Abstract

Waste poly(ethylene terephthalate) (PET) drinking bottles and end-of-life scrap rubber tires are common municipal solid wastes discarded and produced every day, which are usually disposed of in landfills and stockpiles, occupying a great quantity of land and causing serious environmental issues. This study aims to first turn waste PET into two value-added derived additives under the chemical treatment of two amines, namely triethylenetetramine (TETA) and ethanolamine (EA), respectively, and then adopt them in association with crumb rubber (CR) to modify virgin bitumen for preparing various rubberized asphalt mixtures. Subsequently, the high- and low-temperature properties of the rubberized binder modified by PET additives (PET-TETA and PET-EA) were comparatively characterized through dynamic shear rheometer (DSR) and bending beam rheometer (BBR) tests, while the rutting resistance, fatigue resistance, and dynamic modulus of the further fabricated mixtures were evaluated and validated through mixture tests. The results obtained indicate that 2 wt.% PET-TETA and PET-EA contribute to increase the rutting failure temperature of asphalt rubber from 82.2 °C to 85.5 °C and 84.2 °C, respectively, retaining the high grade of PG 82; the low-temperature grade of asphalt rubber slightly decreased from PG-28 to PG-22 as the additive was added; the rut depth slightly changed from 3.10 mm to nearly 3.70 mm; and PET-TETA exhibits the potential to be capable of extending the fatigue life of asphalt rubber in contrast with PET-EA at different stress levels within 450 kPa. Based on the findings of this study, the developed recycling approach is considered to be applicable to not only alleviate the environmental concerns caused by the landfills and stockpiles of those wastes but also make them valuable for building more durable pavement.

1. Introduction

Waste plastics and waste tire rubbers are regarded as ever-increasing municipal solid wastes and pollutants that are normally disposed of in landfills and stockpiles [1,2,3], are not easy to degrade in nature, even with incineration [4], and finally lead to various associated environmental problems such as soil and water pollution [5,6,7]. High-efficiency and environmentally friendly disposal of these wastes is definitely a challenging and serious problem all over the world, especially in cities where the landfill space is very limited and precious. Some of these wastes, during the past few years, have been recycled for new industrial applications through various pathways [8,9,10], but the recycling rate appears to still be less than the rate at which they are discarded and produced. Therefore, new recycling approaches developed for consuming more of these wastes are keenly desired.

Plastics form a large family of thousands of various materials with different characteristics, properties, and usages, and are naturally divided into two categories: thermoplastic and thermoset [11,12]. Thermoplastics, such as poly(ethylene terephthalate) (PET), polyethylene (PE), and polypropylene (PP), are largely used in our daily life and can be melted when heated and hardened when cooled [13]. Thermosets, on the other hand, are those plastics that undergo a chemical crosslinking process when heated, creating a three-dimensional network, and, after this, they cannot be re-melted and reformed during recycling [14]. Examples of thermosets include polyurethane (PU) and epoxy resins [15,16]. As for waste tire rubbers, they are vulcanized elastomers that have similar crosslinking characteristics to thermosets and contain large proportions of reinforcing fillers, especially carbon black [17], which also cannot be thermally re-processed and re-molded into thermosets. Accordingly, these waste tire rubbers are usually mechanically crushed and pulverized into crumb rubber for further value-added use in different practices, particularly in asphalt pavement and concrete pavement because of the tremendous consumption [18,19].

Plastics and tire rubbers may be considered strategic resources to be applied in paving engineering fields for smart cities and countries [20]. Various efforts have been made by researchers and implementors to optimally recycle and reutilize these polymer wastes in asphalt pavement [21,22,23,24]. Haider et al. [25] confirmed that waste plastics made of low-density polyethylene (LDPE) and high-density polyethylene (HDPE) as modifiers are capable of enhancing the adhesion properties of and improving the moisture-induced damage to asphalt mixtures. Dalhat et al. [26] pointed out that ground waste PP, HDPE, or LDPE reused in the modification of an asphalt binder tends to improve the resistance to fatigue and rutting, while the PP-modified binder possesses better rutting resistance and elastic recovery compared with the binder modified by HDPE or LDPE. Silva et al. [27] concluded that waste rubber particles blended into conventional asphalt mixtures through a dry processing method can contribute to improve the resistance to fatigue, permanent deformation, and reflection cracking. Therefore, waste plastics and end-of-life tire rubbers are not truly municipal and industrial garbage as they can be considerably reutilized as value-added supplementary modifying materials to enhance the performance properties of asphalt materials from the perspective of sustainable pavement.

PET is a commodity plastic that is very common and widely used in our daily life, the most representative of which is the body material of drinking bottles [28]. Clearly, as disposable products, extremely large numbers of PET bottles will be cast away, reclaimed, and finally sent to stockpiles or landfills after use. Along with the passing days and months, these abandoned pieces of “plastic rubbish” will rapidly increase to a large number, which implies that these wastes will cause a terrible environmental risk [29]. Hence, the recycling of PET-based waste plastics in building asphalt pavement is undoubtedly an optional pathway for a large amount of consumption.

With regard to relevant studies, there have been some publications that mainly focused on directly adopting waste PET slices or powders as modifiers or alternatives of fine aggregates to upgrade the overall performance properties of asphalt binders and mixes [30,31,32,33]. As a result, the bonding characteristic between the binder and aggregates is still the most focused-on point that determines the moisture damage resistance and long-term properties of asphalt mixtures, and is thus needed to be strengthened further for the goal of better field applications. For this, the authors made an attempt to chemically convert these wastes into functional value-added additives for modifying bitumen and confirmed that they are useful and effective to improve the adhesion of binders to aggregates [34,35]. However, the engineering performances of asphalt materials, especially mixtures, with the incorporation of PET additives, were not validated in detail in previous studies. To fill this research gap, a new method of collectively using PET additives and crumb rubber as performance-enhancing modifiers for asphalt pavements will be employed in this study to investigate the engineering performances of rubberized asphalt materials.

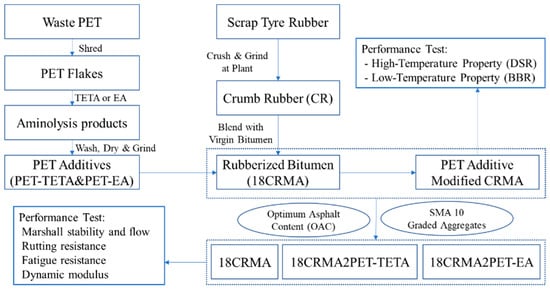

To achieve the research objectives, the superpave high- and low-temperature properties of a rubberized binder modified by PET additives were first characterized through dynamic shear rheometer (DSR) and bending beam rheometer (BBR) tests. Then, the engineering performances of the further fabricated mixtures, including the Marshall stability, rutting resistance, fatigue resistance, and dynamic modulus, were validated through a Marshall test, a Wheel Tracking Test (WTT), an Indirect Tensile Fatigue Test (ITFT), and a Simple Performance Test (SPT). Figure 1 presents the flowchart of the research plan of this study.

Figure 1.

Flowchart of the research plan of this study.

2. Materials and Research Methodology

2.1. Raw Materials

Waste PET-based drinking bottles were collected locally. To ensure purity, they were first rinsed and dried, and then the labels, caps, and other impurities were manually removed. After this procedure, the PET bodies were thrown into a grinding machine to obtain small flakes with a maximum size of 10 mm. Those flakes were made ready for the synthesis of value-added additives applied in bituminous materials. CR from end-of-life scrap tires with a size of 30~50 mesh was provided by a local supplier for preparing the rubberized bitumen. Two chemicals with different numbers of amino groups (TETA and EA), supplied by Sigma-Aldrich Corporation, were used to degrade the PET flakes for deriving the additives. The virgin bitumen used in this study is a bitumen with a penetration grade of 60/70 (Pen. 60/70). Granite aggregates and fillers were supplied by the local quarry.

2.2. Synthesis of PET Additives

The additives were chemically derived from waste PET with the existence of TETA or EA through an aminolysis process that was carried out in line with similar procedures adopted in previous studies [34,35]. To be more specific about the synthesis procedures, we fixed the mass ratio of PET and amine at 1:2, the reaction temperature at 140 °C, and the reaction time at 2 h based on preliminary trial tests. To this end, the derived additives, denoted as PET-TETA and PET-EA, respectively, were ultimately obtained after a series of necessary procedures including vacuum filtration, repeated washing, vacuum drying at room temperature, and pulverizing. The basic characteristics of these two additives are shown in Table 1.

Table 1.

Basic characteristics of the waste-PET-derived additives.

2.3. Preparation of Rubberized Bitumen Modified by PET Additives

The CR particles were first preheated at 120 °C for 30 min in the oven and, with a percentage of 18 wt.% by weight of virgin bitumen, were then incorporated into the virgin binder at 180 °C and mixed at 3500 rpm for 1 h to prepare the 18 wt.% CR-modified asphalt binder (18CRMA). After this, 2 wt.% PET-TETA and 2 wt.% PET-EA, by weight of 18CRMA, were added into and blended with the 18CRMA at 180 °C for 30 min to prepare the target binders, which were labelled 18CRMA2PET-TETA and 18CRMA2PET-EA, respectively. The primary properties of the binders involved are presented in Table 2.

Table 2.

Primary properties of the binders involved in this study.

2.4. Superpave High-Temperature Properties of Asphalt Binders

The high-temperature properties of the target binders were evaluated by the Superpave rutting factor (G */sin δ) in this study. For grading their performance, all binders first underwent a short-term aging process at 163 °C for 85 min (AASHTO T240), which is required by AASHTO M 320-10 for preconditioning. Then, these binder samples were tested at the fixed angular frequency of 10 rad/s with temperature variables of 64 °C, 70 °C, 76 °C, 82 °C, and 88 °C using a MCR 702 DSR instrument produced by Anton Paar Inc. During the testing, the gap distance of 25 mm diameter parallel plates was set at 2 mm. After testing, the failure temperature and high grade of each binder were determined using the threshold rutting factor value of 2.2 kPa according to the Superpave specification.

2.5. Bending Beam Rheology (BBR) for Asphalt Binders

The low-temperature properties of the studied binders were evaluated by measuring the flexural creep stiffness (S(t)) and flexural creep rate (m-value, ) using the BBR test in accordance with AASHTO T 313-12. The S(t) and m-value can be calculated using Equations (1)–(3).

where S(t) refers to the time-dependent flexural creep stiffness, MPa; δ(t) refers to the time-dependent deflection of the beam at midspan, mm; P refers to the applied load, N; L refers to the span length, mm; b refers to the width of the beam, mm; h refers to the thickness of the beam, mm; S′(t) refers to the time-dependent flexural creep stiffness estimated using Equation (1), MPa; A, B, and C are regression coefficients; and refers to the time-dependent creep rate, which is the slope of the logarithm of stiffness versus the logarithm of the time curve.

2.6. Preparation of Asphalt Mixtures

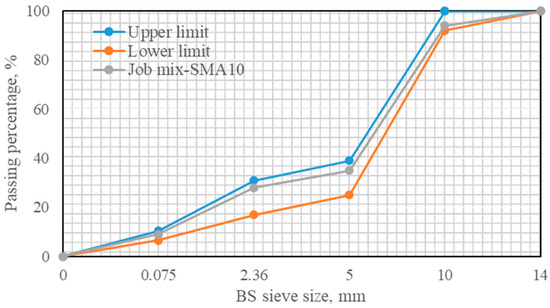

The 10 mm maximum aggregate size stone mastic asphalt (SMA10) is a commonly used type of asphalt mixture. A gradation of SMA10 was adopted to determine the suitable gradation for the job mix, as illustrated in the gradation curves shown in Figure 2.

Figure 2.

The SMA10 gradation curve used for the job mix of the asphalt rubber.

According to the mix design, the optimum asphalt content (OAC) was determined to be 6.7% and applied to fabricate the target SMA10 mixture specimens for validating their engineering performances, including the rutting resistance, fatigue resistance, and dynamic modulus, through a Wheel Tracking Test (WTT), an Indirect Tensile Fatigue Test (ITFT), and a Simple Performance Test (SPT). The SPT and ITFT specimens were prepared by a Superpave Gyratory Compactor (SGC), and the WTT specimens were prepared by a Rolling Compactor (RC). The mixing temperatures of the studied mixtures were set at 180 °C, and the compacting temperatures were decreased by 15 °C. The fabricating and testing programs for these mixture specimens are presented in Table 3.

Table 3.

Fabricating and testing programs for different studied mixtures.

2.7. Test Methodologies for Mixtures

To perform the dynamic modulus tests, cylindrical mixture specimens with a 150 mm diameter and a 175 mm thickness were first fabricated using a Superpave Gyratory Compactor (SGC). Then, these specimens were cut and cored into 100 mm diameter by 150 mm thickness specimens. The dynamic modulus of three mixtures, namely 18CRMA, 18CRMA2PET-TETA, and 18CRMA2PET-EA, was measured at the temperatures of 7 °C, 20 °C, and 40 °C and the loading frequencies of 0.1 Hz, 1 Hz, and 10 Hz for each temperature using a Simple Performance Tester (SPT) according to AASHTO TP-13.

Rutting slabs with the dimensions of 300 mm × 300 mm × 50 mm were prepared for the test characterizing the rutting resistance of 18CRMA, 18CRMA2PET-TETA, and 18CRMA2PET-EA in reference to BS 598-110. The tests were performed with an applied load of 520 N and a total pass of 2100 cycles under a controlled temperature of 60 °C.

The fatigue of the studied mixtures was evaluated through the indirect tensile fatigue test (ITFT) in accordance with BS DD ABF. ITFT specimens with a diameter of 100 mm and a height of 46 mm were prepared using the Superpave Gyratory Compactor (SGC). The tests were conducted at the target stresses of 250 kPa, 300 kPa, 350 kPa, 400 kPa, and 450 kPa at 20 °C.

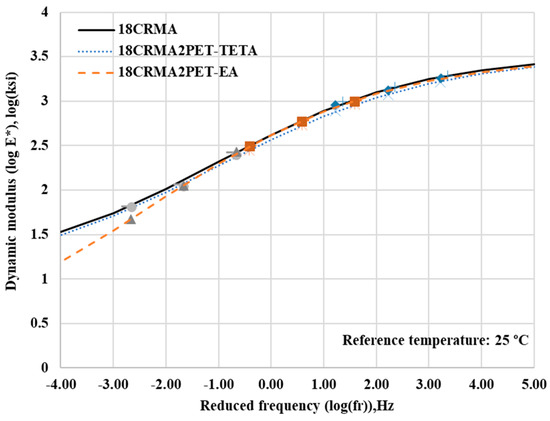

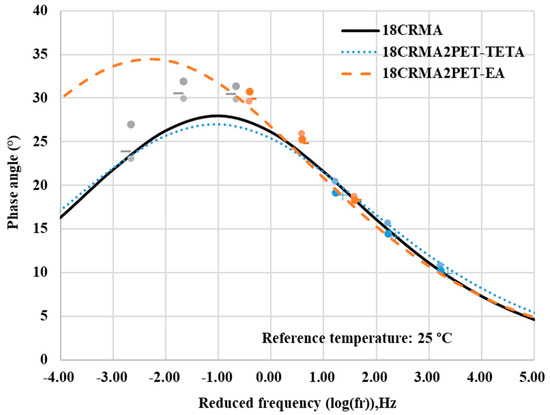

2.8. Dynamic Modulus and Phase Angle Master Curves of Asphalt Mixtures

For the target asphalt mixtures, the dynamic modulus (|E∗|) and phase angle (ϕ) were obtained using a dynamic modulus testing system at temperatures of 7 °C, 20 °C, and 40 °C and frequencies of 0.1 Hz, 1 Hz, and 10 Hz without a confining pressure. The measured results are summarized in Table 4.

Table 4.

Dynamic modulus and phase angle of the target asphalt mixtures.

According to the above test results, the dynamic modulus and phase angle master curves of the target asphalt mixtures were fitted using Equations (4) and (5):

where = the dynamic modulus, psi; = the fitting parameters; Max = the limiting maximum modulus, psi; α = Max − ; and = the reduced frequency, Hz.

To calculate the and , Equations (6)–(8) below were adopted.

where = the reduced frequency at the reference temperature, Hz; = the loading frequency at the test temperature, Hz; = the activation energy (treated as a fitting parameter); = the test temperature, °K; = the reference temperature, °K; and = the shift factor at temperature T.

where

= the limiting maximum asphalt mixture dynamic modulus, psi; VMA = the voids in the mineral aggregate, %; and VFA = the voids filled with asphalt, %.

To better fit the dynamic modulus master curve, the fitting parameters (β, γ, δ, and ), standard error (Se), and explained variance (R2) were optimized and checked following AASHTO P61-13. Among them, the initial values of β, γ, δ, and are recommended to be 0.5, −1.0, −0.5, and 200,000, respectively, and the values of Se and R2 are required to be less than 0.05 and greater than 0.99, respectively. The relevant fitting parameters and error values of the dynamic modulus and phase angle master curves are presented in Table 5.

Table 5.

The results of the fitting parameters and errors for master curves.

3. Results and Discussion

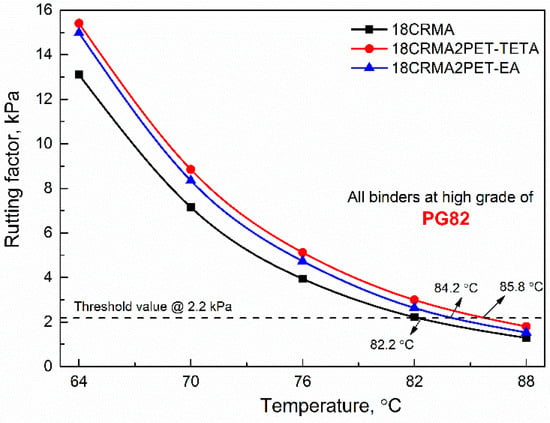

3.1. High-Temperature Properties of CRMA Binder Modified by PET Additives

Figure 3 describes the changes in the rutting factors of the target binders over the Superpave graded temperatures. As observed, the incorporation of 2 wt.% PET-TETA or 2 wt.% PET-EA slightly increases the rutting factor of the 18CRMA binder at elevated temperatures, which appears to cause an increase in the rutting failure temperature from 82.2 °C to 85.8 °C or 84.2 °C, with no contributing changes in the high grade that was originally located at PG 82. This result indicates that these two PET additives at a dosage of 2 wt.% have an insignificant effect on the improvement of the high-temperature rutting deformation resistance of the 18CRMA binder. The reason for this is that these PET additives, which are derived from macromolecular PET through chemical aminolysis and have almost totally lost their original elastic response and crystalline structure, just function as functionalized modifiers with a lower molecular weight for the modification of rubberized bitumen, which may chemically interact with the polarized oxidative active groups of the rubberized binder to gather more asphaltenes during the short-term aging process and thus enhance the high-temperature properties.

Figure 3.

Rutting factors of the target binders versus Superpave graded temperatures.

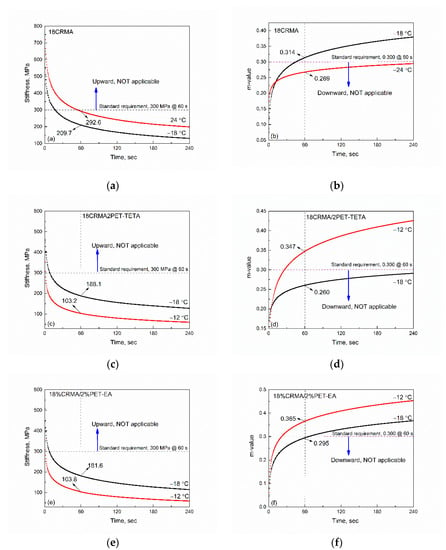

3.2. Low-Temperature Properties of the CRMA Binder Modified by PET Additives

Figure 4 illustrates the time dependency of S(t) and the m-value of the target binders at low temperatures. The corresponding low-temperature PG grades are also presented in Table 6. To identify the low PG grade, tests at −24 °C and −18 °C were first conducted on 18CRMA, and the results are shown in Figure 4a,b. It can be observed that the stiffness at both temperatures at 60 s meets the Superpave requirement (less than 300 MPa). The m-values at −24 °C and −18 °C are 0.269 and 0.314, respectively, which indicate that the binder meets the m-value requirement (greater than 0.3) at −18 °C, but not at −24 °C. Thus, the low-temperature PG grade of the binder was determined to be −28 °C. It is worth noting that the Superpave low-temperature PG grade is 10 °C lower than the lowest testing temperature at which the binder can meet the Superpave binder specification requirement. From Figure 4c–f, it can be further concluded that the low-temperature PG grades for 18CRMA2PET-TETA and 18CRMA2PET-EA are −22 °C. In other words, both PET additives slightly compromise the low-temperature performance of the rubberized binder. The results obtained depend upon the fact that the molecules of PET additives dispersed in the rubberized binder at such low temperatures are totally frozen and cannot freely move such that they somehow block the creeping behavior of the bitumen molecules. Overall, a small dosage of PET additives will not be able to have a significant impact on the low-temperature property of the rubberized binder, while the corresponding modified binders with PG-22 are considered to be applicable in tropical regions and many other places worldwide.

Figure 4.

Time dependency of the flexural creep stiffness and m-value of the binders at low temperatures (a,b) 18CRMA; (c,d) 18CRMA2PET-TETA; (e,f) 18CRMA2PET-EA.

Table 6.

Low-temperature gradings of the studied binders based on Figure 3.

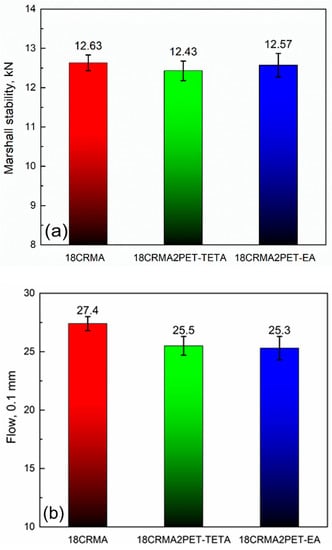

3.3. Marshall Stability and Flow Value of CRMA Mixtures Incorporating PET Additives

Figure 5 displays the Marshall stability and flow value of the 18CRMA, 18CRMA2PET-TETA, and 18CRMA2PET-EA mixtures. It is clear that the load values of the 18CRMA2PET-TETA and 18CRMA2PET-EA mixtures are close to that of the 18CRMA mixture, and the corresponding flow values are slightly lower than that of the 18CRMA mixture. The results indicate that the incorporation of a small amount of PET-TETA or PET-EA will not significantly affect the load-bearing capacity and can slightly enhance the high-temperature deformation resistance of the original rubberized mixture. This is because the addition of a smaller amount of PET additives does not significantly affect the physical and rheological properties of the rubberized binder and change the thermal stability and deformation behavior of the corresponding mixture.

Figure 5.

Marshall stability (a) and flow value (b) of rubberized asphalt mixtures incorporating PET additives.

3.4. Rutting Resistance of CRMA Mixtures Incorporating PET Additives

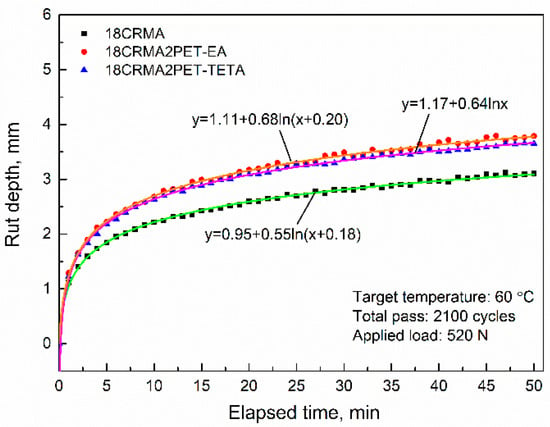

The 60 °C wheel tracking deformation results of the studied CRMA mixtures incorporating PET additives inside the binders are displayed in Figure 6, and the fitted non-linear curve equations used to predict the rut development for all mixtures are presented in Table 7. As depicted, the rut depth of the 18CRMA mixture is slightly increased when PET additives are used, and there is no significant difference in rutting depth between the 18CRMA2PET-TETA and 18CRMA2PET-EA mixtures. Meantime, all mixtures have rutting depths of less than 4 mm at the end of the loading cycle at 60 °C. The results demonstrate that PET additives slightly compromise the rutting deformation resistance of the 18CRMA mixture but have no significant influence on the practical applications of the target mixtures under environmental temperatures in terms of rutting behavior. In addition, with the elapsing time under the same conditions, the trends of the rut development of these mixtures are in good compliance with the fitted non-linear curve equations because the correlation coefficient (R2) reaches 0.998. Furthermore, it is possible to predict the rut development and rate of change under the same conditions based on the fitted results obtained.

Figure 6.

Rut depth development of CRMA mixtures containing PET additives at 60 °C.

Table 7.

Non-linear fitted curve equations of rut development for the studied mixtures.

According to the rutting slab tests, the rate of rut development can be calculated by Equation (9):

where Rrd means the rate of rut development, mm/min; RDi means the rut depth, mm; and ti means the elapsed time, min.

Based on the data, fitted equations, and calculation formula above, the changes in the Rrd of these mixtures with the loading time are plotted in Figure 7. Clearly, the Rrd value of the 18CRMA mixture becomes slightly larger when the 2 wt.% PET additives are used, and similar Rrd values for the 18CRMA2PET-TETA and 18CRMA2PET-EA mixtures are also observed. In addtion, it is evident that the Rrd values of all three mixtures are less than 0.5 mm/min, even at the very beginning of the loading cycle. These results indicate that both PET-TETA and PET-EA will slightly compromise the rutting resistance of the 18CRMA mixture, but the difference is not significant. In addition, it is worth noting that the use of PET additives leads to an opposite subtle change in the high-temperature properties between the asphalt binder and the mixture. The reason for this phenomenon is that the incorporation of PET-TETA somewhat improves the rheological properties of the rubberized binder at the testing temperature, and PET-EA has a relatively poor capacity to enhance the bonding properties of the rubberized binder with aggregates. Overall, these two types of PET additives do not significantly increase the high-temperature susceptibility of the original rubberized asphalt mixture in rutting deformation, so they will not affect the engineering applications of rubberized asphalt mixtures.

Figure 7.

Rate of rut development of CRMA mixtures containing PET additives with elapsing time at 60 °C.

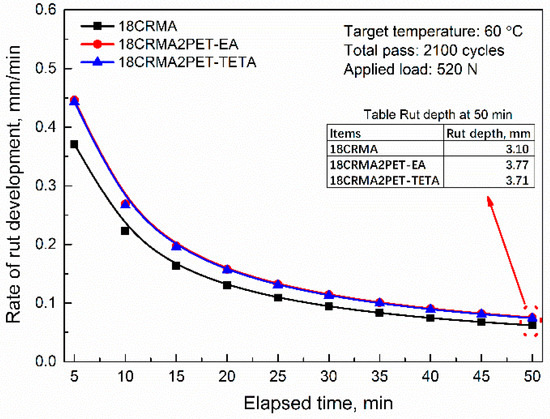

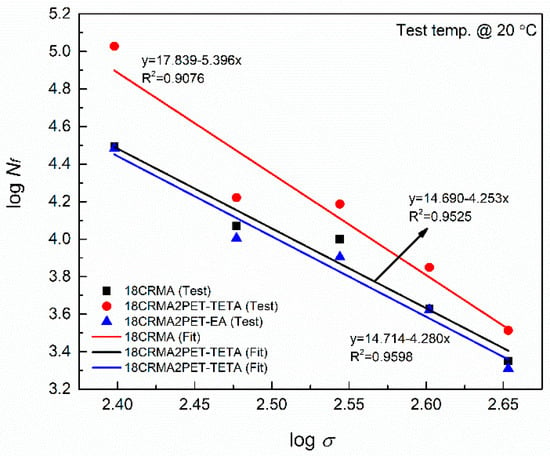

3.5. Fatigue Properties of CRMA Mixtures Incorporating PET Additives

To better evaluate the fatigue lives of the CRMA mixtures incorporating PET additives, ITFT tests were carried out with target stress control of 250 kPa, 300 kPa, 350 kPa, 400 kPa, and 450 kPa at 20 °C. Equation (10) below is typically adopted to describe the relationship between the cycles to fatigue failure and loading stress [36]:

where refers to the loading stress; refers to the cycles to fatigue failure; and and are the coefficients of the fatigue equation.

To further obtain the values of the coefficients, Equation (6) was transferred to the following linear expression (see Equation (11)) by taking the logarithm (base 10) of both sides of the equation:

where and are the y-axis intercept and the slope of the fitted fatigue curve, respectively, and higher values of and , indicate better fatigue resistance.

Table 8 presents the ITFT results of CRMA mixtures incorporating PET additives at 20 °C. As expected, the value dramatically decreases as the loading stress increases, but the two PET additives have different effects on the fatigue resistance of the 18CRMA mixture. It is worth noting that the value of the 18CRMA mixture is significantly increased when 2 wt.% PET-TETA is used, indicating that PET-TETA has a strong ability to improve the fatigue resistance of the 18CRMA mixture. By contrast, the value of the 18CRMA2PET-EA mixture is very close to that of the 18CRMA mixture, implying that incorporating 2 wt.% PET-EA has an insignificant effect on the resistance of the 18CRMA mixture. This is because PET-TETA can be thermally melted and evenly dispersed in the rubberized binder at the processing temperature and cause the binder to be produced with a powerful electrostatic force on aggregates due to the attachment of amino and amide-based structural characteristics, while PET-EA acts as a functional filler dispersed into the binder in association with less amine-derived groups. This explanation can be made by the fact that the thermal behavior and amine-based characteristic groups of both PET additives are totally different.

Table 8.

ITFT results of CRMA mixtures incorporating PET additives at 20 °C.

Based on the results from Table 8, the fitted fatigue curves of CRMA mixtures incorporating PET additives are plotted in Figure 8, and the corresponding fatigue equations and relevant coefficients are listed in Table 9. It can be found that the regression coefficients (R2) of all mixtures exceed 0.90, indicating that the fitted fatigue curves can well represent the correlation between cycles to fatigue failure and loading stress. In terms of k1 and , the values of the 18CRMA2PET-TETA mixture are obviously higher than that of the 18CRMA mixture, indicating that PET-TETA can effectively improve the fatigue resistance of the 18CRMA mixture. However, the coefficient values of the 18CRMA2PET-EA mixture are very close to that of the 18CRMA mixture, demonstrating that PET-EA has no significant effect on the fatigue resistance of the 18CRMA mixture. This can also be explained by the above analyses of the Nf-σ results for these mixtures.

Figure 8.

Fatigue curves of 18CRMA mixtures incorporating PET additives.

Table 9.

Fatigue equations and related coefficients of the target rubberized mixtures.

3.6. Dynamic Modulus and Phase Angle Master Curves of CRMA Mixtures Incorporating PET Additives

Figure 9 and Figure 10 present the dynamic modulus and phase angle master curves of the 18CRMA, 18CRMA2PET-TETA, and 18CRMA2PET-EA mixtures. It is clear that the dynamic modulus of all asphalt mixtures sharply increases as the loading frequency increases, and the corresponding phase angles present first-increase-and-then-decrease trends. From the results, the dynamic modulus and phase angle of the 18CRMA2PET-TETA mixture are very close to those of the 18CRMA mixture from a low frequency to a high frequency. However, for the 18CRMA2PET-EA mixture, the dynamic modulus appears to be lower and the phase angle appears to be higher compared with those of the 18CRMA mixture at a low frequency (<1 Hz), and then their trends become close to those of the 18CRMA mixture after the frequency further increases. These results indicate that the viscoelastic characteristics of the 18CRMA2PET-TETA mixture are similar to those of the 18CRMA mixture over a wide frequency range, which for the 18CRMA2PET-EA mixture slightly lag behind those of the a18CRMA mixture at a low frequency and become similar afterwards at a high frequency.

Figure 9.

Dynamic modulus master curves of CRMA mixtures incorporating PET additives.

Figure 10.

Phase angle master curves of CRMA mixtures incorporating PET additives.

4. Summary and Conclusions

In this study, PET wastes were first chemically recycled into derived additives, namely PET-TETA and PET-EA, by amine treatment from TETA and EA, respectively. Afterwards, the Superpave high- and low- temperature rheological properties of the 18CRMA binder modified by both additives at 2 wt.% were assessed. Finally, the engineering performances of the corresponding SMA10 mixtures were validated in terms of rutting, fatigue, and dynamic modulus. The following valuable and interesting findings were obtained:

- -

- The rutting factor results indicate that 2 wt.% PET-TETA and PET-EA can slightly increase the rutting failure temperature of the asphalt rubber from 82.2 °C to 85.5 °C and 84.2 °C, respectively, and exhibit no change in the high grade of PG 82.

- -

- The BBR analyses indicate that both PET additives slightly compromise the low-temperature performance of the rubberized binder, just causing a decrease in the corresponding grade from PG-28 to PG-22, which means that it can be subjected to the climate of many field practices worldwide.

- -

- Marshall test results show that these two PET additives have almost no influence on the thermal stability and deformation resistance of the rubberized asphalt mixture.

- -

- The ITFT analyses illustrate that PET-TETA exhibits a strong capability to extend the fatigue life of the rubberized asphalt mixture, but PET-EA fails to do so.

- -

- The WTT results demonstrate that both additives slightly compromise the rutting resistance of the rubberized asphalt mixture, leading to a decrease in the rut depth from 3.10 mm to around 3.70 mm, which is an insignificant difference.

- -

- The results of the dynamic modulus and phase angle tests indicate that the addition of a small amount of PET-TETA does not affect the viscoelastic characteristic of the rubberized asphalt mixture over a wide frequency range, but for PET-EA, it tends to slightly enhance the viscous behavior of the 18CRMA mixture at a low frequency (below approximately 1 Hz).

Overall, PET-TETA is regarded as a more suitable and valuable additive in contrast with PET-EA from the research findings. We recommended that it be applied in rubberized asphalt pavement due to its significant capacity to extend the fatigue life of asphalt rubber. The recycling approach proposed in this study can not only seriously alleviate the environmental pressures caused by the landfilling and stockpiling of waste PET and scrap tires, but it also makes these waste products more valuable in durable pavement. Furthermore, a determination on the feasibility of using the recommended waste-PET-derived additive in other asphalt mixture types, such as porous asphalt and glassphalt, through performance evaluations, still needs to be carried out in the laboratory and in the field.

Author Contributions

Conceptualization, X.X. and S.S.; data curation, Y.C.; formal analysis, Q.W. and X.C.; funding acquisition, S.S.; investigation, Y.L.; methodology, X.X.; resources, Q.W., X.C. and S.S.; supervision, X.X.; writing—original draft, Y.C. and Y.L.; writing—review & editing, Y.C. and Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Research Project of the Education Department of Hubei Province (B2021084) and the Science Foundation of the Wuhan Institute of Technology (K201932 & K201731).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- El-Naga, I.A.; Ragab, M. Benefits of utilization the recycle polyethylene terephthalate waste plastic materials as a modifier to asphalt mixtures. Constr. Build. Mater. 2019, 219, 81–90. [Google Scholar] [CrossRef]

- Karmakar, S.; Roy, T.K. Effect of Waste Plastic and Waste Tires Ash on Mechanical Behavior of Bitumen. J. Mater. Civ. Eng. 2016, 28, 04016006. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, Z.; Zhang, Z.; Yu, J.; Oeser, M.; Wang, D. Recycling waste packaging tape into bituminous mixtures towards enhanced mechanical properties and environmental benefits. J. Clean. Prod. 2019, 229, 22–31. [Google Scholar] [CrossRef]

- Lee, U.; Chung, J.N.; Ingley, H.A. High-Temperature Steam Gasification of Municipal Solid Waste, Rubber, Plastic and Wood. Energy Fuels 2014, 28, 4573–4587. [Google Scholar] [CrossRef]

- Sigler, M. The Effects of Plastic Pollution on Aquatic Wildlife: Current Situations and Future Solutions. Water Air Soil Pollut. 2014, 225, 1–9. [Google Scholar] [CrossRef]

- Dobrota, D.; Dobrotă, G. An innovative method in the regeneration of waste rubber and the sustainable development. J. Clean. Prod. 2018, 172, 3591–3599. [Google Scholar] [CrossRef]

- Monteiro, R.C.P.; Sul, J.I.D.; Costa, M.F. Plastic pollution in islands of the Atlantic Ocean. Environ. Pollut. 2018, 238, 103–110. [Google Scholar] [CrossRef] [PubMed]

- Ha, K.H.; Kim, M.S. Application to refrigerator plastics by mechanical recycling from polypropylene in waste-appliances. Mater. Des. 2012, 34, 252–257. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Singh, R.; Singh, N.; Fabbrocino, F.; Fraternali, F.; Ahuja, I.S. Waste management by recycling of polymers with reinforcement of metal powder. Compos. Part B Eng. 2016, 105, 23–29. [Google Scholar] [CrossRef]

- Chu, B.; Salem, D.R. Flexoelectricity in several thermoplastic and thermosetting polymers. Appl. Phys. Lett. 2012, 101, 103905. [Google Scholar] [CrossRef]

- Nash, N.; Young, T.; McGrail, P.; Stanley, W. Inclusion of a thermoplastic phase to improve impact and post-impact performances of carbon fibre reinforced thermosetting composites—A review. Mater. Des. 2015, 85, 582–597. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Krishnakumar, B.; Sanka, R.V.S.P.; Binder, W.H.; Parthasarthy, V.; Rana, S.; Karak, N. Vitrimers: Associative dynamic covalent adaptive networks in thermoset polymers. Chem. Eng. J. 2020, 385, 123820. [Google Scholar] [CrossRef]

- Lu, G.; Wang, H.; Zhang, Y.; Liu, P.; Wang, D.; Oeser, M.; Grabe, J. The hydro-mechanical interaction in novel polyurethane-bound pervious pavement by considering the saturation states in unbound granular base course. Int. J. Pavement Eng. 2021, 1–14. [Google Scholar] [CrossRef]

- Li, R.; Leng, Z.; Zhang, Y.; Ma, X. Preparation and characterization of waterborne epoxy modified bitumen emulsion as a potential high-performance cold binder. J. Clean. Prod. 2019, 235, 1265–1275. [Google Scholar] [CrossRef]

- de Sousa, F.D.; Scuracchio, C.; Hu, G.-H.; Hoppe, S. Devulcanization of waste tire rubber by microwaves. Polym. Degrad. Stab. 2017, 138, 169–181. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, Z.; Leng, Z.; Wu, C.; Zhang, Z.; Wang, D.; Oeser, M. Effect of mixing sequence on asphalt mixtures containing waste tire rubber and warm mix surfactants. J. Clean. Prod. 2020, 246, 119008. [Google Scholar] [CrossRef]

- Presti, D.L. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Xu, X.; Leng, Z.; Lan, J.; Wang, W.; Yu, J.; Bai, Y.; Sreeram, A.; Hu, J. Sustainable Practice in Pavement Engineering through Value-Added Collective Recycling of Waste Plastic and Waste Tyre Rubber. Engineering 2021, 7, 857–867. [Google Scholar] [CrossRef]

- Lastra-González, P.; Calzada-Pérez, M.A.; Castro-Fresno, D.; Vega-Zamanillo, Á.; Indacoechea-Vega, I. Comparative analysis of the performance of asphalt concretes modified by dry way with polymeric waste. Constr. Build. Mater. 2016, 112, 1133–1140. [Google Scholar] [CrossRef] [Green Version]

- Moreno, F.; Sol, M.; Martín, J.; Pérez, M.; Rubio, M. The effect of crumb rubber modifier on the resistance of asphalt mixes to plastic deformation. Mater. Des. 2013, 47, 274–280. [Google Scholar] [CrossRef]

- Modarres, A.; Hamedi, H. Effect of waste plastic bottles on the stiffness and fatigue properties of modified asphalt mixes. Mater. Des. 2014, 61, 8–15. [Google Scholar] [CrossRef]

- Angelone, S.; Casaux, M.C.; Borghi, M.; Martinez, F.O. Green pavements: Reuse of plastic waste in asphalt mixtures. Mater. Struct. 2015, 49, 1655–1665. [Google Scholar] [CrossRef]

- Haider, S.; Hafeez, I.; Jamal, M.; Ullah, R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Wahhab, H.I.A.-A. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2017, 18, 349–357. [Google Scholar] [CrossRef]

- Silva, L.; Benta, A.; Santos, L.P. Asphalt rubber concrete fabricated by the dry process: Laboratory assessment of resistance against reflection cracking. Constr. Build. Mater. 2018, 160, 539–550. [Google Scholar] [CrossRef]

- Raheem, A.B.; Noor, Z.Z.; Hassan, A.; Hamid, M.K.A.; Samsudin, S.A.; Sabeen, A.H. Current developments in chemical recycling of post-consumer polyethylene terephthalate wastes for new materials production: A review. J. Clean. Prod. 2019, 225, 1052–1064. [Google Scholar] [CrossRef]

- Li, R.; Leng, Z.; Yang, J.; Lu, G.; Huang, M.; Lan, J.; Zhang, H.; Bai, Y.; Dong, Z. Innovative application of waste polyethylene terephthalate (PET) derived additive as an antistripping agent for asphalt mixture: Experimental investigation and molecular dynamics simulation. Fuel 2021, 300, 121015. [Google Scholar] [CrossRef]

- Islam, M.J.; Meherier, M.S.; Islam, A. Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Constr. Build. Mater. 2016, 125, 946–951. [Google Scholar] [CrossRef]

- Taherkhani, H.; Arshadi, M.R. Investigating the mechanical properties of asphalt concrete containing waste polyethylene terephthalate. Road Mater. Pavement Des. 2019, 20, 381–398. [Google Scholar] [CrossRef]

- Silva, J.D.A.A.E.; Rodrigues, J.K.G.; De Carvalho, M.W.; Lucena, L.C.D.F.L.; Cavalcante, E.H. Mechanical performance of asphalt mixtures using polymer-micronized PET-modified binder. Road Mater. Pavement Des. 2017, 19, 1001–1009. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 78, 79–93. [Google Scholar] [CrossRef]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Leng, Z.; Sreeram, A.; Padhan, R.K.; Tan, Z. Value-added application of waste PET based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (RAP). J. Clean. Prod. 2018, 196, 615–625. [Google Scholar] [CrossRef]

- Wu, S.; Ye, Q.; Li, N. Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr. Build. Mater. 2008, 22, 2111–2115. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).