Abstract

This publication presents changes in sawdust of selected deciduous trees as a consequence of impulse electric field (PEF) stimulation. The analyzed changes concerned the time–temperature characteristics created during the measurement of the heat of combustion of the audited material. Based on experience from previous studies, two alternatives of electric field strength and one variant of capacitor discharges (pulses) were adopted. The results were compared with the sample not treated with PEF. The selected parameters were the result of previous studies, in which the applied variants seemed to be the most promising, i.e., they gave the most diverse results. The research presented in this work has shown that the pulsed electric field affects the time and temperature characteristics of biological material. The changes are most pronounced for the last period of the combustion process, from the moment the maximum temperature was reached to the end of the process. The obtained results indicate that birch and ash react to PEF conditioning in a similar manner. The second group, due to the similarity of the obtained results, is oak and linden. It seems that, apart from the electric field strength, the obtained results are also influenced by the cellulose content in the tested wood. The described process has a very low energy-efficiency, but the reduction of the energy needed to generate the impulse could lead to the possibility of applying the obtained results in industry.

1. Introduction

Among the multitude of energy sources used to generate both electricity and heat, biomass is considered the most promising fuel in many countries [1,2,3,4]. This opinion is confirmed by the fact that statistically, biomass is one of the most-used energy sources in the world [2]. An even greater increase in the share of energy derived from the combustion of wood biomass was seen in energy plants such as willow (Salix viminalis) or poplar (Populus tremula). However, in retrospect, these systems turned out to be economically unprofitable. The reason for this is that growth is not fast enough to achieve profitable biofuel production [5]. Therefore, various, often highly advanced technologies began to be used to transform the energy contained in the wood of trees [6,7,8,9]. From the point of view of energy use of fuel (including wood), some of the most important physicochemical parameters are the heat of combustion and the calorific value [10,11]. The aforementioned parameters may have different—often very different—values, even for the same fuel. An example is birch wood, which in an air-dry state can reach a calorific value from 17.90 MJ∙kg−1 [12] to 18.72 MJ∙kg−1 [13]. The heat of combustion is influenced by many factors, including the content of nonflammable parts (often due to contamination of the wood) and the water content. Water in wood may be present in the form of transient moisture, which is the result of the material and the surrounding air reaching the moisture balance, as well as permanent moisture, i.e., that stored in the cell walls and in the spaces between dead cells [14,15]. Usually, the determination of the heat of combustion is carried out with the use of a calorimeter. The combustion process in the calorimetric bomb is automatically registered. Due to this, it is possible to determine the duration of individual combustion stages and the temperature increase, which is an indirect measurement of the temperature of the medium receiving heat from the bomb body [16]. As a result of this registration, a time–temperature characteristic is created. To obtain reliable data, it is also necessary to designate the so-called corrected temperature-rise and corrections for heat exchange between the calorimeter and the thermostat [17].

Some researchers suggest that using appropriate conditioning of biological material, it is possible to modify the heat of combustion of this material [18,19,20,21,22]. Thermal methods constitute a large group among the methods of pretreatment of biological material. The action of the temperature factor contributes to the improvement of the mass exchange conditions, but at the same time, irreversibly changes some properties of the conditioned products, such as their color or the amount of biologically active compounds [23,24,25]. However, from the perspective of wood used for combustion in energy-generating installations, these negative effects are of minor importance. Among the techniques of nonthermal processing, the use of high voltage pulses, which generate a time-varying electric field—PEF (Pulsed Electric Field), is becoming interesting and gaining popularity [26,27,28]. PEF causes the effect of electroporation in biological material, i.e., changes in the structure of the cell membrane by enlarging the existing or creating new pores of the membranes. The resulting perforation of the natural structure of the cell membrane causes the diffusion of water. Thus, the resistance to mass movement is reduced, which contributes to osmotic dehydration, acceleration of the drying process, and improvement of the extraction conditions [29,30].

The aim of the research presented in this study was to determine the effect of pulsed electric field on the time–temperature characteristics of the heat of combustion of selected broadleaved wood species by determining the combustion curve for each of the analyzed variants.

2. Materials and Methods

The research material selected for analysis in this study was sawdust from four broad-leaved trees, i.e., birch, oak, linden, and ash tree. The sawdust was subjected to a pulsed electric field with an electric field intensity of 25 kV∙cm−1 and the number of 300 capacitor discharges (pulses) and an electric field intensity of 30 kV∙cm−1, where the number of 300 capacitor discharges (pulses) was also used. The results were compared with the sample not treated with PEF. The selected parameters were the result of previous studies [31], in which the applied variants seemed to be the most promising, i.e., they gave the most diverse results. A constant time between successive capacitor discharges (pulses) was assumed, regardless of the test variant used. The entire research process, i.e., preparation of the material for research, its conditioning, and measurement of the calorific value was carried out at the Laboratory of Experimental Research Techniques for Biological Products and Raw Materials, which is part of the University of Agriculture in Krakow.

In addition to comparing the results of studies of individual broadleaved tree species with a different number of discharges (pulses), a so-called blank sample was also introduced. It was made of a material that had not been treated with PEF.

Conditioning of sawdust with pulsed electric field was performed on the Ertec Su-1 stand (Figure 1a) used daily as a tool for low-temperature inactivation of microorganisms in food products. For the purposes of this research, minor adjustments were made to the stand. The PEF interaction device consists of a high-voltage pulse generator, a working chamber, and a control system. In the apparatus used in these tests, it is possible to generate a voltage up to 31 kV, which—with a distance between bases of the cylinder of c—gives a maximum electric field strength of 31 kV∙cm−1. The station is equipped with control programming that enables process conditions to be set for several hundred PEF pulses, with widths from 1 to 400 µs and spacing between them in the range of 1–10 s. The generated pulses have an exponential shape. The average energy consumption when generating a single impulse is 65.6 mWh, with a variation coefficient of 6.9% [31].

Figure 1.

Ertec Su-1 test stand: (a) discharge chamber; (b) stationary sterilization cell.

A detailed description of the devices used in this study was described in the previous article by the authors [32], where analogous studies were carried out for sawdust from coniferous trees.

Properly prepared sawdust, constituting the test material, was introduced into a stationary sterilization cell (Figure 1b). The material tightly filled the 1 cm wide space between the steel cylinders. The remainder of the cell is made of Teflon dielectric. The cells were introduced into the stand chamber, where the electrodes were attached to the bases of the cylinder. In the presented research, stimulation with a pulsed electric field was used with a pulse time width of 160 µs and a time between successive discharges equal to 10 s.

In accordance with the requirements set by the accredited laboratories, before starting the experiments, the material was homogenized and dried to an air-dry state in accordance with the EN 14780:2017-07 standard [33]. In accordance with the assumption presented earlier, a control sample, also known as a blank sample, was separated from the stabilized material (within each species of wood). In each of the variants, the moisture content in the analytical state was tested in accordance with the EN ISO 18134-3:2015 standard [34]. For samples of the material subjected to the pulsed electric field, the measurement of analytical moisture was carried out both before and after stimulation. This was to exclude any discrepancies in the obtained results of the heat of combustion, which, if the control was not carried out, could be caused not by the action of PEF itself, but by a reduction of the water content in the tested material. The value of 0.1% was adopted as the limit of reproducibility of the moisture results. The combustion heat of the tested biological material was determined by the method of combustion in a calorimetric bomb, based on the EN ISO 18125:2017 standard [17].

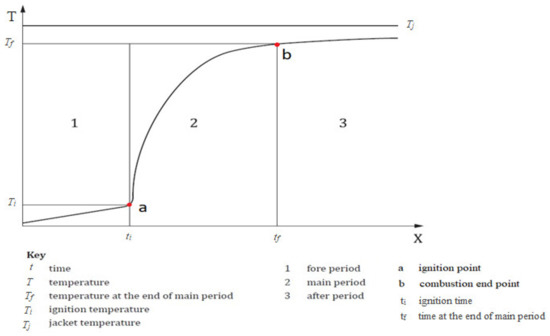

The measurement is based on the combustion of a fuel sample in the amount of 1 ± 0.1 g in a vessel called a calorimetric bomb. A special nickel–chromium wire, pressed in its central part into the material, is connected to the electrodes that extend outside the vessel. The bomb is tightly closed and filled with oxygen. The excess gas guarantees the correct combustion stoichiometry. The thus-prepared element of the station is introduced into a vessel of known capacity, previously filled with water. The water jacket surrounding the calorimetric vessel is the thermal insulation from the environment. The only elements protruding above the water level are the electrode leads, which are connected to the central unit of the station. After stabilizing the water temperature with the use of a stirrer, current flows through the electrodes, and the resistance wire in direct contact with the fuel sample causes it to ignite. The calorimeter measures and then automatically records three characteristic temperature values, three basic time-temperature periods of the combustion process and, most importantly, to determine the heat of combustion, the temperature and time at which ignition occurred and the combustion period ended. All the listed elements of the characteristics are shown in Figure 2 [17]. Due to the methodology used and the low density of sawdust, the material had to be compressed with a manual press before taking measurements. Only such a prepared portion could be used to make measurements.

Figure 2.

Example time-temperature curve from EN ISO 18125:2017-07.

Based on the designated characteristics and knowing the sample quantity of the tested material, as well as the content of nitrogen and sulfur (determined by titration in accordance with the method presented in the above-mentioned standard [17]), it is possible to determine the value of the heat of combustion.

The hypothesis about the existence of a normal distribution among the obtained results was verified based on the Kolmogorov–Smirnov test, at the significance level of α = 0.05. This is a nonparametric significance test that gives you the opportunity to check whether two populations have the same distribution most commonly used for exponential distributions. Afterwards, selected basic descriptive statistics significant due to the described phenomena were calculated in accordance with ISO standards [35].

3. Results

Each of the tested materials (birch, oak, linden, and ash tree) was subjected to a separate analysis.

3.1. Birch Sawdust

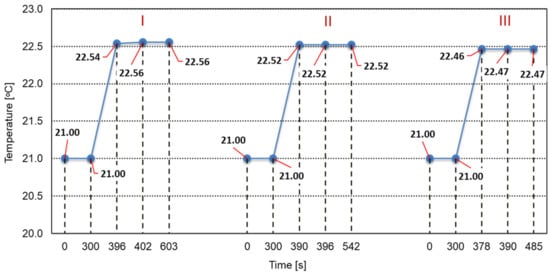

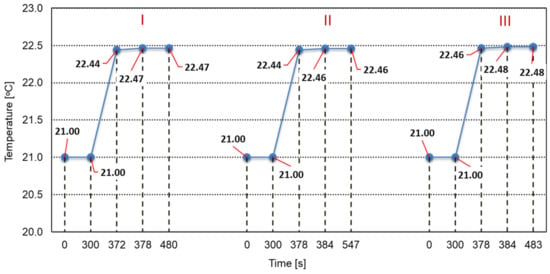

Birch sawdust samples, both those that were not conditioned with PEF and those that were the control sample, had analytical moisture at the level of 7.7 ± 0.1%. By analyzing the temperature characteristics during combustion of the biological material, which was birch (Figure 3), it was found that the highest temperature was obtained for the sample not exposed to a pulsed electric field. PEF-conditioned sawdust with an electric field strength of 30 kV∙cm−1 and a number of pulses of 300 showed the lowest temperature during material combustion. For birch sawdust, in all three variants used, the temperatures obtained at individual points of the characteristic were characterized by low variability. These results indicate that for a given biological material, no significant influence of PEF on the temperature characteristics of the combustion process was observed. It was found that the obtained differences are not statistically significant and are not of great importance for the entire analyzed process.

Figure 3.

Temperature characteristics of individual variants of birch three combustion: I (nonconditioned with a pulsed electric field) and conditioned with a pulsed electric field: II (electric field intensity 20 kV·cm−1 and number of pulses 300); III (electric field intensity 30 kV·cm−1 and number of pulses 300).

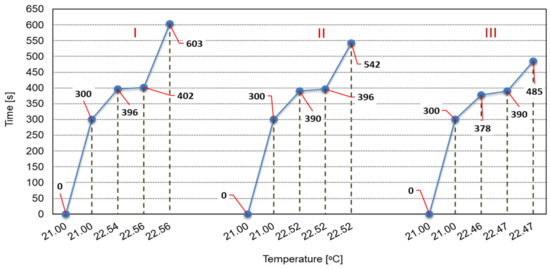

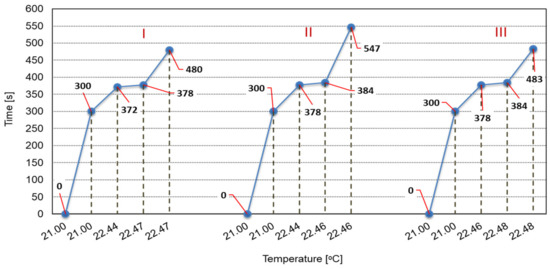

The second of the analyzed elements of the heat of combustion characteristics is the duration of individual stages of the combustion process. The main period seems to be particularly important when there is a rapid increase in the measured temperature as a result of heat released by the combustion sample. Nevertheless, the total duration of the process seems to be important, taking into account not only the period of temperature rise, but also the interval, including the time when the high temperature is kept constant. Figure 4 shows the time characteristics of individual stages of calorimetric tests on birch, previously subjected to stimulation with an impulse electric field, and compared with the control sample.

Figure 4.

Time characteristics of individual combustion stages of a of birch tree: I (nonconditioned with a pulsed electric field) and conditioned with a pulsed electric field: II (electric field intensity 20 kV·cm−1 and number of pulses 300); III (electric field intensity 30 kV·cm−1 and number of pulses 300).

It was found that both the entire combustion process and the main period (from ignition to reaching the maximum temperature) lasted the longest for the sample nonconditioned with a pulsed electric field. These times were 603 s and 96 s, respectively. As the electric field intensity increased, the periods mentioned were decreasing and in the case of material under the influence of PEF with an electric field intensity of 30 kV·cm−1, where the number of pulses was 300, they were shorter by 118 s and 18 s, respectively. These differences are significant in terms of absolute values. Much less within the range of interest for the setting phenomenon, it represents a significant proportion of the value. It proves the measurable effect of the pulsed electric field on the biological material

3.2. Oak Sawdust

Oak sawdust samples, both those that were not conditioned with PEF and those that were the control sample, had analytical moisture at the level of 7.2% ± 0.1%. Analyzing the temperature characteristics during combustion of biological material, i.e., oak sawdust, previously subjected to the impulse electric field (Figure 5) and without the influence of PEF, it was found that the temperature differences are insignificant—the temperature changes reached a maximum of three hundredths of a degree Celsius. The highest temperature was obtained for PEF with an electric field strength of 20 kV·cm−1, where the number of pulses was 300. The lowest combustion temperature concerned sawdust that was not subjected to the pulsating electric field. As in the case of sawdust from birch wood, the obtained differences are not statistically significant and are not of great importance for the entire analyzed process.

Figure 5.

Temperature characteristics of individual variants of oak three combustion: I (nonconditioned with a pulsed electric field) and conditioned with a pulsed electric field: II (electric field intensity 20 kV·cm−1 and number of pulses 300); III (electric field intensity 30 kV·cm−1 and number of pulses 300).

In the case of the time from ignition to reaching the maximum temperature, no significant differentiation of the obtained results was observed, but the total burning time of the materials was clearly different for individual variants. Figure 6 shows the time characteristics of individual stages of calorimetric tests on oak sawdust previously exposed to a pulsating electric field, compared to the control sample. It was found that the longest duration of the discussed process was obtained for the interaction of PEF with the parameters of the second combination (electric field strength 20 kV·cm−1 and number of pulses 300), while the shortest time was obtained for the third combination of the experiment.

Figure 6.

Time characteristics of individual combustion stages of oak tree: I (nonconditioned with a pulsed electric field) and conditioned with a pulsed electric field: II (electric field intensity 20 kV·cm−1 and number of pulses 300); III (electric field intensity 30 kV·cm−1 and number of pulses 300).

Referring to the characteristics representing the time of individual stages of the combustion process, it can be seen that in the second phase, from the recording of the second temperature to the recording of the third temperature, the values for the material treated with PEF were the same. At the same time, this stage was extended by 6 s in relation to the analogous stage of burning the unconditioned sample. In the case of the last combustion phase (the difference between the time values recorded for the fifth and fourth temperatures), much greater differences in their duration were noted. It should be emphasized that there was a difference of over a minute in the duration of the phase between the combinations of experiments II and II, where the differentiation of the stimulation resulted only from the applied intensity of the electric field of the discharge with the same number of pulses. The difference between combinations I and III is insignificant and amounts to 8 s. The trend noted for birch wood was not repeated in the case of beech wood.

3.3. Linden Sawdust

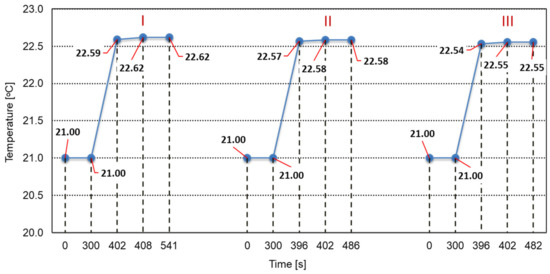

The linden sawdust samples were characterized by analytical moisture at the level of 8.1%. As a result of exposure to a pulsating electric field, their humidity decreased by 0.1%. This difference was within the assumed error limit. Analyzing the temperature characteristics during combustion of biological material, which was linden sawdust previously subjected to the impulse electric field (Figure 7), a tendency was found that was almost identical to that for beech wood. The differences within the recorded temperatures were insignificant for all three variants, and the maximum difference in absolute values was recorded for variants II and III and amounted to two hundredths of a degree Celsius. The main period lasted the same for the material not subjected to the pulsed electric field as for the interaction with the field with the discharge intensity equal to 20 kV·cm−1 and the number of pulses equal to 300. From a statistical point of view, the obtained results do not differ significantly.

Figure 7.

Temperature characteristics of individual variants of linden three combustion: I (nonconditioned with a pulsed electric field) and conditioned with a pulsed electric field: II (electric field intensity 20 kV·cm−1 and number of pulses 300); III (electric field intensity 30 kV·cm−1 and number of pulses 300).

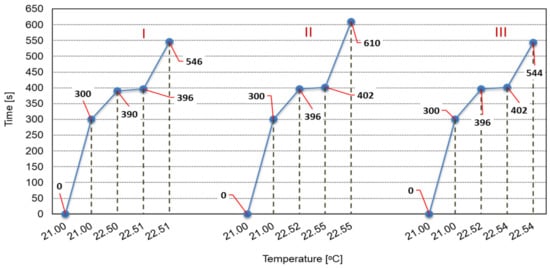

Similarly to oak sawdust, the main period (time from ignition to reaching the maximum temperature) for burning lime sawdust did not differ between materials stimulated with a field intensity of 20 kV·cm−1 and 30 kV·cm−1. Figure 8 shows the time characteristics of individual stages of calorimetric tests on linden sawdust previously exposed to a pulsating electric field, compared to the control sample. The duration of the discussed process was longer by 6 s in the case of variants II and III of the experiment than for the sample not stimulated with the pulsating electric field. In terms of absolute values, the observed time differences are relatively small. However, when analyzing the phenomenon as a whole and taking into account the specificity of the measurement of the calorific value, including the mass of the test sample and the mass of the medium receiving thermal energy, the obtained discrepancies constitute a significant value.

Figure 8.

Time characteristics of individual combustion stages of a fir tree: I (nonconditioned with a pulsed electric field) and conditioned with a pulsed electric field: II (electric field intensity 20 kV·cm−1 and number of pulses 300); III (electric field intensity 30 kV·cm−1 and number of pulses 300).

The analysis of the total burning time of lime wood sawdust indicates a trend similar to that observed in the case of oak sawdust. The longest time, 547 s, was obtained for PEF with an electric field strength of 20 kV·cm−1, where the number of pulses was 300. This is an increase of nearly 14% compared to the PEF-untreated sample. Again, these differences are a result of the lengthening of the last analyzed period; that is, between the fourth and fifth temperature recorded. This relationship is not in line with the trend obtained for birch sawdust, where increasing the field intensity decreased the duration of the entire combustion process. There was no significant difference between variant I and variant III. Only the discussed variant II differs significantly from the others.

3.4. Ash Sawdust

Ash sawdust samples, both those that were not conditioned with PEF and those that were the control sample, had analytical moisture at the level of 8.6% ± 0.1%. By analyzing the temperature characteristics during combustion of the biological material, which was ash tree (Figure 9), as in the case of other tree species discussed in this study, no statistically significant differences were found in the characteristic temperatures of the combustion process in the calorimetric bomb. As for birch, a slight decrease in the maximum and final temperature was observed for the subsequent variants of the experiment. The differences were small and amounted to a maximum of seven hundredths of a unit.

Figure 9.

Temperature characteristics of individual variants of ash three combustion: I (nonconditioned with a pulsed electric field) and conditioned with a pulsed electric field: II (electric field intensity 20 kV·cm−1 and number of pulses 300); III (electric field intensity 30 kV·cm−1 and number of pulses 300).

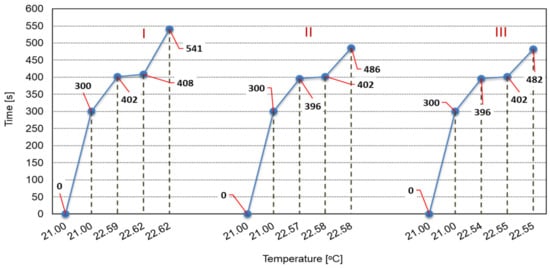

Figure 10 shows the time characteristics of individual stages of calorimetric tests on ash sawdust previously exposed to a pulsating electric field, compared to the control sample. As for oak and linden, there were no significant differences in the time between ignition and reaching the maximum temperature. This statement applies to all three analyzed variants. These differences did not exceed the value of 6 s, and the longest time was recorded for the sample not subjected to stimulation by pulsed electric field.

Figure 10.

Time characteristics of individual combustion stages of ash tree: I (nonconditioned with a pulsed electric field) and conditioned with a pulsed electric field: II (electric field intensity 20 kV·cm−1 and number of pulses 300); III (electric field intensity 30 kV·cm−1 and number of pulses 300).

Similar to birch, and also in the case of ash sawdust, a trend was noticed according to which the duration of the combustion process, and above all the last of the analyzed periods, decreased with increasing field intensity. For the control sample (variant I), the difference between the fifth and fourth recorded temperature was 133 s, while for the material stimulated with a field with a intensity of 20 kV·cm−1 (variant II) and 300 pulses was 84 s, and for 30 kV·cm−1 (variant III) and the same number of pulses—80 s. It was stated that the resulting differences are statistically significant and are of great importance for the entire analyzed process.

4. Discussion and Conclusions

The use of pulsed electric field (PEF) to stimulate, condition, or change some properties of biological materials is the subject of numerous studies [36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51]. However, the scientific literature lacks the use of PEF for wood, especially in the context of changes that could affect its energy use.

The heat of combustion of firewood is the basic parameter for determining its energy potential. During calorimetric tests, modern calorimeters automatically determine the time–temperature characteristics. They have not been the subject of interest so far, and their role has been limited to only one of the stages of the process determining the value of the heat of combustion. It seems, however, that in addition to the amount of energy produced, the time in which it was released is also important, especially during commercial use of wood as a raw energy material.

Rhen et al. [52] presented the results of research on the combustion time of coal from the pyrolysis of spruce sawdust pellets, suggesting at the same time that knowledge of the fuel combustion time is necessary for the proper control of this process. The authors obtained results ranging from 4.5 to 6.5 min, and in their opinion, these differences mainly result from the type of fuel used. There is few research on combustion time. The situation is different with the combustion temperature. The authors of such publications [53,54,55] believe that the most important role is played by the ignition point and the peak temperature. The aforementioned researchers point out that the first of them, regardless of the type of fuel, has similar values, while the second depends mainly on the content of volatile substances. The time–temperature characteristics of fuel combustion, which is an element of the combustion heat determination process, allow for the analysis of both these parameters, i.e., the duration and temperature obtained at individual stages of the process. The research on the influence of PEF on lignocellulosic material carried out so far indicates the formation of the phenomenon of electroporation causing changes in the structure of the cell membrane. The effect of this is the loss of semi-permeability, which leads to the passage of enzymes hydrolyzing polysaccharides and lignin [29,30]. Such an effect was already obtained at an electric field of 1 to 10 kV·cm−1, with which wood chips were treated [56]. Still, the described mechanisms have not been precisely parameterized [57]. It seems, however, that the same mechanisms may cause differences in the temperature and duration of individual stages of the combustion process.

Both the studies presented in this paper and the authors’ previous studies [32] have shown that the pulsating electric field affects the temperature–time characteristics of the wood combustion process. The previously published results allowed us to conclude that the dominant factor of changes in the combustion characteristics of biological material treated with PEF is the electric field intensity. However, extending the research to new types of wood and limiting to two combinations of stimulation parameters partially changes the proposed thesis. The key issue to note is the fact that in each of the analyzed variants, the value of the heat of combustion (expressed in energy units per unit of mass) is the same. Slight temperature differences in the subsequent periods of the combustion process between the variants used do not cause changes exceeding the standardized repeatability limit. The situation is different in the case of time measurements. The observed changes are most pronounced in the last period of the combustion process, i.e., from the moment of reaching the maximum temperature to the end of the process. These results seem to be interesting because, as can be concluded from the research, it is possible to modify the time of obtaining thermal energy depending on one’s needs. Thus, it becomes possible to accelerate certain technological processes based on the production of energy from fuel combustion, or, on the contrary, to extend the time of energy release, which is important, for example, from the point of view of central heating installations in buildings.

Therefore, we propose introducing the term of rate of heat of combustion, which will cover both the amount of heat produced and the time of its release. Its basic unit should be the expression kW∙kg−1, which is also used in some fields to express the so-called specific power.

The presented results indicate that birch and ash react to PEF conditioning in a similar manner. The second group, due to the similarity of the obtained results, comprises oak and linden. Within both groups, the trees were compared in terms of their botany, especially the content of elementary chemical elements, the composition and structure of cell membranes, physical properties (weight density, porosity, contractility), as well as anatomical features (size and arrangement of vessels in the growth ring). It would seem that the main factor of changes should be porosity, which affects electroporation, and this in turn is the basis for modifications caused in wood during treatment with a pulsed electric field. However, the only demonstrated correlation between the obtained results and the biological, physical, and chemical parameters of the tested samples concerned the average content of pentosan-free cellulose in wood. Its values are 45.50% for birch, 45.50% for ash, 42.80% for oak, and 43.16% for linden, respectively [58]. Therefore, it seems that it is the cellulose content (in addition to the electric field strength shown in previous studies) that will be the factor determining the effect caused by PEF in wood.

Analyzing the obtained data in terms of their utilitarian use, an important parameter is the energy efficiency of the described process. The highest recorded consumption of electricity needed to generate an electric impulse in the used station is equal to 71.3 mWh, as described in the introduction [31]. Taking into account the amount of material that is introduced into the cell and the number of pulses used in each variant, the energy needed to stimulate 1 kg of sawdust is about 17.1 MJ. Referring again to the introduction to this paper—where, as an example, the amount of energy obtained from the combustion of 1 kg of birch sawdust, which is in the range from 17.90 to 18.72 MJ∙kg−1 [12,13], is possible without any analysis—this process is unprofitable from an energy point of view. It should be emphasized, however, that the devices used by the authors were made in 2017, and its subsequent modifications concerned the control elements, and not the components responsible for generating the pulse. It seems that the use of the most modern methods would be able to reduce the amount of energy needed during stimulation, but research is still required to reduce the energy consumption of this process. Likewise, further experimentation is needed to cover a wider range of plants and other electric field parameters, leading to the parameterization of the described phenomenon.

Author Contributions

Conceptualization, P.K. and E.P.; methodology, P.K.; software, E.P.; validation, P.K. and E.P.; formal analysis, E.P.; investigation, E.P.; resources, P.K.; data curation, P.K.; writing—original draft preparation, E.P.; writing—review and editing, P.K.; visualization, E.P.; supervision, P.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request of the respective author. The data are not publicly available due to the possibility of their commercial use by the unit in which the authors are employed and the use of source data for further research and development works of an accredited laboratory (Polish accreditation number AB 1698), whose staff are the authors of this publication.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Balat, M.; Acici, N.; Ersoy, G. Trends in the Use of Biomass as an Energy Source. Energy Sources Part B Econ. Plan. Policy 2006, 1, 367–378. [Google Scholar] [CrossRef]

- Uddin, M.; Techato, K.; Taweekun, J.; Rahman, M.; Rasul, M.; Mahlia, T.M.I.; Rahman, S.M.A. An Overview of Recent Developments in Biomass Pyrolysis Technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef] [Green Version]

- Papoutsidakis, M.; Symeonaki, E.; Tseles, D.; Drosos, C. The biomass as an energy source and its application benefits. Int. J. Eng. Appl. Sci. Technol. 2018, 2, 1–5. [Google Scholar]

- Spîrchez, C.; Lunguleasa, A.; Croitoru, C. The importance of the wood biomass in environment protection. AIP Conf. Proc. 2017, 1918, 20007. [Google Scholar]

- Ko, J.H.; Kim, W.C.; Cho, J.S.; Choi, Y.I.; Park, E.J.; Im, J.H.; Han, O.; Keathley, D.; Han, K.H. EliteTree TM: An advanced biomass tree crop technology that features greater wood density and accelerated stem growth. Biofuels Bioprod. Biorefin. 2017, 11, 521–533. [Google Scholar] [CrossRef]

- Karlsson, O.; Sidorova, E.; Moren, T. Influence of Heat Transferring Media on Durability of Thermally Modified Wood. Bioresources 2011, 6, 356–372. [Google Scholar] [CrossRef]

- Nanda, S.; Reddy, S.N.; Vo, D.V.N.; Sahoo, B.N.; Kozinski, J.A. Catalytic gasification of wheat straw in hot compressed (subcritical and supercritical) water for hydrogen production. Energy Sci. Eng. 2018, 6, 448–459. [Google Scholar] [CrossRef] [Green Version]

- Norouzi, O.; Safari, F.; Jafarian, S.; Tavasoli, A.; Karimi, A. Hydrothermal gasification performance of Enteromorpha intestinalis as an algal biomass for hydrogen-rich gas production using Ru promoted Fe–Ni/γ-Al2O3 nanocatalysts. Energy Convers. Manag. 2017, 141, 63–71. [Google Scholar] [CrossRef]

- De Araujo Guilherme, A.; Dantas, P.V.F.; Padilha, C.E.D.A.; dos Santos, E.S.; de Macedo, G.R. Ethanol production from sugarcane bagasse: Use of different fermentation strategies to enhance an environmental-friendly process. J. Environ. Manag. 2019, 234, 44–51. [Google Scholar] [CrossRef]

- Toscano, G.; Foppa, P.E. Calorific value determination of solid biomass fuel by simplified method. J. Agric. Eng. 2009, 3, 1–6. [Google Scholar] [CrossRef]

- Bell, D.A.; Towler, B.F.; Fan, M. (Eds.) The Nature of Coal. In Coal Gasification and Its Applications, 1st ed.; William Andrew Publishing: Norwich, NY, USA, 2011; Volume 1, pp. 1–15. [Google Scholar]

- Günther, B.; Gebauer, K.; Barkowski, R.; Rosenthal, M.; Bues, C.T. Calorific value of selected wood species and wood products. Eur. J. Wood Wood Prod. 2012, 70, 755–757. [Google Scholar] [CrossRef]

- Dibdiakova, J.; Wang, L.; Li, H. Heating value and ash content of downy birch forest biomass. Energy Procedia 2017, 105, 1302–1308. [Google Scholar] [CrossRef]

- Demirbaş, A. Effects of moisture and hydrogen content on the heating value of fuels. Energy Sources Part A Recovery Util. Environ. Eff. 2007, 29, 649–655. [Google Scholar] [CrossRef]

- Charbel, A.T.; Trinchero, B.D.; Morais, D.D.; Mesquita, H.; Birchal, V.S. Evaluation of the Potential of Fruit Peel Biomass after Conventional and Microwave Drying for Use as Solid Fuel. Appl. Mech. Mater. 2015, 798, 480–485. [Google Scholar] [CrossRef]

- Aniszewska, M.; Gendek, A. Comparison of heat of combustion and calorific value of the cones and wood of selected forest trees species. For. Res. Pap. 2014, 75, 231–236. [Google Scholar] [CrossRef] [Green Version]

- European Standard EN ISO 18125:2017; Solid Biofuels—Determination of Calorific Value. ISO: Geneva, Switzerland, 2007.

- Jayakumar, E.; Chittibabu, S.; Shanmugasundaram, S.; Lope, G.T. Synergetic effect of microwave heated alkali pre-treatment on densification of rice (Oryza sativa) husk biomass grinds. Energy Sources Part A Recovery Util. Environ. Eff. 2019. [Google Scholar] [CrossRef]

- Phanphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef]

- Yu, N.; Cai, Y.; Li, X.; Fan, Y.; Yin, H.; Zhang, R. Catalytic pyrolysis of rape straw for upgraded bio-oil production using HZSM-5 zeolite. Nongye Gongcheng Xuebao Trans. Chin. Soc. Agric. Eng. 2014, 30, 264–271. [Google Scholar]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour. Technol. 2018, 262, 310–318. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Zhang, L.; Liu, D. Pretreatment of Siam weed stem by several chemical methods for increasing the enzymatic digestibility. Biotechnol. J. 2010, 5, 493–504. [Google Scholar] [CrossRef]

- Aguilera, J.M.; Chiralt, A.; Fito, P. Food dehydration and product structure. Trends Food Sci. Technol. 2003, 14, 432–437. [Google Scholar] [CrossRef]

- Welti-Chanes, J.; Guerrero, J.; Bárcenas, M.E.; Aguilera, J.; Vergara, F.; Barbosa-Cánovas, G. Glass transition temperature (Tg) and water activity (aw) of dehydrated apple products. J. Food Process Eng. 2007, 22, 91–101. [Google Scholar] [CrossRef]

- Donsì, F.; Ferrari, G.; Pataro, G. Applications of Pulsed Electric Field Treatments for the Enhancement of Mass Transfer from Vegetable Tissue. Food Eng. Rev. 2010, 2, 109–130. [Google Scholar] [CrossRef]

- Toepfl, S. Pulsed Electric Fields (PEF) for Permeabilization of Cell Membranes in Food- and Bioprocessing—Applications, Process and Equipment Design and Cost Analysis. Ph.D. Thesis, Technischen Universität, Berlin, Germany, 2006. [Google Scholar]

- Tylewicz, U.; Tappi, S.; Mannozzi, C.; Romani, S.; Dellarosa, N.; Laghi, L.; Ragni, L.; Rocculi, P.; Dalla Rosa, M. Effect of pulsed electric field (PEF) pre-treatment coupled with osmotic dehydration on physico-chemical characteristics of organic strawberries. J. Food Eng. 2017, 4, 66–78. [Google Scholar] [CrossRef]

- Wiktor, A.; Witrowa-Rajchert, D. Applying Pulsed Electric Field to enhance plant tissue dehydration process. Żywność Nauka Technol. Jakość 2012, 2, 22–32. [Google Scholar] [CrossRef]

- Kumar, A.K.; Sharma, S. Recent updates on different methods of pretreatment of lignocellulosic feedstocks: A review. Bioresour. Bioprocess 2017, 4, 7. [Google Scholar] [CrossRef] [Green Version]

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res. Int. 2015, 77, 773–798. [Google Scholar] [CrossRef]

- Wesolowski, M.; Necka, K.; Drozdz, T.; Kiełbasa, P. The concept of modeling a pulsed electric field discharge (PEF) in products of the agri-food industry. Prz. Elektrotech. 2018, 94, 119–123. (In Polish) [Google Scholar]

- Kiełbasa, P.; Dróżdż, T.; Popardowski, E. Influence of Coniferous Wood Conditioning by Pulsed Electric Field on Its Combustion Heat Characteristics. Appl. Sci. 2021, 11, 983. [Google Scholar] [CrossRef]

- European Standard EN ISO 14780:2017-07; Solid Biofuels—Sample Preparation. ISO: Geneva, Switzerland, 2017.

- European Standard EN ISO 18134-3:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part: Moisture in General Analysis Sample. ISO: Geneva, Switzerland, 2015.

- Standard ISO 3534-1:2006; Statistics—Vocabulary and Symbols—Part: General Statistical Terms and Terms Used in Probability. ISO: Geneva, Switzerland, 2006.

- Sepulveda, D.R.; Gongora-Nieto, M.M.; Guerrero, J.A.; Barbosa Canovas, G.V. Shelf life of whole milk processed by pulsed electric fields in combination with PEF-generated heat. Food Sci. Technol. 2009, 42, 735–739. [Google Scholar] [CrossRef]

- Monfort, S.; Gayán, E.; Condón, S.; Raso, J.; Álvarez, I. Design of a combined process for the inactivation of Salmonella enteritidis in liquid whole egg at 55 °C. Int. J. Food Microbiol. 2011, 145, 476–482. [Google Scholar] [CrossRef] [PubMed]

- Monfort, S.; Saldaña, G.; Condón, S.; Raso, J.; Álvarez, I. Inactivation of Salmonella spp. in liquid whole egg using pulsed electric fields, heat, and additives. Food Microbiol. 2012, 30, 393–399. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, P.; Mittal, G.S. Inactivation of natturally occuring microorganisms in tomato juice using pulsed electric field (PEF) with and without antimicrobials. Chem. Eng. Process. 2007, 46, 360–365. [Google Scholar] [CrossRef]

- Mosqueda-Melgar, J.; Raybaudi-Massilia, R.M.; Martin-Belloso, O. Non-thermal pasteurization of fruit juices by combining high-intensity pulsed electric fields with natural antimicrobials. Innov. Food Sci. Emerg. Technol. 2008, 9, 328–340. [Google Scholar] [CrossRef]

- Grimi, N.; Mamouni, F.; Lebovka, N.; Vorobiev, E.; Vaxelaire, J. Impact of apple processing modes on extracted juice quality: Pressing assisted by pulsed electric fields. J. Food Eng. 2011, 103, 52–61. [Google Scholar] [CrossRef]

- Liang, Z.; Cheng, Z.; Mittal, G.S. Inactivation of spoilage microorganisms in apple cider using a continuous flow pulsed electric field system. Food Sci. Technol. 2006, 39, 351–357. [Google Scholar] [CrossRef]

- Iu, J.; Mittal, G.S.; Griffiths, M.W. Reduction in levels of Escherichia coli O157:H7 in apple cider by pulsed electric fields. J. Food Prot. 2001, 64, 964–969. [Google Scholar] [CrossRef]

- Abenoza, M.; Benito, M.; Saldaña, G.; Álvarez, I.; Raso, J.; Sánchez-Gimeno, A.C. Effects of pulsed electric field on yield extraction and quality of olive oil. Food Bioprocess Technol. 2013, 6, 1367–1373. [Google Scholar] [CrossRef]

- Lamaunauskas, N.; Pataro, G.; Bobinas, C.; Satkauskas, S.; Viskelis, P.; Bobonaite, R.; Ferarri, G. Impact of pulsed electric field treatment on juice yield and recovery of bioactive compounds from raspberries and their by-products. Zemdirb. Agric. 2016, 103, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Guo, Y.; Zhang, D. Study of the Effect of High-Pulsed Electric Field treatment on Vacuum Freeze-Drying of Apples. Dry. Technol. 2011, 29, 1714–1720. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, D. Effect of Pulsed Electric Field on Freeze-Drying of Potato Tissue. Int. J. Food Eng. 2014, 10, 857–862. [Google Scholar] [CrossRef]

- Dalvi-Isfahan, M.; Hamdami, N.; Le-Bail, A.; Xanthakis, E. The principles of high voltage electric field and its application in food processing: A review. Food Res. Int. 2016, 89, 48–62. [Google Scholar] [CrossRef] [PubMed]

- Raschke, D. Pulsed Electric Fields—Influence on Physiology, Structure and Extraction Processes of the Oleaginous Yeast Waltomyces lipofer. Ph.D. Thesis, Technischen Universität, Berlin, Germany, 2010. [Google Scholar]

- Bobinaitė, R.; Pataro, G.; Raudonis, R.; Vškelis, P.; Bobinas, C.; Šatkauskas, S.; Ferrari, G. Improving the extraction of juice and anthocyanin compounds from blueberry fruits and their by-products by pulsed electric fields. IFMBE Proc. 2015, 53, 363–366. [Google Scholar]

- Mahnič-Kalamiza, S.; Vorobiev, E.; Miklavčič, D. Electroporation in food processing and biorefinery. J. Membr. Biol. 2014, 247, 1279–1304. [Google Scholar] [CrossRef] [PubMed]

- Rhen, C.; Ohman, M.; Gref, R.; Wasterlund, I. Effect of raw material composition in woody biomass pellets on combustion characteristics. Biomass Bioenergy 2007, 31, 66–72. [Google Scholar] [CrossRef]

- Haykırı-Acma, H. Combustion characteristics of different biomass materials. Energy Convers. Manag. 2003, 44, 155–162. [Google Scholar] [CrossRef]

- Kucukbayrak, S.; Haykırı-Acma, H.; Ersoy-Mericboyu, A.; Yaman, S. Effect of lignite properties on reactivity of lignite. Energy Convers. Manag. 2001, 42, 613–626. [Google Scholar] [CrossRef]

- Haykırı-Acma, H.; Ersoy-Mericboyu, A.; Kucukbayrak, S. Effect of mineral matter on the reactivity of lignite chars. Energy Convers. Manag. 2001, 42, 11–20. [Google Scholar]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Pulsed electric field pretreatment of switchgrass and wood chip species for biofuel production. Ind. Eng. Chem. Res. 2011, 50, 10996–11001. [Google Scholar] [CrossRef]

- Qin, J.; Pasko, V.P. On the propagation of streamers in electrical discharges. J. Phys. Part D Appl. Phys. 2014, 47, 435202. [Google Scholar] [CrossRef]

- Galewski, W.; Korzeniowski, A. Atlas of the Most Important Types of Wood, 1st ed.; Panstwowe Wydawnictwo Rolnicze i Lesne: Warsaw, Poland, 1958; pp. 52–55, 71–75, 169–172, 206–208. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).