Abstract

The aim of this study was to use a directed mode of cultivation of the microalgae Chlorella for biomass production, followed by the subsequent extraction of carotenoids. The effect of a stress inducer of carotenogenesis (hydrogen peroxide) and a growth stimulator (pyridoxine, vitamin B6) on the accumulation of photosynthetic pigments by the biomass of the microalga C. vulgaris BIN in the process of directed cultivation was studied. It was revealed that the combination of these additives in the culture medium increases the content of chlorophylls and carotenoids in the biomass twofold compared to the control sample. The preliminary activation of the biomass by high-speed ultra-homogenization (a rotor rotation range from 6000 to 12,000 rpm) was also investigated. Using ultrasound extraction, the pigment complex was isolated from the activated biomass. The saponification and subsequent neutralization of carotenoids were carried out in an inert medium. The resulting sample contained carotenoids in the amount of 52 ± 3 mg/mL. The chemical profile of the carotenoids in the biomass of the microalga Chlorella vulgaris BIN was also established. The major carotenoid was lutein (45%), followed by fucoxanthin (12%) and β-carotene (4.3%). The oil extract of the carotenoids may be used for the further production of a microencapsulated product with the aim of targeted delivery to the lower parts of the gastrointestinal tract.

1. Introduction

The imbalance of the food rations of the population in megalopolises in the absence of the required amount of essential food micronutrients is a global problem of modern civilization. The deficiency of vitamin A (retinol) was found to be about 10–30%, and that of vitamin E (tocopherol) was 15–35%. This is a major problem in all groups of the population, regardless of age and/or profession. The deterioration of the ecological status of urban areas, the industrialization of the food industry (including the deep processing of the raw materials, long-term storage, refining, and the use of dry substitutes for natural products, etc.) leads to a high necessity for the additional enrichment of the diet with biologically valuable components which are necessary for the prevention of alimentary-dependent diseases [1].

One of the possible solutions of this problem is to expand the range of functional food products and food additives obtained from the alternative types of plant materials. These plants contain numerous biologically active substances, including natural pigments (carotenoids), α- and β-carotene, fucoxanthin, astaxanthin, lutein, violaxanthin, and zeaxanthin [2].

The system of conjugated double bonds in carotenoid molecules, as well as structural similarity with some fat-soluble vitamins, determines their high biological value for plants and humans, including their role as a provitamin, their detoxifying activity, the strengthening of the immune system, the chemoprevention of cancer, and the prevention of cardiovascular diseases, cataracts, and other degenerative disorders [3].

Currently, unconventional raw materials, including microalgae, are considered to be significant sources of carotenoids [4]. Single-celled green algae D. salina are known for their ability to accumulate about 0.5 to 10% β-carotene per unit of dry matter [5]. β-carotene in D. salina has a high biological activity due to its isomeric composition, which cannot be achieved by chemical synthesis [6]. The microalgae Chlorella are considered to be the most valuable, because of their high content of essential amino acids, carbohydrates, vitamins, and lipids, as well as lipid-like compounds, including carotenoids and other valuable plastid pigments [7,8,9,10]. Algae contain xanthophylls of a unique chemical structure. This is characteristic of the individual taxa, as algae’s oxycarotenoids are derivatives of not only β- but also α- and γ-carotenes. Thus, algae of the Chlorophyta group contain special pigments: phycocyanin, siphonoxanthin, astaxanthin, loroxanthin, zeinoxanthin, and neoxanthin, as well as allene and acetylenic carotenoids such as diatoxanthin and diadinoxanthin, and many others.

Depending on the cultivation conditions, the nutrient composition of the Chlorella cell can vary significantly. Taking into account the specificity of the Chlorella pigments’ application and the variety of directed cultivation techniques, it is possible to stimulate the biosynthesis of secondary carotenoids in order to isolate and apply them further for nutraceuticals and para-pharmaceuticals.

The effect of the culture medium’s composition and bubbling on the quantitative accumulation of pigments, including carotenoids, in the microalgae Chlorella vulgaris was studied [11]. Due to their high adaptive activity, unicellular algae are able to synthesize a large number of secondary carotenoids under various stress conditions, e.g., the osmotic shock of nitrogen and/or phosphorus deficiency, a high intensity of absorbed light, non-optimal temperatures, and the presence of reactive oxygen species in the culture medium or their synthesis. The connection between the presence of reactive oxygen species in the culture medium and the biosynthesis of astaxanthin by heamatococci was proven [12]. Therefore, it is possible to stimulate the biosynthesis of secondary carotenoids with a simple variation in the cultivation conditions.

An equally important element of the carotenoid production technology is the preliminary activation of the obtained biomass. Despite the fact that the cell membrane of the microalgae C. vulgaris of the planktonic strain has a thinner membrane than the other species of C. vulgaris, the homogenization of the biomass has a positive effect on the yield of the final product [13].

High significance is attached to the method of carotenoid extraction from the microalgae biomass. Different solvents are used to extract carotenoids from the biomass. For example, ethanol and 2-methyltetrahydrofuran (MTHF) were used to maximize the extraction of individual carotenoids [14] at a temperature of 110 °C, where 45% of all of the carotenoids were extracted. A mixture of MTHF and ethanol in a 1:1 ratio from the raw biomass led to an increase of the extractable carotenoids to 66%. However, MTHF is quite toxic, and cannot be used to produce a dietary supplement.

Microalgae represent a successful model for the commercial production of carotenoids. In addition, the global carotenoid market is projected to reach US $ 1.7 billion by 2022, with the largest shares being in lutein, astaxanthin, and β-carotene [15].

The aim of this work is to investigate the modes of directed cultivation of Chlorella microalgae in order to obtain biomass with a high content of carotenoids, and to develop a method for their isolation from the resulting biomass.

2. Materials and Methods

The objects of the study were the mother culture of the planktonic strain Chlorella vulgaris BIN [16,17], the concentrate of the cell suspension of microalgae C. vulgaris, and the extract of the total carotenoids isolated from the obtained biomass.

2.1. Cultivation

The cultivation of the microalgae was carried out according to the previously described method [14] in a laboratory photobioreactor (PBR) with a volume of 10 dm3. Combined additives were used to stimulate the biosynthesis of the carotenoids. As a stress inducer of carotenogenesis, a 3% solution of hydrogen peroxide (“Innovation”, Voronezh, Russia) was added to the nutrient medium. A solution of pyridoxine hydrochloride (“BioChemica”, Moscow, Russia) with an initial concentration of 50 mg/mL was used to prevent oxidative stress.

A culture medium should have the well-balanced content of macro- and microelements in order to cultivate microalgae [18]. Table 1 shows the composition of the growing medium consisting of components used to prepare the culture media A and B, with the addition of macroelements after the mixing thereof.

Table 1.

Composition of the microalgae culture medium.

The mother culture of C. vulgaris BIN was removed from the refrigerating chamber (Melling YCD-519, Jackson, MS, USA) and introduced into the prepared PBR. The initial number of cells in the PBS was 8.0–8.5 million cells per mL. Then, the PBR was filled with the prepared culture medium. The stirring of the system during cultivation was carried out by bubbling with a Xilong AP-001 (Shantou, China) compressor at 1.5 L/min, and once a day with a mechanical stirrer for 15 min at 500 rpm (to prevent the formation of stagnant zones). The temperature range of the cultivation was 23 ± 3 °C. The illumination modes—“day–night” (16–8 h)—were maintained using LED TIS-15M1R lamps with a luminous flux of 3000 lumens [19].

The change in the concentration of cells in the culture during the cultivation was monitored by the daily measurement of the optical density on a UV-1280 spectrophotometer (SHIMADZU, Duisburg, Germany) at a wavelength of 750 nm. The culture medium was used as a reference solution. The change in pH in the PBR was determined by using a Mini PH Meter (AQUA-LAB, Russia, Moscow). In order to study the morphological characteristics of the C. vulgaris cells, digital images of the “crushed drop” preparations were used with a magnification of at least 400 times using an IS-500 digital camera (LOMO JSC, St-Petersburg, Russia). The digital images were processed using the FOTO Microanalysis software (LOMO JSC, St-Petersburg, Russia) and Levenhuk (Levenhuk LabZZ manufacturer, China).

The additives were added to the PBR according to the following scheme: Day 1, without additives; day 2, 1 mL 3% hydrogen peroxide was added; day 3, 1 mL 3% hydrogen peroxide and 10 mL pyridoxine hydrochloride with a concentration of 50 mg/mL (the calculation of the additive amount was performed per 10 L of the culture medium). A cell suspension of microalgae without any additions was used as a control sample.

After the end of the cultivation cycle (4 days), the suspension was settled for 1 day. After settling, about 9 L of the suspension was poured through the lower drain hole of the PBS, leaving about 1 L PBS to start a new cultivation cycle. The specific growth rate of the biomass was determined by the following equation:

where X0 and X are the concentration of microalgae cells in the suspension before and after the cultivation, respectively, in million cells/mL; µ is the specific growth rate of biomass, day−1; and t is the cultivation time, in days.

2.2. Concentration of the Biomass

A solution 0.1 M NaOH was added to the cell suspension extracted from the PBR until a pH of 10–11 was reached. The formation of the flocks occurred within 2–3 h, after which the concentrate was separated from the culture medium by decantation, followed by the centrifugation of the sediment in a Thermo FS centrifuge Sorvall LYNX 6000 (Thermo Scientific, Waltham, MA, USA), at 6000 rpm/min for 5 min, followed by the decantation of the supernatant fluid.

2.3. Activation

The biomass was activated on a Silent Crusher M installation (IKA® Werke, T25 Basic, Heidolph, Germany) by high-speed ultra-homogenization (6000, 8000, 10,000, and 12,000 rpm for 5 min) in an ice bath, after the pre-mixing of the biomass with the liquid phase in a ratio of 1:5. A mixture of hexane and ethyl alcohol (95.6%) in a 2:1 ratio was used as the liquid phase. Pigments were then extracted from the obtained homogenate by ultrasonic extraction.

2.4. Extraction

In order to extract the pigments from the biomass, modified techniques were used [20]. The pigments were extracted with a mixture of hexane and ethyl alcohol (95.6%) in a 2:1 ratio (v/v) using an ultrasonic disperser (Scientz—IID, Zhejiang, Hangzhou, China). The ratio of the homogenate’s mass and the extraction mixture was 1:30 (by weight). The extraction process was carried out once. The separation of the pigment complex extract from the residual biomass was carried out using a Thermo FS centrifuge at 3300 rpm for 5 min. The resulting extract of the pigment complex was subjected to the fractionation.

2.5. Fractionation of the Pigments

The separation of the total carotenoids from the chlorophylls was carried out by saponification with KOH, followed by the separation of the fractions. The saponification process removed fatty acids, chlorophyll, and wax esters from the carotenoids.

KOH was added to the obtained extract in the amount of 0.05 g per 10 mL of the extract. The mixture was shaken for 10 min and then centrifuged using a Thermo FS centrifuge at 3300 rpm for 5 min. In this case, the carotenoid fraction (the upper phase in hexane) was colored yellow–orange, and the fraction of chlorophyllic acid salts (the lower phase in an aqueous solution of ethanol) was dark green. During the saponification, ethyl alcohol (95.6%) was added to the sample in order to prevent the precipitation of fatty acid salts.

The obtained extract of carotenoids in hexane was washed three times in a nitrogen atmosphere with cold distilled water in order to neutralize the pH, and was subjected to the concentration of the final volume of 0.5 mL using a LabTech Ev311Vac rotary evaporator (GWSI, Zhengzhou, China) in a vacuum (2 kPa) at a temperature of 45 °C. The resulting dry residue was analyzed for its carotenoid content.

2.6. Analysis of the Obtained Carotenoids

The carotenoid yield was determined spectrophotometrically on a UV-1280 (SHIMADZU, Duisburg, Germany) spectrophotometer in the spectral range of 350–700 nm. In order to determine the content of chlorophyll and carotenoids, the absorption bands of the pigments in the range of 470, 649, and 664 nm were used. The calculation of the chlorophyll and carotenoid concentration in the biomass of the microalgae was carried out according to the previously described procedure. Previously, we carried out studies and selected the conditions for the determination of carotenoids in extracts from C. vulgaris biomass by reverse phase method HPLC [21,22].

The analysis of the individual carotenoids was performed using the HPLC technique. An autonomous modular device with a simple piston pump for HPLC Varian 03-919000-00 9010 Gradient HPLC Pump DT VAC Case Scratched, Discolored REF VA248 (USA) was used as the HPLC pump (USA). The eluent speed was 1 mL/min. In order to identify the carotenes and xanthophylls in the obtained extracts, standard samples of β-carotene (Merck, Germany) and fucoxanthin (Shanxi Fuhen Biotechnology Co., Ltd., Xi’an, China) were used.

Detection was carried out spectrophotometrically (Kratos Spectroflow 783 detector) at wavelengths of 440 nm and 650 nm. The identification and quantitative analysis of the components in the analyzed mixture were carried out according to the retention time and intensity of the analytical signal (height and peak area), followed by the recalculation of the concentrations according to the formula, taking into account dilution and using a computer-based data acquisition and processing system according to previously described method [23]. The value of the analytical signal for the fractions of the identified pigments varied from 0.5 to 3.0.

2.7. Statistical Analysis

The statistical processing of the experimental results was carried out by means of the Statistica version 13.3 program using the t-criteria. In the study of each of the indicators for the comparison of homogeneous groups, one-factor dispersing analysis and F-criteria analysis were used. The significant difference between the compared groups was p < 0.05.

3. Results and Discussion

3.1. Dynamics and Specific Rate of C. vulgaris BIN Population Growth

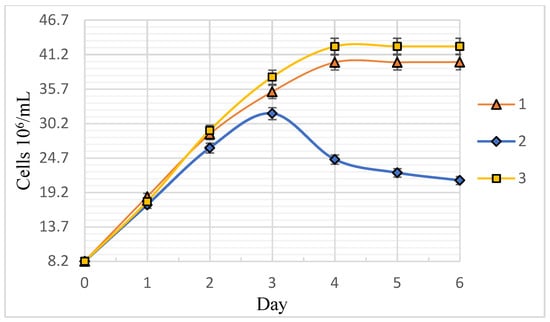

Figure 1 shows the effects of the peroxide and pyridoxine additives effects on the growth dynamics of C. vulgaris BIN microalgae. The analysis showed that the application of peroxide additives as a stress agent reduced the C. vulgaris BIN biomass growth rate, while the gradual accumulation of oxidation products reduced the population life cycle to 3 days. Thus, H2O2 as an independent stress inducer of carotenogenesis is recommended for addition to the culture medium at the rate of not more than 0.1 mL per 1 dm3. The combined use of hydrogen peroxide and pyridoxine additives in the cultivation of C. vulgaris BIN microalgae allows us to slightly accelerate the biomass growth. It was revealed that the active growth phase ends after 4–5 days, followed by the stabilization phase.

Figure 1.

Influence of the additives introduced into the culture medium on the dynamics of the population growth of C. vulgaris BIN microalgae: 1, control (no additives); 2, H2O2 additive; 3, H2O2 additives + pyridoxine.

Martin-Gordillo et al. [24] proposed, in their study, the use of the byproducts of the wine industry to obtain biomass with a high content of carotenoids. Optimal growth was obtained with the extraction of the wine residues of 5% and 10% wt./rev. With the addition of 10% wine residue, the growth of the biomass in the culture medium stimulates antioxidant activity and the production of carotenoids in C. sorokiniana cells. The wine residue contains tartar and yeast, which are the source of pyridoxine hydrochloride, which cause biomass growth.

Parra, Stahl, and Hellmann [25] reported on the effect of the pyridoxine on the intensification of the bio-synthesis of photosynthetic pigments. This is possibly associated with the synthesis of amino acids to be used as precursors for the synthesis of light-trapping pigment–protein complexes. For pigment–protein complexes, chlorophylls are stabilizers and an important cofactor due to their non-covalent interaction with the proteins. This means that, in order to maintain the stability of the newly formed pigment–protein complexes, it is necessary to immobilize a larger number of photosynthetic pigments, primarily chlorophylls, as well as their auxiliary pigment-antennae-carotenoids.

It is known that besides stimulating plastic processes, pyridoxine is able to partially neutralize the processes of oxidative stress. Farghl [26] showed that pyridoxine significantly increased the activity of protective antioxidant enzymes in C. vulgaris, such as peroxidase, superoxide dismutase, catalase and ascorbate peroxidase.

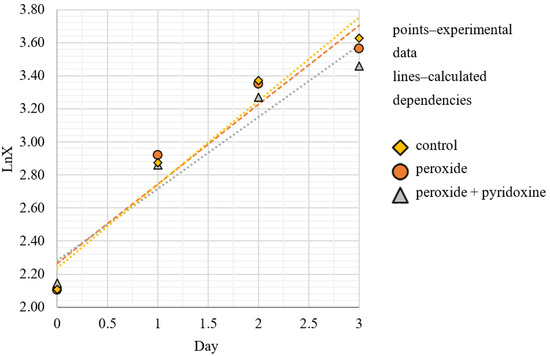

Figure 2 shows the exponential growth phase of C. vulgaris BIN microalgae in semi-logarithmic coordinates. The approximation of the exponential growth phase is a straight line with the slope tangent corresponding to the value of the population-specific growth rate μ, in day−1. The specific growth rate varied from 22 to 25 days−1. It was noted that the cell fluid of sample 3 had a more saturated dark green color, indicating the increased synthesis of photosynthetic pigments.

Figure 2.

Exponential growth phase of the C. vulgaris BIN microalgae population in semi-logarithmic coordinates.

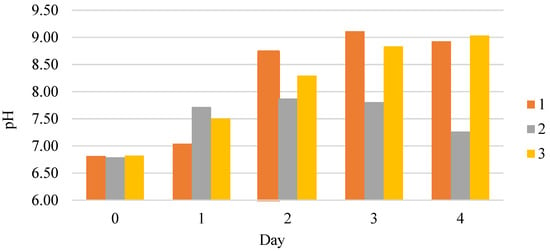

Figure 3 shows the effects of the additives on the pH dynamics in the process of C. vulgaris cultivation. The relationship between the cultivation curves and pH dynamics is noted. According to Farghl [26], it is connected to the metabolism of the cells and their photosynthetic activity. The work [27] reports that medium alkalization can occur due to algae absorbing the nitrate form of nitrogen due to the export of ammonium ions’ excess during photorespiration and other metabolic processes. The viability indicator of C. vulgaris microalgae is the increase of the medium’s acidity agreeing well with the dynamics of the biomass accumulation shown in Figure 1.

Figure 3.

Additive effects on the pH dynamics of C. vulgaris cultivation: 1, control (no additives); 2, added H2O2; 3, added H2O2 + pyridoxin. In order to compare homogeneous groups in the determination of pH, one-factor dispersing analysis and F-criteria analysis were used. A significant difference was found between the compared groups (F was significantly greater than 1), which was assessed at p < 0.05.

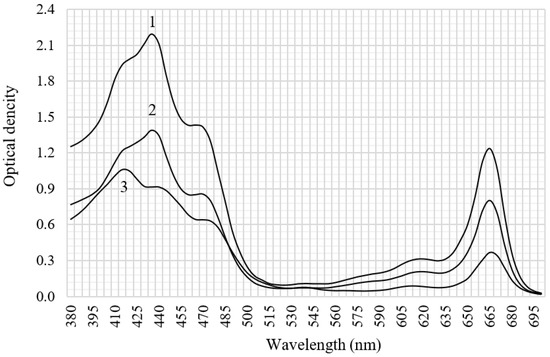

3.2. Spectral Characteristics and Carotenoid Content of C. vulgaris BIN Biomass Extracts

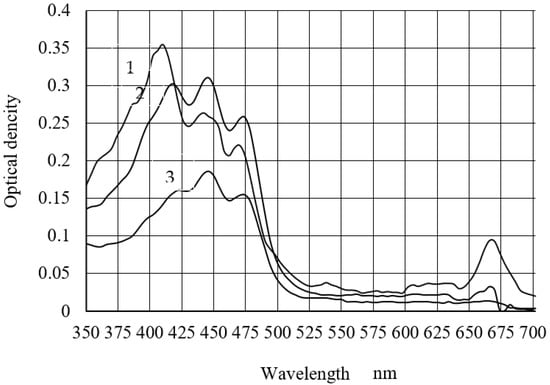

The cultivation factors’ influence on the spectral profiles of pigment extracts from the microalgae is shown in Figure 4. Two absorption bands were noted in the blue–violet (380–500 nm) and in the red (600–680 nm) spectrum range. The arm (420 nm) and the absorption maximum (664 nm) correspond to chlorophyll a. The carotenoid absorption band is in the spectral range of 420–480 nm, with absorption maxima of 440 and 470 nm [28,29]. This allows us to talk about the predominance of carotenoids in the pigments of sample 3.

Figure 4.

Spectral profiles of pigment extracts from C. vulgaris BIN biomass obtained using various additives (extractant—ethanol, dilution 1:4). 1, control; 2, H2O2; 3, H2O2 + pyridoxine.

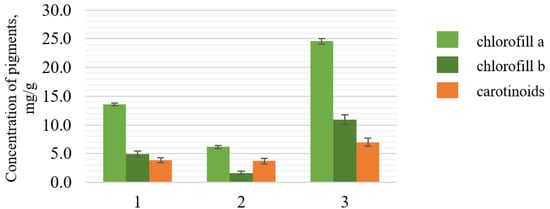

Figure 5 shows the composition of photosynthetic pigments in the obtained samples of C. vulgaris biomass. The highest content of carotenoids was observed in the biomass sample with H2O2 and pyridoxine additives, while the content of carotenoids was about 1.8 times higher than that in the control sample. A biomass sample with H2O2 showed a 0.2 mg/g reduction in carotenoids compared to the control sample. The contents of chlorophyll a and b in samples show the same logic.

Figure 5.

Influence of additives on the content of pigments in the samples of C. vulgaris BIN biomass: 1, control (no additives); 2, H2O2 additive; 3, H2O2 additives + pyridoxine. In order to compare homogeneous groups in the determination of pH, one-factor dispersing analysis and F-criteria analysis were used. A significant difference was found between the compared groups (F significantly greater than 1), which was assessed at p < 0.05.

The highest content of carotenoids was observed in the extracted biomass with added H2O2 and pyridoxine; the content of carotenoids was about 1.8 times higher than that in the control sample.

3.3. Influence of Activated C. vulgaris BIN Biomass on the Yield of Carotenoids in the Extracts

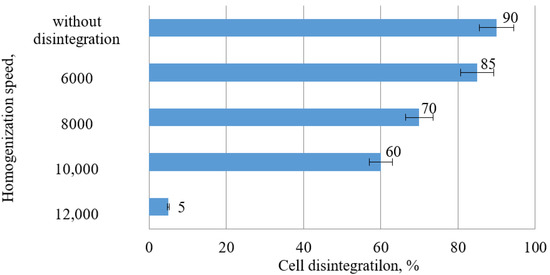

The influence of high-speed homogenization on the microalgae activation rate, evaluated with cell microscopy, is shown in Figure 6.

Figure 6.

Influence of the rate of homogenization on the quantity of cell disintegration.

Table 2 shows the effect of the rate of homogenization on the yield of carotenoids in the extracts.

Table 2.

Influence of the rate of homogenization on the yield of carotenoids in the extracts.

It was found that an increased rotor speed of more than 6000 rpm leads to a significant increase of destroyed cells, causing the mixing of plastid pigments with oxidases, as well as the rapid oxidation thereof. This was proven by the decreased yield of carotenoids in the extracts. Thus, the most optimal mode of cell membrane activation with preserved cell integrity and shape is the rotation speed of 6000 rpm.

3.4. Extraction and Fractionation of the Pigments

We proposed to use a mixture of hexane and ethanol alcohol in a ratio of 2:1 as an extracting agent, which resulted in the high yield of the pigment complex.

The saponification step to separate chlorophylline acids is the key to obtain the carotenoid fraction. Saponification at low KOH concentrations (0.01 and 0.2 M) gives the best results for astaxanthin extraction.

Long-term saponification with relatively high KOH concentrations (0.2 and 0.5 M) gives the best results for xanthophyll extraction.

The research of the KOH concentration’s effect on the spectral profile of C. vulgaris extracted pigments is shown in Figure 7. It was found that an alkali concentration of 0.2 M is most appropriate, and that it allows us to obtain the highest concentrations of the determined substances.

Figure 7.

Influence of the KOH cconcentration during the saponification of carotenoids with alkali (KOH) on the spectral profiles of microalgae pigments. 1, 0.05 M; 2, 0.2 M; 3, 0.5 M.

The alkali-free extract of carotenoids in hexane had a pH level of 5.5. Shivalkar and Prabha [30] reported that the major stability of carotenoids is revealed in the pH range from 6 to 7. Thus, it is required that we remove excess alkali after the carotenoids’ saponification in order to obtain neutral pH values. The required pH values are reached after the third stage of washing with oxygen-free distilled water in an inert atmosphere.

It was found that the amount of impurities (carotenoid ethers and chlorophyll derivatives) in the extract was reduced. The carotenoid loss amounted to an average of 6%. The spectral profile of the carotenoids showed a distinctive “corona”, with three peaks at 420, 445 and 472 nm. A complex of peaks similar to those obtained was described by the author for neurosporene (414, 439, 467 nm), and by the authors for α-carotene (423, 444, 473 nm) and β-carotene (425, 450, 478 nm) [31].

The carotenoid pigments’ composition is analyzed in Table 3.

Table 3.

Composition of C. vulgaris BIN biomass extract, in mg/mL.

The obtained sample of carotenoids had a bright orange color, and the content of the main substance was 52 ± 3 mg/mL. The carotenoids of C. vulgaris microalgae are represented by lutein (about 45%), fucoxanthin (about 12%) and β-carotene (4.3%). The total carotenoids were resuspended in soybean (castor) oil in order to obtain the oil concentrate that we propose to use as a dietary supplement in the future.

4. Conclusions

The application of carotenoids to produce functional products is not easy due to the low bioavailability of the pigments in their native form. Therefore, the search for additional sources of carotenoids is of paramount importance. Innovative food and additives based on hydrobionts with a high content of carotenoids are promising in this sphere.

This study showed that microalgae can be successfully used as a source of carotenoids. In order to prepare the biomass for the further extraction of the necessary pigments, the directed cultivation of C. vulgaris BIN was used. The pigments were efficiently extracted using ultrasound. The carotenoid sample obtained after vacuum thickening contained the main substance in the amount of 52 ± 3 mg/mL. The product’s composition was determined: lutein, 45%; fucoxanthin, 12%; and β-carotene, 4.3%.

The obtained sample of carotenoids was further prepared in order to develop the functional product enriched with bioactive compounds. The carotenoid sample was re-dissolved in castor oil to produce a microencapsulated product for targeted delivery to the lower gastrointestinal tract. This potential application is of high importance because of the growing demand for functional products contributing to a healthy lifestyle.

Author Contributions

Conceptualization, J.B.; methodology, J.B.; formal analysis, S.Đ.; investigation, A.S. and A.B.; data curation, Y.S.; writing, Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the Ministry of Science and Higher Education of the Russian Federation under the strategic academic leadership program ‘Priority 2030’ (Agreement 075-15-2021-1333, dated 30 September 2021).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Eggersdorfer, M.; Wyss, A. Carotenoids in human nutrition and health. Arch. Biochem. Biophys. Res. Commun. 2018, 652, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Machado Sierra, E.; Serrano, M.C.; Manares, A.; Guerra, A.; Aranguren Díaz, Y. Microalgae: Potential for Bioeconomy in Food Systems. Appl. Sci. 2021, 11, 11316. [Google Scholar] [CrossRef]

- Hyrslova, I.; Krausova, G.; Smolova, J.; Stankova, B.; Branyik, T.; Malinska, H.; Huttl, M.; Kana, A.; Curda, L.; Doskocil, I. Functional Properties of Chlorella vulgaris, Colostrum, and Bifidobacteria, and Their Potential for Application in Functional Foods. Appl. Sci. 2021, 11, 5264. [Google Scholar] [CrossRef]

- Singh, D.P.; Khattar, J.S.; Rajput, A.; Chaudhary, R.; Singh, R. High production of carotenoids by the green microalga Asterarcys quadricellulare PUMCC 5.1.1 under optimized culture conditions. PLoS ONE 2019, 14, e0221930. [Google Scholar] [CrossRef]

- Kleinegris, D.M.M.; Janssen, M.; Brandenburg, W.A. The Selectivity of Milking of Dunaliella salina. Mar. Biotechnol. 2010, 12, 14–23. [Google Scholar] [CrossRef][Green Version]

- Harvey, P.J.; Ben-Amotz, A. Towards a sustainable Dunaliella salina microalgal biorefinery for 9-cis β-carotene production. Algal Res. 2020, 50, 102002. [Google Scholar] [CrossRef]

- Diprat, A.B.; Thys, R.C.S.; Rodrigues, E.; Rech, R. Chlorella sorokiniana: A new alternative source of carotenoids and proteins for gluten-free bread. LWT 2020, 134, 109974. [Google Scholar] [CrossRef]

- Guedes, A.C.; Amaro, H.M.; Malcata, F.X. Microalgae as sources of carotenoids. Mar. Drugs 2011, 9, 625–644. [Google Scholar] [CrossRef]

- Matsukawa, R.; Hotta, M.; Masuda, Y.; Chihara, M.; Karube, I. Antioxidants from carbon dioxide fixing Chlorella sorokiniana. J. Appl. Phycol. 2000, 12, 263–267. [Google Scholar] [CrossRef]

- Marino, T.; Casella, P.; Sangiorgio, P.; Verardi, A.; Ferraro, A.; Hristoforou, E.; Molino, A.; Musmarra, D. Natural be-ta-carotene: A microalgae derivate for nutraceutical applications. Chem. Eng. Trans. 2020, 79, 103–108. [Google Scholar] [CrossRef]

- Menezes, R.; Soares, A.; Marques, J.; Lopes, R.; Arantes, R.; Derner, R.; Antoniosi, F.N. Culture medium influence on growth, fatty acid, and pigment composition of Choricystis minor var. minor: A suitable microalga for biodiesel production. J. Appl. Phycol. 2016, 28, 2679–2686. [Google Scholar] [CrossRef]

- Ambati, R.R.; Phang, S.-M.; Ravi, S.; Aswathanarayana, R.G. Astaxanthin: Sources, Extraction, Stability, Biological Activities and Its Commercial Applications—A Review. Mar. Drugs 2014, 12, 128–152. [Google Scholar] [CrossRef] [PubMed]

- Shlykova, A.N.; Balabaev, A.A.; Trukhina, E.V.; Bazarnova, Y.G. Obtaining carotenoid pigments from Chlorella microalgae. Vestn. PNRPU. Chem. Technol. Biotechnol. 2020, 3, 20–37. Available online: https://cyberleninka.ru/article/n/poluchenie-karotinoidnyh-pigmentov-iz-mikrovodorosley-chlorella (accessed on 10 February 2022).

- Damergi, E.; Schwitzguébel, J.-P.; Refardt, D.; Shivom, S.; Holliger, C.; Ludwig, C. Extraction of carotenoids from Chlorella vulgaris using green solvents and syngas production from residual biomass. Algal Res. 2017, 25, 488–495. [Google Scholar] [CrossRef]

- Novoveská, L.; Ross, M.E.; Stanley, M.S.; Pradelles, R.; Wasiolek, V.; Sassi, J.F. Microalgal Carotenoids: A Review of Production, Current Markets, Regulations, and Future Direction. Mar. Drugs 2019, 17, 640. [Google Scholar] [CrossRef] [PubMed]

- Kul’nev, V.; Stupin, V.; Borzenkov, A. Biological Waste Water Rehabilitation of Sugar Factories by Algocoenosis Correction. Ecol. Ind. Russ. 2017, 21, 16–20. (In Russian) [Google Scholar] [CrossRef]

- Kulnev, V.; Nasonov, A.; Zhogin, I.; Tsvetkov, I.; Grabarnik, V.; Karelin, N. The Experiences of the Managed Algoritmization Recreational Pond. Ecol. Ind. Russ. 2020, 24, 58–64. (In Russian) [Google Scholar] [CrossRef]

- Becker, E.W. Microalgae in human and animal nutrition. In Handbook of Microalgal Culture; Richmond, A., Ed.; Blackwell: Oxford, UK, 2004; pp. 312–351. [Google Scholar]

- Kuznetsova, T.A.; Nikitina, M.S.; Sevastyanova, A.D. Directed cultivation of Chlorella sorokiniana to increase carotenoid synthesis. Vestn. VGUIT 2019, 81, 34–39. [Google Scholar] [CrossRef]

- Machmudah, S.; Goto, M. Methods for extraction and analysis of carotenoids. Nat. Prod. 2013, 3367–3411. [Google Scholar] [CrossRef]

- Bazarnova, J.; Kuznetsova, T.; Aronova, E.; Popova, L.; Pochkaeva, E. A method for obtaining plastid pigments from the biomass of Chlorella microalgae. Agron. Res. 2020, 18, 2317–2327. [Google Scholar] [CrossRef]

- Bazarnova, J.; Nilova, L.; Trukhina, E.; Bernavskaya, M.; Smyatskaya, Y.; Aktar, T. Use of microalgae biomass for fortification of food products from grain. Foods 2021, 10, 3018. [Google Scholar] [CrossRef] [PubMed]

- Saseendran, S. A revised method for pigment extraction from marine nannoplanktonic algal cultures. J. Algal Biomass Util. 2017, 4, 47–52. [Google Scholar]

- Martin-Gordillo, L.; Cuaresma, M.; Fernández-Recamales, M.Á.; Sayago, A.; Vílchez, C.; Garbayo, I. Cultivation of Microalgae Chlorella Using Wine Industry by-products. Proceedings 2020, 66, 30. [Google Scholar] [CrossRef]

- Parra, M.; Stahl, S.; Hellmann, H. Vitamin B₆ and Its Role in Cell Metabolism and Physiology. Cells 2018, 22, 84. [Google Scholar] [CrossRef]

- Farghl, A.A. Thiamine and Pyridoxine Alleviate Oxidative Damage by Copper Stress in Green Alga Chlorella vulgaris. Egypt. J. Microbiol. 2012, 47, 97–110. [Google Scholar] [CrossRef][Green Version]

- Shavirina, O.B. Toxicity of copper for green algae culture Scenedesmus quadricauda during pH fluctuations. Int. J. Appl. Basic Res. 2016, 4, 741–743. [Google Scholar]

- Bazarnova, Y.G.; Kuznetsova, T.; Trukhina, E. Aquabiotechnology of directed cultivation of microalgae Chlorella sorokiniana biomass. IOP Conf. Ser. Earth Environ. Sci. 2019, 288, 012037. [Google Scholar] [CrossRef]

- Britton, G.B. Biochemistry of natural pigments. Mosc. Mir 1986, 422. [Google Scholar]

- Shivalkar, Y.K.; Prabha, R. Effect of pH and temperature on carotenoid pigments produced from Rhodotorula minuta International. J. Fermented Foods 2014, 3, 105–113. [Google Scholar] [CrossRef]

- Kuregyan, A.G. Spectrophotometry in carotenoid analysis. Basic Res. 2015, 2, 5166–5172. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).