Abstract

This scientific article investigates the mechanical properties of a novel three-dimensional-printing resin specifically designed for orthodontic aligners and compares it to other commonly used resins. The resin was made by blending two commercially available and certified resins to produce aligners with improved mechanical properties compared to each separate resin. The study examined the effect of the addition of NextDent Ortho Rigid resin on the mechanical properties of the specimens, more specifically analyzing the relationship between the amount of the added rigid resin and the mechanical properties of the specimens. The mechanical properties of the specimens and the nickel-titanium wires were analyzed using a three-point bending test setup. The results showed no statistically significant differences within the different groups of specimens. The study provides valuable insights into the potential of the resin to meet the mechanical demands of orthodontic treatments. It will contribute to the advancement of personalized orthodontic care through three-dimensional-printing technology. Blending commercially available and certified resins enables orthodontic practitioners to select the most suitable resin for each case, providing better outcomes for patients and increasing the efficiency of the treatment process. Further research and evaluation would be required to determine the suitability of the blended resin for orthodontic treatments.

1. Introduction

Orthodontic treatment has undergone significant advancements in recent years, offering patients more options. The latest advancement is clear aligners, which have revolutionized orthodontic treatment by providing a discreet and convenient alternative to traditional braces. This technique involves using a series of custom-made, transparent aligners that gradually move the teeth into their desired positions [1].

Traditionally, orthodontic aligners were made via the thermoforming technique, which is a widely employed method in orthodontics for the fabrication of orthodontic appliances, such as retainers and aligners. This technique uses heat to soften a thermoplastic material, allowing it to be shaped and molded over a dental model. The process begins with selecting the appropriate thermoplastic material, which is then heated to its specific softening temperature. Once heated, the softened plastic is draped over the dental model and formed into the desired shape using a vacuum or pressure. The thermoplastic material quickly cools and hardens, retaining the molded shape and creating a custom-fitted appliance. The thermoforming technique offers several advantages, including cost-effectiveness, ease of use, and the ability to fabricate appliances relatively quickly. However, it is important to ensure precise adaptation of the material to ensure optimal fit and function.

Three-dimensional-printed orthodontic aligners have emerged as a cutting-edge and innovative solution in orthodontics. Utilizing direct 3D-printing technology, these aligners are custom-designed and fabricated for each patient [2,3]. The digitally designed aligners are sent to a 3D printer, which utilizes specially formulated biocompatible resins to produce the aligners without a thermoforming process. The resulting aligners are precise, durable, and exhibit the desired characteristics of flexibility, transparency, and fit. This advanced technology enables orthodontists to achieve highly customized treatment plans, ensuring optimal tooth movement and aligner performance. Among the multiple factors that determine the effectiveness of orthodontic treatment with clear aligners, their design accuracy and mechanical properties are crucial [4].

Currently, various thermoplastic materials, such as polyethylene terephthalate glycol (PETG), polypropylene (PE), polycarbonate (PC), polyurethane (PU), and polypropylene (PP), are being used to manufacture clear aligners since they are biocompatible, transparent, and characterized by low hardness, good elasticity, and resistance in the oral environment [5,6].

Lately, multi-hybrid materials have been developed to overcome the limitations of single materials and to improve their maximum tensile load-bearing capacity [6].

The conventional workflow for manufacturing a set of clear aligners starts with digital scanning of the patient’s dental arches and the virtual planning of the treatment by computer-aided design (CAD) software. Thus, a physical dental model is 3D-printed for each stage and arch, fabricated by stretching the clear plastic sheets over the 3D printed model by means of thermoforming (vacuum or high pressure) machines, and finally, trimmed and polished [7].

Ideal orthodontic treatment requires clear aligners to exert constant light forces, leading to a maximum rate of tooth movement with minimal irreversible tissue damage [8].

Despite that both the production efficiency and functional effectiveness of thermoformed aligners have significantly improved over the last years [9], the geometric inaccuracies induced by the shrinkage and expansion of the plastic foil during the thermoforming process have not yet been solved [6], affecting the fit of the aligner to the teeth, the inter-arch occlusal relationship, and the planned distribution of the orthodontic force. The decrease in the thermoplastic sheet thickness with the thermoforming process is well-known [4,6,10,11].

Moreover, resin polymers are not inert: the mechanical properties of these materials are known to highly depend on environmental conditions [12]. In the oral cavity, aligners are subjected to intermittent short- and long-term loads [13] and, as viscoelastic materials, lose a substantial amount of their initial strength in the first few hours [12]. They are also prone to changes due to heat, humidity, and saliva absorption, making tooth movement less predictable [14,15]. To overcome the limitations of the conventional manufacturing method, direct 3D printing of clear aligners has recently been attempted, since the first photocurable dental resin explicitly indicated for this purpose was launched onto the market (TC-85DAC, Graphy, Seoul, Republic of Korea). This procedure allows to directly print aligners, without the need to print the corresponding dental models and bypassing the thermoforming process [4,6]. As an emerging technology, despite its practical advantages, the biocompatibility, geometrical accuracy, physical and mechanical properties, as well as chemical stability of the 3D-printed aligners are yet to be tested and validated with respect to the conventional thermoformed aligners.

Can and colleagues recently examined, through indentation testing, the mechanical properties of a few samples of aligners 3D-printed with the aforementioned resin after intraoral exposure, reporting no deterioration after an intraoral exposure period of one week [16].

Lee et al. analyzed some static and dynamic mechanical properties of the same photocurable resin and compared the outcomes with a control PETG material [6].

The choice of the resin to be used to print the aligners is a fundamental step because it significantly influences the final product’s mechanical properties [17]. In this article, the mechanical properties of a new experimental resin, made by mixing, in different proportions, two commercially available and certified resins, specifically designed for 3D printing of orthodontic aligners, will be examined. Then, it will be compared to the mechanical properties of TC-85DAC samples (Graphy), and nickel-titanium wires used as control samples. The aim of this research is to determine if the resin blend can produce aligners with improved mechanical properties compared to those made separately with each resin. Furthermore, the purpose is to obtain a resin that meets the specific needs of different clinical cases by blending commercially available and certified resins in different percentages. This approach will enable orthodontic practitioners to select the most suitable resin blend for each case or for each stage of treatment, providing better outcomes for patients and increasing the efficiency of the treatment process.

The research hypothesis for this study is that custom-designed 3D-printing resins with varying force properties will exhibit comparable or superior mechanical characteristics to commercially available resins and nickel-titanium wires. By tailoring the properties of the resin-based materials to specific orthodontic requirements, these novel resins can potentially offer alternative solutions in orthodontic treatments. The study aims to investigate the mechanical properties of these custom resins and compare them with commercially available resins and nickel-titanium wires, expecting that the custom resins will demonstrate a favorable performance, such as improved flexibility, strength, and shape-memory capabilities. The results of this study will contribute to the advancement of personalized orthodontic care through 3D-printing technology.

2. Materials and Methods

In this study, we compared the load-deflection of a commercial aligner resin (Graphy Resin TC-85DAC) with a resin created by blending two different (Ortho Flex, New York, NY, USA and NextDent Ortho Rigid, Soesterberg, The Netherlands) resins and classic nickel-titanium wires (0.016″ × 0.016″ and 0.016″ × 0.022″ Forestadent). For the 3D-printed resin samples, a 25 × 5 × 0.6 mm parallelepiped was designed using Rhinoceros Software (v7.13 Robert McNeel & Associates, Seattle, WA, USA) and exported as an STL binary file and generated machine code with 3D Sprint (NextDent). In addition to nickel-titanium wires, Graphy samples, and OrthoFlex specimens (sample 1), we decided to test six new blended resins (samples 2–7), obtained by adding different percentages of NextDent Ortho Rigid to NextDent Ortho Flex resin (increments of 10%, 19%, 27%, 42%, 54%, and 65%, respectively). Five samples were produced for each material type. As regards Graphy Clear Aligners, they were printed, according to the company guideline, by an AccuFab-L4D printer (Shining 3D Tech. Co., Ltd., Hangzhou, China) using Tera Harz TC-85 DAC resin. Printing was performed under 45° alignment to the building platform with a standard of 100 µm layers. After printing, the specimens were removed from the printer’s platform and put in a spinner machine for 6 min. The specimens were then dried using compressed air to avoid an excess of resin during the post-curing of aligners.

The printing supports were removed from specimens, cured in the Tera Harz Cure with nitrogen generator (THC2) curing machine (Graphy, Seoul, Republic of Korea), and post-polymerized for 14 min.

Then, the specimens were washed in an ultrasonic cleaning machine at 80° for 2 min and then in water for 1 min. After the washing procedures, samples were dried for 5 min in a dryer machine.

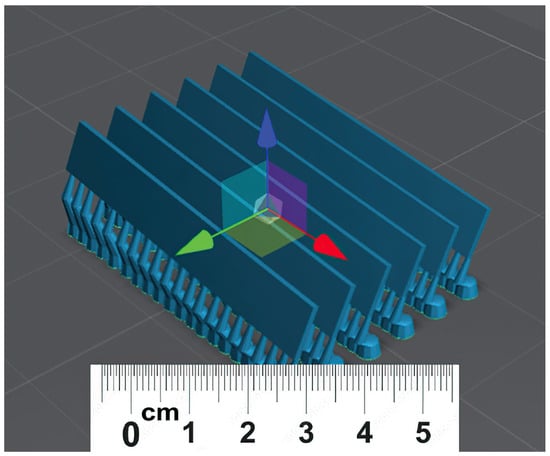

Finally, samples 1–7 (OrthoFlex specimens and the six blended resins) were printed using a NextDent 5100 3D Printer and cured with the recommended settings for the NextDent Ortho Flex resin (Figure 1).

Figure 1.

Positioning of the samples in the slicing software.

The cleaning process was divided into two steps: First, the printed parts were cleaned in ethanol for three minutes to remove any excess resin. For this purpose, an ultrasonic bath was used (Elma EP20H Easy, Elma Schmidbauer GMBH, Singen, Germany). Later, the printed parts were subjected to another bath in ethanol for two minutes. After a rest of at least 10 min, as indicated in the official instructions for the use of the resin, the printed samples were placed in a UV-light-curing box to complete polymerization (LC-3DPrint Box, NextDent, Soesterberg, The Netherlands).

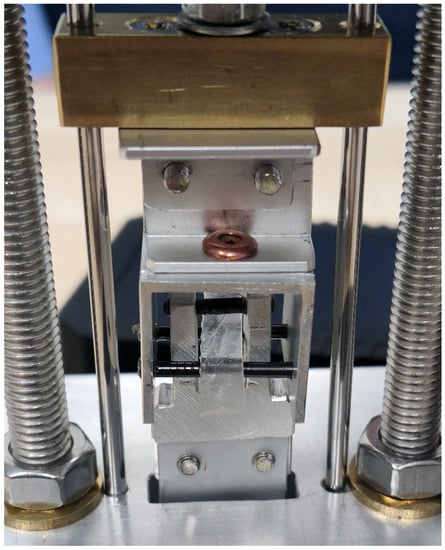

After curing, the specimens were subjected to mechanical testing using a three-point bending test. The specimen was securely clamped into the testing machine, ensuring the test region was free from obstructions or constraints. The device applied a controlled bending force at specific points along the sample while measuring the applied load and the resulting deflection [18,19]. More specifically, we used a three-point bending test instrument owned by the University of Insubria (Buster model 8526) (Figure 2). The setup of the test consisted of a three-point bending test with 5 mm between the center and the ends. Each sample was evaluated with bending of 1 mm, the instrument was calibrated to perform 20 steps, and each step was 50 microns. The descent speed was set at 500 microns/minute. Then, 20 steps in one direction, and when the maximum deflection point was reached, 20 steps in the opposite direction, were taken to assess the deflection, and a total of 40 steps were sampled. The chamber in which the tests were carried out was a controlled atmosphere, with a temperature of 28 °C and 80% humidity, the maximum operating temperature at which the testing instrument maintains its accuracy and reliability. Each test was repeated 5 times for each sample. The obtained data were exported to Excel (v365 Microsoft, Redmond, WA, USA), reporting a distance column and a force column for each test. All the obtained data were thus statistically analyzed using SPSS v26 software (SPSS Inc., Chicago, IL, USA).

Figure 2.

Three-point bending machine.

The analysis aims to determine the relationship between the added rigid resin amount and the specimens’ mechanical properties.

Furthermore, comparing the mechanical properties of the resin specimens and the nickel-titanium wires can provide valuable insights into the potential of the resin to meet the mechanical demands of orthodontic treatments.

3. Results

In this study, the results of the mechanical tests were analyzed to determine the mean and standard deviation for each test point. The data were then summarized in a table to present the mean values point-by-point. The mean values were calculated by averaging the results of the five repetitions of each test, and the standard deviation was used to indicate the variability of the results. The results of the t-test showed that there were no statistically significant differences within the different groups of specimens. This information was crucial in determining the overall mechanical performance of the resin specimens and the nickel-titanium wires. The summary table allowed for an easy comparison of the mean values and visually represented the results (Table 1).

Table 1.

Raw data of load-deflection test in grams.

After calculating the mean values and standard deviations, the next step in analyzing the results was to select the maximum load value for each test (Table 2). The maximum load value was determined as the highest force recorded during each test, and it provided a measure of the maximum strength of the specimens and the nickel-titanium wires. This value was used to compare the mechanical performance of the tested materials, and it provided valuable information on the potential use of resin-based materials in orthodontic applications.

Table 2.

Maximum load value.

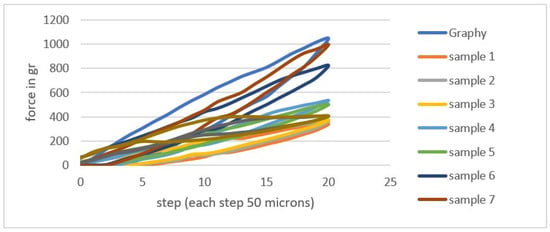

The results of the mechanical tests showed that all the tested specimens and nickel-titanium wires displayed the classic load-deflection pattern of shape-memory materials. This pattern is characterized by a non-linear relationship between the load applied and the resulting deflection, with a significant increase in deflection under increasing load (Figure 3).

Figure 3.

Load deflection.

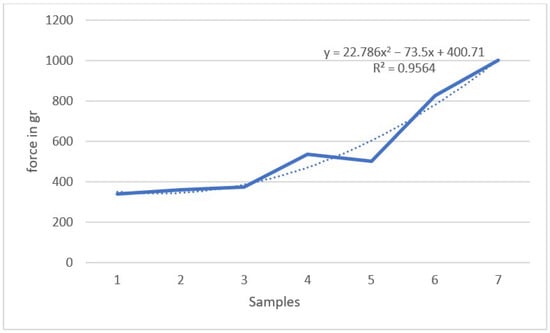

Using the maximum load values obtained from the mechanical tests, a graph was constructed to evaluate the behavior of the materials. This table allowed for a direct comparison of the mechanical properties of the resin-based materials and the nickel-titanium wires, including their maximum strength and overall mechanical performance. The table was used to highlight any trends or patterns in the results and to identify all the areas where the resin-based materials performed similarly or differently from the nickel-titanium wires. This information was crucial in determining the potential use of resin-based materials as an alternative to traditional orthodontic materials and in understanding their behavior under stress. The graph provided a visual representation of the results. It allowed for an easy comparison of the mechanical properties of the tested materials (Figure 4). Figure 4 will be useful in future studies on the use of resin-based materials in orthodontic treatments.

Figure 4.

Maximum load (continuous line) and polynomial linear regression (dotted line).

To further understand and predict the behavior of the materials, a polynomial linear regression function was calculated (Figure 4). This function was used to model the relationship between the load applied and the resulting deflection and to make predictions about the materials’ behavior under different conditions. The regression function was calculated using the maximum load values obtained from the mechanical tests. The resulting formula had an r2 value of 0.9564, which indicates a strong correlation between the variables. This high correlation provides confidence in the ability of the regression function to accurately predict the behavior of the materials.

4. Discussion

This study has several limitations that should be acknowledged. Firstly, the sample size used in the study was relatively small, which may restrict the generalizability of the findings to a larger population. Future studies should consider increasing the sample size to enhance the robustness of the results. Another limitation is that the printed material was exposed to a single testing session, which may not accurately reflect its long-term behavior under repeated cyclic loads. It is essential to investigate the material’s durability and stability over time to assess its suitability for orthodontic applications. The geometry of the diaphragm samples was simplified, as they were printed in a rectangular shape rather than replicating the complex dental arch shape. This simplified geometry may not fully capture the intricate mechanical behavior and stress distribution observed in real-life orthodontic scenarios. Future studies could explore more realistic sample geometries to better reflect clinical conditions. Furthermore, the study focused on a limited set of evaluation indexes for mechanical properties, potentially overlooking other important parameters. A more comprehensive assessment, encompassing a wider range of evaluation indexes, would provide a complete understanding of the material’s mechanical behavior. It is important to note that this study was conducted in an in vitro laboratory setting, which may not fully replicate the dynamic and complex oral environment. To validate the findings and ensure their relevance in clinical practice, further research involving in vivo or clinical studies is necessary. Additionally, the study primarily compared the printed material to nickel-titanium wires, neglecting a comparison with other commonly used orthodontic materials. Such comparisons are necessary for the ability to assess the material’s relative performance and advantages compared to alternative options.

The mechanical properties of thermoplastic materials play a key role in achieving the planned orthodontic movements. Aligners should be biocompatible, transparent, and they should have good elasticity, resilience, and low hardness. In this context, it is important to experimentally evaluate the mechanical properties of each material before using it because the data provided by the companies cannot always be considered a reference [5]. In our study, the results of the mechanical tests on the resin-based materials and nickel-titanium wires showed that the resin-based materials had mechanical properties comparable to those of traditional orthodontic materials [6,13,20]. Nowadays, thermoforming techniques are the most widespread and used method to produce clear aligners, but 3D-printed aligners are increasingly spreading in the global orthodontic world. The aim of this paper was to compare the mechanical properties of traditional orthodontic materials with new 3D-printing resins [12,21,22,23,24].

All the samples exhibited the classic load-deflection pattern of shape-memory materials, demonstrating their ability to revert to their original shape after being subjected to stress and suggesting their possible use in orthodontic treatments. The load-deflection pattern provides valuable information on the mechanical behavior of the materials under stress. It will be useful in future studies on the use of resin-based materials in orthodontic treatments. As previously stated by Groth et al., the response to flexural forces is fundamental in orthodontic applications because a model will flex when the aligner is removed [25,26].

Furthermore, selecting the maximum load value was an important step in analyzing the results, as it allowed for an evaluation of the mechanical properties of the materials under maximum stress. The maximum load values and the other results provided valuable insights into the potential use of resin-based materials as an alternative to traditional orthodontic materials.

The addition of NextDent Ortho Rigid resin to the NextDent Ortho Flex resin base significantly increased the materials’ maximum load values and overall mechanical performance. More specifically, the resin blend with the highest concentration of NextDent Ortho Rigid resin (65%) produced the greatest increase in maximum load values.

The results of this study suggest that the resin blend can be adjusted to meet the specific mechanical requirements of different clinical cases, though further studies are necessary to determine the optimal concentration of this resin mixture.

We can, therefore, hypothesize that in the future, it will be possible to choose different mixtures of resins according to the treatment phase or the patient’s needs to have more or less flexible materials. Finally, the polynomial linear regression function calculated from the maximum load values obtained from the mechanical tests showed a strong correlation (r2 = 0.9564) between the applied load and the resulting deflection. This provides confidence in the ability of the regression function to accurately predict the behavior of the resin-based materials under different conditions and loads.

Besides the information related to the materials’ properties, this research also provided valuable insight for orthodontists in evaluating and predicting the performance of 3D-printed aligners, providing data which are not usually reported in technical sheets. Further mechanical tests are suggested to have a complete picture of the characteristics of these materials. For example, it would be useful to investigate the behavior of the tested materials over time. A clear aligner should be able to exert constant light forces, but this is a challenging task.

Orthodontists know the elastic properties of nitinol and steel arch wires, which exert a constant force until the deflection changes. On the contrary, clear aligners are viscoelastic, so their behavior may considerably vary over time [13]. The force exerted by aligners decreases over time (stress relaxation), which may influence the treatment efficacy. It is important to evaluate this decay to have an idea of whether it will provide effective tooth movement [22].

Among the limitations of this study, it is important to note that these days, NextDent Ortho Flex is intended only for use as a 3D-printing resin for dental splints and retainers. Any use of this material that deviates from the manufacturer’s instructions may impact its chemical and physical properties. For this reason, the results of this research should be interpreted bearing in mind that this is an in vitro study. Similarly, the manufacturer has not approved the six tested resin blends for clinical use. Therefore, further research and evaluation would be required to determine their suitability for orthodontic treatments. Other studies are necessary to determine their clinical efficacy and long-term performance.

5. Conclusions

In conclusion, the results of this study suggest that resin-based materials may have potential as an alternative to traditional orthodontic materials. The ability to adjust the mechanical properties of the materials through blending and their high correlation with conventional orthodontic materials make them a promising option for orthodontic treatments. The results of this study indicate that resin-based materials have comparable mechanical properties to traditional orthodontic materials. The blend of the NextDent Ortho Flex resin base with varying percentages of NextDent Ortho Rigid resin produced materials with a range of mechanical properties, offering the potential to tailor the material properties to specific clinical needs. The strong correlation between the maximum load values and the predicted behavior of the resin-based materials, as determined by the polynomial linear regression function, further supports the potential use of these materials in orthodontic treatments. Further research is necessary to fully evaluate these materials’ clinical efficacy and long-term performance.

Author Contributions

Conceptualization, P.A.Z. and M.R.; methodology, P.A.Z.; software, M.R.; validation, A.C. (Alessandra Campobasso), G.B. and A.C. (Alberto Caprioglio); formal analysis, M.B.; investigation, C.D.; resources, S.B.; data curation, C.D.; writing—original draft preparation, C.D. and P.A.Z.; writing—review and editing, S.B. and P.A.Z.; visualization, M.R.; supervision, A.C. (Alberto Caprioglio); project administration, M.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kwon, J.S.; Lee, Y.K.; Lim, B.S.; Lim, Y.K. Force delivery properties of thermoplastic orthodontic materials. Am. J. Orthod. Dentofac. Orthop. 2008, 133, 228–234. [Google Scholar] [CrossRef]

- Maspero, C.; Tartaglia, G.M. 3D Printing of Clear Orthodontic Aligners: Where We Are and Where We Are Going. Materials 2020, 13, 5204. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, C.; Xu, X.; Wang, J.; Hou, X.; Li, K.; Lu, X.; Shi, H.; Lee, E.S.; Jiang, H.B. A Review of 3D Printing in Dentistry: Technologies, Affecting Factors, and Applications. Scanning 2021, 2021, 9950131. [Google Scholar] [CrossRef]

- Tartaglia, G.M.; Mapelli, A.; Maspero, C.; Santaniello, T.; Serafin, M.; Farronato, M.; Caprioglio, A. Direct 3D Printing of Clear Orthodontic Aligners: Current State and Future Possibilities. Materials 2021, 14, 1799. [Google Scholar] [CrossRef]

- Tamburrino, F.; D’Anto, V.; Bucci, R.; Alessandri-Bonetti, G.; Barone, S.; Razionale, A.V. Mechanical Properties of Thermoplastic Polymers for Aligner Manufacturing: In Vitro Study. Dent. J. 2020, 8, 47. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, H.; Kim, H.J.; Chung, C.J.; Choi, Y.J.; Kim, S.J.; Cha, J.Y. Thermo-mechanical properties of 3D printed photocurable shape memory resin for clear aligners. Sci. Rep. 2022, 12, 6246. [Google Scholar] [CrossRef] [PubMed]

- Vardimon, A.D.; Robbins, D.; Brosh, T. In-vivo von Mises strains during Invisalign treatment. Am. J. Orthod. Dentofac. Orthop. 2010, 138, 399–409. [Google Scholar] [CrossRef]

- Proffit, W.R.; Fields, H.W.; Larson, B.; Server, D.M. Contemporary Orthodontics, 6th ed.; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Rossini, G.; Parrini, S.; Castroflorio, T.; Deregibus, A.; Debernardi, C.L. Efficacy of clear aligners in controlling orthodontic tooth movement: A systematic review. Angle Orthod. 2015, 85, 881–889. [Google Scholar] [CrossRef] [PubMed]

- Bucci, R.; Rongo, R.; Levate, C.; Michelotti, A.; Barone, S.; Razionale, A.V.; D’Anto, V. Thickness of orthodontic clear aligners after thermoforming and after 10 days of intraoral exposure: A prospective clinical study. Prog. Orthod. 2019, 20, 36. [Google Scholar] [CrossRef] [PubMed]

- Palone, M.; Longo, M.; Arveda, N.; Nacucchi, M.; Pascalis, F.; Spedicato, G.A.; Siciliani, G.; Lombardo, L. Micro-computed tomography evaluation of general trends in aligner thickness and gap width after thermoforming procedures involving six commercial clear aligners: An in vitro study. Korean J. Orthod. 2021, 51, 135–141. [Google Scholar] [CrossRef]

- Fang, D.; Zhang, N.; Chen, H.; Bai, Y. Dynamic stress relaxation of orthodontic thermoplastic materials in a simulated oral environment. Dent. Mater. J. 2013, 32, 946–951. [Google Scholar] [CrossRef] [PubMed]

- Lombardo, L.; Martines, E.; Mazzanti, V.; Arreghini, A.; Mollica, F.; Siciliani, G. Stress relaxation properties of four orthodontic aligner materials: A 24-hour in vitro study. Angle Orthod. 2017, 87, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Dalaie, K.; Fatemi, S.M.; Ghaffari, S. Dynamic mechanical and thermal properties of clear aligners after thermoforming and aging. Prog. Orthod. 2021, 22, 15. [Google Scholar] [CrossRef] [PubMed]

- Ihssen, B.A.; Willmann, J.H.; Nimer, A.; Drescher, D. Effect of in vitro aging by water immersion and thermocycling on the mechanical properties of PETG aligner material. J. Orofac. Orthop. 2019, 80, 292–303. [Google Scholar] [CrossRef]

- Can, E.; Panayi, N.; Polychronis, G.; Papageorgiou, S.N.; Zinelis, S.; Eliades, G.; Eliades, T. In-house 3D-printed aligners: Effect of in vivo ageing on mechanical properties. Eur. J. Orthod. 2022, 44, 51–55. [Google Scholar] [CrossRef]

- Schonhoff, L.M.; Mayinger, F.; Eichberger, M.; Reznikova, E.; Stawarczyk, B. 3D printing of dental restorations: Mechanical properties of thermoplastic polymer materials. J. Mech. Behav. Biomed. Mater. 2021, 119, 104544. [Google Scholar] [CrossRef]

- Drake, S.R.; Wayne, D.M.; Powers, J.M.; Asgar, K. Mechanical properties of orthodontic wires in tension, bending, and torsion. Am. J. Orthod. 1982, 82, 206–210. [Google Scholar] [CrossRef]

- Kapila, S.; Sachdeva, R. Mechanical properties and clinical applications of orthodontic wires. Am. J. Orthod. Dentofac. Orthop. 1989, 96, 100–109. [Google Scholar] [CrossRef]

- Zhang, N.; Fang, D.Y.; Bai, Y.X.; Ding, X.J.; Zhang, Y. A comparative study of mechanical properties of commercialized dental thermoplastic materials. Chin. J. Stomatol. 2011, 46, 551–553. [Google Scholar] [CrossRef]

- Ahn, H.W.; Kim, K.A.; Kim, S.H. A new type of clear orthodontic retainer incorporating multi-layer hybrid materials. Korean J. Orthod. 2015, 45, 268–272. [Google Scholar] [CrossRef]

- Albertini, P.; Mazzanti, V.; Mollica, F.; Pellitteri, F.; Palone, M.; Lombardo, L. Stress Relaxation Properties of Five Orthodontic Aligner Materials: A 14-Day In-Vitro Study. Bioengineering 2022, 9, 349. [Google Scholar] [CrossRef]

- Jindal, P.; Juneja, M.; Siena, F.L.; Bajaj, D.; Breedon, P. Mechanical and geometric properties of thermoformed and 3D printed clear dental aligners. Am. J. Orthod. Dentofac. Orthop. 2019, 156, 694–701. [Google Scholar] [CrossRef] [PubMed]

- Johal, A.; Sharma, N.R.; McLaughlin, K.; Zou, L.F. The reliability of thermoform retainers: A laboratory-based comparative study. Eur. J. Orthod. 2015, 37, 503–507. [Google Scholar] [CrossRef] [PubMed]

- Kravitz, N.D.; Groth, C.; Shannon, T. CAD/CAM software for three-dimensional printing. J. Clin. Orthod. 2018, 52, 22–27. [Google Scholar] [PubMed]

- Groth, C.; Kravitz, N.D.; Shirck, J.M. Incorporating three-dimensional printing in orthodontics. J. Clin. Orthod. 2018, 52, 28–33. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).