Abstract

Buckwheat honey is proven to demonstrate health beneficial properties; however, its application in the industry is limited due to its high viscosity and syrupy-like consistency. The paper aimed to investigate process performance and physiochemical properties of carrier-reduced buckwheat honey. Honey was spray dried conventionally (inlet/outlet drying temperature: 180 °C/80 °C) and at low drying temperature with dehumidified air application (inlet/outlet drying temperature: 80 °C/45 °C) with maltodextrin as traditional carrier and alternatively with skim milk powder. The results of this study indicate that lowering the humidity of drying air enabled a decrease in carrier content of up to 25% (w/w solids), following powder recovery over 87%, which has not been recorded before for buckwheat honey powders. The results for the physicochemical properties proved that the application of the dehumidified air and skim milk powder as a carrier ameliorated their physiochemical properties and the antioxidant activity. Furthermore, the energy consumption of dehumidified-air-assisted spray drying was investigated as a basis for potential industrial application of this innovative method, which has not been studied in the literature before. The industrial application of this method must be carefully analyzed with regard to its advantages, as the energy consumption is significantly higher than in conventional spray drying.

1. Introduction

Honey is recognized as a traditional medicine and has been applied in many cultures as a treatment for wounds, burns and microbial infections. The health beneficial properties of honey have been widely studied, and multiple papers have reported on the anti-inflammatory, antibacterial, radical scavenging and antioxidant properties resulting from its composition of phenolic acids, carotenoids, flavonoids, ascorbic acid, products of Maillards’s reactions, catalase and peroxidase [1,2,3,4,5,6]. Generally, the antioxidant activity of honey is associated either with its phenolic content or its color—darker honeys tend to present higher antioxidant potential [2]. The main characteristics of buckwheat honey are dark brown to black color, specific strong aroma and molasses-like flavor [1]. This type of honey has been widely investigated over the years and has been proven to demonstrate multiple health beneficial properties. Jiang et al. (2020) reported that buckwheat honey positively affects intestinal microbes, which results in the increase in probiotics [7]. Hammond et al. (2016) noted that antibiotic-resistant pathogens were susceptible to buckwheat honey originating from the USA [8]. Baranowska-Wójcik et al. (2020) investigated 47 different honeys as a source for acetyl- and butyrylcholinesterase inhibitors (AChE and BChE), which are a possible therapeutic strategy in maintaining Alzheimer’s disease [9]. The acetylcholinesterase activity (AChE) can decrease the acetylcholine neurotransmitter, leading to Alzheimer’s disease. The authors draw attention to the highest capacity of buckwheat honey for AChE inhibition and accentuate its possible use in medical treatments.

Due to its favorable organoleptic and health beneficial properties, honey is widely applied in the food industry. However, its use is limited due to its syrupy-like consistency and viscosity. In order to solve this problem, honey powder was introduced to broaden the possibility of its dosing, transportation and storage, as the risk of crystallization and fermentation decreases the potential use as a dietary supplement and functional food ingredient [10,11]. Spray drying is a method that enables a production of free-flowing powder in a single operation and is usually used in honey powder production [11,12]. However, it should be underlined that, as a result of high content of low molecular weight sugars (fructose and glucose), honey spray drying can be a difficult operation because of the low glass transition temperature (Tg) of fructose and glucose: 5 °C and 31 °C, respectively [13]. Problems associated with spray drying of sugar-rich materials such as honey are manifested by inter-particle stickiness, particles’ stickiness to the walls of the drying chamber, or by the material remaining in the form of a syrup. These issues lower product yield and quality. It is crucial to adjust drying parameters, device design or material composition with the addition of carriers to prevent the aforementioned problems. As observed in the literature, the most widely applied carrier in spray dried sugar-rich materials is maltodextrin. However, consumers are increasingly becoming more aware of products’ composition, consequently looking for healthier alternatives, as maltodextrin is characterized by high glycemic index (GI) [14]. The protein-based carriers are attracting considerable interest due to their skin-forming properties and promising results in sugar-rich materials spray drying. Suhag and Nanda (2016) noted that whey protein concentrate (WPC) in honey spray drying led to the highest powder recovery (Rp), the lowest bulk density and good flowability in comparison to the traditional carriers of maltodextrin and Arabic gum [15]. Moreover, the authors reported that WPC fully protected vitamin C and enabled them to obtain more spherical powder particles. Samborska et al. (2015), who spray dried buckwheat and rapeseed honey with the addition of 1% w/w sodium caseinate (NaCas) and Arabic gum as carriers, observed higher Rp and better powder flowability [12]. Barańska et al. (2019), who obtained multifloral honey powders, concluded that skim milk powder as a carrier and milk as a diluent made possible an increase in honey content in the product of up to 70% [16]. Samborska et al. (2020) reported that it was possible to increase honey content in honeydew honey powders as a result of skim milk powder application as a carrier [17]. Furthermore, authors noted very high Rp and powder particles scattered and of small diameters, which is distinctive for spray drying of non-sticky materials. Apart from the film-forming properties of proteins present in milk, the presence of lactose is important as well in relation to the reduction of stickiness during drying when the skim milk powder is applied as a carrier. Lactose of high Tg (101 °C) increases the overall Tg of spray dried material and prevents problems that may occur during powder preparation [13]. Few researchers have questioned the application of lactose as a carrier; however, Angel et al. (2009) analyzed the effectiveness of lactose-maltodextrin blends in passion fruit juice spray drying [18]. The authors concluded that the low lactose-maltodextrin blends (8:5, 10:5, 12:5% w/v) enabled successful spray drying and prevented stickiness-related problems.

A major disadvantage of honey spray drying is the high amount of carrier (35–50%) that is added in order to avoid problems of stickiness [10]. The dehumidified air as a drying medium is increasingly becoming a vital factor in resolving previously mentioned problems in spray drying. As a result of lowering the air humidity, it is possible to lower drying temperature as a consequence of higher intensity of water evaporation. This phenomenon leads to successfully avoiding the issues resulting from the material’s low Tg [19]. Several studies, for instance Jedlińska et al. (2019), Goula and Adamopoulos (2008) and Chasekioglou et al. (2017) have been carried on dehumidified-air-assisted spray drying [20,21,22]. Jedlińska et al. (2019) reported that application of dehumidified air as a drying medium successfully enabled the lowering of the carrier content to 20% while maintaining above 90% the powder recovery in rapeseed honey spray drying [20]. As aforementioned, the carrier content in honey spray drying typically ranges from 35 to 50%; thus the achievement of Jedlińska et al. (2019) in increasing honey content in powders should be highlighted [20]. Goula and Adamopoulos (2008) noted product recovery of tomato pulp powders ranging from 80 to 90%, and these values were significantly higher than results presented in other studies [21]. Authors underlined that such high Rp values were a result of the low humidity of drying air. Chasekioglou et al. (2017) spray dried olive mill wastewater and reported 87–94% powder recovery when dehumidified air was used as a drying medium in comparison to traditional spray drying with and without carrier and noted Rp was <3% and 1–24%, respectively [22]. It should be pointed out that previous studies did not address the energy consumption of dehumidified-air-assisted spray drying, and authors focused solely on process performance and powder properties. This is a major drawback, as it does not provide information on the economic aspects of this innovative technology that might be implemented into the industry.

The aim of this study was to investigate the process performance and energy consumption of buckwheat honey spray drying using the traditional method (SD) and with the application of dehumidified air (DASD) in order to lower the carrier content. Despite the increasing interest in dehumidified-air-assisted spray drying, no one to the best of the authors’ knowledge has studied the economic aspects of this technology. Moreover, previous works have not focused on the application of dehumidified-air-assisted spray drying with reduced carrier in this type of honey. Skim milk powder (MP) was used as an alternative carrier and was compared to common maltodextrin (MD). Furthermore, obtained powders were analyzed to compare their physiochemical properties.

2. Materials and Methods

2.1. Materials

Buckwheat (Fagopyrum esculentum Moench) honey was supplied by Miody Mazurskie (Tomaszkowo, Poland). The characterization of used buckwheat honey is presented in Table 1. Maltodextrin DE 15 (MD; Amylon, Přibyslav, Czech Republic) and skim milk powder (MP; Polsero, Poland) were used as carrier agents. The chemicals that were used in antioxidant activity analysis were supplied by POCH (Gliwice, Poland).

Table 1.

Characterization of raw buckwheat honey.

2.2. Feed Solutions

Liquid feeds with 50% (w/w) honey and carrier (distilled water was used as a diluent) were prepared to achieve powders of different composition (Table 2). In order to increase honey content in feed solutions and honey powders, the content of carrier solids was 50 and 25% (w/w), and the content of honey solids was 50 and 75% (w/w).

Table 2.

Variants of spray dried buckwheat honey.

2.3. Viscosity Determination

Viscosity was analyzed on rheometer MARS40 Haake (Thermo Fisher Scientific, Waltham, MA, USA) with coaxial cylinder geometry. Samples were measured at 25 °C, with an operating shear rate of 0 to 100 s−1. Reograms were determined using empirical models, and the apparent viscosity was then calculated as the relationship of shear stress and rate.

2.4. Spray Drying

A laboratory spray dryer MOBILE MINOR (GEA, Skanderborg, Denmark), equipped with rotary atomizer (rotation speed of 26,000 rpm), was used to spray dry buckwheat honey solutions. Spray drying of 500 g liquid feeds was performed at a drying air temperature of 180 °C/80 °C (inlet/outlet) for conventional spray drying (SD) and 80 °C/45 °C (inlet/outlet) for spray drying using dehumidified air (DASD) in duplicates for every variant (under proposed conditions). Thus, each variant was represented by two individual samples of the final product, for which the results were averaged. Liquid feeds were pumped at a feed ratio speed of 0.20 mL∙s−1. The application of dehumidified air was achieved using an air dehumidification system composed of a cooling unit TAEevo TECH020 (MTA, Codogno, Italy), a condensation unit (SWEGON, Västra Frölunda, Sweden) and an adsorption unit ML270 (MUNTERS, Kista, Sweden). The inlet air humidity for DASD variants was 0.5 g·m−3, while for SD it was 9.0 g·m−3. Each powder sample was stored at 4 °C in the dark in two PET/PE sealed bags before the performed analyses.

2.4.1. Powder Recovery

Powder recovery (Rp) of spray drying was expressed in [%] as the ratio of solids content in the produced honey powder to the amount of solids in the feed solution prior to spray drying.

2.4.2. Energy Consumption and Energy Efficiency

The rate of energy consumption Q [kW] was expressed according to Al-Mansour et al. (2011) by the equation Q = (Ef − Ei)/t, where Ei and Ef [kWh] were the initial and final values of energy consumption read from the power meter (Pawbol, Andrychów, Poland), respectively, and t was time of spray drying for each variant [23]. The specific energy consumption (Es) was expressed as the energy used during spray drying per kg of evaporated water. The energy efficiency (η) was calculated as the ratio of the energy used for water evaporation to the energy supplied to the spray dryer.

2.5. Powder Characterization

Physiochemical Properties

Analysis of the particle morphology was performed utilizing SEM microscope TM-3000 (HITACHI, Tokyo, Japan) at 500× magnification. Prior to analysis, samples were prepared by metalizing the surface of the sample placed on double sticky tape by coating with a layer of gold using automatic coater Cressington 108auto (EO Elektronen-Optik-Service GmbH, Dortmund, Germany).

Particle size distribution was carried out using laser diffraction on apparatus 1190 (CILAS, Orléans, France). Powders were suspended in ethanol at the obscuration of 10%. The results were presented as particle size distribution diagrams and expressed as the median diameter D50.

Moisture content (MC) was determined using an oven method: approximately 1 g of powder was dried at 105 °C for 4 h.

Water activity (aw) was determined on apparatus Hygro Lab1 (Rotronic, Bassersdorf, Switzerland) at 24 ± 2 °C.

Hygroscopicity (H) was analyzed as a weight gain of 1 g powder samples incubated at 25 °C, 75% RH (saturated NaCl solution) during 144 h. Results were calculated as the amount of water absorbed per 100 g powder solids and expressed in percent.

Powder loose bulk density (DL) was determined as the weight of powder that occupied a 25 mL cylinder. The automatic tapper STAV 2003 (Engelsmann AG, Ludwigshafen, Germany) was employed to measure tapped bulk density (DT) after 100 taps and determine the volume occupied by the powder. The Hausner ratio (HR) was calculated to evaluate powder flowability and was expressed as HR = DT/DL.

Apparent density (Dap) was carried out on helium pycnometer Stereopycnometer (Quantachrome Instruments, Boynton Beach, FL, USA). Loose bulk porosity was calculated as εL = 1 − (DL/Dap).

The Colorimeter CR-5 (Konica-Minolta, Tokyo, Japan) was applied to determine color in CIE L*a*b* system.

Antioxidant Activity

Prior to determination of antioxidant activity, the extracts of buckwheat honey and obtained powders were prepared in duplicate. Samples were diluted in distilled water and filtrated at ambient temperature using Chemland medium filter papers (125 mm) and rinsed twice with 10 mL of distilled water. Antioxidant activity was analyzed using an ABTS•+ (2,2′-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid) radical cation method with minor modifications [24]. The ABTS•+ solution was diluted with distilled water, and it was measured at 734 nm using a spectrophotometer Helios Gamma (Thermo Fischer Scientific, Waltham, USA) to establish 0.7 ± 0.1 absorbance. A total of 3 mL of ABTS solution was added to an adequate volume of honey and powder extracts. The samples were stored in darkness at ambient temperature for 6 min. The absorbance was measured at 734 nm against distilled water. Each sample was prepared in duplicate. The antioxidant activity was expressed as EC50 ABTS.

2.6. Statistical Analysis

All of the determinations were performed in triplicate and the results were presented as average ± standard deviation. The ANOVA and Tukey tests were performed at α = 0.05 in order to determine significant differences between average values of analyzed parameters (powder recovery, energy consumption, energy efficiency, viscosity of liquid feeds, physiochemical properties and antioxidant activity of obtained powders). Moreover, the Pearson correlation coefficient was determined to assess the correlations between investigated physiochemical properties of obtained powders (MC, aw, H, D50, DL, DT, HR, Dap, εL, color parameters), Rp and antioxidant activity. Hierarchical cluster analysis (HCA) was used to present the similarities between the variants of spray dried buckwheat honey as a dendrogram graph. The statistical analysis was done with software STATISTICA 13.3 (Statsoft, Tulsa, OK, USA).

3. Results

3.1. Buckwheat Honey Characterization

The characterization of raw buckwheat honey is presented in Table 1. Sugar extract of spray dried honey (80.9%) was similar to the results presented by Dżugan et al. (2020), who analyzed the physiochemical properties of 23 samples of buckwheat honey from different beekeepers in Poland [1]. The authors noted the sugar extract varying from 76.6 ± 0.5 to 82.1 ± 0.2%. The sum of glucose and fructose is in compliance with the Codex Alimentarius standards and COUNCIL DIRECTIVE 2001/110/EC, which require a sum higher than 60 g·100 g−1, and is consistent with results of Deng et al. (2018), who reported the sum of glucose and fructose of analyzed buckwheat honey as 71.2 g·100 g−1 [25,26,27]. As for the sucrose content, the obtained result is also in complete agreement with Codex Alimentarius standards, COUNCIL DIRECTIVE 2001/110/EC (<5%) and in line with the research of Deng et al. (2018) (0.60 ± 0.03 g·100 g−1) and Kowalski et al. (2013) (0.30 ± 0.2–0.67 ± 0.13 g/100 g) [25,26,27]. The free acidity of buckwheat honey (48.5 mval·kg−1) supports previous findings in the literature. Kowalski et al. (2013) reported that the free acidity of three commercial buckwheat honeys purchased in Poland varied from 46.19 ± 0.54 to 62.61 ± 0.88 mval·kg−1 [28]. Moreover, the authors noted that the electrical conductivity of commercial honeys ranged from 2.74 ± 0.002 to 4.88 ± 0.002 mS·cm−1, which is in line with analysis done on spray dried buckwheat honey (4.24 mS·cm−1).

3.2. Viscosity of Feed Solutions

The viscosity was measured, as it is considered to be an important factor affecting the course of spray drying and thus the properties of obtained powders. It varied from 16.5 ± 0.8 to 51.7 ± 2.6 mPa·s (Table 2). Obtained results point to the significant effect of the carrier type: the viscosity of liquid feeds with MP was significantly higher than with MD, comparing the solutions of the same carrier share in solids. Samborska et al. (2015), who spray dried buckwheat honey powders, noted liquid feed viscosity ranging from 30.2 ± 1.6 to 34.6 ± 0.8 mPa·s, though different solution concentration (30% w/w), carrier type and content (Arabic gum at honey:carrier solids ratio 50:50, with additional 1–2% of NaCas) were applied [12]. Moreover, it can be noted in this research that viscosity decreased with increasing honey share in solids. This is in complete agreement with the results of Samborska et al. (2015) and Jedlińska et al. (2019), who observed the same relationship between honey content and viscosity of spray dried liquid feeds [20,29]. Jedlińska et al. (2019) concluded that carriers generally tend to increase viscosity more than diluted honey [20].

3.3. Powder Recovery

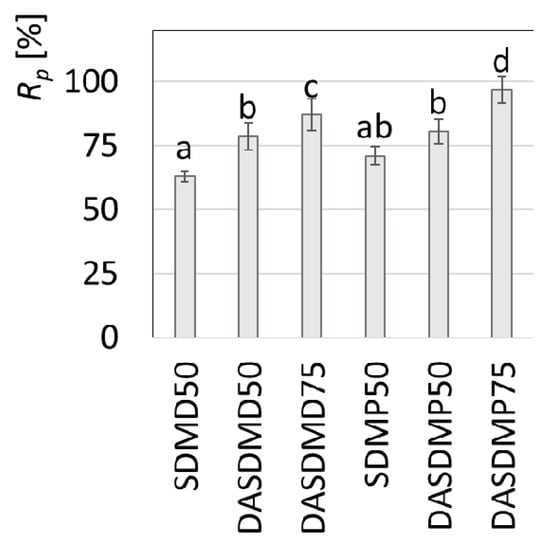

Spray drying performed at laboratory or pilot scale is considered to be successful when Rp is higher than 50% [13]. Results noted in this research varied from 62.9 ± 2.1 to 96.8 ± 5.2%, indicating successful spray drying of all of the variants (Figure 1). Moreover, in the case of DASD variants, values exceeded 75%. Several studies, i.e., Suhag and Nanda (2015), Shi et al. (2013), Samborska et al. (2015), Samborska et al. (2020) and Jedlińska et al. (2019), have been conducted on honey spray drying and process performance [12,17,20,30,31]. The Rp of buckwheat honey spray drying was presented only by Samborska et al. (2015), and the authors observed results ranging from 67.8 ± 2.1% to 75.8 ± 4.9% [12]. However, the authors spray dried honey conventionally with different carriers and their content than presented in this paper (sodium caseinate and/or Arabic gum as a carrier, honey solids to carrier solids 50:50).

Figure 1.

Powder recovery (Rp) after conventional spray drying (SD) and dehumidified-air-assisted spray drying (DASD) of buckwheat honey solutions containing 50 and 75% honey solids and maltodextrin (MD) or milk powder (MP) as carriers. a–c The differences between mean values with the same letter in rows are statistically insignificant (p < 0.05).

The results obtained in this paper have confirmed the previous observations made by Jedlińska et al. (2019) and Samborska et al. (2020): that the application of dehumidified air enables the production of honey powders with significantly higher Rp than presented in previous literature for SD [17,20]. Truong et al. (2005) explained in their work that the greater difference between material’s Tg and product’s temperature (Tp) leads to greater stickiness and consequently to lower Rp [32]. As dehumidified air enables lower drying temperature, the degree of stickiness is smaller because of the smaller Tg and Tp difference, which was noted in this research as manifested in high Rp in DASD variants.

It is crucial to underline that the highest Rp values (87% and 97%) were obtained at the lowest carrier content, in variants DASDMD75 and DASDMP75, respectively. This non-evident relationship can be explained in relation to cyclone efficiency. Dap and D50 are parameters that influence particle separation from drying air in a cyclone [33,34]. Powder particles of bigger Dap and D50 result in more effective particle separation, thus manifesting in greater Rp. This presumably explains the high Rp of variants DASDMD75 and DASDMP75, which had high D50 and Dap, respectively (Table 3). On the contrary, SDMD50, which had the highest D50, did not show high Rp, due to increased stickiness at high temperature SD.

Table 3.

Viscosity of feed solutions, physiochemical properties and antioxidant activity expressed as EC50 ABTS of buckwheat honey and powders containing 50 and 75% honey solids obtained with maltodextrin (MD) or milk powder (MP) as carriers by conventional spray drying (SD) and dehumidified-air-assisted spray drying (DASD).

Moreover, obtained results indicate the significance of the carrier used, which can be observed in the variants with the lowest carrier content. The Rp of buckwheat honey powder spray dried with MP as a carrier was significantly higher than with MD, though only for sample DASD75 was the difference statistically significant. As presented before by Jayasundera et al. (2009), Shi et al. (2013) and Bhusari et al. (2014), obtained results confirm that carriers containing proteins with film-forming ability prevent inner particles’ sticking and particles sticking to the walls of the drying chamber, which in turn increases Rp [31,35,36]. Despite the fact that lactose characterizes with significantly lower Tg (101 °C) than MD (100–243 °C, depending on dextrose equivalent), due to the additional combination of film-forming properties of milk proteins, variants with MP as carrier resulted in higher Rp [13].

3.4. Energy Consumption and Energy Efficiency

Previous works studying dehumidified-air-assisted spray drying have been limited only to the process characterization, mainly focusing on powder recovery. As this technology is leading to increased interest from researchers and industry, it is crucial to address the economic aspects, which have been never presented in the literature before. The rate of energy consumption (Q) during spray drying ranged from 3.4 ± 0.0 to 7.3 ± 0.0 kW, while the specific energy consumption (Es) varied from 22.9 ± 2.6 to 41.8 ± 0.9 MJ/kg H2O (Table 4). Few researchers have addressed the issue of the Es of traditional spray drying; however, Bhandari (2008) stated that spray drying consumes 5 MJ/kg H2O in industrial scale operations [37]. The author highlights that spray drying is not a cost-effective method of drying in comparison to other methods, but it enables drying thermolabile materials and obtaining products of high quality; it is also less energy-consuming than freeze drying. Baker and McKenzie (2005) reported that the Es for industrial spray dryers usually varies from 3 to 20 MJ/kg H2O, while for pilot scale spray dryers of lower throughput it can increase up to five times; this is confirmed as well by this research [38]. The effect of dehumidified air application can be observed: both Q and Es increased for spray drying in the case of DASD, which resulted from an extra energy expenditure related to air dehumidification. The Es of spray drying can be improved if a higher feed rate is applied; thus, the same amount of supplied energy is used for the evaporation of higher amounts of water. However, as was presented by Jedlińska et al. (2019) and Samborska et al. (2020), during DASD, especially at an inlet drying temperature as low as 80 °C, the feed rate has to be relatively low to make the evaporation possible [17,20].

Table 4.

Rate of energy consumption (Q), specific energy consumption (Es) and energy efficiency (η) of conventional spray drying (SD) and dehumidified-air-assisted spray drying (DASD) of buckwheat honey solutions containing 50 and 75% honey solids and maltodextrin (MD) or milk powder (MP) as carriers.

The energy efficiency (η) of spray drying ranged from 5.7 ± 0.0 to 10.5 ± 1.2% (Table 4). The effect of the drying method can be clearly observed; however, there was no statistically significant importance of the carrier type and content, which is in good agreement with the conclusions of Aghbashlo et al. (2012) [39]. The authors spray dried fish oil and reported that there was no effect of carrier type on the η, as the solvent content in liquid feed prior to drying was the same. Regarding spray dried buckwheat honey, the difference in amount of water added to the liquid feeds was negligible. In contradiction to the findings of Aghbashlo et al. (2012) and Julklang and Golman (2015), the η increased with an increase in temperature [39,40]. However, previous studies did not include the drying air dehumidification that affected the η in this research due to additional heat consumption by the air dehumidification system. Due to such low energy efficiency of dehumidified-air-assisted spray drying, its application on an industrial scale has to be carefully deliberated, taking into account the possible benefits (higher content of sugar-rich material) and disadvantages (low feed rate and energy efficiency).

3.5. Physiochemical Properties of Powders

3.5.1. Particle Morphology and Size

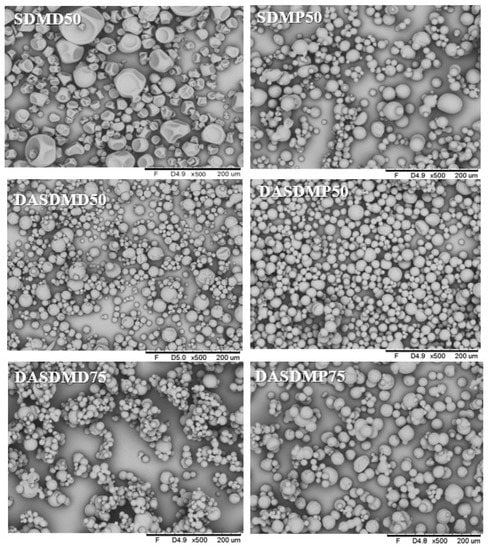

Particles of obtained buckwheat honey powders (Figure 2) were mostly spherical, with the exception of SDMD50, which had more irregular particles that were bigger in size (the highest D50). Spray drying at higher drying temperatures, as in the case of SDMD50, leads to early structure formation of rigid particles, which results in greater D50. Samborska et al. (2020) stated that an increase in particle size is usually observed when the stickiness related to low Tg, increases [17]. This implies that variant SDMD50 was more difficult to spray dry than other variants, which was confirmed previously by the lowest Rp and can be observed as well on cumulated particle size distribution curves (Figure 3). Moreover, particles were usually scattered, except for DASDMD75, in which clusters were formed. The cluster-type morphology is also characteristic of materials difficult to spray dry due to a stickiness; thus the variant DASDMD75, with high honey content, can be classified as problematic as well based on morphology analysis. Moreover, difficulties in spray drying of this variant can also be seen on cumulated particle size distribution curves (Figure 3). However, this was not confirmed by Rp, presumably due to the increased size of created clusters that can be observed in high D50 (Table 3), which promoted the effective powder separation in a cyclone. Smaller bridges between particles were also present in SDMP50 and DASDMP75 variants, with SDMP50 having the lowest Rp. However, DASDMP75 had the highest Rp even though the morphology indicated that it could have been a variant that caused problems during spray drying, as particles were visibly more piled up together as a result of the high honey content. This lends support to previous findings in the literature by Samborska et al. (2017), who noted the same results when carrier content in honey spray drying was decreased from 50 to 25% [41]. As discussed before, Rp is a factor that can also be dependent on other properties like Dap due to the impact on cyclone efficiency. DASDMD50 and DASDMP50 had small, scattered particles, indicating easy drying at low temperature and with a high content of carrier.

Figure 2.

Scanning electron microphotographs (SEMs) of buckwheat honey powders containing 50 and 75% honey solids obtained with maltodextrin (MD) or milk powder (MP) as carriers by conventional spray drying (SD) and dehumidified-air-assisted spray drying (DASD).

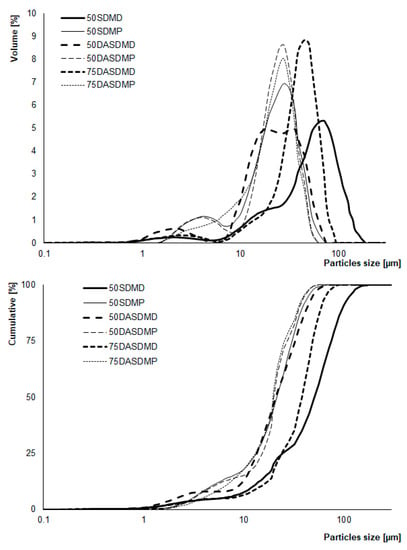

Figure 3.

Particle size distribution and cumulated particle size distribution of buckwheat honey powders containing 50 and 75% honey solids obtained with maltodextrin (MD) or milk powder (MP) as carriers by conventional spray drying (SD) and dehumidified-air-assisted spray drying (DASD).

Variants where MP was used as a carrier (DASDMP50, DASDMP75) in comparison to variants with the same carrier content where MD was applied (DASDMD50, DASDMD75) were more spherical, smooth, uniform, less conglomerated and had particles that were less scattered. These results validate the usefulness of MP as a carrier with regard to particle morphology and prove its skin-forming properties. These findings are in good agreement with Suhag and Nanda (2016), who traditionally spray dried honey with a protein-based carrier (WPC) and observed particles with a smooth surface that were less susceptible to cracking [15]. Samborska et al. (2020), who spray dried honey conventionally and with the application of dehumidified air, observed the same relationship when MP was used as a carrier [17].

Generally speaking, if the powders were characterized solely based on the particle morphology, the most problematic drying would be reported for SDMD50 and DASDMD75 variants, SDMP50 and DASDMP75 would be less problematic, and DASDMD50 and DASDMP50 would be considered as having issue-free processes. These findings highlight an important role of the application of dehumidified air in the powder production of particles that are more spherical and smaller in size and that have smooth surfaces.

Particle size distribution and cumulated particle size distribution figures (Figure 3) confirm the above-presented differences between variants. Particle diameters of variants with MD as a carrier ranged up to 150 µm, whereas variants with MP as a carrier ranged up to 90 µm. Powders with MP as a carrier (SDMP50, DASDMP50, DASDMP75) had uniform particle size distribution, while for powders with MD as a carrier (SDMD50, DASDMD50, DASDMD75), the distribution varied depending on the drying parameters and carrier content. Obtained results would seem to suggest that MP might be a better carrier to produce buckwheat honey powders with uniform particle size distribution—regardless of the given parameters—than MD, as was confirmed as well by particle morphology. Moreover, a variant spray dried at lower drying temperatures with MD as a carrier (DASDMD50) was distinguished with bimodal particle size distribution, which presumably was an effect of many smaller particles filling the space between bigger particles; this can be observed as well on SEM photographs (Figure 2). Values of median diameter D50 are presented in Table 3, and obtained results revealed that particles of powders where MP was used as a carrier (SDMP50, DASDMP50, DASDMP75) were characterized with the smallest D50, and there was no statistically significant difference between variants, regardless of the parameters and carrier content. This is in good agreement with Shi et al. (2013), who noted a decrease in D50 (from 66.8 to 16.5 μm) when MD was replaced with protein carrier in a solution containing 60% honey solids [31]. Samborska et al. (2015) observed a decrease as well after addition of 2% sodium caseinate to honey and gum Arabic solutions [12].

There was no reported relationship between the feed’s viscosity and D50, as generally it can be observed that the greater the viscosity, the larger the powder’s particles [42]. It has been suggested by Samborska et al. (2015) that, in honey spray drying, viscosity does not influence particles size as it is more affected by feed solution composition (carrier/honey content) [29]. The same observation was noted in more recent research by Jedlińska et al. (2019) [20].

The Pearson correlation coefficient was determined to confirm correlations between investigated physiochemical parameters (Table A1), and it showed that D50 was highly correlated with MC. MC decreased with an increase in drying temperature when both carriers were applied and was affected by carrier type. At the same time, D50 increased with an increase in drying temperature, and it was significantly influenced by carrier type.

3.5.2. Moisture Content and Water Activity

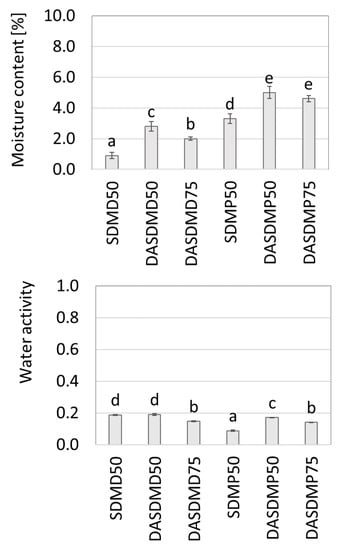

The MC of obtained buckwheat honey powders did not exceed 5% (0.9 ± 0.2–5.0 ± 0.4%), which in combination with water activity (aw) well below 0.3 (0.088 ± 0.005–0.190 ± 0.005) (Figure 4), indicates good storage stability due to low free water availability for potential microbial growth and biochemical reactions [31,43]. It can be observed that the MC of powders spray dried with MD as a carrier was significantly lower than powders with MP as a carrier, and aw was higher. This phenomenon was related to proteins’ ability to hold water in the amorphous matrix, resulting from the formation of a film on the particle surface; this was noted as well by Bhusari et al. (2014), who spray dried tamarind pulp powder with whey protein concentrate (WPC) as a carrier [36]. Suhag and Nanda (2016) studied honey powders with different carrier agents, including MD and WPC, noting significantly higher moisture content when WPC was used a carrier than when MD was applied [15].

Figure 4.

Moisture content (MC) and water activity (aw) of buckwheat honey powders containing 50 and 75% honey solids obtained with maltodextrin (MD) or milk powder (MP) as carriers by conventional spray drying (SD) and dehumidified-air-assisted spray drying (DASD).

Variants SDMD50 and SDMP50, which were spray dried at high drying temperatures, had lower MC than corresponding DASD variants due to higher heat transfer. The MC values of spray dried buckwheat honey powders were in compliance with results noted by other authors. Shi et al. (2013) reported an MC of honey powders spray dried traditionally at 150 °C with MD and whey protein isolate as carriers (WPI) (honey solids to MD solids and WPI solids was 40:60 and 70:30, respectively) that ranged from 3.1 ± 0.5% to 5.0 ± 0.9% [31]. Samborska et al. (2015) recorded an MC of rapeseed and buckwheat honey spray dried at 180 °C with sodium caseinate and/or Arabic gum as a carrier (honey solids to carrier solids 50:50) varying from 3.7 ± 0.1% to 5.8 ± 0.3% [12]. However, it should be highlighted that in this work the drying temperature and carrier content were lower than in the present literature. Nevertheless, it was possible to obtain stable honey powders that were characterized with a WC below 5% as a result of the application of dehumidified air.

Obtained results for aw are also consistent with the literature, i.e., the results of Jedlińska et al. (2019), who spray dried rapeseed and honeydew honey with the application of dehumidified air and NUTRIOSE® as a carrier agent and noted aw values from 0.074 ± 0.003 to 0.178 ± 0.006 [20]. Powders where MP was used as a carrier and its content was the highest (SDMP50 and DASDMP50) were characterized with lower aw than variants where MD was applied. This phenomenon might be the result of the high water capacity of protein-based carriers in an amorphous state, which in turn lowers the aw of obtained powders [44]. Moreover, it can be observed that powders spray dried with MP had the lowest aw, but at the same time the highest MC (thus, there was no significant Pearson correlation between these two parameters, as presented in Table A1). This phenomenon points to the likelihood that water present in the powder was bound in the structure, being unavailable for microbial growth and thus ensuring stability. Furthermore, milk proteins form a protective membrane on the particles’ surface, which lowers water availability and results in lower aw. There was no statistically significant difference observed for powders with the lowest carrier content (DASDMD75 and DASDMP75). Obtained results point to the usefulness of MP as a carrier for buckwheat honey spray drying with regard to aw, which results in better storage stability.

3.5.3. Hygroscopicity

Honey powders have shown to be highly hygroscopic due to their high sugar content, and fructose has been proven to exhibit a high capacity for absorbing moisture [30]. Nurhadi et al. (2012) presented that powders with H higher than 20% are considered to be very hygroscopic [45]. The H of obtained buckwheat honey powders ranged from 10.1 ± 0.6 to 20.5 ± 0.4 (Table 3), whereas Suhag and Nanda (2015), Jedlińska et al. (2019), and Samborska et al. (2020) noted H values of different honey powders varying from 20.11% to 27.28%, from 20.1 to 27.4% and from 23.9 to 31.4%, respectively [17,20,30]. The results presented in this research thus offer evidence that it is possible to obtain honey powders that are less hygroscopic, in contrast to previous studies. It is interesting to note that the variants with the highest honey content (DASDMD75 and DASDMP75) were characterized with the lowest H, in contradiction with findings by Shi et al. (2013), Jedlińska et al. (2019) and Samborska et al. (2020) [17,20,31]. Shi et al. (2013), who traditionally spray dried capilano natural Australian honey (blend of Australian eucalyptus and ground flora honeys) also found that H increased with an increase in honey content, comparing variants with 40, 60 and 70% of total soluble honey solids and using MD and WPI as carrier agents [31]. Jedlińska et al. (2019) noted the same relationship when spray drying honey powders with the application of dehumidified air and using NUTRIOSE® as the carrier; H content decreased up to 20% [20]. Samborska et al. (2020) chose the same approach as in this research, spray drying honeydew honey with the application of dehumidified air (inlet/outlet temperature of 75/50 °C) and using MP as a carrier; H content decreased up to 25% [17]. The authors observed the same relationship as in previous studies—H increased with a decrease in carrier content. It is worth highlighting that the aforementioned literature describes the properties of different honey types, with the exception of Samborska et al. (2015), who also spray dried buckwheat honey powder, though using different methods and drying parameters [12]. The authors described the H of two honey types (buckwheat and rapeseed honey) and noted the honey variety’s effect. Moreover, this study supports the previous findings of Bringas-Lantingua et al. (2016), who traditionally spray dried multifloral honey powders and observed that H decreased with a decrease in drying temperature [46].

3.5.4. Bulk Density and Flowability

The loose bulk density (DL) of obtained buckwheat honey powders varied from 0.51 ± 0.02 to 0.73 ± 0.01 g/cm3 (Table 3). Obtained results differed to some extent from those of Samborska et al. (2015), Bringas-Lantingua et al. (2016) and Leyva-Moguel et al. (2019) [12,46,47]. Samborska et al. (2015), who traditionally spray dried rapeseed and buckwheat honey powders, with gum Arabic as a carrier and with the addition of 1–2% of w/w NaCas, noted DL from 0.43 ± 0.01 to 0.61 ± 0.01 g/cm3 [12]. Bringas-Lantigua et al. (2016) observed DL values of multifloral honey powders with maltodextrin as a carrier ranging from 0.42 to 0.59 g/cm3 [46]. Leyva-Moguel et al. (2019), who spray dried honey powder of stingless bee Scaptotrigona pectoralis, reported a DL of 0.33 g/cm3 [47]. However, it should be highlighted that authors spray dried honey powders traditionally, using different carriers and different content and drying parameters than presented in this study. Moreover, the effect of carrier type can be noted: powders with MP had higher DL than variants with MD. Generally speaking, high DL indicates that there are fewer spaces filled with air between particles, which in turn lowers the risk of oxidative degradation of health beneficial compounds during powder storage. This implies that MP might be a better carrier than MD with regard to compound degradation during storage, regardless of carrier content and drying parameters. Normally, the DL decreases with increasing particle size [48]. Contrary to expectations, obtained results did not confirm this relationship entirely, except for variants SDMD50 and DASDMD75. It should be noted that these variants had the biggest particle size (Table 3) as well as the most visible particle stickiness and agglomeration (Figure 2), which in turn led to the lowest DL. Interestingly, there was no statistically significant difference between variants spray dried traditionally with higher carrier content and variants spray dried at lower drying temperatures with lower carrier content, with both MD and MP applied as carriers (compare SDMD50 with DASDMD75, SDMP50 with DASDMP75).

The Hausner ratio (HR) is a parameter used to describe powder flowability, which indicates its quality. According to Geldart et al. (1984), obtained buckwheat honey powders showed good (<1.2) and average (1.2–1.4) flowability [49]. The results reported in this paper are consistent with previous studies on honey powder spray drying. The authors reported an HR of honey powders ranging from 1.30 ± 0.04 to 1.38 ± 0.02, from 1.27 to 1.36 and from 1.20 to 1.49 [17,41,46]. Broadly speaking, particle size diameter affects powder flowability; with increasing particle size diameter, flowability ameliorates, which is confirmed in this paper (excluding variant SDMD50, which presented significant stickiness) [49]. Powder of the best flowability (<1.2 HR) and greater D50 was noted for variant spray dried at low drying temperature and with the lowest carrier content (DASDMD75); this was an effect of particles’ agglomeration (Figure 2), which ameliorated overall flowability despite high honey content. Shishir et al. (2014), who spray dried pink guava (Psidium guajava) powder, also observed that flowability deteriorated with increased drying temperature and MD concentration [50]. It should be highlighted that powders where MP was used as a carrier did not differ with regard to flowability. Samborska et al. (2020) reported as well that there was no effect of drying temperature (traditional spray drying and spray drying with the application of dehumidified air) on the flowability of honeydew honey when MP was used as a carrier, which was an effect of similar particle size in MP variants [17]. Obtained results point to the probability that MP might be a better carrier than MD in buckwheat honey spray drying, ensuring its uniform flowability regardless of carrier content and drying parameters. This might be a result of protein-based carriers’ ability to form film on the surface of the particles, which prevents their stickiness and ensures uniform flowability, as mentioned before. Moreover, the significant effect of carrier content and drying parameters can be noted in variants with MD. The variant with the highest carrier content spray dried at higher temperature (SDMD50) showed the poorest flowability of all of the obtained buckwheat honey powders. According to Santhalakshmy et al. (2015), flowability is correlated to a powder’s moisture content; however, this relationship was not observed in this paper (Pearson correlation was not significant; see Table A1), as the variant with the lowest MC (0.9%) had the poorest flowability (SDMD50) [51].

3.5.5. Apparent Density and Loose Bed Porosity

The apparent density (Dap) of obtained buckwheat honey powders ranged from 1.42 ± 0.02 to 1.51 ± 0.00 g/cm3 (Table 3). Generally speaking, the values are consistent with previous results presented in the literature concerning honey powders. Barańska et al. (2019) noted Dap of multifloral honey powders spray dried at 180 and 80 °C with MD and MP as carrier agents ranging from 1.44 ± 0.00 to 1.54 ± 0.00 g/cm3 [16]. Jedlińska et al. (2019) reported Dap of honeydew and rapeseed honey powders spray dried traditionally and with the application of dehumidified air and with NUTRIOSE® as a carrier varying from 1.49 ± 0.01 to 1.56 ± 0.01 g/cm3 [20]. Presented results revealed that there was a statistically significant effect of drying temperature and carrier content in variants where MD was applied. However, the influence of drying temperature could not be observed for variants where MP was used as a carrier, though the effect of the carrier content could be noted. Moreover, a statistically significant difference could be observed as well when comparing variants with the same carrier content but different carrier type, with the exception of variants spray dried traditionally at high drying temperatures (SDMD50 and SDMP50). In contrast to the earlier findings of Jedlińska et al. (2019), who noted higher values of Dap in variants spray dried traditionally than in variants spray dried with the application of dehumidified air, a similar relationship was not observed in this paper [20]. It would seem to appear that a higher drying temperature increased the rate of evaporation, which in turn resulted in lower Dap and more porous powders.

The loose bed porosity (εL) of produced buckwheat honey powders varied from 50.5 ± 0.6 to 67.8 ± 0.8% (Table 5). Bed porosity is an important parameter in terms of a product’s stability and its storage, as it describes the relative share of free spaces between particles that are filled with air. As a result, at higher porosity the compounds that are susceptible to oxidation are more likely to degrade [52]. The greatest εL was noted for variant DASDMD75, which was due to the lowest DL and highly conglomerated particles, as observed on SEM photographs (Figure 2). The Pearson negative correlation between εL and DL was observed: powders with higher DL had lower εL (Table A1).

Table 5.

Color parameters L*a*b* of buckwheat honey powders obtained by high temperature traditional spray drying (SD) and low temperature spray drying with the application of dehumidified air (DASD) with maltodextrin (MD) and milk powder (MP) as a carrier, containing 50–75% honey solids.

The results found in this study are lesser with respect to those reported in the literature. Samborska et al. (2020) produced honey powders of porosity ranging from 58.2 ± 1.1 to 70.5 ± 3.4%, using traditional spray drying and with the application of dehumidified air and decreasing carrier content, as presented in this paper [17]. Jedlińska et al. (2019), who applied the same spray drying methods to obtain honey powders, noted porosity varying from 63.3 ± 0.7 to 72.5 ± 0.92% [20]. In comparison to previous values, it seems likely that the type of a carrier and honey lowered εL. The statistically significant difference between variants both with MD and MP with the same carrier content but spray dried at different drying temperatures could be observed (SDMD50 and DASDMD50, SDMP50 and DADMP50). Lowering drying temperature as a result of the application of dehumidified air significantly lowered εL. Moreover, variants where MP was used as a carrier in comparison with variants with MD were characterized by lower εL. The utility of the application of dehumidified air and MP in buckwheat honey spray drying is thus proven with regard to powder porosity.

3.5.6. Color

The lightness of obtained buckwheat honey powders, expressed as L* parameter, ranged from 79.8 ± 0.1 to 86.7 ± 0.5 (Table 5). Reported results revealed that powders where MP was used as a carrier were darker than powders with MD. This is in good agreement with Samborska et al. (2015), who noted a decrease in lightness when NaCas was applied to honey powders as a carrier, which is a consequence of proteins’ ability to form brown complexes with polyphenols, which decreases lightness [12].

In comparison with study of Samborska et al. (2015), who observed buckwheat and rapeseed honey powders’ lightness after spray drying varying from 33.5 ± 0.2 to 38.1 ± 0.3, the powders obtained in this study were considerably lighter [12]. It is worth highlighting that powders spray dried with the application of dehumidified air were significantly lighter than powders spray dried traditionally, which underlines the validity of this innovative method in honey spray drying. The a* parameter indicates the green/red color, and reported results point to the effect of drying temperature, carrier content and type. It can be noted that increasing carrier content in honey powders spray dried at lower drying temperature (DASDMD50 and DASDMP50) decreased their redness. It is worth highlighting that for traditional spray drying there was no effect of the carrier type. The b* parameter, which signifies the yellowness, was considerably higher for variants where MP was applied as a carrier. This observation, along with that for the L* parameter, according to Cui et al. (2008), suggests a higher degree of browning that occurred during spray drying with MP than for variants with MD as a carrier; this correlation was confirmed by the Pearson correlation coefficient (Table A1) [53].

3.6. Antioxidant Activity

The antioxidant activity of raw buckwheat honey and spray dried powders, expressed as EC50 ABTS—a material’s ability of scavenging 50% of free radicals in ABTS solution—was 2.69 ± 0.00 mg solids·ml−1 for raw honey, and for powders it ranged from 0.18 ± 0.00 to 8.24 ± 0.36 mg solids·ml−1 (Table 3) [54]. Obtained results point to the significant effect of carrier type in all variants and drying parameters for variants where MD was used as a carrier. The highest antioxidant activity was noted for variants where MP was applied as a carrier, which further strengthened the authors confidence in MP’s validity in buckwheat honey spray drying. Samborska et al. (2020) reported the same effect of MP in dehumidified-air-assisted spray drying of honey [17]. The authors noted better results in powders’ antioxidant activity in comparison to other carriers (maltodextrin, kleptose, NUTRIOSE®). It should be emphasized as well that higher antioxidant activity was observed for powdered honey in the case of MP variants (in contrast to MD variants) than for raw buckwheat honey. Samborska et al. (2019) underlined that a concentration of milk present in the honey powder as a carrier should be considered in antioxidant activity assessment, as milk itself manifests antioxidant activity due to its composition [55]. However, the presented results do not seem to confirm this observation, as carrier concentration did not affect powders’ antioxidant activity with regard to MP variants. It should be outlined as well that the formation of products of Maillard reaction could have affected the antioxidant activity of MP variants in comparison to MD variants. The color analysis (Table 5) indicated that MP variants were more susceptible to browning than MD variants, suggesting greater formation of Maillard reaction products in the powder and consequently ameliorating the antioxidant activity of final product. However, this correlation was not assessed by the Pearson coefficient (Table A1). Nevertheless, the findings of this research likely imply the protective effect of MP on buckwheat honey spray drying. Moreover, there was no statistically significant effect of drying parameters on antioxidant activity with regard to powders spray dried with MP as a carrier. Generally speaking, high drying temperatures deteriorate antioxidant activity [55]. However, in this research this relationship was not observed. As can be noted, MD variants manifested lower antioxidant activity than MP variants, and variants spray dried at lower drying temperature and with high carrier content (DASDMD50) can be considered as the worst variants to scavenge free radicals. However, obtained results would seem to suggest that smaller particles in variant DASDMD50 consequently increased the particle surface exposed to the heat, which resulted in greater compound degradation and lower antioxidant activity than in high temperature variant SDMD50.

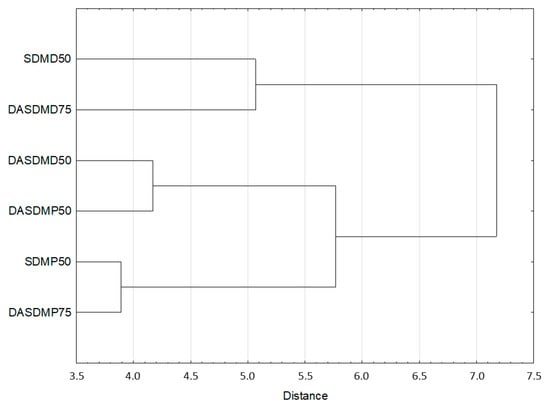

3.7. Hierarchical Cluster Analysis

The HCA analysis (Figure 5) supported previous findings that variants SDMD50 and DASDMD75 are considered as the most problematic during spray drying, as they create one cluster. This was especially manifest in particle morphology, Rp and on cumulated particle size distribution curves. Variants DASDMD50, DASDMP50, SDMP50 and DASDMP75 were grouped in two other clusters; however, they also created one cluster, confirming that these variants were less problematic to spray dry, as was explained before.

Figure 5.

Dendrogram plot from HCA of obtained buckwheat honey powders.

4. Conclusions

This study investigated the possibility of low temperature spray drying of buckwheat honey with the application of dehumidified air and its properties in comparison to traditional spray drying, which has not been done before for this type of honey. The findings of this study indicate the successful spray drying of all of the variants. The production of honey powders with high Rp (87% and 97% for variants DASDMD75 and DASDMP75, respectively) and, at the same time, with low carrier content (25%) was accomplished. This paper also describes the energy consumption analysis of dehumidified-air-assisted spray drying, which has not been presented in the literature before. This provides practical information for a possible implementation of this innovative technique in industry.

Obtained results point to the statistically significant differences in the physiochemical properties of powders spray dried conventionally and at low drying temperatures. Powders produced with the application of dehumidified air showed smaller and more spherical particles with smooth surfaces in comparison to variants spray dried traditionally. Moreover, variants with skim milk powder as a carrier, in comparison to maltodextrin, were more spherical and less conglomerated and had particles that were less scattered. All of the buckwheat honey powders had low moisture content and water activity, below 5% and 0.3, respectively, which ensured their stability. It is worth underlining that powders with skim milk powder as a carrier had lower aw, which highlights the usefulness of MP as a carrier in buckwheat honey spray drying as it points to its better storage stability. It should also be emphasized that powders with skim milk powder as a carrier exhibited the highest antioxidant activity. The results presented in this paper provide further evidence of the validity of dehumidified-air-assisted spray drying and of skim milk powder as a carrier of buckwheat honey as an example material.

Author Contributions

Analysis, writing of the original draft, review and editing were done by A.B. The methodology and analysis were done by A.J. The conceptualization, methodology, review and editing were done by K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Acknowledgments

The authors would like to thank Małgorzata Ignaczewska for participation in the experimental part of the research.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Pearson correlation coefficients of between powder recovery (Rp) and physiochemical properties of buckwheat honey powders obtained by high temperature traditional spray drying (SD) and low temperature spray drying with the application of dehumidified air (DASD) with maltodextrin (MD) and milk powder (MP) as a carrier, containing 50–75% honey solids.

Table A1.

Pearson correlation coefficients of between powder recovery (Rp) and physiochemical properties of buckwheat honey powders obtained by high temperature traditional spray drying (SD) and low temperature spray drying with the application of dehumidified air (DASD) with maltodextrin (MD) and milk powder (MP) as a carrier, containing 50–75% honey solids.

| MC | aw | H | D50 | DL | DT | HR | Dap | εL | L* | a* | b* | EC50 ABTS | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rp | 0.593 | −0.142 | −0.721 | −0.495 | 0.178 | −0.046 | −0.720 | 0.314 | 0.025 | 0.188 | −0.360 | −0.050 | −0.215 |

| MC | −0.271 | 0.034 | −0.886 * | −0.705 | 0.718 | −0.355 | 0.510 | −0.700 | −0.054 | −0.700 | 0.335 | −0.704 | |

| aw | −0.294 | 0.456 | 0.184 | 0.130 | 0.105 | 0.012 | −0.201 | 0.884 * | −0.406 | −0.929 * | 0.616 | ||

| H | −0.224 | 0.265 | 0.502 | 0.539 | 0.169 | −0.445 | −0.474 | 0.117 | 0.503 | −0.282 | |||

| D50 | −0.705 | −0.616 | 0.459 | −0.616 | 0.619 | 0.161 | 0.504 | −0.427 | 0.539 | ||||

| DL | 0.910 * | −0.256 | 0.431 | −0.966 * | 0.347 | −0.909 * | −0.062 | −0.305 | |||||

| DT | 0.145 | 0.523 | −0.978 * | 0.113 | −0.732 | 0.113 | −0.475 | ||||||

| HR | −0.002 | 0.003 | −0.366 | 0.399 | 0.195 | −0.179 | |||||||

| Dap | −0.452 | 0.064 | −0.241 | 0.021 | −0.163 | ||||||||

| εL | −0.249 | 0.821 * | 0.000 | 0.353 | |||||||||

| L* | −0.596 | −0.949 * | 0.650 | ||||||||||

| a* | 0.329 | 0.163 | |||||||||||

| b* | −0.796 |

* Values with significant correlation for p < 0.05.

References

- Dżugan, M.; Grabek-Lejko, D.; Swacha, S.; Tomczyk, M.; Bednarska, S.; Kapusta, I. Physicochemical quality parameters, antibacterial properties and cellular antioxidant activity of Polish buckwheat honey. Food Biosci. 2020, 34, 100538. [Google Scholar] [CrossRef]

- Pentoś, K.; Łuczycka, D.; Oszmiański, J.; Lachowicz, S.; Pasternak, G. Polish honey as a source of antioxidants—A comparison with Manuka honey. J. Apic. Res. 2020, 59, 939–945. [Google Scholar] [CrossRef]

- Liu, J.R.; Ye, Y.L.; Lin, T.Y.; Wang, Y.W.; Peng, C.C. Effect of floral sources on the antioxidant, anti-microbial, and anti-inflammatory activities of honeys in Taiwan. Food Chem. 2013, 139, 938–943. [Google Scholar] [CrossRef] [PubMed]

- Erejuwa, O.O.; Sulaiman, S.A.; Ab Wahab, M.S. Honey: A novel antioxidant. Molecules 2012, 17, 4400–4423. [Google Scholar] [CrossRef] [PubMed]

- Flanjak, I.; Kenjeric, D.; Bubalo, D.; Primorac, L. Characterisation of selected Croatian honey types based on the combination of antioxidant capacity, quality parameters, and chemometrics. Eur. Food Res. Technol. 2016, 242, 467–475. [Google Scholar] [CrossRef]

- Gheldof, N.; Engeseth, N.J. Antioxidant capacity of honeys from various floral sources based on the determination of oxygen radical absorbance capacity and inhibition of in vitro lipoprotein oxidation in human serum samples. J. Agric. Food Chem. 2002, 50, 3050–3055. [Google Scholar] [CrossRef]

- Jiang, L.; Xie, M.; Chen, G.; Qiao, J.; Zhang, H.; Zeng, X. Phenolics and Carbohydrates in Buckwheat Honey Regulate the Human Intestinal Microbiota. Evid. Based Complement. Altern. Med. 2020, 6432942. [Google Scholar] [CrossRef]

- Hammond, E.N.-A.; Duster, M.; Musuuza, J.S.; Safdar, N. Effect of United States buckwheat honey on antibiotic-resistant hospital acquired pathogens. Pan Afr. Med. J. 2016, 25, 212. [Google Scholar] [CrossRef]

- Baranowska-Wójcik, E.; Szwajgier, D.; Winiarska-Mieczan, A. Honey as the Potential Natural Source of Cholinesterase Inhibitors in Alzheimer’s Disease. Plant Foods Hum. Nutr. 2020, 75, 30–32. [Google Scholar] [CrossRef]

- Samborska, K. Powdered honey—Drying methods and parameters, types of carriers and drying aids, physicochemical properties and storage stability. Trends Food Sci. Technol. 2019, 88, 133–142. [Google Scholar] [CrossRef]

- Samborska, K.; Barańska, A.; Bodel, D. Investigation on the possibility to enhancing honey spray drying process and powders properties by ultrafiltration pre-treatment. Chem. Process Eng. 2019, 40, 305–313. [Google Scholar] [CrossRef]

- Samborska, K.; Langa, E.; Kamińska-Dwórznicka, A.; Witrowa-Rajchert, D. The influence of sodium caseinate on the physical properties of spray-dried honey. Int. J. Food Sci. Technol. 2015, 50, 256–262. [Google Scholar] [CrossRef]

- Bhandari, B.R.; Datta, N.; Howe, T. Problems Associated with Spray Drying of Sugar-Rich Foods. Dry. Technol. 1997, 15, 671–684. [Google Scholar] [CrossRef]

- Stevenson, E.J.; Watson, A.; Theis, S.; Holz, A.; Harper, L.D.; Russel, M. A comparison of isomaltulose versus maltodextrin ingestion during soccer-specific exercise. Eur. J. Appl. Physiol. 2007, 117, 2321–2333. [Google Scholar] [CrossRef] [PubMed]

- Suhag, Y.; Nanda, V. Evaluation of different carrier agents with respect to physico-chemical, functional and morphological characteristics of spray dried nutritionally rich honey powder. J. Food Process. Preserv. 2016, 40, 1429–1437. [Google Scholar] [CrossRef]

- Barańska, A.; Jedlińska, A.; Konachowicz, M.; Samborska, K. The investigation of the application of skim milk as a carrier and diluent during honey solution spray drying. Zesz. Probl. Postępów Nauk Rol. 2019, 597, 3–13. [Google Scholar] [CrossRef]

- Samborska, K.; Barańska, A.; Szulc, K.; Jankowska, E.; Truszkowska, M.; Ostrowska-Ligęza, E.; Wołosiak, R.; Szymańska, E.; Jedlińska, A. Reformulation of spray-dried apple concentrate and honey for the enhancement of drying process performance and the physicochemical properties of powders. J. Sci. Food Agric. 2020, 100, 2224–2235. [Google Scholar] [CrossRef]

- Angel, R.C.M.; Espinosa-Muñoz, L.C.; Aviles-Aviles, C.; González-García, R.; Moscosa-Santillán, M.; Grajales-Lagunes, A.; Abud-Archila, M. Spray-drying of passion fruit juice using lactose-maltodextrin blends as the support material. Brazilian Arch. Biol. Technol. 2009, 52, 1011–1018. [Google Scholar] [CrossRef]

- Barańska, A.; Samborska, K.; Jedlińska, A. Application of Dehumidified Air During Spray Drying for the Production of Food Powders. In Mechatronics 2019: Recent Advances towards Industry 4.0. MECHATRONICS 2019. Advances in Intelligent Systems and Computing; Szewczyk, R., Krejsa, J., Nowicki, M., Ostaszewska-Liżewska, A., Eds.; Springer: Cham, Switzerland, 2020; Volume 1044, pp. 463–468. [Google Scholar] [CrossRef]

- Jedlińska, A.; Samborska, K.; Wieczorek, A.; Wiktor, A.; Ostrowska-Ligęza, E.; Jamróz, W.; Skwarczyńska-Maj, K.; Kiełczewski, D.; Błażowski, Ł.; Tułodziecki, M.; et al. The application of dehumidified air in rapeseed and honeydew honey spray drying—Process performance and powders properties considerations. J. Food Eng. 2019, 245, 80–87. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Effect of Maltodextrin Addition during Spray Drying of Tomato Pulp in Dehumidified Air: I. Drying Kinetics and Product Recovery. Dry. Technol. 2008, 26, 714–725. [Google Scholar] [CrossRef]

- Chasekioglou, A.N.; Goula, A.M.; Adamopoulos, K.G.; Lazarides, H.N. An approach to turn olive mill wastewater into a valuable food by-product based on spray drying in dehumidified air using drying aids. Powder Technol. 2017, 311, 376–389. [Google Scholar] [CrossRef]

- Al-Mansour, H.E.; Al-Busairi, B.H.; Baker, C.G.J. Energy consumption of a pilot-scale spray dryer. Dry. Technol. 2011, 29, 1901–1910. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Codex Alimentarius Commission Standards. Revised Codex Standards for Honey. Codex Standard 121981, Rev. 2. Available online: http://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B12-1981%252FCXS_012e.pdf (accessed on 24 March 2021).

- Council Directive 2001: No. 2001/110/EC of 20 December 2001 Relating to Honey. Official Journal of the European Communites, L 10. pp. 47–52. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32001L0110&from=EN (accessed on 24 March 2021).

- Deng, J.; Liu, R.; Lu, Q.; Hao, P.; Xu, A.; Zhang, J.; Tan, J. Biochemical properties, antibacterial and cellular antioxidant activities of buckwheat honey in comparison to manuka honey. Food Chem. 2018, 252, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Kowalski, S.; Łukasiewicz, M.; Berski, W. Applicability of physico-chemical parameters of honey for identification of the botanical origin. Acta Sci. Pol. Technol. Aliment. 2013, 12, 51–59. [Google Scholar] [PubMed]

- Samborska, K.; Gajek, P.; Kamińska-Dwórznicka, A. Spray Drying of Honey: The Effect of Drying Agents on Powder Properties. Polish J. Food Nutr. Sci. 2015, 65, 109–118. [Google Scholar] [CrossRef]

- Suhag, Y.; Nanda, V. Optimisation of process parameters to develop nutritionally rich spray-dried honey powder with vitamin C content and antioxidant properties. Int. J. Food Sci. Technol. 2015, 50, 1771–1777. [Google Scholar] [CrossRef]

- Shi, Q.; Fang, Z.; Bhandari, B. Effect of Addition of Whey Protein Isolate on Spray-Drying Behavior of Honey with Maltodextrin as a Carrier Material. Dry. Technol. 2013, 31, 1681–1692. [Google Scholar] [CrossRef]

- Truong, V.; Bhandari, B.R.; Howes, T. Optimization of co-current spray drying process of sugar-rich foods. Part I—Moisture and glass transition temperature profile during drying. J. Food Eng. 2005, 71, 55–65. [Google Scholar] [CrossRef]

- Poozesh, S.; Bilgili, E. Scale-up of pharmaceutical spray drying using scale-up rules: A review. Int. J. Pharm. 2019, 562, 271–292. [Google Scholar] [CrossRef]

- Gimbun, J.; Choong, T.S.; Fakhruâ, A.; Chuah, T.G. Prediction of the effect of dimension, particle density, temperature, and inlet velocity on cyclone collection efficiency. J. Teknol. 2004, 40, 37–50. [Google Scholar] [CrossRef]

- Jayasundera, M.; Adhikari, B.; Aldred, P.; Ghandi, A. Surface modification of spray dried food and emulsion powders with surface-active proteins: A review. J. Food Eng. 2009, 93, 266–277. [Google Scholar] [CrossRef]

- Bhusari, S.N.; Muzaffar, K.; Kumar, P. Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technol. 2014, 266, 354–364. [Google Scholar] [CrossRef]

- Bhandari, B. Spray drying and powder properties. In Food Drying Science and Technology: Microbiology, Chemistry, Applications; DEStech Publications, Inc.: Lancaster, PA, USA, 2008; pp. 215–248. [Google Scholar]

- Baker, C.G.J.; McKenzie, K.A. Energy consumption of industrial spray dryers. Dry. Technol. 2005, 23, 365–386. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Mobli, H.; Rafiee, S.; Madadlou, A. Energy and exergy analyses of the spray drying process of fish oil microencapsulation. Biosyst. Eng. 2012, 111, 229–241. [Google Scholar] [CrossRef]

- Julklang, W.; Golman, B. Effect of process parameters on energy performance of spray drying with exhaust air heat recovery for production of high value particles. Appl. Energy 2015, 151, 285–295. [Google Scholar] [CrossRef]

- Samborska, K.; Sokołowska, P.; Szulc, K. Diafiltration and agglomeration as methods to improve the properties of honey powder obtained by spray drying. Innov. Food Sci. Emerg. Technol. 2017, 39, 33–41. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M. D Influence of process conditions on the physicochemical properties of acai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Belščak-Cvitanović, A.; Lević, S.; Kalušević, A.; Špoljarić, I.; Đorđević, V.; Komes, D.; Mršić, G.; Nedović, V. Efficiency assessment of natural biopolymers as encapsulants of green tea (Camellia sinensis L.) bioactive compounds by spray drying. Food Bioprocess Technol. 2015, 8, 2444–2460. [Google Scholar] [CrossRef]

- Muzaffar, K.; Kumar, P. Comparative efficiency of maltodextrin and protein in the production of spray-dried tamarind pulp powder. Dry. Technol. 2016, 34, 802–809. [Google Scholar] [CrossRef]

- Nurhadi, B.; Andoyo, R.; Indiarto, R. Study the properties of honey powder produced from spray drying and vacuum drying method. Int. Food Res. J. 2012, 19, 907–912. [Google Scholar]

- Bringas-Lantingua, M.; Pino, J.A.; Aragüez-Fortes, Y. Influence of process conditions on the physicochemical properties of honey powder produced by spray drying. Rev. CENIC Cienc. Quim. 2016, 47, 64–69. [Google Scholar]

- Leyva-Moguel, K.; Sosa-Moguel, O.; A Pino, J.; Bolivar-Moreno, D.; Cuevas-Glory, L. Physicochemical parameters of liquid and spray-dried honey of stingless bee Scaptotrigona Pectoralis. J. Apic. Res. 2019, 1–9. [Google Scholar] [CrossRef]

- Ferrari, C.C.; Germer, S.P.M.; Alvim, I.D.; Vissotto, F.Z.; de Aguirre, J.M. Influence of carrier agents on the physicochemical properties of blackberry powder produced by spray drying. Int. J. Food Sci. Technol. 2012, 47, 1237–1245. [Google Scholar] [CrossRef]

- Geldart, D.; Harnby, N.; Wong, A.C.Y. Fluidization of cohesive powders. Powder Technol. 1984, 37, 25–37. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Taip, F.S.; Aziz, N.A.; Talib, R.A. Physical Properties of Spray-dried Pink Guava (Psidium guajava) Powder. Agric. Agric. Sci. Procedia 2014, 2, 74–81. [Google Scholar] [CrossRef]

- Santhalakshmy, S.; Don Bosco, S.J.; Francis, S.; Sabeena, M. Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technol. 2015, 274, 37–43. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; da Silva, V.M.; Durigon, A.; Hubinger, M.D.; Laurindo, J.B. Production of mango powder by spray drying and cast-tape drying. Powder Technol. 2017, 305, 447–454. [Google Scholar] [CrossRef]

- Cui, Z.W.; Sun, L.J.; Chen, W.; Sun, D.W. Preparation of dry honey by microwave–vacuum drying. J. Food Eng. 2008, 84, 582–590. [Google Scholar] [CrossRef]

- Biskup, I.; Golonka, I.; Gamian, A.; Sroka, Z. Antioxidant activity of selected phenols estimated by ABTS and FRAP methods. Postepy Hig. Med. Dosw. 2013, 67, 958–963. [Google Scholar] [CrossRef]

- Samborska, K.; Jedlińska, A.; Wiktor, A.; Derewiaka, D.; Wołosiak, R.; Matwijczuk, A.; Jamróz, W.; Skwarczyńska-Maj, K.; Kiełczewski, D.; Błażowski, Ł.; et al. The Effect of Low-Temperature Spray Drying with Dehumidified Air on Phenolic Compounds, Antioxidant Activity, and Aroma Compounds of Rapeseed Honey Powders. Food Bioprocess Technol. 2019, 12, 919–932. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).