Abstract

Mixed matrix membranes (MMMs) are seen as promising candidates to overcome the fundamental limit of polymeric membranes, known as the so-called Robeson upper bound, which defines the best compromise between permeability and selectivity of neat polymeric membranes. To overcome this limit, the permeability of the filler particles in the MMM must be carefully matched with that of the polymer matrix. The present work shows that it is not sufficient to match only the permeability of the polymer and the dispersed phase, but that one should consider also the individual contributions of the diffusivity and the solubility of the gas in both components. Here we compare the gas transport performance of two different MMMs, containing the metal–organic framework CuNi-MOF in the rubbery Pebax®1657 and in the glassy poly(ether-ether-ketone) with cardo moiety, PEEK-WC. The chemical and structural properties of MMMs were investigated by means of FT-IR spectroscopy, scanning electron microscopy and EDX analysis. The influence of MOF on the mechanical and thermal properties of both polymers was investigated by tensile tests and differential scanning calorimetry, respectively. The MOF loading in Pebax®1657 increased the ideal H2/N2 selectivity from 6 to 8 thanks to an increased H2 permeability. In general, the MOF had little effect on the Pebax®165 membranes because an increase in gas solubility was neutralized by an equivalent decrease in effective diffusivity. Instead, the addition of MOF to PEEK-WC increases the ideal CO2/CH4 selectivity from 30 to ~48 thanks to an increased CO2 permeability (from 6 to 48 Barrer). The increase in CO2 permeability and CO2/CH4 selectivity is maintained under mixed gas conditions.

1. Introduction

The research field on materials for gas separation membranes is constantly expanding due to the pressing industrial request for more performing materials to employ in gas treatment, such as hydrogen recovery (H2/CO2) [1], oxygen-enriched air production (O2/N2) [2,3], biogas up-grading [4,5] and natural gas treatment (CO2/CH4) [6], and post-combustion carbon capture from flue gas (CO2/N2) [7]. This increasing interest is dictated by the advantages of membrane technology compared to traditional gas separation techniques. Gas separation by means of membrane technology is an economical process; it is easily scalable and it can be used in non-drastic temperature and pressure conditions, which are more environmentally friendly. Despite numerous efforts to develop new materials for gas separation, the membrane market still needs to overcome some challenges. In fact, the highly permeable rubbery polymers present low selectivity, and the highly-selective glassy polymers are less permeable. To overcome this trade-off between permeability and selectivity, extensively reported by Robeson in 1991 and in 2008 [8,9], researchers are focusing on the design and development of hybrid membranes based on the combination of two different materials in order to get the advantages of both [10]. According to this concept, a valid strategy is the embedding of porous metal-organic frameworks (MOFs) in the polymer matrix in order to obtain mixed matrix membranes (MMMs) with enhanced gas transport properties [11,12,13,14,15,16]. MOFs are an attractive new class of microporous materials built by the combination of metal atoms/clusters with a wide variety of organic ligands, which can be specifically designed for improving the compatibility with the organic polymer phase and with high specificity for gases [17,18]. The gas transport in polymer membranes occurs following the solution-diffusion mechanism in which permeability and selectivity are determined by kinetic parameters (diffusion) and thermodynamic factors (solubility), via ; . The addition of MOFs can improve the gas transport properties of the neat polymer by influencing these two parameters [10]. The diffusion, being a kinetic phenomenon, is strongly linked to the free volume of the polymer materials and to the molecular size of the penetrating species. In the MOFs, the link between metals and organic units forms a three-dimensional structure with cages having well-defined shape and size, which can improve free volume elements of a matrix, increasing gas transport in terms of permeability. At the same time, the cages of MOF forming a preferential pathway for a specific gas can act as a molecular sieve, increasing membrane selectivity. On the contrary, the main factor that determines the solubility in a polymer matrix is the ability of the penetrant gases to condense, which in turn is correlated with the interactions that occur between the gas and the matrix of membrane. MOFs chemical structure can be easily designed or functionalized synthetically in order to improve its affinity for specific gases [19]. In this case, the membrane permeability is expected to improve as a consequence of an increased contribution in solubility due to the gas condensability in the MOF. Furthermore, the introduction of chemical groups with a specific affinity to one gas in a mixture will also increase its selectivity. The choice of the materials combination for MMMs preparation must be made on the basis of specific physical and chemical properties, in order to tailor in advance the membrane for a desired gas separation. For this reason, it is necessary to understand how the addition of MOF can influence the gas transport properties of different polymers, rubbery or glassy.

In this work, the gas transport properties for MMMs prepared by embedding the same oxamate-based MOF in two different polymers, Pebax®1657 rubbery polymer and PEEK-WC glassy polymer, will therefore be investigated. The oxamate-based MOF, previously reported [20], with formula NiII2{NiII4[CuII2(Me3mpba)2]3}·54H2O (where Me3mpba is the N,N′-2,4,6-trimethyl-1,3-phenylenebis (oxamate) ligand), has already shown interesting gas separation properties [21].

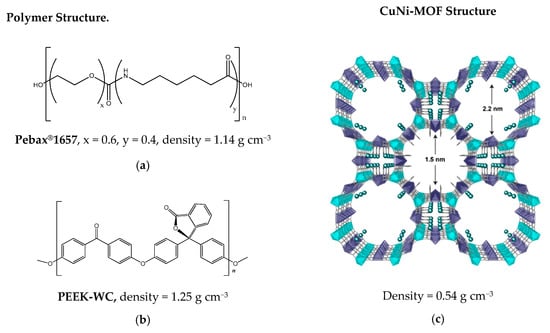

Single-crystal X-ray diffraction measurements unveil the crystal structure of CuNi-MOF. The anionic NiII6CuII6 open-framework structure exhibits a pillared square/octagonal layer architecture, where nickel(II) and copper(II) ions are located on the vertices and midpoints of the edges, respectively, featuring three types of pores, different in size and shape, propagating along the c axis and enfolding up to 60% of the total lattice volume. Free nickel(II) cations are further accommodated within pores of the MOF. It consists of regularly spaced, small, almost square-sized pores (with a virtual diameter of ca 0.4 nm) and two kinds of hydrophobic and hydrophilic octagonal pores (Figure 1) resulting from the different disposition of the trimethyl-substituted phenylene spacers, pointing inwards or outwards from the voids, which accounts for their virtual diameters of ca. 1.5 and 2.2 nm, respectively (Figure 1). PEEK-WC is a glassy poly(ether-ether-ketone) with a cardo group in the polymer backbone, which makes it soluble in various common organic solvents. It has been used extensively in membrane preparation and characterization under the names PEEK-WC, PEEKWC or PEK-C [22]. Membranes have been prepared in the form of hollow fibres for liquid filtration [23] and as flat films for liquid filtrations [24] or for gas separation [25,26,27] and numerous other applications [22]. In this work, we take advantage of its good solubility in chloroform for the preparation of mixed matrix membranes by the solvent evaporation method. PEEK-WC presents a high selectivity but a too low permeability to be interesting as a material for industrial application. For this reason, different researchers have tried to improve its permeability without loss in selectivity by means of nanoparticle addition. An extensive protocol to obtain MMMs based on PEEK-WC, embedding NaA (LTA) zeolite, was developed in order to improve gas separation parameters [28]. However, no one procedure has enhanced gas transport properties of the neat polymer, and a decrease in selectivity was observed probably due to a presence of defects at interface between polymer and zeolite. Some methods have been developed in order to further improve the adhesion of PEEK-WC for 3D-mesoporous nanoparticles. For example, the MIL-101 was functionalized with a sulfonic acid group to further increase the affinity for the polymer matrix. The resulting membranes have shown an improved CO2 permeability and CO2/gas selectivity. The increased selectivity was mainly attributed to the increased polar interaction between CO2 and sulfonic acid groups, as well as the good filler–polymer interface compatibility [29].

Figure 1.

Chemical structure and density of (a) Pebax®1657, (b) PEEK-WC; and (c) CuNi-MOF. Cu and Ni atoms from the network are represented by cyan and green polyhedra, respectively, whereas organic ligands are depicted as sticks. Green spheres represent Ni2+ metal ions in pores.

Pebax®1657 is a thermoplastic elastomer multiblock-copolymer containing linear chains of rigid polyamide segments interspaced with flexible polyether segments. The hard polyamide (PA) blocks supply mechanical strength and the presence of the polar ethylene oxide (PEO) group, increases the affinity for CO2, allowing for a good CO2/non-polar (H2, N2, and CH4) species separation and permselectivity. Several membranes have been prepared in the form of composite hollow fibre membranes [30,31,32], hybrid and mixed matrix membranes for gas separation [33,34,35,36,37,38,39,40,41,42,43]. Mixed matrix membranes based on amine-functionalized and pristine MIL-53(Al) in Pebax1657 have shown an increased CO2 separation and the higher permeability (PCO2 100 Barrer and αCO2/CH4 = 17; CO2/N2 = 50), was attributed to high porosity introduced by the presence of the MOF, as well as the selective adsorption of CO2 inside the MOF [41]. Liu et al. designed nanosheet-enhanced Pebax-MoS2 mixed matrix membranes for CO2 capture, increasing CO2/N2 selectivity until 90 [44]. Composite hollow fibre membranes with a selective layer of Pebax®1657 and different functionalized Uio-66 MOF have demonstrated a simultaneous improvement in gas permeance and selectivity. The enhanced selectivity was attributed to an increased rigidity of the polymer matrix due to a formation of a hydrogen bond between the MOF and Pebax®1657 polymer chains [45]. Pebax®1657 containing Cu3BTC2-MOF have shown an increased CO2/CH4 ideal selectivity about 15% compared to the neat Pebax®1657 [46]. The improvement in selectivity was attributed to the improvement in the CO2 solubility, which, having a strong quadrupole moment, presents a higher affinity with unsaturated Cu sites than CH4, leading to a higher CO2 permeability. In this work, the CuNi-MOF was dispersed in the Pebax®1657 rubbery polymer and in the PEEK-WC glassy polymer, which, presenting a Cu site and well-defined cages (1.5 nm and 2.2 nm), is expected to influence at the same time the solubility and diffusion coefficient. The aim is to understand the main factors that determine the behaviour when a MOF is dispersed within a glassy or rubbery polymeric matrix. FT-IR, EDX, DSC and SEM analyses investigate the potential chemical interaction between CuNi-MOF and polymers. Besides, pure gas permeability tests with six different gases were carried out to obtain a general understanding of the MMM performance, while permeation tests were also carried out with binary CO2/N2 and CH4/CO2 gas mixtures to evaluate its potential performance in a real separation process. These two gas pairs simulate flue gas in view of the potential use of the membranes in CO2 capture, and biogas in view of the potential exploitation of renewable energy in a strongly emerging market.

2. Materials and Methods

Pebax®1657, a poly(ethylene-oxide) (PEO) and poly[imino(1-oxohexamethylene)] (PA6) multi-block co-polymer in the molar ratio 60/40, was kindly provided by Arkema in the form of pellets.

PEEK-WC was provided as a powder by the Institute of Applied Chemistry, Changchun, China, and was used as received, without further purification.

The CuNi-MOF was obtained as crystalline phase through a double cation-exchange reaction in the solid state by immersing crystals of MgII2{MgII4[CuII2-(Me3mpba)2]3}·45H2O in saturated aqueous solutions of Ni(NO3)2·6H2O for several weeks [47]. Alternatively, a large scale synthesis of Ni2II{NiII4[CuII2(Me3mpba)2]3}·54H2O (2) was carried out by direct reaction of two aqueous solutions of Na4[Cu2(Me3mpba)2]·4H2O (0.1 mol) and Ni(NO3)2·6H2O (0.13 mol) in water and subsequent addition, after filtration and re–suspension in water of the resulting compound, of 0.067 mol of Ni(NO3)2·6H2O (Yield 99 %) [20].

2.1. Membranes Preparation

Mixed matrix membranes were prepared by loading different concentrations of CuNi-MOF (9 wt %, 17 wt %, 23 wt %) in Pebax®1657 and in PEEK-WC. The Pebax®1657 solution at 10 wt % was prepared by swelling polymer pellets in a mixture of distilled water and ethanol (ratio 30:70 wt/wt) at room temperature overnight, in agreement with previously-reported procedure [30]. Then a homogeneous dope solution was obtained by heating to 80 °C under magnetic stirring for at least 10 min. The CuNi-MOFs were dispersed and sonicated in water-ethanol mixture for 30 min and subsequently added to the Pebax®1657 solution under magnetic stirring. While, homogenous solution at 5 wt % of PEEK-WC was obtained by dissolving the polymer powder in chloroform at room temperature for 24 h. Concurrently, the CuNi-MOFs were separately dispersed in chloroform and sonicated in an ultrasonic bath for 30 min before filtering the PEEK-WC solution through glass wool into the suspension. One hour of mechanical stirring and 30 min of sonication made each solution homogeneous. The resulting solutions were cast into levelled flat Teflon petri-dish and left to evaporate over 2–3 days. The MMMs produced were dried in the oven at 70 °C under vacuum conditions for 24 h.

2.2. Membranes Characterization

2.2.1. Structural Characterization

Chemical and morphological analysis of membranes were performed by scanning electron microscopy (Phenom Pro X desktop SEM, Phenom-World). The samples for cross-section SEM characterization were prepared by freeze-fracturing in liquid nitrogen. Samples were analyzed without sputter-coating with gold. Elemental analysis was performed with the Phenom- Pro X desktop SEM, which is equipped with an energy dispersive X-ray spectroscopy detector (EDX). Infrared spectroscopy (FT-IR) analyses were performed by means of Spectrum Spotlight Chemical Imaging Instrument (PerkinElmer) in ATR mode.

2.2.2. Thermal and Mechanical Characterization

DSC analysis was carried out using a Pyris Diamond Differential Scanning Calorimeter (Perkin Elmer, Shelton, CT, USA) equipped with an intracooler refrigeration system. Samples of 15–20 mg were used. Unless specified otherwise, three cycles were performed. The PEEK-WC samples were first heated from −60 °C to 300 °C, kept at this temperature for 1 min, and cooled down to 0 °C, where they were kept for 5 min. In the second run, the samples were heated up again to 300 °C. The DSC runs were performed at a scan rate of 15 °C min−1. Before the measurements, the samples were kept at 50 °C under vacuum for one night in order to remove possibly adsorbed water. The Pebax®1657-based samples were tested using an identical method in the range from −40 °C → 220 °C → −75 °C → 225 °C.

Tensile tests were carried out at room temperature on a single column Universal Testing Machine, Zwick/Roell model Z2.5, equipped with a 50 N load cell and pneumatic clamps. The surface of one flat clamp was covered with adhesive rubber to avoid slipping or damaging of the samples, while the second clamp had a convex surface to increase the local pressure and to avoid the extraction of the sample. The average value and the standard deviation of the Young’s modulus, the tensile strength and the maximum deformation were determined on a series of at least four samples. The sample width was 5 mm, and the grip-to-grip distances 40 and 30 mm for Pebax®16 and PEEK-WC, respectively. The tests were carried out at a deformation rate 20 mm min−1 (200% min−1) for Pebax®1657-based samples and 6 mm min−1 (20% min−1) for PEEK-WC-based samples.

2.2.3. Single Gas Permeation Method

Single gas permeation tests were carried out at 25 °C and at a feed pressure of 1 bar, using a fixed-volume pressure increase instrument (ESSR), described elsewhere [48]. Permeability coefficients, P, and diffusion coefficients, D, were determined by the time-lag method [49]. The permeability coefficient, P, is calculated from the permeation curve in the steady state described by:

The last term in (Equation (1)) represents the so-called permeation time lag, Θ, which is inversely proportional to the diffusion coefficient of the gas:

The approximate gas solubility coefficient, S, was obtained indirectly as the ratio of the permeability to the diffusion coefficient by assuming the solution-diffusion transport mechanism:

Permeabilities are reported in Barrer [1 Barrer = 10−10 cm3 (STP) cm cm−2 s−1 cm Hg−1].

2.2.4. Mixed Gas Permeation Measurement

Mixed gas permeation tests were carried out using a custom made constant pressure/variable volume instrument, described in detail elsewhere [50], equipped with a quadrupole mass filter (HPR-20 QIC Benchtop residual gas analysis system, Hiden Analytical, Warrington, UK). Measurements were performed from 1 to 6 bar(a) with two binary gas mixtures of CO2/N2 (15:85 vol %) and CO2/CH4 (35:65 vol %), simulating flue gas and biogas, respectively. Argon was used as a sweeping gas and as the internal standard for the calculation of the permeate gas composition.

3. Results and Discussion

3.1. Chemical and Morphological Characterization

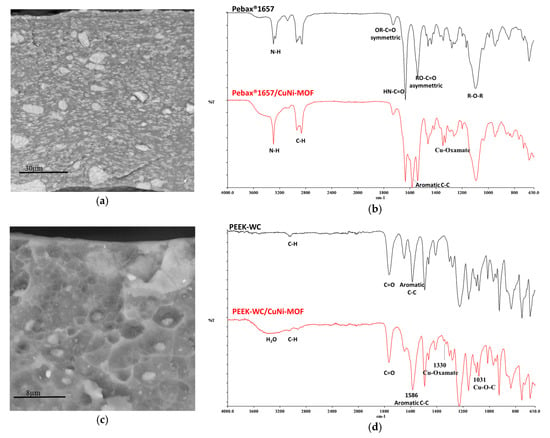

The MOF loading in polymer matrix was evidenced by the distinctive color of obtained membranes, and it was accurately confirmed by the EDX analysis, which revealed the attendance of Cu and Ni metals in both Pebax®1657 and PEEK-WC polymers (See SI, Figure S1a,b, respectively). The chemical characterization of neat membranes and MMMs, as well as the interaction between polymer chains and nanoparticles were investigated by FTIR-ATR. Figure 2b,d shows the spectrum for neat Pebax®1657 and for Pebax®1657/CuNi-MOF membranes. The functional groups of Pebax®1657 give characteristic peaks at 3297 cm−1 for N-H group, at 2943 and 2859 cm−1 attributed to the asymmetric and symmetric stretching of the C-H bound, 1731 cm−1 for the symmetric stretches of carboxylate R-O-C=O, while asymmetric R-O-C=O at ca. 1430, 1636 cm−1 for H-N–C=O and 1099 cm−1 for –C–O–C.

Figure 2.

SEM image of the samples showing the interface between MOF and polymer phase (a) for Pebax®1657 and (c) PEEK-WC. FT-IR of neat polymer and MMMs with 23 wt % of CuNi, for Pebax®1657 (b) and PEEK-WC (d).

In the spectrum of Pebax®1657/CuNi-MOF, characteristic peaks appear at 1578 cm−1 due to C–C aromatic band of MOF’s phenylene, at 1608 cm−1 of stretching of oxamate ligand of MOF and a peak at 1330 cm−1, which could be considered diagnostic of the presence of bridging oxamate between Cu and Ni [51]. Finally, the characteristic peaks between 2900 cm−1 and 2800 cm−1 due to the symmetric and asymmetric C-H stretching are slightly shifted to lower wavelengths, confirming the interaction of hydrogen bonds at the interface between MOF and Pebax®1657, as it was also seen by Khosravi et al. for Pebax1657/CuBTC mixed matrix membranes [52]. Figure 2d offers a comparison of PEEK-WC membrane and PEEK-WC/CuNi spectrum. The functional groups of PEEK-WC give characteristic peaks at 3052 cm−1 and 3075 cm−1 for aromatic C–H stretch, at 1767 cm−1 for ketonic and esteric C=O stretching, and at 1589 cm−1 for the C–C aromatic band [53]. In PEEK-WC/CuNi, the peak for the C-C aromatic band is shifted on the lower wavelengths, probably due to the π⋯π stacking interaction between the benzene rings of polymers and MOF. In fact, when the ring is very conjugated, a weak band can be observed at around 1580 cm−1, such as the one is visible from the PEEK-WC/CuNi spectrum. The peaks due to the stretch of the aromatic C–H appear to be totally fused with the water peak (3370 cm−1) that reveals the relatively hydroscopic nature of the MOFs. The interaction between the Pebax®1657 and CuNi-MOF was also confirmed by SEM analysis, and in the enlarged particular of Figure 2a, it is possible to see that polymer phase of Pebax®1657creates a sort of circular compressed polymer region around the MOF, which Koros defined as “Case I matrix rigidification” [37]. On the other hand, the distribution of MOF in the PEEK-WC polymer produces a defined and regular network structure (Figure 2c) with a homogenous dispersion of nanoparticles without significant sedimentation across the membranes (See SI Figure S-2). Instead, the addition of MOFs in Pebax®1657 shows no significant agglomeration at the lowest 9 wt % that becomes more significant at highest 29 wt % concentration.

3.2. Mechanical and Thermal Properties

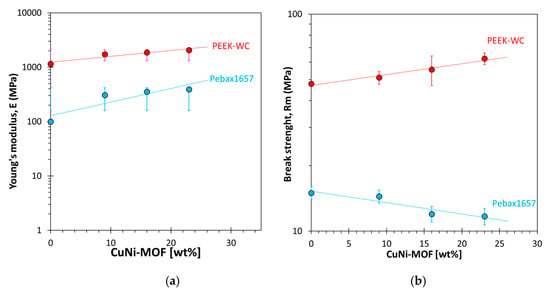

All membranes are dense mixed matrix membranes with good mechanical resistance for handling. The results of the tensile tests, performed on the nanocomposite films obtained on the series with different concentrations of CuNi-MOFs in Pebax®1657 and in PEEK-WC, are shown in Figure 3. The PEEK-WC presents a Young’s module about 1.14 GPa [54] and Pebax®1657 has a Young’s module about 0.10 GPa [55]. In both polymers, the loading of CuNi-MOF increases the Young’s modulus. The increase of the Young’s modulus indicates an increase of stiffness for both polymers, increasing the MOF concentrations. The glassy PEEK-WC presents a higher modulus compared to the rubbery Pebax®1657, as expected, and it remains higher even when the MOF concentration was increased. On the other hand, the maximum deformation is higher in the more flexible MMMs based on the rubbery Pebax®1657 compared to the MMMs based on the rigid glassy PEEK-WC.

Figure 3.

Young’s modulus (a), tensile strength (b) and maximum deformation (c) as a function of the CuNi-MOF concentration in Pebax®1657 and PEEK-WC. Values of the neat PEEK-WC [50] and Pebax [51] samples from the literature. Trend lines are given as a guide to the eye.

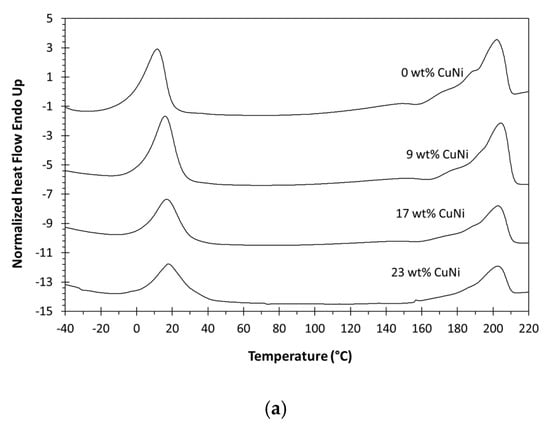

The break strength decreases for Pebax®1657/CuNi membranes, indicating that the membranes become weaker compared to the neat polymer. On the contrary, the break strength increases for PEEK-WC/CuNi membranes, suggesting a good adhesion between MOF and polymer that makes the MMMs stronger than the neat PEEK-WC membrane. The thermal properties of the membranes were studied using DSC analysis, and the results are displayed in Figure 4. For neat Pebax®1657, the two dominant endothermal peaks at 19 °C and 200 °C are attributed to the fusion of the crystalline fraction of the soft poly(ethylene oxide) (PEO) blocks and the hard polyamide (PA) blocks, respectively. In the presence of MOF, the melting enthalpy of both PEO and PA decreases. However, the peak maximum shifts to a higher temperature, indicating that the MOF stabilizes the crystalline PEO and that it mainly interacts with this phase. On the other hand, no significant changes occur in the glass transition temperature of PEEK-WC at 230 °C as a function of the MOF concentration.

Figure 4.

DSC thermograms for the membrane of (a) neat Pebax1657 and (b) neat PEEK-WC and MMMs with different concentration of CuNi-MOF during the second eating.

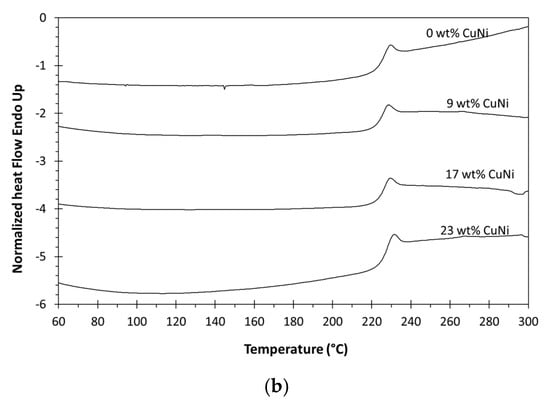

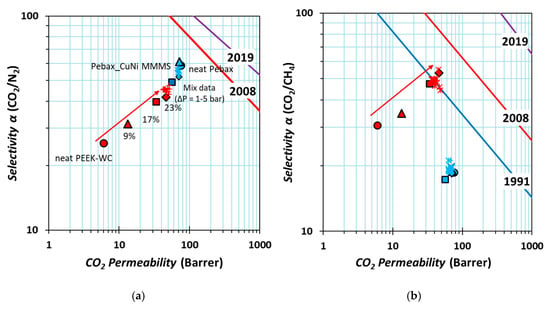

3.3. Pure Gas Transport Properties

Single gas permeation experiments were carried out in the order H2, O2, N2, CH4 and CO2 at 25 °C, but repeated experiments with N2 and O2 at the end of the cycle were identical and revealed no structural changes in the material. An overview of the results of the Pebax®1657-based MMMs and PEEK-WC based MMMs with different filler loadings is given in Figure 5 and Figure 6, respectively. All permeability, diffusivity and solubility data, and their respective selectivities, are given in the supporting information (See SI Tables S2 and S3). The dispersion of CuNi-MOF does not produce a substantial change in the permeability of the rubbery Pebax®1657. The most permeable species is CO2, confirming a solubility controlled transport (CO2 > H2 > CH4 > O2 > N2), typical for the rubbers (Figure 5a). A remarkably strong decrease in the effective diffusion coefficients of all gases as a function of the MOF loading (Figure 5b) is balanced by a proportional increase in their solubility coefficients (Figure 5c). This results in a similar permeability and selectivity (Figure 5d) for MMMs as in the neat Pebax®1657, with the only exception of the H2/CH4 gas pair, which suggests a favourable effect of the MOF on the size-selectivity. This is confirmed by the slight increase in the diffusion selectivities (Figure 5e), apparently because the MOF’s provide preferential diffusion paths for smaller gases.

Figure 5.

(a) Permeability, (b) diffusivity, and (c) solubility coefficients, and their respective selectivity towards N2 (d,e,f) for each gas as functions of the weight percentage of CuNi-MOF in Pebax®1657.

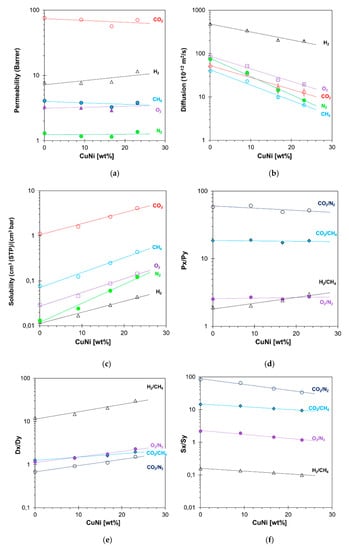

Figure 6.

(a) Permeability, (b) diffusivity, (c) solubility coefficients, and respective N2 selectivity (d,e,f) for each gas as functions of weight percentage of MOF loaded in PEEK-WC.

While the gas solubility upon addition of the MOF to Pebax increases as expected, given the generally high sorption capacity of MOFs for gases, it was not expected that this increase was more or less similar for all gases, and it was even less expected that the porous fillers would effectively lead to a decrease in the diffusion coefficient. The explanation is that the filler does not effectively decrease the diffusion coefficient in the membrane, but the highly-sorbing MOF transforms the permeation experiment in a sort of breakthrough experiment. The reason for the apparently slower diffusion is the accumulation of the gas inside the pores of the filler, similar to the phenomenon of immobilizing adsorption [56,57], but in this case it has a virtually negligible net effect on the permeability.

In contrast to the effect in Pebax®1657, CuNi-MOF causes a drastic increase in the gas permeability for all gases as function of MOFs loading in the glassy PEEK-WC, and the order of permeation obeys that of the diffusion-controlled gas transport mechanism with H2 > CO2 > O2 > N2 > CH4, typical for glassy polymers (Figure 6a). The increase in permeability is a direct consequence of an increase in diffusion coefficient (Figure 6b), whereas there is no substantial change in solubility coefficient (Figure 6c). The enhanced diffusion clearly indicates transport within the pore structure of CuNi-MOFs, which increases the total free volume of MMMs promoting the gas diffusion for all gases. The presence of MOF with chemical groups having a high affinity for CO2 increases its solubility, its CO2/CH4 and CO2/N2 solubility selectivity (Figure 6f), and ideal selectivity for these two gas pairs (Figure 6d). Instead, the diffusion selectivity is not strongly affected by CuNi-MOF.

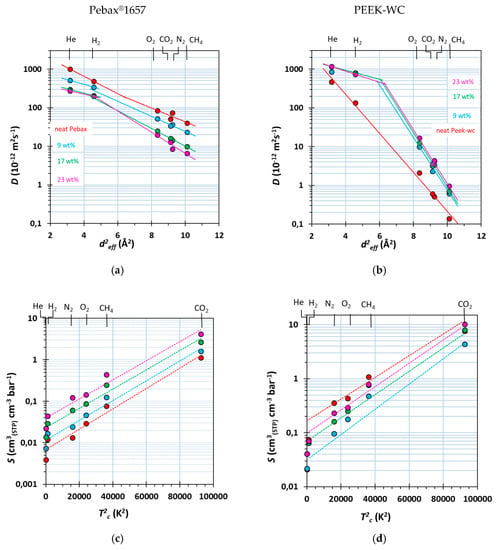

For a better understanding of the transport phenomena of gas separation membranes, the diffusion and solubility coefficients are often correlated with the molecular properties of gases [58]. Both neat polymers show a linear dependency of the diffusivity (D) on the squared gas diameter (d2eff) (Figure 7a,b), suggesting that the gas transport in neat polymers follows the diffusion solution model. In the presence of the MOF, both polymers show non-linearity of the D vs. d2eff correlation (Figure 7), which becomes more evident at higher MOF loading. A similar trend was recently observed for PIMs [59], where it was attributed to a different size-selectivity for small and large gas species due to the highly-interconnected free volume. These results suggest that the CuNi-MOF particles, with their internal void structure, have a similar effect on the gas diffusion of Pebax®1657 and PEEK-WC, introducing preferential diffusion pathways into the system which change the main transport mechanism, especially for the small molecules. As described above, the remarkably lower effective diffusion in Pebax®1657 is due to the much higher sorption capacity of the MOFs than of the neat Pebax®1657 [43]. Only for the CO2/N2 gas pair, there is a remarkable inversion from preferential N2 diffusion in the neat Pebax®1657 to preferential CO2 diffusion for the sample with the highest MOF concentration. Instead, in the glassy PEEK-WC, with much lower intrinsic diffusion coefficients in the neat polymer, the MOF has a strong positive effect on the total permeability of the mixed matrix membrane due to the far more rapid diffusion through the cages of the MOFs. In PEEK-WC, after an initial decrease, compared to the neat polymer, the solubility of all gases increases with the CuNi-MOF concentration. This is similar to what was observed in Pebax®1657, but only in PEEK-WC leads to an increasing permeability due to the positive effect on the diffusivity as well.

Figure 7.

Correlation of the effective diffusion coefficient as a function of the molecular diameter of six light gases in (a) Pebax®1657/CuNi MMMs and (b) PEEK-WC/CuNi MMMs. Correlation of the effective solubility coefficient of the gases as a function of their critical temperature in (c) Pebax®1657/CuNi MMMs and (d) PEEK-WC/CuNi MMMs. The legend is identical in all individual graphs.

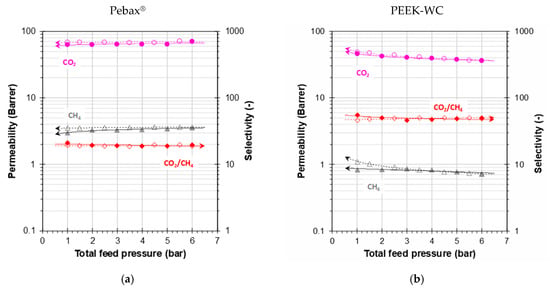

3.4. Mixed Gas Transport Properties

Mixed gas permeation measurements were carried out on the representative membranes with the highest MOF concentration in each polymer in view of two relevant industrial gas separations, namely biogas upgrading and CO2 capture from flue gas, involving CO2 separation from CH4 and N2, respectively (Figure 8) (See Table SI 4-5). For this purpose, measurements were performed from 1 to 6 bar(a) with simulated flue gas (CO2/N2, 15/85 vol %) and simulated biogas (CO2/CH4, 35/65 vol %). The glassy PEEK-WC MMM exhibits typical dual-mode behavior with the CO2/CH4 mixture, showing a decrease of CO2 permeability as a function of the increased feed pressure, which causes a simultaneous and slightly smaller decrease of CO2/CH4 selectivity. This indicates that the free volume in the PEEK-WC phase and in the MOFs’ pores is gradually becoming occupied by CO2, and as a result, the CH4 permeability slightly decreases as a function of pressure. Moreover, some hysteresis of CO2 and CH4 permeability is observed when reducing the pressure after the initial pressure increase steps. This is ascribed to a slight CO2-induced dilation of the polymer, leaving a higher free volume when the pressure is decreased, and thus a higher CH4 permeability and a slightly lower selectivity. In the separation of the CO2/N2 mixture, no further hysteresis takes place because of the lower CO2 partial pressure, and for the same reason the CO2 permeability is slightly higher than in the biogas mixture.

Figure 8.

Pressure dependence of CO2 and CH4 permeabilities and CO2/CH4 selectivity using the binary mixture of CO2/CH4 (35:65 vol %) for Pebax®1657_23 wt % CuNi-MOF (a) and PEEK-WC_23% CuNi-MOF (b). Pressure dependence of CO2 and N2 permeabilities and CO2/N2 selectivity in binary mixture conditions for CO2/N2 (15:85 vol %) of Pebax®1657_23 wt % CuNi (c) and PEEK-WC_23% CuNi (d). Closed symbols for stepwise increase of the pressure and open symbols for the subsequent stepwise decrease of the pressure. Trend lines are plotted as a guide to the eye.

Contrary to the glassy PEEK-WC, the rubbery Pebax®1657/CuNi-MOF (23 wt %) membrane shows essentially pressure-independent permeability and selectivity (Figure 8a), after only a slight increase in permeability with pressure in the first run, apparently due to a certain conditioning of the sample. The transport properties of the Pebax-based membrane are dominated by the rubbery phase, and the dispersed MOFs only provide a higher gas sorption capacity in the membrane but do not significantly affect the overall performance.

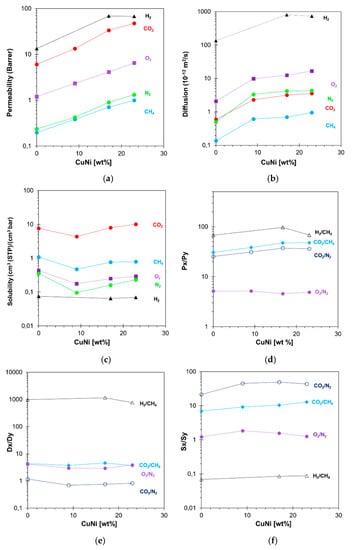

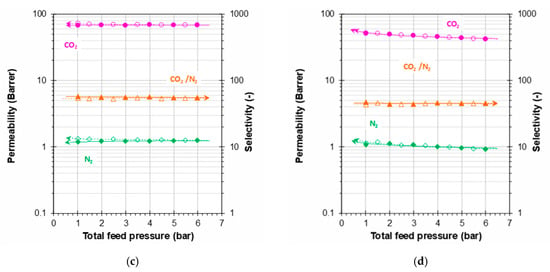

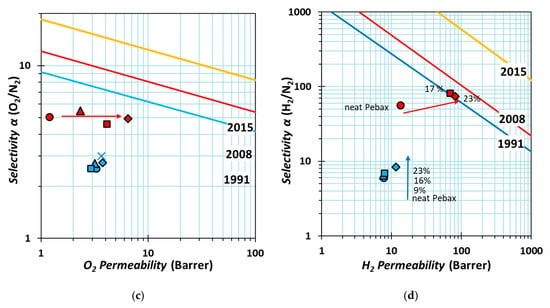

3.5. Robeson’s Plots and Performance Overview

The gas transport properties for all membranes are summarized in the Robeson diagrams in Figure 9 for four gas pairs representing industrially important separations: CO2/N2, CO2/CH4, O2/N2 and H2/N2.

Figure 9.

Robeson’s plots for CO2/N2 (a) CO2/CH4 (b) O2/N2 (c) H2/N2 (d) showing the data of Pebax1657/CuNi (blue) and PEEK-WC/CuNi at different MOF loadings of 0 wt % (= neat polymers, ●,●), 9 wt % (▲,▲), 17 wt % (■,■) and 23 wt % (♦,♦). Blue line 1991 upper bound, red line 2008 upper bound [8,9]; yellow line 2015 [60]; purple line 2019 upper bound [61]. The arrows qualitatively indicate the direction of increasing MOF loading. The clouds of blue “X” and red “X” symbols represent the mixed gas data in the pressure range of 1–6 bar for Pebax1657/CuNi-MOF at 29 wt % and PEEK-WC/CuNi-MOF at 23 wt % of MOF loading. Please refer to the electronic version for colour figures.

For all gases except H2, the neat rubbery Pebax®1657 is more permeable than the neat glassy PEEK-WC. On the other hand, PEEK-WC is more selective than Pebax®1657 for all gas pairs, except for the CO2/N2 separation (Figure 9a). For the CO2/N2 gas pair, with the nearly identical diameters of the molecules, the selectivity is almost entirely due to solubility selectivity, which is higher in Pebax then in PEEK-WC. However, whereas CuNi-MOF in Pebax®1657 has a marginal effect, CuNi-MOF in the glassy PEEK-WC increases drastically not only the CO2/N2 selectivity (from 25 to 37), but also the CO2 permeability (from 6 to ~50 Barrer), near the CO2 permeability of the rubbery Pebax®1657 (PCO2 ~69 Barrer) (Figure 9a).

For CO2/CH4 separation, the PEEK-WC-based MMMs show far superior properties than the Pebax®-based membranes, which hardly change with the MOF concentration. A strong contribution of size selectivity between CO2 and the much bulkier CH4 molecules (Figure 7b) and a further increase of both solubility and diffusivity with increasing MOF concentration leads to enhanced selectivity (from 30 to ~50, above that of Pebax) and CO2 permeability (from 6 to ~50 Barrer), exceeding the 1991 Robeson upper bound. For both mixtures, the performance is very similar to the ideal selectivity and pure gas permeability, indicating the absence of a significant coupling effect (Figure 9b).

The O2/N2 separation (Figure 9c) is mainly due to diffusion selectivity. Neither the permeability nor the selectivity changes much in Pebax®1657 upon the addition of CuNi-MOF, but in PEEK-WC the permeability of both gases increases 5-fold in the presence of 23 wt % CuNi-MOF, maintaining an almost constant O2/N2 selectivity.

Finally, the trend for H2/N2 separation is similar to that of O2/N2, but in this case, for both polymers, the MOFs also have a slightly higher H2/N2 selectivity than the neat polymers, as a result of increased diffusion selectivity. The H2 permeability in Pebax® 1657 slightly increases from 8 to 11 Barrer, and the H2/N2 selectivity and permeability in the PEEK-WC/CuNi-MOF MMMs both strongly increase, surpassing the 1991 upper bound.

4. Conclusions

The development of novel, well-performing gas separation membranes requires a good understanding of their transport properties. This is even more important for complex systems such as mixed matrix membranes in which a porous filler is dispersed in the polymer matrix. Therefore, this work describes the comparison of the performance of two sets of membranes, glassy PEEK-WC membranes and rubbery Pebax®1657 membranes, with different concentrations of an oxamate-based CuNi-MOF. An increase of the Young’s modulus for both membrane sets confirms that the MOF increases the stiffness of the polymer. In the case of the Pebax®1657 membrane, this is also accompanied by a slight shift of the melting peak of the PEO phase to higher temperatures, which suggests a good interaction of the MOF with the PEO phase. On the other hand, the presence of the MOF reduces the melting enthalpy and thus the overall crystallinity of both the PEO phase and the PA phase of Pebax®, whereas it does not affect the glass transition temperature of PEEK-WC. Only for PEEK-WC, along with the Young’s modulus, the tensile strength also increases, but for both polymers, the maximum deformation decreases with the addition of the MOF.

In terms of transport properties, the permeability of PEEK-WC strongly increases with increasing MOF content, mostly due to an increase in the effective diffusion coefficient, whereas unexpectedly, the effective diffusion coefficient in Pebax®1657 drastically decreases upon addition of the MOF. This is almost completely compensated by an increase in solubility so that the permeability remains nearly constant. The increase in diffusivity favors especially the smaller gas species, and as a result, the PEEK-WC MMMs show a simultaneous increase in CO2 permeability and CO2/CH4 selectivity, and the membranes with the highest MOF loading approach Robeson’s 2008 upper bounds for these gas pairs. In the range of 1–6 bar(a), the mixed gas permeation tests with CO2/N2 15/85 vol % and CO2/CH4 35/65 vol % mixtures show only a weak pressure-dependence for the CO2/CH4 mixture in PEEK-WC with 30% MOF, typical for materials with dual-mode sorption behaviour, but not for the CO2/N2 mixture in PEEK-WC and for both mixtures in the Pebax-based MMMs.

In summary, the detailed analysis of the gas transport properties of the two series of MMMs highlights the enormous impact of the polymer matrix on the effectiveness of the same MOF when it is embedded in a rubbery or a glassy polymer. Even if the MOF improves significantly the gas solubility, this may not have a positive effect on the permeability if the diffusivity is not increased simultaneously. The successful development of better-performing MMMs can therefore not rely on studies of only the overall permeability but necessitates knowledge of the individual solubility and diffusion coefficient. For both parameters, the values of the polymer and the porous filler should be carefully matched to yield optimum performance.

Supplementary Materials

The following are available online at https://www.mdpi.com/2076-3417/10/4/1310/s1, Table SI-1. List of MMMs prepared. Figure S-1 EDX of Pebax®1657/CuNi-MOF (a) and PEEK-WC/CuNi-MOF (b) at an accelerating voltage of 15 Kv. Figure S-2 SEM images of cross section for MMMs of Pebax®1657/CuNi-MOF and PEEK-WC/CuNi-MOF. Table S-2 Pure gas permeability, solubility and diffusion coefficients, and respective selectivity for neat Pebax1657 and Pebax1657/CuNi MMMs. Table S-3 Pure gas permeability, solubility and diffusion coefficients, and respective selectivity for neat PEEK-WC and PEEK-WC/CuNi MMMs. Table S-4 Mixed gas permeabilities and selectivities of PEEK-WC/CuNi 23 wt % membrane using binary mixture CO2/CH4 (35/65) at pressure of 1–6 bar. Table S-5 Mixed gas permeabilities and selectivities of PEEK-WC/CuNi 23 wt % membrane using binary mixture CO2/N2 (15/85) at pressure of 1–6 bar.

Author Contributions

E.E. and R.B. conceived, designed and performed the membrane preparation and characterization experiments under the supervision of J.C.J. and D.A.; J.F.S. and E.P. synthetized and provided CuNi-MOF; E.E. and A.F. performed the single gas permeation and DSC experiments; E.E. and J.C.J. performed mechanical tests. M.M. performed the mixed gas permeation experiments under the supervision of J.C.J. All authors analyzed the data and wrote the paper with similar effort. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Ministero dell’Istruzione, dell’Università e della Ricerca (Italy). Phenom-World B.V., Eindhoven (NL), is gratefully acknowledged for providing a Phenom Pro X desktop SEM for evaluation. C. Cantoni (Arkema Italy) is gratefully acknowledged for providing the Pebax®1657 pellets. E.P. acknowledges the financial support of the European Research Council under the European Union’s Horizon 2020 research and innovation programme/ERC Grant Agreement No 814804, MOF-reactors.

Acknowledgments

Phenom-World B.V., Eindhoven (NL), is gratefully acknowledged for providing a Phenom Pro X desktop SEM for evaluation. R.B. thanks the MIUR (project PON R & I FSE-FESR 2014–2020) for predoctoral grants.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ockwig, N.W.; Nenoff, T.M. Membranes for hydrogen separation. Chem. Rev. 2007, 107, 4078–4110. [Google Scholar] [CrossRef] [PubMed]

- Himma, N.F.; Wardani, A.K.; Prasetya, N.; Aryanti, P.T.P.; Wenten, I.G. Recent progress and challenges in membrane-based O2/N2 separation. Rev. Chem. Eng. 2019, 35, 591–625. [Google Scholar] [CrossRef]

- Coombe, H.S.; Nieh, S. Polymer membrane air separation performance for portable oxygen enriched combustion applications. Energy Convers. Manag. 2007, 48, 1499–1505. [Google Scholar] [CrossRef]

- Chen, X.Y.; Vinh-Thang, H.; Ramirez, A.A.; Rodrigue, D.; Kaliaguine, S. Membrane gas separation technologies for biogas upgrading. RSC Adv. 2015, 5, 24399–24448. [Google Scholar] [CrossRef]

- Esposito, E.; Dellamuzia, L.; Moretti, U.; Fuoco, A.; Giorno, L.; Jansen, J.C. Simultaneous production of biomethane and food grade CO 2 from biogas: An industrial case study. Energy Environ. Sci. 2019, 12, 281–289. [Google Scholar] [CrossRef]

- Galizia, M.; Chi, W.S.; Smith, Z.P.; Merkel, T.C.; Baker, R.W.; Freeman, B.D. 50th Anniversary Perspective: Polymers and Mixed Matrix Membranes for Gas and Vapor Separation: A Review and Prospective Opportunities. Macromolecules 2017, 50, 7809–7843. [Google Scholar] [CrossRef]

- Brunetti, A.; Scura, F.; Barbieri, G.; Drioli, E. Membrane technologies for CO2 separation. J. Memb. Sci. 2010, 359, 115–125. [Google Scholar] [CrossRef]

- Robeson, L.M. The upper bound revisited. J. Memb. Sci. 2008, 320, 390–400. [Google Scholar] [CrossRef]

- Robeson, L.M. Correlation of separation factor versus permeability for polymeric membranes. J. Memb. Sci. 1991, 62, 165–185. [Google Scholar] [CrossRef]

- Chuah, C.Y.; Goh, K.; Yang, Y.; Gong, H.; Li, W.; Karahan, H.E.; Guiver, M.D.; Wang, R.; Bae, T.H. Harnessing filler materials for enhancing biogas separation membranes. Chem. Rev. 2018, 118, 8655–8769. [Google Scholar] [CrossRef]

- Zhu, H.; Liu, D. The synthetic strategies of metal–organic framework membranes, films and 2D MOFs and their applications in devices. J. Mater. Chem. A 2019, 7, 21004–21035. [Google Scholar] [CrossRef]

- Najari, S.; Saeidi, S.; Gallucci, F.; Drioli, E. Mixed matrix membranes for hydrocarbons separation and recovery: A critical review. Rev. Chem. Eng. 2019, 35, 591–625. [Google Scholar] [CrossRef]

- Prasetya, N.; Himma, N.F.; Doddy Sutrisna, P.; Wenten, I.; Ladewig, B.P. A Review on Emerging Organic-containing Microporous Material Membranes for Carbon Capture and Separation. Chem. Eng. J. 2019, 123575. [Google Scholar] [CrossRef]

- Deng, Y.H.; Chen, J.T.; Chang, C.H.; Liao, K.S.; Tung, K.L.; Price, W.E.; Yamauchi, Y.; Wu, K.C.W. A Drying-Free, Water-Based Process for Fabricating Mixed-Matrix Membranes with Outstanding Pervaporation Performance. Angew. Chem. Int. Ed. 2016, 55, 12793–12796. [Google Scholar] [CrossRef]

- Vinu, M.; Senthil Raja, D.; Jiang, Y.-C.; Liu, T.-Y.; Xie, Y.-Y.; Lin, Y.-F.; Yang, C.-C.; Lin, C.-H.; Alshehri, S.M.; Ahamad, T.; et al. Effects of structural crystallinity and defects in microporous Al-MOF filled chitosan mixed matrix membranes for pervaporation of water/ethanol mixtures. J. Taiwan Inst. Chem. Eng. 2018, 83, 143–151. [Google Scholar] [CrossRef]

- Fuoco, A.; Khdhayyer, M.R.; Attfield, M.P.; Esposito, E.; Jansen, J.C.; Budd, P.M. Synthesis and transport properties of novel MOF/PIM-1/MOF sandwich membranes for gas separation. Membranes 2017, 7, 7. [Google Scholar] [CrossRef]

- Ebadi Amooghin, A.; Mashhadikhan, S.; Sanaeepur, H.; Moghadassi, A.; Matsuura, T.; Ramakrishna, S. Substantial breakthroughs on function-led design of advanced materials used in mixed matrix membranes (MMMs): A new horizon for efficient CO2 separation. Prog. Mater. Sci. 2019, 102, 222–295. [Google Scholar] [CrossRef]

- Ahmadi, M.; Saravanan, J.; Dai, Z.; Ansaloni, L.; Deng, L. Performance of Mixed Matrix Membranes Containing Three-Dimensional (3D) Fillers for CO2 Separation A Review. Membranes 2018, 8, 50. [Google Scholar] [CrossRef]

- Cohen, S.M. The Postsynthetic Renaissance in Porous Solids. J. Am. Chem. Soc. 2017, 139, 2855–2863. [Google Scholar] [CrossRef]

- Fortea-Pérez, F.R.; Mon, M.; Ferrando-Soria, J.; Boronat, M.; Leyva-Pérez, A.; Corma, A.; Herrera, J.M.; Osadchii, D.; Gascon, J.; Armentano, D.; et al. The MOF-driven synthesis of supported palladium clusters with catalytic activity for carbene-mediated chemistry. Nat. Mater. 2017, 16, 760–766. [Google Scholar] [CrossRef]

- Mon, M.; Tiburcio, E.; Ferrando-Soria, J.; Gil San Millán, R.; Navarro, J.A.R.; Armentano, D.; Pardo, E. A post-synthetic approach triggers selective and reversible sulphur dioxide adsorption on a metal-organic framework. Chem. Commun. 2018, 54, 9063–9066. [Google Scholar] [CrossRef] [PubMed]

- Jansen, J.C.; Drioli, E. Poly(ether ether ketone) derivative membranes—A review of their preparation, properties and potential. Polym. Sci. Ser. A 2009, 51, 1355–1366. [Google Scholar] [CrossRef]

- Tasselli, F.; Jansen, J.C.; Drioli, E. PEEKWC Ultrafiltration Hollow-Fiber Membranes: Preparation, Morphology, and Transport Properties. J. Appl. Polym. Sci. 2004, 91, 841–853. [Google Scholar] [CrossRef]

- Buonomenna, M.G.; Figoli, A.; Jansen, J.C.; Drioli, E. Preparation of Asymmetric PEEKWC Flat Membranes with Different Microstructures by Wet Phase Inversion. J. Appl. Polym. Sci. 2004, 92, 576–591. [Google Scholar] [CrossRef]

- Jansen, J.C.; Buonomenna, M.G.; Figoli, A.; Drioli, E. Asymmetric membranes of modified poly(ether ether ketone) with an ultra-thin skin for gas and vapour separations. J. Memb. Sci. 2006, 272, 188–197. [Google Scholar] [CrossRef]

- Iulianelli, A.; Algieri, C.; Donato, L.; Garofalo, A.; Galiano, F.; Bagnato, G.; Basile, A.; Figoli, A. New PEEK-WC and PLA membranes for H2 separation. Int. J. Hydrogen Energy 2017, 42, 22138–22148. [Google Scholar] [CrossRef]

- Iulianelli, A.; Clarizia, G.; Gugliuzza, A.; Ebrasu, D.; Bevilacqua, A.; Trotta, F.; Basile, A. Sulfonation of PEEK-WC polymer via chloro-sulfonic acid for potential PEM fuel cell applications. Int. J. Hydrogen Energy 2010, 35, 12688–12695. [Google Scholar] [CrossRef]

- Clarizia, G.; Algieri, C.; Regina, A.; Drioli, E. Zeolite-based composite PEEK-WC membranes: Gas transport and surface properties. Microporous Mesoporous Mater. 2008, 115, 67–74. [Google Scholar] [CrossRef]

- Xin, Q.; Liu, T.; Li, Z.; Wang, S.; Li, Y.; Li, Z.; Ouyang, J.; Jiang, Z.; Wu, H. Mixed matrix membranes composed of sulfonated poly(ether ether ketone) and a sulfonated metal–organic framework for gas separation. J. Memb. Sci. 2015, 488, 67–78. [Google Scholar] [CrossRef]

- Esposito, E.; Clarizia, G.; Bernardo, P.; Jansen, J.C.; Sedláková, Z.; Izák, P.; Curcio, S.; de Cindio, B.; Tasselli, F. Pebax®/PAN hollow fiber membranes for CO2/CH4 separation. Chem. Eng. Process. Process Intensif. 2015, 94, 53–61. [Google Scholar] [CrossRef]

- Kim, K.; Ingole, P.G.; Kim, J.; Lee, H. Separation performance of PEBAX/PEI hollow fiber composite membrane for SO2/CO2/N2 mixed gas. Chem. Eng. J. 2013, 233, 242–250. [Google Scholar] [CrossRef]

- Asghari, M.; Mosadegh, M.; Riasat Harami, H. Supported PEBA-zeolite 13X nano-composite membranes for gas separation: Preparation, characterization and molecular dynamics simulation. Chem. Eng. Sci. 2018, 187, 67–78. [Google Scholar] [CrossRef]

- Dai, Z.; Bai, L.; Hval, K.N.; Zhang, X.; Zhang, S.; Deng, L. Pebax®/TSIL blend thin film composite membranes for CO2 separation. Sci. China Chem. 2016, 59, 1–9. [Google Scholar] [CrossRef]

- Ehsani, A.; Pakizeh, M. Synthesis, characterization and gas permeation study of ZIF-11/Pebax® 2533 mixed matrix membranes. J. Taiwan Inst. Chem. Eng. 2016, 66, 414–423. [Google Scholar] [CrossRef]

- Song, C.; Li, R.; Fan, Z.; Liu, Q.; Zhang, B.; Kitamura, Y. CO2/N2 separation performance of Pebax/MIL-101 and Pebax /NH2-MIL-101 mixed matrix membranes and intensification via sub-ambient operation. Sep. Purif. Technol. 2020, 238, 116500. [Google Scholar] [CrossRef]

- Jomekian, A.; Bazooyar, B.; Behbahani, R.M.; Mohammadi, T.; Kargari, A. Ionic liquid-modified Pebax® 1657 membrane filled by ZIF-8 particles for separation of CO2 from CH4, N2 and H2. J. Memb. Sci. 2017, 524, 652–662. [Google Scholar] [CrossRef]

- Liu, G.; Chernikova, V.; Liu, Y.; Zhang, K.; Belmabkhout, Y.; Shekhah, O.; Zhang, C.; Yi, S.; Eddaoudi, M.; Koros, W.J. Mixed matrix formulations with MOF molecular sieving for key energy-intensive separations. Nat. Mater. 2018, 17, 283–289. [Google Scholar] [CrossRef]

- Jomekian, A.; Behbahani, R.M.; Mohammadi, T.; Kargari, A. High speed spin coating in fabrication of Pebax 1657 based mixed matrix membrane filled with ultra-porous ZIF-8 particles for CO2/CH4 separation. Korean J. Chem. Eng. 2016, 34, 1–14. [Google Scholar] [CrossRef]

- Jomekian, A.; Behbahani, R.M.; Mohammadi, T.; Kargari, A. CO2/CH4 separation by high performance co-casted ZIF-8/Pebax 1657/PES mixed matrix membrane. J. Nat. Gas Sci. Eng. 2016, 31, 562–574. [Google Scholar] [CrossRef]

- Atash Jameh, A.; Mohammadi, T.; Bakhtiari, O. Preparation of PEBAX-1074/modified ZIF-8 nanoparticles mixed matrix membranes for CO2 removal from natural gas. Sep. Purif. Technol. 2020, 231, 115900. [Google Scholar] [CrossRef]

- Meshkat, S.; Kaliaguine, S.; Rodrigue, D. Mixed matrix membranes based on amine and non-amine MIL-53(Al) in Pebax® MH-1657 for CO2 separation. Sep. Purif. Technol. 2018, 200, 177–190. [Google Scholar] [CrossRef]

- Noroozi, Z.; Bakhtiari, O. Preparation of Amino Functionalized Titanium Oxide Nanotubes and Their Incorporation within Pebax/PEG Blended Matrix for CO2/CH4 Separation. Chem. Eng. Res. Des. 2019, 152, 149–164. [Google Scholar] [CrossRef]

- Mon, M.; Bruno, R.; Tiburcio, E.; Grau-Atienza, A.; Sepúlveda-Escribano, A.; Ramos-Fernandez, E.V.; Fuoco, A.; Esposito, E.; Monteleone, M.; Carolus Jansen, J.; et al. Efficient Gas Separation and Transport Mechanism in Rare Hemilabile Metal-Organic Framework. Chem. Mater. 2019, 31, 5856–5866. [Google Scholar] [CrossRef]

- Liu, Y.-C.; Chen, C.-Y.; Lin, G.-S.; Chen, C.-H.; Wu, K.C.-W.; Lin, C.-H.; Tung, K.-L. Characterization and molecular simulation of Pebax-1657-based mixed matrix membranes incorporating MoS2 nanosheets for carbon dioxide capture enhancement. J. Memb. Sci. 2019, 582, 358–366. [Google Scholar] [CrossRef]

- Sutrisna, P.D.; Hou, J.; Zulkifli, M.Y.; Li, H.; Zhang, Y.; Liang, W.; D’Alessandro, D.M.; Chen, V. Surface functionalized UiO-66/Pebax-based ultrathin composite hollow fiber gas separation membranes. J. Mater. Chem. A 2018, 6, 918–931. [Google Scholar] [CrossRef]

- Kim, J.; Choi, J.; Soo Kang, Y.; Won, J. Matrix effect of mixed-matrix membrane containing CO2-selective MOFs. J. Appl. Polym. Sci. 2016, 133, 1–8. [Google Scholar] [CrossRef]

- Grancha, T.; Ferrando-Soria, J.; Zhou, H.C.; Gascon, J.; Seoane, B.; Pasán, J.; Fabelo, O.; Julve, M.; Pardo, E. Postsynthetic Improvement of the Physical Properties in a Metal-Organic Framework through a Single Crystal to Single Crystal Transmetallation. Angew. Chem. Int. Ed. 2015, 54, 6521–6525. [Google Scholar] [CrossRef]

- Jansen, J.C.; Friess, K.; Drioli, E. Organic vapour transport in glassy perfluoropolymer membranes: A simple semi-quantitative approach to analyze clustering phenomena by time lag measurements. J. Memb. Sci. 2011, 367, 141–151. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion; Oxford Science Publications; Clarendon Press: Oxford, UK, 1975; ISBN 9780198534112. [Google Scholar]

- Fraga, S.C.; Monteleone, M.; Lanč, M.; Esposito, E.; Fuoco, A.; Giorno, L.; Pilnáček, K.; Friess, K.; Carta, M.; McKeown, N.B.; et al. A novel time lag method for the analysis of mixed gas diffusion in polymeric membranes by on-line mass spectrometry: Method development and validation. J. Memb. Sci. 2018, 561, 39–58. [Google Scholar] [CrossRef]

- Fernandes, T.S.; Melo, W.D.C.; Kalinke, L.H.G.; Rabelo, R.; Valdo, A.K.; Da Silva, C.C.; Martins, F.T.; Amorós, P.; Lloret, F.; Julve, M.; et al. 2D and 3D mixed MII/CuII metal-organic frameworks (M = Ca and Sr) with: N, N ′-2,6-pyridinebis(oxamate) and oxalate: Preparation and magneto-structural study. Dalt. Trans. 2018, 47, 11539–11553. [Google Scholar] [CrossRef]

- Khosravi, T.; Omidkhah, M.; Kaliaguine, S.; Rodrigue, D. Amine-functionalized CuBTC/poly(ether-b-amide-6) (Pebax® MH 1657) mixed matrix membranes for CO2/CH4 separation. Can. J. Chem. Eng. 2017, 95, 2024–2033. [Google Scholar] [CrossRef]

- Luo, H.; Vaivars, G.; Mathe, M. Cross-linked PEEK-WC proton exchange membrane for fuel cell. Int. J. Hydrogen Energy 2009, 34, 8616–8621. [Google Scholar] [CrossRef]

- Li, W.; Galiano, F.; Estager, J.; Monbaliu, J.C.M.; Debecker, D.P.; Figoli, A.; Luis, P. Sorption and pervaporation study of methanol/dimethyl carbonate mixture with poly(etheretherketone) (PEEK-WC) membrane. J. Memb. Sci. 2018, 567, 303–310. [Google Scholar] [CrossRef]

- Longo, M.; De Santo, M.P.; Esposito, E.; Fuoco, A.; Monteleone, M.; Giorno, L.; Jansen, J.C. Force spectroscopy determination of Young’s modulus in mixed matrix membranes. Polymer (Guildf) 2018, 156, 22–29. [Google Scholar] [CrossRef]

- Paul, D.R. Effect of immobilizing adsorption on the diffusion time lag. J. Polym. Sci. Part A-2 Polym. Phys. 1969, 7, 1811–1818. [Google Scholar] [CrossRef]

- Grzywna, Z.; Podkowka, J. Effect of immobilizing adsorption on mass transport through polymer films. J. Memb. Sci. 1981, 8, 23–31. [Google Scholar] [CrossRef]

- Yampolskii, Y. Polymeric gas separation membranes. Macromolecules 2012, 45, 3298–3311. [Google Scholar] [CrossRef]

- Fuoco, A.; Rizzuto, C.; Tocci, E.; Monteleone, M.; Esposito, E.; Budd, P.M.; Carta, M.; Comesaña-Gándara, B.; McKeown, N.B.; Jansen, J.C. The origin of size-selective gas transport through polymers of intrinsic microporosity. J. Mater. Chem. A 2019, 7, 20121–20126. [Google Scholar] [CrossRef]

- Swaidan, R.; Ghanem, B.; Pinnau, I. Fine-Tuned Intrinsically Ultramicroporous Polymers Redefine the Permeability/Selectivity Upper Bounds of Membrane-Based Air and Hydrogen Separations. ACS Macro Lett. 2015, 4, 947–951. [Google Scholar] [CrossRef]

- Comesaña-Gándara, B.; Chen, J.; Bezzu, C.G.; Carta, M.; Rose, I.; Ferrari, M.-C.; Esposito, E.; Fuoco, A.; Jansen, J.C.; McKeown, N.B. Redefining the Robeson upper bounds for CO2/CH4 and CO2/N2 separations using a series of ultrapermeable benzotriptycene-based polymers of intrinsic microporosity. Energy Environ. Sci. 2019, 12, 2733–2740. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).