Abstract

In the last decades, Reconfigurable Manufacturing Systems (RMSs) rose as an emerging manufacturing strategy matching the modern industrial and market requirements asking for a wide variety of products in flexible batches. A traditional reconfigurable manufacturing environment consists of dynamic cells, called Reconfigurable Machine Cells (RMCs), including a set of machines called Reconfigurable Machine Tools (RMTs). Such machines are characterized by fixed elements, i.e., basic modules, and dynamic elements, i.e., auxiliary modules, allowing them to perform different operations. Despite their automation level, these systems require the intervention of the human operators in performing specific tasks, e.g., handling of the auxiliary modules from the warehouse to the RMTs and their assembly/disassembly to/from the RMTs. This issue rises relevant ergonomic and safety questions due to the human–machine collaboration. Following this stream, this paper proposes and applies a bi-objective optimization model for the design and management of RMSs. The technical objective function minimizes the reconfiguration time, i.e., the time needed to equip the RMTs with the required auxiliary modules, and the part and auxiliary module travel time among the RMCs. The ergonomic objective function minimizes the repetitive movements performed by the human operators during the working activities according to the ISO 11228-3 standard. Results show the existence of a good trade-off between the two objective functions, proving the possibility to improve the ergonomic conditions of the human operators without excessively increasing the total time needed for RMTs reconfiguration and for part and auxiliary module travelling.

1. Introduction and Literature Review

The recent years are characterized by the advent of the forth industrial revolution, known as Industry 4.0 [1,2]. This revolution is marked by a set of radical changes in the industrial and market context, as flexible production batches, short product life cycles, and a dynamic market demand, which require being efficiently managed. In this scenario, Reconfigurable Manufacturing Systems (RMSs) appear as effective solutions able to manage such modern trends. They were conceived in 1999 by Professor Yoram Coren from the University of Michigan and defined as systems “designed at the outset for rapid change in structure as well as in hardware and software components to quickly adjust production capacity and functionality within a part family in response to sudden change in market or in regulatory requirement” [3,4,5,6]. In these two decades, RMSs became a strategic pillar and mentioned as one of the main challenges by the Committee on Visionary Manufacturing Challenges for the year 2020 [7]. In the field of optimization models for RMS design and management, a high number of studies exist in current literature [8,9,10]. Koren et al. [11] defined a mathematical model that maximizes the system throughput after the reconfiguration phases and an industrial case study to validate the proposed methodology. The key value of this paper is to provide a set of principles for RMS design for scalability to support designers and practitioners of modern manufacturing systems. Moghaddam et al. [7] addressed the problem of configuration design for RMS producing different products. To do this, the Authors defined two new mathematical models to address the system configuration design in different periods and compared the results according to different aspects, such as the total system design costs and the total number of reconfigurations. Maniraj et al. [12] proposed a two-step approach for the configuration selection of a single-item flow-line RMS using ant colony optimization. The former step aims at finding feasible clusters of operations by using priority-based encoding techniques, the latter step uses the ant colony optimization to minimize the capital cost of the RMS. Aljuneidi and Bulgak [13] presented a simultaneous investigation of cellular RMSs and hybrid manufacturing–remanufacturing systems and proposed an integrated approach for the design optimization, analysis, and process planning. To reach this goal, the Authors proposed a mixed integer linear programming model, which links the cell formation problem typical of cellular manufacturing to the production planning problem. Asghar et al. [14] proposed a study based on the co-evolution of machine configurations and process planning, in which machine capabilities are generated through the application of multi-objective genetic algorithms. The model assigns the optimum number of machines by minimizing the machining capabilities to carry out different operations to streamline production responses. Touzout and Benyoucef [15] addressed the multi-objective single-product multi-unit process plan generation problem in an RMS environment proposing three hybrid heuristics. Besides the minimization of the global completion time and the production cost, the minimization of the maximum machines exploitation time is considered an innovative optimization criterion to reach high quality products. Benderbal et al. [16] proposed a multi-objective approach for the RMS design optimization, considering as objective functions the maximization of the modularity of the system, the minimization of the overall cost of the system, and the minimization of the completion time. The authors solved this model using an archived multi-objective simulated annealing method. Bortolini et al. [9,17] defined an optimization model for the RMS design and management balancing the trade-off between the machine reconfiguration and the inter-cell part travel time.

As emerged from the literature review analysis, most of the existing studies face the RMS design and management from a techno-economic perspective. The inclusion of the ergonomic dimension has not yet been explored properly and few studies exist. Among these, Ben Cheikh et al. [18] proposed an approach based on an analytic hierarchy process (AHP) to support the decision makers in the selection of the best RMS configuration, according to both technical and health and safety (HS) performance indicators, e.g., a musculoskeletal trouble indicator, a repeatability indicator, and a noise indicator. The authors proved the benefits of including HS aspects in the RMS design. Kouki et al. [19] introduced a multi-criteria decision tool based on TOPSIS methodology for the evaluation and selection of alterative RMS configurations according to technical and ergonomic indicators, e.g., load, postures, and working conditions. Recently, Bortolini et al. [20] defined a practical methodological and operative framework supporting the integration of ergonomics, safety, and human factors in the emerging reconfigurable manufacturing environments. The main relevant feature of this methodology is to collect the main activities to be performed in an RMS that requires manual operations and to link these actions to specific HR critical areas, i.e., working postures, manual handling tasks, safety, fatigue, and stress. However, quantitative methods and tools supporting the design and management of RMSs including ergonomic aspects are missing in the current literature and highly expected. To fill this gap, this paper proposes and applies an innovative bi-objective techno-ergonomic optimization model for the design and management of RMSs. According to the ISO 11228-3 standard, the ergonomic issue is addressed in terms of minimization of the repetitive movements performed by the human operators during the working activities, using the Occupational Repetitive Actions (OCRA) index. Specifically, the OCRA method is an ergonomic risk assessment methodology developed to analyze the risk factors in repetitive work that may cause work-related upper limb disorders [21]. The quantitative measure for the ergonomic risk assessment with the OCRA method is the OCRA index, which represents the ratio between the overall number of actual technical actions (ATA) performed by the worker during the work-shift and the number of reference technical actions (RTA), for each upper limb, performed in the same time slot. The overall number of ATA carried out in the work-shift is determined from the analysis of the technical actions performed in a representative cycle and the net duration of the investigated repetitive task. The number of RTA within the same work-shift is based on the analysis of the risk factors for work-related upper limb disorders, including the force exertions associated with the work, awkward postures and movements of the upper body segments, job control and work organization, and a set of environmental factors such as, for example, noise, vibration, the requirement for absolute accuracy, and the use of personal protective equipment that may interfere with handling ability. This risk assessment methodology is commonly used in industrial research as well as in the field of Occupational Medicine.

In this study, the ergonomic risk assessment with the OCRA method was based on the characteristics of the repetitive tasks required to accomplish the manual operations in the RMS, e.g., the assembly and the disassembly of the auxiliary modules.

According to this background, the remainder of this paper is organized as follows: Section 2 introduces the mathematical bi-objective optimization model for the techno-ergonomic RMS design, while the application to an industrial scenario and the results discussion are in Section 3 and Section 4, respectively. Finally, Section 5 concludes this paper with final remarks and future opportunities for research.

2. Bi-Objective Model for the Design and Management of RMSs

The aim of this section is to introduce the mathematical model for the design and management of cellular RMSs. Traditionally, the system layout type is cellular, i.e., cellular reconfigurable manufacturing systems (CRMS), including a set of dynamic cells, i.e., reconfigurable machine cells (RMCs) and intelligent machines with a dynamic structure, called reconfigurable machine tools (RMTs). Such machines consist of fixed basic modules and of a variable number of auxiliary customized modules, which can be assembled and disassembled when needed to allow RMTs to perform different tasks. The auxiliary module assembly and disassembly operations represent repetitive movements continuously performed by the human operators within the working activities. To manage this relevant aspect, the model proposed in this paper includes the risk assessment methodology for the evaluation of repetitive movements requiring the manual handling of low loads at high frequency, i.e., the OCRA method. As discussed in the previous Section 1, this method assesses the worker exposure to ergonomic risk factors, comparing the daily number of actions performed by the upper limbs of the workers to the corresponding number of recommended actions that the worker may perform under the so-called optimal conditions [21,22,23]. Figure 1 shows a general schematic of a CRMS, underlining the RMCs and the RMTs.

Figure 1.

Schematic structure of a CRMS (AM: auxiliary module; BM: basic module).

2.1. Optimization Model Design: Assumptions, Notations, and Analytic Formulation

The bi-objective model aims to best manage the trade-off among the inter-cell travel time among RMTs, the effort to install and disassemble the auxiliary modules on/from the RMT on which the part is located, i.e., RMT reconfiguration, and the ergonomics of the work activity in terms of repetitive movements, i.e., auxiliary module assembly/disassembly, performed during the work-shift. To reach this goal, two objective functions are considered: the former, i.e., technical, minimizes the sum of the inter-cell part and auxiliary module travel time and the RMT reconfiguration time in terms of auxiliary modules assembly and disassembly. The latter, i.e., ergonomics, minimizes the repetitive movements in terms of number of auxiliary module assembly/disassembly performed by the human operators within the working activities to reduce the risk of biomechanical overload. Relevant input data used to explore this trade-off are the information about the part work cycles and the compatibility among tasks, RMTs, and modules.

Moreover, the following assumptions are adopted in the model formulation:

- the part work cycles and compatibility data among tasks, RMTs, and auxiliary modules are known;

- auxiliary module units are available in a limited number per type, marking that they represent scarce resources existing in limited quantities;

- the layout of the reconfigurable production system is given;

- parts travel among RMTs according to their work cycles organized in batches;

- at the end of each period, all batches move to the next task of their work cycle;

- part travel, reconfiguration, and working times are known and deterministic.

Such assumptions are derived by relevant existing studies proposing optimization model formulations for CRMSs design and management [17,24,25]. The aim is to reproduce a realistic industrial setting having a defined layout (re-layout actions are usually time and cost consuming) and in which basic data about parts, auxiliary modules, and machines are collected and available.

The following notations are used.

Indices

| c | RMCs |

| m | modules type m |

| n | auxiliary modules n |

| o | operations in part work cycle |

| p | parts |

| r | RMTs |

| t | time periods |

Parameters (Standard and OCRA)

| additional multiplier for the assembly of module type m on RMT r | |

| additional multiplier for the disassembly of module type m on RMT r | |

| definition of the operation in which the batch of part is in period | |

| assembly time of module type on RMT | |

| Bnm | 1 if auxiliary module n belongs to type m; 0 otherwise [binary] |

| planned production volume during a predefined period of time for part p [parts] | |

| duration multiplier | |

| disassembly time of module type from RMT | |

| force multiplier for the assembly of module type m on RMT r | |

| force multiplier for the disassembly of module type m from RMT r | |

| 1 if operation can be performed on RMT using an auxiliary module of type ; 0 otherwise | |

| constant of frequency of technical actions per minute | |

| maximum number of modules per RMT and period [#] | |

| 1 if RMT is assigned to RMC ; 0 otherwise | |

| number of technical actions for the assembly of module type m on RMT r [#] | |

| number of technical actions for the disassembly of module type m from RMT r [#] | |

| posture multiplier for the assembly of module type m on RMT r | |

| posture multiplier for the disassembly of module type m from RMT r | |

| recovery period multiplier | |

| repetitiveness period multiplier for the assembly of module type m on RMT r | |

| repetitiveness period multiplier for the disassembly of module type m from RMT r | |

| time to process operation on RMT | |

| travel time for batch of part from cell to cell | |

| travel time for auxiliary module type from RMC to RMC | |

| available time per RMT | |

Decisional Variables

| 1 if auxiliary module moves from RMC to RMC in period ; 0 otherwise | |

| 1 if RMT works part using module in period , otherwise | |

| 1 if module is assembled on RMT in period , otherwise | |

| 1 if module is disassembled from RMT in period , otherwise | |

| 1 if batch of part is processed by RMT in period ; 0 otherwise | |

| 1 if batch of part moves from RMC to RMC in period ; 0 otherwise | |

| 1 module is on RMT in period ; 0 otherwise |

Objective functions

| Total part and auxiliary modules travel time and module assembly/disassembly time | |

| OCRA-based index for the auxiliary module assembly/disassembly operations |

2.2. Optimization Model Formulation

The technical objective function (1) minimizes the time needed for RMTs reconfiguration, i.e., first and second terms, respectively, for the assembly and disassembly of the auxiliary modules, and for the part and auxiliary module travel time, i.e., respectively, the third and the fourth terms. The analytic formulation is as follows.

The ergonomic objective function (2) minimizes the overall repetitive movements performed by the human operators for the auxiliary module assembly/disassembly on/from the RMTs, as follows.

Moreover, the model is subject to the following feasibility constraints, adapted from Bortolini et al. [17]:

| (3) | ||

| (4) | ||

| (5) | ||

| (6) | ||

| (7) | ||

| (8) | ||

| (9) | ||

| (10) | ||

| (11) | ||

| (12) | ||

| (13) | ||

| (14) | ||

| (15) | ||

| (16) | ||

| (17) | ||

| (18) | ||

| (19) | ||

| (20) | ||

| (21) | ||

| (22) | ||

| (23) | ||

| (24) | ||

| (25) | ||

| (26) | ||

| (27) | ||

| (28) | ||

| (29) | ||

| (30) | ||

| ,, | (31) | |

| (32) |

Equation (3) prevents the part processing by more RMTs simultaneously. (4) ensures the availability of a module unit n of type m on RMT r, if the RMT has to process part p in period t. (5) sets the disassembly of module n from RMT r if not needed for the manufacturing of part batch p in period t. (6) allows using module type m to manufacture part p in period t by RMT r if it is available in that period on that RMT. (7) assures that each module unit n is located on just one RMT r in each period t. (8) allows the presence of part batches on RMTs if the machines are equipped with the auxiliary module types required for the execution of the part task. (9) defines the maximum capacity of RMTs in terms of number of auxiliary module units n they can simultaneously host in each period t. (10) prevents the use of a number of auxiliary module units n higher than their available number, per each module type m and period t. Constraints (11–14) set the auxiliary module assembly and disassembly process on/from RMTs. (15) and (16) admit part batch p to flow from cells c to c1, if such cells can work that part. Constraints (17) and (18) link the decision variables and , while (19) and (20) guarantee the continuity of part batch flow. (21) ensures the available working times per period and RMT are not exceeded. Constraints (22) and (23) link the decision variables and , while (24) and (25) control the auxiliary module flows among the RMCs. (26) prevents the global time spent by each auxiliary module unit n in installation and disassembly operations, to flowing among RMTs and for part batch manufacturing to be higher than the available time per RMT and period. Equation (27) represents the OCRA constraint. It derives from the ISO 11228-3 standard [26] and limits the OCRA index to an upper value for each task equal to 2.2, guaranteeing an acceptable risk level. Finally, (28–32) gives consistence to the decisional variables. The industrial scenario adopted to apply the proposed model is introduced in Section 3.

3. Case Study

The proposed bi-objective model is applied to a numeric case study exemplifying an operative industrial setting. It refers to the manufacturing of five products through a set of six tasks. Three RMCs, indicated from 1 to 3, and five RMTs, indicated from A to E, are present, i.e., RMTs A and D are in RMC 1, RMT B is in RMC 2, and RMTs C and E are in RMC 3. Moreover, a set of three auxiliary module types exists, including a total of 12 module units, i.e., four module units per type. Additional information about part work cycles, production volumes, and the auxiliary modules assembly and disassembly times are in Appendix A. The compatibility matrix among tasks, RMTs, and auxiliary modules is in Table 1. This matrix shows the task execution modes, i.e., the RMT/RMTs needed for their processing, the required modules (in round brackets), and the unitary processing times, expressed in seconds (in squared brackets).

Table 1.

Compatibility data among tasks, RMTs, and modules.

As example, task 5 can be processed on RMT B equipped with the auxiliary modules of type 1 and 2 and a unitary processing time equal to 0.12 s or on RMT D equipped with the auxiliary modules of type 1 and 2 and a unitary processing time equal to 0.108 s.

The part travel times among the available RMCs are in the next Table 2, expressed in minutes. The return routing policy is adopted to connect RMCs.

Table 2.

Travel times among RMCs (minutes).

Other relevant data are the parameter MAX, set to a value equal to 20 units, and the parameter T, equal to 120 periods. Table 3 and Table 4 show the OCRA parameters for the ergonomic risk assessment [20,21]. The values of the technical actions for both the assembly and disassembly tasks refer to the most stressed arm. The values for the OCRA parameters in Table 3 are based on the characteristics of the repetitive tasks required to accomplish the manual operations in the reference RMS, e.g., the assembly and the disassembly of the auxiliary modules. Punctual values are from the ISO 11228-3 standard [26]. The force multiplier refers to the force exertions required during the manual task. Repetitive tasks with require very weak force exertions, e.g., the assembly of the auxiliary modules type 2 and 3 in Table 3. Moderate force is necessary in case of , e.g., the assembly of the auxiliary module type 1 in Table 3. The posture multiplier is equal to 1 when awkward postures or movements of the upper limbs, e.g., pinch or wrist extension, are present for less than one third of the cycle time. Lower values of such multipliers identify the presence of awkward postures for a relevant part of the cycle time. When the cycle time is shorter than 15 s, or when the manual task requires the performance of the same technical actions for at least 50% of the cycle time, the repetitiveness multiplier is equal to 0.7, e.g., the assembly of the auxiliary module type 2 in Table 3. Otherwise, , e.g., the assembly of auxiliary modules type 1 and 3 in Table 3. The additional multiplier considers the presence of additional factors that may increase the ergonomic risk for the investigated task. Such factors include the use of vibrating tools, the use of gloves that may affect the handling ability, gestures implying countershocks, requirement for absolute accuracy, high pace determined by the machinery operation, localized compressions of the anatomical structures, and the exposure to cold surfaces and environments. The value of is lower than 1 if one or more additional factors are present, e.g., the assembly of auxiliary modules type 1 and 2 in Table 3. Otherwise, , e.g., the assembly of auxiliary module type 3 in Table 3.

Table 3.

OCRA parameters for the ergonomic risk assessment (assembly tasks).

Table 4.

OCRA parameters for the ergonomic risk assessment (disassembly tasks).

The OCRA parameter values are specific for each auxiliary module type and they do not depend on the RMTs on which the auxiliary modules are installed.

Moreover, the OCRA method includes two additional multipliers for considering the presence of recovery periods during the workshift, i.e.,, and the overall duration of the repetitive tasks, i.e.,. Specifically, is the recovery period multiplier and it investigates the distribution of the breaks during the workshift. is equal to 1 when the distribution of the breaks during the workshift allows the restoration of the musculoskeletal function of the workers’ muscle and tendon groups. The duration multiplier is higher than 1 when the total time of repetitive tasks during the workshift is lower than eight hours. In the reference case study, and . Finally, and refer to the number of technical actions required to perform each assembly/disassembly task.

Globally, the set of the input data leads to 78,960 decision variables and 168,226 constraints. The model is coded in AMPL language and processed adopting the solver Gurobi Optimizer© v.4.0.1.0 on an Intel® CoreTM i7 CPU @ 2.40GHz and 8.0GB RAM workstation. The solving method to build the Pareto frontier is the Normalized Normal Constraint Method (NNCM) presented by Messac et al. [27]. Starting from these data, 150 points of the Pareto frontier are computed. The solving time is approximately of about 3 min per point. The key results are described in the following Section 4.

4. Results and Discussion

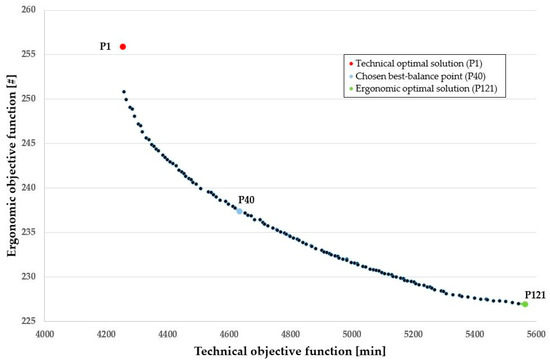

Figure 2 presents the Pareto frontier obtained by applying the NNCM method. In the figure, the non-dominated points are shown, only. Points P1 (in red) and P121 (in green) are the so-called anchor points of the frontier, i.e., the best solutions in terms of technical performances (P1) and ergonomics (P121), respectively, while the other points balance the two divergent objective functions. Each point of the frontier corresponds to a specific RMS configuration.

Figure 2.

Pareto frontier.

Focusing on the anchor points, the technical objective function values range from 4253.41 min, by optimizing the technical objective function, to 5563.71 min, by optimizing the ergonomic objective function. On the other hand, the ergonomic objective function values range from 255.89, by optimizing the technical objective function, to 226.92, by optimizing the ergonomic objective function. The smaller range of variation of the ergonomic objective function is due to the OCRA constraint (Equation (27)), which limits the OCRA index to assume values corresponding to a non-risk situation. Globally, the anchor point values and Pareto frontier trend show the existence of a significant trade-off between technical and ergonomic performances.

Among the non-dominated points, the choice of the final RMS configuration structure is according to any suitable informal approach. In the numerical application, together with P1 and P121, i.e., the technical and ergonomic optima, point P40 (in blue in Figure 2) rises up, representing a break point, because it allows getting good technical performances without a relevant increase of the ergonomic indicator. In detail, this point is selected according to the criteria of the minimum Euclidean distance from the utopia point, i.e., the point with technical and ergonomic optima as coordinates [28]. Compared to the technical anchor point P1, the selected break point involves an improvement of the ergonomic performances of about 7.25%, accepting a worsening of the technical objective function of about 8.50%. On the other hand, compared to the ergonomic anchor point P2, the RMS configuration in P40 involves an improvement of the technical performances of about 16.75%, accepting a worsening of the ergonomic objective function of about 4.60%.

Impact of the Part Batches and Auxiliary Module Inter-Cell Travelling over the Pareto Points

A relevant issue to explore is the impact of the part batches inter-cell flows on the total objective function value, showed in Figure 3.

Figure 3.

Part batches trend over the Pareto points.

As expected, the part batches appear to travel more frequently in correspondence of the solutions characterized by good ergonomic performances. This happens because in correspondence of such Pareto points, the part batches move toward the RMT already equipped with the necessary auxiliary modules, rather than stay on the same RMT, changing its configuration.

5. Conclusions and Future Research

Reconfigurable Manufacturing Systems (RMSs) have been introduced in the last years as an emerging manufacturing solution able to face the fluctuant market and industrial conditions. Despite their automation technology level, such systems still require actions to be performed by the human operators, raising relevant safety and ergonomic issues. Particularly, RMSs require the frequent assembly and disassembly of the auxiliary customized modules based on the manual intervention to achieve new system configurations. Such tasks arise as repetitive movements, which need to be efficiently managed according to the ISO 11228-3 standard. According to this background, this paper proposes and applies a bi-objective optimization model for the design and management of RMSs. The technical objective function minimizes the reconfiguration time and the part and auxiliary module travel time among the manufacturing cells, while the ergonomic objective function minimizes the repetitive movements performed by the human operators during their working activities. Results show the existence of a significant trade-off between the two objective functions, proving the possibility to improve the ergonomic conditions of the human operators, i.e., to reduce the number of repetitive movements, without excessively increasing the total time needed for the RMT reconfiguration and for part and auxiliary module travelling. Future research activities deal with the extension of the model to include relevant issues not considered at this stage, i.e., cost drivers, and their application to larger real industrial instances.

Author Contributions

Conceptualization: M.B., F.G.G., and L.B; methodology, M.B., F.G.G., and L.B.; supervision: M.B. and A.R.; writing—original draft preparation: F.G.G. and L.B.; writing—review and editing: M.B. and A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article or supplementary material.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Part production volumes and work cycles.

Table A1.

Part production volumes and work cycles.

| Part (p) | Work Cycle | |

|---|---|---|

| 1 | 50 | 2-3-1-2-4 |

| 2 | 150 | 5-2-3-1-2-4-6-2 |

| 3 | 500 | 1-2-3-4 |

| 4 | 75 | 5-2-1-2-6 |

| 5 | 500 | 1-4-6-2-3-5 |

Table A2.

Auxiliary module assembly and disassembly times.

Table A2.

Auxiliary module assembly and disassembly times.

| RMT | Auxiliary Module Type (m) | at [Min] | dt [Min] |

|---|---|---|---|

| 1 | 1 | 3.32 | 2.49 |

| 1 | 2 | 3.73 | 2.80 |

| 1 | 3 | 3.56 | 2.67 |

| 2 | 1 | 3.87 | 2.90 |

| 2 | 2 | 4.22 | 3.16 |

| 2 | 3 | 6.10 | 4.57 |

| 3 | 1 | 3.90 | 2.92 |

| 3 | 2 | 7.20 | 5.40 |

| 3 | 3 | 9.00 | 6.75 |

| 4 | 1 | 4.60 | 3.45 |

| 4 | 2 | 5.80 | 4.35 |

| 4 | 3 | 6.34 | 4.75 |

| 5 | 1 | 9.40 | 7.05 |

| 5 | 2 | 14.95 | 11.21 |

| 5 | 3 | 8.50 | 6.37 |

Table A3.

List of the non-dominated Pareto points (P.P.).

Table A3.

List of the non-dominated Pareto points (P.P.).

| P.P. | λ | μ | P.P. | λ | μ | P.P. | λ | μ |

|---|---|---|---|---|---|---|---|---|

| P1 | 4253.41 | 255.89 | P41 | 4651.42 | 237.22 | P81 | 5043.90 | 231.11 |

| P2 | 4257.53 | 250.82 | P42 | 4661.95 | 236.93 | P82 | 5058.67 | 230.89 |

| P3 | 4264.75 | 249.95 | P43 | 4672.26 | 236.86 | P83 | 5070.50 | 230.83 |

| P4 | 4276.98 | 249.07 | P44 | 4683.84 | 236.45 | P84 | 5079.25 | 230.73 |

| P5 | 4285.17 | 248.89 | P45 | 4700.81 | 236.42 | P85 | 5088.01 | 230.71 |

| P6 | 4292.17 | 248.08 | P46 | 4710.11 | 236.10 | P86 | 5096.77 | 230.48 |

| P7 | 4304.40 | 247.20 | P47 | 4714.70 | 235.95 | P87 | 5105.52 | 230.38 |

| P8 | 4312.59 | 247.02 | P48 | 4725.88 | 235.76 | P88 | 5119.43 | 230.28 |

| P9 | 4316.63 | 246.33 | P49 | 4743.25 | 235.50 | P89 | 5130.14 | 230.22 |

| P10 | 4330.67 | 245.64 | P50 | 4754.44 | 235.32 | P90 | 5134.20 | 230.05 |

| P11 | 4338.86 | 245.45 | P51 | 4756.74 | 235.25 | P91 | 5143.63 | 229.97 |

| P12 | 4348.10 | 244.87 | P52 | 4767.93 | 235.07 | P92 | 5158.38 | 229.87 |

| P13 | 4356.28 | 244.68 | P53 | 4780.71 | 234.96 | P93 | 5167.56 | 229.79 |

| P14 | 4361.95 | 244.36 | P54 | 4785.29 | 234.81 | P94 | 5172.30 | 229.64 |

| P15 | 4370.14 | 244.18 | P55 | 4796.48 | 234.63 | P95 | 5181.05 | 229.54 |

| P16 | 4384.00 | 243.67 | P56 | 4798.78 | 234.56 | P96 | 5192.89 | 229.49 |

| P17 | 4392.18 | 243.48 | P57 | 4809.97 | 234.38 | P97 | 5201.96 | 229.45 |

| P18 | 4399.33 | 243.18 | P58 | 4822.75 | 234.27 | P98 | 5208.14 | 229.26 |

| P19 | 4408.04 | 242.98 | P59 | 4827.34 | 234.12 | P99 | 5219.16 | 229.14 |

| P20 | 4416.22 | 242.79 | P60 | 4840.83 | 233.87 | P100 | 5233.91 | 229.04 |

| P21 | 4428.37 | 242.49 | P61 | 4852.01 | 233.69 | P101 | 5246.25 | 228.86 |

| P22 | 4436.71 | 242.00 | P62 | 4867.10 | 233.51 | P102 | 5254.10 | 228.85 |

| P23 | 4445.42 | 241.80 | P63 | 4869.38 | 233.43 | P103 | 5260.00 | 228.76 |

| P24 | 4453.60 | 241.61 | P64 | 4882.87 | 233.18 | P104 | 5269.77 | 228.53 |

| P25 | 4458.75 | 241.31 | P65 | 4901.05 | 232.99 | P105 | 5290.67 | 228.43 |

| P26 | 4469.46 | 241.10 | P66 | 4909.14 | 232.82 | P106 | 5298.11 | 228.35 |

| P27 | 4477.12 | 240.94 | P67 | 4918.42 | 232.74 | P107 | 5307.88 | 228.12 |

| P28 | 4482.79 | 240.62 | P68 | 4927.33 | 232.64 | P108 | 5328.78 | 228.02 |

| P29 | 4492.98 | 240.43 | P69 | 4931.91 | 232.49 | P109 | 5349.69 | 227.93 |

| P30 | 4506.84 | 239.93 | P70 | 4944.69 | 232.38 | P110 | 5357.08 | 227.81 |

| P31 | 4533.11 | 239.57 | P71 | 4955.00 | 232.31 | P111 | 5377.98 | 227.71 |

| P32 | 4541.42 | 239.51 | P72 | 4958.18 | 232.13 | P112 | 5398.89 | 227.62 |

| P33 | 4548.88 | 239.23 | P73 | 4970.77 | 231.98 | P113 | 5419.79 | 227.52 |

| P34 | 4557.28 | 239.01 | P74 | 4982.80 | 231.97 | P114 | 5438.28 | 227.50 |

| P35 | 4570.12 | 238.65 | P75 | 4983.55 | 231.87 | P115 | 5440.70 | 227.42 |

| P36 | 4588.13 | 238.50 | P76 | 4997.04 | 231.62 | P116 | 5461.60 | 227.33 |

| P37 | 4598.67 | 238.21 | P77 | 5008.88 | 231.57 | P117 | 5480.09 | 227.30 |

| P38 | 4612.16 | 237.96 | P78 | 5017.63 | 231.47 | P118 | 5501.00 | 227.21 |

| P39 | 4620.56 | 237.73 | P79 | 5019.81 | 231.39 | P119 | 5521.90 | 227.11 |

| P40 | 4633.40 | 237.37 | P80 | 5035.15 | 231.21 | P120 | 5542.81 | 227.02 |

| P121 | 5563.71 | 226.92 |

References

- Galizia, F.G.; ElMaraghy, H.; Bortolini, M.; Mora, C. Product platforms design, selection and customisation in high-variety manufacturing. Int. J. Prod. Res. 2020, 58, 893–911. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Mora, C. Reconfigurable manufacturing systems: Literature review and research trend. J. Manuf. Syst. 2018, 49, 93–106. [Google Scholar] [CrossRef]

- Mehrabi, M.G.; Ulsoy, A.G.; Koren, Y. Reconfigurable manufacturing systems: Key to future manufacturing. J. Intell. Manuf. 2000, 11, 403–419. [Google Scholar] [CrossRef]

- Mehrabi, M.G.; Ulsoy, A.G.; Koren, Y.; Heytler, P. Trends and perspectives in flexible and reconfigurable manufacturing systems. J. Intell. Manuf. 2002, 13, 135–146. [Google Scholar] [CrossRef]

- Molina, A.; Rodriguez, C.A.; Ahuett, H.; Cortes, C.A.; Ramirez, M.; Jimenez, G.; Martinez, S. Next-generation manufacturing systems: Key research issues in developing and integrating reconfigurable and intelligent machines. Int. J. Comput. Integr. Manuf. 2005, 18, 525–536. [Google Scholar] [CrossRef]

- Hasan, F.; Jain, P.K.; Kumar, D. Service level as performance index for reconfigurable manufacturing system involving multiple part families. Procedia Eng. 2014, 69, 814–821. [Google Scholar] [CrossRef][Green Version]

- Moghaddam, S.K.; Houshmand, M.; Saitou, K.; Fatahi Valilai, O. Configuration design of scalable reconfigurable manufacturing systems for part family. Int. J. Prod. Res. 2020, 58, 2974–2996. [Google Scholar] [CrossRef]

- Liu, M.; An, L.; Zhang, J.; Chu, F.; Chu, C. Energy-oriented bi-objective optimisation for a multi-module reconfigurable manufacturing system. Int. J. Prod. Res. 2019, 57, 5974–5995. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Mora, C. Dynamic design and management of reconfigurable manufacturing systems. Proc. Manuf. 2019, 33, 67–74. [Google Scholar] [CrossRef]

- Dou, J.; Li, J.; Xia, D.; Zhao, X. A multi-objective particle swarm optimisation for integrated configuration design and scheduling in reconfigurable manufacturing system. Int. J. Prod. Res. 2020. [Google Scholar] [CrossRef]

- Koren, Y.; Wang, W.; Gu, X. Value creation through design for scalability of reconfigurable manufacturing systems. Int. J. Prod. Res. 2017, 55, 1227–1242. [Google Scholar] [CrossRef]

- Maniraj, M.; Pakkirisamy, V.; Jeyapaul, R. An ant colony optimization-based approach for a single-product flow-line reconfigurable manufacturing systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1229–1236. [Google Scholar] [CrossRef]

- Aljuneidi, T.; Bulgak, A.A. A mathematical mode for designing reconfigurable cellular hybrid manufacturing-remanufacturing systems. Int. J. Adv. Manuf. Technol. 2016, 87, 1585–1596. [Google Scholar] [CrossRef]

- Asghar, E.; uz Zaman, U.K.; Baqai, A.A.; Homri, L. Optimum machine capabilities for reconfigurable manufacturing systems. Int. J. Adv. Manuf. Technol. 2018, 95, 4397–4417. [Google Scholar] [CrossRef]

- Touzout, F.A.; Benyoucef, L. Multi-objective multi-unit process plan generation in a reconfigurable manufacturing environment: A comparative study of three hybrid metaheuristics. Int. J. Prod. Res. 2019, 57, 7520–7535. [Google Scholar] [CrossRef]

- Benderbal, H.H.; Dahane, M.; Benyoucef, L. Modularity assessment in reconfigurable manufacturing system (RMS) design: An archived multi-objective simulated annealing-based approach. Int. J. Adv. Manuf. Technol. 2018, 94, 729–749. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Mora, C.; Pilati, F. Reconfigurability in cellular manufacturing systems: A design model and multi-scenario analysis. Int. J. Adv. Manuf. Technol. 2019, 104, 4387–4397. [Google Scholar] [CrossRef]

- Ben Cheikh, S.; Hajri-Gabouj, S.; Darmoul, S. Manufacturing configuration selection under arduous working conditions: A multi-criteria decision approach. In Proceedings of the 2016 International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 8–10 March 2016; Volume 25, pp. 32–33. [Google Scholar]

- Kouki, S. A TOPSIS based multi-criteria decision support approach for facility layout reconfiguration. Int. Res. J. Emerg.Trends Multidiscip. 2016, 2, 1–10. [Google Scholar]

- Bortolini, M.; Botti, L.; Galizia, F.G.; Mora, C. Safety, ergonomics and human factors in reconfigurable manufacturing systems. In Reconfigurable Manufacturing Systems: From Design to Implementation; Springer: Cham, Germany, 2020; pp. 123–138. [Google Scholar]

- Occhipinti, E. OCRA: A concise index for the assessment of exposure to repetitive movements of the upper limbs. Ergonomics 1998, 41, 1290–1311. [Google Scholar] [CrossRef]

- Botti, L.; Mora, C.; Regattieri, A. Integrating ergonomics and lean manufacturing principles in a hybrid assembly line. Comput. Ind. Eng. 2017, 111, 481–491. [Google Scholar] [CrossRef]

- Bortolini, M.; Botti, L.; Ferrari, E.; Galizia, F.G.; Mora, C. Including ergonomic principles in the design and management of reconfigurable manufacturing systems. In Sustainable Design and Manufacturing; Springer: Singapore, 2020; pp. 183–192. [Google Scholar]

- Pattanaik, L.M.; Jain, P.K.; Metha, N.K. Cell formation in the presence of reconfigurable machines. Int. J. Adv. Manuf. Technol. 2007, 34, 335–345. [Google Scholar] [CrossRef]

- Eguia, I.; Molina, J.C.; Lozano, S.; Racero, J. Cell design and multi-period machine loading in cellular reconfigurable manufacturing systems with alternative routing. Int. J. Prod. Res. 2017, 55, 2775–2790. [Google Scholar] [CrossRef]

- International Standard Organization. Ergonomics. Manual Handling. Part 3: Handling of Low Loads at High Frequency; ISO 11228-3:2007; British Standards: London, UK, 2007. [Google Scholar]

- Messac, A.; Ismil-Yahaya, A.; Mattson, C.A. The normalized normal constraint method for generating the Pareto frontier. Struct. Multidiscip. Opt. 2003, 25, 86–98. [Google Scholar] [CrossRef]

- Clempner, J.B.; Poznyak, A.S. Solving the Pareto front for multiobjective Markov chains using the minimum Euclidean distance gradient-based optimization method. Math. Comp. Simul. 2016, 119, 142–160. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).