writing—review & editing, A.A.-M. and M.D. All authors have read and agreed to the published version of the manuscript.

Funding

This article is funded by the Researchers Supporting Project of King Saud University, Riyadh, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors gratefully acknowledge the Researchers Supporting Project number RSPD2023R1059, King Saud University, Riyadh, Saudi Arabia, for their financial support for the research work reported in this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dafalla, M. Response of subsurface soils covered by sand clay liners to temperature variations. In Proceedings of the 19th EGU General Assembly, EGU2017, Vienna, Austria, 23–28 April 2017; p. 18537. [Google Scholar]

- Johnson, G.C.; McTaggart, K.E.; Wanninkhof, R. Antarctic Bottom Water temperature changes in the western South Atlantic from 1989 to 2014. J. Geophys. Res. Ocean. 2014, 119, 8567–8577. [Google Scholar] [CrossRef]

- Côté, J.; Konrad, J.M. A generalized thermal conductivity model for soils and construction materials. Can. Geotech. J. 2005, 42, 443–458. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Reeder, R.C. Soil Thermal Conductivity Effects of Density, Moisture, Salt Concentration, and Organic Matter. Soil Sci. Soc. Am. J. 2000, 64, 1285–1290. [Google Scholar] [CrossRef]

- Farouki, O.T. Thermal properties of soils. In Series on Rocks and Soil Mechanics; Trans Tech Publications: Clausthal-Zellerfeld, Germany, 1986; Volume 11. [Google Scholar]

- Tien, Y.M.; Chui, C.A.; Chuang, W.S. The prediction model of thermal conductivity of sand-bentonite based buffer material. In Proceedings of the Clays in Natural and Engineering Barriers for Radioactive Waste Confinement, Tours, France, 14–18 March 2005. [Google Scholar]

- Boukelia, A.; Eslami, H.; Rosin-Paumier, S.; Masrouri, F. Effect of temperature and initial state on variation of thermal parameters of fine compacted soils. Eur. J. Environ. Civ. Eng. 2019, 23, 1125–1138. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.; Liu, S.; Puppala, A.J. Investigation on thermal characteristics and prediction models of soils. Int. J. Heat Mass Transf. 2017, 106, 1074–1086. [Google Scholar] [CrossRef]

- Shi, Z.; Wood, D.M.; Huang, M. Interpreting temperature effects in soils using thermally-enhanced viscoplastic model. Comput. Geotech. 2021, 136, 104208. [Google Scholar] [CrossRef]

- Coccia, C.J.R.; McCartney, J.S. Thermal volume change of poorly draining soils II: Model development and experimental validation. Comput. Geotech. 2016, 80, 16–25. [Google Scholar] [CrossRef]

- Xie, T.; Lin, S.L.; Li, F.; Cong, F.; Li, Z.H.; Zou, G.F. Characteristics of the Longling–Ruili fault at the Luxi area and its significance. Geotecton. Metallog. 2011, 35, 216–220. [Google Scholar]

- Kim, K.-H.; Cho, J. Predicting potential epidemics of rice diseases in Korea using multi-model ensembles for assessment of climate change impacts with uncertainty information. Clim. Chang. 2016, 134, 327–339. [Google Scholar] [CrossRef]

- Bond-Lamberty, B.; Wang, C.K.; Gower, S.T. Spatiotemporal measurement and modeling of stand-level boreal forest soil temperatures. Agric. For. Meteorol. 2005, 131, 27–40. [Google Scholar] [CrossRef]

- Bergman, T.; Incripera, F.; Dewitt, D.; Lavine, A. Fundamentals of Heat and Mass Transfer; John Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Campbell, G.S. Soil Physics with Basic Transport Models for Soil-Plant Systems; Elsevier Science Publishing Company: New York, NY, USA, 2011. [Google Scholar]

- Paul, K.I.; Polglase, P.J.; Smethurst, P.J.; O’Connell, A.M.; Carlyle, C.J.; Khanna, P.K. Soil temperature under forests: A simple model for predicting soil temperature under a range of forest types. Agric. For. Meteorol. 2004, 121, 167–182. [Google Scholar] [CrossRef]

- Ghavam-Nasiri, A.; El-Zein, A.; Airey, D.; Rowe, R.K.; Bouazza, A. Numerical Simulation of Geosynthetic Clay Liner Desiccation under High Thermal Gradients and Low Overburden Stress. Int. J. Geomech. 2019, 19, 04019069. [Google Scholar] [CrossRef]

- Yu, B.; El-Zein, A. Challenges and solutions in using geosynthetic clay liners exposed to thermal desiccation risks. Jpn. Geotech. Soc. Spec. Publ. 2021, 9, 61–66. [Google Scholar] [CrossRef]

- Aldaeef, A.A.; Rayhani, M.T. Hydraulic performance of compacted clay liners under simulated daily thermal cycles. J. Environ. Manag. 2015, 162, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Dalla Santa, G.; Cola, S.; Tateo, F.; Galgaro, A. Hydraulic conductivity changes in compacted clayey barriers due to temperature variations in landfill top covers. Bull. Eng. Geol. Environ. 2020, 79, 2893–2905. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M. The distribution and mineralogy of expansive clay in a semi-arid region. Arab. J. Geosci. 2023, 16, 283. [Google Scholar] [CrossRef]

- ASTM D2487-17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017. Available online: www.astm.org (accessed on 13 July 2021). [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M. Impact of placement and field conditions on hydraulic conductivity and lifetime of liners. J. King Saud Univ. Sci. 2021, 33, 101410. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Al-Shamrani, M.A.; Dafalla, M.; Basu, D. Effect of Temperature on Hysteretic Behavior of Water Retention Capacity for Clay–Sand Liners. Indian Geotech. J. 2021, 51, 924–934. [Google Scholar] [CrossRef]

- Lovering, T.S.; Goode, H.D. Measuring Geothermal Gradients in Drill Holes Less than 60 Feet Deep, East Tintic District, Utah (No. 1172); US Geological Survey Bulletin: Washington, DC, USA, 1963. [Google Scholar]

- Friedman, S.P. Soil properties influencing apparent electrical conductivity: A review. Comput. Electron. Agric. 2005, 46, 45–70. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).