Abstract

Windmills constitute a valuable part of cultural heritage, especially in Greece, as unique structures of popular architecture and know-how of the pre-industrial era. Their wooden mechanisms were of exceptional constructional ingenuity, with the Mediterranean ones bearing a vertical wing and a rotating roof (“trula”), with a manual torsion mechanism that allowed for operation in all wind directions. Sikinos is a small Aegean island characterized by rich landscapes, which do not have wood-producing forests, but only sparse Juniperus phoenicea shrub land mixed with evergreen hardwood species and the presence of numerous sclerophyllus vegetation species (maquis). Three abandoned windmills are still preserved on the island today, but only two of them appear to have their wooden mechanisms left. In the one windmill mechanism examined, it was found that different wood species were used to manufacture its individual parts. Oak wood was used in most of the large elements, with the exception of the sprattle beam (“zigos”), which is made of fir wood. The local juniper was not used in any crucial part of the mechanism, though it was used only as a structural material on the first floor (“anogio”) flooring, along with large-diameter olive trunks. The findings of this study highlighted the thorough knowledge of the properties of various wood species and the effective use of simple tools toward the construction of functional and effective windmill mechanisms.

Keywords:

architecture; building; construction; culture; heritage; island; properties; structure; timber; windmill; wood 1. Introduction

Wood is undoubtedly an important element of cultural heritage, as it has been the raw material of a large number of products (the Greek word used for the “material” comes from the ancient word “ύλη”, which means both “forest” and “wood”) since prehistoric times, essentially contributing to human survival and the development of civilization. As a material, it has offered mankind a variety of possibilities, including the manufacture of furniture, tools, constructions, musical instruments, various objects of daily use, etc. This multivariate use transformed wood from a natural material to a cultural product and led to the development of a particularly interesting culture, the “wood culture” [1]. In recent years, there has been an international effort to promote and highlight this culture, whereas in 2007, the International Wood Culture Society (IWCS), a non-profit, non-governmental international network dedicated to the research, education and promotion of wood culture was founded and supported to work in this direction.

The windmills were impressively cylindrical, stone-built buildings resembling to towers [2], adapted to the local construction practices of each island [3], which were built usually in a prominent [2], windy location, near paths [3], closer to settlements than fields [4]. Despite the fact that the time of their appearance is not yet totally clear, during the 16th century, they were already widespread in the Aegean area, grinding mainly grain for the production of flour and other seeds for the production of animal feed. At the beginning of the 20th century, they gradually began to be abandoned, first on big islands and gradually on smaller and isolated ones. The main motives of depreciation were the supply of flour from other places, development of bakeries providing bread, sale of barley for beer production, etc. [3], until they finally fell into disuse due to the appearance of diesel engines in the technological era [2].

Windmills constitute a remarkable, complex example of a mechanism of the pre-industrial era [2,5], with the Mediterranean ones usually including vertical windmill sail frames (windmill wings) and a rotating roof (“trula”) [3], with a manual turning mechanism, which enabled operation with all wind directions [2]. Depending on the number of floors, the windmills were classified into three categories:

- Single-floor buildings (ground floor and “anogio”);

- Two-floor ones (including the ground floor, mezzanine floor and “anogio”);

- Three-floor ones (including the ground floor and two floors).

The “anogio” was the most important space, since that was the location of the drive mechanism and millstones for grinding, as well as the torsion mechanism of the rotating roof (“trula”) [3]. Access to the “anogio” was implemented through a narrow, stone, spiral staircase that was always built to the left of the entrance [2], while the rest of the internal structures were, on most islands, wooden, at least for single- and two-floor windmills [3], with the flooring of the upper floor consisting of wooden beams of large diameters so that they could withstand the weight of the millstone [6].

The construction of a windmill, in combination with the necessary large wooden mechanism construction (analyzed in the following section), was considered an extremely expensive investment, many times higher than other buildings (e.g., churches), carried out mainly through the prominent ones of these islands since it required years to build and import of appropriate materials (e.g., wood for parts of the mechanism) [3], while its presence during those years was a sign of economic prosperity [7].

Windmills constitute a valuable part of cultural heritage, presenting a dual character, as they are architectural monuments, examples of folk architecture and knowledge, but also examples of wooden mechanisms of special manufacturing intelligence in relation to their mode of operation [6] that smartly combined simple engineering principles [8,9].

Windmills in some areas have already been studied, such as those in the province of ancient Halicarnassus in Turkey [8], Iran [10], Castile of Spain [11] and Scotland [12]. In general, differences have been detected between those in the East and the West, with the East windmills mainly bearing horizontal windmill wing frames (“fteroti”) which rotate horizontally on the top of the building, and the West ones bearing vertical rigid windmill wing frames, rotating vertically on the side of the building. In windmills in the Mediterranean area, there was an interesting fusion of Eastern and Western features, with a dominant form that included a vertical flexible windmill sail frame and rotating roof, a construction that probably evolved and became standardized over the centuries [8]. In Greece, windmills were located mainly on islands, since they required a constant supply of wind energy [3,13], even though the rest of Greece was quite familiar with these conditions as well [14]. Although a few horizontal windmills have also been found (Karpathos), vertical ones with a rotating roof dominated, while fixed ones that operated with a single wind direction were rare and limited mainly to Crete and Karpathos [15].

The moving part of the windmill (mechanism) was traditionally made of wood [16] and was the most important part. In general, it consisted of a horizontal beam (Figure 1), which carried the system for converting the force of the wind into motion on the outside and a large wooden wheel on the inside, the rotary motion of which set the millstone system in motion. The turning mechanism allowed to simply and manually change the position of the above system, so that the mill worked with all wind directions [2]. In general, the mechanism construction was based on the raw materials available in the area [14], as well as on those that could be imported. This especially concerned places where the local timber amount was not adequate, mainly for the construction of the windshaft, wooden ring located at the top of the windmill on which the roof rotated and the wallower, where wood imported from Mount Athos or Asia Minor were used [3], or wherever else it was available. For example, in Karpathos, “Tsikoudia” (Pistacia terebinthus) was imported from the island of Tilos in the Dodecanese area [15].

Figure 1.

Main wooden parts of the windmill mechanism (a. “katoplakes”, b. “panarika”, c. windshaft, d. wheel, e. “zigos”, f. “bratsolia”, g. “antixono”).

The wooden mechanism of the windmill, as well as the wooden mechanisms of water and oil mills, are complex examples of mechanisms of the pre-industrial era [2,5], and therefore monuments of technological cultural heritage [17] that gradually disappear or have already disappeared, both due to abandonment and looting for other uses [14]. Wood mechanism was replaced with mechanisms made of other materials in the case of water mills [18] and oil mills [2,19].

In the current study, a thorough examination of the Sikinos island windmills and their mechanisms is carried out, aiming to highlight the way of thinking and action of windmill manufacturers of that pre-industrial era (and therefore, of other wooden structures of that time), as well as the use of tools, manufacturers know-how and potential deep knowledge of different wood species properties and behavior.

2. Sikinos Island

The island of Sikinos is located at the south part of the Cyclades island complex (a group of varying-sized islands scattered over the deep blue waters of the Aegean Sea), between the Folegandros island (west) and the Ios island (east), covering an area of approximately 41 km2. Despite the rich landscape, the island does not have wood-producing forests, as along with the rest of the Cycladic islands. These areas include only sparse and low-height juniper-Juniperus phoenicea shrubs that dominate, with evergreen hardwood species (mainly Pistacia lentiscus), pistacia also growing in areas where juniper is not spread. A characteristic of the above-mentioned areas is the presence of numerous sclerophyllus (fryganic) vegetation species. Moreover, the Sikinos island did not have a natural port, and a ferry boat approached the island for the first time in the year 1988. Consequently, due to the absence of a port, there was an isolation of the island and difficulties in transporting materials, which contributed to the preservation of a large part of traditional constructions, nowadays offered for a thorough study.

Therefore, the Sikinos island was chosen to be the study area of this research, since it was it was considered of even greater interest to record and study windmills constructed during the pre-industrial era on an island that had neither wood-producing forests, nor a port (at that time) and as a result, making the difficulties of such windmill construction even greater.

3. Windmill Mechanisms on the Sikinos Island

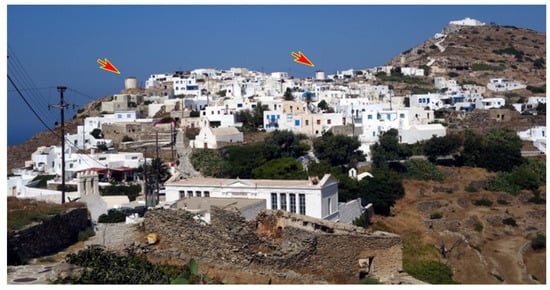

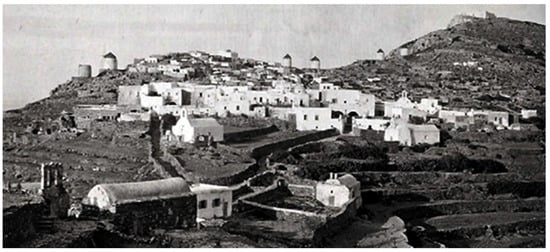

In the “Kastro” district, at the steep northern edge of Sikinos Chora (main town), three abandoned windmills (Figure 2) are preserved today, one of which, in the northeast, is partially demolished. According to Vaos and Nomikos [3], there were six windmills in Chora (Figure 3).

Figure 2.

The “Kastro” district of Sikinos Chora and the two of three abandoned windmill buildings, pointed out with arrows in a photograph taken in the year of 2019.

Figure 3.

Windmills in Sikinos Chora at the end of the 19th c. [20].

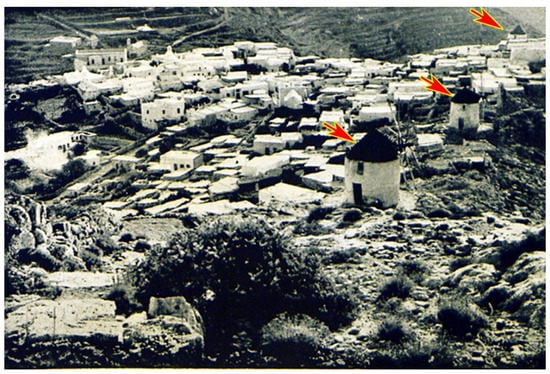

According to the testimonies of residents, the rest of the windmill buildings were destroyed at least 80 years ago, which is also confirmed by a photo taken before 1935, which includes only the three remaining windmills at that time (Figure 4). Overall, taking into account all the relevant findings (with testimonies and old photographs, etc.), it can be concluded that before 1900, the Sikinos Chora had ten windmills: six in the “Kastro” district and four in the “Chorio” district, arranged in five groups of two. All these windmills were privately owned by wealthy residents of the island, as continued to this day. The remaining windmills are being gradually destroyed because of their abandonment, even though they constitute cultural heritage monuments with a dual meaning; on the one hand, as architectural structures, and on the other hand, as complex examples of wooden mechanisms of the past. It is worth noting that none of them have been classified as historical monuments to be preserved, while no effort has been implemented by the state and the local government to protect and highlight their existence and value. The danger can be detected both in the buildings and their wooden mechanisms, which are susceptible to biological attacks, but also to illegal removal for other uses.

Figure 4.

Windmill buildings in Sikinos Chora in a photo taken before 1935 [21].

The mechanisms are being preserved today only in the two most western-located windmills (Figure 5), as the wooden part has been completely removed and destroyed in the one located further east. Both windmills that retained the wooden mechanism nowadays are of the vertical single-floor type, with a rotating roof (“trula”), which allows for the main mechanism to be repositioned so that the mill can operate with all wind directions, although they no longer include the external conversion frame of wind power in motion through sails. One of them, in the north–northeast side of Chora, was in operation until 1977 and is considered to be in a relatively good condition, retaining part of the conical roof, while it remains locked by its owners.

Figure 5.

The two windmills on Sikinos in which the wooden mechanisms are preserved.

The other windmill, located in the northwest of Chora and the subject of a thorough study, stopped its operation possibly in the 1960s, while nowadays, it does not have a door and is completely abandoned. Its mechanism includes the following main parts of the large dimensions (Figure 1):

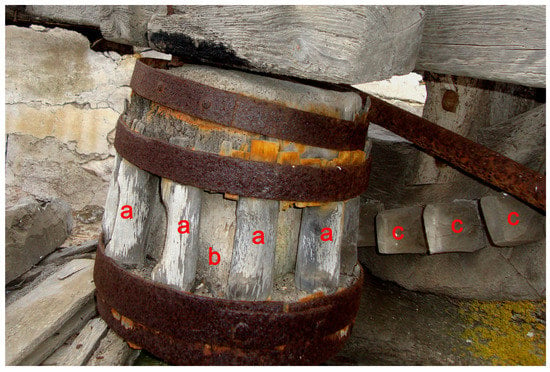

- The manual roof rotation–orientation system (Figure 1 and Figure 6), which includes a wide fixed wooden ring (probably nailed to “hidden” vertical wooden parts located inside the masonry), consisting of individual pieces of wood (“katoplakes”, Figure 1a and Figure 6a), on which rotation occurs in a special groove, a second wooden ring (Figure 1b), also consisting of thoroughly sanded pieces of wood (“panarika”), which have a special projection tongue (Figure 6b) in the center, entraining the entire upper part of the mechanism in the rotational movement;

Figure 6. The manual roof rotation–orientation system (a. “katoplakes”, b. “panarika”).

Figure 6. The manual roof rotation–orientation system (a. “katoplakes”, b. “panarika”). - The long horizontal beam (windshaft/“axoni”) (Figure 1c), which formerly externally carried the system of converting the force of the wind into motion by means of the sails, and internally, the vertical break wheel, the rotary motion of which set the upper millstone in motion through one more wooden component and a vertical iron shaft (“royal iron”);

- The horizontal beam, called “zigos” (yoke), known also as the “sprattle beam” (Figure 1e), is placed lower than the windshaft, perpendicular to it and parallel to the wheel (from the side of the cogs, the teeth of the break wheel), through the center of which the “royal iron” passes, while the ends of the “zigos” terminate at two other beams (“bratsolia”, sprattle beam supporting arms) for better weight distribution (Figure 1f), which have probably been cut off and reattached using metal parts;

- The “antixono” (anti-axle) is another horizontal beam on which the windshaft rests on its rear side to limit the pressure exerted on the movable base of the torsion system (Figure 1g).

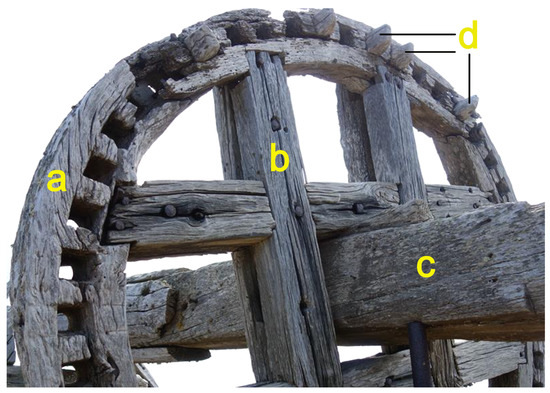

The break wheel consists of “stavros” (the clasp arms of the break wheel) and the rim (Figure 7). The “stavros” consists of four continuous or interrupted double rectangular wooden parts, fastened together with bolts, while a square gap is formed in the center of the “stavros” for anchoring the wheel to the windshaft. Also, the rim is composed of four curved pieces of wood joined together with a lap joint, and includes 48 gaps that carry corresponding cogs (Figure 5), which are held by nails at the back of their protrusion. The rotary motion of the wheel sets the upper millstone in motion by means of a large-diameter wooden cylinder called the “anemi” (Figure 8b), located at the bottom of the wheel, which is intended to accommodate smaller cylinders, “pentaravda” (rod system, Figure 8a), that create the necessary vacancies for the cogs of the wheel to enter, thus causing the rotational movement of the wallower, but also of the “royal iron” passing vertically through both the interior of the “anemi” and the millstone system. The “anemi”, in combination with “pentaravda”, creates the wallower, something that resembles a cage-type gear. This type of wallower gear can be constructed or repaired using very simple tools, since the teeth are not integrated into the central body of the gear, and for its construction, special cuttings are not required. In this way, the vertical rotational movement of the break wheel is transformed into a horizontal rotational movement of the wallower and correspondingly of the upper millstone, with a simultaneous multiplication of rotations (speed), due to the difference in the number of cogs of the wheel and the number of recesses of the wallower (48:8 = 6, which represents the “speed ratio”), which means that one complete rotation of the wheel corresponds to six rotations of the wallower and the respective millstone.

Figure 7.

The break wheel of the windmill (a. rim, b. “stavros”, c. windshaft, d. cogs).

Figure 8.

Wallower gear (a. “pentaravda”, b. “anemi”, c. teeth of the brake wheel).

Additionally, the mechanism includes several other parts of smaller dimensions, some of which are referred in the following:

- On the ground floor of the windmill building, the main part of the auxiliary system was used for adjusting the millstones;

- The flooring of the “first floor” of windmills is made of slates fixed to unprocessed, or almost unprocessed, logs of various cross-sections;

- Also, the windmill mechanism no longer carries the outer part of converting the energy of the wind into motion, and therefore, there is no current evidence of the timbers of the aerial system used to hang the sails, and the way they were connected to the shaft;

- The usual number of “antennas” (supporting sail spars) was 10 [2,3] or 12 [2,3,15], although there are a few cases with 8 or 14 “antennas”;

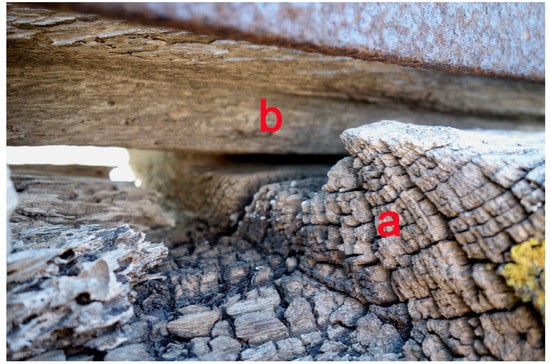

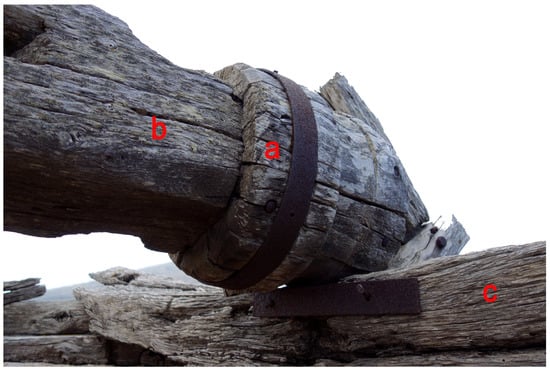

- The wooden strips of curved cross-section sides (“violas”) together form a hollow cylinder found at the rotation points of the windshaft in order to reduce its wear, and could be quite easily replaced with other new pieces of wood when the need arises (Figure 9).

Figure 9. “Violas” (a), found at the windshaft (b), and antixono (c).

Figure 9. “Violas” (a), found at the windshaft (b), and antixono (c).

4. Wood Species Used in Windmills (Sikinos)

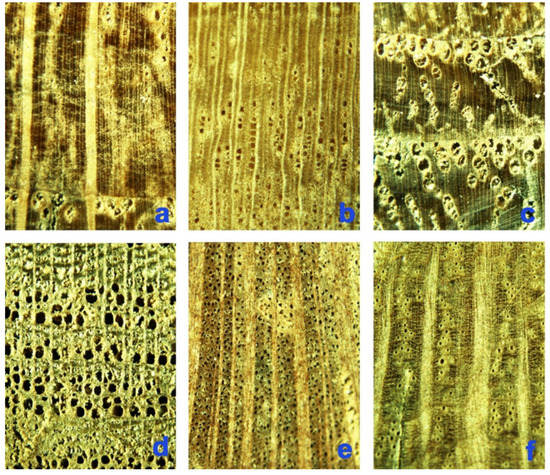

In the windmill mechanism on Sikinos, various wood species were used for the construction of its individual parts (Table 1 and Figure 10). In particular, in most large-sized parts (windshaft, “panarika”, “katoplakes”, “antixono”, “bratsolia”), deciduous oak, red (Q. cerris and Q. Trijana) or white (all the other Quercus sp.) (according to the wood identification keys of European timber species [22] (p. 582), was used, with the exception of the “zigos”, which is made of fir (Abies sp.) wood. Additionally, since the wheel is made of many different individual parts, it was usually constructed employing a variety of wood species. Thus, two of the four parts of the wheel rim were made of plane (Platanus sp.) wood species and one part was made of elm (Ulmus sp.) wood. Unfortunately, from the fourth part, it was not feasible to obtain a sample to be analyzed. Also, chestnut (Castanea sativa) was used for the “stavros” construction and evergreen oak wood (kermes: Quercus coccifera; or holm oak: Quercus ilex) for the cogs. For the part of “anemi”, ash (Fraxinus sp.) wood was used, while for the smaller parts, the use of both olive (Olea europaea) and evergreen oak (Quercus sp.) was frequently applied. The local juniper (Juniperus sp.) was not used in any key part of the mechanism, probably because of the various wood structure defects it presents [23]. Nevertheless, it was used as a structural element on the flooring of the “anogio” together with olive logs of a large diameter, but also in the three holes that start from the “anogio” and end approximately in the middle of the ground floor, carrying two small logs, horizontally placed, used for the tying of the cord, in order to stop the rotation of the “sail system”.

Table 1.

Sikinos windmill mechanism wood species scientifically recognized: comparison with those reported in the literature (empirically recognized [2,3,15]).

Figure 10.

Wood species used in the windmill mechanism on Sikinos ((a). red oak (Quercus sp.), (b). olive (Olea Eurepaea), (c). chestnut (Castanea sativa), (d). elm (Ulmus sp.), (e). plane (Platanus sp.), (f). holm oak (Quercus ilex)) (stereomicroscope 16×, Nikon SMZ800).

Several wood species coincide with those reported in the literature relating Cycladic windmills [3], which are empirically recognized (Table 1) in the use of:

- Oak (Quercus sp.) wood for the windshaft, “antixono” and “bratsolia”, as well as kermes oak (Quercus coccifera) for the wheel cogs and “pentaravda”;

- Fir (Abies sp.) wood for the “zigos”;

- Plane (Platanus sp.) wood for the rim of the break wheel,

While there are no similarities with the windmill studied on the island of Ios (Cyclades island), which provides evidence of for the overwhelming use of elm wood [15].

Furthermore, there are no common wood species with the windmills reported on the Kasos (Dodecanese), with the exception of the use of kermes oak wood for the cogs of the wheel and the “pentaravda”, although the available literature is very limited [2], covering only a few individual parts of the mechanism.

It is concluded that for the construction of the studied windmill mechanism on Sikinos, hardwood species were used, with the exception of one beam that comes from a softwood species (fir). A clear predominance of oak can even be detected, which is found in almost all very long (windshaft) or relatively long parts (“panarika”, “katoplakes”, “antixono”, “bratsolia”), though also in smaller parts (cogs, “pentaravda”). In general, oak is a hardwood species of high mechanical strength, with the deciduous oak showing moderate-to-very high density (0.45–0.95 g/cm3) and evergreen oak being very heavy (0.80–1.10 g/cm3) [22]. The latter (kermes oak or holm oak) was the most suitable species for the construction of the cogs and “pentaravda”, since these parts were under a lot of mechanical stress because of the continuous rotational movement. Of course, the choice of wood species was also determined by the availability and possibility of their supply, since finding oaks was impossible on most of the Cyclades islands, with a potential exception of the low-height kermes oak species. Thus, the large shaft, which is made of oak wood, probably red, i.e., from the species of turkey oak (Quercus cerris) or Macedonian oak (Quercus trojana), may come either from Northern Greece or Asia Minor, where the main distribution areas of the above species are located. Corresponding information is available from the study of Vaos and Nomikos [3], who reported timber imports from Mount Athos or Asia Minor mainly for the windshaft, “katoplakes” and “anemi”, respectively. A heavy weight (0.82–1.02 g/cm3) and high hardness are also evident in olive wood [22], which was used for the construction of individual components of small dimensions and could have come from the Sikinos island due to the high availability. In fact, the choice of olive wood species for the “violas” construction, i.e., at the pivot points of the shaft, facilitated its rotational movement, preventing damage, attributed to the natural oiliness of the specific wood. Furthermore, the ash wood used for the construction of “anemi” is a species of moderate-to-heavy weight (0.52–0.87 g/cm3) [22] and hard, though of a high modulus of elasticity, with great mechanical strength and particular resistance to the impact of bending forces [24], properties that are both of great significance because of its continuous rotation, as well as in cases where, because of an inappropriate adjustment of the wheel position, its cogs may collide with the body of the “anemi”.

On the contrary, for the construction of the wheel, with the exception of the cogs, the wood of plane, elm and chestnut were used [22], with the plane and elm being mainly of medium weight (0.60–0.72 g/cm3 and 0.46–0.70 g/cm3, respectively) and hardness, while the chestnut shows a low-to-medium weight (0.37–0.70 g/cm3) and low-to-medium hardness [22].

The use of these wood species is probably related to the desire to decrease the weight of the structure for an easier rotation due to the large size of the wheel, which produced a higher pressure on the cogs. That is the reason why they were made of a hard and very heavy wood species (evergreen oak). Also, the use of chestnut in the “stavros” construction is justified by the high dimensional stability of this species. In this way, the risk of developing defects in the connection of the individual parts of the wheel is eliminated.

Additionally, for the construction of the wheel rim, some species with an already curved trunk or characterized by the ease of the curvature had to be used, since the rim of the wheel was composed of four curved pieces. Plane and elm species are, among others, some of the species that bend comparatively easier [24]. The use of elm in constructions with curved parts, such as the wheels of carriages, has been established since ancient times [25]. The curved wooden part, in some cases, seems to be achieved by applying a combination of curvature and a suitable cutting.

On the contrary, in the rotation and orientation system of the “fteroti” (“panarika”, “katoplakes”), many individual pieces were used that created an almost polygonal structure in places, thus limiting the necessity of using already curved elements. The choice of hardwood species for specific components, attributed to their great ease of bending, is also reinforced by the fact that softwood species that are difficult to be bent were not used, despite their high strength in combination with their relatively low weight (like fir wood presenting a density of 0.44 g/cm3) [22] (p. 111), although the reduction in weight of the overall mechanism was obviously desired, aiming to make it easier to operate. The same conclusion can be drawn from the use of elm species in the aforementioned individual parts of the windmill mechanism studied on the island of Ios [15]. Of course, the availability of various wood species seems to have been a decisive factor that forced the use of the same species in several individual sections, where possible, based on the properties that each application required, depending on the use–location of the windmill mechanism. This also proves the thorough empirical knowledge of each wood species property. Additionally, it should be noted that some of these components might have been replaced over the windmills’ long service lifespan using any wood species available at that period.

Regarding the biological resistance of wood species that have been applied, most demonstrate a long natural durability (oak, olive, chestnut) [22], although the mechanism was intended to work in a sheltered area. Therefore, wood biological durability may not be the primary selection criterion, with the exception of the unsheltered “fteroti” mechanism that protruded and was exposed to both biotic and abiotic actions. However, due to abandonment and subsequent destruction/removal of the roof, the wooden mechanism has been directly exposed to abiotic factors and biological attacks for many years, as a result of which it appears to bear disintegration signs, corrosion and cracks, with the greatest extent of attack being found in the wood species of ash used in the part of the “anemi”, which is susceptible to the catastrophic action of wood-destroying microorganisms, such as fungi (durability class 4 to 5 according to EN 350:2016) [22], followed by the species of fir, used in the “zigos”. Extensive bio-deterioration also appears in one of the four parts that make up the wheel rim. However, due to the extensive biological attack in relation to the rest of the region, it is assumed that this wood species is different from the other two species used (plane, elm), possibly suggesting a later addition or at least another part of the trunk, as the natural strength varies not only among different species, but also among different parts of the same species or the same log/trunk (heartwood and sapwood) [24,26].

As it appears from the limited oral testimonies of elderly residents, no means were used in the past to protect these wooden parts that have survived biological attacks, although in the literature, there is a reference to the initial protection of the shaft via a burning–smoking process, which was later replaced by the use of pine tar [3]. Of course, parts of the studied windmill mechanism (mainly “violas”, cogs, “pentaravda” and “panarika”) had been regularly smeared with grease or soapy water, which, however, did not aim to protect against biological attacks, but facilitate the rotational movement and the subsequent damage reduction.

5. Conclusions

As a unique example of the popular pre-industrial-era architecture and technological advancements, windmills constitute an important component of cultural heritage. The Sikinos island windmills, as well as the Mediterranean windmills, typically included a vertical sail frame and a rotating roof (“trula”), with a manual torsion mechanism that permitted for operation in all wind directions. Their wooden mechanisms were of exceptional technical ingenuity. Sikinos is a small Aegean island with intense landscapes and scant Juniperus phoenicea vegetation, combined with evergreen hardwood species and an abundance of sclerophyllus vegetation species, without wood-producing forests. For this reason, it was of even greater interest to record and study the windmills of this particular island. Currently, only two of the island’s three abandoned windmills still have their wooden mechanisms.

It was discovered that several wood species were utilized to manufacture each element of the two windmill mechanisms that were studied. With the exception of the “zigos” part, which was constructed with fir wood, most substantial pieces were constructed using oak wood. The indigenous juniper, together with large-diameter olive trunks, was employed only for the structural elements of the “anogio” flooring, without being used in any essential part of the mechanism. The present study highlights the level of know-how in the construction of windmills, and the thorough knowledge of the characteristics and properties of the different available wood species that has been established since ancient times. Evidence of the utility, durability and simplicity of these windmill mechanisms, the techniques employed in windmill construction and the proper application of different wood species to serve ideally at the appropriate point in the construction, in accordance with their properties and characteristics, were recorded in order not to lose this existing knowledge. Undoubtedly, the goal of future research should be to accurately date the specific windmills on Sikinos, as well as examine other Greek islands’ corresponding wooden monuments of cultural heritage. The current study, as well as future studies that are going to be implemented, aims to raise awareness in the local community and motivate the stakeholders toward the achievement of governmental support for the protection, preservation and projection of these significant cultural monuments.

Author Contributions

Conceptualization, I.B.; methodology, E.A. and I.B.; software, E.A. and I.B.; validation, E.A.; formal analysis, E.A. and I.B.; investigation, E.A.; resources, E.A.; data curation, E.A., I.B. and V.K.; writing—original draft preparation, E.A. and I.B.; writing—review and editing, V.K.; visualization, I.B.; supervision, I.B.; project administration, E.A. and I.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| Terminology used for Cycladic windmills | |

| “anemi” | The root cylinder of the wallower gear. “Anemi”, with the “pentaravda”, constitutes the wallover, a horizontal cage-type gear, driven by the brake wheel. |

| “anogio” | First floor. |

| “antenes” | Spar support sails. |

| “antixono” | Anti-axle, a horizontal beam on which the windshaft rests on its rear side (also known as the tail beam). |

| “axoni” | Windshaft. |

| “bratsolia” | Supporting arms of the “zigos”, also referred to as cross beams in previous studies. |

| “fteroti” | Windmill sail structural system outside the windmill building (windmill wings). |

| “katogio” | Basement. |

| “katoplakes” | A wide, fixed wooden ring with a special groove, placed on top of the windmill. |

| “panarika” | Wooden ring with a special tongue in the center, moving over “κatoplakes” and entraining the entire upper part of the mechanism in rotational movement. |

| “patari” | Mezzanine floor. |

| “pentaravda” | Cylindrical rods, the teeth of the wallower. |

| “roda” | The brake wheel. |

| “stavros” | Cross, clasp arms of the break wheel. |

| “trula” | The rotating roof. |

| “violes” | The curved cross-sectional strips at the pivot points of the windshaft. |

| “zigos” | The sprattle beam, a horizontal beam which supports the windshaft (known also as the yoke). |

References

- Hatzitoulousis, S. Wood as Archaeological Material in Prehistory: The Case Study of the Neolithic Lake Side Settlement at Dispilio Kastoria. Ph.D. Thesis, Department of History and Archaeology, Aristotle University of Thessaloniki, Thessaloniki, Greece, 2006; p. 493. [Google Scholar] [CrossRef]

- Skoulias, M. The Windmills and the Plowing of Kasos; Ministry of the Aegean and Municipality of Kasos: Athens, Greece, 2001; 178p. [Google Scholar]

- Vaos, Z.; Nomikos, S. The Windmill in the Cyclades; Dodoni: Athens, Greece, 1993; 406p. [Google Scholar]

- Radford, A.; Clark, C. Cyclades-Study of an Anonymous Architecture; Doumani, O.B., Oliver, P., Eds.; Architectural Issues; Shelter in Greece: Athens, Greece, 1974; pp. 64–82. [Google Scholar]

- Sarantakou, E. Architecture of the Rural Residence in the Aegean. Cultural Gateway of the Aegean Archipelago—Greater Hellenism Foundation. 2005. Available online: http://www2.egeonet.gr/Forms/fLemmaBodyExtended.aspx?lemmaID=6979 (accessed on 13 January 2018).

- Tapanli-Dania, M.; Malakos, G.; Diagouma, A. Restoration of a windmill in Perama, Lesvos. In Proceedings of the 2nd National Conference “Mild Interventions for the Protection of Historic Structures”, Thessaloniki, Greece, 14–16 October 2004; Thessaloniki, TEE and Ephorate of Newer Monuments of Central Macedonia. Volume 2, pp. 91–101. [Google Scholar]

- Kotsakis, A. The Formation of the Cultural Landscape of the Island of Naxos from 1204 to the Foundation of the Greek State. Ph.D. Thesis, University of Peloponnese, Kalamata, Greece, 2013; p. 566. [Google Scholar]

- Medioli, A.; Özkan, S.; Plunz, R. The Grain Cycle and a Windmill at a Village on the Aegean. Middle East Technical University. J. Fac. Archit. 1977, 3, 39–62. [Google Scholar]

- Barboutis, I.; Koutis, P.; Kamperidou, V.; Chryssoulaki, S. Knowledge and quality of woodworking in ancient Greece; revealed from a simple finding. In Proceedings of the 12th International Conference “Wood Science and Engineering in the Third Millennium”, Brașov, Romania, 7–9 November 2019; Transilvania University of Brașov: Brașov, Romania, 2019; pp. 233–240. [Google Scholar]

- Saeidian, A. Windmills in Iran. Elixir Hist. Preserv. 2012, 42, 6507–6515. [Google Scholar]

- Pérez-Martín, E.; Herrero-Tejedor, T.R.; Gómez-Elvira, M.Á.; Rojas-Sola, J.I.; Conejo-Martin, M.Á. Graphic study and geovisualization of the old windmills of La Mancha (Spain). Appl. Geogr. 2011, 31, 941–949. [Google Scholar] [CrossRef]

- McLaren, T. Old Windmills in Scotland, with Special Reference to the Windmill Tower at Dunbarney, Perthshire. Proc. Soc. Antiqu. Scotl. 1945, 79, 6–14. [Google Scholar] [CrossRef]

- Siaxampani-Stefanou, X. Byzantine and Post-Byzantine Watermills in the Vicinity of Thessaloniki. Ph.D. Thesis, Polytechnic School of Aristotle University of Thessaloniki, Thessaloniki, Greece, 2014; p. 360. [Google Scholar]

- Koumanoudis, I. Windmills: Kythira-Mani-Argolis-Arcadia-Messinia-Akarnania & Three Opposite Islands (Kalamos-Kastos-Meganisi); Technical Chronicles of the Technical Chamber of Greece: Athens, Greece, 2004; Issue 6; 29p. [Google Scholar]

- Leimona-Trembela, E. Aegean Windmills; (In Greek: “Aιγαιοπελαγίτικοι ανεμόμυλοι”); Technical Chronicles of the Technical Chamber of Greece: Athens, Greece, 1974; pp. 319–338. [Google Scholar]

- Hunt, D. Properties of wood in the conservation of historical wooden artifacts. J. Cult. Herit. 2012, 13S, S10–S15. [Google Scholar] [CrossRef]

- Axiotis, E. Watermills of Lesvos. Ph.D. Thesis, Department of Cultural Technology and Communication, University of the Aegean, Mytilini, Greece, 2008; 237p. [Google Scholar]

- Valavanidou, A. The Watermills of Macedonia. Ph.D. Thesis, Polytechnic School of Aristotle University of Thessaloniki, Thessaloniki, Greece, 2008. Volume A. 889p. [Google Scholar]

- Dimitropoulos, D. Olive mills, mills, ovens, churches in the island area in the 17th century—An approach to the issue of co-ownership based on the example of Mykonos. Memory 1994, 16, 37–70. [Google Scholar]

- Byzantine and Christian Museum. Journeys of Georgios Lambakis—Γεωργίου Λαμπάκη περιηγήσεις—Calendar; Lapourtas, A., Ed.; Ministry of Culture—Byzantine and Christian Museum: Athens, Greece, 2000; 60p. [Google Scholar]

- Perilla, F. (Ed.) Les îles de la Grèce; Athenes aprox.1935, 130 pages, 4o, Greece; 87p. (In French)

- Tsoumis, G. Structure, Properties and Utilization of Wood, 1st ed.; Aristotle University of Thessaloniki Publications Service: Thessaloniki, Greece, 1983; 351p. [Google Scholar]

- Kamperidou, V.; Aidinidis, E.; Barboutis, I. Impact of Structural Defects on the Surface Quality of Hardwood Species Sliced Veneers. Appl. Sci. 2020, 10, 6265. [Google Scholar] [CrossRef]

- Voulgaridis, H. Quality and Uses of Wood; Association of Greek Academic Libraries: Athens, Greece, 2015; Available online: http://hdl.handle.net/11419/5260 (accessed on 29 April 2018).

- Kakaras, I. Applications of Wood in Antiquity. In Technology of Wooden Structural Constructions; Kakaras, I., Ed.; Ion: Athens, Greece, 2013; pp. 101–172. [Google Scholar]

- Kamperidou, V. The Biological Durability of Thermally-and Chemically-Modified Black Pine and Poplar Wood Against Basidiomycetes and Mold Action. Forests 2019, 10, 1111. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).