Abstract

Due to the high impact of the building sector on the environment, a growing interest focuses on insulating materials able to ensure good thermo-acoustic performance for the building envelope from a sustainable and circular economy perspective. In this context, Moroccan natural gypsum was mixed with local natural waste materials. The thermal and acoustic properties of the samples were measured; they were compared to those of synthetic- and mineral-based gypsum plasters manufactured with the same technique. A Small Hot Box apparatus was used for thermal characterization, whereas acoustic performance was investigated by means of a Kundt’s Tube. Natural and synthetic additives result in a reduction in density and an improvement in thermal performance. Conductivity values in the 0.181–0.238 W/mK range were obtained, depending on the type of natural additive, with respect to 0.275–0.323 W/mK of mineral-based gypsum plasters. The acoustic measurements showed that all the composites have similar performance in terms of acoustic absorption, whereas high transmission loss values were obtained for the natural additives (TL = 35–59 dB). Petiol of Palm and Stipa Tenacissima were found to be materials able to improve both thermal and acoustic properties.

1. Introduction

The building sector is one of the largest consumers of energy in the world and generates greenhouse gases and CO2 emissions [1]. Worldwide, the building sector is responsible for approximately 40% of global energy consumption and 39% of global CO2 emissions, compared to around 22 and 30% of the industrial and transport sectors, respectively [2]. This prompts the scientific community to develop different solutions and strategies to solve the problem and bring significant improvements to the construction industry, taking effective and sustainable actions against climate change. Therefore, reducing the impact of the building sector has become a key point in the sustainable development of building materials to develop high-performance thermal and acoustic insulation biomaterials able to improve the comfort of buildings while reducing the environmental impact. In this context, bio-composite materials are a first step towards the integration of an ecological, green, and sustainable approach. The incorporation of vegetable aggregates in building materials resulted in several benefits in addition to a reduction in environmental impact. Positive effects of bio-composites can be obtained in terms of thermal insulation and mechanical and hygro-thermal properties [3,4,5,6,7].

Plasters have an important role in opaque building envelope performance. In the literature, several studies focus on the addition of natural or waste materials to plasters, resulting in a great environmental benefit, although they are characterized by a slight improvement in thermal and acoustic performance with respect to conventional solutions [8,9,10,11,12,13,14,15,16]. Gypsum plaster is one of the most standard materials used by many ancient civilizations in construction applications due to its aesthetic and thermo-acoustic qualities [17]. Gypsum plaster is an economical and easily exploitable product, offering good thermo-acoustic comfort as well as protection against fire (Lushnikova & Dvorkin, 2016). Several authors tried to improve its physical, thermal, mechanical, and hygrothermal properties by adding additives. Among the synthetics, polystyrene was widely used. A complete study of the mechanical, thermal, and acoustic properties of gypsum-plasters mixed with EPS was carried out by Bouzit et al. [18], taking into account the different contents and diameters of the polystyrene balls. By increasing the size of the beads, the maximum value of flexural strength occurred with a lower percentage of polystyrene. The thermal values were 0.191 and 0.116 W/mK for 10% and 30% weight content of smaller polystyrene beads (3 mm diameter), respectively. Transmission loss values ranged up to 45 dB, with a reduction of only 2–3 dB compared to pure samples due to the reduction of density. Similar results were found in Bicer et al. [19] for a composite material based on expanded polystyrene and tragacanth gum in different percentages.

Better thermal performance was obtained in plasters with the incorporation of granular aerogel, reaching values of thermal conductivity of 0.05 W/mK (90% weight of granules in the mixture) [20,21,22].

Over the years, researchers have worked on numerous gypsum plaster solutions with natural, vegetable, and recycled fiber additives. For instance, Khalil et al. [23] showed good reinforcing and thermal insulation properties of rice husk. Pennisetum Setaceum (a herbaceous plant) fibers were of interest for lightweight thermal insulating materials [24]. A small amount of date palm fibers (6% by weight) resulted in a thermal conductivity reduction of about 48% [25]. The addition of 2% by weight of Alfa fibers increased the thermal performance of bio-sourced earth-based composites, as demonstrated by Charai et al. [26]. Ferula Communis collected from Ait Ishaq city (Morocco) had a positive impact on both the thermal performance and the lightness of the dough [17]. For a mass fraction of additive ranging from 0 to 8%, the thermal conductivity decreased from 0.372 to 0.263 W/mK (a reduction of about 29%). The study of Saira et al. [27] contributed to the development of a gypsum composite with cork fibers and cardboard waste, showing the positive influence of increasing cork and reducing paper contents on thermal conductivity values. The good properties of cork from a thermal and acoustic point of view were already confirmed in previous studies [28,29]. The size and content of peanut shells affected the thermal behavior of plasters; the thermal conductivity value was reduced by more than 50% with a 20% additive, characterized by a diameter in the 2.5–5 mm range [30]. Hemp and Alfa fibers also had positive effects on sound absorption performance [31,32]. Wood waste improved the thermo-acoustic properties of gypsum composites [33]. Straw is one of the most used additives; when only 4 wt.% is added to the gypsum plaster, reductions in thermal conductivity and in greenhouse gas emissions up to, respectively, 68% and 13% were achieved in different climate zones of Morocco [34]. However, all these additives resulted in a deterioration of the mechanical performance.

In Morocco, there are extensive amounts of high-quality gypsum ores, and the use of different additives to improve the thermal performance of gypsum-based plasters has been the subject of a research collaboration between the University of Perugia and the University of Agadir for several years. Based on the preliminary results obtained in terms of physical, thermal, and acoustic properties [35], gypsum plaster from the Safi region (southwestern Morocco) was used to manufacture composites with different additives. Natural fibers were collected in the local area to fabricate bio-based gypsum plasters. In the present paper, the thermal and acoustic performance of these mixtures is measured and discussed. A comparison with those obtained for plasters with the most common synthetic and mineral fiber additives is also carried out. The aim of the study is to identify the most promising solutions from a thermo-acoustic point of view.

2. Materials and Methods

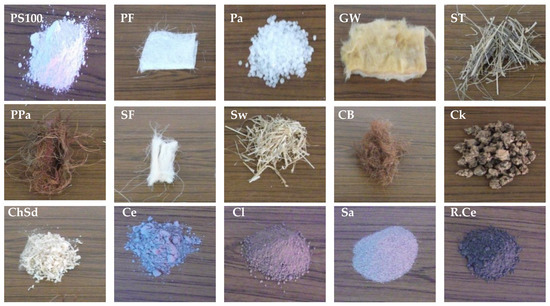

Natural gypsum powder from the rocks of the Safi region (Morocco) was used to assemble the samples. Its features were deeply discussed in [17,34]. The powder (p) was mixed with water (w) (mass ratio w/p equal to 0.8) in about 90 s, in order to obtain a fluid and homogenous porous plaster without any air bubbles. The paste was added with different components and mixed by means of a conventional stirrer, the Ika Rw 20 (helical moves for about 3 min at a speed equal to 100 rpm). The selected additives are of the following three types (Figure 1):

Figure 1.

Safi gypsum powder and synthetic, natural, and mineral additives used in the samples.

- -

- Synthetic: Polyester Fiber (PF), Paraffin (Pa), and Glass Wool (GW), selected among the most used commercial ones;

- -

- Natural: Stipa Tenacissima (ST) or Alfa fiber, Palm Petiol (PPa), Sisal Fiber (SF), Straw (Sw), Corn Bristles (CB), Cork (Ck), and Chip-Sawdust (ChSd), very diffused in the local Moroccan area;

- -

- Mineral: Cement (Ce), Clay (Cl), Sand (Sa), and Refractory Cement (R.Ce).

Natural fibers were collected and shredded by hand, obtaining a homogeneous size of about 1 cm. Several tests were carried out to identify the optimal additive value among the different types to obtain stable samples; it was found to be equal to 20 wt.% of the total volume. Also, a reference panel with pure hardened gypsum plaster and water (called PS 100) was assembled.

The mixture was placed in molds purposely made and left under controlled laboratory conditions (relative humidity equal to 70% and temperature in the 23–25 °C range) for about 3 h. Once removed, the samples were dried in a climatic chamber at 45 °C for 2 days to eliminate all the interstitial water. For each composite, three square-shaped panels of 300 × 300 mm2 dimensions and cylindrical specimens of 100 and 29 mm diameter were fabricated in order to investigate the thermal and acoustic properties, respectively (Table 1).

Table 1.

Features of the examined samples.

Despite the use of molds, the thickness of the samples was not the same due to their different shrinkage during the drying step; the thickness of the square panels was in the 0.023–0.030 m range, slightly smaller than that of the cylindrical ones (about 0.040–0.060 m). For the acoustic tests, only specimens with similar thicknesses and densities ρ were considered in the analysis for a reliable comparison.

In general, the insertion of the synthetic and natural additives in the plaster matrix did not result in significant changes in density values with respect to the reference panel (Table 1); the mineral materials involved an increase in density up to about 32% (with 20% of refractory cement).

According to the heat flow meter method, the thermal performance of the samples was evaluated by means of the Small Hot Box experimental apparatus available at the Department of Engineering (University of Perugia) [36]. The tests (lasting at least 2 h each) were carried out under steady-state conditions. The temperature inside the hot chamber was set at 45 °C to ensure a difference between the air temperature in the box (the hot side) and in the laboratory room (the cold side) higher than 20 °C, according to [37]. The thermal resistance of each panel was calculated by measuring the heat flux through the sample (with a heat flow meter, ±5% precision) and its hot and cold side surface temperatures (with thermo-resistances, ±10% precision). The relative type B uncertainties of each test were calculated in compliance with JCGM 100:2008 [38].

The sound absorption coefficient (α) and transmission loss (TL) at normal incidence of each panel were measured in a conventional Kundt’s tube (Brüel & Kjær, model 4187), by means of the two- and four-microphone configurations (1/4-inch microphones, Brüel & Kjær, model 4187), according to ISO 10534-2 [39]. Both large (100–1600 Hz, 100 mm diameter cylindrical sample) and small tube (400–6400 Hz, 29 mm diameter cylindrical sample) configurations were considered to investigate the entire frequency range (100–6400 Hz). The transfer function and the two-load methods were used to measure sound absorption and insulation properties, respectively.

A detailed description of the thermal and acoustic calculation procedures can be found in [40].

3. Results

3.1. Thermal Properties

The thermal conductivity of the tested samples is reported in Table 2. Data measured at an average temperature in the 31.2–32.8 °C range were reported at the standard temperature of 10 °C, according to ISO 10456 [41].

Table 2.

Thermal properties of the samples.

Thermal performance with synthetic additives improves when glass wool (PS 80-GW 20) and polyester fibers (PS 80-PF 20) are inserted in the mixture, with a reduction of thermal conductivity in the 40–44% range (λ = 0.144–0.155 W/mK) with respect to Safi plaster (PS 100 [35]), whereas a higher value is obtained for the paraffin. The addition of natural additives involves an improvement in thermal properties (λ = 0.181–0.238 W/mK vs. 0.257 W/mK of the reference, with a reduction of λ in the 7–30% range); the best results were obtained with 20% Petiol of Palm in the mixture, close to synthetic additive ones. Conversely, the addition of mineral additives (clay, cement, refractory cement, and sand) leads to a worsening of performance due to the higher density values; the increase in thermal conductivity varies in the 6% (with cement and sand)–20% (refractory cement) range.

Results are consistent with the thermal properties of polystyrene gypsum plasters measured by means of the same apparatus [18]. The samples were fabricated with the same Safi natural gypsum, adding 10% and 30% by weight of EPS balls with 5 mm diameter (λ = 0.216 and 0.146 W/mK, respectively). Smaller particles involve thermal conductivity values in the range of 0.191 W/mK (10 wt.%)–0.116 W/mK (30 wt.%), close to the performance obtained with Stipa Tenacissima and Petiol of Palm. Furthermore, the study carried out by Charai et al. [26] on concrete composites incorporating Alfa fibers (ST) showed similar performance; the mixture with 10 wt.% of 3 cm fiber length was characterized by a thermal conductivity of 0.193 W/mK.

3.2. Acoustic Properties

Sound absorption and insulation measurements were carried out, taking into account several test specimens with similar thicknesses and densities; only the most significant measurements were considered.

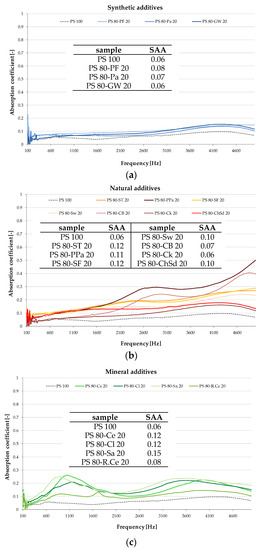

The average normal incidence absorption coefficient trends of each sample are reported in Figure 2 in the 100–5000 Hz frequency range (combination of the large and small tube measurements), depending on the additive type in the mixture. The addition of additives improves the sound absorption properties compared to pure Safi plaster (PS 100, dotted line in Figure 2 [35]) for all three groups of additives. This behavior is hardly emphasized with synthetic additives, especially glass wool (GW), paraffin (Pa), or polyester fibers (PF) (Figure 2a). A maximum improvement of 0.02 of the sound absorption average (SAA) [42] value (from 0.06 to 0.08) is observed for Polyester Fiber.

Figure 2.

Absorption coefficient at normal incidence vs. frequency: gypsum plasters with synthetic (a), natural (b), and mineral (c) additives.

Better performance with respect to synthetic additives was obtained with natural ones, such as Petiol of Palm (PS 80-PPa 20), Sisal Fiber (PS 80-SF 20), and Stipa Tenacissima (PS 80-ST 20), characterized by lower densities (Figure 2b). In terms of SAA, values in the 0.10–0.15 range were obtained, double or more with respect to the value of the reference sample (0.06).

The insertion of mineral additives (Figure 2c) in the composites leads to results comparable to those of natural additives, with a sound absorption peak value of 0.25–0.28 at about 900–1000 Hz, especially with 20% of sand (PS 80-Sa 20, SAA = 0.15).

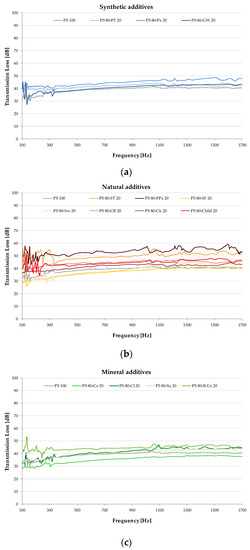

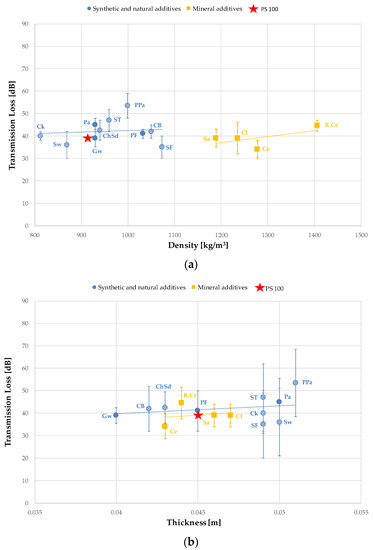

The transmission loss (TL) values measured with the large tube configuration (100–1700 Hz) are shown in Figure 3; the measurements carried out on the small samples (small tube configuration, 400–6400 Hz) are not shown because they are not significant. Additives, which involve an increase in densities, also improve the sound insulation properties. The samples with Stipa Tenacissima ST and Petiol of Palm PPa are characterized by higher sound insulation performance, with TL values up to 59 dB (Figure 3b). For composites with 20% straw (Sw), TL values are slightly lower than the pure Safi gypsum plaster PS 100 (TL values are in the 32–41 dB range for PS 100 with respect to 30–40 dB for PS 80-Sw 20), but they are also characterized by a lower density. Even with cement (PS 80-Ce 20) and Sisal fiber (PS 80-SF 20) the properties are lower despite having higher densities, probably due to an imperfect mixing of the material during the sample preparation. Both synthetic and mineral additives, in general, involve a slight improvement in the sound insulation properties with respect to pure plaster (up to 4–5 dB).

Figure 3.

Transmission loss at normal incidence vs. frequency: gypsum plasters with synthetic (a), natural (b), and mineral (c) additives.

Compared to polystyrene [18], the sound absorption performance of natural additives is improved; 30 wt.% and 10% of the smallest EPS balls (d = 3 mm, ρ = 700–840 kg/m3) have peak values of α equal to 0.19 and 0.17 at high frequencies (about 4200–4400 Hz), whereas the natural additive peaks are in the 0.25–0.30 and in the 0.30–0.40 range at mid and high frequencies, respectively. TL values were similar with synthetic and mineral additives (TL = 30–45 dB, depending on the percentage and size of the EPS balls). Bio-additives have values even 12–13 dB higher.

4. Discussion

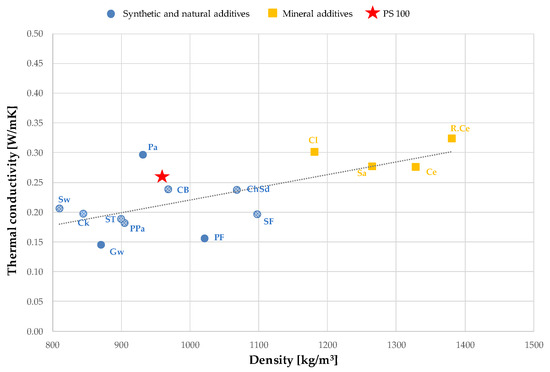

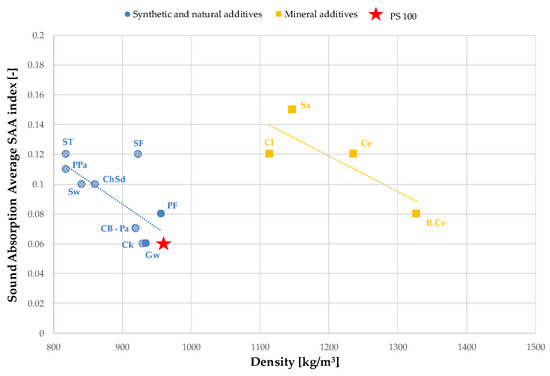

The decrease in plasters’ density due to the additives improves thermal and sound absorption performance, resulting in a decrease in thermal conductivity and an increase in SAA values, according to linear trends. However, there is a decrease in transmission loss, as expected from the mass low.

Natural additives (dotted blue markers in Figure 4) improve the thermal properties of the plasters, especially when Petiol of Palm (PPa), Stipa Tenacissima (ST), Sisal Fiber (SF), or Cork (CK) are added in the matrix. Higher λ-values of the pure plaster (PS 100) are obtained with the mineral additives and also with paraffin (synthetic), characterized by a density of the same magnitude (ρ = 960 kg/m3). However, glass wool and polyester fiber perform better.

Figure 4.

Thermal conductivity vs. density of the plasters with additives.

All additives result in a sound absorption index SAA in the 0.06–0.12 range (Figure 5). Only sand has a SAA value slightly higher (0.15). Among the naturals, ST, SF, PPa, Sw, and ChSd have the best behavior. However, the acoustic insulation is of the same magnitude (TL = 35–45 dB) as the one produced by mineral additives, which have higher densities (Figure 6a). Higher TL values in bio-plasters were measured with PPa and ST, even though PPA has a slightly higher thickness (0.051 m, Figure 6b). With the same thickness (0.049 m), ST has better acoustic insulation properties than Ck and SF; the TL of SF-based plaster is lower despite its higher density.

Figure 5.

Sound absorption average index vs. density of the plasters with additives.

Figure 6.

Transmission loss of the plasters with additives: influence of the density (a) and the thickness (b).

5. Conclusions

Based on preliminary natural Safi gypsum rock characterization, several plasters were fabricated by adding natural, synthetic, and mineral additives. Seven natural additives (Stipa Tenacissima (ST), Petiol of Palm (PPa), Sisal Fiber (SF), Straw (Sw), Corn Bristles (CB), Cork (Ck), and Chips-Sawdust (ChSd)) were collected in the same area and mixed with the gypsum plaster at 20% by weight. The composites’ thermo-acoustic performance was measured and compared with plasters with synthetic and mineral additives. The most promising composites were identified to promote the use of materials with low environmental impacts in building refurbishment. Based on the experimental characterization, the following results were obtained:

- -

- An increase in thermal performance with bio-additives: thermal conductivity in the 0.118 W/mK (with Petiol of Palm, PPa) to 0.238 W/mK (with Corn Bristles, CB) range, with a reduction up to 30% compared to pure gypsum plaster.

- -

- An improvement in the sound absorption properties with all types of additives. Sound absorption average index (SAA) in the 0.06 (cork, Ck) to 0.12 (Stipa Tenacissima, ST, and Sisal Fiber, SF) range were measured.

- -

- Higher sound insulation properties with ST and PPa (TL = 48–59 dB). However, straw and Sisal Fiber did not seem to affect the performance.

- -

- The density of the samples affects the performance. The reduction in density leads to better thermal performance with comparable sound absorption values. TL is slightly reduced, but significant values were measured.

The experimental campaigns highlighted the good thermal and acoustic behavior of bio-based gypsum plasters, especially when Petiol of Palm and Stipa Tenacissima were added to the composites. However, the mechanical and hygrothermal performance of the most promising solutions will have to be investigated in order to optimize and identify the best solutions from a thermal, acoustic, mechanical, and vapor permeability point of view. The great added value of additives from material recycling and reuse chains is the lower environmental impact of production processes; this aspect could be investigated by means of life-cycle analysis in terms of the embodied energy and energy carbon contributions of each additive. Moreover, the long-term impact of bio-additives in the plasters will be analyzed by means of accelerated aging processes.

Author Contributions

Conceptualization, C.B. and M.T.; methodology, C.B. and F.M.; investigation, F.M. and S.B.; writing—original draft preparation, F.M. and S.B.; writing—review and editing, C.B.; supervision, C.B. and M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cornaro, C.; Buratti, C. Energy Efficiency in Buildings and Innovative Materials for Building Construction. Appl. Sci. 2020, 10, 2866. [Google Scholar] [CrossRef]

- UNEP, United Nations Environment Programme—2022 Global Status Report for Buildings and Construction. 2022. Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 20 July 2023).

- Hussain, A.; Calabria-Holley, J.; Lawrence, M.; Jiang, Y. Hygrothermal and mechanical characterisation of novel hemp shiv based thermal insulation composites. Constr. Build. Mater. 2019, 212, 561–568. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Ind. Crops Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef]

- El Hajj, N.; Dheilly, R.M.; Goullieux, A.; Aboura, Z.; Benzeggagh, M.L.; Quéneudec, M. Innovant agromaterials formulated with flax shaves and proteinic binder: Process and characterization. Compos. B Eng. 2012, 43, 381–390. [Google Scholar] [CrossRef]

- Collet, F.; Prétot, S.; Lanos, C. Hemp-straw composites: Thermal and hygric performances. Energy Procedia 2017, 139, 294–300. [Google Scholar] [CrossRef]

- Ismail, B.; Belayachi, N.; Hoxha, D. Optimizing performance of insulation materials based on wheat straw, lime and gypsum plaster composites using natural additives. Constr. Build. Mater. 2020, 254, 118959. [Google Scholar] [CrossRef]

- Sathiparan, N.; Rupasinghe, M.N.; Pavithra, B.H.M. Performance of coconut coir reinforced hydraulic cement mortar for surface plastering application. Constr. Build. Mater. 2017, 142, 23–30. [Google Scholar] [CrossRef]

- Belayachi, N.; Hoxha, D.; Slaimia, M. Impact of accelerated climatic aging on the behaviour of gypsum plaster-straw material for building thermal insulation. Constr. Build. Mater. 2016, 125, 912–918. [Google Scholar] [CrossRef]

- Gourlay, E.; Glé, P.; Marceau, S.; Foy, C.; Moscardelli, S. Effect of water content on the acoustical and thermal properties of hemp concretes. Constr. Build. Mater. 2017, 139, 512–523. [Google Scholar] [CrossRef]

- Lima, H.C., Jr.; Willrich, F.L.; Barbosa, N.P.; Rosa, M.A.; Cunha, B.S. Durability analysis of bamboo as concrete reinforcement. Mater. Struct. 2008, 41, 981–989. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Page, J.; Khadraoui, F.; Boutouil, M.; Gomina, M. Multi-physical properties of a structural concrete incorporating short flax fibers. Constr. Build. Mater. 2017, 140, 344–353. [Google Scholar] [CrossRef]

- Jiang, Y.; Phelipot-Mardele, A.; Collet, F.; Lanos, C.; Lemke, M.; Ansell, M.; Hussain, A.; Lawrence, M. Moisture buffer, fire resistance and insulation potential of novel bio-clay plaster. Constr. Build. Mater. 2020, 244, 118353. [Google Scholar] [CrossRef]

- Palumbo, M.; McGregor, F.; Heath, A.; Walker, P. The influence of two crop by products on the hygrothermal properties of earth plasters. Build. Environ. 2016, 105, 245–252. [Google Scholar] [CrossRef]

- Herrero, S.; Mayor, P.; Hernández-Olivares, F. Influence of proportion and particle size gradation of rubber from end-of-life tires on mechanical, thermal and acoustic properties of plaster–rubber mortars. Mater. Des. 2013, 47, 633–642. [Google Scholar] [CrossRef]

- Touil, M.; Rahmoun, O.; Iken, O.; El Harti, K.; Saadani, R.; Rahmoune, M. Exploring the thermal behaviour and thermo-mechanical properties of Ferula Communis reinforced plaster and mortar composites: An integrated experimental and numerical approach. Energy Convers. Manag. 2023, 289, 117119. [Google Scholar] [CrossRef]

- Bouzit, S.; Merli, F.; Sonebi, M.; Buratti, C.; Taha, M. Gypsum-plasters mixed with polystyrene balls for building insulation: Experimental characterization and energy performance. Constr. Build. Mater. 2021, 283, 122625. [Google Scholar] [CrossRef]

- Bicer, A.; Kar, F. Thermal and mechanical properties of gypsum plaster mixed with expanded polystyrene and tragacanth. Therm. Sci. Eng. Prog. 2017, 1, 59–65. [Google Scholar] [CrossRef]

- Fantucci, S.; Fenoglio, E.; Grosso, G.; Serra, V.; Perino, M.; Marino, V.; Dutto, M. Development of an aerogel-based thermal coating for the energy retrofit and the prevention of condensation risk in existing buildings. Sci. Technol. Built. Environ. 2019, 25, 1178–1186. [Google Scholar] [CrossRef]

- Stahl, T.; Brunner, S.; Zimmermann, M.; Ghazi Wakili, K. Thermo-hygric properties of a newly developed aerogel based insulation rendering for both exterior and interior applications. Energy Build. 2012, 44, 114–117. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E.; Agosti, F. Development of innovative aerogel based plasters: Preliminary thermal and acoustic performance evaluation. Sustainability 2014, 6, 5839–5852. [Google Scholar] [CrossRef]

- Khalil, A.A.; Tawfik, A.; Hegazy, A.A.; El-Shahat, M.F. Effect of some waste additives on the physical and mechanical properties of gypsum plaster composites. Constr. Build. Mater. 2014, 68, 580–586. [Google Scholar] [CrossRef]

- Charai, M.; Salhi, M.; Horma, O.; Mezrhab, A.; Karkri, M.; Amraqui, S. Thermal and mechanical characterization of adobes bio-sourced with Pennisetum setaceum fibers and an application for modern buildings. Construct. Build. Mater. 2022, 326, 126809. [Google Scholar] [CrossRef]

- Mellaikhafi, A.; Tilioua, A.; Souli, H.; Garoum, M.; Alaoui Hamdi, M.A. Characterization of different earthen construction materials in oasis of south-eastern Morocco (Errachidia Province). Case Stud. Constr. Mater. 2021, 14, e00496. [Google Scholar] [CrossRef]

- Charai, M.; Mezrhab, A.; Moga, L.; Karkri, M. Hygrothermal, mechanical and durability assessment of vegetable concrete mixes made with Alfa fibers for structural and thermal insulating applications. Construct. Build. Mater. 2022, 335, 127518. [Google Scholar] [CrossRef]

- Saira, S.; Mandili, B.; Taqi, M.; El Bouari, A. Development of a new eco-friendly composite material based on gypsum reinforced with a mixture of cork fibre and cardboard waste for building thermal insulation. Compos. Commun. 2019, 16, 20–24. [Google Scholar] [CrossRef]

- Mounir, S.; Maaloufa, Y.; Cherki, A.B.; Khabbazi, A. Thermal properties of the composite material clay/granular cork. Constr. Build. Mater. 2014, 70, 183–190. [Google Scholar] [CrossRef]

- Hernández-Olivares, F.; Bollati, M.R.; Del Rio, M.; Parga-Landa, B. Development of cork-gypsum composites for building applications. Constr. Build. Mater. 1999, 13, 179–186. [Google Scholar] [CrossRef]

- Lamrani, M.; Laaroussi, N.; Khabbazi, A.; Khalfaoui, M.; Garoum, M.; Feiz, A. Experimental study of thermal properties of a new ecological building material based on peanut shells and plaster. Case Stud. Constr. Mater. 2017, 7, 294–304. [Google Scholar] [CrossRef]

- Charai, M.; Mghazli, M.O.; Channouf, S.; El hammouti, A.; Jagadesh, P.; Moga, L.; Mezrhab, A. Lightweight waste-based gypsum composites for building temperature and moisture control using coal fly ash and plant fibers. Constr. Build. Mater. 2023, 393, 132092. [Google Scholar] [CrossRef]

- Brencis, R.; Skujans, J.; Iljins, U.; Ziemelis, I.; Osits, N. Research on foam gypsum with hemp fibrous reinforcement. Chem. Eng. Trans. 2011, 25, 159–164. [Google Scholar]

- Morales-Conde, M.J.; Rodríguez-Liñán, C.; Pedreño-Rojas, M.A. Physical and mechanical properties of wood-gypsum composites from demolition material in rehabilitation works. Constr. Build. Mater. 2016, 114, 6–14. [Google Scholar] [CrossRef]

- El hammouti, A.; Charai, M.; Channouf, S.; Horma, O.; Mezrhab, A.; Karkri, M.; Tankari, M.A. Application analysis and environmental impact of straw reinforced gypsum plaster for improving the energy efficiency in buildings in the six climate zones of Morocco. J. Build. Eng. 2023, 74, 106829. [Google Scholar] [CrossRef]

- Bouzit, S.; Laasri, S.; Taha, M.; Laghzizil, A.; Hajjaji, A.; Merli, F.; Buratti, C. Characterization of Natural Gypsum Materials and Their Composites for Building Applications. Appl. Sci. 2019, 9, 2443. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Lunghi, L.; Barbanera, M. Thermal Conductivity Measurements By Means of a New ‘Small Hot-Box’ Apparatus: Manufacturing, Calibration and Preliminary Experimental Tests on Different Materials. Int. J. Thermophys. 2016, 37, 47. [Google Scholar] [CrossRef]

- UNI EN 1934; Thermal Performance of Buildings—Determination of Thermal Resistance by Hot Box Method Using Heat Flow Meter—Masonry. Brithis Standards Institutions: London, UK, 2000.

- JCGM 100; GUM 1995 with Minor Corrections Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement. BIPM, Bureau International des Poids et Mesures: Sèvres, France, 2008.

- ISO 10534-2; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method. ISO: Geneva, Switzerland, 1998.

- Buratti, C.; Merli, F.; Moretti, E. Aerogel-based materials for building applications: Influence of granule size on thermal and acoustic performance. Energy Build. 2017, 152, 472–482. [Google Scholar] [CrossRef]

- ISO 10456; Building Materials and Products—Hygrothermal Propertie—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values. ISO: Geneva, Switzerland, 2007.

- ASTM C423-09A; Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method. ASTM International: West Conshohocken, PA, USA, 2009.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).