Abstract

In order to explore the sound absorption and noise reduction performance of closed-cell aluminum foam in the tunnel, the field test of the sound absorption performance of aluminum foam board was carried out based on the installation of aluminum foam board in the whole line of Haoshanyu Tunnel on Qinglan Expressway. Combined with the existing loudspeaker test and typical tunnel measurements, a new field test method for the noise reduction performance of closed-cell aluminum foam board was proposed for two different working conditions including fixed-point pure tone sound source condition and mobile vehicle sound source condition. The testing results of the new methods were analyzed, and it showed that the closed-cell aluminum foam has good sound absorption property at the frequency spectra between 250 Hz and 1000 Hz, and the farther away from the sound source, the better the sound absorption effect. In the research on the noise reduction effect of actual vehicle, it was found that the insertion loss of the closed-cell foam aluminum board is about 4 dB(A), which indicated that the closed-cell aluminum foam can play a certain noise reduction effect in the tunnel.

1. Introduction

Noise pollution has attracted more and more people’s attention. Noise not only causes damage to people’s hearing, but also affects people’s physiology and endangers people’s physical and mental health. In many situations, the noise pollution in the tunnel is particularly serious. In recent years, tunnel construction in China has developed rapidly. As a consequence, there were 21,316 graded highway tunnels with a total length about 21,999.3 km operated by the end of 2020. Compared with the previous two years, the number of graded highway tunnels increased by 40% and 49% respectively. Besides, more and more tunnels were constructed at a complex environment [1,2,3]. While the tunnel construction is highly developed, the noise pollution problem in the tunnel has also become more serious. Due to the closed environment of the tunnel, the noise generated during the driving process is difficult to dissipate, seriously affecting the driver’s comfort [4], and causing harm to the staff on the shoulder.

Kang [5,6] believed that the sound field in the tunnel is similar to a sound field in long enclosures, as a consequent it is impossible to predict the propagation law of noise by classical room acoustic theory. Li et al. [7] established a coherent model that considers the interference caused by direct waves and reflected waves. Besides, the total sound field can be calculated by coherent summation of the contributions of image source. However, under the normal circumstances, the tunnel is not a simply long straight passage. Usually, there are many branches such as connecting channel and escape route in the tunnel. The existence of these branches will affect the propagation of acoustic waves, which is slightly different from the calculation of coherent model. In order to solve the above problems, Liu et al. [8] studied the propagation law of sound in long enclosures with vertical or inclined branches.

The noise in the tunnel mainly comes from the traffic flow [9], which is composed of the noise generated by the automobile engine and the noise generated by the friction between the wheel and the road surface. The former is difficult to improve from the sound source except improving the engine manufacturing technology level to enhance the quality of engine, while the latter can achieve the same effect by improving the pavement material. An et al. [10] found that asphalt pavements can effectively reduce noise between wheels. However, due to the fire protection requirements and construction maintenance considerations in highway tunnels, cement concrete pavement is more suitable than asphalt pavement in this condition. Fang et al. [11] found that the noise level of ordinary grooved cement concrete pavement is high, but the cement concrete pavement modified by polymer has a low noise level. Although the above method can achieve the effect of reducing vehicle noise in tunnels, it does not have strong feasibility in existing tunnels, and it has no effect on other noise sources in the tunnel. Laying sound-absorbing boards on the side walls of the tunnel is the most common and excellent method. Most of the initial sound-absorbing are flexible porous materials. Gupta et al. [12] studied the sound absorption properties of polyurethane, glass wool and melamine, three kinds of common flexible porous sound-absorbing materials. The above materials have excellent sound absorption properties, but due to the lack of fire resistance and high production cost, the prospect of extensive application in tunnels is not high. As a consequent, more and more scholars concentrated more on the metal foams. Xu et al. [13] studied the sound absorption properties of stainless steel foam. Liang et al. [14] compared the sound absorption properties of metal foams and flexible porous materials, and confirmed that aluminum foam materials have better sound absorption properties. However, it was found in the study that the internal holes of metal foams with good sound absorption performance were mostly through-holes, and such metal foams have low strength and high cost. Therefore, the research on sound absorption properties of closed-cell metal foams came into being. Opiela et al. [15] studied the drilled closed-cell aluminum foam and found that it has sufficient sound absorption capacity.

Although many scholars have confirmed that the closed-cell aluminum foam after treatment has enough sound absorption capacity, most of the conclusions obtained by laboratory experiments. These research results are lack of confirmation in practical application., not to mention the application of closed-cell aluminum foam boards in the tunnel. The noise reduction effect of closed-cell aluminum foam boards in tunnels was still unknown. This paper evaluates the effect of closed-cell aluminum foam boards in tunnel noise reduction under two different working conditions, and obtains the noise reduction effect of fixed pure sound sources and moving vehicle noise in the tunnel, which can provide theoretical basis for the promotion of closed-cell aluminum foam in tunnel application.

2. Possibility Analysis and Testing Method of the Structure Sound Absorption Performance

2.1. Analysis of the Possibility of Sound Absorption

Most studies have shown that viscous dissipation and resonant sound absorption [16,17] are the main sound absorption modes of porous metal foams. Viscous dissipation is due to the velocity gradient of air vibration in pores caused by the existence of pore walls, and acoustic energy is transformed into heat energy dissipation through internal friction [18,19]. Resonant sound absorption relies on the resonance of the resonator to acoustic energy dissipation. When the frequency of the incident acoustic wave is close to the natural frequency of the resonator, resonance occurs. At this time, the velocity of air vibration reaches the maximum, and the acoustic energy loss reaches the maximum, so the sound absorption effect is the best.

The existing research have shown that the closed-cell aluminum foam does not have good sound absorption performance [20], but according to mechanism of the above two sound absorption methods, it is feasible to improve its sound absorption performance by improving the structure of the closed-cell aluminum. Some scholars have found that the resonant sound absorption structure composed of holes can improve the sound absorption effect [21,22]. Other scholars have also found that by compressing to make small cracks appear through the pore wall, a better viscous dissipation effect can be achieved [23]. It can be seen that the installation structure of closed-cell aluminum foam board plays a sound absorption and noise reduction effect in the tunnel is reasonable.

2.2. Testing Method

The sound absorption coefficient is an important index to evaluate the sound absorption performance of materials [24,25,26]. Among the many methods of acoustic performance testing, the reverberation chamber method and tube measurement method are the most commonly used methods to measure the sound absorption coefficient of materials. Tube measurement method is divided into standing wave ratio method and transfer function method. Standing wave ratio method calculates the sound absorption coefficient of the material to the vertical incident wave by measuring the maximum and minimum values of the standing wave sound pressure. Transfer function method separates the incident wave and the reflected wave by processing the signal delay to obtain the sound absorption coefficient of the material. The above two methods measure the vertical sound absorption coefficient of the material. The reverberation chamber method is used to measure the random incident sound absorption coefficient of the material, which is obtained by the reverberation time before and after the material is placed.

There are a variety of noise sources in the tunnel, including fan noise and vehicle noise. The incident trajectory of acoustic waves is untraceable, so it cannot be measured by pipe measurement method. In addition, because of the unique structure of the tunnel, the distribution of the internal sound field is different, and it is impossible to simulate the sound field with a simple reverberation chamber. Therefore, it is necessary to seek a novel testing method, which requires accurate evaluation criteria and can be applied to tunnels. The testing method proposed in this paper refers to the loudspeaker test and typical tunnel measurements, which are the two typical methods in the existing tunnel noise research. The loudspeaker test is carried out in the tunnel by using a fixed sound source. And the fixed sound source is used to release several octave pure tone signals, then the sound pressure level changes along the longitudinal direction of the tunnel can be measured. Typical tunnel measurement is to compare the noise level before and after sound absorption treatment of the actual tunnel, and to effectively evaluate the actual effect of the sound absorption materials. This test is based on the actual measurement of a typical tunnel and combined with some ideas in the loudspeaker test, the new fashioned two test conditions Case I and Case II have been formulated. In Case I, a fixed sound source was selected to release several octave pure tones separately, and the sound pressure level changes were measured along the longitudinal direction of the tunnel before and after the installation of the aluminum foam boards. In Case II, the change of vehicle noise before and after the installation of the aluminum foam boards were measured, and the insertion loss of the closed-cell aluminum foam was analyzed and studied. The two test conditions will be described in detail below.

3. Field Test

3.1. Engineering Background

The Haoshanyu Tunnel of Qinglan Expressway is located at the junction of Zhangjiapo Town and Shiqiao Town in Yiyuan County. The Haoshanyu Tunnel is a separate one-way double-track tunnel. The starting and ending pile number of the left line of the tunnel are K221 + 597~K222 + 297, the length is 700 m. The starting and ending mileage of the right line is YK221 + 617~YK222 + 332, the length is 715 m. The Haoshanyu Tunnel belongs to the middle tunnel. As shown in Figure 1.

Figure 1.

Spatial position of tunnel.

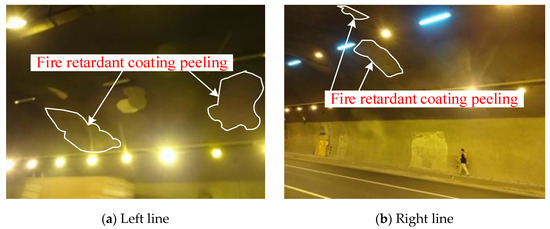

Fire prevention and noise reduction are two of the key points in the tunnel operation. The previous main fire prevention method used in the Haoshanyu Tunnel was spraying fire retardant coatings. However, due to the cool and humid environment in the tunnel and the lack of ventilation, the fire retardant coatings are prone to mildew and discoloration. During the review of the Haoshanyu tunnel, it was found that the average fire retardant coating of the Haoshanyu tunnel peeled off about 6 pcs/80 m2, as shown in Figure 2. Therefore, measures need to be taken to enhance the tunnel fire performance.

Figure 2.

The scene of the peeling off of the fire-retardant coating.

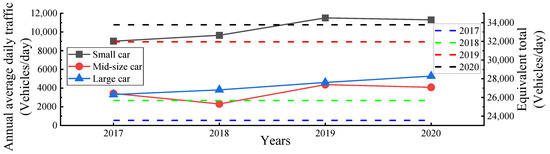

According to statistics from the transport sector, the traffic volume in the Haoshanyu tunnel has increased year by year, and the equivalent total traffic volume increasing from 23,550 vehicles per day in 2017 to 33,773 vehicles per day in 2020, as shown in Figure 3. With the increase of traffic flow, the noise pollution in the tunnel becomes more and more serious. Therefore, it is necessary to take noise reduction measures.

Figure 3.

Traffic flow diagram of the Haoshanyu Tunnel.

The closed-cell aluminum foam board have great fire resistance and heat insulation performance [27,28,29]. The existing research shows that the thermal conductivity of aluminum foam is very low, and the aluminum foam will not produce toxic and harmful gases at high temperature. So, it can be used as a substitute for the traditional thermal insulation refractory in tunnels. As for the sound absorption properties of closed-cell aluminum foams, it has been preliminarily confirmed [17]. Since the closed-cell aluminum foam board has the properties of fire prevention and sound absorption, it meets the needs of the Haoshanyu Tunnel. The research on the sound absorption performance of closed-cell aluminum foam board in the tunnel was carried out based on the installing project of aluminum foam board in the Haoshanyu Tunnel. The Haoshanyu Tunnel has also become the first highway tunnel in China to install aluminum foam boards.

3.2. Installation Method

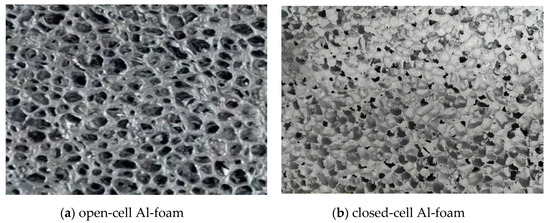

The aluminum foam board used in this project was prepared by melt foaming method, that is, adding tackifier and foaming agent successively in molten aluminum. The specific parameters of aluminum foam board are shown in Table 1. Due to the closed and disconnected pores in the closed aluminum foam board (Figure 4), the sound absorption performance is weaker than that of the open aluminum foam board. Therefore, it is necessary to improve its sound absorption performance through appropriate installation methods.

Table 1.

Performance index of aluminum foam.

Figure 4.

Aluminum foam sample diagram.

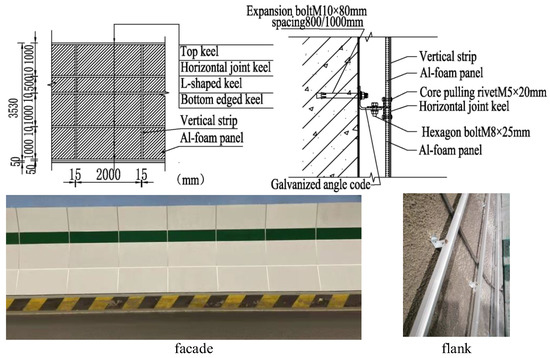

The installation method of aluminum foam board will affect the punch rate, punch depth and cavity depth behind the board. It is introduced above that the resonant sound absorption structure can be formed by drilling, and the drilling rate, drilling depth and the cavity depth behind will affect the performance of resonant sound absorption [21,22]. Therefore, it is necessary to explain the installation method of closed-cell aluminum foam board in the tunnel.

The thickness of aluminum foam board installed in the project is 10 mm, and the average pore diameter is 5 mm. The aluminum foam board was connected with light steel keel. During installation, the galvanized angle code was first fixed on the second lining with an expansion bolt, and then the light steel keel and the galvanized angle code were connected with bolts. Finally, the aluminum foam boards were inserted from the side into the groove between the light steel frame. The specific installation method is shown in Figure 5. Using the galvanized angle code as the connecting piece between the dragon frame and the second lining can effectively ensure the depth of the cavity behind the aluminum foam boards, so that effectively improve the resonance sound absorption effect of the Helmholtz resonator. However, due to the use of embedded groove fixation, the surface porosity of the aluminum foam board is not high, so it may suppress the sound absorption to a certain extent. In addition, the groove does not completely limit the aluminum foam boards, so when the car passes, the aluminum foam boards will produce vibration to play a certain active noise reduction effect, but this paper does not consider the effect of active noise reduction on the test.

Figure 5.

Installation of aluminum foam board in tunnel.

3.3. Case I

Case I mainly studies the sound absorption performance of closed-cell aluminum foam under a fixed pure sound source. By analyzing the sound pressure level changes along the longitudinal direction of the tunnel under the fixed-point pure sound source before and after the installation of the closed-cell aluminum foam boards, the effect of frequency, position and distance is explored. Because the human ear is more sensitive to mid-to-high frequency sounds (1–5 kHz), but not to low-frequency sounds (below 100 Hz), and the frequency response of the A-weighted network is close to the sensitivity of the human ear to wideband sounds, so A-weighted sound level has become the most widely used evaluation index. In addition, although the working condition is tested under stable pure tone, other noises such as testers and tunnel fans are inevitably generated inside the tunnel. Therefore, the equivalent continuous A sound level is selected as the evaluation index of Case I, which can effectively reduce the impact of unnecessary noise, and will not affect the results when there is no external noise.

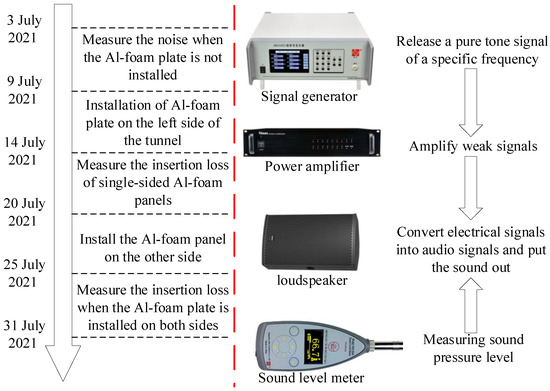

This experiment was carried out following the installation progress of the aluminum foam boards in the tunnel. Repeated tests were carried out in three stages: before installation, one-sided installation was completed, and two-sided installation was completed. The details were shown in Figure 6. During the test, the power amplifier and loudspeaker were connected to the signal generator, and the loudspeaker was placed on the middle line of the tunnel at the central mileage of the tunnel to avoid the influence of the middle and short tunnel entrances as far as possible. Referring to the height of the car engine from the ground and set the height of the loudspeaker to 0.25 m from the ground. After the equipment is connected and placed, used a signal generator to release a 125 Hz octave pure tone signal, and adjusted the power amplifier so that the external sound can be heard clearly. At the same time, the setting value of the power amplifier was recorded, and the subsequent tests were based on this value. The pure tone signal was continuously released by the signal generator and placed outside the tunnel through the loudspeaker. After the sound was stable, the equivalent continuous A-weighted sound pressure level within 10S was measured by the sound level meter at the specified measuring point. Based on the requirements for the height of the sensor from the ground in the indoor measurement of noise-sensitive buildings and the requirements of the human ear for the height of noise acceptance, the height of the sound level meter from the ground was 1.2 m. Repeated the measurement for each measuring point 3 times, then changed the measuring point after the measurement was completed. After all measuring points were measured, stopped the signal generator from vibration. Finally, adjusted the frequency and restarted the vibration measurement.

Figure 6.

Test flow chart of Case I.

The noise frequency in the tunnel is mainly distributed in 250–1000 Hz, and there is no need to analyze each frequency in the spectrum analysis of the sound signal. Therefore, in this experiment, the octave bandwidth was selected as the analysis bandwidth, which was 125 Hz, 250 Hz, 500 Hz, 1000 Hz, and 2000 Hz.

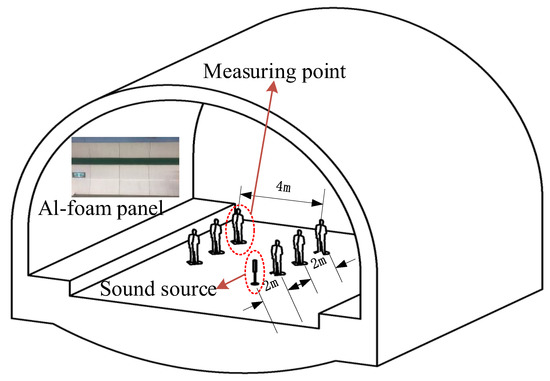

The groups affected by noise in the tunnel are mainly the staff at the shoulder of the road and the drivers in the car, so the measuring points were arranged at the center line of the tunnel and the shoulder of the road. In order to explore the distribution law of the sound absorption effect along the longitudinal direction of the tunnel, the measuring points were arranged at a longitudinal distance of 2 m, 4 m and 6 m from the sound source, as shown in Figure 7. This test was carried out following the installation progress of the aluminum foam boards in the tunnel. Repeated tests were carried out in three stages: before installation, one-sided installation is completed, and two-sided installation is completed. The detail can be seen in Figure 6.

Figure 7.

Sound source and measuring point layout.

Table 2 shows all 30 working conditions that need to be tested in Case I, and each working condition was tested repeatedly 3 times. In order to reduce the interference of external sound and ensure the accuracy of the data, when the deviation between the maximum value and the minimum value of the three data in a working condition exceeds 1 dB(A), the measurement shall be performed again.

Table 2.

Test condition of Case I.

3.4. Case II

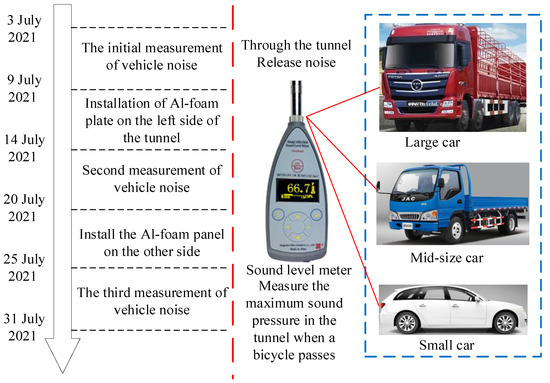

Case II mainly studies the sound absorption performance of closed-cell aluminum foam under moving sound sources, that is, the research on the insertion loss of closed-cell aluminum foam boards in tunnels. By comparing the maximum sound pressure level of the vehicle from entering the tunnel to leaving the tunnel before and after the installation of the aluminum foam board, then the effect of the aluminum foam board in the noise reduction application of the tunnel was obtained. The noise generated by the vehicle was affected by the type of vehicle, use time, brand and speed. In the field measurement of highway tunnels, it is impossible to adopt a unified standard for past vehicles. Therefore, the vehicle is divided into large, middle and small categories according to the size of the vehicle, limit the speed of the vehicle on the lane, collect large amounts of data and other methods to reduce the impact on the test results caused by the above reasons.

The test of Case II is similar to that of Case I. Following the installation progress of the aluminum foamed board, the test was also carried out in three stages before installation, one-sided installation is completed, and two-sided installation is completed, as shown in Figure 8. Before the test, the two lanes were blocked at 500 m from the entrance and only allowed to pass through the only lane, which can achieve the effect of limiting the speed of the vehicle and avoid some accidental noise interference caused by the lane change when the car is driving. During the test, turn on the continuous sampling function in the sound level meter when the vehicle enters the tunnel. The sampling interval of the sound level meter is 1S. When the vehicle exits the tunnel, stop sampling and read the maximum instantaneous A-weighted sound pressure level during the sampling period. For each vehicle type, at least 100 data samples were taken in each test, and the 100 data samples were divided into 10 groups evenly, and the average value of each group was calculated as the representative value of this group. Finally, the representative values were analyzed to explore the noise reduction law of closed-cell aluminum boards in tunnels.

Figure 8.

Test flow chart of Case II.

4. Results and Discussion

For different test purposes, this article gave two test methods under different working conditions. And in this section, we will analyze the results measured by the above method, and explain the sound absorption effects of the closed-cell aluminum foam board under the fixed pure sound source and the moving sound source. Furthermore, the sound absorption performance of the closed-cell aluminum foam board in the tunnel was comprehensively evaluated.

4.1. Test Results of Fixed-Point Pure Tone in the Tunnel

Case I studied the sound absorption performance of closed-cell aluminum foam board under fixed pure tone. The method adopted combined the loudspeaker test method with the typical tunnel measurement. Considering the process of field test and the key factors affecting the sound field distribution of the tunnel, the position, distance and frequency were taken as the key points to analyze which may have the effects on sound absorption under the fixed-point pure sound source.

- (1)

- Effect of location and distance

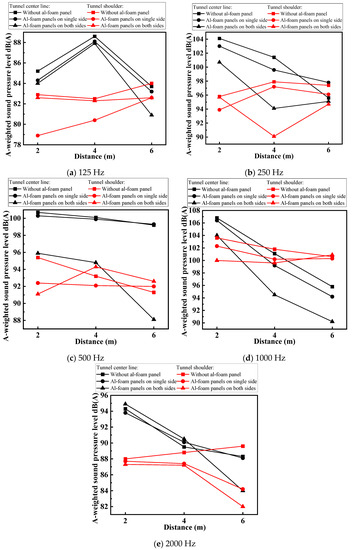

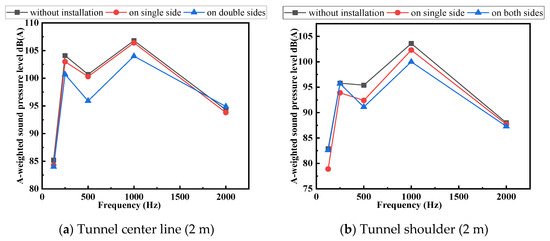

Figure 9a–e not only show the distribution law of the sound field inside the tunnel, but also show the sound absorption effect of closed-cell aluminum foam boards under different sound field positions and distances. On the whole, the sound pressure at the center line of the tunnel is slightly greater than that at the tunnel shoulder. This is because the sound source of the tunnel is arranged on the center line of the tunnel. The linear distance between the measuring point on the center line is larger than the measuring point at the shoulder of the same cross section, so the sound energy has a longer dissipation distance. In addition, it can be found that the farther away from the sound source, the smaller the sound pressure level measured no matter the measurement is on the centerline of the tunnel or the shoulder of the road. This is because the longer the distance, the more the sound energy is dissipated. However, there are special cases that do not conform to the general rules in the data points measured this time. For example, the equivalent continuous A-weighted sound pressure level measured at the measurement which is on the center line of the tunnel and 4 m away from the sound source at 125 Hz is obviously greater than the distance is 2 m and 6 m; the sound level measured at the shoulder 6 m longitudinal distance from the sound source at 1000 Hz is higher than that measured at the tunnel midline. This is because the pure tone signal released is a sine wave. The positive superposition of the amplitude of the reflected sound wave and the direct sound wave at these measuring points enhances the sound pressure level, while the superposition of the reflected acoustic wave and the direct acoustic wave at other locations is very weak or the superposition is reversed.

Figure 9.

Influence of location and distance.

From these five pictures, it can be seen that after the aluminum foamed boards were installed on one side, the results measured at each measuring point have a certain decrease compared with the unlaid aluminum foamed boards but the reduction is not large. After the double-sided aluminum foam boards were installed, the measured results at each measuring point were significantly reduced. This is because the sound waves reflected from the side where the aluminum foam boards were not installed, and interfere with the direct sound waves. When the double-sided aluminum foam boards were installed, the reflected sound waves on both sides were affected. Comparing the slopes of the curves of the three test results, it can be seen that the slope of the results measured after the aluminum foam boards were installed on both sides is significantly greater than that of the single-sided installation and non-installation. From this analysis, we can see that the equivalent continuous A-weighted sound pressure level in the tunnel that the aluminum foam boards were installed on both sides drops faster along the longitudinal direction of the tunnel, which means that the installation of aluminum foam boards on both sides has the best noise reduction effect on the sound in the tunnel.

Analyzed from the position, the measured results at the center line of the tunnel vary significantly more than the shoulder of the tunnel. From the results measured at the road shoulder, the closed-cell aluminum foam also has a certain sound absorption effect on the noise at the road shoulder, but the sound absorption capacity is limited, so the line graph shows the characteristics of small slope and flatness. However, the noise reduction is more obvious at the center line of the tunnel. The possible reason is that the interference between the reflected sound wave and the reflected sound wave at the shoulder of the road closer to the side wall is more obvious, and the interference between the reflected sound wave and the direct sound wave is also more obvious, but at the center line of the tunnel, the interference effect between the reflected sound wave and the reflected sound wave is weakened. From the distance point of view, the farther away from the sound source, the reflected sound wave can go through more reflections, and there is enough distance for the sound energy to be dissipated, whether it is in the center line of the tunnel or at the shoulder of the road.

In general, the noise reduction effect at the center line of the tunnel is better than that at the tunnel shoulder in the noise reduction of the tunnel, and the longer the distance, the more obvious the noise reduction effect. The noise reduction effect of the double-sided aluminum foam board is better than that of the single-sided aluminum foam board and the unmounted aluminum foam board. The single-sided aluminum foam board has a small noise reduction effect.

- (2)

- Effect of frequency

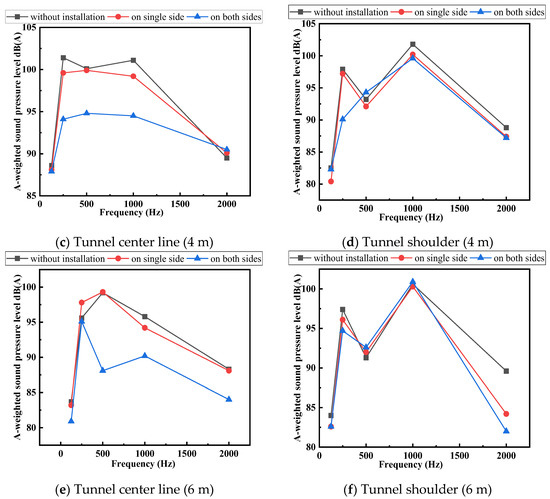

Figure 10a–f reveal the sound absorption performance of closed-cell aluminum foam boards for pure sounds at different frequencies. In general, the equivalent continuous A-weighted sound pressure level measured in the tunnel presents a M-shaped distribution, that is, the equivalent continuous A-weighted sound pressure level is higher at the frequency of 250 Hz and 1000 Hz, and the results measured at the frequency of 125 Hz and 2000 Hz are very low.

Figure 10.

Influence of frequency.

As for the insertion loss, the closed-cell aluminum foam board has the best sound absorption effect for pure sound with a frequency of 250–1000 Hz. According to the relationship between the speed of sound, frequency and wavelength, for pure sound with a frequency lower than 250 Hz, since the speed of sound is equal to the product of wavelength and frequency, the sound wave has a longer wavelength at low frequencies. However, the average pore diameter of closed-cell aluminum foam is only 5 mm, so the scattering effect of aluminum foam surface on low frequency acoustic wave is very weak. In addition, there are cavities behind the aluminum foam boards that were drilled, so the entire installation structure of the aluminum foam boards can be regarded as a structure in which multiple Helmholtz resonators are connected in parallel. According to the principle of resonance sound absorption, the natural frequency of the aluminum foam board is just close to the testing frequency, so when sound waves of the same frequency are transmitted to the aluminum foam boards, it can achieve the effect of sound absorption and noise reduction by resonate.

From the discount slope in Figure 10, it can be seen that the sound absorption performance of the closed-cell aluminum foam for pure tones with frequencies between 250–1000 Hz is relatively similar, while the sound absorption effect of closed-cell aluminum foam board increases rapidly from 125 Hz to 250 Hz. Besides, from 1000 Hz to 2000 Hz, the sound absorption effect of closed-cell aluminum foam board decreased obviously.

By comparing the figures of left column and right column, it can be seen that the influence of frequency on sound absorption effect of closed-cell aluminum foam board is more obvious at the center line of tunnel. At the shoulder, the influence of frequency on sound absorption effect is relatively small.

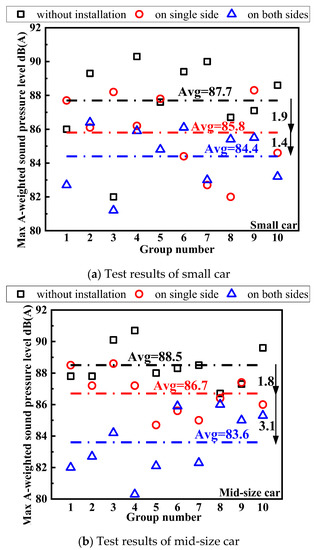

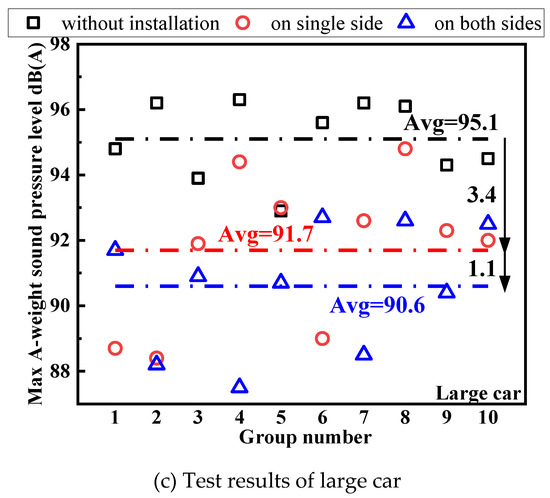

4.2. Test Results of Car Noise in the Tunnel

Case II mainly studies the sound absorption performance of closed-cell aluminum foam under moving sound sources. Analysis of the measurement results in Case II can more accurately reveal the noise reduction effect of closed-cell aluminum foam boards on vehicle noise in tunnels. Since the impact of the vehicle model on the noise generated was considered in the test, when analyzing the possible noise reduction effect of closed-cell aluminum foam in tunnel applications, the analysis was carried out according to the three common vehicle models in the tunnel, as shown in Figure 11a–c.

Figure 11.

Test results of Case II.

It can be seen from the above that each point in the figure is the representative value of the average of 10 test data. It can be seen from the figure that when the aluminum foam board is not installed, the noise generated by the large car in the tunnel is the largest, and the maximum instantaneous A-weighted sound pressure level reaches 95.1 dB(A). The sound pressure level of noise produced by small cars is slightly lower than that of mid-sized cars, at 87.7 dB(A) and 88.5 dB(A) respectively. After the single-sided aluminum foam boards were installed, the noise generated by small and middle-sized cars is decreased to a limited extent. The maximum instantaneous A-weighted sound pressure level in the tunnel when a bicycle passes through the tunnel is reduced by less than 2 dB(A). However, the single-sided aluminum foam board has a more obvious reduction effect on the traffic noise generated by large vehicles, which is reduced by 3.4 dB(A). The attenuation of the vehicle noise by the double-sided aluminum foam boards is greater than the vehicle noise when installed on single side or not installed. After installation on both sides, the noise attenuation for medium-sized cars is the strongest, reaching 4.9 dB(A). The vehicle noise reduction for small cars and large cars are 3.3 dB(A) and 4.5 dB(A). This may be due to the fact that the frequency of the noise generated by the medium-sized car is closer to the natural frequency of the aluminum foam board structure.

5. Field Application Effect Evaluation

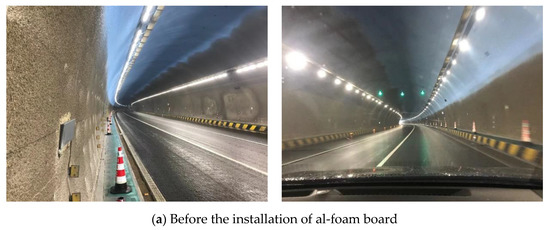

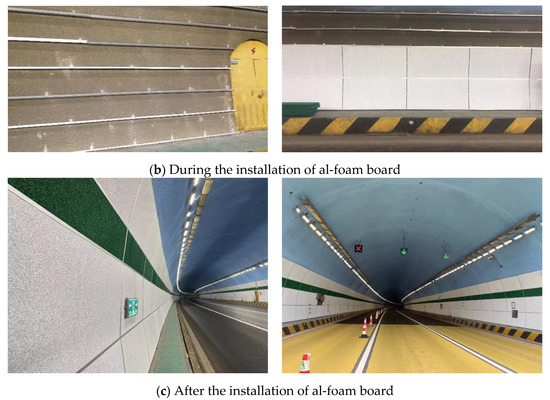

Closed-cell aluminum foam is a kind of material with both fire prevention and sound absorption and noise reduction functions. The Haoshanyu Tunnel on the Qinglan Expressway has become the first expressway tunnel in China to complete the whole line laying of aluminum foam board due to the needs of noise reduction and fire prevention improvement. The field performance of closed-cell aluminum foam board in the tunnel before installation, during installation and after installation were shown in Figure 12. Before the installation, the concrete on both side walls of the tunnel lacked fire protection treatment, which can be seen from the on-site photos before installation. According to the relevant regulations in China’s “Code for Fire Protection of Building Design” GB 50016-2014, it is known that the interior decoration in the tunnel should be made of non-combustible materials, and the temperature of the concrete surface should not exceed 380 °C. The closed-cell aluminum foam has a good effective thermal conductivity at high temperatures [27], and its installation in the tunnel perfectly compensates for the lack of fire protection and meets the national fire protection standards.

Figure 12.

Comparison of the effect before and after installation of the al-foam board.

According to the relevant requirements in the “Regulations of the People’s Republic of China on the Prevention and Control of Environmental Noise Pollution”, “Urban Area Environmental Noise Standards” GB 3096-93, and “External Noise Limits and Measurement Methods for Accelerated Vehicles” GB 1495-2002, the maximum allowable noise level generated by trucks traveling in tunnels is 89 dB, which does not exceed 85 dB for small cars. According to the above field test results, before the aluminum foam boards were installed on both sides of the tunnel, the noise of vehicles in the tunnel is higher than the standard. After the installation of the aluminum foam board, the vehicle noise generated by small and medium-sized cars in the tunnel has been lower than the standard value. However, the noise generated by the large truck is still slightly higher than the standard value after noise reduction treatment, the possible reason is the influence of noise that is unavoidable in the test. Generally speaking, it has a good noise reduction effect.

In summary, the laying of aluminum foam boards on the entire line of the Haoshanyu Tunnel of the Qinglan Expressway not only improves the fire prevention and noise reduction capabilities in the tunnel, but also beautifies the tunnel environment, and play a very good effect in the field application. In addition, aluminum foam boards are more economical than fire-resistant panels and sound-absorbing panels. The aluminum foam boards have a service life of up to 50 years and can be recycled and reused with ultra-high value. Therefore, it has very good application prospects in tunnels.

6. Conclusions

Relying on the Qinglan Expressway Haoshanyu Tunnel full line installation of closed-cell aluminum board project. Aiming at the two different working conditions of fixed pure sound source and mobile sound source, combining the existing loudspeaker test and typical tunnel measurement, the two new methods are proposed to measure the sound absorption performance of closed-cell aluminum foam in the tunnel.

(1) Using the method that proposed in Case I in this paper, it is found that the closed-cell aluminum foam has a better sound absorption performance for sounds with a frequency of 250~1000 Hz, and the noise reduction effect at the center line of the tunnel is better than that at the shoulder of the tunnel. As the distance increases, the reflected sound waves are dissipated more, and the farther away from the sound source, the more obvious the sound absorption effect.

(2) The test results of the two test methods given in this paper are comprehensively analyzed. Overall, the closed-cell aluminum foam board can play a certain sound absorption and noise reduction effect in the tunnel. The application of closed-cell aluminum foam board as a new noise reduction material in the tunnel is feasible. However, due to the acoustic characteristics of the closed-cell aluminum foam board itself and the lack of installation methods, the sound absorption effect is not obvious. However, it can be changed by drilling to improve the sound absorption performance.

Author Contributions

Conceptualization, Z.L.; methodology, Z.L.; validation, W.G., L.W. and J.S.; investigation, H.Z.; resources, J.H.; data curation, B.Z.; writing—original draft preparation, Z.L.; writing—review and editing, B.Z.; supervision, J.H.; project administration, W.G.; funding acquisition, W.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Shandong Province Enterprise Technology Innovation Project ‘Research and Application of Noise Reduction and Refractory Functional Materials for Highway Tunnels’.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Some or all data, models, or code generated or used during the study are available from the corresponding author by request.

Acknowledgments

This research was funded by Shandong Province Enterprise Technology Innovation Project ‘Research and Application of Noise Reduction and Refractory Functional Materials for Highway Tunnels’.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gong, C.; Ding, W.; Mosalam, K.M.; Günayc, S.; Sogac, K. Comparison of the structural behavior of reinforced concrete and steel fiber reinforced concrete tunnel segmental joints. Tunn. Undergr. Space Technol. 2017, 68, 38–57. [Google Scholar] [CrossRef]

- Ding, W.; Gong, C.; Mosalam, K.M.; Soga, K. Development and application of the integrated sealant test apparatus for sealing gaskets in tunnel segmental joints. Tunn. Undergr. Space Technol. 2017, 63, 54–68. [Google Scholar] [CrossRef]

- Lei, M.; Zhu, B.; Gong, C.; Ding, W.; Liu, L. Sealing performance of a precast tunnel gasketed joint under high hydrostatic pressures: Site investigation and detailed numerical modeling. Tunn. Undergr. Space Technol. 2021, 115, 104082. [Google Scholar] [CrossRef]

- Zeng, S. Analysis of the influence of the characteristics of mountain soil and the noise in the tunnel on people: Active noise control system. Arab. J. Geosci. 2021, 14, 912. [Google Scholar] [CrossRef]

- Kang, J. A method for predicting acoustic indices in long enclosures. Appl. Acoust. 1997, 51, 169–180. [Google Scholar] [CrossRef]

- Kang, J. The Unsuitability of the Classic Room Acoustical Theory in Long Enclosures. Archit. Sci. Rev. 1996, 39, 89–94. [Google Scholar] [CrossRef]

- Li, K.M.; Iu, K.K. Propagation of sound in long enclosures. J. Acoust. Soc. Am. 2004, 116, 2759–2770. [Google Scholar] [CrossRef]

- Liu, J.C. Sound propagation in long enclosures with a vertical or inclined branch. Appl. Acoust. 2006, 67, 1022–1030. [Google Scholar] [CrossRef]

- Wang, G.; Smith, G.; Shores, R. Pavement noise investigation on North Carolina highways: An on-board sound intensity approach. Can. J. Civ. Eng. 2012, 39, 878–886. [Google Scholar] [CrossRef]

- An, D.; Lee, J.; Ohm, B.; Son, H.; Kwon, S. A study of pavement noise for asphalt pavements with different service life in national highway. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Kaist, Korea, 16–19 November 2014. [Google Scholar]

- Fang, J.; Tu, J.; Wu, K. Analysis of Skid Resistance and Noise Characteristics for Varieties of Concrete Pavement. Adv. Mater. Sci. Eng. 2020, 2020, 1–8. [Google Scholar] [CrossRef]

- Gupta, P.; Parey, A. To investigate the influence of sound-absorbing materials on the transmission loss of double-wall panel. Mater. Today Proc. 2021, 44, 1500–1503. [Google Scholar] [CrossRef]

- Xu, X.B.; Liu, P.S.; Chen, G.F.; Li, C.P. Sound Absorption Performance of Highly Porous Stainless Steel Foam with Reticular Structure. Met. Mater. Int. 2021, 27, 3316–3324. [Google Scholar] [CrossRef]

- Liang, L.S.; Wu, X.L.; Ma, N.N.; Du, J.J.; Liu, M.B. The Sound Absorption Properties Comparison of Metal Foams and Flexible Cellular Materials. Materials Science Forum; Trans Tech Publications Ltd.: Zürich, Switzerland, 2018; pp. 357–366. [Google Scholar]

- Opiela, K.C.; Zieliński, T.G.; Dvorák, T.; Kudela, S., Jr. Perforated closed-cell aluminium foam for acoustic absorption. Appl. Acoust. 2021, 174, 107706. [Google Scholar] [CrossRef]

- Umnova, O. Propagation of Sound in Porous Media: Modelling of Sound Absorbing Materials. J. Sound Vib. 2010, 329, 4333–4334. [Google Scholar]

- Allard, J.F.; Daigle, G. Propagation of Sound in Porous Media: Modeling Sound AbsorbingMaterials. J. Acoust. Soc. Am. 1994, 95, 2785. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Li, Z.; Han, F. Air Flow Resistance and Sound Absorption Behavior of Open-celled Aluminum Foams with Spherical Cells. Procedia Mater. Sci. 2014, 4, 187–190. [Google Scholar] [CrossRef] [Green Version]

- Lu, T.J.; Chen, F.; He, D. Sound absorption of cellular metals with semiopen cells. J. Acoust. Soc. Am. 2000, 108, 1697–1709. [Google Scholar] [CrossRef] [PubMed]

- Lu, T.J.; Hess, A.; Ashby, M.F. Sound absorption in metallic foams. J. Appl. Phys. 1999, 85, 7528–7539. [Google Scholar] [CrossRef]

- Akiwate, D.C.; Date, M.D.; Venkatesham, B.; Suryakumar, S. Acoustic characterization of additive manufactured perforated panel backed by honeycomb structure with circular and non-circular perforations. Appl. Acoust. 2019, 155, 271–279. [Google Scholar] [CrossRef]

- Wang, K.; Wang, W.; Yan, X. Effect of hole on sound absorption coefficient of micro-perforated panels investigated by Melling computing. Concurr. Comput. Pract. Exp. 2019, 31, e4725. [Google Scholar] [CrossRef]

- Byakova, A.; Gnyloskurenko, S.; Bezimyanniy, Y.; Nakamura, T. Closed-Cell Aluminum Foam of Improved Sound Absorption Ability: Manufacture and Properties. Metals 2014, 4, 445–454. [Google Scholar] [CrossRef] [Green Version]

- Xia, X.; Zhang, Z.; Zhao, W.; Li, C.; Ding, J.; Liu, C.; Liu, Y. Acoustic properties of closed-cell aluminum foams with different macrostructures. J. Mater. Sci. Technol. 2017, 33, 1227–1234. [Google Scholar] [CrossRef]

- Cheng, W.; Duan, C.-Y.; Liu, P.-S.; Lu, M. Sound absorption performance of various nickel foam-base multi-layer structures in range of low frequency. Trans. Nonferrous Met. Soc. China 2017, 27, 1989–1995. [Google Scholar] [CrossRef]

- Kim, S.Y.; Park, S.H.; Um, Y.S.; Hur, B.Y. Sound Absorption Properties of Al Foam. Materials Science Forum; Trans Tech Publications Ltd.: Zürich, Switzerland, 2005; pp. 468–471, 486–487. [Google Scholar]

- Ye, H.; Ma, M.; Ni, Q. An experimental study on mid-high temperature effective thermal conductivity of the closed-cell aluminum foam. Appl. Therm. Eng. 2015, 77, 127–133. [Google Scholar] [CrossRef]

- Ye, H.; Ma, M.; Yu, J. Anomalies in mid-high-temperature linear thermal expansion coefficient of the closed-cell aluminum foam. Chin. Sci. Bull. 2014, 59, 3669–3675. [Google Scholar] [CrossRef]

- Navacerrada, M.A.; Fernández, P.; Díaz, C.; Pedrero, A. Thermal and acoustic properties of aluminium foams manufactured by the infiltration process. Appl. Acoust. 2013, 74, 496–501. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).